Abstract

The inherently complex chemical and crystallographic nature of oxide materials has suppressed the purities achievable in laboratory environments, obscuring the rich physical degrees of freedom these systems host. In this manuscript we provide a systematic approach to defect identification and management in oxide molecular beam epitaxy grown MgZnO/ZnO heterostructures which host two-dimensional electron systems. We achieve samples displaying electron mobilities in excess of 1 × 106 cm2/Vs. This data set for the MgZnO/ZnO system firmly establishes that the crystalline quality has become comparable to traditional semiconductor materials.

Similar content being viewed by others

Introduction

Reducing the dimensionality of an electrically conducting system is known to have a dramatic effect on the nature of the observable physical phenomena. In the case of two-dimensional systems, where charge carriers are free to move in the x − y directions but confined spatially in the z, a vast array of ground states1 and non-equilibrium2 effects have been revealed, concomitant to improvements in material quality. A figure often used to gauge such quality is the carrier mobility (μ). In the Drude picture of DC conductivity, this value probes large momentum loss scattering events and is reflected in the sample’s longitudinal resistivity ρxx = 1/μen, where e is the elementary charge and n is the charge carrier density. At low temperature, once the effects of phonon scattering have been mitigated, this value may reach exceptionally high values. In the case of the AlGaAs/GaAs two-dimensional electron systems (2DES), mobilities beyond 3 × 107 cm2/Vs have revealed a plethora of exotic phenomena at low temperatures3,4,5. Responsible for these advances is the molecular beam epitaxy (MBE) apparatus; the work-horse of ultra-high purity thin film growth, whereby the evaporation of high purity source materials allows the control of film composition and structure on an atomic scale as designed. The nature of the disorder limiting μ in state-of-the-art AlGaAs/GaAs 2DES is the back-ground impurity content of films6, despite samples being grown using source materials with purity of roughly 7N and using apparatus manufactured from refractory metals. The adaptation of MBE to the field of oxide thin film growth has similarly resulted in higher quality crystallinity compared with other growth techniques, in turn enabling the exploration of the rich degrees of freedom available7,8,9,10.

The deployment of this technique to the growth of the relatively simple chemical and crystallography natured ZnO is the focus of this report. We present the current state-of-the-art growth apparatus and techniques for achieving high quality MgxZn1−xO/ZnO heterostructures which host a 2DES at the heterointerface11,12. Similar to AlGaN/GaN heterostructures13, the polar nature of the inversion asymmetric Wurtzite structure of ZnO is exploited for the formation of a 2DES, without the need for remote doping techniques. As a result, long range potential fluctuations typically imposed by such doping techniques are absent, with short range scattering events relatively dominant14. This scenario is different to the AlGaAs/GaAs 2DES and therefore these ZnO 2DES allow for the exploration of alternate facets of the interplay between the types of disorder and observable physical phenomena. Here we target individual scattering origins through a systematic study of growth conditions and sample design.

Results

Previous reports10,12,15 on this system have revealed that the 2DES charge density depends intimately on the Mg content of the capping MgxZn1−xO layer down to dilute concentrations x ≤ 0.01. In the following sections, we address prominent impurity sources within the oxide MBE apparatus and refine the growth conditions, which, in combination with tuning the Mg content, enable reproducible growth of films with μ exceeding 1 × 106 cm2/Vs. While this μ occurs for only a narrow charge density range, significant enhancements in μ are achieved for the full range of n. We also gain access to dilute samples where n = 2.1 × 1010 cm−2.

Contamination sources

We begin by addressing some technical aspects of the MBE apparatus which have evolved. Their implementation has been a prerequisite for enabling the results of this work. The basic configuration of the apparatus is presented in the methods section. Many technical aspects are common with ref. 15, including the use of pure ozone as the oxygen source, while the purity of Zn has been improved from 7N to beyond 7N5, where quantitative analysis of impurities becomes commercially unviable. In addition to the inherently lower impurity content of ozone compared to oxygen radical cells15, ozone as an oxygen source offers the benefit of an expanded temperature window for uniform growth. This is important as the presence of oxygen simultaneous to high temperatures leads to stringent requirements in apparatus design and handling to avoid increased impurities being expelled. Previous works using oxygen radical cells16 found the minimum growth temperature to achieve a smooth sample surface to be roughly Tg ≥ 810 °C under similar Zn flux conditions. As illustrated in Fig. 1, the temperature range is expanded through the use of ozone down to Tg ≥ 730 °C. In this figure, the left column of panels displays the surface morphology measured by atomic force microscopy (AFM) while the right column depicts an optical microscope image. Notably, in the Tg = 700 °C film, the surface is covered by an overwhelmingly high density of pits. The higher temperature films display clean local surface morphology, as measured by AFM and a relatively low density of macroscopic defects (mostly pits) in optical microscopy. We have not been successful in completely eliminating the finite density of pits despite performing wet-etching and annealing of each substrate prior to the growth17. These originate from the substrate surface15 and are likely due to point defects generated during the manufacturing process which prohibit epitaxial growth.

The presence of oxygen within the chamber places limitations on the suitability of refractory metals (W, Mo, Ta). These are widely used in traditional MBE chambers, but their oxides may be highly volatile and therefore contaminate grown films. In light of this, we have extensively employed superalloys for hot components. Specifically, we have found the nickel-based super-alloy Haynes®-230 and to a lesser extent Inconel®-601 to be useful in the heating apparatus itself and substrate holders. We also have endeavoured to eliminate pyrolytic boron nitride (pBN) components from the main substrate heating unit, as a peak of 28 amu (corresponding to what is thought to be N2) was resolved in the residual gas analysis of the chamber when the indicated temperature of the heating coil exceeded 1000 °C. This was accompanied with a strong suppression of μ. The ability to go to lower growth temperature with ozone has therefore mitigated the impurities originating from the heating unit. As an additional precaution, the pre-growth substrate anneal temperature too has been lowered from ≈1000 °C to Tg itself. Currently, the heating apparatus consists of a pure SiC coil with a diameter of 80 mm encased in a super-alloy construction. Only electrical insulating components have been made out of pBN. The coil itself remains oversized relative to the size of the substrates in use and therefore further reductions in impurity content may be achieved through downsizing the coil18, or replacement by a long wavelength laser heating system19 which would eliminate the need for pBN electrical isolators altogether.

Equally crucial has been the choice of substrate holder material, as this part is exposed to particularly strenuous conditions due to the direct and continual ozone flow and high temperatures. Previous studies using Inconel® substrate holders found Mn impurities originating from the holder itself within grown films in secondary ion mass spectroscopy (SIMS)20. These were eliminated by using quartz holders in combination with high Tg (≈920 °C). However, as discussed above, this heralds the inclusion of impurities from the heating apparatus. To overcome this, we again employ superalloys for the substrate holder and find that the content of atomic species that are unintentionally incorporated in grown films as impurities is below the detection limit of SIMS. The use of superalloy substrate holders also results in roughly half the power dissipation (≈250 W) in comparison with the use of quartz. We have however identified two scenarios which lead to disastrous results and significant impurities. These encompass both the choice and handling of the substrate holder forming superalloy. We have found that hundreds of samples maybe grown consecutively using substrate holders made from Haynes®-230, with grown films remaining clean to the edge of the substrate. Impurities from the alloy itself can not be detected in SIMS. In contrast, films grown with Haynes®-214 either display a high density of pit-defects on the sample edges, or are completely insulating at cryogenic temperatures. This occurs in spite of the superior oxidation resistance of the Al-rich protective layer (referred to as the oxide scale) of Haynes®-214 at high temperature according to manufacturer specifications.

Even when selecting a suitable material such as Haynes®-230, it is crucial to maintain the original protective oxide scale formed from the virgin alloy after initial use. A photograph of the underside of the substrate holder is displayed in Fig. 2a and shows a typical scale after multiple growths. The hole in the middle demarcated by a white box is where the substrate is placed. The green tinge is the scale and is primarily composed of Ni and Cr oxides. This layer may be removed through exposure to nitric acid, returning it to a metallic appearance (not shown). However, films grown following such a procedure are known to display surface morphologies like that shown in panel b, where the corners are of a clouded visual appearance due to a high density of pits. Measuring SIMS locally in this region yields the depth profile in panel c. Up to the substrate the impurity density is below the detection limit. However entering the homoepitaxial ZnO layer, a large (1017 atoms/cm−3) Cr signal is resolved. While this content is far below the solubility limit of Cr in ZnO21, it evidently has a negative impact on the ability to form an abrupt step-like distribution of Mg, which is representative of the MgZnO barrier and hence the 2DES-hosting quantum well. It may be that a different phase, perhaps spinel ZnCr2O4 or Cr2O3, forms microscopically here and inhibits the proceeding growth. Accordingly, such regions are insulating at cryogenic temperatures. It is therefore only if the original oxide scale is retained that a substrate holder may be used hundreds of times to deliver consistently high mobility samples, whereas the removal of the scale has irreversible and detrimental consequences.

(a) Photograph of the underside of an oxidized Haynes®-230 substrate holder. The opening is indicated by a white square and hosts the 1 × 1 cm ZnO wafer. (b) a post-growth photograph of a wafer which has been grown following descaling of the substrate holder. The white scale bar is 1 cm for both photographs. The arrow points to the section of the film which is analysed by SIMS. The result is shown in (panel c), where Cr impurities are detected in the grown MgZnO and ZnO layers.

We now set the growth temperature to be Tg = 750 ± 10 °C and explore the growth conditions. In line with previous reports15, all films are grown under Zn rich conditions. This is conveyed in Fig. 3 where the growth rate of films is shown to depend solely on the O3 flow across a wide range of Zn flux pressures. The ozone flow is read by a capacitive baratron gauge near the leak value and the Zn flux by a naked ion gauge placed at the location of the substrate (see methods for details). The samples are comprised of both a ZnO homoepitaxial and MgxZn1−xO capping layer (x ≈ 0.01). At such x content, it is not possible to detect a difference in growth rate for the ZnO and MgxZn1−xO layers. For all growth rates the pit density is comparable, however when reducing the ozone flow and increasing Zn flux a number of macroscopic defects emerge on the surface, as shown in the inset for a representative sample grown with a Zn flux of 15 × 10−4 Pa.

Film thickness

We now return to μ as a gauge of the quality of the 2DES at the heterointerface. Figure 4 explores the effect of the thickness (t) of the MgZnO layer. For all films the growth conditions are kept constant (Zn ≈ 10 × 10−4 Pa, O3 = 90 mTorr). A 500 nm homoepitaxial layer of ZnO is deposited first and is capped with a MgZnO layer of t varied between 30 ~ 500 nm by controlling the growth time. Two data sets are presented in panel a; Mg flux = 3.5 and 7 × 10−7 Pa. Even for the thinnest film of t = 30 nm charges accumulate to form the 2DES, in agreement with previous reports for higher density samples12. However, it can be seen that μ is greatly suppressed as t is made thinner for both datasets. Moreover, this suppression occurs at a thicker t for the lower density samples. In panel b the ratio of transport (τtr) and quantum (τq) scattering times are presented for this dilute dataset (here T = 40 mK). This ratio can aid in differentiating between short- or long-range scattering limited mobilities, with a lower ratio indicating short-range scattering is dominant. A similar, more extensive analysis has been published in ref. 14 and we refer the reader to this for details of the analysis. This ratio reduces with lower t, suggesting a trend towards enhanced short-range scattering. We recall that no intentional modulation doping is present in the MgZnO/ZnO heterostructure, as opposed to the AlGaAs/GaAs system, which may screen surface disorder. The data therefore conveys that the surface of the heterostructure is a prominent source of disorder, and, while an increased density of the 2DES acts to screen this, bringing this close to the 2DES drastically affects not only the magnitude but also nature of scattering.

Flux ratios

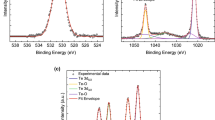

We now set t = 500 nm, Mg flux = 5.5 × 10−7 Pa and  = 90 mTorr in order to explore the characteristics of heterostructures as a function of Zn flux (i.e. Zn cell temperature). As conveyed in Fig. 3, all film growth takes place under Zn rich conditions. However, ZnO is notorious for defect formation whose exact nature remains under debate22,23,24. It results in finite room temperature conductivity, despite the large band-gap of the bulk. Figure 5a–c confirms that the exact ratio of Zn and O3 affects the 2DES. While a rather forgiving window is observed, both deficient (Zn ≤ 4 × 10−4 Pa) or over-rich (Zn ≥ 10 × 10−4 Pa) Zn flux conditions suppress μ (panel 5a), while n is not significantly affected. When the flux is increased beyond 10 × 10−4 Pa a significant density of particles develops on the surface, as shown in the inset in Fig. 3 for the case of flux = 15 × 10−4 Pa. These occur in addition to a finite density of pits ubiquitous in each growth. The suppression of μ in the high Zn flux regime is likely a consequence of both these particles as well as an increase in defects encountered within the crystal structure.

= 90 mTorr in order to explore the characteristics of heterostructures as a function of Zn flux (i.e. Zn cell temperature). As conveyed in Fig. 3, all film growth takes place under Zn rich conditions. However, ZnO is notorious for defect formation whose exact nature remains under debate22,23,24. It results in finite room temperature conductivity, despite the large band-gap of the bulk. Figure 5a–c confirms that the exact ratio of Zn and O3 affects the 2DES. While a rather forgiving window is observed, both deficient (Zn ≤ 4 × 10−4 Pa) or over-rich (Zn ≥ 10 × 10−4 Pa) Zn flux conditions suppress μ (panel 5a), while n is not significantly affected. When the flux is increased beyond 10 × 10−4 Pa a significant density of particles develops on the surface, as shown in the inset in Fig. 3 for the case of flux = 15 × 10−4 Pa. These occur in addition to a finite density of pits ubiquitous in each growth. The suppression of μ in the high Zn flux regime is likely a consequence of both these particles as well as an increase in defects encountered within the crystal structure.

Zn flux dependence of (a) μ and n, (b) the width of the ν = 2 integer quantum Hall state in Rxx, (c) Rxx at ν = 3/2 and (d) the magnetotransport around ν = 2. (Panel e) displays the magnetotransport for a film grown with Zn flux = 8 × 10−4 Pa. All data corresponds to T = 500 mK, with O3 pressure = 90 mTorr and thickness = 500 nm of MgZnO.

Quantifying the quality of 2DES samples beyond μ remains a controversial and formidable process. This is evidenced in the case of the ν = 5/2 fractional quantum Hall (FQH) state which, in AlGaAs/GaAs heterostructures4,25,26, shows only a loose correlation with μ. While a full exploration between sample parameters and the stability of correlated ground states is beyond the scope of this work, we lay the foundations by exploring the nature of transport observed at the standard characterization temperature of T = 500 mK. While 5a solely focused on μ for evaluating samples, we present two more facets of analysis; the width of the ν = 2 integer quantum Hall state minimum in Rxx in 5b and Rxx at ν = 3/2 in 5c. The motivation to address the first quantity stems from a correlation that has been established between the amplitude of the density variations in the sample and plateau widths in experiments that have addressed the microscopic origin of localization in the quantum Hall regime by measuring the local compressibility1,27. Narrower integer quantum Hall minima should therefore reflect a cleaner 2DES. The second quantity, the resistance at an even denominator fractional filling, measures the mobility of composite fermions, which are responsible for the formation of correlated ground states at fractional fillings1. In comparison with the electron mobility derived from the zero field resistivity this quantity should reflect more directly their backscattering probability. The lower the resistivity at this fillings the more pronounced fractional quantum Hall states are expected to be. It has been used to predict the quality of the ν = 5/2 ground state in AlGaAs/GaAs heterostructures5. In MgZnO/ZnO heterostructures filling 3/2 has the unique potential of hosting an even-denominator fractional quantum Hall state through sample rotation28.

A typical transport trace of a heterostructure is shown in 5e, for a film of Zn flux = 8 × 10−4 Pa. At this temperature, both the integer and FQH effect are observed, allowing a study of their correlation with μ. A close-up of the ν = 2 state is shown in 5d for a number of films growth with different Zn fluxes. We avoid plotting the data on a B-field axis as n varies slightly (~10%) between films, instead plotting it on ν. The width of the zero resistance minimum is referred to as Δν. Its Zn flux dependence is plotted in panel b for the same set of films as in panel a. A good correlation is observed with μ of the films; the highest μ samples show the sharpest integer states (lowest Δν). As shown in panel c, the lowest resistance at ν = 3/2 is achieved concomitant to the peak μ and narrowest ν = 2 state. The above analysis suggests a significant correlation between μ and other facets of the magnetotransport available at T = 500 mK used to gauge quality. This is distinct from the occasional lack of correlation between mobility and quality that has been reported on AlGaAs/GaAs heterostructures4,29.

The analysis also allows us to determine that the most suitable conditions occur at Zn flux = 6 ~ 8 × 10−4 Pa when the ozone flow is set to 90 mTorr. Having established these growth parameters we vary x in MgxZn1−xO to modify the charge density15. The dataset is presented in Fig. 6 where μ is plotted as a function of n. Data adapted from refs 11, 30 and 31 are included to illustrate the historical advances achieved. This data must be interpreted taking in mind that the temperature of each data set varies, but all are for T ≤ 2 K and generally represent the saturated mobility. The values presented for the data set of this work have been accumulated at T ≤ 500 mK, since μ saturates at increasingly lower temperatures for samples of n ≤ 1.5 × 1011 cm−2 (ref. 15). In fact, T ≈ 100 mK are required for dilute samples, necessitating the use of a dilution refrigerator. The highest μ film is achieved for n = 8.3 × 1010 cm−2 and displays 1,300,000 cm2/Vs. A mobility in excess of 1,000,000 cm2/Vs may be maintained even when increasing n to 1.5 × 1011 cm−2. For both lower and higher n from this range, μ is suppressed due to different scattering mechanisms; insufficient screening of impurities within the crystal structure in the case of dilute films and increased interface roughness or alloy scattering induced by the random potential of Mg content in higher density films. The analysis performed in ref. 14 corroborates such scattering mechanisms as being prominent for each regime. In Fig. 6 we also include reported scaling behaviour as guidelines corresponding to charged impurity scattering (μ ∝ n) and interface/alloy scattering limitations (μ ∝ n−3/2) for each data set32. Ultimately, according to Matthiessen’s rule, the interplay between these two mechanisms determines the maximum mobility which may be achieved. In comparison to historic data, the maximum μ of films has occurred at decreasing densities. This is a reflection of the reduced impurity content achieved, with the employment of O3 as an example. Less dramatic gains have been achieved in high density samples, reflecting the difficulty inevitably encountered in mitigating the detrimental effect the random distribution of Mg atoms in the MgZnO alloy has. Mg is of course inherently required to induce the 2DES in the first place. Finally, we note that conducting samples of density n = 2.1 × 1010 cm−2 have been achieved. This μ is for T = 500 mK, as below this a surprising upturn in resistance occurs, whose nature remains to be understood, but may indicate the transition to a new type of electronic ground state at low temperature.

Mobility as a function of density for historical growth regimes (For all data T ≤ 2 K).

Data is adapted from refs 11, 15, 30 and 31. For this work, bold symbols correspond to T ≤ 100 mK while lightly shaded are for T = 500 mK. The guidelines given by μ ∝ n and μ ∝ n−3/2 for each data set represent charged impurity scattering and interface/alloy scattering limitations to the mobility.

Discussion and Conclusions

In this work we have described in detail technical aspects and growth conditions utilised in the ozone-assisted MBE growth of high mobility MgZnO/ZnO heterostructures. Each data set presented aims to identify unique sources of disorder. Addressing these culminates in the realization of heterostructures which display μ in excess of 106 cm2/Vs. We conclude this work by summarising the gains in Fig. 7a where the peak μ for respective historical growth regimes and the physics they enabled, namely the integer quantum Hall effect (IQHE) and fractional quantum Hall effect (FQHE), is displayed as a function of temperature using a similar representation to refs 3 and 33. Steady technological advances have enabled each step above the previous. Namely, the introduction of MBE as a replacement to pulsed laser deposition (PLD) between refs 11 and 30. Further refining the MBE growth conditions while still retaining oxygen plasma as the oxidizing species enabled the data in ref. 31. The use of ozone in ref. 15 reduced the residual impurity content of films and hence boosted the mobility significantly by enabling lower density ad therefore lower Mg content samples. Finally, refining the growth conditions using ozone in addition to the other technical advances detailed in this work gives the current data set. As analysed in ref. 14 in detail, the current generation of samples display τtr (≈600 ps) and τq (≈30 ps) comparable to AlGaAs/GaAs heterostructures of similar charge density. The magnetotransport of a heterostructure of μ = 1,200,000 cm2/Vs and n = 1.5 × 1011 cm−2 is shown in 7b at T < 20 mK. A rich array of FQH states is revealed at this temperature, including those in the lowest Landau level (ν < 2), where FQH sequences centred on both ν = 1/2 and 3/2 are observed. They are consistent with the hierarchy predicted by the composite fermion model1. In addition, states at higher filling factors (ν > 2) are resolved and are consistent with the conclusions drawn in ref. 28. We finally note that the Wigner-Seitz radius (rs) of the dilute (n ≈ 2 × 1010 cm−2) yet high mobility (μ ≈ 100,000 cm2/Vs) films realised in this work approaches values of 30 (assuming an effective mass of m* = 0.3 m0). In such a parameter space the ground state of a 2DES is predicted to show instability towards ferromagnetism or even Wigner crystallization34, which may account for the observed increase in resistance for T ≤ 500 mK. Exploring this entails the need for detailed I − V characteristics, as well as an understanding of the spin susceptibility of the 2DES, perhaps through rotation and/or electron spin resonance techniques. This opens the exciting avenue to study highly correlated electron physics in an rs regime previously inaccessible with heterostructures of this quality level.

Methods

Samples have been grown using an Epiquest RC2100 MBE chamber of base pressure 1 × 10−8 Pa when the liquid nitrogen jacket is filled. Single crystal Zn-polar [0001] ZnO substrates supplied by Tokyo Denpa of resistivity ρ ≤ 4 Ωcm were utilised. Low resistivity substrates were exclusively used due to their lower residual Li content resulting from their growth via hydrothermal method. These are prepared by dipping in HCl:H2O = 7:200 solution as described in ref. 17 and then heated to 200 °C within the MBE load-lock chamber (of pressure ~1 × 10−5 Pa). This temperature was increased from 150 °C used in previous studies after replacing the heating apparatus with a more efficient tungsten coil. Once inside the growth chamber, the substrate is gradually heated to Tg over a 30 minute time span and then held for 30 minutes under high vacuum before flux is introduced. The power dissipation of the heating unit is roughly 250 W. Two Zn (7N5) and two Mg (6N) conventional effusion cells are equipped and provide metallic flux from opposing directions within the growth chamber. The typical working temperatures for all cells is about 270 °C with a power dissipation of roughly 40 W. For the Zn flux, both cells are adjusted to be equal and used simultaneously whereas for Mg only one cell is opened. A Zn flux of 1.6 × 10−4 Pa resulted in a measured deposition rate of 1 Å/s of metal, corresponding to a flux of 6.5 × 1014 atoms/cm2 s. Liquid ozone is generated by a Meidensha MPOG-104A1-TH pure ozone generator and fed into the MBE chamber via a PID controlled piezoelectric leak valve (Oxford Applied Research PLV1000) where the pressure is read by a capacitive baratron and a feedback loop is established. O3 is delivered to the vicinity of the substrate through a Veeco low temperature gas cell set at T = 80 °C encased within a water cooled jacket. The exact purity of O3 reaching the substrate is unknown but should be close to 100% while within the gas lines. The substrate is rotated at a speed of 7 rpm during growth to enhance the uniformity of the sample35. The substrate temperature is monitored by both a thermocouple located at the centre of the heating coil and an infrared camera (detecting 8 μm wavelength radiation) located outside the chamber, which monitors the local substrate temperature, which we define as Tg, through a BaF2 viewport. The thickness of films is determined by a surface profiler, as the dilute Mg content in most films prevents an analysis via X-ray diffraction36. The exact Mg content for each film has not been investigated for similar reasons, but may be estimated through the relationship n = 1.5 x × 1013 cm−2 (ref. 10). Electrical measurements were performed using the van der Pauw method, where raw samples were cut into roughly 3 × 3 mm chips and then indium electrodes soldered at the corners. The high uniformity of Mg as a result of rotation during the growth allows the study of such large samples35. These were performed at temperatures T ≤ 500 mK in 3He and dilution refrigerators.

Additional Information

How to cite this article: Falson, J. et al. MgZnO/ZnO heterostructures with electron mobility exceeding 1 × 106 cm2/Vs. Sci. Rep. 6, 26598; doi: 10.1038/srep26598 (2016).

References

Sarma, S. D. & Pinczuk, A. Perspectives in the Quantum Hall Effects (John Willey & Sons, New York, 1997).

Dmitriev, I. A., Mirlin, A. D., Polyakov, D. G. & Zudov, M. A. Nonequilibrium phenomena in high Landau levels. Rev. Mod. Phys. 84, 1709–1763 (2012).

Pfeiffer, L. & West, K. The role of MBE in recent quantum Hall effect physics discoveries. Physica E: Low-dimensional Systems and Nanostructures 20, 57–64 (2003).

Umansky, V. et al. MBE growth of ultra-low disorder 2DEG with mobility exceeding 35 × 106 cm2/Vs. Journal of Crystal Growth 311, 1658–1661 (2009).

Manfra, M. J. Molecular Beam Epitaxy of Ultra-High-Quality AlGaAs/GaAs Heterostructures: Enabling Physics in Low-Dimensional Electronic Systems. Annual Review of Condensed Matter Physics 5, 347–373 (2014).

Hwang, E. H. & Das Sarma, S. Limit to two-dimensional mobility in modulation-doped GaAs quantum structures: How to achieve a mobility of 100 million. Phys. Rev. B 77, 235437 (2008).

Hwang, H. et al. Emergent phenomena at oxide interfaces. Nature materials 11, 103–113 (2012).

Schlom, D. G. Perspective: Oxide molecular-beam epitaxy rocks! APL Materials 3, 062403 (2015).

Tsukazaki, A. et al. High Electron Mobility Exceeding 104 cm2 V−1 s−1 in Mgx Zn1−xO/ZnO Single Heterostructures Grown by Molecular Beam Epitaxy. Applied Physics Express 1, 055004 (2008).

Kozuka, Y., Tsukazaki, A. & Kawasaki, M. Challenges and opportunities of ZnO-related single crystalline heterostructures. Applied Physics Reviews 1, 011303 (2014).

Tsukazaki, A. et al. Quantum Hall Effect in Polar Oxide Heterostructures. Science 315, 1388–1391 (2007).

Tampo, H. et al. Polarization-induced two-dimensional electron gases in ZnMgO/ZnO heterostructures. Applied Physics Letters 93, 202104 (2008).

Ambacher, O. et al. Two-dimensional electron gases induced by spontaneous and piezoelectric polarization charges in n-and ga-face algan/gan heterostructures. Journal of Applied Physics 85, 3222 (1999).

Falson, J. et al. Electron scattering times in ZnO based polar heterostructures. Applied Physics Letters 107, 082102 (2015).

Falson, J., Maryenko, D., Kozuka, Y., Tsukazaki, A. & Kawasaki, M. Magnesium doping controlled density and mobility of two-dimensional electron gas in MgxZn1−xO/ZnO heterostructures. Applied Physics Express 4, 091101 (2011).

Yuji, H. et al. Optimization of the Growth Conditions for Molecular Beam Epitaxy of MgxZn1−xO (0 ≤ x ≤ 0.12) Films on Zn-Polar ZnO Substrates. Japanese Journal of Applied Physics 49, 071104 (2010).

Akasaka, S. et al. Preparation of an Epitaxy-Ready Surface of a ZnO(0001) Substrate. Applied Physics Express 4, 035701 (2011).

Umansky, V., de Picciotto, R. & Heiblum, M. Extremely high-mobility two dimensional electron gas: Evaluation of scattering mechanisms. Applied Physics Letters 71, 683–685 (1997).

Ohashi, S. et al. Compact laser molecular beam epitaxy system using laser heating of substrate for oxide film growth. Review of Scientific Instruments 70, 178–183 (1999).

Akasaka, S., Tsukazaki, A., Nakahara, K., Ohtomo, A. & Kawasaki, M. Improvement of Electron Mobility above 100,000 cm2 V−1 s−1 in MgxZn1−xO/ZnO Heterostructures. Japanese Journal of Applied Physics 50, 080215 (2011).

Jin, Z. et al. High throughput fabrication of transition-metal-doped epitaxial ZnO thin films: A series of oxide-diluted magnetic semiconductors and their properties. Applied Physics Letters 78, 3824–3826 (2001).

Selim, F. A., Weber, M. H., Solodovnikov, D. & Lynn, K. G. Nature of Native Defects in ZnO. Phys. Rev. Lett. 99, 085502 (2007).

Janotti, A. & Van de Walle, C. G. Native point defects in ZnO. Phys. Rev. B 76, 165202 (2007).

McCluskey, M. D. & Jokela, S. J. Defects in ZnO. Journal of Applied Physics 106, 071101 (2009).

Gamez, G. & Muraki, K. ν = 5/2 fractional quantum Hall state in low-mobility electron systems: Different roles of disorder. Phys. Rev. B 88, 075308 (2013).

Deng, N. et al. ν = 5/2 Fractional Quantum Hall State in the Presence of Alloy Disorder. Phys. Rev. Lett. 112, 116804 (2014).

Ilani, S. et al. The microscopic nature of localization in the quantum Hall effect. Nature 427, 328–332 (2004).

Falson, J. et al. Even denominator fractional quantum Hall physics in ZnO. Nature Physics 11, 347–351 (2015).

Gamez, G. & Muraki, K. ν = 5/2 fractional quantum hall state in low-mobility electron systems: Different roles of disorder. Phys. Rev. B 88, 075308 (2013).

Nakano, M. et al. Electronic-Field Control of Two-Dimensional Electrons in Polymer-Gated-Oxide Semiconductor Heterostructures. Advanced Materials 22, 876–879 (2010).

Tsukazaki, A. et al. Observation of the fractional quantum Hall effect in an oxide. Nature materials 9, 889–893 (2010).

Manfra, M. J., Baldwin, K. W., Sergent, A. M., Molnar, R. J. & Caissie, J. Electron mobility in very low density GaN/AlGaN/GaN heterostructures. Applied Physics Letters 85, 1722–1724 (2004).

Schlom, D. G. & Pfeiffer, L. N. Oxide electronics: Upward mobility rocks! Nature materials 9, 881–883 (2010).

Tanatar, B. & Ceperley, D. M. Ground state of the two-dimensional electron gas. Phys. Rev. B 39, 5005–5016 (1989).

Uchida, M. et al. Calibration and control of in-plane Mg doping distribution in MgxZn1−xO/ZnO heterostructures grown by molecular beam epitaxy. Japanese Journal of Applied Physics 54, 028004 (2015).

Kozuka, Y. et al. Precise calibration of Mg concentration in MgxZn1−xO/ZnO thin films grown on ZnO substrates. Journal of Applied Physics 112, 043515 (2012).

Acknowledgements

We acknowledge discussions with K. von Klitzing, W. Dietsche, D. Maryenko and the technical assistance of S. Akasaka, K. Nakahara and the staff at Epiquest. This work was partly supported by JSPS Grant-in-Aid for Scientific Research(S) No. 24226002 and for Young Scientist (A) No. 23686008 and the “Funding Program for World-Leading Innovative R&D on Science and Technology (FIRST Program)”, initiated by the Council for Science and Technology Policy (CSTP). This work was carried out by joint research of the Cryogenic Research Center, the University of Tokyo.

Author information

Authors and Affiliations

Contributions

J.F. performed the experiments, analysed the data and wrote the manuscript. J.F., Y.K., M.U., J.H.S., T.-h.A., A.T. and M.K. discussed the MBE design, results and manuscript. M.K. supervised the project.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Falson, J., Kozuka, Y., Uchida, M. et al. MgZnO/ZnO heterostructures with electron mobility exceeding 1 × 106 cm2/Vs. Sci Rep 6, 26598 (2016). https://doi.org/10.1038/srep26598

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep26598

- Springer Nature Limited

This article is cited by

-

Strong Rashba parameter of two-dimensional electron gas at CaZrO3/SrTiO3 heterointerface

Scientific Reports (2023)

-

Velocity-field characteristics of MgxZn1−xO/ZnO heterostructures

Journal of Computational Electronics (2023)

-

Photo-oscillations in MgZnO/ZnO heterostructures

Scientific Reports (2022)

-

Competing correlated states around the zero-field Wigner crystallization transition of electrons in two dimensions

Nature Materials (2022)

-

Strong-correlation induced high-mobility electrons in Dirac semimetal of perovskite oxide

Nature Communications (2019)