Abstract

On the basis of the idea that the injecting energy will improve the conditions for the formation of Cooper pairs, a smart meta-superconductor (SMSC) was prepared by doping luminescent nanocomposite Y2O3:Eu3+/Ag in MgB2. To improve the superconducting transition temperature (TC) of the MgB2-based superconductor, two types of Y2O3:Eu3+/Ag, which has the strong luminescence characteristic, with different sizes were prepared and marked as m-Y2O3:Eu3+/Ag and n-Y2O3:Eu3+/Ag. MgB2 SMSC was prepared through an ex situ process. Results show that when the dopant content was fixed at 2.0 wt.%, the TC of MgB2 SMSC increased initially then decreased with the increase in the Ag content in the dopant. When the Ag content is 5%, the TC of MgB2 SMSC was 37.2–38.0 K, which was similar to that of pure MgB2. Meanwhile, the TC of MgB2 SMSC doped with n-Y2O3:Eu3+/Ag increased initially then decreased basically with the increase in the content of n-Y2O3:Eu3+/Ag, in which the Ag content is fixed at 5%. The TC of MgB2 SMSC doped with 0.5 wt.% n-Y2O3:Eu3+/Ag was 37.6–38.4 K, which was 0.4 K higher than that of pure MgB2. It is thought that the doping luminescent nanocomposite into the superconductor is a new means to improve the TC of SMSC.

Similar content being viewed by others

Introduction

Improving the superconducting critical transition temperature of materials is an important scientific and technical problem in condensed matter physics and materials science. Recently, Fausti et al.1 used mid-infrared femtosecond pulses to transform non-superconducting La1.675Eu0.2Sr0.125CuO4 into a transient 3D superconductor. A similar method was also applied to investigate YBa2Cu3O6.52 and K3C603,4 and good experimental results were achieved. Ye et al. have reported the observation of field-induced superconductivity of ZrNCl and MoS2 by quasi-continuous electrostatic carrier doping achieved by combining liquid and solid gating5,6. Drozdov et al.7 reported conventional superconductivity at 203 K under high pressure in a sulfur hydride system. Adu et al.8 increased the TC of commercial “dirty” MgB2 by conducting non-substitutional hole-doping of the MgB2 structure using minute, single-wall carbon nanotube inclusions. In accordance with homogeneous system theory9, Smolyaninov et al.10,11,12 stated that a superconducting metamaterial with an effective dielectric response function that is less and approximately equal to zero may exhibit high TC, and they verified this theory in their subsequent experiments. Recently, Cao et al.13,14 investigated correlated insulator behavior at half-filling in magic-angle graphene superlattices and reported the realization of intrinsic unconventional superconductivity in a 2D superlattice created by stacking two sheets of graphene that are twisted relative to each other at a small angle. Another important method for studying superconductivity is the topological superconductors15,16,17,18,19,20, which have attracted great attention in condensed matter physics. However, obtaining a practical superconductor with high TC remains difficult.

The superconductivity of MgB2 was discovered in 200121. MgB2 is a promising material with large-scale applications because of its excellent superconducting properties and simple crystal structure22,23,24,25,26,27. Considering that the TC of MgB2 is close to the McMillan temperature limit28,29, developing an effective experimental method to improve the TC of MgB2 is beneficial to its practical application and to the understanding of the superconducting mechanism. Chemical doping is a simple, effective, commonly used method to change the TC of superconducting materials. However, many experimental results have confirmed that conventional chemical doping decreases the TC of MgB230,31,32,33,34,35,36. To date, no effective method has been developed to improve the TC of MgB2. The use of metamaterial structures to achieve special properties is an important method developed in recent decades37,38,39,40,41, and it provides a new approach to improve the TC of superconducting materials.

On the basis of metamaterials, our group investigated the effects of ZnO electroluminescent (EL) material doping on the superconductivity of BSCCO in 2007 and attempted to change the TC of this superconductor42. Meanwhile, it is proposed that the combination of chemical doping and EL excitement, that is, doping EL materials in superconducting materials to form a meta structure, may be an effective method to improve the TC of superconductors43. On the basis of these results, a smart meta-superconductor (SMSC) model for improving the TC of materials has been proposed recently. In the model, the dopant phase is used to inject energy through its EL under the external field to strengthen the Cooper pairs, thereby achieving the purpose of changing the TC. Zhang et al.44 prepared MgB2 doped with Y2O3:Eu3+ particles through an in situ process. Tao et al.45 prepared MgB2 doped with Y2O3:Eu3+ nanorods with different EL intensities through an ex situ process. Their results indicated that doping EL materials is favorable for the improvement of TC compared with conventional doping, which always reduces the superconducting transition temperature of the sample. In addition, similar experimental results were obtained by replacing Y2O3:Eu3+ with Y3VO4:Eu3+ flakes46. Meanwhlie, results also indicated that the TC can be changed by adjusting the Y2O3:Eu3+ concentration and EL exciting current47. However, there are some problems need to improve in the experiments. Y2O3:Eu3+ particles or flakes tended to agglomerate during the preparation process and its EL intensity was weak44,45,46,47. The quality of commercial MgB2 was poor and its superconducting transition width (ΔT) is 4.6 K46,47, further experiment and improvement will be needed. Moreover, the dopants would decrease the TC in the case of double dopants, i.e., simultaneous incorporation of Y2O3:Eu3+ and nano-Ag into MgB2 47.

In this paper, a kind of new phase of luminescent nanocomposite Y2O3:Eu3+/Ag was prepared by compounding nano Ag into the Y2O3:Eu3+ matrix directly48. The luminescent intensity of Y2O3:Eu3+/Ag is three times higher than that of Y2O3:Eu3+ due to the composite illumination of EL and photoluminescence (PL). Two kinds of nanocomposite illuminator Y2O3:Eu3+/Ag with different sizes, namely, micro Y2O3:Eu3+/Ag (m-Y2O3:Eu3+/Ag) and nano Y2O3:Eu3+/Ag flakes (n-Y2O3:Eu3+/Ag), are prepared. Meanwhile, a new kind of commercial MgB2 with a small ΔT of 0.8 K was used. SMSC was prepared by doping Y2O3:Eu3+/Ag in MgB2 through an ex situ process49. The TC of the MgB2-based superconductor is investigated by changing the Ag content in the dopant phase, the sizes of the dopant phase, and the doping concentration. The results indicate that the TC of MgB2 doped with 0.5 wt.% n-Y2O3:Eu3+/Ag is 37.6–38.4 K, which is 0.4 K higher than that of pure MgB2, which further confirmed that the SMSC is a new way to improve the critical transition temperatures.

Experiment

Preparation of m-Y2O3:Eu3+/Ag and n-Y2O3:Eu3+/Ag

Y2O3 and Eu2O3 were weighed (the atomic ratio of Y and Eu is 0.95:0.05) and dissolved in a beaker with excess concentrated hydrochloric acid and subsequently heated and dried at 70 °C for 2 h to obtain a white precursor. One of the precursor was dissolved in 4 mL of deionized water to form a solution, and ammonium oxalate was added to it dropwise. The solution was subsequently stirred vigorously at 2 °C in a temperature-controlled water bath. A certain amount of AgNO3 was added to the solution after been stirred for 30 min. After another 30 min of stirring, the pH value of the solution was adjusted to 9–10 by adding NaOH. The final solution, designated as solution A, was obtained after another 30 min of stirring. Another precursor was also prepared into solution with 24 mL benzyl alcohol. Octylamine (4 mL) was added dropwise to the solution, which was subsequently stirred for 1 h. Afterward, a certain amount of AgNO3 was added to the solution. After stirring for another hour, another solution was obtained and designated as solution B. Solutions A and B were then transferred to two reaction kettles, respectively. A hydrothermal reaction occurred at 160 °C for 24 h. The products were washed several times with deionized water and absolute ethanol and sintered at 800 °C for 2 h to form Y2O3:Eu3+/AgCl. After illumination, the Y2O3:Eu3+/AgCl transformed into two kinds of luminescent Y2O3:Eu3+/Ag nanocomposite with different sizes and a certain amount of Ag. The two luminescent nanocomposite materials were designated as m-Y2O3:Eu3+/Ag and n-Y2O3:Eu3+/Ag. Y2O3:Eu3+/Ag with different Ag contents was prepared by changing the AgNO3 content. In this paper, Ag contents uniformly refers to the initial nominal atomic ratio of Ag and Y. For example, 5% Ag means that the initial nominal atomic ratio of Ag to Y is 0.05:0.95. Meanwhile, similar method was applied to synthesize Y2O3 and Y2O3:Sm3+.

Preparation of MgB2–based SMSC

At a certain ratio, commercial MgB2 powder (Alfa Aesar) and the luminescent nanocomposite Y2O3:Eu3+/Ag were weighed and prepared into an alcohol solution. The two suspensions were sonicated for 20 min, then the dopant was added dropwise to MgB2. After sonication for more than 20 min, the mixed solution was transferred to a culture dish. Subsequently, the culture dish was placed in a vacuum oven at 60 °C for 4 h to yield a black powder. The powder was pressed into a pellet with a diameter of 11 mm and a thickness of 2 mm and placed in a small tantalum container, which was annealed at 800 °C for 2 h in high-purity argon atmosphere. The MgB2-based superconductor doped with luminescent nanocomposite materials of different sizes and Ag contents was synthesized to investigative the TC of SMSC.

Results and Discussion

Figure 1a shows the EL spectra of Y2O3, Y2O3:Eu3+, m-Y2O3:Eu3+/Ag, and n-Y2O3:Eu3+/Ag. The Ag content of the luminescent nanocomposite materials was 5.0%. It shows that Y2O3 is a non-EL material and becomes a kind of EL material after the addition of a small amount of Eu element. The results also indicate that the EL intensity of the luminescent m-Y2O3:Eu3+/Ag nanocomposite and n-Y2O3:Eu3+/Ag is remarkably improved primarily due to the composite luminescence of the electroluminescence of Eu3+ centric and the surface plasma-enhanced photoluminescence of Ag. Among the four dopants, n-Y2O3:Eu3+/Ag had the highest EL intensity. Figure 1b shows the SEM image of m-Y2O3:Eu3+/Ag. The surface size and thickness of the m-Y2O3:Eu3+/Ag flake are approximately 300 nm and 30 nm, respectively. Figure 1c,d show AFM images of n-Y2O3:Eu3+/Ag and Fig. 1d presents a cross section of the AFM image in Fig. 1c. Figure 1e,f show TEM images of n-Y2O3:Eu3+/Ag. It can be seen that the surface size of n-Y2O3:Eu3+/Ag was 20 nm, and its thickness was approximately 2.5 nm, which is much smaller than that of m-Y2O3:Eu3+/Ag.

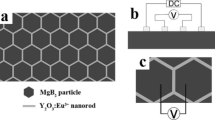

Figure 2a shows the SEM image of pure MgB2. The size of the MgB2 particle was approximately 0.1–1 μm. The TC of the samples was determined based on the R–T curve, which was measured using a four-probe method in a liquid helium cryogenic system developed by the Advanced Research Systems Company. Figure 2b shows the normalized R–T curve of pure MgB2 and indicates that the onset temperature (Ton c) and offset temperature (Toff c)50,51 of pure MgB2 were 38.0 and 37.2 K, respectively. The ΔT of pure MgB2 was 0.8 K. Figure 2c shows the XRD spectra of pure MgB2 and partially doped samples, in which the standard card of MgB2 (PDF#38-1369) is demonstrated using black vertical lines. The results showed that the XRD spectrum of pure MgB2 (black curve) matched the standard card of MgB2 well, except for the inevitable small amount of the MgO phase52,53,54,55. The red and blue curves represent the XRD spectra of MgB2 doped with 2.0 wt.% m-Y2O3:Eu3+/Ag and 2.0 wt.% n-Y2O3:Eu3+/Ag, respectively. The Ag content was 5.0%. The main phase of the doped samples was MgB2. Moreover, apart from a small amount of the MgO phase, the Y2O3 phase was also found in the XRD spectra of the doped samples. The XRD spectra of the other doped samples were similar.

Figure 3 shows the normalized R–T curves of MgB2 doped with m-Y2O3:Eu3+/Ag with different Ag contents. On the basis of the results of our previous study45,46, the content of m-Y2O3:Eu3+/Ag in the four samples was fixed at 2.0 wt.%. The Ag contents of m-Y2O3:Eu3+/Ag in the four samples were 1.0%, 4.0%, 5.0%, and 8.0%, as shown in the figure, and their TC values were 34.8–35.6, 36.0–36.8, 37.2–38.0, and 34.8–35.6 K, respectively. The TC of the doped samples initially increased then decreased with the increase in Ag content. Meanwhile, the corresponding doped sample had the highest TC when the concentration of m-Y2O3:Eu3+/Ag was fixed at 2.0 wt.% and the Ag content was 5.0%, which is equal to that of pure MgB2. The experimental results are similar to those of our previous studies, that is, doping EL materials may improve TC in several cases compared with conventional doping, which always reduces the TC of the sample. As a dopant, m-Y2O3:Eu3+/Ag exerts an impurity effect that decreases TC. Meanwhile, as an EL material, m-Y2O3:Eu3+/Ag exerts an EL exciting effect that increases TC 45,46. An obvious competitive relationship exists between the impurity effect and the EL exciting effect. The final TC of the samples increased when the EL exciting effect was fully utilized and the impurity effect was minimized.

Figure 4 shows the normalized R–T curves of MgB2 doped with 0.1–2.0 wt.% n-Y2O3:Eu3+/Ag. Ag concentration was fixed at 5.0%. It can be seen that TC of MgB2 doped with n-Y2O3:Eu3+/Ag initially decreased, increased, then decreased again with the increase in doping concentration. A too low or too high doping concentration reduces TC, which is similar to the finding of our previous study. When the doping concentration was in a low range, TC decreased with the increase in doping concentration due to the dominance of the impurity effect of the dopant, which is similar to the results of conventional doping. The EL exciting effect of the dopant dominated with the further increase in doping concentration, resulting in the increase in TC. The samples doped with 0.5 wt.% n-Y2O3:Eu3+/Ag had the highest TC of 37.6–38.4 K, which is 0.4 K higher than that of pure MgB2. However, the impurity effect of the dopant dominated when the doping concentration increased to a high range, which led to a low TC. These results indicate that doping luminescent nanocomposite materials effectively adjusts and improves TC at an appropriate doping concentration.

MgB2 doped with non-EL materials Y2O3 and Y2O3:Sm3+ were synthesized to prove the conclusions above. Figure 5 shows the normalized R–T curves of MgB2 doped with Y2O3, Y2O3:Sm3+, Y2O3:Eu3+, and n-Y2O3:Eu3+/Ag. The doping concentration was fixed at 0.6 wt.%, and the Ag content in n-Y2O3:Eu3+/Ag was 5.0%. Results indicated that TC of MgB2 doped with non-EL materials Y2O3 or Y2O3:Sm3+ was much lower than that of pure MgB2, which is different from MgB2 doped with EL materials at the same concentration. MgB2 doped with Y2O3:Eu3+ increased to 36.6–37.4 K due to the EL exciting effect. Meanwhile, MgB2 doped with the luminescent n-Y2O3:Eu3+/Ag nanocomposite further increased to 37.0–37.8 K. The results show that doping EL materials facilitates an increase in TC in several cases compared with conventional doping, which always reduces the TC of the sample. Meanwhile, luminescent Y2O3:Eu3+/Ag nanocomposite materials increase the TC of MgB2 due to the strong EL intensity.

The results in Fig. 4 show that the optimum concentration of n-Y2O3:Eu3+/Ag is 0.5 wt.%, which is lower than the value in our previous study44,45,46 due to the small size of n-Y2O3:Eu3+/Ag. The disadvantages caused by the impurity effect can be reduced if luminescent nanocomposite materials have a small size and are relatively evenly distributed in the sample. Moreover, the ΔT of commercial MgB2 in our previous study46 was too large to accurately determine the influence of the dopant phase on TC. In the current study, a new kind of commercial MgB2 with a small ΔT of 0.8 K was used, and we obtained a similar conclusion, which further proves the effectiveness of this method.

Conclusions

In this paper, two types of luminescent nanocomposite Y2O3:Eu3+/Ag with different sizes were prepared and marked as m-Y2O3:Eu3+/Ag and n-Y2O3:Eu3+/Ag. SEM and AFM images indicated that the surface size and thickness of m-Y2O3:Eu3+/Ag are approximately 300 nm and 30 nm, which are 20 nm and 2.5 nm for n-Y2O3:Eu3+/Ag. The EL spectra showed that the luminescent intensity of Y2O3:Eu3+/Ag is three times higher than that of Y2O3:Eu3+. MgB2 of SMSC was prepared through an ex situ process to improve the TC of the MgB2-based superconductor on the basis of the idea that the injecting energy will improve the conditions for the formation of Cooper pairs. The TC of MgB2 SMSC was determined based on the measured R–T curve by using the four-probe method in a liquid helium cryogenic system. Results show that the TC of MgB2 SMSC initially increased then decreased with the increase in the Ag content when m-Y2O3:Eu3+/Ag content was fixed at 2.0 wt.%. When the Ag content was 5.0%, the TC of MgB2 SMSC doped with 2.0 wt.% m-Y2O3:Eu3+/Ag was 37.2–38.0 K, which was equal to that of pure MgB2. Meanwhile, the TC of MgB2 SMSC doped with n-Y2O3:Eu3+/Ag increased initially then decreased basically with the increase in the content of n-Y2O3:Eu3+/Ag, in which the Ag content is fixed at 5%. The TC of MgB2 SMSC doped with 0.5 wt.% n-Y2O3:Eu3+/Ag was 37.6–38.4 K, which was 0.4 K higher than that of pure MgB2. It is thought that the doping luminescent nanocomposite into the superconductor is a new means to improve the TC of SMSC. However, the increase in the TC remains insufficient. In future work, new dopant phases with improved characteristics will be prepared to increase the TC of MgB2. Meanwhile, we will attempt to apply this method to other superconductors.

References

Fausti, D. et al. Light-Induced Superconductivity in a Stripe-Ordered Cuprate. Science 331, 189–191 (2011).

Hu, W. et al. Optically enhanced coherent transport in YBa2Cu3O6.5 by ultrafast redistribution of interlayer coupling. Nat. Mater. 13, 705–711 (2014).

Mitrano, M. et al. Possible light-induced superconductivity in K3C60 at high temperature. Nature 530, 461–464 (2016).

Cantaluppi, A. et al. Pressure tuning of light-induced superconductivity in K3C60. Nat. Phys. 14, 837–841 (2018).

Ye, J. T. et al. Liquid-gated interface superconductivity on an atomically flat film. Nat. Mater. 9, 125–128 (2010).

Ye, J. T. et al. Superconducting Dome in a Gate-Tuned Band Insulator. Science 338, 1193–1196 (2012).

Drozdov, A. P., Eremets, M. I., Troyan, I. A., Ksenofontov, V. & Shylin, S. I. Conventional superconductivity at 203 kelvin at high pressures in the sulfur hydride system. Nature 525, 73–76 (2015).

Ma, D. H. et al. Enhancing the superconducting temperature of MgB2 by SWCNT dilution. Physica C 497, 43–48 (2014).

Kirzhnits, D. A., Maksimov, E. G. & Khomskii, D. I. The description of superconductivity in terms of dielectric response function. J. Low Temp. Phys. 10, 79–93 (1973).

Smolyaninova, V. N. et al. Experimental demonstration of superconducting critical temperature increase in electromagnetic metamaterials. Sci. Rep. 4, 7321 (2014).

Smolyaninova, V. N. et al. Using metamaterial nanoengineering to triple the superconducting critical temperature of bulk aluminum. Sci. Rep. 5, 15777 (2015).

Smolyaninov, I. I. & Smolyaninova, V. N. Theoretical modeling of critical temperature increase in metamaterial superconductors. Phys. Rev. B 93, 184510 (2016).

Cao, Y. et al. Correlated insulator behaviour at half-filling in magic-angle graphene superlattices. Nature 556, 80–84 (2018).

Cao, Y. et al. Unconventional superconductivity in magic-angle graphene superlattices. Nature 556, 43–50 (2018).

Qi, X. L. & Zhang, S. C. Topological insulators and superconductors. Rev. Mod. Phys. 83, 1057–1110 (2011).

Wang, Z., Qi, X. L. & Zhang, S. C. Topological field theory and thermal responses of interacting topological superconductors. Phys. Rev. B 84, 014527 (2011).

Leijnse, M. & Flensberg, K. Introduction to topological superconductivity and Majorana fermions. Semicond. Sci. Technol. 27, 124003 (2012).

Schnyder, A. P. & Brydon, P. M. Topological surface states in nodal superconductors. J. Phys.: Condens. Matter 27, 243201 (2015).

Sato, M. & Ando, Y. Topological superconductors: a review. Rep. Prog. Phys. 80, 076501 (2017).

Fatemi, V. et al. Electrically tunable low-density superconductivity in a monolayer topological insulator. Science, https://doi.org/10.1126/science.aar4642 (2018).

Nagamatsu, J., Nakagawa, N., Muranaka, T., Zenitani, Y. & Akimitsu, J. Superconductivity at 39 K in magnesium diboride. Nature 410, 63–64 (2001).

Buzea, C. & Yamashita, T. Review of the superconducting properties of MgB2. Supercond. Sci. Technol. 14, R115–R146 (2001).

Eisterer, M. Magnetic properties and critical currents of MgB2. Supercond. Sci. Technol. 20, R47–R73 (2007).

Vinod, K., Varghese, N. & Syamaprasad, U. Superconductivity of MgB2 in the BCS framework with emphasis on extrinsic effects on critical temperature. Supercond. Sci. Technol. 20, R31–R45 (2007).

Xi, X. X. Two-band superconductor magnesium diboride. Rep. Prog. Phys. 71, 116501 (2008).

Ma, Z. Q., Liu, Y. C. & Cai, Q. The synthesis of lamellar nano MgB2 grains with nanoimpurities, flux pinning centers and their significantly improved critical current density. Nanoscale 4, 2060–2065 (2012).

Prikhna, T. A. et al. Nanostructural inhomogeneities acting as pinning centers in bulk MgB2 with low and enhanced grain connectivity. Supercond. Sci. Technol. 27, 044013 (2014).

Bardeen, J., Cooper, L. N. & Schrieffer, J. R. Theory of Superconductivity. Phys. Rev. 108, 1175–1204 (1957).

McMillan, W. L. Transition Temperature of Strong-Coupled Superconductors. Phys. Rev. 167, 331–344 (1968).

Slusky, J. S. et al. Loss of superconductivity with the addition of Al to MgB2 and a structural transition in Mg1-xAlxB2. Nature 410, 343–345 (2001).

Zhao, Y. G. et al. Effect of Li doping on structure and superconducting transition temperature of Mg1−xLixB2. Physica C 361, 91–94 (2001).

Luo, H., Li, C. M., Luo, H. M. & Ding, S. Y. Study of Al doping effect on superconductivity of Mg1−xAlxB2. J. Appl. Phys. 91, 7122–7124 (2002).

Cava, R. J., Zandbergen, H. W. & Inumaru, K. The substitutional chemistry of MgB2. Physica C 385, 8–15 (2003).

Kazakov, S. M. et al. Carbon substitution in MgB2 single crystals: Structural and superconducting properties. Phys. Rev. B 71, 024533 (2005).

Bianconi, A. et al. Controlling the Critical Temperature in Mg1−xAlxB2. J. Supercond. Nov. Magn. 20, 495–501 (2007).

Monni, M. et al. Role of charge doping and lattice distortions in codoped Mg1−x(AlLi)xB2 compounds. Physica C 460–462, 598–599 (2007).

Liu, H., Zhao, X. P., Yang, Y., Li, Q. W. & Lv, J. Fabrication of Infrared Left‐Handed Metamaterials via Double Template‐Assisted Electrochemical Deposition. Adv. Mater. 20, 2050–2054 (2008).

Qiao, Y. P., Zhao, X. P. & Su, Y. Y. Dielectric metamaterial particles with enhanced efficiency of mechanical/electrical energy transformation. J. Mater. Chem. 21, 394–399 (2011).

Kurter, C. et al. Switching nonlinearity in a superconductor-enhanced metamaterial. Appl. Phys. Lett. 100, 121906 (2012).

Zhao, X. P. Bottom-up fabrication methods of optical metamaterials. J. Mater. Chem. 22, 9439–9449 (2012).

Ma, X. et al. Meta-Chirality: Fundamentals, Construction and Applications. Nanomaterials 7, 116 (2017).

Jiang, W. T., Xu, Z. L., Chen, Z. & Zhao, X. P. Introduce uniformly distributed ZnO nano-defects into BSCCO superconductors by nano-composite method. J. Funct. Mater 38, 157–160, in Chinese, available at, http://www.cnki.com.cn/Article/CJFDTOTAL-GNCL200701046.htm (2007).

Xu, S. H., Zhou, Y. W. & Zhao, X. P. Research and Development of Inorganic Powder EL Materials. Mater. Rev. 21, 162–166, in Chinese, available at, http://www.cnki.com.cn/Article/CJFDTotal-CLDB2007S3048.htm (2007).

Zhang, Z. W., Tao, S., Chen, G. W. & Zhao, X. P. Improving the Critical Temperature of MgB2 Superconducting Metamaterials Induced by Electroluminescence. J. Supercond. Nov. Magn. 29, 1159–1162 (2016).

Tao, S., Li, Y. B., Chen, G. W. & Zhao, X. P. Critical Temperature of Smart Meta-superconducting MgB2. J. Supercond. Nov. Magn. 30, 1405–1411 (2017).

Li, Y. B., Chen, H. G., Qi, W. C., Chen, G. W. & Zhao, X. P. Inhomogeneous Phase Effect of Smart Meta-Superconducting MgB2. J. Low Temp. Phys. 191, 217–227 (2018).

Chen, H. G., Li, Y. B., Chen, G. W., Xu, L. X. & Zhao, X. P. The Effect of Inhomogeneous Phase on the Critical Temperature of Smart Meta-superconductor MgB2. J. Supercond. Nov. Magn. 31, 3175–3182 (2018).

Wang, M. Z., Xu, L. X., Chen, G. W. & Zhao, X. P. Topological luminophor Y2O3:Eu3+ + Ag with high electroluminescence performance. ACS Appl. Mater. Interfaces 11, 2328–2335 (2019).

Zhao, X. P., Li, Y. B., Chen, H. G. & Chen, G. W. MgB2-based superconductor constructed by inhomogeneous phase of topological illuminator and its preparation method. Chinese Patent 201810462942.X.

Kušević, I. et al. Flux pinning and critical currents in polycrystalline MgB2. Solid State Commun. 122, 347–350 (2002).

Bhadauria, P. P. S., Gupta, A., Kishan, H. & Narlikar, A. V. Connectivity and critical current density of in-situ processed MgB2 superconductors: Effect of excess Mg and non-carbon based additives. J. Appl. Phys. 115, 183905 (2014).

Eyidi, D. et al. Phase analysis of superconducting polycrystalline MgB2. Micron 34, 85–96 (2003).

Shi, Q. Z., Liu, Y. C., Gao, Z. M. & Zhao, Q. Formation of MgO whiskers on the surface of bulk MgB2 superconductors during in situ sintering. J. Mater. Sci. 43, 1438–1443 (2007).

Ma, Z. Q., Liu, Y. C., Shi, Q. Z., Zhao, Q. & Gao, Z. M. The improved superconductive properties of MgB2 bulks with minor Cu addition through reducing the MgO impurity. Physica C 468, 2250–2253 (2008).

Singh, D. K., Tiwari, B., Jha, R., Kishan, H. & Awana, V. P. S. Role of MgO impurity on the superconducting properties of MgB2. Physica C 505, 104–108 (2014).

Acknowledgements

This work was supported by the National Natural Science Foundation of China for Distinguished Young Scholar under Grant No. 50025207.

Author information

Authors and Affiliations

Contributions

X.Z. conceived and led the project; Y.L., H.C. and X.Z. designed the experiments; Y.L., H.C., M.W. and L.X. performed the experiments and characterized the samples; all authors discussed and analyzed the results; Y.L. wrote the paper with input from all co-authors; X.Z. and Y.L. discussed the results and revised the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, Y., Chen, H., Wang, M. et al. Smart meta-superconductor MgB2 constructed by the dopant phase of luminescent nanocomposite. Sci Rep 9, 14194 (2019). https://doi.org/10.1038/s41598-019-50663-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-50663-6

- Springer Nature Limited

This article is cited by

-

Green-light p-n junction particle inhomogeneous phase enhancement of MgB2 smart meta-superconductors

Journal of Materials Science: Materials in Electronics (2024)

-

Smart Metastructure Method for Increasing TC of Bi(Pb)SrCaCuO High-Temperature Superconductors

Journal of Superconductivity and Novel Magnetism (2020)