Abstract

para-Substituted bis(3-aminopropyl)hexaisobutyl-cage octasilsesquioxane (T8 cage) (1) was polymerized with several diisocyanates; methylenediphenyl 4,4’-diisocyanate (2a), 4,4’-diisocyanato-3,3’-dimethylbiphenyl (2b), m-xylene diisocyanate (2c), 1,3-bis(isocyanatomethyl)cyclohexane (2d), tolylene-2,4-diisocyanate (2e), and tolylene-2,6-diisocyanate (2f), at room temperature to prepare T8-polyureas (3). Gel formation was observed immediately during the addition of 2 to the solution of 1 when above the critical gel concentrations (Cgs). T8-polyureas with phenylurea moieties, 3a, 3b, 3e, and 3f, promoted organogel formation in comparison with T8-polyureas with nonphenylurea moieties, 3c and 3d. The substitution of methyl groups at the ortho position of the phenylurea groups provided lower Cgs. FT-IR analysis suggests that increasing the intermolecular hydrogen bonding between the ureido groups in T8-polyurea enhanced the organogel formation. We also studied the POSS structure-dependent properties of the polyureas, in which the T8 cages were replaced by double-decker-shaped phenyl-substituted silsesquioxane (DDSQ) units. Polymerization was conducted at various concentrations, and it was found that no organogels were formed below the solubility limit of the monomers except when 2f was used. This observation suggests that the polyureas containing the isobutyl-substituted T8 units promoted organogel formation in comparison with those containing DDSQ units.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

Obtaining organogels of low-molecular-weight compounds, oligomers, and polymers via a self-assembly process is attractive interested not only in supramolecular chemistry but also for a wide variety of applications [1,2,3]. Low-molecular-weight gelators (LMWGs) self-assemble into one-dimensional fibrillar structures in organic solvents by using noncovalent interactions such as electrostatic interactions, hydrogen bonding, π–π-stacking, and van der Waals interactions. Gelation may cause rather than a solution or a precipitate in a suitable solvent, if the gelator–solvent and gelator–gelator interactions are suitably balanced [4]. However, the molecular design and controlling the gel performance of LMWGs are hardly well established, because most of LMWGs have been serendipitously discovered. Most LMWGs form organogels at less than 0.05 g/ml but tend to crystallize during long-term storage [5]. On the other hand, polymer type organogelators form organogels without crystallization, while critical gel concentrations are relatively high [2]. Although many polymeric hydrogels have been reported, most conventional polymers do not form an organogel in organic solvents. There are only a limited number of polymeric organogelators and their organogelation abilities are lower than those of LMWGs [6].

Polyhedral oligomeric silsesquioxanes (POSSs), denoted as (RSiO1.5)8, have recently been regarded as promising frameworks for designing polymeric materials based on element-blocks [7,8,9,10]. POSSs are well-defined organic–inorganic hybrid molecules containing rigid inorganic cores with flexible organic substituents in the periphery. Several types of POSS-containing polymers have been prepared, including main-chain types from bifunctional POSS monomers [11,12,13,14,15,16,17,18,19], side-chain and end-cap types from monofunctional POSS monomers, and network types from octa-functional POSSs. Hydrogels containing POSSs have been designed to achieve improved thermal and mechanical properties, thereby broadening the applications of these materials [20]. Organogels were obtained by chemical cross-linking of poly(styrene-co-chloromethylstyrene) with multifunctional POSS nanoparticles [21]. End-cap and pendant type polymers have been reported to form hydrogels via the hydrophobic nature of the POSS units [22, 23].

However, POSS-based organogels via self-assembly processes have seldom been reported [24]. We have been investigating the preparation of POSS-main chain type polymers based on the development of difunctional cage octasilsesquioxane (T8 cage) monomers [16,17,18]. Previously, we showed that the incorporation of the isobutyl-substituted T8-unit in the poly(azomethine) main chain provided homogeneous polymerization solution from a para-substituted bis(3-aminopropyl)hexaisobutyl-T8 cage (1) with several dialdehyde comonomers (Fig. 1) [19]. Organogels were formed after the resulting homogeneous polymerization solution was concentrated under a reduced pressure at room temperature. We replaced the T8 cages in the poly(azomethine)s with double-decker-shaped phenyl-substituted silsesquioxane (DDSQ) units to study the POSS structure-dependent physical gel formation behavior [25]. In contrast to the T8 cage-containing poly(azomethine)s, precipitates appeared when the homogeneous polymerization solutions of the DDSQ-containing poly(azomethine)s were sufficiently concentrated under reduced pressure. The higher solubility in a wide range of solvents for the isobutyl-substituted-T8 unit may provide a suitable balance for the organogel formation in the case of the poly(azomethine)s with the isobutyl-substituted T8 units in the main chains. The lowest critical gel concentration (Cg) for the T8-polyazomethines was 0.30 g/ml. This value is significantly higher than that of most LMWGs, which form organogels at less than 0.05 g/ml.

Previously, we reported polymerization of 1 with several diisocyanates to prepare beads-on-string-shaped polyureas, which showed high thermal conductivities as well as good optical transparencies [26]. Polymerization in 4-methyltetrahydropyran (MTHP) proceeded in a homogeneous solution in a relatively diluted solution. When toluene and p-xylene were used instead of MTHP for polymerization at similar concentrations, organogel formation was observed during the polymerizations. Introducing the ureido groups in the T8-based polymers may promote organogel formation. Indeed, various LMWGs with ureido groups have been widely developed [27, 28]. Herein, we studied the organogel formation behaviors of beads-on-string-shaped polyureas. Gel formation was observed immediately during the addition of diisocyanate and complete gel formation above Cg. Gels were formed during the polymerization. We found that the lowest Cg was observed for polyurea at 0.022 g/ml in toluene. This concentration was comparable to that of usual low-molecular-weight organogels. Cg was highly dependent on the comonomer structures. The Fourier transform infrared (FT-IR) analysis suggested that increasing the intermolecular interaction between the ureido groups in T8-polyurea enhanced organogel formation. We also replaced the T8 cages with DDSQ units to study the POSS structure-dependent organogel formation behavior.

Experimental procedures

Materials

All the solvents and chemicals used here were obtained as reagent-grade quality and used without further purification. para-Bis(3-aminopropyl)hexaisobutyl-substituted T8 cage (1) [17] and 3,13-bis(3-aminopropyl) DDSQ (4) [25] were prepared according to our previous reports.

Instruments

FT-IR spectra were obtained with a JASCO FT/IR-4600 (JASCO, Tokyo, Japan) spectrometer. The surface of the films was observed using scanning electron microscopy (SEM) (VE-8800, KEYENCE, Osaka, Japan). X-ray diffraction (XRD) experiments were performed with a Rigaku MiniFlex600 X-ray diffractometer using X-rays from 600 W X-ray tubes (CuKα, λ = 1.54 Å) and a D/teX Ultra2 semiconductor detector.

Polymerization

A typical polymerization for gel formation is as follows. First, 1 (0.105 g, 0.120 mmol) and 2a (0.0298 g, 0.119 mmol) were mixed in THF (1.0 mL) and stirred at room temperature for 2 h to obtain a gel.

Results and discussion

Gelation behavior

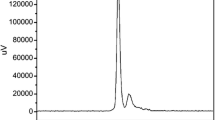

para-Bis(3-aminopropyl)hexaisobutyl-substituted T8 cage (1) was polymerized with several diisocyanates, namely, methylenediphenyl 4,4’-diisocyanate (2a), 4,4’-diisocyanato-3,3’-dimethylbiphenyl (2b), m-xylene diisocyanate (2c), 1,3-bis(isocyanatomethyl)cyclohexane (2d), tolylene-2,4-diisocyanate (2e), and tolylene-2,6-diisocyanate (2f), in THF at room temperature (Scheme 1). A solution of diisocyanate was added to a solution of 1 under stirring at room temperature. Polymerization was conducted at various concentrations (Supplementary Fig. S1). The critical gel concentrations (Cgs) were determined as the lowest concentrations of gel formation within the range of the experimental polymerization concentrations. Gel formation was observed immediately during the addition of the diisocyanate to a solution of 1 when stirring above the Cgs and completely swollen gels were formed after finishing the addition of diisocyanate. The homogeneous polymerization solutions at below the Cgs were maintained for at least several hours at room temperature. We found that the Cgs were dependent on the structures of 2 (Table 1). The tested T8-polyureas can be classified into two categories, i.e., T8-polyureas with nonphenylurea moieties (3c and 3d) and T8-polyureas with phenylurea moieties (3a, 3b, 3e, and 3f). The Cgs of the latter were lower than those of the former. The lowest Cg was observed for 3b at 0.080 g/ml in THF. This concentration was comparable to that of typical LMWGs [5]. Transparent gels were formed in the case of 3c and 3d, whereas cloudy gels were obtained in the case of 3a and 3b (Fig. 2b). Other T8-polyureas with phenylurea moieties, 3e and 3f, provided slightly cloudy gels. Lower critical gel concentrations tended to form cloudy gels. Cloudy sols were initially observed for 3a and 3b during the addition of diisocyanate into a THF solution of 1.

XRD patterns of all the dried gels from the THF polymerization solutions showed broad peaks, indicating their amorphous character (Supplementary Fig. S2). d-Spacing evaluated from the broad diffraction peaks at a 2θ value of 8.2° was 1.1 nm, of which value is in good agreement with the size of the isobutyl-substituted T8 caged unit [29]. These data indicate that the T8-cages in the T8-polyureas were densely packed without crystalline structures.

Free-standing films were obtained by casting diluted homogenous polymerization solutions of THF onto Teflon sheets. The concentrations of the polymerization solutions for 3 were 0.11 g/ml except for 3b (0.068 g/ml), which were just below the Cgs. At these concentrations, the polymerizations proceeded in a homogeneous solution. Opaque films were obtained from the polymerization solutions from 1 with 2a and 2b. The optical transmittances of the colorless films of the T8-polyureas with nonphenylurea moieties 3c and 3d were over 90% in the visible region (400–780 nm) at film thicknesses of 0.1 mm (Supplementary Fig. S3). Smooth and homogeneous surfaces were observed for the transparent films of 3c, 3d, 3e, and 3f by SEM analyses (Fig. 3). On the other hand, spherical spots were recognized on the surfaces of the opaque films of 3a and 3b. Since the XRD traces of the films produced using 3a and 3b indicate amorphous character, the spherical spots were not derived from crystallized domains. They may be caused by precipitation during casting of the polymerization solution. Inhomogeneous phase separation proceeded in these cases.

The Cgs were studied using various other solvents, MTHP, toluene, and p-xylene. The results are also summarized in Table 1. Compared with other polyureas, the T8-polyureas of 3a, 3b, and 3f tended to promote organogel formation. The lower the polarity of the solvents leads to a decrease in the Cgs. The lowest Cgs were observed for 3b in all the tested solvents. We found that the lowest Cg was observed for the polyurea of 3b at 0.022 g/ml in toluene. Although the Cg for 3f in THF was higher than that of 3a, a lower Cg of 0.084 g/ml was observed in MTHP for 3f. In the case of using MTHP as a solvent, cloudy gels were also observed for 3f in addition to 3a and 3b (Fig. 2c).

The gel of 3c obtained in p-xylene (0.13 g/ml) became completely fluid at 75 °C for 40 min, and reformed into a gel after being cooled to 25 °C. This observation suggests that the network structure of the gel was formed by a noncovalent interaction between the polymer chains. However, the gels of 3a and 3b in MTHP and THF (0.14 and 0.10 g/ml, respectively) hardly became fluid even when the gel was heated at 75 °C for 40 min. These observations suggest that the noncovalent interaction of 3a and 3b was higher than that of 3c. The higher the noncovalent interaction may cause the lower the Cgs.

We replaced the T8 cages with DDSQ units to elucidate the POSS structure-dependent organogel formation behavior. The polymerization of 3,13-bis(3-aminopropyl)-DDSQ (4) with several diisocyanates (2) was performed in THF at room temperature (Scheme 1), because 4 was hardly soluble in p-xylene, toluene, and MTHP. Polymerization was conducted at various concentrations, and it was found that no organogels were formed below the solubility limit of the monomers except 5f (Table 1). The Cg for 5f was 0.06 g/ml in THF. Although all the dried T8-polyureas (3) were insoluble in all tested solvents, the dried DDSQ-polyureas (5) were readily soluble in THF.

Characterization of the dried gels

The FT-IR spectra of the dried gels after heating the obtained gels in vacuo showed characteristic peaks assignable to the urea units at approximately 1550 cm−1 (CO-N-H, amide H), and approximately 1640 cm−1 (C=O, amide I) (Supplementary Fig. S4). A -N=C=O stretching band at 2265 cm−1 was hardly observed in all the cases, indicating that little 2 remained even though gels formed during the addition of the diisocyanate. Characteristic asymmetric stretching of the Si-O-Si of the cage framework at 1090 cm−1 suggested no decomposition of the T8 cage structure.

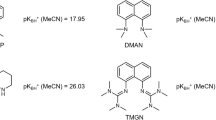

Polyureas can form hydrogen-bonding networks between the hydrogen atoms in the two urea groups (-NH-) and the oxygen atoms in the carbonyl groups (-CO-). In the case of N-aryl-N’-alkyl ureas, for example, the C=O stretching bands at 1690, 1650, and 1630 cm−1 can be assigned to “free,” “disorder,” and “order” or “crystalline” carbonyl groups, respectively [30, 31]. In other words, the number of vibrations for the C=O stretching bands decreases with increasing the hydrogen-bonding strength [32]. The dried gels prepared from MTHP solutions were subjected to measured FT-IR analysis (Fig. 4). Among the T8-polyureas with phenylurea moieties 3a, 3b, 3e, and 3f, the FT-IR analysis of 3b and 3f showed relatively sharp C=O stretching bands centered at 1640 and 1643 cm−1, respectively. On the other hand, the FT-IR analysis of 3a and 3e showed broad C=O stretching bands centered at approximately 1650 cm−1, indicating relatively weaker hydrogen-bonding strengths than those of 3a and 3e. These observations suggest that increasing the hydrogen bonding exhibited decreased the Cgs among the T8-polyureas with phenylurea moieties. The T8-polyureas with nonphenylurea moieties, 3c and 3d, exhibited relatively broad C=O stretching bands centered at 1637 and 1640 cm−1, respectively, suggesting relatively weaker hydrogen-bonding strengths than those of reported aliphatic polyureas [32]. In the N-H stretching regions at 3200–3400 cm−1, broad bands apparently centered at 3307 and 3285 cm−1 were observed for 3b and 3f, of which numbers of vibrations were lower than those of others (Supplementary Fig. S5). These data also support a higher the hydrogen-bonding strength between the ureido groups in 3b and 3f. FT-IR spectra of the dried gels prepared from the THF solutions were also performed (Supplementary Fig. S6). No recognizable difference was observed.

It was reported that intermolecular interactions through hydrogen bonding for an aromatic bis-urea were strongly enhanced by substitution at the ortho position of the phenylurea groups [33]. The ortho substitutions provide a noncoplanar conformation of the urea and phenyl moieties; thus, these substitutions results in better preorganization of the monomer for hydrogen bonding. Upon self-assembly of the phenylurea moiety, π-stacking interactions can be allowed. Therefore, compared with nonphenylureas, the T8-polyureas with phenylurea moieties promoted organogel formation. In addition, substitution by methyl groups at the ortho position of the phenylurea groups provided lower Cgs than 3b and 3f. These observations suggest that the stronger the intermolecular interaction between the ureido groups in T8-polyurea enhanced the organogel formation.

In a previous paper [25], we studied the gel formation behavior of the T8-poly(azomethine) in several polymerization solvents in comparison with that of DDSQ-poly(azomethine)s to study the POSS structure-dependent gel formation behavior. Organogels were formed after the polymerization solutions of T8-poly(azomethine) were concentrated. In contrast to T8-poly(azomethine), no gelation was observed when the polymerization solution of DDSQ-poly(azomethine) in THF was concentrated at a reduced pressure. In the present study, no organogels were formed below the solubility limit of the monomers except 5f, as described above (Table 1). The FT-IR spectra of 5b and 5f showed relatively sharp C=O stretching bands centered at 1637 and 1638 cm−1, respectively (Fig. 5). Careful analysis in the region of the C=O stretching bands showed that relatively broader bands were observed at the higher wavenumber in the case of 5b in comparison with those of 5f. These observations also suggest that increasing the intermolecular interaction between the ureido groups in DDSQ-polyurea enhanced the organogel formation.

In our previous paper [26], we checked the polymerization behavior of an aliphatic polyurea without containing POSS units. We observed precipitates instead of gel formation during polymerization (0.078 g/ml) of 1,4-phenylene diisocyanate with ethylenediamine instead of 1 in THF. The FT-IR analysis of the precipitated polyurea showed a sharp C=O stretching band at 1630 cm−1, indicating crystalline hydrogen-bond network domains. This controlled experiment suggests that including the POSS unit in the polyurea inhibits the formation of crystalline hydrogen-bond network domains due to the sterically hindering the cage frameworks. The combination of the POSS units and ureido groups may provide a suitable balance for organogel formation.

Conclusions

We studied the organogel formation behavior of POSS-based polyureas. Usually, organogels are obtained after heating a solution of organogelators followed by cooling. In the present case, organogel formation was observed during the addition of diisocyanate at room temperature, showing no need for a heating process. Compared with nonphenylurea moieties, the T8-polyureas with phenylurea moieties promoted organogel formation. Substitution by the methyl groups at the ortho position of the phenylurea groups provided lower Cgs. Increasing the intermolecular interaction between the ureido groups in the T8-polyurea enhanced organogel formation, which was supported by the FT-IR analysis of the dried gels. We also studied the POSS structure-dependent physical gel formation behavior of the polyureas by replacing the T8 cages with DDSQ units. Although no organogels were observed in the polymerization solution even below the solubility limit of the monomers in THF, an organogel was formed for 5f at a relatively low Cg of 0.06 g/ml. These observations suggest that compared with the DDSQ units, the isobutyl-substituted T8 units tend to promote organogel formation. However, the selection of appropriate comonomers provides organogels even in the case of DDSQ-containing polyureas. Substitution by the methyl groups at the ortho position of the phenylurea groups provided an organogel for 5f, as was the case for the T8-polyureas. The present findings contribute to the design of POSS-based organogelators by self-assembly. The detail properties of the POSS-based organogel are now underway.

References

Terech P, Weiss RG. Low molecular mass gelators of organic liquids and the properties of their gels. Chem Rev. 1997;97:3133–59.

Suzuki M, Hanabusa K. Polymer organogelators that make supramolecular organogels through physical cross-linking and self-assembly. Chem Soc Rev. 2010;39:455–63.

Weiss RG. The past, present, and future of molecular gels. What is the status of the field, and where is it going. J Am Chem Soc. 2014;136:7519–30.

Lan Y, Corradini MG, Weiss RG, Raghavan SR, Rogers MA. To gel or not to gel: correlating molecular gelation with solvent parameters. Chem Soc Rev. 2013;44:6035–58.

Hanabusa K, Suzuki M. Development of low-molecular-weight gelators and polymer-based gelators. Polym J. 2014;46:776–82.

Seitz ME, Burghardt WR, Faber KT, Shull KR. Self-assembly and stress relaxation in acrylic-triblock copolymer gels. Macromolecules. 2007;40:1218–26.

Cordes DB, Lickiss PD, Rataboul F. Recent developments in the chemistry of cubic polyhedral oligosilsesquioxanes. Chem Rev. 2010;110:2081–173.

Laine RM. Nanobuilding blocks base on the [OSiO1.5]x (x = 6, 8, 10) octasilsesquioxanes. J Mater Chem. 2005;15:3725–44.

Chujo Y, Tanaka K. New polymeric materials based on element-blocks. Bull Chem Soc Jpn. 2015;88:633–43.

Tanaka K, Chujo Y. Advanced functional materials based on polyhedral oligomeric silsesquioxane (POSS). J Mater Chem. 2012;22:1733–46.

Jung JH, Laine RM. Beads on a chain (BOC) polymers formed from the reaction of [NH2PhSiO1.5]x[PhSiO1.5]10-x and [NH2PhSiO1.5]x[PhSiO1.5]12-x mixtures (x = 2-4) with the diglycidyl ether of bisphenol A. Macromolecules. 2011;44:7263–72.

Seino M, Hayakawa T, Ishida Y, Kakimoto M, Watanabe K, Oikawa H. Hydrosilylation polymerization of double-decker-shaped silisesquioxane having hydrosilane with diynes. Macromolecules. 2006;39:3773–5.

Wu S, Hayakawa T, Kikuchi R, Grunzinger SJ, Kakimoto M, Oikawa H. Synthesis and characterization of semiaromatic polyimides containing POSS in main chain derived from double-decker-shaped silsesquioxane. Macromolecules. 2007;40:5698–705.

Yoshimatsu M, Komori K, Ohnagamitsu Y, Sueyoshi N, Kawashima N, Chinen S, et al. Necklace-shaped dimethylsiloxane polymers bearing a polyhedral oligomeric silsesquioxane cage prepared by polycondensation and ring-opening polymerization. Chem Lett. 2012;41:622–4.

Hoque MA, Kakihana Y, Shinke S, Kawakami Y. Polysiloxanes with periodically distributed isomeric double-decker silsesquioxane in the main chain. Macromolecules. 2009;42:3309–15.

Maegawa T, Irie Y, Imoto H, Fueno H, Tanaka K, Naka K. para-Bisvinylhexaisobutyl-substituted T8 caged monomer: synthesis and hydrosilylation polymerization. Polym Chem. 2015;6:7500–4.

Maegawa T, Irie Y, Fueno H, Tanaka K, Naka K. Synthesis and polymerization of a para-disubstituted T8-cages hexaisobutyl-POSS monomer. Chem Lett. 2014;43:1532–4.

Maegawa T, Miyashita O, Irie Y, Imoto H, Naka K. Synthesis and properties of polyimides containing hexaisobutyl-substituted T8 cages in their main chains. RSC Adv. 2016;6:31751–7.

Fujii S, Minami S, Urayama K, Suenaga Y, Naito H, Miyashita O, et al. Beads-on-string-shaped poly(azomethine) applied for solution processing of bilayer devices using a same solvent. ACS Macro Lett. 2018;7:641–5.

Shi H, Yang J, You M, Li Z, He C. Polyhedral oligomeric silsesquioxanes (POSS)-based hybrid soft gels: Molecular design, material advantages, and emerging applications. ACS Mater Lett. 2020;2:296–316.

Kilic D, Balta DK, Saloglu D, Temel G. Synthesis and characterization of POSS hybrid organogels using Menschutkin quaternization chemistry. Polym Int. 2019;68:369–76.

Qin Z, Qu B, Yuan L, Yu X, Li J, Wang J, et al. Injectable shear-thinning hydrogels with enhanced strength and temperature stability based on polyhedral oligomeric silsesquioxane end-group aggregation. Polym Chem. 2017;8:1607–10.

Wang L, Zeng K, Zheng S. Hepta(3,3,3-trifluoropropyl) polyhedral oligomeric silsesquioxane-capped poly(N-isopropylacrylamide) telechelics and behavior of physical hydrogels. ACS Appl Mater Inter. 2011;3:898–909.

Zhou W, Shi J, Yuan S, Chen Y. Crystallization and shear-induced formation of organogels in novel poly[(butylene succinate)-co-diolisobutyl]-[polyhedral oligomeric silsesquioxane] copolyesters. Polym Int. 2014;63:626–32.

Ishida A, Fujii S, Sumida A, Kamitani T, Minami S, Urayama K, et al. Supramolecular organogel formation behaviors of beads-on-string shaped poly(azomethine)s dependent on POSS structures in the main chains. Polym Chem. 2012;12:3169–76.

Hashimoto M, Imoto H, Matsukawa K, Naka K. Coexistence of optical transparency, hydrophobicity, and high thermal conductivity in beads-on-string-shaped polyureas induced by disordered hydrogen-bond networks. Macromolecules. 2020;53:2874–81.

Yokoya M, Kimura S, Yamanaka M. Urea derivatives as functional molecules: Supramolecular capsules, supramolecular polymers, supramolecular gels, artificial hosts, and catalysts. Chem Eur J. 2021;27:5601–14.

Yamanaka M. Urea derivatives as low-molecular-weight gelotors. J Incl Phenom Macrocycl Chem. 2013;77:33–48.

Waddon AJ, Coughlin EB. Crystal structure of polyhedral oligomeric silsesquioxane (POSS) nano-materials: A study by x-ray diffraction and electgron microscopy. Chem Mater. 2003;15:4555–2561.

Coleman MM, Sobkowiak M, Pehlert GJ, Painter PC. Infrared temperature studies of a simple polyurea. Macromol Chem Phys. 1997;198:117–36.

Mattia J, Painter P. A comparison of hydrogen bonding and order in a polyurethane and poly(Urethane-urea) and their blends with poly(ethylene glycol). Macromolecules. 2007;40:1546–54.

Bergsman DS, Closser RG, Tassone CJ, Clemens BM, Nordlund D, Bent SF. Effect of backbone chemistry on the structure of polyurea films deposited by molecular layer deposition. Chem Mater. 2017;29:1192–203.

Isare B, Pembouong G, Boué F, Bouteiller L. Conformational control of hydrogen-bonded aromatic bis-ureas. Langmuir. 2012;28:7535–41.

Acknowledgements

This work was supported by a Grant-in-Aid for Scientific Research (No. 19H02764) from the Ministry of Education, Culture, Sports, Science, and Technology, Government of Japan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Kamitani, T., Ishida, A., Imoto, H. et al. Supramolecular organogel of polyureas containing POSS units in the main chain: dependence on the POSS and comonomer structures. Polym J 54, 161–167 (2022). https://doi.org/10.1038/s41428-021-00578-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-021-00578-9

- Springer Nature Limited

This article is cited by

-

Preparation of urea- and isocyanurate-containing polysilsesquioxane membranes for CO2 separation

Journal of Sol-Gel Science and Technology (2023)

-

Subnanometer nanowires as gelators for volatile organic liquids

Science China Chemistry (2022)