Abstract

Inexpensive cloth masks are widely used in developing countries to protect from particulate pollution albeit limited data on their efficacy exists. This study examined the efficiency of four types of masks (three types of cloth masks and one type of surgical mask) commonly worn in the developing world. Five monodispersed aerosol sphere size (30, 100, and 500 nm, and 1 and 2.5 μm) and diluted whole diesel exhaust was used to assess facemask performance. Among the three cloth mask types, a cloth mask with an exhaust valve performed best with filtration efficiency of 80–90% for the measured polystyrene latex (PSL) particle sizes. Two styles of commercially available fabric masks were the least effective with a filtration efficiency of 39–65% for PSL particles, and they performed better as the particle size increased. When the cloth masks were tested against lab-generated whole diesel particles, the filtration efficiency for three particle sizes (30, 100, and 500 nm) ranged from 15% to 57%. Standard N95 mask performance was used as a control to compare the results with cloth masks, and our results suggest that cloth masks are only marginally beneficial in protecting individuals from particles<2.5 μm. Compared with cloth masks, disposable surgical masks are more effective in reducing particulate exposure.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.INTRODUCTION

Exposure to particulate matter is associated with respiratory and cardiovascular health effects and premature mortality,1 and it reflects a global public health concern. Particles<2.5 μm (PM2.5) are often considered more harmful than larger-sized particles because of their ability to penetrate to human bronchi and lungs.2 The 68th World Health Assembly passed a resolution in 2015 that underlined the importance of air pollution, attributing it to a cause of global health inequities.3

Wearing personal facemasks has been thought to provide an immediate and short-term practical solution to individuals living in developing nations, who seek to reduce their exposure to high levels of air pollution without having to avoid highly polluted environments. Cloth masks are a popular choice, particularly in the developing world because they are inexpensive, locally available, and washable. They usually consist of a synthetic or natural cloth material worn across the mouth and nose; they come with elastic straps, which can be worn behind the head or over the ears to maintain a fit to the face. There is anecdotal evidence that supports the widespread personal use of cloth masks, with local newspaper stories suggesting increases in retail sales of protective masks as air pollution rises.4 A few commercial vendors have launched products that claim to be highly effective in particle exposure reduction; however, these products are rarely the mask of choice by residents of developing nations because of their comparatively high cost and limited availability in the local marketplace. The most commonly encountered inexpensive masks are marketed to users through popular media, including through fashion shows in Beijing, suggesting these are products embraced by the public.5

Anecdotal news reports, and our own personal observations, show that cloth facemasks are commonly used in many nations in South, Southeast, and Southwest Asia and beyond, including Nepal, India, Bangladesh, China, United Arab Emirates, and Indonesia. It is thus plausible that the combined population using such cloth facemasks could be easily estimated to reach many millions of individuals. Such cloth facemasks are also used occupationally in agriculture6 and in healthcare.7, 8 However, peer-reviewed studies that evaluate the efficacy of such cloth masks are limted9 despite its importance to millions of people. Most of these studies focus on industrial exposure or respiratory infection prevention than on ambient airborne particles.

The work here reports on the effectiveness of cloth masks commonly worn by millions of individuals, by comparing the cloth masks against commercially available N95 masks. The main research objective is to evaluate the filtration efficiency of various cloth facemasks against standard particle of different sizes and the particles emitted from diesel combustion.

MATERIALS AND METHODS

Tested Masks

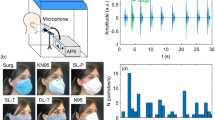

In this study, four different facemasks were assessed against laboratory-generated particles of five different sizes under well-constrained laboratory conditions and using the state-of-the-art particle instrumentation. Three cloth masks, and one pleated surgical mask, were purchased from street vendors in Kathmandu, Nepal in 2014. Two commercially available N95 masks from two different manufacturers in the United States were also tested, including a rigid Moldex model (2701) and a 3M model (8200). The Moldex mask (N95 mask2) and one of the cloth masks (cloth mask 1) had a plastic and latex exhalation valve. N95 filtering facepiece respirators (N95 masks) are a class of certified respirators that have undergone a certified and laborious process to test their efficacy.10, 11, 12, 13 Photographs of the tested cloth mask of three different types, along with two N95 masks, are given in Supplementary Figure S1.

Polystyrene Latex Spherical Particles

Polystyrene latex (PSL) microspheres sizes were generated using a constant output atomizer (model 3076; TSI, Shoreview, MN, USA). PSL are a colloidal solution of single-size latex spheres that, when aerosolized, produce a stream of monodisperse particles of a known size. PSL used in this study include Thermo Scientific Nanosphere Size Standards 30 nm (30±1), 100 nm (102±3), and 500 nm (498±9), and Duke Standards 1 μm (1.019±0.015) and 2.5 μm (2.504±0.027). PSL drops were added to deionized water (~300 ml) and pure nitrogen was used as the motive gas. The aerosol was passed through a silica-based water vapor denuder to dry the particles, and then into a controlled exposure chamber that contains an inanimate model (polystyrene mannequin head). Conductive tubing inserted inside the mannequin head extended from the mouth region and acted as an inlet behind any experimental masks, and carried samples to two particle sizing classifiers that detect the size and number of particles that penetrate the masks. These include an aerodynamic particle sizer (APS; Model: TSI 3321) and a SMPS (SMPS; Model: TSI 3080 Electrostatic Classifier and TSI 3775 Condensation Particle Counter). These instruments are able to count and size particles with excellent precision and accuracy. A layer of parafilm was used around the edge of the mask to minimize leaks and to provide a better seal on the face of mannequin. Use of parafilm showed the increased efficiency of masks compared with those without a parafilm, and thus all the experiments discussed here were performed by using a parafilm seal.

Diluted Whole Diesel Particles

Each mask was also tested against primary diesel particles generated in the laboratory to simulate real-world urban conditions. Whole exhaust from a single-cylinder diesel generator (Yanmar L100) operating under light load was injected into a 13 m3 laboratory smog chamber made of fluorinated ethylene propylene, which then was diluted with zero air to bring the concentrations down to atmospherically relevant values that simulate a polluted environment in developing countries. Experiments were conducted with particle mass concentrations ranging from 45 to 1060 μg/m3. Commercially available, ultralow sulfur diesel was used for combustion. Once diluted sufficiently, the aerosol from this chamber was passed onto the small sealed chamber constructed of stainless steel and aluminum, which contained the mannequin head (Figure 1) and mask. An experiment lasts for several hours, and wall loss corrections were observed by averaging concentrations before and after a mask trial.

Experimental Setup

Experiments were performed separately for smaller-sized particles (30–500 nm) using an SMPS (which is capable of sizing particles <~700 nm) and larger-sized particles (1–2.5 μm) with the APS. During experiments, particles were continuously generated. Particles were first measured from the mannequin head without a mask to quantify a free exposure. The mannequin then was fitted with each mask type and the experiments were repeated. Eight consecutive runs were made for each of the mask types; the first run was discarded, and only the remaining seven runs from each experiment were used for the analysis. The first run was also discarded for the free exposure condition. Particles were measured between mask changes (i.e. no mask in place) to assess aerosol generation stability. The performance of each mask type was compared against the average of the particles measured before and after testing the specific mask type. A similar procedure for calculation was used for diesel-generated particles. Experiments were repeated three times for each mask type against PSL particles, and two times against diesel-generated particles at a total flow rate of 19 L/min. Each of these experiments included eight sets of consecutive measurements. An experiment was also conducted at the lower flow rate of 8 L/min to assess the effects of face velocity on filtration efficiency.

A bypass flow design was used to introduce the aerosols in the chamber at 8 or 19 L/min to assess for effects attributed to changes in face velocity across the mask surface. The APS and SMPS were sampled from this stream of aerosol. Unsampled air was passed through a pump and was exhausted from the room. For each of the tested particles, a range of particle size bins were used for data analysis. For 30 nm particles, we computed the total particle counts to include three sizes (28.9, 30, and 31.1 nm), and for 100 and 500 nm particles, we compared the particles of two sizes, 98.2 and 101.8 and 495.8 and 514 nm, respectively. Similarly, for comparing 1 and 2.5 μm sized particles, we compared the particles of three sizes, 1.037, 1.114, and 1.197 μm, and of two sizes, 2.458 and 2.642 μm, respectively. All other data from outside these specific ranges was discarded. This was to ensure SMPS or APS instrument imprecision bias had no effect on the results. Particle removal efficiency of each mask was calculated by dividing the non-penetrated particles (difference between the particle counts from mannequin with and without mask) by the total number of particles (no mask):

RESULTS

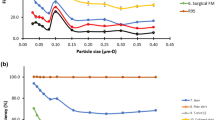

Performance of Cloth Facemasks Against PSL Standard Particles (at 19 L/min)

PSL experiments allow an evaluation of specific size penetration across the different mask types (Figure 2). Overall, cloth facemasks lead to a measureable reduction of total particle counts. However, there was variability among the performance of cloth masks and also among different particle sizes. Among the tested cloth mask types, a cloth mask with an exhalation valve (cloth mask 1) performed better compared with the cloth masks without the exhalation valve (cloth masks 2 and 3). The filtration efficiencies of cloth masks 2 and 3 varied among the different PSL sizes. The greatest penetration through the cloth masks 2 and 3 occurred for smaller particle sizes. It is interesting to note that the two worst-performing masks (cloth masks 2 and 3) performed better for larger particle sizes, that is, they perform poorly on removal of the smallest particles. Reproducibility of the two experiments was worse for two cloth masks (cloth masks 2 and 3). At a flow rate of 19 L/min, average particle number concentrations of laboratory-generated PSL particles were 2.77 × 105, 1.05 × 105, and 2.84 × 103 (no./cm3) for 30-, 100-, and 500-nm size ranges, respectively. Because of the lower particle number concentrations, total raw counts were used for comparing the particle sizes 1 and 2.5 μm. Raw counts are raw detected particle counts, but without any corrections for splitting across the channels.

Performance of Cloth Facemasks Against PSL Standard Particles at Lower Flow Rate (at 8 L/min)

When the experiments were repeated at the flow rate of 8 L/min, the efficiency of all types of masks improved (Figure 3). The largest increase was observed with two cloth masks (cloth masks 2 and 3) that performed worse at 19 L/min.

Performance of Cloth Facemasks Against Diesel-Combustion Particles

We also compared the performance of masks for particles generated from diesel engine exhaust. Not surprisingly, most of the diesel-combustion particles were of a size <500 nm (Figure 4). Unlike the PSL trials, where particles are present in discrete size ranges, diesel exhaust is generated in a polydispersed manner with particles present across the entire size range. This allows for an analysis across discrete sizes consistent with the PSL experiments, and also as a bulk efficiency calculation by integrating particles across the entirety of the size distribution from diesel.

The efficiency of cloth masks against particle of three specific sizes, 30, 100, and 500 nm are shown in Figure 5, which match the size bins chosen for study in the PSL experiments. Again, the cloth mask with an exhaust valve (cloth mask 1) had the highest efficiency for 30 and 100 nm particle sizes among the three cloth mask types. However, cloth mask 2 outperformed cloth mask 1 for 500 nm particles.

By assuming an average particle density, particle mass distribution was computed for the experimental size range (14.6–710.5 nm). This allows us to integrate the total mass of particles across the entire size distribution, and better reflects real-world exposures. Average particle concentration for whole diesel was 4.13 × 102, 2.66 × 104, and 4.46 × 103 (no./cm3) for 30-, 100-, and 500-nm size ranges, respectively. Average total mass concentrations from all the experiments were 529±306 μg/m3. Cloth mask types 1 and 2 had filtration efficiency of 34% and 40% of particulate mass, respectively. Cloth mask 3 performed the worst, with the efficiency of only 14% of particulate mass.

Comparison of Three Cloth Face Mask Types with a Surgical Mask and N95 Mask

Not surprisingly, N95 masks performed better compared with any cloth face masks for all particle sizes (Figure 2). At a lower flow rate (Figure 3), the efficiency of cloth mask 1 and surgical mask was comparable to N95 masks, suggesting that these masks are sensitive to flow rate. Cloth mask 1 had less penetration of smaller particles compared with the surgical mask. Observed filtration efficiency of the surgical mask appears to be similar to cloth mask 1, with overall efficiency being slightly better for the surgical mask (Figure 3).

A single factor analysis of variance test showed that efficiency of all masks against PSL particles were significantly different to each other (P<0.01) except for 2.5 μm (P=0.05). An independent t-test (Table S1) confirmed the performance differences between all cloth masks and N95 mask 1 (P<0.01) (Table S1), indicating that all cloth mask types were significantly different for all sizes compared with the N95 mask 1. There was no significant difference between the performances of N95 mask 1, the surgical mask, and the N95 mask2 for particle sizes of 30 and 500 nm. Efficiency of cloth masks were better (69–94%) for large-sized particles (>1 μm) compared (44–93%) with small-sized particles (<1 μm). However, N95 mask, a cloth mask with the exhalation valve (cloth mask 1), and a surgical mask performed the best for this size range.

N95 mask 1 performed better compared with N95 mask 2 for PSL particles at a flow rate of 19 L/min. The three replications of experiments using PSL particles were consistent for two N95 masks and the surgical mask (Figure 2). An exception to this was the 30 nm PSL for both N95 masks, and 500 nm PSL for N95 mask 2 and surgical mask, where the results vary among the replication of experiments (Figure 2). Variability among the repeated experiments was the poorest for cloth mask 2 and cloth mask 3 trials. The performance of the surgical mask was comparable to those of the N95 mask for large-sized particles (>1 μm). The results suggest greater protection from particles by wearing a surgical mask (78%) and a cloth mask with the exhaust valve (cloth mask 1) (81%) compared with simple cloth masks (39–46%) (Figure 2).

Similar to PSL particles trials, the surgical mask also performed better compared with cloth masks for diesel-generated particles (Figure 5). Filtration efficiency of cloth masks 1 and 2 was better compared with cloth mask 3. Cloth mask 1 performed the best among the three cloth masks except for 500 nm PSL. Interestingly, efficiency of cloth mask 2 was also comparable to cloth mask 1. Consistent with results from the PSL particle experiments, N95 mask 2 performed worse than N95 mask 1 in the whole diesel experiments.

DISCUSSION

Among the four mask types tested, cloth mask 1 and the surgical mask were the most efficient in preventing the penetration of PSL particles at both flow rates (8 and 19 L/min). When these masks were tested against diesel-generated particles, the surgical mask was still reasonably effective, and the other mask types were less effective.

Unfortunately, the least effective two mask types (cloth masks 2 and 3) are also inexpensive, reusable, and are widely used in developing countries, implying they are a popular consumer choice where pollution mitigation is warranted. These two masks were purchased by our team for 10 Nepali rupees (1 US$=95 Nepali rupees on the purchase date). Surgical masks also remain a popular choice to reduce personal exposure to particulates. Penetration through these two cloth masks (2 and 3) decreased when the particle size increases (Figure 2). Previous studies have reported an increase in efficiency with an increase in particle size for other types of respirators.14, 15 Overall, simpler cloth masks (cloth masks 2 and 3) provide the least amount of apparent protection from particulate exposure, where penetration of particles through cloth masks was >50% for the smallest particles (≤500 nm) tested at a flow rate of 19 L/min.

Cloth mask 1, the best performer of the cloth masks, also has a conical or tetrahedral shape, allowing the edge to conform closely to the mannequin’s contours. The worst performing cloth masks were simple rectangles with loops to connect behind the ear. It is possible that this design does not allow a sufficient fit on the mannequin, allowing the leakage of significant fraction of particles to penetrate through the mask. Although this was apparently true on a test mannequin, the leaks from such shape of masks is also likely true for real-world uses.

In general, all tested masks were deficient in capturing diesel-generator exhaust particles. For these experiments, the particle mass averaged between 45 and 1060 μg/m3 and was meant to reflect a highly polluted urban location. Only N95 mask 1 and the surgical mask demonstrated particle removal efficiency above 65%, with the remaining masks removing fewer particles. This is an important concern because diesel exhaust comprises a significant fraction of urban emissions, particularly in developing nations where low-cost diesel vehicles are frequently used. These particles tend to be small, with typical mean particle sizes in the range of 100–150 nm, which suggests that they are especially difficult to capture on filtration material, even though they are known to induce a number of significant health impacts.16 Physical properties such as sizes, shapes, and aspect ratios affect the penetration of particles through the masks.17 Diesel particles have different and variable physical properties than uniform PSL particles, and maintaining identical diesel aerosol concentrations between different experiments was particularly challenging. Compared with the experiments with PSL particles, diesel particle concentrations delivered to the chamber were more variable for the control conditions (i.e. without mask), which might have resulted in additional uncertainty in filtration efficiency calculations between PSL particles and diesel particle experiments. Further studies with better-controlled and more consistent diesel particle concentrations are needed to better quantify the efficiency of cloth masks against diesel particles. Relevant, real-world aerosol exposure models—that is, diesel and ambient particles—need additional focus and research because most facemask studies to date focus either on PSL, sodium chloride (NaCl), DOP (dioctyl phthalate) particles, or biological media. Filtration efficiency of masks may depend on particle types, particle loading, or other features. For example, with the increased particle mass loading, penetration increases for DOP particles, whereas it decreases for NaCl particles,18 although this is based on results from aerosol exposures unlikely in the real world and we know even less about facemask performance under ambient uses.

This study shows that wearing cloth masks reduced the exposure to some extent (~39–65% for cloth masks 2 and 3, and 80–90% for cloth mask 1 against PSL particles for the flow rates of 8 and 19 L/min). The results also showed that such masks could reduce personal exposure to large (>1 μm in diameter) particles (Figures 2 and 3). This has clear public health relevance as many millions of individuals are estimated to be living in regions with high levels of particulate matter,19, 20 many of who may choose to select an intervention to reduce their health risk. However, a more informed choice in mask type is warranted because many of the least expensive, and commonly used, cloth mask products perform poorly when compared with alternative options available on the market.

The comparatively high degree of protection of the surgical masks was a surprising finding in this study. These masks are typically made of woven polyester and cellulose with small elastic ear loops. These types of masks are typically the least expensive, but are usually considered disposable. Previous studies have shown that the penetration of particles through the surgical mask was greater compared with N95 masks.11, 12, 13, 21 He et al.12 also observed particle penetration across a surgical mask to be within 20% and concluded that surgical masks may be beneficial only for the particles >500 nm. Sande et al.22 observed the highest particle removal efficiency from the simultaneous use of a respiratory mask (European equivalent of a N95 mask), followed by surgical mask, compared with using only homemade cloth mask. Our findings show that compared to some cloth masks, surgical masks alone can provide better protection from particulate exposure. While Sande et al's.22 work suggest the simultaneous use of an N95 mask to reduce exposure, this is not likely an option for the developing world where these masks are not physically or economically available to the general population.

Mask fit on the selected model is one of the main uncertainties of this study and likely explains most of the experimental variability in this study. The experiments were performed on the mannequin head placed inside a controlled exposure chamber with a known concentration of specific size ranges. Real-world environmental conditions will be different and factors such as perspiration, relative humidity, wind, and tidal volume can all affect facial geometry and fit and may have a role on the filtration efficacy of such masks. The tested particles were latex spheres of same composition and the particles generated from the same source such as diesel combustion. The real environment samples will have highly variable particle components. While the testing used an inanimate model, real-world conditions were satisfactorily simulated across both monodispersed PSL testing, and a more diverse mixture of diesel pollutants, the latter of which more closely reflects common real-world exposure mixtures. Although we compared the penetration of particles through masks with the concentrations measured before and after testing of masks, there may be uncertainties that arise from not having the consistent aerosol concentrations throughout the experiments.

Typical respiratory rate for adults is 12–18 breaths/min with an average of 8 L of air inspired per minute. We performed the experiments at a constant flow rate (19 and 8 L/min), while human breathing flow is most likely to be of a sinusoidal pattern. The use of variable flow rates would introduce significant uncertainty because it would vary the face velocity across the mask itself, and this would affect particle residence time in the mask and alter rates of particle loss from diffusion. Thus, flow rates of our experiments may not be representative of variable human breath rates (normal breathing, deep breathing, light exercise, etc.). Efficiency of all the masks was noted to improve at lower flow rates; thus, the flow rate and the pattern of flow might also affect the efficiency of such masks. A decrease in collection efficiency from N95 respirators compared with expected level against virions (20–300 nm) were also reported by Balazy et al.23 Such decrease in efficiency was observed mainly at high respiratory flow rates.24, 25 Although the facemasks were tightly fit around the mannequin head, the experimental setup might still be more prone to error than the real environment because of the use of a continuous sampling flow. Uncertainties also exist in extrapolating observed results here to real-world conditions due to variability and differences in facial structures in these nations.26, 27 For example, mannequin heads used in this study are likely to be smaller than Asian faces (Supplementary Table S2).27 Filter penetration and faceseal leakage are the two principal factors that contribute to the effectiveness of a mask.12, 21, 28 Particle collection processes are affected by diffusion, electrostatic attraction, impaction, and interception depending on the particle sizes.28, 29 Pressure drop across the filter media can also lead to poor performance of the masks.25

There were some important differences between our experimental setup and traditional N95 testing protocols, which are conducted with monodispersed particles that consist of dried NaCl crystals. The samples collected here were collected at ~8 or 19 L/min.10 This difference is important because of the objective of the N95 test itself is to demonstrate the effectiveness of a commercial product under worst-case scenarios, whereas the methods described here reflect more typical uses by the public. Further, a robust ‘fit test’ is indicated in N95 testing, where masks are custom fit to conform to the geometry of a face; here, where an expanded polystyrene mannequin head was used, may permit particles to penetrate into the sampling area by small leaks around the mask. Even with parafilm, the leaks were not completely avoided because expanded polystyrene does not mock skin and the leakage is not completely sealed at the edges of the mask. As a result, 95% efficiency was elusive, even for certified N95 masks where our results were closer to 76–92% efficiency. However, the results observed were reasonable approximations of mask performance, and are likely to be reflective of real-world applications of face masks by the general public where formal fit testing is rarely, if ever, performed.

CONCLUSIONS

In selecting a choice to reduce personal exposure, a cloth mask with an exhaust valve performed best compared with other styles, where efficiency of cloth masks against standard particle sizes of five sizes, 30, 100, and 500 nm, and 1 and 2.5 μm, ranged from 39% to 65%. All masks performed worse for diesel combustion particles compared with monodispersed particles. The filtration efficiency of cloth masks for particles emitted from diesel combustion ranged from 15% to 57% for total particle concentrations (for 30, 100, and 500 nm) and 13% to 40% for total particulate mass. As expected, N95 masks were effective in removing most tested particles. Disposable surgical masks were found to be surprisingly effective (efficiency of 78–94% for PSL particles; 79% for whole diesel). Given the observed variability in mask efficacy across different particle types and components, one cannot assume that the use of an inexpensive facemask leads to significant decreases in exposure, especially if an individual makes personal choices to not avoid high concentration environment because they assume they are protected from these contaminants. As a widely used public health intervention strategy, especially across the developing world, great care must be given in selection of inexpensive cloth masks for exposure reduction efforts.

References

Davidson C, Phalen RF, Solomon PA . Airborne particulate matter and human health: a review. Aer Sci Technol 2005; 39: 737–749.

Pope CA, III, Dockery DW . Health effects of fine particulate air pollution: Lines that connect. J Air Waste Manage Assoc 2006; 56: 709–742.

UNEP. World Health Assembly Passes Landmark Resolution on Air Pollution and Health. United Nations Environment Programme New Centre, 2015. Available at: http://www.unep.org/NewsCentre/default.aspx?DocumentID=26816&ArticleID=35060 (last accessed 25 August 2015).

Seattle Times. Businesses cashing in on China’s air pollution, 4 February 2013. Available at: http://www.seattletimes.com/nationworld/businesses-cashing-in-on-chinarsquos-air-pollution (last accessed 4 November 2015).

Climate Progress. China’s Smog Is So Bad It’s Affecting Fashion Trends, 1 November 2014. Available at: http://thinkprogress.org/climate/2014/11/01/3587488/chinafashionweeksmogmasks/ (last accessed on 4 November 2015).

Pandit RN, Paudel DP . Health hazards due to pesticide use and its protective/preventive practice among vegetable farmers in Bhaktapur district of Nepal. J Nepal Public Health Assoc 2013; 5 –1: 13–18.

Chughtai AA, Seale H, Maclntyre CR . Use of cloth masks in the practice of infection control—Evidence and policy gaps. Int J Infect Control 2013; v9: i3; doi:10.3396/IJIC.v9i3.020.13.

Maclntyre CR, Seale H, Dung TC, Hien NT, Nga PT, Chughtai AA et al. A cluster randomized trial of cloth masks compared with medical masks in healthcare workers. BMJ Open 2015; 5: e006577.

Rengasamy S, Eimer B, Shaffer R . Simple respiratory protection—Evaluation of the filtration performance of cloth masks and common fabric materials against 20–1000 nm size particles. Ann Occup Hyg 2010; 54: 789–798.

Electronic Code of Federal Regulations (eCFR). Title 42: Public Health, Part 84—Approval of Respiratory Protective Devices. Available at: http://www.ecfr.gov/cgi-bin/text-idx?SID=a88cb0699d6516257a0aa2aaaf40b2b8&node=42:1.0.1.7.67&rgn=div5#42:1.0.1.7.67.6.19 (28 August 2014).

Lee SA, Grinshpun SA, Reponen T . Respiratory performance offered by N95 respirators and surgical masks: Human subject evaluation with NaCl aerosol representing bacterial and viral particle size range. An Occup Hyg 2008; 52: 177–185.

He X, Reponen T, McKay RT, Grinshpun SA . Effect of particle size on the performance of an N95 filtering facepiece respirator and a surgical mask at various breathing conditions. Aer Sci Technol 2013; 47: 1180–1187.

He X, Reponen T, McKay R, Grinshpun SA . How does breathing frequency affect the performance of an N95 filtering facepiece respirator and a surgical mask against surrogates of viral particles. J Occup Environ Hyg 2013; 11: 178–185.

Cho KJ, Jones S, Jones G, McKay R, Grinshpun SA, Dwivedi A et al. Effect of particle size on respiratory protection provided by two types of N95 respirators used in agricultural settings. J Occup Environ Hyg 2010; 7: 622–627.

Lee SA, Adhikari A, Grinshpun SA, McKay R, Shukla R, Zeigler HL et al. Respiratory protection provided by N95 filtering facepeiece respirators against airborne dust and microorganisms in agricultural farms. J Occup Environ Hyg 2005; 2: 577–585.

Kagawa J . Health effects of diesel exhaust emissions—a mixture of air pollutants of worldwide concern. Toxicology 2002; 181–182: 349–353.

Rengasamy A, Zhuang Z, BerryAnn R . Respiratory protection against bioaerosols: Literature review and research needs. Am J Inf Control 2004; 32: 345–354.

Fissan HJ, Neumann S, Schurmann G 1984 Electrostatic enhanced filtration. In: Proceedings of the First International Aerosol Conference, Minnesota, pp 17–21. In Martin Jr SBP, Moyer ES (eds). Electrostatic respirator filter media: Filter efficiency and most penetrating particle size effects, 2000. Appl Occup Environ Hyg 2000; 15: 609–617.

Brauer, Amann M, Burnett RT, Cohen A, Dentener F, Ezzati M et al. Exposure assessment for estimation of the global burden of disease attributable to outdoor air pollution. Environ Sci Technol 2012; 46: 652–660.

van Donkelaar A, Martin RV, Brauer M, Kahn R, Levy R, Verduzco C et al. Global estimates of ambient fine particulate matter concentrations from satellite-based aerosol optical depth: Development and application. Environ Health Perspect 2010; 118: 847–855.

Grinshpun SA, Haruta H, Eninger RM, Reponen T, McKay RT, Lee SA . Performance of an N95 filtering facepiece particulate respirator and a surgical mask during human breathing: Two pathways for particle penetration. J Occup Environ Hyg 2009; 6: 593–603.

Sande MV, Teunis P, Sabel R . Professional and homemade face masks reduce exposure to respiratory infections among the general population. PLoS One 2008; 3: e2618.

Balazy A, Toivola M, Adhikari A, Sivasubramani SK, Reponen T, Grinshpun SA . Do N95 respirators provide 95% protection level against airborne viruses, and how adequate are surgical masks? Am J Infect Control 2006; 34: 51–57.

Bałazy A, Toivola M, Reponen T, Podgorski A, Zimmer A, Grinshpun SA . Manikin-based performance evaluation of N95 filtering-facepiece respirators challenged with nanoparticles. Ann Occup Hyg 2006; 50: 259–269.

Eninger RM, Honda T, Adhikari A, Heinonen-Tanski H, Reponen T, Grinshpun SA . Filter performance of N99 and N95 face-piece respirators against viruses and ultrafine particles. Ann Occup Hyg 2008; 52: 385–396.

Zhuang Z, Bradtmiller B . Head-and-face anthropometric survey of US respirator users. J Occup Environ Hyg 2005; 2: 567–576.

Yu Y, Benson S, Cheng W, Hsiao J, Liu Y, Zhuang Z et al. Digital 3-D headforms representative of Chinese workers. Ann Occup Hyg 2012; 56: 113–122.

Cho KJ, Reponen T, McKay R, Shukla R, Haruta H, Sekar P et al. Large particle penetration through N95 respirator filters and face-piece leaks with cyclic flow. Ann Occup Hyg 2010; 54: 68–77.

Huang S-H, Chen C-W, Chang C-P, Lai C-Y, Chen C-C . Penetration of 4.5 nm to 10 μm aerosol particles through fibrous filters. J Aerosol Sci 2007; 38: 719–727.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Author contributions

REP, AN, and KMS contributed to the design, method, and data analysis. AN, RK, and KMS performed the experiments. All authors contributed to the article.

Supplementary Information accompanies the paper on the Journal of Exposure Science and Environmental Epidemiology website

Supplementary information

Rights and permissions

About this article

Cite this article

Shakya, K., Noyes, A., Kallin, R. et al. Evaluating the efficacy of cloth facemasks in reducing particulate matter exposure. J Expo Sci Environ Epidemiol 27, 352–357 (2017). https://doi.org/10.1038/jes.2016.42

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/jes.2016.42

- Springer Nature America, Inc.

Keywords

This article is cited by

-

How different face mask types affect interpersonal distance perception and threat feeling in social interaction

Cognitive Processing (2024)

-

Protective face mask: an effective weapon against SARS-CoV-2 with controlled environmental pollution

Environmental Science and Pollution Research (2023)

-

Particle filtration efficiency measured using sodium chloride and polystyrene latex sphere test methods

Scientific Data (2022)

-

Influence of expiratory flow pulsatility on the effectiveness of a surgical mask

Journal of Exposure Science & Environmental Epidemiology (2022)

-

Comment on “Measurement of particulate matter 2.5 in surgical smoke and its health hazards”

Surgery Today (2022)