Abstract

In this paper, a green hydrophobic deep eutectic solvent (HDES) composed of menthol and hexanoic acid was employed to dissolve cosmetics containing Cd2+ and Cd2+ was extracted using an EDTA-2Na saturated solution, analyzed by FAAS. The study found that HDES-1 can be recycled and reused well; the stability constants of Cd2+ EDTA chelates play an important role in the extracting process; the optimum conditions were: the solubility of HDES-1 was 20 mL/g for cosmetic sample at an indoor temperature of around 10 °C; the dissolver–extractant ratio was 2:1; the LOD was 0.037 mg/kg; the RSD was 3.5%; and the recovery was 85.5–118.3%. The developed method was successfully applied to actual cosmetic samples with satisfactory results, and it was also applied for the determination of Mg2+, Mn2+, and Cu2+ in cosmetic samples.

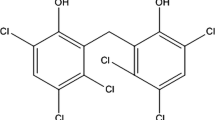

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Being toxic, hazardous and harmful to the environment, heavy metal ions in cosmetics are subject to strict limits. Heavy metal ion content in cosmetics mainly comes from raw materials and environmental pollution. How to quickly and accurately mensurate heavy metal ions in cosmetics under restricted conditions is a challenging problem many analysts have to face.

The common methods of detecting metal ions include multicollector-ICP-MS [1], ICP-MS [2], HR-CS GF AAS [3], liquid–liquid extraction [4,5,6], solid-phase extraction [7], complexometric method using mercaptoethane (EtSH) as the demasking agent [8], spectrofluorimetry [9], flame atomic absorption spectrometry after preconcentration [10], voltammetry [11] and derivative stripping chronopotentiometry [12].

In recent years, deep eutectic solvents (DESs) are regarded as one kind of eco-friendly solvents [13]. DESs have numerous advantages, such as nonvolatility, low cost, easy preparation, and good biodegradability; they have been used as ideal alternatives to conventional organic solvents [14,15,16,17]. In 2017, Kroon et al. [18] presented a new DES with hydrophobic character called HDES. Marrucho et al. [19] also reported another hydrophobic DES consisting of two neutral components: DL-menthol and natural acids. HDESs can extract carotenoid [20], bioactives [21] and Sudan I [22]. Furthermore, liquid–liquid microextraction techniques based on DESs have been widely used, such as ultrasonic-assisted liquid–liquid microextraction technique [23, 24] and air-assisted liquid–liquid microextraction [25]. Different DESs have been used to extract different target analytes, such as phenolic compounds [26], phenolic acids [27] and inorganic heavy metal ions [28].

The aim of this study is to find a new cosmetic sample pretreatment method to substitute traditional digestion. HDESs are capable of dissolving oily substances. Therefore, using HDESs as solvent and EDTA-2Na saturated solution as stripping agent, metal ions in cosmetics were extracted. Several metal ion extractions effected by EDTA were investigated. The recycling and reusing of HDES-1 were studied. The developed method was successfully applied to detect the actual sample with satisfactory results.

Materials and methods

Apparatus and reagents

The apparatus consisted of FAAS (SOLLAR M6 atomic absorption spectrometer, ThermoElemental Instrument Corp, American), FT-IR spectrometer (IRXROSS, Shimadzu, Japan), dielectric constant detector (PCM-1A, Institute of Applied Physics, Nanjing University), constant temperature magnetic stirrer (SHJ-6CS, Changzhou Jintan Youlian Instrument Research Institute), separatory funnel, cololrimeter tubes with glass stopper (Tianjin Tianke Glass Instrument Manufacturing Co., Ltd) and pipettor (BIOBASE).

A sample of cosmetics containing cadmium ions (Cd2+, 10 mg/kg, National Institute of Metrology, China) and another containing no metal ions (Changsha Cosmetics Market) were obtained. The standard solution contained: Ag+, Cd2+, Mg2+, Mn2+ and Cu2+ (all are 1000 mg/kg, National Institute of Metrology, China). Menthol, hexanoic acid, octanoic acid, decanoic acid, lauric acid, oleic acid, EDTA-2Na and HNO3 All were all guaranteed reagents (GRs).

Preparation and characterization of HDESs

HDESs were prepared by the heating method [29]. The menthol and alkanoic acid were mixed at different molar ratios and stirred continuously at 80 ℃ for about 2 h to obtain a homogeneous transparent liquid, which was characterized by FT-IR. The details of these HDESs are shown in Table 1.

Preparation and determination of samples

Samples were prepared with standard solutions and metal-free cosmetics sample. In a 10 mL test tube, a certain amount of cosmetic samples and a certain volume of HDESs were added. The sample was shaken vigorously to dissolve and then a certain stripping back extraction reagent was added. The solution was shaken vigorously again to obtain a homogeneous, standing and layered solution. Take upper and lower solution to a constant volume, detected by FAAS. The extraction efficiency (E, %) of metal ions in the bottom phase was calculated by Eq. (1).

C1: metal ion concentration of the bottom phase; V1: volume of the bottom phase;

C2: metal ions concentration of the top phase; V2: volume of the top phase.

Results and discussion

Selection of the optimal HDES

The ability of HDES to dissolve samples is given by (2)

V is the the volume of HDES; m is the the weight of the sample.

Dissolve the prepared cosmetic sample (Cd2+: 100 mg/kg) with HDESs; the results are shown in Fig. 1. It can be observed from Fig. 1 that HDES-1 has the highest dissolving capacity (12.99 mL/g) at approximately 10 °C (indoor temperature). As shown in Table 2, HDES-1 has the highest dielectric coefficient, which can be attributed to like dissolves like that HDES-1 dissolve more cosmetics sample, relatively. By comprehensive consideration, HDES-1 was selected for further studies, and 20 mL/g was selected for use in subsequent experiments when the indoor temperature was about 10 ℃. Furthermore, it was observed that the type of metal ions present in the prepared sample had little impact on the dissolving capacity of HDES-1.

We also found that more mass was dissolved by HDESs with rise in temperature. After the cosmetic samples dissolved, the metal ion extraction was not affected by temperature drops and a sample with fine particles was formed. It indicated that the metal ions had completely dissolved in HDESs, and there were no metal ions in the precipitate. Metal ions cannot be effected by the fine particles substances.

Characterization of HDESs

It can be seen from Fig. 2 and Figures. S1–S4 that the location of the –OH characteristic peak of menthol and COO− characteristic peak of alkanoic acid shifted. FT-IR spectra results show the strong hydrogen bond interaction between menthol and alkanoic acid. It indicated that hydrophobic deep eutectic solvents were successfully prepared.

Effect of stripping back extraction reagent

Three prepared cosmetics samples (Cd2+: 100 mg/kg) were dissolved by HDES-1, Cd2+ was extracted by EDTA-2Na saturated solution, pure water and HNO3(GR), respectively. Take upper and lower solution to a constant volume, and detected by FAAS. We found that the samples were digested by HNO3. As shown in Table.3, extraction effects of pure water and HNO3 did not show a significant difference, and Cd2+ was almost entirely extracted by EDTA-2Na saturated solution (near 100%). The samples purchased from National Institute of Metrology were also investigated, and the results were consistent with those mentioned above. This can be because the metal ion and oil substances failed to form compounds, or metal ion simply exists as a free metal ion in cosmetic samples. Therefore, the prepared cosmetic sample and EDTA-2Na saturated solution were selected for the following studies.

Effect of EDTA

To estimate the effect of EDTA, the extraction of EDTA for five metal ions (Ag+, Mg2+, Mn2+, Cd2+, Cu2+) was investigated. Standard solution and metal-free cosmetic samples were employed to make up the prepared cosmetic samples (only one metal ion, 100 mg/kg). In a 10 mL test tube, 0.1 g prepared cosmetic samples and 2 mL HDES-1 were added. The sample was shaken vigorously to dissolve and then 1 mL stripping back extraction reagent was added. The solution was shaken vigorously again to obtain a homogeneous, standing and layered solution. Take upper and lower solution to a constant volume, detected by FAAS. The results are shown in Table 4.

We can gather from Table.4 that almost all of the metal ions were extracted into the aqueous phase except for Ag+. The aqueous phase was dried and characterized by FT-IR. As shown in Fig. 2S, EDTA-2Na and the dried of Ag+ extracted by EDTA-2Na show stretching vibration of the carbonyl peak at 1625.992 cm−1. The stretching vibration absorption peak of C–N was at 956.693 cm−1, but other residues were not at this wavelength. The FT-IR results indicated that Ag+ EDTA chelates were not formed and the other four metal ions (Mg2+, Mn2+, Cd2+, Cu2+) formed metal EDTA chelates in the extraction solution.

The conditional stability constants of metal ion EDTA chelates is shown in (3, 4) [30].

KMY is the stability constant of metal ion EDTA chelates; Ki is the stability constant of EDTA and H+.

According to formulas (3, 4), when the pH is 4.7, lgαY(H) is 7.04 and lgK´MY is 0. It indicated that at the stability constant of (lgKMY) > 7.04, metal EDTA chelates can be formed. The greater the stability constants of metal EDTA chelates, the more are the metal EDTA chelates formed and the more are metal ions extracted in the aqueous phase.

We can gather from Fig. 2S and Formula (3, 4) that the stability constant of Ag+ and EDTA chelates is 7.32, and Ag+ exists as a free ion in the extraction solution because of the small stability constants of chelates; the stability constant of Mg2+ and EDTA chelates is 8.7, and Mg2+ EDTA chelates formed but in small amounts. So, Ag+ and Mg2+ [31] were extracted using extraction liquid because the metal ions are insoluble in HDES-1, due to their inherent properties. But Mn2+(lgKMnY = 13.87), Cd2+(lgKCdY = 16.46) and Cu2+(lgKCuY = 18.8) exist as metal EDTA chelates in the extraction solution because of the greater stability constants of the chelates. The greater the stability constants of metal EDTA chelates, the more will be the metal EDTA chelates and the more will the metal ion be extracted. It indicates that EDTA plays a very important role in the extraction process of Mn2+, Cd2+, and Cu2+.

Optimization of re-extraction conditions

The cosmetic samples (Cd2+: 100 mg/kg) were dissolved in HDES-1, and EDTA-2Na saturated solution was added. The mixture was vigorously shaken to obtain a homogeneous solution and left to settle before decanting the liquid. We found that the shake time did not affect the extraction yield of metal ion, indicating that the re-extraction was very fast. Therefore, metal ion extracted by EDTA-2Na saturated solution, only shake the sample vigorously to homogeneous solution.

The effect of dissolver–extractant ratio from 1:1 to 3:1 on the extraction yield of metal ion was investigated. As shown in Fig. 3, the extraction yield of Mg2+ and Mn2+ had no significant changes (near 100%), whereas that of other metal ions (Ag+, Cd2+, Cu2+) continued to decline with the increase of liquid–solid ratio. Meanwhile, on increasing the volume of the extraction solution and maintaining the volume of dissolved liquid, we found that the extraction yield of Ag+ increased while those of other metal ions (Mg2+, Mn2+, Cd2+, Cu2+) had no significant changes (near 100%). It can be because Mg2+ and Mn2+ are insoluble in HDES-1 and the three metal ions (Ag+, Cu2+, Cd2+) are in an equilibrium state. By comprehensive consideration, the dissolver–extractant ratio of 2:1 was chosen for further studies. The developed method is not suited to extract metal ions which have smaller conditional stability constants and cannot be completely extracted by aqueous solutions, such as Ag+.

Evaluation of the analytical method

To evaluate the developed method, take Cd2+ for example, the limit of detection (LOD), recovery, and precision(RSD) were investigated. The results showed that the linear regression equation was y = 0.19816x + 0.0035(R2 = 0.9992), the calibration showed good linearity in the range of 0.05–4.0 mg/kg, and the three times background signal of the instrument (LOD) was 0.037 mg/kg. A prepared cosmetic sample spiked with the standard solution of Cd2+ at three different concentration levels was analyzed using three replicate measurements, and the recovery was 85.5–118.3%. A sample was determined on three different days, and the RSD was 3.5%.

Reusability of HDES-1

The HDES-rich phase was separated, K3PO4 saturated solution was added and mixed to a homogeneous solution at about 25 ℃. On allowing to stand for about 3 h (excessive time, recommend centrifuging), three clear phases were formed: a HDES-1-rich top phase, a salt-rich bottom phase, and a middle solid phase (Fig. 4a). Separate the top phase and dry it, dissolving the metal-free cosmetics again at about 10 ℃. According to this procedure, the HDES-1 was recycled and reused five times. As shown in Fig. 4b, the dissolving ability of HDES-1 decreases slightly after five cycles. The dissolving ability of HDES in the five cycles is about 13.88 mL/g. These recycling studies demonstrate that HDES-1 can be recycled and reused well. But, based on our experiences, using recycled HDES-1 for sensitive and accurate detection is not a recommended practice because of unforeseeable residues. Meanwhile, we also found that only saturated salt solution can make the HDES-rich phase divide into three phases. It can be attributed to the salting-out effect: the high salt concentration provides high salt-out ability. The solution changes to a solid when K3PO4 saturated solution is mixed with HDES-rich phase and then remains at about 10 ℃. It can be attributed to salting-out crystallization, because low temperature will increase the solution viscosity, and at each phase the solution has already undergone crystallization and precipitation before phase separation.

Sample analysis

Two samples of cosmetics containing Cd2+ (National Institute of Metrology, China) were prepared. For comparison, these samples were analyzed using the developed method and GB-recommended method [32], respectively. The results are shown in Table 5. It can be seen from the results that the developed method is reliable. Furthermore, the pretreatment used in our developed method was simpler and faster than that used in the GB-recommended method. Obviously, the method based on HDESs was highly efficient and environmentally friendly.

Conclusion

This study used recyclable HDESs to substitute traditional digestion. HDES-1(menthol and hexanoic acid) was screened as the optimal solvent to dissolve the cosmetic samples, and EDTA-2Na saturated solution was screened as stripping back extraction reagent. We found that the stability constants of Cd2+ EDTA chelates play an important role in the re-extracting process. The recycling studies demonstrate that HDES-1 can be recycled and reused well. The developed method was also applied for the determination of Mg2+, Mn2+ and Cu2+ in cosmetic samples, which provides a new idea for determination of metal ion in oily substances.

References

Y. Gao, Xu. Mo, R.E. Sturgeon, Z. Mester, Z. Shi, R. Galea, P. Saull, Lu. Yang, Anal. Chem. 87, 4495–4502 (2015)

Wu. Debo, S. Yang, F. Li, T. Zhu, H. Chen, Anal. Chem. 92, 14309–14313 (2020)

Alan L. Vieira, Edilene C. Ferreira, Silvana R. Oliveira, Fernando Barbosa, Jr., José A. Gomes Neto, Microchemical Journal, 160, 105637–105645 (2021)

Tyler Z. Sodia, Alexa A. David, Ashley P. Chesney, Juliana N. Perri,etc, ACS Sens. 6, 4408–4416 (2021).

M. Wang, Qi. Wang, J. Wang, R. Liu, G. Zhang, Y. Yang, ACS Sustainable Chem. Eng. 9, 4894–4902 (2021)

Yu. Yi Zhang, W.G. Deng, ACS Sustainable Chem. Eng. 9, 9932–9940 (2021)

Y.H. Zhai, Y.W. Liu, X.J. Chang, S.B. Chen, X.P. Huang, Anal. Chim. Acta 593, 123–128 (2007)

M. Soylak, S. Saracoglu, U. Divrikli, L. Elci, Talanta 66, 1098–1102 (2005)

M.A. Taher, S.Z.M. Mobarakeh, F.S. Mahani, Bull. Chem. Soc. Ethiopia. 19, 17–22 (2005)

M. Krachler, J. Zheng, D. Fisher, W. Shotyk, Anal. Chim. Acta 530, 291–298 (2005)

H.D. Revanasiddappa and T.N., Anal. Sci. 18, 1275–1278 (2002)

L. La Pera, Rosario Lo Curto, Giuseppa Di Bella and Giacomo Dugo. J. Agric. Food Chem. 53, 5084–5088 (2005)

Abbott, A. P., Boothby, D., Capper, G., Davies, D. L., & Rasheed, R. K., 126, 9142–9147 (2004)

Q. Chen, L. Chaihu, X. Yao, X. Cao, W. Bi, J. Lin, D.D.Y. Chen, ACS Sustainable Chem Eng 9, 10083–10092 (2021)

J.P. Wojeicchowski, A.M. Ferreira, D.O. Abranches, M.R. Mafra, J.A.P. Coutinho, ACS Sustainable Chem Eng 8, 12132–12141 (2020)

S. El Kantar, H.N. Rajha, N. Boussetta, E. Vorobiev, R.G. Maroun, N. Louka, Food Chem. 295, 165–171 (2019)

L. Li, K. Liu, H. Xing, X. Li, Q. Zhang, D. Han, H. He, H. Yan, B. Tang, J. Catal. 374, 306–319 (2019)

J. Cao, M. Yang, F. Cao, J. Wang, Su. Erzheng, J. Clean. Prod. 152, 399–405 (2017)

I.M. Aroso, A. Paiva, R.L. Reis, J Molecular Liquids 241, 654–661 (2017)

A. Viñas-Ospino, M. Panić, I. Radojčić- Redovniković, J. Blesa, M.J. Esteve, Food Bioscience. 53, 102570 (2023)

A. Viñas-Ospino, M. Panić, M. Bagović, K. Radošević, M.J. Esteve, I. Radojčić Redovniković, Sustainable Chemistry and Pharmacy. 31, 100942 (2023)

W. Liu, B. Zong, X. Wang, J. Caic, Yu. Jingjing, RSC Adv. 9, 17432–17439 (2019)

P. Reboredo-Rodriguez, L. Rey-Salgueiro, J. Regueiro, C. Gonzalez-Barreiro, B. Cancho-Grande, J. Simal-Gandara, Food Chem. 150, 128–136 (2014)

W. Liu, B. Zong, J. Yu, Y. Bi, Food Anal. Methods 11, 1797–1803 (2018)

N. Lamei, M. Ezoddin, K. Abdi, Talanta 165, 176–181 (2017)

Aránzazu García, Elisa Rodríguez-Juan, Guillermo Rodríguez-Gutiérrez, José Julian Rios, Juan Fernández-Bolaños, Food Chem. 197, 554–561 (2016)

W. Bi, M. Tian, K.H. Row, J. Chromatogr. A 1285, 22–30 (2013)

R.A. Zounr, M. Tuzen, N. Deligonul, M.Y. Khuhawa, Food Chem. 253, 277–283 (2018)

J. Chen, Y. Li, X. Wang, W. Liu, Molecules 24, 4594–4605 (2019)

Wuhan University, Analytical chemistry, Beijing: Higher Education Press, 3, 154–232 (1995)

Wuhan University, Jilin University, etc, Inorganic Chemistry, Beijing: Higher Education Press, 3, 299–816(1992)

Ministry of Health of the PRC, Hygienic Standard for Cosmetics, Standards Press of China, 2015

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, B., Zhou, Lz., He, Gw. et al. Highly efficient determination of metal ion in cosmetic samples by reversed-phase liquid–liquid microextraction based on green hydrophobic deep eutectic solvent. ANAL. SCI. 40, 115–121 (2024). https://doi.org/10.1007/s44211-023-00437-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s44211-023-00437-y