Abstract

In present study, a reversed-phase dispersive liquid–liquid microextraction method followed by flame atomic absorption spectrometry as a low cost, easy operation, high sensitivity, and accuracy analytical approach has been developed for the analysis of lead(II) and cadmium(II) ions in cosmetic samples. For this purpose, the samples were diluted by toluene and then a mixture of diluted nitric acid solution and acetonitrile was used as the extraction solvent and disperser solvent, respectively. Effect of some important parameters on efficiency of the method was investigated to reach high enrichment factors. Under optimum experimental conditions, the calibration curves were linear in the ranges of 10.0–200 and 1.0–175 μg Kg−1 for lead(II) and cadmium(II), respectively. Moreover, relative standard deviations of the developed procedure for intra- (n = 6) and inter-day (n = 4) precisions were in the ranges of 3.4–6.5% ( C= 20 μg Kg−1 of each cation). Eventually, the suggested method was successfully used in analysis of the chosen ions in various cosmetic brands.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, due to human desire for beauty, cosmetic products are extensively used in daily life to enhance appearance or ameliorate skin quality as well as boosting confidence (Liu et al. 2020; Zafarzadeh et al. 2018). The application of cosmetics is as old as human civilization and regardless of age, sex or country of residence (Arshad et al. 2020; Michalek et al. 2019). There are many types of cosmetics such as creams, lotions, shampoos, hair colors, personal hygiene products, perfumes, lipsticks, skincare products, and makeup products, which their ingredients are complex to achieve specific functions. They are natural and synthetic chemical substances (Massadeh et al. 2017; Zhong et al. 2015). Accordingly, it is necessary to investigate the composition of cosmetics and their adverse impact on consumer health, because they are straightly applied to mucosa, oral cavity, and human skin (Zhong et al. 2015; Kazi et al. 2019).

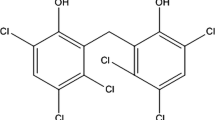

Evidences suggest that some cosmetic products may contain harmful levels of heavy metals as impurities during their formulation, impurities in the raw ingredients or owing to releasing from the metallic devices used during their manufacturing. Even at very low levels of heavy metals, their exposure is extremely hazardous and might create adverse effects on the face and body of users via bonding to sulfhydryl groups of proteins and depletion of glutathione (Wang et al. 2019; Capelli et al. 2014; Kilic et al. 2020). Specifically, lead and cadmium are the pollutants found in various types of cosmetics such as foundation creams, lipsticks, and eyeliners (Balarastaghi et al. 2018; Brandão et al. 2012). Lead is extremely harmful to the human body by damaging the neurological, reproductive, hepatic, and renal systems. Also it causes cancer due to exceeding agglomeration in the human body (Wang et al. 2019). Cadmium is a golden orange pigment and is found in some natural dyes and mineral pigments in cosmetics. It can cause bone damage, renal dysfunction, and increase the risk of lung cancer (Özzeybek et al. 2020; Ayenimo et al. 2010). Many countries have defined hard restrictions for heavy metals as the impurities in cosmetics, and they are strictly inspected and determined by the local authorities (Zhong et al. 2015).

Therefore, it is necessary to measure concentration of these metallic ion in cosmetic products with an accurate and reliable analytical method. One of the recommended and widely used analytical techniques for detecting metalic ions in different matrices is flame atomic absorption spectrometry (FAAS) (Naeemullah and M. Tuzen 2019; Sixto et al. 2019; Soylak and Elci 1997; Narin et al. 2003). It is one of the simplest, most powerful, fastest, and accurate methods of analysis in quality control that can measure about seventy metallic ions with low detection limits (Şahan et al. 2010). However, this technique suffers from several problems in direct measurement of heavy metals in cosmetic samples such as their high viscosity, low concentrations of the analytes, and attendance of a lot of organic and inorganic substances in these samples. Therefore, a sample preparation process is usually needed to determine trace concentrations of the analytes in cosmetic samples. In recent years, dispersive liquid–liquid microextraction (DLLME) has been one of the most beloved extractions methods to enrich the analytes and eliminate or minimize matrix effect (Sorouraddin et al. 2019, 2020; Soylak and Yilmaz 2011). It was introduced by Assadi and coworkers (Rezaee et al. 2006) for the first time. It is used as a rapid, simple, inexpensive, and efficient method for various samples. In the conventional DLLME method, the analytes are transferred from an aqueous sample solution into an organic phase (as an extraction solvent) with the help of a disperser solvent. Although this method reduces sample preparation time and minimizes the use of organic solvents, it still uses harmful organic solvents such as toxic chlorinated or aromatic organic solvents. DLLME is also difficult to apply in solid and lipophilic samples (Sorouraddin et al. 2020). To solve the problems of DLLME method, a reversed-phase (RP) DLLME was proposed for the preparation of lipophilic samples (Hashemi et al. 2010). In this method, analytes are extracted from the samples into a low volume (at µL-level) of an aqueous solution such as pure water and an acidic solution. Inversion of the sample and extraction solvent polarities makes it possible to extract metallic ions from nonpolar samples for better determination of them by FAAS (Lourenço et al. 2019). RP-DLLME method is more environmentally friendly, low cost, and safe compared to the conventional DLLME method because of replacing toxic organic solvents with aqueous solutions (Liu et al. 2013).

In this study, we focused on using an RP-DLLME-FAAS method to determine concentration of two heavy metal cations in the selected cosmetic products. The method provides a quick, easy, and low-cost sample preparation procedure for the extraction and preconcentration of cadmium(II) and lead(II) ions from cosmetic samples followed by a sensitive and selective determination of the analytes by FAAS.

Materials and methods

Chemicals and solutions

A stock solution (10 mg L−1, each analyte) of Pb(II) and Cd(II) was prepared in ethyl acetate by dissolving sufficient amounts of Pb(NO3)2·6H2O and Cd(NO3)2·6H2O (Merck, Darmstadt, Germany). To prepare a working standard solution, toluene (analyte-free) was spiked with 20 µg L−1 of each Pb(II) and Cd(II). It was used in optimization steps of the procedure. Also, to control quality of the detection apparatus and compute enrichment factors (EFs) and extraction recoveries (ERs), a standard solution of the analytes (1 mg L−1 of each analyte) in deionized water (Ghazi Company, Tabriz, Iran) was prepared, and injected (three times) into the instrument every day. Toluene, ethyl acetate, nitric acid (65%, w/w), and acetonitrile were prepared from Merck.

Real samples

Three lipstick and two cream samples were bought from local cosmetic stores (East Azerbaijan province, Tabriz, Iran). A 0.3 g of each sample was mixed with 25 mL toluene, vortexed for 5 min, and centrifuged at 5000 rpm for 10 min to remove solid particles.

Instrumentation

An atomic absorption spectrometer (Shimadzu AA-6300, Kyoto, Japan) equipped with a 100-mm burner head, an electrothermal graphite tube atomizer, and deuterium background correction was used to analysis the extracted analytes. An air–acetylene flame was used. Cadmium and lead hollow-cathode lamps were used as the radiation sources (Hamamatsu Photonics, Shizuoka, Japan) operating at the wavelengths of 283.3 and 228.8 nm, and the currents of 12 and 10 mA, respectively. Their spectral bandwidths were 0.5 nm. A laboratory hot plate from Gerhardt (Konigswinter, Germany) was used for heating the solution. Phase separation in extraction process was performed using A Hettich centrifuge (ROTOFIX 32A, Kirchlengern, Germany).

Procedure

A 5.0 mL of the standard solution (containing 20 µg L−1of each analyte in toluene) or diluted sample solution (Sect. 2.2) was transferred into a dry 10-mL glass test tube with conical bottom. Then, it was transferred into a water bath and its temperature was set at 60 °C. Afterward, 1.75 mL acetonitrile (as a disperser solvent) was mixed with 225 μL nitric acid solution (5%, w/w) (as an extraction solvent) and rapidly dispersed into the solution by a 5-mL glass syringe. This operation resulted in spreading the extracting solvent throughout the solution and a cloudy state was formed in the test tube. Then, the solution was centrifuged at 6000 rpm for 10 min. The sedimented aqueous phase containing the extracted analytes (205 ± 3 µL) was obtained. Finally, to determine the amount of the extracted analytes, two 100-μL aliquots of the sedimented aqueous phase were removed by a 100-µL microsyringe (zero dead volume, Hamilton, Switzerland). They were injected into the instrument separately.

Graphite furnace atomic absorption spectrometry (GFAAS)

To assess accuracy of the proposed procedure, concentration of Pb(II) and Cd(II) ions in the real samples were also determined by GFAAS (Okamoto et al. 1971). For this purpose, 1.0 g of the sample was digested in the presence of 20 mL H2O2 and HNO3 mixture (1:3, v/v). After filtration, volume of the filtrate was increased with deionized water to an ultimate volume of 50 mL. The digestion was done in a fume chamber at a temperature of 225 °C for 2 h. Concentration of the analytes were determined by GFAAS.

Calculation of EF and ER

EF and ER were used to assess efficiency of the method. The ratio of analyte concentration in the sedimented aqueous phase (Csed) to its initial concentration in organic phase (C0) is defined as EF:

To calculate Csed, a calibration graph was used. The percentage of total analyte amount (n0) extracted into the sedimented aqueous phase (nsed) is defined as ER:

where Vsed and M are volume of the sedimented aqueous phase (mL) and sample weight (g), respectively.

Results and discussion

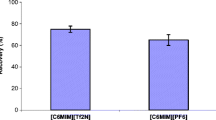

Selection of type and volume of disperser solvent

In a RP-DLLME method, disperser solvent nature is an important parameter, because it can affect extraction efficiency by changing quality of the cloudy state. The disperser solvent should be miscible with both aqueous and organic phases, and in this study it must disperse nitric acid solution (extraction solvent) into toluene (dilution solvent for the samples). For this purpose, three semi-polar solvents including ethanol, acetonitrile, and acetone were investigated as the dispersive solvents. The results (Fig. 1a) show that the highest ERs are achieved when acetonitrile was used as the disperser solvent. Moreover, to study the effect of its volume, different volumes of acetonitrile (1.00, 1.25 1.50, 1.75, and 2.00 mL) were tested. Regarding the results shown in Fig. 1b, the highest ERs in the proposed method were obtained in acetonitrile volume of 1.75 mL. Therefore, acetonitrile with the volume of 1.75 mL was chosen as the disperser solvent.

a Effect of dispersive solvent type on the ERs of Pb(II) and Cd(II) ions. Extraction conditions: sample, 5 mL Pb(II) and Cd(II) solution with a concentration of 20 µg L−1 of each in toluene; dispersive solvent volume, 1.5 mL; extraction solvent, nitric acid 2% (v/v); temperature, 60 °C; and centrifugation at 6000 rpm for 8 min. The error bars represent standard deviations (n = 3). b Effect of dispersive solvent volume on ERs of the analytes. Extraction conditions: dispersive solvent; acetonitrile. The other conditions are the same as those used in a

Selection of type and volume of extraction solvent

In implementing the proposed method, selecting concentration of nitric acid solution as the extraction solvent is very important. Because it must oxidize organometallic compounds of cations in the real samples and release the analytes as their cationic forms. For this reason, different percentages (v/v) of nitric acid were evaluated by comparing ERs of the analytes. The results (Fig. 2) show that 5% (v/v) of nitric acid is more efficient as an extraction solvent in the proposed method, and it was employed in the subsequent experiments.

Effect of nitric acid concentration on ERs of the analytes. Extraction conditions: dispersive solvent (volume); acetonitrile (1.75 mL), and the other conditions are the same as those used in Fig. 1b

In addition, volume of the extraction solvent is directly affected the final sedimented phase volume and extraction efficiency. So, to investigate the effect of the extraction solvent volume on the extraction efficiency of the developed method, various volumes (175, 200, 225, 250, 275, and 300 µL) of nitric acid solution (5%, v/v) were investigated. According to the obtained results, in the volumes of 175 and 200 µL, volume of the sedimented phase was less than 200 µL (to analysis of each cation, 100 µL is needed). On the other hand, by increasing volume of the extraction solvent to more than 225 µL, the sedimented phase volume was also increased and the analytical signals reduced due to dilution effect. Therefore, in the volume of 225 µL of nitric acid solution highest EFs were obtained, in which volume of the sedimented phase was 205 ± 3 µL. So it was selected as the optimal volume of the extracting solvent.

Effect of temperature

Due to effect of temperature on diffusion coefficient, mass transfer, and extraction rate of the analytes, it is considered as a main parameter in performance of the suggested procedure. Commonly, in liquid phase microextraction procedures by temperature enhancement high extraction efficiency is acquired due to the increased diffusion coefficient and mass transfer of the analytes into extractant (Arpa and Arıdaşır 2019). According to these points, the effect of this parameter on extraction performance of the proposed procedure was studied at various temperatures in the range of 25–70 °C. As shown in Fig. 3, the ER values for Pb(II) and Cd(II) ions increase by increasing the extraction temperature up to 60 °C and remain nearly at 70 °C. Therefore, 60 °C was chosen for the next experiments.

Effect of temperature on ERs of the analytes. Extraction conditions are the same as those used in Fig. 2, except nitric acid 5%, v/v, was used as the extraction solvent

Study of centrifuging speed and time

In the presented RP-DLLME method, centrifugation is necessary to collect the dispersed tiny droplets of the aqueous extracting solvent at the bottom of the conical test tube. To investigate the impact of this feature, centrifugation time and speed were investigated in the ranges of 5–14 min and 5000–8000 rpm, respectively. Based on the results, 10 min and 6000 rpm were chosen as the optimum centrifugation time and speed, respectively.

Influence of coexisting ions

In a real sample, in addition to the investigated metallic ions, other compounds are usually present which cause matrix effect and affect the extraction performance. Therefore, the effect of possible ions in the cosmetic samples on ERs of the target metallic ions was studied under the optimum experimental conditions using a standard solution of 20 µg L−1 of Pb(II) and Cd(II) (each ion) and various concentrations of the interfering ions. Variation of ERs of the analytes higher or lower than 5% was considered as interference. The results listed in Table 1 indicate that all studied coexisting ions do not significantly affect the ER values.

Analytical performance of the proposed method

The figures of merit of the proposed RP-DLLME-FAAS method including relative standard deviation (RSD), limit of quantification (LOQ), limit of detection (LOD), linear range, ERs, EFs, coefficient of determination (r2) for measurement of Pb(II) and Cd(II) ions in cosmetic samples were considered. The obtained results are collected in Table 2. In this method, the calibration curves were linear in the ranges of 10.0–200 and 1.0–175 µg Kg−1 with the r2 values of 0.993 and 0.995 for Pb(II) and Cd(II) ions, respectively. As can be seen, LOQs as the measurable lowest concentration level of each analyte by the proposed method were obtained 10.0 and 1.0 μg Kg−1 for Pb(II) and Cd(II) ions, respectively. Moreover, the LODs calculated as 3SB/m (SB is standard deviation of the blank and m is slope of the calibration graph) were 3.2 and 0.30 μg Kg−1 for Pb(II) and Cd(II) ions, respectively. In order to investigate repeatability of the proposed method, RSDs% were calculated based on performing six replicate measurements on the same day (intraday) and different days (inter-day) at a concentration of 20 µg L−1 of each cation. A good repeatability with RSD ≤ 8% was obtained for intra- (n = 6) and inter-day (n = 4) precisions. According to the results (low LODs and LOQs, and good repeatability), the present procedure can be applied as a suitable extraction and preconcentration procedure for the determination of the selected heavy metal ions in cosmetic samples.

Analysis of real samples

To evaluate performance of the present procedure, it was applied for the measurement of lead(II) and cadmium(II) ions in several cosmetic samples. The results are summarized in Table 3. Pb(II) was detected in all samples. Concentration of Pb(II) ions was obtained in the range of 25.0–90.0 µg Kg−1. Cd(II) ions were found in all samples, except one of the cream samples. Its concentration was between 5.9 and 6.9 µg Kg−1 in the samples. To study accuracy of the proposed method, the real samples and pure toluene were spiked with two concentrations (15 and 25 µg Kg−1 of each cation) and the method was performed on them. The resulted relative recoveries were between 88.0 and 103.0%, which demonstrate that matrices of the samples have no significant effect on efficiency of the present procedure. Therefore the presented microextraction method can be useful for the extraction and preconcentration of Pb(II) and Cd(II) ions in cosmetic samples without a significant matrix effect.

Accuracy evaluation

To study accuracy of the suggested procedure, in addition to added–found method (Sect. 3.7), analysis of the analytes in cream sample (II) in Table 3 was also performed by another method. For this purpose, GFAAS was used according to Sect. 2.5. The obtained concentrations were 31.6 ± 2.0 and 6.7 ± 0.5 µg Kg−1 for Pb(II) and Cd(II), respectively, which are in a good agreement with those obtained by the proposed RP-DLLME-FAAS method, and no meaningful difference (t test, obtained = 1.35 for Pb(II) and 0.87 for Cd(II); t 0.05,2 = 4.3) was observed.

Comparison the characteristics of the proposed method with other reported approaches

Analytical parameters of the presented method were compared with those of the other methods used in the extraction and measurement of Pb(II) and Cd(II) ions in various matrices. LOD, LR, and RSD values of the method along with those of the other methods are listed in Table 4. Briefly, the proposed RP-DLLME-FAAS method has wider LRs and comparable LODs and RSDs in comparison with the other methods mentioned in Table 3. However, the used determination systems in most other methods (e.g., GFAAS) are inherently more sensitive than FAAS. Additionally this procedure is rapid, easy, inexpensive, and low toxic compared to the others.

Conclusions

In this study, an RP-DLLME method was successfully validated for the extraction and preconcentration of Pb(II) and Cd(II) ions from cosmetic samples before their analysis by FAAS. The method overcame the drawbacks of routine DLLME from the viewpoint of toxicity of extraction solvent. Dispersive microextraction with a small volume of a slightly acidic aqueous solution allowed both cations to be completely back-extracted from the organic phase into the aqueous phase. Considering the results, the method is reliable, efficient, sensitive, rapid, and easy to use procedure for the preconcentration and extraction of the selected metallic ions from complicated samples. Besides, the analysis of two cream and three lipstick samples demonstrated that the developed method provided precise and accurate results as well as quantitative extraction. Pb(II) was found in all selected samples and Cd(II) in four samples at µg Kg−1 level. The results proved feasibility of the proposed method for routine analysis of the selected heavy metal cations in cosmetic samples.

Abbreviations

- EF:

-

Enrichment factor

- ER:

-

Extraction recovery

- FAAS:

-

Flame atomic absorption spectrometry

- LOD:

-

Limit of detection

- LOQ:

-

Limit of quantification

- RP-DLLME:

-

Reversed-phase dispersive liquid–liquid microextraction

References

Arpa Ç, Arıdaşır I (2019) Food Chem 284:16

Arshad H, Mehmood MZ, Shah MH, Abbasi AM (2020) Saudi Pharm J 28:779

Ayenimo JG, Yusuf AM, Adekunle AS, Makinde OW (2010) Bull Environ Contam Toxicol 84:8

Balarastaghi S, Khashaiarmanesh Z, Makhdoumi P, Alavizadeh SH, Moghadam ZS, Shirani K, Karimi G (2018) Toxin Rev 37:117

Brandão JDO, Okonkwo OJ, Sehkula M, Raseleka RM (2012) Toxicol Environ Chem 94:70

Cadorim HR, Schneider M, Hinz J, Luvizon F, Dias AN, Carasek E, Welz B (2019) Anal Lett 52:2133

Capelli C, Foppiano D, Venturelli G, Carlini E, Magi E, Ianni C (2014) Anal Lett 47:1201

Chamsaz M, Atarodi A, Eftekhari M, Asadpour S, Adibi M (2013) J Adv Res 4:35

de Jesus Ferreira V, Almeida JS, Lemos VA, de Oliveira OM, Garcia KS, Teixeira LS (2021), Talanta 222:121514.

Hashemi P, Raeisi F, Ghiasvand AR, Rahimi A (2010) Talanta 80:1926

Kalfa OM, Yalçınkaya Ö, Türker AR (2009) J Hazard Mater 166:455

Kazi TG, Afridi HI, Bhatti M, Akhtar A (2019) Ultrason Sonochem 51:40

Kilic S, Kilic M, Soylak M (2020) Biol Trace Elem Res 2020(199):2272

Liu S, Xie Q, Chen J, Sun J, He H, Zhang X (2013) J Chromatogr A 1295:16

Liu Y, Chu Y, Hu Z, Zhang S, Ma S, Khan MS, Chen F, Zhang D, Guo L, Lau C (2020) Microchem J 158:105322.

Lourenço EC, Eyng E, Bittencourt PRS, Duarte FA, Picoloto RS, Flores ÉLM (2019) Talanta 199:1

Maltez HF, Borges DL, Carasek E, Welz B, Curtius AJ (2008) Talanta 74:800

Massadeh AM, El-khateeb MY, Ibrahim SM (2017) Pub Health 149:130

Michalek IM, Benn EKT, dos Santos FLC, Gordon S, Wen C, Liu B (2019) Environ Res 170:187

Naeemullah, Tuzen M (2019) Talanta 196:71.

Narin I, Soylak M, Kayakirilmaz K, Elci L, Dogan M (2003) Anal Lett 36:641

Okamoto M, Kanda M, Matsumoto I, Miya Y (1971) J Soc Cosmet Chem 22:589

Özzeybek G, Şahin İ, Erarpat S, Bakirdere S (2020) J Food Compos Anal 90:103486.

Rezaee M, Assadi Y, Hosseini MRM, Aghaee E, Ahmadi F, Berijani S (2006) J Chromatogr A 1116:1

Şahan S, Saçmacı Ş, Şahin U, Ülgen A, Kartal Ş (2010) Talanta 80:2127

Sixto A, Mollo A, Knochen M (2019) J Food Compos Anal 82:103229.

Sorouraddin SM, Farajzadeh MA, Okhravi T (2019) J Iran Chem Soc 16:1537

Sorouraddin SM, Farajzadeh MA, Okhravi T (2020) J Food Compos Anal 93:103590.

Soylak M, Elci L (1997) Int J Environ Anal Chem 66:51

Soylak M, Yilmaz E (2011) Desalination 275:297

Wang W, Bao N, Yuan W, Si N, Bai H, Li H, Zhang Q (2019) Microchem J 148:240

Zafarzadeh A, Shahryari A, Taziki S, Ahmadi N, Mirkarimi K, Charkazi A (2018) Natl J Physiol Pharm Pharmacol 8:1200

Zhong Z, Li G, Luo J, Chen W, Liu L, He P, Luo Z (2015) Anal Methods 7:3169

Acknowledgements

The authors thank the Research Council of the University of Tabriz for financial support.

Funding

Saeed Mohammad Sorouraddin has received research grants from University of Tabriz.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Saeed Mohammad Sorouraddin declares that he has no conflict of interest. Mir Ali Farajzadeh declares that he has no conflict of interest. Rana Pinou declares that he has no conflict of interest. Tohid Okhravi declares that he has no conflict of interest.

Ethical approval

This article does not contain any studies with human or animal subjects.

Informed consent

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sorouraddin, S.M., Farajzadeh, M.A., Pinou, R. et al. Development of a reversed-phase dispersive liquid–liquid microextraction method for the extraction and preconcentration of lead and cadmium ions in some cosmetic products. Chem. Pap. 76, 2085–2092 (2022). https://doi.org/10.1007/s11696-021-01954-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-021-01954-8