Abstract

The Sustainable Development Goals (SDGs) encourage sustainable practices in organisations opting to use renewable energy resources. The current study focuses on the development of a framework for the adoption of Industry 4.0 technologies (I4.0T) and Circular Economy (CE) practices that can help to achieve the SDGs for the manufacturing sector. The I4.0T-CE practices and the performance metrics were identified from the literature. The Pythagorean fuzzy analytical hierarchy process (PF-AHP) was used to compute the weights of the 30 identified I4.0-CE practices and the Pythagorean fuzzy combined compromise solution (PF-CoCoSo) method was used to prioritise the 18 performance metrics. The PF-AHP and the PF-CoCoSo are the advanced computational methods used in multi-criteria decision analysis. The data was collected from 15 experts of Indian manufacturing industries. The industrial expert panel was asked to provide their input through a pairwise comparison matrix. The analysis of the results shows that the top three I4.0-CE practices are “Reduced”, “Collaborations and Partnerships” and “Continuous Improvement”. In contrast, the top three performance metrics are the “No. of global policy measures”, “No. of government budget appropriations” and “No. of innovation using low carbon technologies”. The study contributes to industrial practitioners in implementation, and researchers in theoretical enhancement. The performance metrics enable tracking progress, identifying improvement areas, and making informed decisions for achieving SDGs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A conceivable route to accomplish the Sustainable Development Goals (SDGs) of the UN is through the combination of Industry 4.0 technologies (I4.0T) and Circular Economy (CE) practices [16]. The use of cutting-edge technologies like artificial intelligence (AI), the Internet of Things (IoT) and big data analytics (BDA) characterises Industry 4.0 (I4.0) to replace manual manufacturing processes with intelligent, interconnected systems [55] [68]. In the meantime, the CE focuses on eliminating waste and pollution, reusing resources and goods, and rebuilding natural systems [66]. CE is receiving a lot of interest from academics, organisations, and international businesspeople [67]. Governments and businesses are aware that sustainable development is necessary due to the quick depletion of resources and environmental deterioration (S. [40]). CE is primarily a blend of concepts borrowed from old economic and environmental perspectives that recommend raising resource usage efficiency to accomplish changes in the present balance between the economy, environment, and society [9]. It is a closed-loop supply chain that enables the industrial system to adapt to the concept of restoration and regeneration [61]. Manufacturing companies play an important role in improving the living standards of people, but at the same time, they contribute to environmental problems. To overcome these problems the United Nations set certain (SDGs), the ’2030 Agenda for Sustainable Development, which consists of 169 targets and 232 indicators to track progress and are relevant for manufacturing organizations [54][10]. [67] cited the relevance of circular economy practices to the SDGs and the findings suggested that CE practices can help achieve several SDG targets.

Organizations will need to give in to traditional practices and use innovative technologies to achieve SDGs [16]. Among the various industry-adopted practices like sustainable supply chain management, Industry 4.0 technology usage, circular economy and reconfigurable manufacturing systems,[54] this paper focuses on the nexus of Industry 4.0 technology and circular economy practices to achieve SDGs. Many authors cited the potential of I4.0T as a facilitator for CE, such as implementing I4.0T tools to enhance the performance of the reverse supply chain, and the benefits of using Big Data (BD) on the agricultural supply chain [16]. Further [63], suggested that universities should play a critical role in transforming the linear economy to CE in the emerging 4th industrial revolution, which is a synergy of Industries 4.0 and CE. As universities train wide professionals, he believed that they have the power to influence supply chains and convince diverse groups including future generations, political bodies and the public.

I4.0T are not just the enablers but amplifiers to increase the attention towards CE and environmental sustainability, as they enable new tools for manufacturing firms that are used to control and measure the use of resources and eventually boost their resource efficiency [17]. The use of I4.0T empowers circular economy in business [81]. For example, [23] Blockchain Technology (BCT) is a facilitator for implementing sustainability and circular economy concepts by increasing systems efficiency and decreasing development and operational costs, Internet of Things (IoT), Cyber-Physical System (CPS), Cloud Computing (CC) can encourage the transition from linear to circular business model and provide a powerful set of tools to overcome barriers for implementation of CE [26][57]. To ensure consumerism and less waste generation during manufacturing, Additive Manufacturing (AM) can be used to provide the advantages of sustainability and the circular production system [72]. concluded that we cannot have a sustainable 4th Industrial Revolution without advancing the CE. Likewise, it is hard to imagine CE without the 4th Industrial Revolution.

Organizations looking towards less polluted energy resources and better resource consumption have adopted I4.0T [58]. Developed countries started applying advanced technologies on the production level to compete with other uprising countries and to offer more value to the customers (A. [37]). The most common way to describe the relation between CE and I4.0T was the digitalisation of CE. In the context of CE, I4.0T is considered a galaxy of opportunities that supports the company in achieving circularity through digitization [65]. However, the adoption of I4.0T in CE is quite complex ([2, 60] believes that digitalization will promote CE by enabling the efficient use of resources through accurate information and increasing its visibility resulting in the closure of resource loops. [65] stated that there needs to be more empirical evidence on how firms apply CE and I4.0T principles. Hence further investigation is needed to identify the potential impact of I4.0T and CE in designing business models.

There is a lot of research that is beginning to explore the nexus between CE and I4.0T [57]. It offers benefits that link advanced technologies to system-wide shifts in economic and industrial models [16]. As a result, a review is also conducted in this paper to identify I4.0T that contributes to achieving CE practices. Many researchers have contributed to different research chunks related to sustainability. [16] is the first publication to simultaneously address CE, I4.0 and SDGs. However, in this paper structural framework during the adoption of CE-I4.0T practices and performance evaluation are included. The combination of the two topics is growing in the manufacturing sector [16]. Hence, investigating general CE practices and I4.0T is essential so researchers and practitioners can make decisions. Investing in research and implementation of these practices that includes the initial production of the raw materials to the final disposal or recycling of the product will have a positive impact over time.

The following research questions (RQ) emerge:

RQ1. What CE practices and I4.0T are described in the literature?

The first research objective is to conduct a literature review for the recognition of CE practices and I4.0T.

RQ2. Which SDGs can be achieved with the help of I4.0T-CE practices?

The second research objective is to understand SDGs and to identify which SDG targets can be accomplished using Industry 4.0 technologies and CE practices through a literature review.

RQ3. What will be the nexus effect of adopting I4.0T-CE practices on SDGs?

The third research objective is to determine the impact of Industry 4.0-CE practices on SDGs.

RQ4. How can the systematic framework be helpful when adopting Industry 4.0-CE practices?

The fourth research objective is to develop a systematic framework along with a set of performance metrics for evaluation.

To achieve the objectives mentioned above, an extensive literature review is conducted to identify CE practices and Industries 4.0 technologies that are interconnected. Apart from this, a literature review is conducted to identify and categorize the SDGs, which are achieved with the help of CE practices and Industries 4.0 technologies. This review also assisted in determining the impact of CE practices and Industries 4.0 technologies on SDGs, creating a set of performance metrics that can reflect CE and Industry 4.0T’s contribution to SDG achievement. Further, ranking performance metrics according to their importance was necessary, and the authors decided to prioritize them. For this purpose, a panel of 15 experts is formed from five medium-scale industries. Their opinions are gathered to create a pairwise comparison matrix. The PF-AHP and PF-CoCoSo method is used for the analysis part.

Theoretical Background

The process of collecting various literature was carried out by retrieving publications from Taylor and Francis, John Wiley, Emerald Insight, SpringerLink and Science Direct. The keywords used for the search include “Circular Economy practices”, “Industry 4.0” and “Sustainable development goals”. The publications considered were peer-reviewed journals and book chapters. Many irrelevant publications were excluded after reading each paper's abstract and conclusion as a part of the initial screening. The second stage of exclusion was done by reading a full-length paper. The relevant publications were stored in a single location. The word relevant refers to the publications that present various CE practices, I4.0T, and assessments of SDGs. Finally, 73 papers were selected for the study. The current section aims to review these articles, and this literature review's important outcomes are summarized below.

Manufacturing industries are transforming from a linear economy to a circular economy and in this context, Industry 4.0 is the key enabler of innovative technology [61]. Table 1 summarises the Industry 4.0 technologies and CE practices that were associated with each publication examined in the literature review. The conducted literature review focused on papers that used either CE practices or Industry 4.0 technologies to obtain sustainability of the system and to eventually achieve SDGs. [61] investigated the CE practices and I4.0T applied in a sustainability context. There is a growing interest in the hands-on applications of both CE and I4.0 as a route to achieving sustainability. [19] believed that Additive manufacturing (AM) techniques like 3D printing enable CE practices such as reuse, modularity, upgrade, refurbishment and remanufacture. Soon Artificial intelligence (AI) could develop at a level, where humans only need to define the goal and show AI the databases, the rest leave everything else for machines to generate the solutions [78]. Further, AI provides precise resource data, enabling CE practices like recycling, refurbishment, remanufacturing, reducing, repair and reverse logistics [29]. CE practices such as recycling, reuse, recovery, repair, reduce are identified. Such practices are achieved using Augmented Reality (AR) [16], Autonomous robots [78], Blockchain Technology (BCT) (S. A. R. [39]), and Cyber-Physical Systems (CPS) [71]. [64] cited that collaborative robots (co-bots) can interact with humans and can support CE practices such as recovery, treatment of hazardous resources, reuse, remanufacturing and reverse logistics. [46] found out that Cybersecurity (CS) has no direct effect on reducing CE problems but when paired with other I4.0T, it promotes CE practices like reducing waste and emissions, reuse, recovery and recycling.

[70] studied the function of the Internet of Things (IoT) in CE practices. The main finding of the study was that IoT remarkably improves CE activities and practices like green manufacturing, circular design, remanufacturing and recycling. Logistics service providers have invested or are likely to invest in technologies like IoT, Big Data Analytics (BDA) and Machine learning to gather real-time data, logistics network visibility, and productivity monitoring [48]. [71] developed a roadmap for achieving reverse logistics 4.0. The author stated that the adoption of I4.0T has extensive impacts on refining data quality, computational intelligence and operations in reverse logistics. In continuation, the author quoted that IoT, CPS, AI and autonomous robots are enablers of reverse logistics 4.0 transformation. The fourth phase of waste management and CE are connected, which considers not only ways of using recycled materials but also the period of their use. Following these new policies, the author found out that mineral nanotechnology is the best alternative for renewable materials supply [52]. Radio Frequency Identification (RFID) tags provide information on the product lifecycle, enabling CE practices like reuse, repair and recycling. However, RFID tags are not treated as e-waste, leading to a huge environmental threat [15]. (A. A. [36]) stated the use of simulation in manufacturing supply chain chains. Simulation helps in product traceability and improves raw materials used in production. After reviewing these articles various I4.0T and CE practices are listed in Table 1.

The Millennium Development Goals (MDGs) were replaced by the Sustainable Development Goals (SDGs), which were formed on September 15, 2015, and are titled “Transforming our World: 2030 Agenda for Sustainable Development”. The SDGs are relevant to all countries and regions of the world and contain 17 agendas that cover around 169 targets [4]. SDG 8 (Decent work and economic growth), SDG 9 (Industry, Innovation and Infrastructure), and SDG 12 (Responsible Consumption and Production) deal with sustainable design, innovation and production while several other SDGs aid in competitive advantage among industries [69]. I4.0-related technological advancements may help organisations achieve their goals and the SDGs [54]. Further [67] concluded that a significant number of SDG targets can be achieved using CE practices and specialized implementation strategies.

According to [16], SDGs 7, 8, 9, 11, 12 and 13 can be achieved with the nexus of CE-I4.0T. As a result, the author decided to look into the nexus effect of CE-I4.0T in achieving the SDGs as mentioned above. The business SDGs that CE-I4.0T addresses are outlined along with the performance metrics in Table 2 and selected performance metrics along with their descriptions are listed in Table 3.

Literature Gaps

The existing research articles were thoroughly read and the authors identified the following gaps during the literature review.

-

The current body of literature does not provide a comprehensive framework to steer CE practices through different stages of implementation. A similar observation was noted regarding the application of I4.0T.

-

The existing publications do not offer a framework that demonstrates the combined impact of I4.0T and CE practices on the SDGs. Moreover, available research articles do not specify performance metrics to assess the contribution of CE and I4.0.

-

No pieces of study were found that assessed the relative importance of I4.0T-CE practices using weight-determining techniques.

-

No studies considered expert opinion to improve the performance of I4.0-CE practices.

The mentioned limitations show the importance of organizing CE practices, I4.0T and interconnectivity between them. Also, it is necessary to determine how CE practices and I4.0T aid each other. As discussed in the introduction section, some of the intellectuals examined SDGs in the CE and I4.0T but failed to measure the success of SDGs in the available literature. As a result, a framework that can aid in measuring SDGs success using CE and I4.0T is intended to be developed in the current study. This study also features the expert’s opinions on the developed framework to ensure proper alignment of the framework with the actual industrial factors.

Research Methodology

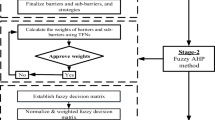

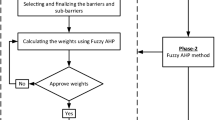

A literature review was conducted to understand the nexus between Industry 4.0 technologies and CE practices to achieve the SDGs. The topics addressed by this study are emerging hence only peer-reviewed papers published in the English language were considered. Since all subjects addressed in this paper are emerging, no time boundaries were set for this review. The search was carried out in March 2023 to find the most up-to-date and relevant literature on this topic. The searched files were stored in a single location to access them when needed. Following these articles were inspected to identify CE practices, Industry 4.0 and SDGs. Accordingly, literature gaps were identified, along with a set of performance metrics to gauge the adoption of SDGs. An expert group was formed to collect their opinion for computing weights and prioritizing the performance metrics. The professionals with 4+ years of experience and from diverse academic backgrounds were chosen. To collect their opinions, the authors took surveys, structured interviews and focus groups to gather detailed feedback. One-on-one interviews using a set of predefined questions were asked to ensure consistency and on the other hand, surveys consisted of both open-ended and closed-ended questions. To compute weights, the Pythagorean Fuzzy Analytical Hierarchy Process (PF-AHP) methodology is used whereas for prioritizing SDG performance metrics Pythagorean Fuzzy Combined Compromised Solution (PF-CoCoSo) technique is used. Expert opinions from 5 different medium-scale industries were taken into consideration. The framework developed constitutes to real-world industrial scenario. Figure 1 shows the research methodology undertaken.

During the expert panel discussion, it was suggested that the selected I4.0T-CE practices be divided into five major criteria based on their area of application. The selected I4.0T-CE practices were linked to the performance metrics. Computing their global weights helps to compare the selected I4.0T-CE practices within and outside the group.

Case Analysis

The current section describes the entire framework development process, including the use of multi-criteria decision-making (MCDM) techniques.

Problem Definition and Data Collection

The authors decided to choose 10 potential organizations that can assist in the first step of the study project. The authors used a proactive outreach approach, contacting these businesses through official study requests. Ultimately, 5 companies agreed to participate in the research study after multiple rounds of negotiations and talks. The nature of each of the five participating companies was remarkably similar. Each business mostly produced or supplied goods for the same industry sector. In terms of volume and scale, the companies’ manufacturing capacities were equivalent. About 100 to 120 employees were working for each organization.

A panel of 15 experts having extensive experience in I4.0 and CE was formed from these organizations. Three of the fifteen experts are PhDs, six are postgraduates in diverse fields and six are graduate engineers (refer to Table 4). In the first meeting itself, the author discussed CE practices, I4.0T, SDGs, framework development and its advantages. During the first brainstorming session, the expert panel was given a summary of the study goals, the pertinent response and the expected outputs required for the analysis. Few experts suggested categorising the practices into various groups based on their similarities. The first survey was prepared to collect data on pair-wise comparisons of major criteria and sub-criteria. This information is used to compute the weights of shortlisted practices by the “PF-AHP” method. After the success of the first session, the author scheduled the second brainstorming session. The author briefed experts on the weights of major criteria and sub-criteria. In the second session, a survey was conducted to collect inputs for prioritizing performance metrics by the “PF-CoCoSo” methodology through agreement with experts. In this survey, the experts were told to make the decision matrix using Table 8. Minor changes if any were made based on expert advocacy. Finally, the decision matrix was developed and the framework analysis was performed, as discussed in the following section.

Framework Development

According to the suggestions given by the experts, the CE-I4.0T were classified into main criteria and sub-criteria. The major criteria are Cyber Layer, Circular Supply Chain Management, CE process, Product Lifecycle Management, Physical Layer and Cyber-Physical Layer. All the CE-I4.0T practices were classified using these criteria. This helps to evaluate all the performance metrics associated with practices. Figure 2 shows the framework developed following the CE-I4.0T practices selected for this study.

Framework Analysis

This research uses a hybrid PF-AHP and PF-CoCoSo framework for analysis purposes. The detailed steps undertaken to achieve the objective of this research are discussed further below.

Application of Pythagorean fuzzy AHP

To find answers for RQ1 and RQ2, the weight determination of I4.0-CE practices influencing selected SDGs was needed. Out of several weight calculation methods such as the best-worst method, stepwise weight assessment ratio analysis, multi-objective optimization based on ratio analysis and other methods, the analytic hierarchy process (AHP) is considered the most powerful MCDM technique to solve complex problems. The AHP method is integrated with the Pythagorean fuzzy sets (PFS) to eliminate impreciseness in MCDM problems [45]. Therefore, this research employs the PF-AHP method.

The procedure for the PF-AHP method is as follows [45]:

Step 1: Finalize the major criteria and construct pairwise comparison matrix A = (aik)m × n obtained from an expert panel with the help of linguistic variables used in PF-AHP method (refer Table 5).

Step 2: Evaluate the differences matrix D = (dik)m × n between lower and upper values of the membership and non-membership functions using following equations.

Step 3: Calculate the Interval multiplicative matrix S = (sik)m × n using the following equations.

Step 4: To calculate weights, calculate determinacy value τ = (τik)m × n of the aik using:

Step 5: Multiply the determinacy degrees with S = (sik)m × n matrix to calculate weights before normalization T = (tik)m × n using:

Table 6 represents the sample pairwise comparison matrix prepared by one of the experts for major criteria practices.

After performing the PF-AHP technique, the values were obtained for major criteria weight and global weights of the enablers in Table 7.

Application of Pythagorean fuzzy CoCoSo

CoCoSo is a significant MCDM method [45]. In a range of decision-making situations, the CoCoSo method provides flexibility, transparency and efficacy. It can be applied in a variety of sectors and utilized as a decision support tool to improve the reliability and calibre of decisions. Researchers have given CoCoSo significant consideration for resolving difficult decision-making issues like risk assessment [56].

[79] integrated PFS theory in the CoCoSo method to have an advantage over other MCDM techniques in terms of differentiating the best options. The following is the computational process of the PF-CoCoSo method [56]:

Step 1: Obtain the decision matrix D = (Dij)m × n (where i =1 to m and j =1 to n) with the help of experts’ opinion by assigning linguistic scale of PF-CoCoSo Table 8.

Step 2: Obtain Pythagorean fuzzy decision matrix by converting the linguistic decision matrix using the equation:

Step 3: Compute the score function R = (rij)m × n of each PFN pij = (uij, vij) using the following equation:

Step 4: Obtain the orthonormal Pythagorean fuzzy matrix \({R}^{\prime }={\left({r}_{ij}^{\prime}\right)}_{m\times n}\) by converting the score function R = (rij)m × n using the following equation:

Step 5: Calculate the total of the weighted comparability sequence for every alternative using equation:

Step 6: Determine the whole of the power weight of comparability sequences for every alternative using the equation:

Step 7: Obtain the relative weights of the alternatives using aggregation strategies using following equations:

Where,

-

1)

Kia= Arithmetic mean of sums of weighted sum method (WSM) and weighted product model (WPM) scores.

-

2)

Kib= Sum of relative scores of WSM and WPM.

-

3)

Kic= Balanced compromise of WSM and WPM models scores.

Step 8: Calculate the assessment value Ki using equation:

Step 9: Ultimately rank the alternatives based on the diminishing value of Ki (i=1, 2. . ., m).

Table 9 depicts the pairwise comparison of the selected performance metrics, while Table 10 shows the rank of the performance metrics.

Discussion

In the current study, a hybrid Pythagorean fuzzy AHP method is used to compute the weights of the major and sub-criteria, while a Pythagorean fuzzy CoCoSo method is used to rank performance metrics. The current section discusses the study's findings and their implications in real-world cases.

Study Findings

The author began by referring to peer-reviewed research articles on CE, I4.0 and SDGs. Only the relevant articles are examined to identify best practices. It has helped facilitate the study of existing literature with the ongoing study. The created framework will help the practitioners evaluate the selected SDGs. This has helped to answer RQ1. The I4.0T-CE practices (refer to Table 1) and the performance metrics are identified from the literature review. Table 2 consists of SDGs and the enablers along with the performance metrics. This answers RQ2 and RQ3.

Figure 3 shows the pie chart for the distribution of weights among the major criteria. The PF-AHP major criteria weight computation (Table 6) shows that the “Circular Economy Process” has the highest weight. [67] supported this by stating that there is the strongest relationship between CP and SDG 7, SDG 8 and SDG 12. Many manufacturing companies have started exploiting CE practices to achieve economic, social and environmental sustainability [10]. The second highest among the major criteria is “Circular Supply Chain Management” followed by “Product Lifecycle Management” in third, with [35] supporting our findings by discovering that the smart sustainable circular supply chain has great influence in achieving SDG 9. Business uses circular supply chain models to extend the product's life span, reduce waste, and advance economic sustainability [1]. Thus, CSCM has the potential for business sustainability. And [21] believed there is a need to deal with PLM to facilitate SDG 11.

The weight calculations of the major criteria have “Cyber-Physical Layer” in fourth place followed by “Cyber Layer”. [34] cited that the utilisation of AI and ML, in conjunction with CPS contributes to the reduction of GHG emissions that leads to the attainment of SDG 13.

“Reduce” comes in first when analysing the overall weights of the I4.0-CE practices that have been shortlisted, followed by “Collaboration and Partnerships”, “Continuous Improvement”, “Reuse” and “Circular Design”. [31] cited the importance of reducing costs and emissions associated with solid waste connection (SWC). Whereas [11] emphasized the role of collaborative partner selection in a supply chain’s optimum course of action.

The performance metrics are ranked using the PF-CoCoSo methodology, with “Number of global policy measures” taking the position on top (refer to Table 7). This metric tells how many policies are adopted and put into practice globally, highlighting the significance of global collaboration and partnerships in addressing sustainability issues successfully. “Government budget appropriations” occupies a second place which is the way of measuring government support for research and development activities. In support [82] cited that financial globalisation significantly enhanced technological innovation, which is more pronounced in nations with higher-quality institutions. The third performance metric is the “Number of innovations using low-carbon technologies”. Encouraging and tracking the development of low-carbon technologies is essential since it plays an important role in achieving sustainable development by assisting in the path dependency of a carbon-intensive economy and current energy infrastructure (W. [12]). “Renewable energy share in total energy used” is ranked fourth. The signing of the Kyoto Protocol in 1997 and the 2015 Paris Conference by international communities on climate change was aimed at achieving a higher proportion of renewable energy consumption [42]. The expression “accessibility and affordability to renewable energy sources” is ranked fifth, and it can help measure the accessibility and affordability of renewable energy supply by all in society. The performance metrics at the bottom of the ranking, however, are “Productivity at bottleneck” and “Energy expenditure on carbon”. Often it is seen in the organisation that when the external stakeholder exerts pressure it usually leads to reactive environmental practices. Here the organisation reacts to external demands rather than taking proactive measures. Therefore, in most cases, businesses adopt green practices to avoid fines, negative publicity and legal issues [5].

Performance metrics such as “No. of cities incorporating smart grid”, “Recycling rate”, “Waste to energy conversion” and “Carbon footprint” have occupied middle-ranking positions. These metrics are related to the environment dimension. [77] evaluated “Total Material Requirement” (TMR) referring to it as Material Footprint (MF) to set a threshold for energy, greenhouse gas (GHG), and material consumption required to attenuate poverty. [84] quoted “Infrastructure efficiency” as overall equipment effectiveness (OEE), a process performance indicator for measuring manufacturing productivity. Whereas [49] explained how pre-market producer responsibility (PPR) would regulate the ways of adopting CE that increase product lifetime. This study provides a strong framework for adopting I4.0-CE practices and can be used by a variety of industries. This answers RQ4.

Theoretical Implications

Few researchers discussed adopting I4.0T-CE practices for SDGs, but none studied the enablers, their weights, and the ranking of the performance metrics to achieve SDGs. Hence this study tries to find enablers and performance metrics that help achieve SDGs using PF-AHP and PF-CoCoSo method. The demonstrated application of the PF-AHP and PF-CoCoSo can be used in other research areas to obtain the relative weights between the enablers and rank the performance outcomes. This can attract more researchers in this domain leading to increased I4.0T-CE practices adoption [18] [75]. This research can be viewed as a significant contribution to MCDM and CE-promoting applications in the domain areas [62]. The framework developed in this study serves as an inspiring model for creating similar frameworks across other research areas, providing a blueprint for addressing complex problems in various fields. Finally, the prioritised performance metrics highlight the future research directions for effective SDG attainment. These implications indicate that I4.0-CE practices can help in achieving SDGs by proper and careful implementation of a circular supply chain, all three layers of information technology (i.e. Cyber Layer, Physical Layer and Cyber-Physical Layer), CE process and product lifecycle management [6]. The importance may vary from organization to organization depending on the level of status of I4.0-CE practices.

Managerial Implications

This study offers significant implications for industrial managers, streamlining the decision-making process related to achieving SDGs. For e.g., tracking innovation using low-carbon technologies can guide managers in investing in research and development initiatives that promote sustainability and mitigate carbon emissions. This will assist the organisation in attaining SDG 9 [6]. Furthermore, the weights can help managers identify the relative importance of identified I4.0T-CE practices so that they can implement them accordingly [18]. After implementing I4.0T-CE practices, it is necessary to evaluate the performance and effectiveness of these implemented practices. The identified set of performance metrics evaluates the same and determines the areas of poor performance. For e.g., metrics like waste-to-energy conversion indicate the ability of the organisation to convert waste into energy, which helps achieve SDG 12. The developed framework also motivates managers to implement I4.0T-CE practices to attain industrial sustainability [62].

Implications for Researchers and Practitioners

The presented work is both theoretically sound and practically applicable to CE, Industry 4.0 and sustainable development. Based on the proposed framework, highlighting concerns, and acquired ranking, the authors contend that this study has the following implications for researchers and practitioners. Researchers and practitioners can consult identified I4.0T-CE practices to learn and identify fresh study areas [51]. MCDM techniques are used to model these practices [30]. Furthermore, product development professionals can use digital technologies to monitor material flows, energy usage, and environmental effects of production processes and products. In addition, new business models and value propositions that rely on sharing, leasing, or remanufacturing things rather than selling them can be made possible by digital technologies [41].

This study concentrated on the combined effect of I4.0-CE practices on the achievement of directly influenced SDGs. This will help young researchers explore the achievement of SDGs discussed in this study. This research will raise awareness about customer needs, energy consumption, environmental protection, and opportunities for digital technologies. This study identified 18 performance metrics that will help researchers and practitioners evaluate the process's effectiveness in achieving sustainability. The metrics also include environmental and social aspects. The ranking emphasizes the importance of certain performance measures and methods. Practitioners can adjust their actions at the right stage if there is a deviation in the output. The current study was carried out with the help of an expert panel with varying educational backgrounds and experience. They contributed to the creation of the framework as well as insight into real-world issues they faced. This will benefit future scholars and practitioners to conduct research and discover new areas related to manufacturing. The nexus of I4.0-CE practices can serve as a basis for exploring the attainment of SDGs in various manufacturing domains, such as industrial equipment, automotive, clothing and so forth.

Conclusion and Future Scope

The current study commenced an extensive literature review, to identify I4.0-CE practices and SDGs. For this study, thirty I4.0-CE practices and a set of eighteen performance metrics were identified. Out of 17 SDGs, SDGs 7, 8, 9, 11, 12 and 13 were taken into consideration. A framework associating I4.0T-CE practices with performance metrics was created and evaluated in a case organization with the help of expert inputs. PF-AHP and PF-CoCoSo are used to calculate the weights of the practices and to prioritize the 18 performance metrics respectively.

In the sub-criteria, “Reduce” secured the highest weight, followed by “Collaboration and Partnerships” and “Continuous improvement” at third. This means that every organisation should prioritize reducing waste. I4.0T such as BDA, IoT and smart manufacturing enable organisations to organize resources leading to responsible consumption and production. On the other hand, sharing best practices, information and innovation can be made possible through the collaborative nature of I4.0, which results in better procedures, products and services for sustainable development. Given the current situation, Continuous improvement can build a competitive edge by increasing the efficiency, accuracy and effectiveness of business operations. Among various performance metrics, the “Number of global policy measures” was ranked first, followed by the “Number of government budget appropriations” and then by the “Number of innovations using low carbon technologies”. Practitioners are expected to keep a watch on these performance metrics to evaluate performance regularly.

It is expected that the case organization will try to strengthen their collaborations with various institutions across the globe. The developed framework will help to reduce social and environmental issues while increasing revenue generation. Researchers and practitioners can further gain detailed knowledge that can be used in achieving SDGs. However, there are some limitations to this framework and some suggestions for future research. This study considered the nexus effect of I4.0T-CE practices in achieving certain SDGs. As a result, further research should investigate the different types of adoption of I4.0T-CE practices in enhancing sustainability. The findings of this study are entirely dependent on the expert panel inputs. Despite an extensive literature review, the author believes that some I4.0T-CE practices may not have been noticed in this study. By incorporating such practices similar studies could be conducted to speed up the process of achieving SGDs. Further, researchers can use different MCDM methods to rank the performance metrics.

Data Availability

Data sharing is not applicable to this article as no datasets were generated or analysed during the current study.

References

Abdullah NHN, Sanusi S (2023) Circular Supply Chain Management in Manufacturing Companies, pp 395–411. https://doi.org/10.4018/978-1-6684-7664-2.ch019

Ajwani-Ramchandani R, Figueira S, Torres de Oliveira R, Jha S, Ramchandani A, Schuricht L (2021) Towards a circular economy for packaging waste by using new technologies: The case of large multinationals in emerging economies. J Clean Prod 281:125139. https://doi.org/10.1016/j.jclepro.2020.125139

Andronie, M., Lăzăroiu, G., Ștefănescu, R., Uță, C., & Dijmărescu, I. (2021). Sustainable, smart, and sensing technologies for cyber-physical manufacturing systems: A systematic literature review. In Sustainability (Switzerland) (Vol. 13, Issue 10). MDPI AG. https://doi.org/10.3390/su13105495

Arora NK, Mishra I (2019) United Nations Sustainable Development Goals 2030 and environmental sustainability: race against time. Environ Sustain 2(4):339–342. https://doi.org/10.1007/s42398-019-00092-y

Baah C, Opoku-Agyeman D, Acquah ISK, Agyabeng-Mensah Y, Afum E, Faibil D, Abdoulaye FAM (2021) Examining the correlations between stakeholder pressures, green production practices, firm reputation, environmental and financial performance: Evidence from manufacturing SMEs. Sustain Prod Consum 27:100–114. https://doi.org/10.1016/j.spc.2020.10.015

Bag S, Gupta S, Kumar S (2021) Industry 4.0 adoption and 10R advance manufacturing capabilities for sustainable development. Int J Prod Econ 231:107844. https://doi.org/10.1016/j.ijpe.2020.107844

Bag S, Pretorius JHC (2022) Relationships between industry 4.0, sustainable manufacturing and circular economy: proposal of a research framework. Int J Organ Anal 30(4):864–898. https://doi.org/10.1108/IJOA-04-2020-2120

Bai C, Zhou H, Sarkis J (2023) Evaluating Industry 4.0 technology and sustainable development goals – a social perspective. Int J Prod Res:1–21. https://doi.org/10.1080/00207543.2022.2164375

Belmonte-Ureña LJ, Plaza-Úbeda JA, Vazquez-Brust D, Yakovleva N (2021) Circular economy, degrowth and green growth as pathways for research on sustainable development goals: A global analysis and future agenda. Ecol Econ 185:107050. https://doi.org/10.1016/j.ecolecon.2021.107050

Bjørnbet MM, Skaar C, Fet AM, Schulte KØ (2021) Circular economy in manufacturing companies: A review of case study literature. J Clean Prod 294:126268. https://doi.org/10.1016/j.jclepro.2021.126268

Chauhan C, Kaur P, Arrawatia R, Ractham P, Dhir A (2022) Supply chain collaboration and sustainable development goals (SDGs). Teamwork makes achieving SDGs dream work. J Bus Res 147:290–307. https://doi.org/10.1016/j.jbusres.2022.03.044

Chen W (2023) Digital economy development, corporate social responsibility and low-carbon innovation. Corp Soc Responsib Environ Manag 30(4):1664–1679. https://doi.org/10.1002/csr.2443

Chen W-M, Kim H (2019) Circular economy and energy transition: A nexus focusing on the non-energy use of fuels. Energy Environ 30(4):586–600. https://doi.org/10.1177/0958305X19845759

COMPREHENSIVE LITERATURE STUDY ON INDUSTRY 4.0. (n.d.). https://www.facebook.com/smnsakib.information

Condemi A, Cucchiella F, Schettini D (2019) Circular economy and e-waste: An opportunity from RFID TAGs. Appl Sci (Switzerland) 9(16). https://doi.org/10.3390/app9163422

Dantas TET, Souza ED, Destro IR, Hammes G, Rodriguez CMT, Soares SR (2021) How the combination of Circular Economy and Industry 4.0 can contribute towards achieving the Sustainable Development Goals. Sustain Prod Consum 26:213–227. https://doi.org/10.1016/j.spc.2020.10.005

De Marchi V, Di Maria E (2020) Achieving Circular Economy Via the Adoption of Industry 4.0 Technologies: A Knowledge Management Perspective, pp 163–178. https://doi.org/10.1007/978-3-030-43589-9_7

de Sousa Jabbour ABL, Jabbour CJC, Foropon C, Godinho Filho M (2018) When titans meet – Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors. Technol Forecast Soc Chang 132:18–25. https://doi.org/10.1016/j.techfore.2018.01.017

Despeisse M, Baumers M, Brown P, Charnley F, Ford SJ, Garmulewicz A, Knowles S, Minshall THW, Mortara L, Reed-Tsochas FP, Rowley J (2017) Unlocking value for a circular economy through 3D printing: A research agenda. Technol Forecast Soc Chang 115:75–84. https://doi.org/10.1016/j.techfore.2016.09.021

Dong K, Li J, Dong X (2023) How do green product exports affect carbon emissions? Evidence from China. Chinese J Popul, Resourc Environ 21(2):43–51. https://doi.org/10.1016/j.cjpre.2023.06.001

Eisen C, Schenten J, Theis A, Rehn-Groenendijk J, Helferich M, Müller H, Hanss D (2024) Toward system innovation for more sustainable chemistry: insights into consumers’ perceptions, knowledge, and behavior related to traceability and product design strategies along leather supply chains. Front Sustain 5:1351638. https://doi.org/10.3389/frsus.2024.1351638

Elistia E, Syahzuni BA (2018) The correlation of the human development index (hdi) towards economic growth (gdp per capita) in 10 asean member countries. Jhss (J Human Soc Stud) 2(2):40–46. https://doi.org/10.33751/jhss.v2i2.949

Esmaeilian B, Sarkis J, Lewis K, Behdad S (2020) Blockchain for the future of sustainable supply chain management in Industry 4.0. Resour Conserv Recyc 163. https://doi.org/10.1016/j.resconrec.2020.105064

Fatimah YA, Govindan K, Murniningsih R, Setiawan A (2020) Industry 4.0 based sustainable circular economy approach for smart waste management system to achieve sustainable development goals: A case study of Indonesia. J Clean Prod 269:122263. https://doi.org/10.1016/j.jclepro.2020.122263

Foster W, Azimov U, Gauthier-Maradei P, Molano LC, Combrinck M, Munoz J, Esteves JJ, Patino L (2021) Waste-to-energy conversion technologies in the UK: Processes and barriers – A review. Renew Sust Energ Rev 135:110226. https://doi.org/10.1016/j.rser.2020.110226

Garcia-Muiña F, González-Sánchez R, Ferrari A, Settembre-Blundo D (2018) The Paradigms of Industry 4.0 and Circular Economy as Enabling Drivers for the Competitiveness of Businesses and Territories: The Case of an Italian Ceramic Tiles Manufacturing Company. Soc Sci 7(12):255. https://doi.org/10.3390/socsci7120255

Garcia-Muiña FE, González-Sánchez R, Ferrari AM, Volpi L, Pini M, Siligardi C, Settembre-Blundo D (2019) Identifying the Equilibrium Point between Sustainability Goals and Circular Economy Practices in an Industry 4.0 Manufacturing Context Using Eco-Design. Soc Sci 8(8):241. https://doi.org/10.3390/socsci8080241

Gebara CH, Laurent A (2023) National SDG-7 performance assessment to support achieving sustainable energy for all within planetary limits. Renew Sust Energ Rev 173:112934. https://doi.org/10.1016/j.rser.2022.112934

Ghoreishi M, Happonen A (2020) Key enablers for deploying artificial intelligence for circular economy embracing sustainable product design: Three case studies AIP Conference Proceedings, vol 2233. https://doi.org/10.1063/5.0001339

Govindan K, Hasanagic M (2018) A systematic review on drivers, barriers, and practices towards circular economy: a supply chain perspective. Int J Prod Res 56(1–2):278–311. https://doi.org/10.1080/00207543.2017.1402141

Hannan MA, Begum RA, Al-Shetwi AQ, Ker PJ, Al Mamun MA, Hussain A, Basri H, Mahlia TMI (2020) Waste collection route optimisation model for linking cost saving and emission reduction to achieve sustainable development goals. Sustain Cities Soc 62:102393. https://doi.org/10.1016/j.scs.2020.102393

Haščič I, Migotto M (n.d.) Measuring environmental innovation using patent data. https://doi.org/10.1787/5js009kf48xw-en

Helander H, Petit-Boix A, Leipold S, Bringezu S (2019) How to monitor environmental pressures of a circular economy: An assessment of indicators. J Ind Ecol 23(5):1278–1291. https://doi.org/10.1111/jiec.12924

Jelinek T, Bhave A, Buchoud N, Bühler MM, Glauner P, Inderwildi O, Kraft M, Mok C, Nübel K, Voss A (2024) International Collaboration: Mainstreaming Artificial Intelligence and Cyberphysical Systems for Carbon Neutrality. IEEE Trans Ind Cyber-Phys Syst 2:26–34. https://doi.org/10.1109/ticps.2024.3351624

Kayikci Y, Kazancoglu Y, Gozacan-Chase N, Lafci C (2022) Analyzing the drivers of smart sustainable circular supply chain for sustainable development goals through stakeholder theory. Bus Strateg Environ 31(7):3335–3353. https://doi.org/10.1002/bse.3087

Khan AA, Abonyi J (2022) Simulation of Sustainable Manufacturing Solutions: Tools for Enabling Circular Economy. Sustainability (Switzerland) 14(15). https://doi.org/10.3390/su14159796

Khan A, Turowski K (2016) A survey of current challenges in manufacturing industry and preparation for industry 4.0. Adv Intel Syst Comput 450:15–26. https://doi.org/10.1007/978-3-319-33609-1_2

Khan MAR, Bilal A (2019) Literature Survey about Elements of Manufacturing Shop Floor Operation Key Performance Indicators. In: 2019 5th International Conference on Control, Automation and Robotics (ICCAR), pp 586–592. https://doi.org/10.1109/ICCAR.2019.8813436

Khan SAR, Razzaq A, Yu Z, Miller S (2021) Industry 4.0 and circular economy practices: A new era business strategies for environmental sustainability. Bus Strateg Environ 30(8):4001–4014. https://doi.org/10.1002/bse.2853

Khan S, Haleem A (2021) Investigation of circular economy practices in the context of emerging economies: a CoCoSo approach. Int J Sustain Eng 14(3):357–367. https://doi.org/10.1080/19397038.2020.1871442

Kiel D, Müller JM, Arnold C, Voigt K-I (2017) Sustainable industrial value creation: benefits and challenges of industry 4.0. Int J Innov Manag 21(08):1740015. https://doi.org/10.1142/S1363919617400151

Klimenko VV, Klimenko AV, Tereshin AG (2019) From Rio to Paris via Kyoto: How the Efforts to Protect the Global Climate Affect the World Energy Development. Therm Eng 66(11):769–778. https://doi.org/10.1134/S0040601519110028

Kurniawan TA, Liang X, O’Callaghan E, Goh H, Othman MHD, Avtar R, Kusworo TD (2022) Transformation of Solid Waste Management in China: Moving towards Sustainability through Digitalization-Based Circular Economy. Sustainability 14(4):2374. https://doi.org/10.3390/su14042374

Kurniawan TA, Meidiana C, Dzarfan Othman MH, Goh HH, Chew KW (2023) Strengthening waste recycling industry in Malang (Indonesia): Lessons from waste management in the era of Industry 4.0. J Clean Prod 382:135296. https://doi.org/10.1016/j.jclepro.2022.135296

Lahane S, Kant R (2021) A hybrid Pythagorean fuzzy AHP – CoCoSo framework to rank the performance outcomes of circular supply chain due to adoption of its enablers. Waste Manag 130:48–60. https://doi.org/10.1016/j.wasman.2021.05.013

Laskurain-Iturbe I, Arana-Landín G, Landeta-Manzano B, Uriarte-Gallastegi N (2021) Exploring the influence of industry 4.0 technologies on the circular economy. J Clean Prod 321:128944. https://doi.org/10.1016/j.jclepro.2021.128944

Lin CSK, Pfaltzgraff LA, Herrero-Davila L, Mubofu EB, Abderrahim S, Clark JH, Koutinas AA, Kopsahelis N, Stamatelatou K, Dickson F, Thankappan S, Mohamed Z, Brocklesby R, Luque R (2013) Food waste as a valuable resource for the production of chemicals, materials and fuels. Current situation and global perspective. Energy Environ Sci 6(2):426. https://doi.org/10.1039/c2ee23440h

Mageto, J. (2022). Current and Future Trends of Information Technology and Sustainability in Logistics Outsourcing. In Sustainability (Switzerland) (Vol. 14, Issue 13). MDPI. https://doi.org/10.3390/su14137641

Maitre-Ekern E (2021) Re-thinking producer responsibility for a sustainable circular economy from extended producer responsibility to pre-market producer responsibility. J Clean Prod 286:125454. https://doi.org/10.1016/j.jclepro.2020.125454

Mantlana KB, Maoela MA (2020) Mapping the interlinkages between sustainable development goal 9 and other sustainable development goals: A preliminary exploration. Bus Strat Develop 3(3):344–355. https://doi.org/10.1002/bsd2.100

Moktadir MA, Rahman T, Rahman MH, Ali SM, Paul SK (2018) Drivers to sustainable manufacturing practices and circular economy: A perspective of leather industries in Bangladesh. J Clean Prod 174:1366–1380. https://doi.org/10.1016/j.jclepro.2017.11.063

Nobre AG, Martínez JAE, Florêncio O (2021) Mineral Nanotechnology in Circular Economy. In: Smart Innovation, Systems and Technologies, vol 233, pp 220–226. https://doi.org/10.1007/978-3-030-75680-2_26

Nordhaus W (2018) Projections and Uncertainties about Climate Change in an Era of Minimal Climate Policies. Am Econ J Econ Pol 10(3):333–360. https://doi.org/10.1257/pol.20170046

Palsodkar M, Yadav G, Nagare MR (2023) Integrating Industry 4.0 and agile new product development practices to evaluate the penetration of sustainable development goals in manufacturing industries. J Eng, Des Technol. https://doi.org/10.1108/JEDT-02-2022-0101

Patyal, V. S., Sarma, P. R. S., Modgil, S., Nag, T., & Dennehy, D. (2022). Mapping the links between Industry 4.0, circular economy and sustainability: a systematic literature review. In Journal of Enterprise Information Management (Vol. 35, Issue 1, pp. 1–35). Emerald Group Holdings Ltd. https://doi.org/10.1108/JEIM-05-2021-0197

Peng X, Huang H (2020) Fuzzy decision making method based on cocoso with critic for financial risk evaluation. Technol Econ Dev Econ 26(4):695–724. https://doi.org/10.3846/tede.2020.11920

Pham TT, Kuo TC, Tseng ML, Tan RR, Tan K, Ika DS, Lin CJ (2019) Industry 4.0 to accelerate the circular economy: A case study of electric scooter sharing. Sustainability (Switzerland) 11(23). https://doi.org/10.3390/su11236661

Pinheiro MAP, Jugend D, Lopes de Sousa Jabbour AB, Chiappetta Jabbour CJ, Latan H (2022) Circular economy-based new products and company performance: The role of stakeholders and Industry 4.0 technologies. Bus Strateg Environ 31(1):483–499. https://doi.org/10.1002/bse.2905

Puntillo P (2023) Circular economy business models: Towards achieving sustainable development goals in the waste management sector—Empirical evidence and theoretical implications. Corp Soc Responsib Environ Manag 30(2):941–954. https://doi.org/10.1002/csr.2398

Quiroz-Flores JC, Aguado-Rodriguez RJ, Zegarra-Aguinaga EA, Collao-Diaz MF, Flores-Perez AE (2023) Industry 4.0, circular economy and sustainability in the food industry: a literature review. Int J Ind Eng Oper Manag. https://doi.org/10.1108/ijieom-12-2022-0071

Rajput S, Singh SP (2019) Connecting circular economy and industry 4.0. Int J Inf Manag 49:98–113. https://doi.org/10.1016/j.ijinfomgt.2019.03.002

Rajput S, Singh SP (2020) Industry 4.0 Model for circular economy and cleaner production. J Clean Prod 277:123853. https://doi.org/10.1016/j.jclepro.2020.123853

Ramakrishna S, Ngowi A, De Jager H, Awuzie BO (2020) Emerging Industrial Revolution: Symbiosis of Industry 4.0 and Circular Economy: The Role of Universities. Sci Technol Soc 25(3):505–525. https://doi.org/10.1177/0971721820912918

Rocca R, Rosa P, Sassanelli C, Fumagalli L, Terzi S (2020) Integrating virtual reality and digital twin in circular economy practices: A laboratory application case. Sustainability (Switzerland) 12(6). https://doi.org/10.3390/su12062286

Rosa P, Sassanelli C, Urbinati A, Chiaroni D, Terzi S (2020) Assessing relations between Circular Economy and Industry 4.0: a systematic literature review. Int J Prod Res 58(6):1662–1687. https://doi.org/10.1080/00207543.2019.1680896

Sahu A, Agrawal S, Kumar G (2022) Integrating Industry 4.0 and circular economy: a review. J Enterp Inf Manag 35(3):885–917. https://doi.org/10.1108/JEIM-11-2020-0465

Schroeder P, Anggraeni K, Weber U (2019) The Relevance of Circular Economy Practices to the Sustainable Development Goals. J Ind Ecol 23(1):77–95. https://doi.org/10.1111/jiec.12732

Silva THH, Sehnem S (2022) Industry 4.0 and the Circular Economy: Integration Opportunities Generated by Startups. Logistics 6(1). https://doi.org/10.3390/logistics6010014

Singh Takhar S, Liyanage K (2020) The impact of Industry 4.0 on sustainability and the circular economy reporting requirements. Int J Integr Supp Manag 13(3)

Sun X, Wang X (2022) Modeling and Analyzing the Impact of the Internet of Things-Based Industry 4.0 on Circular Economy Practices for Sustainable Development: Evidence From the Food Processing Industry of China. Front Psychol 13. https://doi.org/10.3389/fpsyg.2022.866361

Sun X, Yu H, Solvang WD (2022) Towards the smart and sustainable transformation of Reverse Logistics 4.0: a conceptualization and research agenda. Environ Sci Pollut Res 29(46):69275–69293. https://doi.org/10.1007/s11356-022-22473-3

Tavares TM, Godinho Filho M, Ganga GMD, Callefi MHBM (2020) The relationship between additive manufacturing and circular economy: a sistematic review. Indep J Manag Prod 11(5):1648. https://doi.org/10.14807/ijmp.v11i5.1290

Teixidó J, Verde SF, Nicolli F (2019) The impact of the EU Emissions Trading System on low-carbon technological change: The empirical evidence. Ecol Econ 164:106347. https://doi.org/10.1016/j.ecolecon.2019.06.002

Trojanowska J, Kolinski A, Galusik D, Varela MLR, Machado J (2018) A Methodology of Improvement of Manufacturing Productivity Through Increasing Operational Efficiency of the Production Process, pp 23–32. https://doi.org/10.1007/978-3-319-68619-6_3

Tseng M-L, Tan RR, Chiu ASF, Chien C-F, Kuo TC (2018) Circular economy meets industry 4.0: Can big data drive industrial symbiosis? Resources. Conserv Recy 131:146–147. https://doi.org/10.1016/j.resconrec.2017.12.028

Vandaele, N., & Porter, W. (2015). Renewable Energy in Developing and Developed Nations: Outlooks to 2040. In Journal of Undergraduate Research (Vol. 15, Issue 3).

Vélez-Henao JA, Pauliuk S (2023) Material Requirements of Decent Living Standards. Environ Sci Technol 57(38):14206–14217. https://doi.org/10.1021/acs.est.3c03957

Wilts H, Garcia BR, Garlito RG, Gómez LS, Prieto EG (2021) Artificial Intelligence in the Sorting of Municipal Waste as an Enabler of the Circular Economy. Resources 10(4):28. https://doi.org/10.3390/resources10040028

Yazdani M, Zarate P, Zavadskas EK, Turskis Z (2019) A combined compromise solution (CoCoSo) method for multi-criteria decision-making problems. Manag Decis 57(9). https://doi.org/10.1108/MD-05-2017-0458

Yildizbasi A (2021) Blockchain and renewable energy: Integration challenges in circular economy era. Renew Energy 176:183–197. https://doi.org/10.1016/j.renene.2021.05.053

Yu Z, Khan SAR, Umar M (2022) Circular economy practices and industry 4.0 technologies: A strategic move of automobile industry. Bus Strateg Environ 31(3):796–809. https://doi.org/10.1002/bse.2918

Zheng M, Feng G-F, Wang Q-J, Chang C-P (2023) Financial globalization and technological innovation: International evidence. Econ Syst 47(1):101048. https://doi.org/10.1016/j.ecosys.2022.101048

Zhou X, Song M, Cui L (2020) Driving force for China’s economic development under Industry 4.0 and circular economy: Technological innovation or structural change? J Clean Prod 271:122680. https://doi.org/10.1016/j.jclepro.2020.122680

Žižek SŠ, Nedelko Z, Mulej M, Čič ŽV (2020) Key Performance Indicators and Industry 4.0 – A Socially Responsible Perspective. Naše Gospodarstvo/Our Economy 66(3):22–35. https://doi.org/10.2478/ngoe-2020-0015

Acknowledgements

Not applicable.

Funding

The authors confirm that they have no financial or non-financial interests in the subject matter or materials covered in this paper.

Author information

Authors and Affiliations

Contributions

Parth Koltharkar carried out the literature review and identified the prominent industry 4.0 and circular economy practices. Manoj Palsodkar and Parth Koltharkar formed the expert panel, collected the inputs required for the analysis and summarized the result, findings and summarization. Both authors approved the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

Not applicable.

Consent for Publication

The authors declare consent for publication.

Competing Interests

The authors declare no competing interests.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Palsodkar, M.A., Koltharkar, P.P. Nexus Effect of Industry 4.0 and Circular Economy Practices in Achieving Sustainable Development Goals. Circ.Econ.Sust. (2024). https://doi.org/10.1007/s43615-024-00390-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43615-024-00390-6