Abstract

Environmental sustainability has become a major concern in the present era. The pressure of sustainable development is not only exerted by the government but also by the customer. Awareness among the society and strict government regulations force the industries to reduce environmental impact from their supply chain. Hence, green supply chain management (GSCM) has become an imperative industrial philosophy to avoid environmental hazards. There are motivational forces which are responsible for the implementation of GSCM practices. These motivational forces are termed as drivers. The objective of this paper is to prioritize the drivers of GSCM in Indian manufacturing industries based on government, industry, environment, and public perspectives using fuzzy TOPSIS methodology. An empirical study is made by collecting the data from a group of 12 decision-makers (DMs), three from each perspective. Sensitivity analysis is performed to check the effect of preferences given by each DM. The results show that the regulations forced by the central government play the most significant role followed by regional/state government legislation. The results obtained help firms in identifying the important drivers to implement GSCM practices in Indian manufacturing industries based on different perspectives. It will also help the policymakers to identify important drivers of GSCM in Indian manufacturing industries and will support in implementing GSCM practices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the twenty-first century, the growth of the industrial sector is important for developing as well as developed countries to improve the living standard of people. At the same time, the growth of the industrial sector is increasing the rate of depletion of natural resources which leads to degradation of environment. The waste and emission released by the industries have become the origin of environmental problems which cause severe health threats to mankind. Hence, sustainability has become the most critical issue to meet the needs of the society with minimum damage to the integrity and stability of the natural system. The factors that force industries to address sustainability issues are known as drivers of green supply chain management (GSCM).

The drivers of GSCM encourage industries to adopt GSCM practices to reduce environmental hazards from their supply chain. Consequently, the researchers and industrial experts have started research in this field. The drivers motivate the industries to implement GSCM practices and reduce environmental hazards. The GSCM emphasizes on optimal utilization of resources considering the environment as a key factor that makes it different from the conventional supply chain management. As per Narasimhan and Carter (1998), GSCM starts from green design, green logistics, recycling, reuse, and the substitution of green materials. The objective of this paper is to prioritize the drivers which help the industries in effective implementation of GSCM practices. The prioritizing of the drivers of GSCM is done based on the four major perspectives, i.e., government, industry, environment, and the public. These perspectives are taken because these are four main stakeholders that play the most significant role in implementing the GSCM practices. These four stakeholders motivate and force the Indian manufacturing industries to reduce environmental hazards from their supply chain management.

According to Chai et al. (2013), fuzzy set theory combined with multi-criteria decision-making (MCDM) technique has been extensively used to deal with vagueness in the decision-making process. The prioritizing of the drivers is done by means of fuzzy set theory with TOPSIS method, which is fundamentally a MCDM problem. In most of the conditions, crisp data is insufficient to model real-life problems. It is evident that human judgments are vague and cannot evaluate approximate preferences meticulously in numerical value. Linguistic assessment of the criteria and alternatives is better than the numerical values (Bellman and Zadeh 1970; Chen 2000; Delgado et al. 1992; Herrera et al. 1996; Herrera and Herrera-Viedma 2000).

Herrera and Herrera-Viedma (1996) presented a consensus model in decision-making using linguistic assessments. This model presented a wide range of consensus measures that allow evaluating, monitoring, and controlling the consensus accomplishment process telling the current consensus point. Chen (2000) used the triangular fuzzy number to express the rating of the alternative and the weight criterion. He also proposed the vertex method to compute the distance between two triangular fuzzy numbers. Herrera and Herrera-Viedma (2000) used linguistic models in decision-making problems that are extremely beneficial when the judgment cannot be given in numerical values. It provides higher flexibility to deal with decision-making problems by means of qualitative information. Therefore, the ratings and weights of criteria in the present paper are taken by means of linguistic variables. The method of fuzzy TOPSIS is also proposed by Bellman and Zadeh in Bellman and Zadeh 1970. Delgado et al. (1992) proposed basic decision rules, based on fuzzy risk intervals and a general model is developed.

Literature Review

The GSCM is a new paradigm in the supply chain management which addresses different issues related to the environment. In the twenty-first century, global supply chain experts are concerned about the environmental issues (Muduli et al. 2013). Ahi and Searcy (2013) in their research focused on growing environmental issues and suggested that organizations must address potential enablers and barriers to sustainability in order to measure and assess the sustainability level of a company. Ansari and Kant (2017) analyzed 286 research articles published during the period of 2002–2016 in the various journals. They observed that there are a lot of scopes and opportunities which need to be explored, such as the practice of advanced techniques and efficient development of algorithms. The effective implementation of GSCM practices depend on the numerous factors. Researchers are trying to find out these factors in terms of drivers of GSCM practices.

Diabat and Govindan (2011) identified the drivers of GSCM in south Indian manufacturing industries and developed an interpretive structural modeling (ISM) model of the drivers of GSCM. Kathiresan and Ragunathan (2016b) developed models using ISM, analytical network process (ANP), and fuzzy ANP techniques of drivers in small- and medium-sized tanneries of Northern Tamilnadu in India. Kathiresan and Ragunathan (2016a) recognized pivotal and obtrusive drivers for implementing GSCM in leather industries in northern Tamilnadu. A model is developed using structural equation modeling (SEM), VIKOR, and fuzzy VIKOR. Luthra et al. (2013) ranked the GSCM implementation strategies in Indian manufacturing industries using analytical hierarchy process (AHP) and categorized these strategies in four dimensions. These four dimensions are as follows: non-members, downward stream, organizational, and upward stream supply chain members. These four dimensions play very important role in implementing GSCM. Bhool and Narwal (2013) identified the important drivers for the implementation of GSCM practices in various Indian manufacturing sectors. These sectors are two-wheelers, four-wheelers, and general manufacturing. Jain and Sharma (2014) in the literature survey identified 14 drivers of GSCM that have a substantial effect on the implementation of GSCM practices. The outcome of this literature survey indicates that regulation, pressure from customers, and competition are the important drivers of GSCM. Mathiyazhagan and Haq (2013) studied 16 auto component manufacturing industries in Tamilnadu (South India) and found that these industries are forced by government regulation to implement GSCM practices. Barve and Muduli (2013) analyzed the Indian mining industries for sustainable development through the GSCM approach and developed an interpretive structural modeling (ISM) framework. Diabat et al. (2014) identified important enablers for GSCM by means of ISM technique in five Indian textile units in South India. The result shows that the five enablers play a major role in adaptation of GSCM practices. These enablers include the adoption of safety standards, adoption of green practices, community economic welfare, health and safety issues, and employment stability.

Mathiyazhagan et al. (2013) emphasized that due to strict government regulation and increased customer’s environmental awareness, the organizations must decrease the environmental effect from their manufacturing activities. Focusing only on manufacturing activities to decrease the pollution is not sufficient but complete supply chain should be converted greener by GSCM practices (Govindan et al. 2015). Malviya and Kant (2016) developed fuzzy decision-making trail and evaluation laboratory and fuzzy multi-criteria decision-making-based framework to predict and measure the success or failure of GSCM implementation. Luthra et al. (2016) documented in their research that competitiveness, regulations, and internal management are critical success factors. Chien and Shih (2007) suggested that green manufacturing companies have a constructive result on both economic and environmental performances. The effect of green initiatives varies from industry to industry and highlighted that power sector has maximum effect on the green initiative in reducing CO2 emissions as compared to other sectors. Mittal and Sangwan (2014a, b) identified 12 drivers that are responsible for implementation of green manufacturing in industries and ranked the drivers according to the environment, social, and economic point of view. Singh et al. (2016) considered 12 drivers that affect the successful implementation of GSCM practices. These drivers are top management commitment, vendor’s development, integration between supply chain members, reverse logistics, environmental friendly packaging, transportation, and green performance measurement system. Zhu and Sarkis (2004) proposed that the employment of GSCM can help to reduce the cost of purchase of materials and energy consumption. The drivers and barriers of GSCM are classified according to the external, internal, customer, and social perspective (Dhull and Narwal 2016).

It is a well-known fact that India is one of the fastest developing economies in the world. The government of India has started “Make in India” initiative campaign. The aim of this campaign is to attract capital and technological investment to make India a manufacturing hub. This will further degrade the environment of the country. Hence, there is a need to identify the vital drivers that will encourage the Indian manufacturing industries to adopt the GSCM practices. A lot of research is going on in the field of GSCM but Indian manufacturing industries are still in the initial phase to implement GSCM practices. The major advantage of this research is that all the four major stakeholders (government, industry, environment, and public perspectives) are considered for study that were not included in the previous studies. The ranking of the drivers will help the industries to identify the top drivers which can encourage implementation of GSCM practices in Indian manufacturing industries.

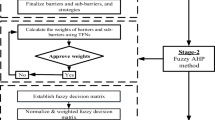

Research Methodology

Twenty drivers are identified from the literature review related to GSCM, environmentally conscious manufacturing, green manufacturing, and sustainable supply chain management as given in Table 1. The identified drivers from the literature review were consulted with the experts working on GSCM through a questionnaire. The experts are from academics, industry, and government handling industrial environmental policies. They were also requested to add more drivers (if any). The suggestions given by the experts were also incorporated. The experts from academics and industries working in the field of green supply chain management again reviewed the developed questionnaire concerning the clarity and understandability. The experts were taken on the basis of their experience (more than 10 years) and knowledge in the field of GSCM. The four perspectives are considered for prioritizing the drivers of GSCM in this study. The literature review suggests that no work has been made by taking these above four perspectives into consideration. This inspires analysis of the drivers for implementation of GSCM practices in manufacturing industries.

In this research, fuzzy TOPSIS technique is adopted for solving the multi-criteria decision-making problem for prioritizing the driver of GSCM in Indian manufacturing environment. This segment describes the fuzzy set and linguistic variables briefly, the TOPSIS technique, and proposed fuzzy TOPSIS technique.

Fuzzy TOPSIS

The TOPSIS technique is widely used and accepted technique used for prioritizing problems in real-time situation. The main limitation of the TOPSIS technique is its incapability to work in the uncertain and vague decision-making process (Yu 2002). The uncertainty and vagueness can be very efficiently handled by using fuzzy set theory. The fuzzy set theory is combined with TOPSIS methodology to work in the uncertain and vague decision-making process. This allows decision-makers to integrate unquantifiable information and incomplete information in the decision-making process. Lee (2005) in his research analyzed that most of the time, the ambiguous answer is reported by the decision-maker rather than accurate value. Consequently, it is very tough to measure this qualitative value. Bellman and Zadeh (1970) introduced the fuzzy sets theory in the decision-making problems. The advantage of using a fuzzy technique is to assign the comparative importance of attribute by means of the fuzzy number, rather than numeric value. According to Gumus (2009), the fuzzy TOPSIS approach is far more effective and suitable approach than conventional TOPSIS.

The relationship between criteria (perspectives) and alternative (drivers) is modeled using the Technique of Order Preference by Similarity to Ideal Solution (TOPSIS) and is introduced by Hwang and Yoon (1981). There are four criteria/perspectives (government, industry, environment, and public perspectives) and 20 alternatives (drivers). TOPSIS methodology uses the concept that selected alternative should have the shortest geometric distance from positive ideal solution (PIS) in the case of benefit criteria and have the longest geometric distance from the negative ideal solution (NIS) that is from cost criteria. This technique is then further extended to the fuzzy environment to account the subjective nature of measuring evaluation of alternatives and criteria using linguistic terms. In this decision-making problem, the most important driver will be prioritized from all the possible drivers (alternatives).

The sensitivity analysis is done to check the influence of the criteria weight given by the decision-maker on the ranking of drivers. The drastic changes may occur in the final ranking if minor changes are made in attribute weights.

The following ten steps are used to determine the ranking of alternatives based on the four perspectives.

According to fuzzy set theory, a triangular fuzzy number ã can be defined by a fuzzy set (triplet) (a1, a2, a3). Conversion scale is used to change the linguistic variable into a fuzzy number. Table 2 is used to get the criteria weight and alternative weight from the experts. The membership function can be written as μ ã (x) (Fig. 1).

-

Step 1:

Assigning of ratings to each criterion and alternative

The decision-makers (DMs)/experts are selected according to four perspectives, government, industry, environment, and public perspectives. The linguistic ratings of the criteria and alternatives are given by three decision-makers from each category for all the 20 drivers as shown in Tables 3 and 4, respectively. The experts are selected based on their experience, position, and having the post of decision-maker in their respective field. The experts taken for the study are those who have more than 10 years of experience in handling industrial environmental policies and are holding the post of General Manager (GM) and above. Government perspective is taken from those experts who are holding the post of Director and handling industrial policy on sustainable development. The industrial perspectives were taken from the experts with at least 10 years of experience in the domain of GSCM and holding the post of General Manager and above, while environmental perspectives were taken from the experts from pollution control department working on the post of executive engineers. The public perspectives were taken from experts of public domain working in the environmental field for the betterment of the society.

-

Step 2:

Calculation of average fuzzy weights for criteria

The criteria’s rating given by the decision-makers in linguistic terms are combined and converted into an aggregate fuzzy number by using Table 2. Let’s consider that fuzzy rating of k decision-makers can be given by a triangular fuzzy number \( {\overset{\sim }{S}}_k=\left({a}_k,\kern0.5em {b}_k,\kern0.5em {c}_k\right) \), where k = 1, 2, 3… k. The aggregate fuzzy weight of the criteria is shown in Table 5.

where

The fuzzy decision matrix for criteria weight (\( \overset{\sim }{W_j}\Big) \) can be given as:

-

Step 3:

Calculation of fuzzy decision matrix

The linguistic rating given by decision-makers is converted into fuzzy rating using Table 2. The converted fuzzy ratings in the various terms are given in Table 6.

The following relation is used to construct the fuzzy decision matrix for alternatives (\( \overset{\sim }{A} \)):

-

Step 4:

Compute aggregate fuzzy ratings for the alternative for each perspective

If the fuzzy ratings and weights for the alternatives of the kth expert is given by \( {\overset{\sim }{x}}_{ijk\kern0.5em }=\left({a}_{ijk},\kern0.5em {b}_{ijk},{c}_{ijk}\ \right) \), then the fuzzy rating (\( {\overset{\sim }{x}}_{ij}\Big) \) of the alternative with respect to each criterion is given in Table 7.

where

-

Step 5:

Normalization of fuzzy decision matrix

The aggregate fuzzy weights given in Table 7 are normalized by means of the linear scale conversion by bringing the various criteria’s and alternatives on a comparable scale (Table 8). The normalized decision matrix is as follows:

where

-

Step 6:

Computation of normalized weighted matrix

To calculate the weighted normalized matrix (\( \overset{\sim }{V} \)) for criteria, it is multiplied by normalized fuzzy decision matrix \( \left({\overset{\sim }{s}}_{ij}\right) \) with the weights (\( {\overset{\sim }{w}}_j\Big) \) of the estimation criteria. The weighted normalized matrix (\( \overset{\sim }{V} \)) for criteria is as shown in Table 9.

-

Step 7:

Calculate the fuzzy positive ideal solution (FPIS) and fuzzy negative ideal solution (FNIS)

TOPSIS methodology uses the concept that selected alternative should have the shortest geometric distance from fuzzy positive ideal solution (FPIS) in the case of benefit criteria and have the longest geometric distance from the fuzzy negative ideal solution (FNIS) that is from cost criteria. The FPIS and the FNIS are computed and tabulated in Table 10.

where

-

Step 8:

Calculate deviation of each alternative from FPIS and FNIS

The distance \( \left({d}_i^{\ast },{d}_i^{-}\right) \) of each weighted alternative i = 1, 2, 3, …, m from the FPIS to FNIS is calculated and tabulated in Table 11.

The vertex method is used to calculate the distance from FPIS and FNIS using the following formula:

-

Step 9:

Calculate the closeness coefficient (CCi) of each alternative

Prioritizing of the drivers of GSCM is done according to closeness coefficient (CCi) value of each alternative in descending arrangement. The CCi represents the distances to FPIS, \( {d}_i^{\ast } \), and the FNIS distances to FPIS, \( {d}_i^{-} \). The closeness coefficient (CCi) represents the geometric distance of alternative from FPIS d∗ (for benefit) and for FNIS d−(for cost criteria). The aggregate closeness coefficient value and the individual perspective closeness coefficients of each driver are given in Table 12. The values of CCi is calculated as follows for each alternative and given in Table 11:

-

Step 10:

Ranking of the alternatives/drivers

The driver that has the highest value of CCi is ranked at the top, while the driver with the least value is ranked at the bottom of the table. The alternative on the top has the shortest geometric distance from the FPIS and longest geometric distance from FNIS. The ranking of the drivers is shown in Table 13.

Figure 2 shows the closeness coefficient (CCi) of individual alternative/driver on public, environment, industry, and government perspectives.

Sensitivity Analysis

According to Awasthi et al. (2011), sensitivity analysis is carried out to check the effect of the preferences specified by the decision-makers on different perspectives on prioritizing the drivers of GSCM. In this analysis, total, nine experiments are performed that are shown in Table 14. Primarily, five experiments carried with the weight of each criteria are placed as (1,1,3) (1,3,5) (3,5,7) (5,7,9), and (7,9,9), respectively. In experiment numbers 1 to 9, one criteria are set to maximum (7,9,9) every time and other criteria were set by a minimum value (1,1,3). The results are given in Table 14.

As shown in Table 14, one can see that the ranking of drivers of GSCM changed slightly with respect to the criteria weight. In the first five experiments, no change in ranking occurs. But in sixth, seventh, and eighth experiments, there is a slight change in the ranking due to criteria weight.

Result

The identification of drivers of GSCM and their prioritizing are based on four perspectives: government, industry, environment, and public perspectives using fuzzy TOPSIS. The analysis furnished very motivating and constructive results. The results obtained from the proposed fuzzy TOPSIS methodology for prioritizing the drivers of GSCM is shown in Table 13. The prioritizing of drivers of GSCM is based on the values of closeness coefficient (CCi). The driver with a maximum value of CCi is considered as the most effective driver and is ranked at the top position while the driver with the minimum value of CCi is considered the least effective driver and is ranked at the bottom position.

The results reveal that central government rules and legislation is ranked at top and this is the most effective driver for the implementation of GSCM practices. The regional/state government legislation and environmental concerns and legislature are ranked at the second and third positions, respectively. The same is evident from the measures taken by central and state government to reduce the pollution from the northern part of India. The strict rules and regulations made by the central as well as state/regional government force the industries to implement these rules and regulations stringently to reduce the environmental hazards in their supply chain management. ISO 14001 certifications is at the fourth position. ISO 14001 certifications helps the organizations to reduce environmental impact by giving more importance to wastes, resources, and energy management. The ISO 14001 also helps to minimize the negative effect on the environment by industrial operations. This will also fulfill supplementary environment-oriented necessities through applicable laws and regulations.

“Environmental mission of the organization” and “Product potential conflict in law” are ranked at the fifth and sixth positions, respectively. After legislation, environment mission of the organization plays a significant role in the implementation of GSCM practices. “Product potential conflict in law” is ranked at the seventh position. The European Union has imposed RoHS (restrictions on the use of hazardous substances) directives in 2006. The EU banned electrical and electronic equipment containing lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB), and polybrominated diphenylethers (PBDE).

The five least important drivers are “Green image, & global marketing,” “Environmental partnership with suppliers,” and “Supplier’s pressure & willingness” at the 16th, 17th, and 18 positions, respectively. The drivers named “Demand for environmentally friendly products” and scarcity of resources, higher waste generation, and waste disposal problem are at the bottom of the ranking. It can be observed from these results that demand of environment friendly goods is very low by the consumers in India. The consumers do not want to pay a higher cost for environmental friendly goods. Their main focus is on economical goods.

Prioritization of drivers helps the policymaker to identify the factors in the order of their importance which motivate the Indian manufacturing industries for implementing GSCM practices. Prioritization helps the government and policymakers in making policies considering the most important factors first and then others in order of their prioritization.

Conclusion

The conclusions of the study help to prioritize and ascertain the significant driver of GSCM for the implementation of GSCM practices in Indian manufacturing industries which is achieved by means of four major perspectives: government, industry, environment, and public perspectives. This study can be enormously valuable to the Indian manufacturing industries that need to exert more pressure for GSCM implementation. Prioritization of drivers helps the industries to decide which factors need to be given more importance in order to get the best possible results in respect of implementation of GSCM practices. Moreover, government can also use this ranking for making new laws and legislations which can further pressurize industries for the implementation of GSCM practices. In this study, only 20 drivers for GSCM implementation are studied under four perspectives based on the extensive investigation and discussion with experts from relevant fields. Further studies can be conducted by taking more drivers under consideration.

The drivers of GSCM are prioritized through fuzzy TOPSIS methodology. Fuzzy TOPSIS does not allow the sub-criteria into a hierarchy structure. The other techniques like PROMETHEE and VIKOR can be employed for imminent research. The results obtained by these techniques can be compared with the results of this research.

References

Ahi P, Searcy C (2013) A comparative literature analysis of definitions for green and sustainable supply chain management. J Clean Prod 52:329–341. https://doi.org/10.1016/j.jclepro.2013.02.018

Ansari ZN, Kant R (2017) A state-of-art literature review reflecting 15 years of focus on sustainable supply chain management. J Clean Prod 142:2524–2543. https://doi.org/10.1016/j.jclepro.2016.11.023

Awasthi A, Chauhan SS, Omrani H, Panahi A (2011) A hybrid approach based on SERVQUAL and fuzzy TOPSIS for evaluating transportation service quality. Comput Ind Eng 61(3):637–646. https://doi.org/10.1016/j.cie.2011.04.019

Azhar SB, Talib P (2015) Green management indicators & environmental sustainability: an ISM based approach. Bus Manag Rev 7(1):377

Bellman RE, Zadeh LA (1970) Decision-making in a fuzzy environment. Manag Sci 17(4):B-141

Bey N, Hauschild MZ, McAloone TC (2013) Drivers and barriers for implementation of environmental strategies in manufacturing companies. CIRP Ann Manuf Technol 62(1):43–46. https://doi.org/10.1016/j.cirp.2013.03.001

Bhool R, Narwal MS (2013) An analysis of drivers affecting the implementation of green supply chain management for the Indian manufacturing industries. Int J Res Eng Technol 2(11):2319–1163

Barve A, Muduli K (2013) Modelling the challenges of green supply chain management practices in Indian mining industries. J Manuf Technol Manag 24(8):1102–1122. https://doi.org/10.1108/JMTM-09-2011-0087

Chai J, Liu JN, Ngai EW (2013) Application of decision-making techniques in supplier selection: a systematic review of literature. Expert Syst Appl 40(10):3872–3885. https://doi.org/10.1016/j.eswa.2012.12.040

Chen CT (2000) Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets Syst 114(1):1–9. https://doi.org/10.1016/S0165-0114(97)00377-1

Chien MK, Shih LH (2007) An empirical study of the implementation of green supply chain management practices in the electrical and electronic industry and their relation to organizational performances. Int J Environ Sci Technol :(IJEST) 4(3):383

Christmann P, Taylor G (2001) Globalization and the environment: determinants of firm self-regulation in China. J Int Bus Stud 32(3):439–458. https://doi.org/10.1057/palgrave.jibs.8490976

Dashore K, Sohani N (2013) Green supply chain management-barriers & drivers: a review. Int J Eng Res Technol 2(4):2021–2030

Delgado M, Verdegay JL, Vila MA (1992) Linguistic decision-making models. Int J Intell Syst 7(5):479–492. https://doi.org/10.1002/int.4550070507

Dhull S, Narwal M (2016) Drivers and barriers in green supply chain management adaptation: a state-of-art review. Uncertain Supply Chain Manag 4(1):61–76

Diabat A, Kannan D, Mathiyazhagan K (2014) Analysis of enablers for implementation of sustainable supply chain management—a textile case. J Clean Prod 83:391–403. https://doi.org/10.1016/j.jclepro.2014.06.081

Diabat A, Govindan K (2011) An analysis of the drivers affecting the implementation of green supply chain management. Resour Conserv Recycl 55(6):659–667. https://doi.org/10.1016/j.resconrec.2010.12.002

Drumwright ME (1994) Socially responsible organizational buying: environmental concern as a noneconomic buying criterion. J Mark 58(3):1–19. https://doi.org/10.2307/1252307

Elkington J (1997) Cannibals with forks: the triple bottom line of 21st century business. Environ Qual Manag 2:37–51

Gangele A, Verma A (2011) The investigation of green supply chain management practices in pharmaceutical manufacturing industry through waste minimization. Int J Ind Eng Technol 3(4):403–415

Georgiadis P, Besiou M (2010) Environmental and economical sustainability of WEEE closed-loop supply chains with recycling: a system dynamics analysis. Int J Adv Manuf Technol 47(5–8):475–493. https://doi.org/10.1007/s00170-009-2362-7

Govindan K, Khodaverdi R, Vafadarnikjoo A (2015) Intuitionistic fuzzy based DEMATEL method for developing green practices and performances in a green supply chain. Expert Syst Appl 42(20):7207–7220. https://doi.org/10.1016/j.eswa.2015.04.030

Gumus AT (2009) Evaluation of hazardous waste transportation firms by using a two-step fuzzy-AHP and TOPSIS methodology. Expert Syst Appl 36(2):4067–4074. https://doi.org/10.1016/j.eswa.2008.03.013

Hall J (2000) Environmental supply chain dynamics. J Clean Prod 8(6):455–471. https://doi.org/10.1016/S0959-6526(00)00013-5

Hanna MD, Newman WR, Johnson P (2000) Linking operational and environmental improvement through employee involvement. Int J Oper Prod Manag 20(2):148–165. https://doi.org/10.1108/01443570010304233

Henriques I, Sadorsky P (1996) The determinants of an environmentally responsive firm: an empirical approach. J Environ Econ Manag 30(3):381–395. https://doi.org/10.1006/jeem.1996.0026

Herrera F, Herrera-Viedma E (1996) A model of consensus in group decision making under linguistic assessments. Fuzzy Sets Syst 78(1):73–87. https://doi.org/10.1016/0165-0114(95)00107-7

Herrera F, Herrera-Viedma E (2000) Linguistic decision analysis: steps for solving decision problems under linguistic information. Fuzzy Sets Syst 115(1):67–82. https://doi.org/10.1016/S0165-0114(99)00024-X

Herrera F, Herrera-Viedma E, Verdegay JL (1996) Direct approach processes in group decision making using linguistic OWA operators. Fuzzy Sets Syst 79(2):175–190. https://doi.org/10.1016/0165-0114(95)00162-X

Hosseini A (2007) Identification of green management system’s factors: a conceptualized model. Int J Manag Sci Eng Manag 2(3):221–228

Hwang CL, Yoon K (1981) Methods for multiple attribute decision making. In Multiple attribute decision making (pp 58–191). Springer, Berlin, Heidelberg

Karimi M, Azizi M, Javanshir H, Ghomi S (2015) A hybrid approach based on SERVQUAL and fuzzy TOPSIS for evaluating banking service quality. Decis Sci Lett 4(3):349–362

Kathiresan G, Ragunathan S (2016a) Impact of drivers for the implementation of green supply chain management in leather industries of northern Tamilnadu. Adv Nat Appl Sci 10(15):31–43

Kathiresan G, Ragunathan S (2016b) An exploratory study of drivers for the adoption of green supply chain management in small and medium-sized tanneries of northern Tamilnadu using ISM, ANP and fuzzy ANP. Adv Nat Appl Sci 10(16):103–115

Lamming R, Hampson J (1996) The environment as a supply chain management issue. Brit J Manag 9,7(Special issue 1):S45–S62

Lee KH (2005) First course on fuzzy theory and applications. Springer-Verlag Berlin, Heidelberg

Lin CY, Ho YH (2011) Determinants of green practice adoption for logistics companies in China. J Bus Ethics 98(1):67–83. https://doi.org/10.1007/s10551-010-0535-9

Luken R, Van Rompaey F (2008) Drivers for and barriers to environmentally sound technology adoption by manufacturing plants in nine developing countries. J Clean Prod 16(1):S67–S77. https://doi.org/10.1016/j.jclepro.2007.10.006

Luthra S, Garg D, Haleem A (2013) Identifying and ranking of strategies to implement green supply chain management in Indian manufacturing industry using Analytical Hierarchy Process. J Ind Eng Manag 6(4):930

Luthra S, Garg D, Haleem A (2016) The impacts of critical success factors for implementing green supply chain management towards sustainability: an empirical investigation of Indian automobile industry. J Clean Prod 121:142–158. https://doi.org/10.1016/j.jclepro.2016.01.095

Malviya RK, Kant R (2016) Hybrid decision-making approach to predict and measure the success possibility of green supply chain management implementation. J Clean Prod 135:387–409. https://doi.org/10.1016/j.jclepro.2016.06.046

Mathiyazhagan K, Govindan K, Noor ul Haq A, Geng Y (2013) An ISM approach for the barrier analysis in implementing green supply chain management. J Clean Prod 47:283–297. https://doi.org/10.1016/j.jclepro.2012.10.042

Mathiyazhagan K, Haq AN (2013) Analysis of the influential pressures for green supply chain management adoption—an Indian perspective using interpretive structural modeling. Int J Adv Manuf Technol 68(1–4):817–833. https://doi.org/10.1007/s00170-013-4946-5

Min H, Galle WP (1997) Green purchasing strategies: trends and implications. J Supply Chain Manag 33(2):10–17

Mittal VK, Sangwan KS (2014a) Development of a model of barriers to environmentally conscious manufacturing implementation. Int J Prod Res 52(2):584–594. https://doi.org/10.1080/00207543.2013.838649

Mittal VK, Sangwan KS (2014b) Fuzzy TOPSIS method for ranking barriers to environmentally conscious manufacturing implementation: government, industry and expert perspectives. Int J Environ Technol Manag 17(1):57–82. https://doi.org/10.1504/IJETM.2014.059466

Montabon F, Melnyk SA, Sroufe R, Calantone RJ (2000) ISO 14000: assessing its perceived impact on corporate performance. J Supply Chain Manag 36(1):4–16. https://doi.org/10.1111/j.1745-493X.2000.tb00073.x

Muduli K, Govindan K, Barve A, Geng Y (2013) Barriers to green supply chain management in Indian mining industries: a graph-theoretic approach. J Clean Prod 47:335–344. https://doi.org/10.1016/j.jclepro.2012.10.030

Narasimhan R, Carter JR (1998) Linking business unit and material sourcing strategies. J Bus Logist 19(2):155

Porter ME, Van der Linde C (1995) Green and competitive: ending the stalemate. Harv Bus Rev 73(5):120–134

Rondinelli DA, Berry MA (2000) Environmental citizenship in multinational corporations: social responsibility and sustainable development. Eur Manag J 18(1):70–84. https://doi.org/10.1016/S0263-2373(99)00070-5

Sarkis J (1998) Evaluating environmentally conscious business practices. Eur J Oper Res 107(1):159–174. https://doi.org/10.1016/S0377-2217(97)00160-4

Sarkis J (2003) A strategic decision framework for green supply chain management. J Clean Prod 11(4):397–409. https://doi.org/10.1016/S0959-6526(02)00062-8

Sarkis, J. (Ed.). (2006). Greening the supply chain. Springer Science & Business Media, DOI: https://doi.org/10.1007/1-84628-299-3

Singh A, Singh A, Trivedi A, Trivedi A (2016) Sustainable green supply chain management: trends and current practices. Compet Rev 26(3):265–288

Singh A, Singh B, Dhingra AK (2012) Drivers and barriers of green manufacturing practices: a survey of Indian industries. Int J Eng Sci 1(1):5–19

Studer S, Welford R, Hills P (2006) Engaging Hong Kong businesses in environmental change: drivers and barriers. Bus Strateg Environ 15(6):416–431. https://doi.org/10.1002/bse.516

Walker H, Di Sisto L, McBain D (2008) Drivers and barriers to environmental supply chain management practices: lessons from the public and private sectors. J Purch Supply Manag 14(1):69–85. https://doi.org/10.1016/j.pursup.2008.01.007

Walton SV, Handfield RB, Melnyk ST (1998) The green supply chain: integrating suppliers into environmental management process. Int J Purch Mater Manag Spring 34:2–11

Yu CS (2002) A GP-AHP method for solving group decision-making fuzzy AHP problems. Comput Oper Res 29(14):1969–2001. https://doi.org/10.1016/S0305-0548(01)00068-5

Yu J, Hills P, Welford R (2008) Extended producer responsibility and eco-design changes: perspectives from China. Corp Soc Responsib Environ Manag 15(2):111–124

Jain VK, Sharma S (2014) Drivers affecting the green supply chain management adaptation: a review. IUP J Oper Manag 13:54–63

Zhang B, Bi J, Liu B (2009) Drivers and barriers to engage enterprises in environmental management initiatives in Suzhou Industrial Park, China. Front Environ Sci Eng China 3(2):210–220. https://doi.org/10.1007/s11783-009-0014-7

Zhu Q, Geng Y (2013) Drivers and barriers of extended supply chain practices for energy saving and emission reduction among Chinese manufacturers. J Clean Prod 40:6–12. https://doi.org/10.1016/j.jclepro.2010.09.017

Zhu Q, Sarkis J (2004) Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J Oper Manag 22(3):265–289

Zhu Q, Sarkis J (2006) An inter-sectoral comparison of green supply chain management in China: drivers and practices. J Clean Prod 14(5):472–486. https://doi.org/10.1016/j.jclepro.2005.01.003

Zhu Q, Sarkis J, Geng Y (2005) Green supply chain management in China: pressures, practices and performance. Int J Oper Prod Manag 25(5):449–468. https://doi.org/10.1108/01443570510593148

Zhu Q, Sarkis J, Lai KH (2007) Green supply chain management: pressures, practices and performance within the Chinese automobile industry. J Clean Prod 15(11):1041–1052. https://doi.org/10.1016/j.jclepro.2006.05.021

Zhu Q, Sarkis J, Lai KH (2008a) Green supply chain management implications for “closing the loop”. Transpor Res Part E: Log Transp Rev 44(1):1–18. https://doi.org/10.1016/j.tre.2006.06.003

Zhu Q, Sarkis J, Lai KH (2008b) Confirmation of a measurement model for green supply chain management practices implementation. Int J Prod Econ 111(2):261–273. https://doi.org/10.1016/j.ijpe.2006.11.029

Zhu Q, Sarkis J, Cordeiro JJ, Lai KH (2008) Firm-level correlates of emergent green supply chain management practices in the Chinese context. Omega 36(4):577–591 http://www.who.int/mediacentre/news/releases/2016/air-pollution-rising/en/ (29 December 2016) (1)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Dhull, S., Narwal, M.S. Prioritizing the Drivers of Green Supply Chain Management in Indian Manufacturing Industries Using Fuzzy TOPSIS Method: Government, Industry, Environment, and Public Perspectives. Process Integr Optim Sustain 2, 47–60 (2018). https://doi.org/10.1007/s41660-017-0030-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41660-017-0030-1