Abstract

The installation of distributed generation (DG) units with optimal capacities at optimal locations is becoming an essential issue in a distribution power network to reduce total power loss and to enhance voltage profile. In this paper, a recently included optimization technique called ant lion optimizer (ALO) has been presented for assessing the optimal size of multiple DG units in a balanced radial distribution system. An integrated methodology of loss sensitivity factor and voltage sensitivity factor is utilized for finding the optimal bus locations for the multiple DG unit installation. The optimal size of DG units at the identified bus locations are computed using ALO algorithm by minimizing the total real power loss of distribution network. The minimization of total real power loss will lead to considerable enhancement in voltage profile. The performance of the proposed algorithm has been evaluated against IEEE 33, 69 and 119 bus balanced radial distribution systems. Furthermore, to outline the superiority of proposed ALO algorithm, the attained results are related with the results of hybrid optimization techniques such as GA-PSO, ABC-CSO and ABC-BAT in terms of total real power reduction and voltage profile improvement.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Distributed generation or dispersed generation is a small scale power generation where power generation takes place at or near the load centre [1]. Typical DG units are generally rated from few kilowatts to few megawatts. Presently solar photovoltaic, wind turbine generator, small hydro, biomass, gas turbine, etc., are used as DG technologies. The role of DGs is to inject real and reactive power into the distribution power network. Inclusion of the DG unit offers numerous benefits to electric utilities and consumers [1].

Among the available DG technologies, renewable energy based DG units are capable of minimizing the greenhouse gases emission which is responsible for global warming. Moreover, DG units provide significant economic and technical benefits such as deferred transmission and distribution investment, line loss reduction and voltage profile enhancement [1]. Furthermore, DG units give saving on fuel investment and thus minimize the electricity prices. Also, DG units improve the voltage stability and voltage stability margin of the system [2]. The aforementioned benefits can be availed only by selecting the optimal site and size of DG units. On the other hand, inappropriate placement of DG units leads to an increase in line losses, system cost and voltage profile beyond the secure limit. Voltage enhancement above the secure limit causes voltage instability problems in the system. Consequently, reliability and security problem may arise. Hence, the optimal placement of DG units in the radial distribution power networks becomes a vital for electric utilities and consumers [1,2,3,4,5,6,7].

Various numerical techniques had been proposed in [3,4,5,6,7,8] for determining the optimal location and size of the DG unit in the distribution network. From the literature, these techniques give encouraging solution only for the linear problems and are not appropriate for the nonlinear problems. Moreover, suitable initial convergence value should be chosen to yield a global solution.

Different optimization based techniques have been adopted to overcome the shortcomings of the numerical techniques. Particle swarm optimization (PSO) algorithm has been applied in [9] to compute the optimal location and size of multiple DG units for various load models. The reference [10] proposed a Cat Swarm optimization (CSO) algorithm to find the optimal capacity of DG units to reduce the total power loss of the radial distribution system (RDS). Bacterial foraging algorithm (BFOA) has been applied in [11] to determine the optimal size of DG units by employing LSF based approach for identifying the optimal location. Tabu search technique has been embedded in [12] for obtaining the optimal size of an isolated hybrid power system. Power loss minimization, voltage profile, and voltage stability enhancement have been done in [13] using hybrid GA/PSO technique where GA is used for the optimal site selection of DG units and PSO is used for optimizing the size of the DG unit. A multi-objective based BAT optimization algorithm was proposed in [14] to find the optimal location and capacity of DG units in a radial distribution network. Ant colony optimization (ACO) algorithm was utilized in [15] to compute the optimal capacity of the DG unit. The reference [16] proposed artificial bee colony (ABC) algorithm for the computation of optimal location and size of DG units to minimize the total real power loss of the system.

Most of the optimization techniques suggested in the above literature have considered only real power injected (PV) type DG unit alone. Therefore, the present study also includes a DG unit which is capable of injecting both real and reactive powers (Wind Turbine) in the distribution network. Moreover, the optimum solution may not be a guarantee from the aforementioned algorithms due to the complex nature of the nonlinear problem.

The present work proposes a recently added meta-heuristic technique called ant lion optimization (ALO) [17] for determining the size of DG units in the radial distribution network. ALO algorithm simulates the hunting behavior of ant lions. It has the advantage of providing an optimal solution at higher speed with few parameters. Also, the use of random walks and the roulette wheel in ALO algorithm makes sure higher probability of resolving local optima stagnation. Moreover, local optima evasion is inherently high for ALO as it is a population-based algorithm. The convergence is a guarantee one in the ALO algorithm by adaptively decreasing the intensity of ant’s movements. Most importantly ALO has only limited parameters to adjust. Due to the above mentioned reasons, the proposed ALO algorithm can able to provide a near global solution for the optimization problems.

The supremacy of ALO algorithm in solving optimization problems in various fields [18,19,20,21] has motivated for finding solution for optimal installation of DG units in the radial distribution system to reduce total real power loss. The present work uses an integrated methodology [22] of loss sensitivity factor (LSF) and voltage sensitivity factor (VSF) for computing the optimal bus location for DG placement. The performance of the proposed algorithm is evaluated against IEEE 33, 69 and 119 bus balanced radial distribution power networks. The ALO results are compared with the results of GA-PSO; ABC-CSO and ABC-BAT algorithms to outline its supremacy in determining optimal size of DG units with better convergence.

The remaining sections of this paper are organized as follows: Sect. 2 presents the problem formulation, while Sect. 3 explains ALO algorithm for an optimization problem. In Sect. 4, an integrated methodology for computing the optimal location of DG units is presented. The simulation results and conclusion are presented in Sects. 5 and 6 respectively.

2 Problem Formulation

The objective of the present work is to minimize the total real power losses of radial distribution power networks. The total real power loss reduction of distribution system is represented using a power loss index [23, 24]. The mathematical representation of objective function, F is expressed as follows:

From Eq. (1), PDG,Tloss is the total real power loss of the system with DG units and PTloss is the total real power loss of system without DG units. The minimum value of ILP indicates maximum reduction of total real power loss in the distribution network system.

The objective function of the proposed work is minimized by satisfying the necessary equality and inequality constraints associated with the distribution power network system. The various constraints to be considered in the optimization problem are described as follows:

2.1 Equality Constraints

2.1.1 Power Balance Constraint of DG Units

In a radial distribution power network, the total incoming power flow must be equal to the total outgoing power [25]. This can be mathematically represented in Eqs. (2) and (3)

where, Ps and Qs are real and reactive power of swing bus respectively. PDG(j) and QDG(j) are the real and reactive power capacity of a DG unit at jth bus respectively. Ploss(j) and Qloss(j) are the active and reactive power line loss of jth bus respectively. P(q) and Q(q) are the real and reactive power demand at bus q respectively. NDG represents the number of installed DG units. L is a total number of transmission lines in a given distribution network and n is a total number of buses in the system.

2.2 Inequality Constraints

2.2.1 Voltage Constraint

The voltage magnitude of a bus in a radial distribution network should be maintained within the following limits to ensure stable operation.

From Eq. (4), Vmin = 0.95 p.u. and Vmax = 1.05 p.u. [17]. Where, Vmin and Vmax are the minimum and maximum allowable voltage of a bus respectively.

2.3 Capacity Limit of DG Units

The installed capacity of the DG units in distribution power network is constrained in a way not exceed total power delivered by the substation to prevent reverse power flow [25]. Equations (5) and (6) illustrates the total minimum and maximum real and reactive power capacity constraints of DG units respectively.

where

3 Ant Lion Optimization Algorithm

Ant lion optimization (ALO) algorithm is a recently added meta-heuristics technique introduced by Mirjalili [26] used for computing optimal solution to various engineering optimization problems. ALO algorithm impersonates the hunting nature of ant lions, i.e. it mimics the hunting behavior of ant lions. The interaction between the predator (ant lions) and the prey (ants) is utilized for solving optimization problems. The capability of balancing between exploration and exploitation makes ALO to be considered as a global optimizer for numerous applications. The hunting nature of ant lions involves five steps such as the random walk of agents, development of trap for ants, entrapment of ants in a trap, catching of prey and reconstruction of traps. The local optima problem in ALO is avoided by roulette wheel and random walks of ants. The mathematical modeling of different phases ALO algorithm is described as follows:

3.1 Random Walk of Ants

Ants are normally moves stochastically in nature while searching of food. Hence, the movement of ants can be modeled as a random walk as follows:

where, cums computes the cumulative sum, n is a number of iteration, t illustrates the step of random walk and r(t) is a stochastic function which can be defined as follows:

From Eq. (10), rand is a randomly generated number between 0 and 1. The position of ants is updated in each step of the optimization process by a random walk. However, the boundary condition of search space makes Eq. (9) cannot be used for updating the position of ants. Hence, the position of ants is normalized by using Eq. (11) in order to make sure that they are inside the given boundary condition.

where, ai and bi represents the minimum and maximum random walk of ith variable respectively, cit and dit represents the minimum and maximum value of ith variable at tth iteration respectively. The Eq. (11) should be applied in every iteration step to make sure the random walks inside the given search space.

3.2 Trapping in Ant Lions Traps

The random walks of ants in a search space get affected by ant lions traps. The effect of ant lions traps on the random walk of ants is mathematically represented using the following equations:

where, ct and dt is a vector with the minimum and maximum values of all variables at tth iteration respectively and \({\text{Ant lion}}_{{_{{\text{j}}} }}^{{\text{t}}}\) indicates the position of jth ant lion for a tth iteration. The Eqs. (12) and (13) illustrates the random walk of ants around a selected ant lion in a hyper sphere defined by c and d vectors.

3.3 Trap Building

The hunting behavior of ant lions is modeled by employing a roulette wheel operator. During the process of optimization, roulette wheel selection operator is utilized for selecting the ant lions according to their fitness value. This approach creates more possibility for the ant lions to catch the prey.

3.4 Sliding Ants Towards Ant Lion

The ant lions construct the traps according to their fitness value using the aforementioned mechanisms. Whenever, the randomly moving ants get caught near the traps, ant lions starts to shoot out the sands outward from the center of the trap. This makes sure there is no chance for ants to escape from the trap. To mathematically represent this process, the radius of random walks of ants in the hyper sphere is adaptively reduced. The mathematical representation of this process is given using the following equations:

where, ct and dt is a vector with the minimum and maximum values of all variables at tth iteration respectively and I is a ratio. From Eqs. (14) and (15), I = 10W \(\frac{\mathrm{t}}{\mathrm{T}}\) where, t points to the current iteration, T is a total number of iteration and w is a constant defined according to the current iteration, t. The Eqs. (14) and (15) decreases the radius of ant’s position and imitates the sliding process of ant within the pits.

3.5 Catching of Prey and Rebuilding of Traps

This phase of ALO is focused on catching of prey (ants) by predator (ant lions) and reconstruction of traps for catching of new prey (ants). For representing this process, it is considered that catching of prey happens only when ants become fitter than the ant lion. The action of this phase is represented using the following equation:

where, \({\text{Ant lion}}_{{_{{\text{j}}} }}^{{\text{t}}}\) and \({\text{Ant}}_{{_{{\text{j}}} }}^{{\text{t}}}\) are points the position of jth ant lion and ith ant at tth iteration respectively.

3.6 Elitism

In evolutionary algorithms, more importance is given to the elitism characteristics. In each and every iteration process of ALO algorithm, best ant lion solution is considered as elite. Since elite is considered as the best ant lion, it should have the tendency to control the entire motion of remaining ants during the iterations. The elitism process can be represented using the following mathematical expression:

where, \({\text{Ant}}_{{_{{\text{i}}} }}^{{\text{t}}}\) points the position of ith ant at tth iteration, \({\text{R}}_{{\text{A}}}^{{\text{t}}}\) is a random walk of ants around the ant lion chosen by roulette wheel at tth iteration and \({\text{R}}_{{\text{E}}}^{{\text{t}}}\) is a random walk of ants around elite at tth iteration.

4 Identification of Optimal Bus Locations for DG units

To compute the objective function value and optimal bus location for DG unit, load flow analysis plays an essential part in the distribution system. Load flow analysis by Gauss Seidal method and Newton Raphson method are not suitable for distribution power system due to its radial structure and high R/X ratio. These methods give desired solution only for the transmission system. Hence, these methods are unsuitable to make power flow computation for the distribution network system. Due to lower memory requirement, faster convergence rate, higher computational efficiency and accuracy, backward-forward sweep algorithm [17] has been selected for a radial distribution network.

4.1 Backward–Forward Sweep Load Flow Method

The backward–forward sweep load flow algorithm for a radial network consists of two processes i.e. forward and backward sweep processes. Forward sweep is employed for computing the node voltage from the near end to far end and backward sweep is used for calculating the branch current from the far end to near end.

4.2 Optimal DG Location by Integrated Methodology

Selection of suitable bus location for installation of DG units is important to attain desired objectives in the distribution power network. The present work uses an integrated approach for determining the optimal bus location by evaluating the loss sensitivity factor (LSF) and voltage sensitivity factor (VSF) of each bus.

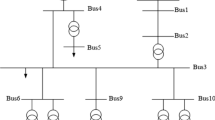

LSF for a line section connected between buses i and i + 1 of a sample three bus distribution network shown in Fig. 1 is evaluated using Eq. (18).

where, Ri,i+1—resistance of a line section between the buses i and i + 1, Qi+1,eff—total effective reactive power beyond the bus i + 1, Vi+1—voltage magnitude of bus i + 1

Initially, the LSF value for all the end buses of line sections is computed with the help of load flow analysis solution. The computation of LSF greatly reduces the search space for the optimization process by pointing out the possible candidate buses for DG placement. The candidate buses are ranked in descending order based on LSF values. Now, VSF corresponding to the bus sequences of LSF is determined by dividing the corresponding bus voltage (Vi) by 0.95.

The buses having VSF greater than 1.01 are considered as healthy buses and are not considered for DG placement. Then, the buses having VSF value less than 1.01 are considered as candidate buses for DG installation. Now, the candidate buses are ranked according to their LSF and VSF values and the optimal bus locations for DG placement are chosen accordingly.

4.3 ALO Algorithm for Computing Optimal Site and Size of DG Units

The step by step algorithm for computing optimal site and size of DG units in a distribution power network is described as follows:

Step 1: Read line and bus data of a distribution network system and perform load flow analysis using backward–forward sweep technique.

Step 2: Locate the optimal bus position for DG units by calculating LSF and VSF for each bus using Eqs. (18) and (19).

Step 3: Initialize the number of DG units, the size of population, maximum number of iteration, the minimum (dgmini) and maximum (dgmax) values of DG unit. No of DG units = 3, Maximum iteration = 50, dgmini = 60 and dgmax = 2000.

Step 4: Using Eq. (20), generate random values for the population of DG size.

Step 5: Compute the total real power loss for the population generated.

Step 6: Choose DG size which gives a low real power loss as a current best solution.

Step 7: Update the position of ant lions using Eqs. (9)–(11).

Step 8: Perform load flow analysis again and compute the total real power loss for the updated population size.

Step 9: Replace the best solution if the obtained total power loss is less than the current best solution, otherwise, go to step 7.

Step10: Check the iteration count and print the results if the maximum iteration reached.

5 Results and Discussion

The necessary program code for implementation of ALO algorithm to determine optimal site and size for multiple DG units has been developed in Matlab16b on Intel core i3, 3.7 GHz, 4 GB RAM processor PC. The present work is examined against IEEE 33, 69 and 119 bus balanced radial distribution networks with constant power loads.

5.1 IEEE 33 Bus Radial Distribution System

IEEE 33 bus test system includes 32 load buses and 32 branches. Also, it has a 3720 kW of total real power and 2300 kVAr of total reactive power. The required bus and line data for IEEE 33 bus radial distribution test system is referred from [27]. Voltage profile and total real power loss of test system without DG units are computed using backward-forward sweep load flow algorithm [17] for a base of 100 MVA and 12.66 kV. The test system has total real power and reactive power losses of 210.98 kW and 143 kVAr respectively. With the help of load flow results, LSF and VSF of all the buses are determined. Based on LSF values, a total of 21 buses have been identified as a candidate buses for DG placement. In this test system, three DG units are optimally integrated. Therefore, buses 30, 13 and 10 are selected as optimal bus locations for DG placement from the candidate buses.

The optimal size of PV and WT type of DG units, total real power loss, percentage of loss reduction and minimum bus voltage of IEEE 33 bus system for ALO, GA-PSO, ABC-CSO and ABC-BAT algorithms is presented in Table 1.

5.1.1 Multiple PV DG Units

Optimal allocation of PV type DG units decreased the total real power loss of the test system from 210.98 to 86.40 kW. Furthermore, DG units enhanced the minimum bus voltage of the test system from 0.9038 to 0.9767 p.u. Referring to Table 1, the proposed ALO algorithm provided better power loss reduction and voltage profile enhancement than studied GA-PSO, ABC-CSO and ABC-BAT algorithms. The voltage profile of IEEE 33 bus test system with PV units for different algorithms is illustrated in Fig. 2.

The comparative illustration of convergence characteristics of ALO, GA-PSO, ABC-CSO and ABC-BAT is shown in Fig. 3. From Fig. 3, it is clearly seen that proposed ALO algorithm converges faster than other studied algorithms to an optimum solution. Also, ALO took only 12 iterations to converge, whereas GA-PSO, ABC-CSO and ABC-BAT algorithms took 16, 21 and 29 iterations respectively. Furthermore, proposed ALO algorithm consumed lesser CPU time to yield an optimal solution compared to other implemented algorithms. Therefore, from test results it can be noted that the proposed ALO algorithm provided maximum power loss reduction with better convergence characteristics than other studied algorithms.

5.1.2 Multiple WT DG units

Inclusion of WT type DG units minimized the total real power loss of the test system from 210.98 to 31.65 kW and improved the minimum bus voltage of the test system from 0.9038 to 0.9802 p.u. Referring to Table 1, compared with the studied GA-PSO, ABC-CSO and ABC-BAT algorithms, the proposed ALO algorithm provided better power loss reduction and voltage profile enhancement. The voltage profile of IEEE 33 bus test system with WT units for different algorithms is illustrated in Fig. 4.

The convergence characteristics of ALO, GA-PSO, ABC-CSO and ABC-BAT are illustrated in Fig. 5. From Fig. 5, it is clearly seen that ALO algorithm not only converges faster than other studied algorithms it also consumes minimum CPU time. This shows the ability of the proposed ALO algorithm in providing optimum solution with better convergence characteristics. The voltage profile of IEEE 33 bus test system with and without inclusion of multiple DG units are illustrated in Fig. 6.

5.2 IEEE 69 Bus Radial Distribution System

This test system includes 68 load buses and 68 branches. The total real power and reactive per demand of this test system is 3800 kW and 2690 kVAr respectively. The necessary bus data and line data required for IEEE 69 bus radial distribution system is referred from [27]. The total real power loss and reactive power loss of this test system are 225 kW and 102.20 kVAr respectively. The candidate bus locations for DG installation are identified by evaluating VSF and LSF values. A total of 21 buses have been considered as a candidate buses for finding the optimal bus locations. The performance of the proposed ALO algorithm and other studied algorithms are examined with optimal placement of multiple PV and WT DG units. For 69 bus test system, three DG units are optimally integrated. Therefore, bus numbers 61, 17 and 65 are identified as optimal bus locations based on LSF and VSF. The optimal capacity of PV and WT type DG units, total real power loss and percentage of real power loss reduction, and minimum bus voltage of IEEE 69 bus test system for ALO, GA-PSO, ABC-CSO and ABC-BAT algorithms are given in Table 2.

5.2.1 Multiple PV DG Units

The optimal installation PV type DG units reduced the total real power loss of test system from 225 to 70.51 kW and also enhanced the minimum bus voltage from 0.9092 to 0.9807 p.u. From Table 2, it can be pointed out that among the studied algorithms, the proposed ALO algorithm have yielded maximum percentage of real power loss reduction and better voltage improvement. The voltage profile of IEEE 69 bus test system with PV units for different algorithms is illustrated in Fig. 7.

The convergence characteristics of ALO, GA-PSO, ABC-CSO and ABC-BAT are illustrated in Fig. 8. The proposed ALO algorithm only took 16 iterations to converge to an optimal solution. However, GA-PSO, ABC-CSO and ABC-BAT algorithms took 32, 25 and 19 iterations respectively to converge. This shows the superiority of ALO algorithm over other implemented algorithms in providing adequate performance.

5.2.2 Multiple WT DG Units

Inclusion of WT type DG units decreased the total real power loss of the test system from 225 to 8.78 kW and enhanced the minimum bus voltage of the test system from 0.9092 to 0.9901 p.u. Compared with studied GA-PSO, ABC-CSO and ABC-BAT algorithms, the proposed ALO algorithm provided maximum percentage of power loss reduction and voltage profile enhancement. The voltage profile of IEEE 69 bus test system with WT units for different algorithms is illustrated in Fig. 9.

The proposed ALO algorithm converges faster than other implemented algorithms with minimum CPU time (Table 2).

The convergence characteristics of ALO, GA-PSO, ABC-CSO and ABC-BAT are illustrated in Fig. 10. This shows the ability of the proposed ALO algorithm in providing optimum solution at better convergence rate. The voltage profile of IEEE 69 bus test system with and without inclusion of multiple DG units are illustrated in Fig. 11.

5.3 IEEE 119 Bus Radial Distribution System

The performance of proposed ALO algorithm is investigated on large distribution power network. i.e., 119 bus RDS. The necessary line and bus data of this system is referred from [28]. The test system has a total real and reactive power demand of 22,709.7 kW and 17,041.1 kVAr respectively at a base of 100 MVA and 11 kV. The total real power and reactive power loss of this test system without DG units are 1296.3 kW and 978.36 kVAr respectively. The number of iteration count for this system is increased to 100. Five number of PV type DG units are placed in this test system for minimizing the total real power loss. The optimal locations, optimal capacity of DG units and total real power loss obtained using ALO, GA-PSO, ABC-CSO and ABC-BAT algorithms are presented in Table 3. Compared with GA-PSO, ABC-CSO and ABC-BAT algorithms, the proposed ALO provided maximum power loss reduction and better voltage profile improvement. The voltage profile of 119 bus test system with and without DG units is illustrated in Fig. 12. The convergence curve for the proposed ALO algorithm along with other studied algorithms is illustrated in Fig. 13. From Fig. 13, it can be noted that ALO algorithm convergence at better rate than the other implemented algorithms.

6 Conclusion

In this paper, an ant lion optimization algorithm has been applied for IEEE 33, 69 and 119 bus balanced radial distribution network systems to compute the optimal capacity of multiple DG units to reduce the total real power losses. The optimal bus locations are identified based on loss sensitivity factor and voltage sensitivity factor. The optimal capacity of different DG units has been determined using ALO, GA-PSO, ABC-CSO and ABC-BAT algorithms. The outcome of ALO algorithm has been related other implemented algorithms to show its superiority over power loss reduction. The comparative studies have clearly highlighted the superiority of ALO algorithm towards the minimization of real power loss. The proposed ALO algorithm provides maximum reduction of total real power with better voltage profile enhancement. Furthermore, ALO converged at faster rate than other studied algorithms. This ability of ALO algorithm in proving optimal solution with minimum computation time makes it ideal to be used for larger distribution power networks. The proposed work can be extended for a distribution networks with unbalanced loads as a future scope.

References

Ackermann T, Andersson G, Söder L (2001) Distributed generation: a definition. Int J Electr Power Syst Res 57(3):195–204

Esmaili M, Firozjaee EC, Shayanfar HA (2014) Optimal placement of distributed generations considering voltage stability and power losses with observing voltage-related constraints. Int J Appl Energy 113:1252–1260

Borghetti and Alberto (2012) A mixed-integer linear programming approach for the computation of the minimum-losses radial configuration of electrical distribution networks. IEEE Trans Power Syst 27(3):1264–1273

Rueda-Medina AC, Franco JF, Rider MJ, Padilha-Feltrin A, Romero R (2013) A mixed integer linear programming approach for optimal type, size and allocation of distributed generation in radial distribution systems. Electr Power Syst Res 97:133–143

Atwa YM, El-Saadany EF, Salama MA, Seethapathy R (2010) Optimal renewable resources mix for distribution system energy loss minimization. IEEE Trans Power Syst 25(1):360–370

Khalesi N, Rezaei N, Haghifam MR (2011) DG allocation with application of dynamic programming for loss reduction and reliability improvement. Int J Electr Power Energy Syst 33(2):288–295

Wang C, Nehrir MH (2004) Analytical approaches for optimal placement of distributed generation sources in power systems. IEEE Trans Power Syst 19(4):2068–2076

Gözel T, Hocaoglu MH (2009) An analytical method for the sizing and siting of distributed generators in radial systems. Electr Power Syst Res 79(6):912–918

Kansal S, Tyagi B, Kumar V (2015) Cost benefit analysis for optimal distributed generation placement in distribution systems. Int J Ambient Energy 38(1):45–54

El-Sehiemy R, Abou El-Ela A, Kinawy A, Ali E (2016) Optimal placement and sizing of distributed generation units using different cat swarm optimization algorithms. In: Eighteenth international middle-east power systems conference (MEPCON), Helwan University, Cairo

Sathish Kumar K, Jayabharathi T (2012) Power system reconfiguration and loss minimization for a distribution systems using bacterial foraging optimization algorithm. Electr Power Energy Syst 36:13–17

Gandomkar M, Vakilian M, Ehsan M (2005) A genetic-based tabu search algorithm for optimal DG allocation in distribution networks. Electr Power Compon Syst 33(12):1351–1362

Moradi MH, Abedini M (2012) A combination of genetic and particle swarm optimization for optimal DG location and sizing in distribution system. Int J Electr Power Energy Syst 34(1):66–74

Remha S, Saliha C (2018) A novel multi-objective bat algorithm for optimal placement and sizing of distributed generation in radial distributed systems. Adv Electr Electron Eng 15:736–746

Farhat I (2013) Ant colony optimization for optimal distributed generation in distribution systems. Int J Comput Inf Eng 7(8):461–465

Abu-Mouti FS, El-Hawary ME (2011) Optimal distributed generation allocation and sizing in distribution systems via artificial bee colony algorithm. IEEE Trans Power Deliv 26(4):2090–2101

Haque MH (1996) Efficient load flow method for distribution systems with radial or mesh configuration. IEEE Proc Gen Transm Distrib 143(1):33–38

Nischal MM, Mehta S (2015) Optimal load dispatch using ant lion optimization. Int J Eng Res Appl 5(8):10–19

Petrović M, Petronijevic J, Mitic M, Vuković N, Plemic A, Miljković Z, Babic B (2015) The ant lion optimization algorithm for flexible process planning. J Prod Eng 18(2):65–68

Mehta S, Nischal MM (2015) Ant lion optimization for optimum power generation with valve point effects. Int J Res Appl Sci Eng Technol 3:1–6

Talatahari S (2016) Optimum design of skeletal structures using ant lion optimizer. Int J Optim Civil Eng 6(1):13–25

Abd-Elaziz AY, Ali ES, Abd-Elazim SM (2016) Flower pollination algorithm for optimal capacitor placement and sizing in distribution systems. Electr Power Compon Syst 44(5):544–555

Singh D, Verma KS (2009) Multi-objective optimization for DG planning with load models. IEEE Trans Power Syst 24(1):427–436

Kowsalya M (2013) Optimal size and siting of multiple distributed generators in distribution system using bacterial foraging optimization. Swarm Evolut Comput 15:58–65

Hassan A, Fahmy F, Nafeh A, Abuelmagd M (2015) Genetic single objective optimization for sizing and allocation of renewable DG systems. Int J Sustain Energy 36:545–562

Mirjalili S (2015) The ant lion optimizer. Adv Eng Softw 83:80–98

Sahoo NC, Prasad K (2006) A fuzzy genetic approach for network reconfiguration to enhance voltage stability in radial distribution systems. Energy Convers Manag 47(18–19):3288–3306

Zhang D, Fu Z, Zhang L (2007) An improved TS algorithm for loss-minimum reconfiguration in large-scale distribution systems. Electr Power Syst Res 77:685–694

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Palanisamy, R., Muthusamy, S.K. Optimal Siting and Sizing of Multiple Distributed Generation Units in Radial Distribution System Using Ant Lion Optimization Algorithm. J. Electr. Eng. Technol. 16, 79–89 (2021). https://doi.org/10.1007/s42835-020-00569-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42835-020-00569-5