Abstract

In-situ burning is one of the methods used for oil spill cleanup. Optimising an in-situ burning method using multiple pool fires (MPF) has not been widely studied. In this study, a novel framework is proposed to assess the effectiveness of an MPF in response to oil spills on water surfaces. The framework is applied to four cases using the Fire Dynamics Simulator (FDS). It is found that an MFP can result in incomplete combustion and negative pressure effects if pools are too close to each other, thereby resulting in a reduction in the mass burning rate. However, an MFP has a higher mass burning rate of spilled oil than a single pool fire if appropriate distances among pool fires are maintained. An MFP can increase the speed of recovering the oil compared with a single pool fire due to high temperature and heat flux.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

An oil spill is the leakage of crude oil into an area. Several sources can cause oil spills, including accidental leakage from offshore platforms, pipelines and tankers (Galieriková and Materna 2020). An oil spill has severe impacts on the marine environment and ecosystem, and it is considered a type of pollution (Obida et al. 2021). The oil spill adversely affects living creatures within the ocean and pollutes the ecosystem (Galieriková and Materna 2020). The oil spill can potentially harm public health through effects on fishing and tourism. Several accidental events (examples include the Deepwater Horizon oil spill and the Castillo de Bellver oil spill) have resulted in oil spills onto ocean surfaces and have caused severe consequences. For instance, the Deepwater Horizon oil spill contaminated surface waters, the water column, deep-sea corals and benthos, nearshore and coastal ecosystems, and natural resources across five states in the Gulf of Mexico (GoM) (Wallace et al. 2017). In the subsequent lawsuits, the responsible party paid $65 billion in compensation to people who relied on the gulf for their livelihoods.

Various physical, chemical, thermal, and biological processes are applied for oil spill remediation in the aquatic environment. The oil and gas industry has commonly used four basic ways to deal with ocean spills, namely, booms to contain the oil (Grubesic et al. 2019), skimmers to remove spilled hydrocarbons (Ndimele et al. 2018), fire to burn spilled hydrocarbons (Fingas 2017) and chemical dispersants (Nyankson et al. 2016). The in-situ burning method for thick slick can have a removal efficiency of more than 95% (Mullin and Champ 2003). It is a two-step process. The first step involves collecting spilled oil within a boom, and the second is the controlled burn. Different phenomena can occur when an in-situ burning method is used with multiple pool fires (MPF). For instance, the interaction of MPF, heat flux and oil spill cleanup conditions are not fully understood. The MPF interaction mechanisms have several explanations. It is suggested that the flame leaning varies with the burning rate of the centre and outer fire while the fire merging has several criteria: fuel type, S/D, burning rate, and flame height (Jiao et al. 2019). S/D is the ratio of the spacing between pool fire and pool fire diameter. Air entrainment is another key component to determine heat and mass flux. The relationship between heat and mass flux and the S/D ratio is different under air entrainment restriction. Furthermore, Vasanth et al. (2014b) used Computational Fluid Dynamics (CFD) to study the effect of varying S/D on the combustion rate. They concluded that flame temperature, flame height, and the burning rate increase with an increase in the pool diameter of the participating pools in the MPF.

Gong et al. (2020) studied the relationship between pool fire length to width ratio (L/W) and the temperature distribution. The study concluded that when L/W is not larger than 6, the temperature of the pool fire’s centre is very similar to that of the pool edge. Meanwhile, in the larger L/W cases (L/W≥8), the study claimed an attenuation of the temperature near the short pool edge. The study also recorded the longitude heat flux received by a horizontally adjacent object and concluded that the heat flux reduces with the increase in horizontal distance. Shi et al. (2017) identified that the aspect ratio of ullage (h) to cavity size (D) with ice cavity is related to the heat release during in-situ burning. The heat release rate increases with the aspect ratio for both quasi-steady and boilover stages. The boilover stage has a higher heat release rate than the quasi-steady stage, with other factors being constant. The recirculation pattern with different aspect ratios causes the heat release rate variation. It was concluded that the base drag tends to increase when wind speed is low during in-situ burning, gradually increasing between 1 to 1.5 m/s, and the tendency afterwards depends on the given scenario (Kong et al. 2019b). Burning efficiency increases with initial fuel layer thickness. It slightly increases with wind speed and tends to drop at higher speeds. Kong et al. (2019b) suggested that the other factors that influence the base drag length are the density of hydrocarbons and air above oil surfaces.

Kong et al. (2019a) studied in-situ burning on open water, stating that the average flame height increases with oil pool diameter in a quasi-steady stage. The burning process is separated into four stages with different flame heights and shapes. Only the pool centre has evaporation of the fuel and visible flame due to the significant cooling effect on the sidewall. The experiment also investigated the burning structure on open water and steel vessel and their differences. It concluded that air recirculation mixes oil vapour into entraining air, enhancing burning and flame height. In addition, Dasgotra et al. (2021) analysed the effect of water mist on multiple pool fires using the Fire Dynamics Simulator (FDS). They claimed that the effectiveness of water-mist fire suppression systems is affected mainly by operational parameters such as S/D ratio, ceiling clearance, nozzle discharge rate, and water mist particle size.

In the past, the effectiveness of an in-situ burning method has been studied considering single pool fires. There is a greater interest in understanding the prospect of using MPF for effective in-situ burning. Although in-situ burning seems to be a straightforward method to clean the spilled oil on the ocean surface, several characteristics of this approach are not thoroughly studied. Weng et al. (2004) developed an empirical model to estimate the merged flame height considering the effect of separation distance in multiple fire scenarios. They claimed that more fire sources could lead to higher flame height with the same heat release rate. Vasanth et al. (2014a) reviewed MPF accidents and catalogued the controlled experiments that have been done to understand the mechanism and impact of MPFs. In the past, some of the influencing parameters such as pool size, number of pools and distance between pools have not been extensively investigated to evaluate the efficiency of the in-situ burning method. Moreover, the interacting effect of multiple fires needs to be examined to assess the overall efficacy of using MPF in an in-situ burning method. The current study aims to investigate the characteristics and the influencing parameters for an effective in-situ burning method. Although oil spills can occur on land, the present study focuses on hydrocarbon spills on the water surface.

“Section 2” presents the developed methodology and validation of the model. “Section 3” illustrates a case study. “Section 4” provides the results and discussion of this case study, and “Section 5” presents the conclusions of this study.

Methodology

A novel methodology has been developed to examine the effectiveness of an MPF and its interaction to clean spilled oil from an ocean surface. Each step of the methodology is illustrated in Fig. 1. The study of MPFs and interactions are conducted through numerical simulation. Among the available CFD tools for fire modelling, the FDS is selected to simulate scenarios because it has been widely validated and verified against different scenarios (Baalisampang et al. 2017a; Lim et al. 2019). Each step of the methodology is explained in detail in the following section.

Identification of influencing parameters for in-situ burning

An in-situ burning method is one of the many solutions to handle oil spills. It is considered an efficient method to clean oil spills, including in ice-covered conditions (Ventikos et al. 2004). Currently, in-situ burning is qualified with its burning efficiency and mass burning rate (Rojas-Alva et al. 2020). However, the goal of the present study is to provide additional indicators to accurately identify other influencing parameters and evaluate their impacts on the in-situ burning technique. This steps identifies various influencing parameters for in-situ burning through an extensive literature review.

Simulation of a single pool fire

The second step focuses on assessing the influencing parameters defined in step 2.1 using the FDS. The FDS code has been employed for modelling characteristics of MPFs in several studies, such as Weng et al. (2004) and Salehi et al. (2021). The vital influencing parameters that can be considered are dimensions of pool fire, such as its diameter, oil thickness, and combustion condition (Kong et al. 2019a). Oil thickness and different sources of crude oil are the examples expected to affect fire performance (Fritt-Rasmussen et al. 2012). The heat release rate (HRR), mass-loss rate, and fire temperature are the factors that can assess fire performance. This step helps to define and evaluate influencing parameters for MPF interaction analysis.

Evaluate influencing parameters

Based on the single pool fire’s simulation outcomes, influencing parameters for MPF interaction analysis are evaluated. MPF interaction is the focus of the current study. The interaction mechanism varies with numerous factors. A previous study showed that the ratio between pool diameter and spacing is related to the interaction (Jiao et al. 2019). The interactions are evaluated using mass burning and heat feedback rates in the study. MPF interaction can occur in various environmental conditions. Buist et al. (2011) revealed that in-situ burning could be possible at even very low temperatures such as -17 °C. However, MPF interaction is more difficult under such harsh conditions, which requires a proper evaluation of the most influencing parameters. This step helps filter out the factors that do not cause significant impacts on MPF interaction.

Simulate MPF by varying each influencing parameter

After evaluating the most influencing parameters, several MPF scenarios are generated and simulated according to the proposed influential factors using the FDS code. This step considers a combination of different parameters which aims to create outcomes for each identified parameter.

Simulate and evaluate the effects of all influencing parameters in in-situ burning

The influence of each identified parameter is assessed while keeping other factors constant using the simulation results. In this way, the overall effects of all influencing parameters are evaluated, and correlations can be developed for an effective in-situ burning technique.

Validation

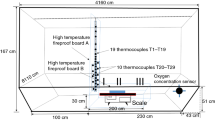

The numerical model is validated with a large-scale pool fire experiment conducted by Sjöström et al. (2015). The study stated that the total HRR is 488 ± 24 MW. The fire temperatures are recorded at set distances from the fire’s edge in four directions using thermocouples. Thermocouples are placed at 0, 5, and 10 m from the pool edge in each direction, as shown in Fig. 2. The simulation setup has maximum width and length of 50 m. The maximum distance between the pool fire edge is 17.5 m by keeping the fire at the centre. The circle is the pool fire with a radius of 9 m. The simulation duration is 2000 s. The simulation setup was precisely matched with all the experiment parameters to increase the accuracy.

Temperatures recorded by thermocouples are compared with experimental results, as shown in Fig. 3. The results from the simulation showed that there is a slight difference between the experiment and the simulation. The maximum percentage difference is 7.6% which is within an acceptable range.

Case study

The proposed methodology is applied to generic case studies. A key component of the simulation is the water surface. Thus, the thermal properties of seawater are considered. The seawater surface with a 1-m depth is applied to the simulation to incorporate the effects of oil–water interfaces. The pool fire is affected by the characteristics of seawater, including the specific heat of seawater, the emissivity, and the heat of vaporisation. The specific heat is considered as 3.85 kJ.kgK, and the emissivity is used as 0.9 (Sharqawy 2013; Sudhamshu et al. 2016). Another factor for seawater is the heat of vaporisation, which is selected as 2300 kJ/kg (Sharqawy et al. 2010). In an in-situ burning method, fire-resistant fabric booms and steel fireproof booms are used to contain the fire (Buist et al. 1999). Though prevailing waves and harsh environmental conditions affect the dynamics of the oil–water interfaces, fixed pool positions are considered in this study.

In the simulation, the geometry dimension is 50 m × 50 m × 20 m. However, the simulation domain is considered 100 m × 100 m × 40 m for accurate results. The circular pool fire with a diameter of 10 m is considered. It is possible to increase the fire size to 20 m or more to simulate the oil spill (Fritz 2003). All the faces are kept open except the sea surface. The z-min is the bottom face that is the sea surface. The HRR of the fire is selected as 1000 kW/m2. The ambient temperature is set as 20 °C with zero wind speed. It is assumed that the fires are under open area conditions, and there is no other obstruction. When the water content of the oil is higher than 25%, most of the oil slick is incombustible. The usual method is to use a towed fireproof fence to capture the leaked crude oil and concentrate it to form a stable pool with a considerable thickness to resist harshness. This study considers MPF models for multiple pools on the surface of offshore water only.

Cases

Four cases are considered by varying number of pools, size and S/D and the variables are shown in Table 1. In case 1, three identical pool fires are considered with S/D 1. In case 2, the distances between pools are reduced, keeping everything the same. The size of the fire can influence the characteristics of the fire interaction. Thus, five different pool sizes are considered in case 4. In case 3, the pool size and S/D are changed.

In case 4, the number of fires varies in each simulation, starting with 1 to 3 fires. The case aims to compare the effectiveness of a standalone pool fire and an MPF based on the temperature recorded at the fixed location, as shown in Fig. 4. The spacing between sensors and fire is 5 m for all three simulations.

Mesh independence analysis

CFD results depend on mesh sizes, and thus, a mesh independence analysis needs to be conducted for accurate results (Baalisampang et al. 2017b). The mesh independence analysis is performed using three mesh sizes based on the maximum temperature recorded by thermocouples. Three thermocouples (THCP05-07) are placed at the centre of the fires, and three thermocouples are located between two fires (THCP02-04), as shown in Fig. 4. A thermocouple (THCP01) is placed at the centre of all three fires to record the thermal performance and interactions. An extra thermocouple is placed at the height of 19 m vertically above the THCP01 to measure the net temperature of the merging flames. The positions of thermocouples and the three pools are given in Table 2.

Three mesh numbers considered for the mesh independent analysis are 400,000, 1,350,000 and 4,556,250. The overall accuracy improvement is less than 3%, with the expense of 10 times more simulation time. The slight difference in the result indicates that the 400,000 mesh number model has sufficient accuracy for the study. Hence, the further increase in mesh number is not cost-effective.

Results and discussion

The results obtained from each case are used to compare the effects of the interaction of fires which are discussed in the following section.

Comparison between case 1 and case 2

In case 2, distances between pools are greater than those of case 1. To identify the interaction of fires, air velocity is used as an indicator based on the drag direction of the fire. Figure 5 shows the horizontal velocity of air. The magnitudes of velocity in the two cases are different. The horizontal velocity in case 1 is higher than in case 2. It is observed that the flames of the two fires tend to gather in the middle. The inclination is significant in case 1 because of the lower air density between the fires. The air velocity distribution indicates that fires drag at a higher velocity when pools are closer to each other. The increase in horizontal velocity proves the increase of fire interaction caused by reducing the spacing between fires. The spacing between fire is a significant factor to influence fire interaction.

Temperature in each fire

Figure 6 demonstrates the temperature of three pool fires. The average temperature of the three fire pools in case 1 is 2260 ℃ and 2324 ℃ in case 2. However, the temperatures in case 1 are relatively less stable than in case 2. The potential reason for less stable temperature in case 1 is that the interaction of fire is relatively strong. Therefore, the temperature variation in case 1 is more prominent than in case 2.

Temperatures between two fires

Figure 7 shows the temperatures recorded by thermocouples which are placed between two pool fires. THCP01 is located at the centre of three fires. Temperatures in case 2 are lower than those of case 1. The reduction of distance between fires has increased the fire interaction, which resulted in increased temperature.

Net temperature after merging into one flame

For an illustrative purpose, the temperature at the height of 19 m from the middle of three fires is recorded to investigate the net temperature of merging fires. However, the temperature can be compared at any height after a merging point. The temperature range for case 2 is 100 to 140 °C, while the temperature for case 1 is up to 240 °C, as shown in Fig. 8. The temperature can reflect the interaction among these fires. In case 2, the combined temperature is much lower than in case 1 because of longer distances among fires, and flames do not wholly merge. The higher temperature in case 1 implied that fires joined at a lower height with increased interaction.

Analysis of the impact of pool fire size on thermal performance (case 3)

Five simulations of different fire sizes are considered. All three fire sizes are identical in each simulation. Thermocouples 05, 06 and 07 are placed at the centre of fires, and five extra thermocouples are placed between the fires, as shown in Fig. 9. The distances between thermocouples and fire edges are kept constant in each simulation. The purpose of THCP01 to THCP04 is to observe the fire interaction impacts on thermal performance and the corresponding effects caused by fire size.

Two influencing factors are used for this analysis. The first one is the spacing between fires directly related to the interaction. Another factor is the size of the pool fire. The fire size reduction can provide high S/D with equal spacing between fire edges. Therefore, S/D is adjusted by changing the fire size. The temperature of all three fires has reduced with the increase in pool diameters from 2.5 to 7.5 m, as illustrated in Fig. 10. The decrease in temperature has indicated the incomplete combustion of the fires. Hence, the interaction has caused insufficient airflow for complete combustion, reducing the temperature of fires. However, the reduction in the S/D has enhanced the fire interaction. In the current study, it is observed that when the diameter of pools is greater than 7.5 m, there is no linear relationship between temperature and pool diameter, as shown in Fig. 10.

The temperatures at the central location from the two fires are recorded. The temperatures recorded by THCP01 to THCP04 are similar since the temperature is obtained on the water surface. The temperature decreases gradually from the diameter of 2.5 to 7.5 m, as shown in Fig. 11. The increase in fire interaction has created negative pressure that drags heat towards the space between fires, increasing their temperature. The negative pressure effects had a larger thermal impact than incomplete combustion when the diameters were 2.5 to 7.5 m. Hence, a slight increase in temperature is obtained. However, the temperature reduces when the diameters are greater than 7.5 to 10 m. It confirms that the mass-loss rate increases at a certain S/D ratio, which decreases after that (Ji et al. 2016). For the diameters 10 to 12.5 m, both incomplete combustion and negative pressure effects contribute to the thermal impacts. There is only a slight temperature variation when the pool diameter is between 10 to 12.5 m.

Impacts of number of fires in thermal performance (case 4)

Temperatures recorded at 5 m away from the pool boundary are compared considering 1, 2, and 3 fires, as shown in Fig. 12. This indicates that the average temperature increases with an increase in the number of fires. It is found that the increase rates are 4.7% and 12.06% for two fires and three fires, respectively, compared with a single fire. It demonstrates that the speed of oil spill cleanup can be improved using multiple pool fires during in-situ burning.

Conclusions

In-situ burning is an efficient method for cleaning oil spills from water surfaces. A novel framework has been proposed to evaluate the efficacy of a multiple pool fire (MPF) in optimising the oil spill cleaning process. The temperature from an MPF is used to assess the effects on the burning rate of the spilled oil. The Fire Dynamics Simulator (FDS) software is used in the current study considering 4 cases. The numerical model was validated, which shows a good agreement with the experimental result. Case 1 and case 2 assessed the impact of changes in distance between pool fires. The fire interaction increases with smaller pool spacing. The temperatures recorded by the thermocouple kept at the centre of all pools provided evidence of stronger pool fire interaction.

Case 3 investigated the thermal performance of different pool fire sizes with the same spacing between fire edges. The temperature at the centre of the fire indicated the pool fire has incomplete combustion, leading to a reduction in temperature for fire with diameters 2.5 to 10 m. However, the temperature increases when the fire diameter is further increased. The temperature recorded between fires is also not linearly related to fire diameter and the ratio of the spacing between fires to fire diameter (S/D). The temperature of pool fire initially increased between 2.5 to 7.5 m but reduced when the diameter was 7.5 to 10 m. There are no significant changes in temperature for the fire with diameters of 10 to 12.5 m. The major influencing factors are the negative pressure effect and incomplete combustion.

In case 4, the effectiveness of a single pool fire and multiple pool fire in cleaning up oil spills is investigated. It is found that the net temperature at the middle point of pools increases with the increase in the number of fires. The total mass burning rate was higher in an MPF than that of a single pool fire. Thus, the MPF can improve the overall mass burning rate and speed up the oil spill cleaning process. Consideration of the effects of actual ocean conditions such as wave motion and oil slick thickness in the current framework can be the future direction of the study.

Availability of data and material (data transparency)

The simulation data is available upon request.

Code availability

Not applicable as no datasets were generated or analysed during the current study.

References

Baalisampang T, Abbassi R, Garaniya V, Khan F, Dadashzadeh M (2017a) Fire impact assessment in FLNG processing facilities using computational fluid dynamics (CFD). Fire Saf J 92:42–52

Baalisampang T, Abbassi R, Garaniya V, Khan F, Dadashzadeh M (2017b) Modelling the impacts of fire in a typical FLNG processing facility. Int Conf Saf Fire Eng SAFE’17

Buist I, Mccourt J, Potter S, Ross S, Trudel K (1999) In situ burning. Pure Appl Chem 71:43–65

Buist I, Potter S, Nedwed T, Mullin J (2011) Herding surfactants to contract and thicken oil spills in pack ice for in situ burning. Cold Reg Sci Technol 67:3–23

Dasgotra A, Rangarajan G, Tauseef S (2021) CFD-based study and analysis on the effectiveness of water mist in interacting pool fire suppression. Process Saf Environ Prot 152:614–629

Fingas M (2017) Chapter 10 - In situ burning: an update. In FINGAS, M. (ed.) Oil Spill Science and Technology (Second Edition). Boston: Gulf Professional Publishing

Fritt-Rasmussen J, Brandvik PJ, Villumsen A, Stenby EH (2012) Comparing ignitability for in situ burning of oil spills for an asphaltenic, a waxy and a light crude oil as a function of weathering conditions under arctic conditions. Cold Reg Sci Technol 72:1–6

Fritz DE (2003) In situ burning of spilled oil in freshwater inland regions of the United States. Spill Sci Technol Bull 8:331–335

Galieriková A, Materna M (2020) World seaborne trade with oil: one of main cause for oil spills? Transp Res Procedia 44:297–304

Gong C, Ding L, Wan H, Ji J, Gao Z, Yu L (2020) Spatial temperature distribution of rectangular n-heptane pool fires with different aspect ratios and heat fluxes received by adjacent horizontal targets. Fire Saf J 112:102959

Grubesic T, Wei R, Nelson J (2019) Protecting sensitive coastal areas with exclusion booms during oil spill events. Environ Model Assess 24:479–494

Ji J, Wan H, Gao Z, Fu Y, Sun J, Zhang Y, Li K, Hostikka S (2016) Experimental study on flame merging behaviors from two pool fires along the longitudinal centerline of model tunnel with natural ventilation. Combust Flame 173:307–318

Jiao Y, Gao W, Liu N, Lei J, Xie X, Zhang L, Tu R (2019) Interpretation on fire interaction mechanisms of multiple pool fires. Proc Combust Inst 37:3967–3974

Kong D, He X, Khan F, Chen G, Ping P, Yang H, Peng R (2019a) Small scale experiment study on burning characteristics for in-situ burning of crude oil on open water. J Loss Prev Process Ind 60:46–52

Kong D, He X, Yang H, Zhang Z (2019b) Experimental study for flame base drag and burning efficiency of spilled crude oil during in-situ burning on water. Process Saf Environ Prot 131:48–54

Lim JW, Baalisampang T, Garaniya V, Abbassi R, Khan F, Ji J (2019) Numerical analysis of performances of passive fire protections in processing facilities. J Loss Prevent Process Ind 103970

Mullin JV, Champ MA (2003) Introduction/overview to in situ burning of oil spills. Spill Sci Technol Bull 8:323–330

Ndimele PE, Saba AO, Ojo DO, Ndimele CC, Anetekhai MA, Erondu ES (2018) Remediation of crude oil spillage. The political ecology of oil and gas activities in the Nigerian aquatic ecosystem. Elsevier

Nyankson E, Rodene D, Gupta RB (2016) Advancements in crude oil spill remediation research after the Deepwater Horizon oil spill. Water Air Soil Pollut 227:1–22

Obida CB, Blackburn GA, Whyatt JD, Semple KT (2021) Counting the cost of the Niger Delta's largest oil spills: Satellite remote sensing reveals extensive environmental damage with >1million people in the impact zone. Sci Total Environ 775:145854

Rojas-Alva U, Fritt-Rasmussen J, Jomaas G (2020) Small-scale in-situ burning (ISB) experiments with chemically confined crude oils on water. Fire Saf J 114:103135

Salehi F, Reddy N, Jalalifar S, Abbassi R (2021) Ceiling temperature assessment of a reduced scale tunnel in the event of two hydrogen jet fires. Saf Extreme Environ 3:133–142

Sharqawy MH (2013) New correlations for seawater and pure water thermal conductivity at different temperatures and salinities. Desalination 313:97–104

Sharqawy MH, Lienhard JH, Zubair SM (2010) Thermophysical properties of seawater: a review of existing correlations and data. Desalin Water Treat 16:354–380

Shi X, Ranellone RT, Sezer H, Lamie N, Zabilansky L, Stone K, Rangwala AS (2017) Influence of ullage to cavity size ratio on in-situ burning of oil spills in ice-infested water. Cold Reg Sci Technol 140:5–13

Sjöström J, Amon F, Appel G, Persson H (2015) Thermal exposure from large scale ethanol fuel pool fires. Fire Saf J 78:229–237

Sudhamshu AR, Pandey MC, Sunil N, Satish NS, Mugundhan V, Velamati RK (2016) Numerical study of effect of pitch angle on performance characteristics of a HAWT. Eng Sci Technol Int J 19:632–641

Vasanth S, Tauseef S, Abbasi T, Abbasi S (2014a) Multiple pool fires: occurrence, simulation, modeling and management. J Loss Prev Process Ind 29:103–121

Vasanth S, Tauseef S, Abbasi T, Rangwala A, Abbasi S (2014b) Assessment of the effect of pool size on burning rates of multiple pool fires using CFD. J Loss Prev Process Ind 30:86–94

Ventikos NP, Vergetis E, Psaraftis HN, Triantafyllou G (2004) A high-level synthesis of oil spill response equipment and countermeasures. J Hazard Mater 107:51–58

Wallace BP, Brosnan T, Mclamb D, Rowles T, Ruder E, Schroeder B, Schwacke L, Stacy B, Sullivan L, Takeshita R (2017) Effects of the Deepwater Horizon oil spill on protected marine species. Endanger Species Res 33:1–7

Weng W, Kamikawa D, Fukuda Y, Hasemi Y, Kagiya K (2004) Study on flame height of merged flame from multiple fire sources. Combust Sci Technol 176:2105–2123

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Sin, M.C., Baalisampang, T., Zhu, P. et al. In-situ burning of spilled hydrocarbons using multiple pool fire numerical models. Saf. Extreme Environ. 4, 59–67 (2022). https://doi.org/10.1007/s42797-022-00052-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42797-022-00052-6