Abstract

The use of plant biomass for biofuel production will require efficient utilization of the sugars in lignocellulose, primarily cellobiose, because it is the major soluble by-product of cellulose and acts as a strong inhibitor, especially for cellobiohydrolase, which plays a key role in cellulose hydrolysis. Commonly used ethanologenic yeast Saccharomyces cerevisiae is unable to utilize cellobiose; accordingly, genetic engineering efforts have been made to transfer β-glucosidase genes enabling cellobiose utilization. Nonetheless, laboratory yeast strains have been employed for most of this research, and such strains may be difficult to use in industrial processes because of their generally weaker resistance to stressors and worse fermenting abilities. The purpose of this study was to engineer industrial yeast strains to ferment cellobiose after stable integration of tabgl1 gene that encodes a β-glucosidase from Thermoascus aurantiacus (TaBgl1). The recombinant S. cerevisiae strains obtained in this study secrete TaBgl1, which can hydrolyze cellobiose and produce ethanol. This study clearly indicates that the extent of glycosylation of secreted TaBgl1 depends from the yeast strains used and is greatly influenced by carbon sources (cellobiose or glucose). The recombinant yeast strains showed high osmotolerance and resistance to various concentrations of ethanol and furfural and to high temperatures. Therefore, these yeast strains are suitable for ethanol production processes with saccharified lignocellulose.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Biofuels are expected to become some of the major sources of renewable energy and mainly include cellulosic ethanol, biodiesel, and biogas. Significant attention has been diverted to ethanol from abundant renewable lignocellulosic feedstocks because of the low cost and good availability of ethanol [1, 2]. However, this is a very costly process owing to the robust and complex structure of lignocelluloses, which requires multistep operations, including pre-treatment, enzymatic hydrolysis, and fermentation. Upon hydrolysis, lignocelluloses yield a mixture of monomeric hexoses (glucose and galactose) and pentoses (xylose and arabinose). To develop an inexpensive process, a different metabolic engineering strategy has been employed in attempts to enable Saccharomyces cerevisiae to simultaneously ferment all available sugars in biomass hydrolysates (Fig. S1). For more efficient conversion of xylose to ethanol, either xylose reductase/xylitol dehydrogenase (XR/XDH) pathway or xylose isomerase (XI) pathway was introduced into S. cerevisiae strains together with overexpression of the host-encoded xylulokinase [3, 4]. Conversion of l-arabinose into d-xylulose-5-phosphate is based on heterologous expression of bacterial genes encoding l-arabinose isomerase (AraA), l-ribulokinase (AraB), and l-ribulose-5-phosphate-4-epimerase (AraD). Further improvements on alcoholic fermentation of these most abundant pentoses have been obtained through directed-evolution strategies aimed to accumulate spontaneous beneficial mutation [5,6,7]. A redox engineering study has revealed that deletion of S. cerevisiae genes encoding glycerol-3-phosphate dehydrogenase and expression of an acetylating acetaldehyde dehydrogenase from Escherichia coli (A-ALD) allow researchers to achieve conversion of inhibitory acetic acid to ethanol and to eliminate glycerol formation in anaerobic cultures of yeast [3]. Likewise, recombinant cellulases (endo-1,4-β-glucanase (ENG), exo-1,4-β-glucanase (CBH), and β-glucosidases (BGL)) are expressed as a cell surface displayed or secreted form [8]. In this strategy, the cellulose is hydrolyzed extracellularly and then, the glucose is transported into the cell and metabolized. Another strategy involves heterologous expression of a cellodextrin transporter and an intracellular β-glucosidase [9]. The cellodextrin transporter allows cellobiose to enter the cell, where it is hydrolyzed to glucose by the intracellular BGL and metabolized by the cell. However, the ethanol yield is not high enough when using engineered yeast strains and further engineering is required to improve the cellobiose utilization.

β-Glucosidases play an important part in the cellulose degradation system because they are responsible for the final step of lignocellulose conversion: transformation of cellobiose and cellodextrins into glucose. In addition, because cellobiose and cellodextrins are potent inhibitors of cellulose hydrolysis, a decrease in the cello-oligosaccharide amount increases saccharification rate by enabling cellulolytic enzymes to work more effectively [10, 11]. Nonetheless, the popular ethanologen, yeast S. cerevisiae, cannot utilize cellobiose; accordingly, genetic engineering studies have been conducted to transfer β-glucosidase genes allowing for cellobiose utilization. Heterologous expression of β-glucosidase-encoding genes has been carried out in yeast, including genes from Thermoascus aurantiacus [12]. The β-glucosidase from T. aurantiacus (TaBgl1) expressed in Pichia pastoris has an optimum temperature of 70 °C and is stable at pH 3–8. In addition, TaBgl1 has been reported to hydrolyze not only cellobiose and cello-oligosaccharides but also pNP-xylose, suggesting that the enzyme is bifunctional and appropriate for use in simultaneous saccharification and fermentation [13]. Despite major efforts to create recombinant strains of S. cerevisiae capable of utilizing cellobiose via the expression of heterologous genes encoding β-glucosidase, the ethanol yield and productivity of the resultant yeast strains still need improvement. Rios-Franquez et al. [14] have employed a codon-optimized β-glucosidase from Cellulomonas flavigena to produce ethanol from cellobiose. This S. cerevisiae recombinant strain displayed an ethanol yield reaching 76% of the theoretical value. Wilde et al. [15] have compared the activity of β-glucosidases from 12 filamentous fungi expressed in S. cerevisiae CEN.PK113-13D and found that the β-glucosidase from Aspergillus niger (Anig-Bgl101) had the highest cellobiose activity. Expressing Anig-Bgl101 from a plasmid gave higher ethanol levels (66.7% of the theoretical maximum yield) when the enzyme was secreted into the medium rather than anchored to the cell surface. The recombinant Y294 S. cerevisiae strain expressing an anchored Saccharomycopsis fibuligera Bgl1 enzyme produced a theoretical ethanol yield of 76.5% [16]. In further studies by Tang et al. [17], the three β-glucosidases from different organisms were respectively expressed in S. cerevisiae, and the β-glucosidase from S. fibuligera showed the best activity (5.2 U/mL). The ethanol yield was 0.33 g/g, and the specific cellobiose consumption rate was 2.16 g·(g dry cell weight)−1 h−1 during oxygen-limited cultivation. However, laboratory yeast strains have been employed for most of this research, and such strains may be difficult to use in industrial processes because of their generally weaker resistance to stress factors and worse fermenting abilities [18]. Industrial strains have several more pronounced features that are necessary for the production of ethanol, such as a high rate of fermentation, high propagation rate, high overall robustness, and high resistance to ethanol and high temperature [19,20,21]. Nevertheless, during hydrolysis of biomass, a lignocellulosic material is often degraded to inhibitory compounds, such as 2-furaldehyde (furfural), weak acids, and phenolics. These inhibitors are toxic to microbial metabolism and slow down the fermentation [22, 23]. Several studies have addressed the selection of industrial S. cerevisiae yeast strains tolerant to various pH conditions, resistant to fermentation inhibitors, and able to ferment lignocellulosic sugars [24]. On the other hand, yeast strains have widely varied inhibitor tolerance rates and fermentation profiles. Consequently, for conversion of biomass-derived sugars to ethanol, it is important to select yeast strains with an industrial background and high tolerance to inhibitors. These naturally robust strains could serve as a platform for engineering the recombinant strains with the ability to utilize cellobiose as a carbon source for ethanol production. Nonetheless, the selection of yeast strains resistant to the numerous fermentation inhibitors is not the only concern. It is reported that different S. cerevisiae strains show variation in heterologous protein production [25], growth rates [26], and the ethanol yield [27]. Furthermore, in S. cerevisiae, the effectiveness of secretion of heterologously expressed proteins and their functional activity are often low due to incorrect glycosylation [28]; therefore, evaluation of the degree of glycosylation performed by each strain is also important.

The aim of our work was the comparative analysis of enzyme expression patterns, stress tolerance, and fermentative behaviour among recombinant industrial S. cerevisiae strains harbouring the β-glucosidase gene from T. aurantiacus. The information obtained in this study will be valuable to select strains with an industrial background and high tolerance to stressors as platforms for future yeast engineering experiments directed to ethanol production from lignocellulosic substrates.

Materials and methods

Strains and culture conditions

Escherichia coli JM109 (Promega, Madison, WI) served for plasmid maintenance and construction. E. coli was cultured in a 50-mL Falcon tube containing 20 mL of the Luria–Bertani medium (5 g/L yeast extract, 10 g/L tryptone, 10 g/L NaCl) at 37 °C and 250 rpm, supplemented with 100 μg/mL ampicillin. S. cerevisiae ATCC 24860 was acquired from the American Type Culture Collection (Manassas, USA), whereas YB-2625, Y-1528, and Y-2034 from the ARS Culture Collection at the National Centre for Agricultural Utilization Research (Peoria, IL). Yeast strains were cultivated in 250-mL Erlenmeyer flasks containing 100 mL of the YP medium (1% of yeast extract, 2% of peptone) with 2% of glucose (YPD) or 2% of cellobiose (YPC). YP medium with 2% of cellobiose was used in fermentation analysis and for plate screening.

S. cerevisiae strains were cultivated at 30 °C (orbital shaking, 250 rpm) for aerobic growth or 100 rpm for anaerobic conditions in baffled flasks. All the yeast transformants were subjected to selection on YPD agar containing 100 μg/mL G418 disulphate, while liquid cultures were conducted on a rotary shaker at 250 rpm (30 °C). The growth performance of recombinant strains expressing the tabgl1 gene was measured over a cultivation period of 72 h in YPD under aerobic conditions, and the parent strains with the empty plasmid served as a control. All the strains were stored at − 80 °C in a 15% glycerol–based standard storage medium. The relevant genotypes of all yeast strains used in this study are listed in Table 1.

Construction of recombinant strains that express the β-glucosidase

The С-terminal 1xflag-tagged tabgl1 gene (DQ114397.1, GenBank) was synthesized artificially (GeneCust Europe, Dudelange – Luxembourg) for expression in S. cerevisiae but with the native secretion signal sequences omitted. Recombinant plasmid pBluescript IISK-tabgl1-flag was digested with NotI and EcoRI, and then, the insert was ligated to the EcoRI and NotI sites of the pMETαB vector (Invitrogen) (Table 2 and Fig. S2), which enabled the fusion of the tabgl1-1xflag gene to the secretion signal sequence of an α-mating factor. Next, the α-tabgl1-1xflag gene sequence was cloned into the pHO-KanMX4-pGAPDH-eng1-tGAPDH-HO vector [30] by overlap extension polymerase chain reaction [31] with the chimeric primers PrE1 and PrE2 (5′-ends complementary to the pHO-KanMX4-pGAPDH-eng1-tGAPDH-HO plasmid; 3′-end complementary to α-tabgl1-flag gene sequence; Table 3). Overlap extension PCR was performed with Thermo Scientific Phusion High-Fidelity DNA Polymerase. The original pHO-KanMX4-pGAPDH-eng1-tGAPDH-HO plasmid was destroyed in reactions with DpnI restriction endonuclease, resulting pHO-KanMX4-pGAPDH-α-tabgl1-flag-tGAPDH-HO expression plasmid vector with flanking homology for targeting the construct to the HO endonuclease locus (Table 2). Correctness of construction was verified by restriction digestion and DNA sequencing.

The primers given in Table 3 were designed using the free online Primer 3 0.4.0 software (http://frodo.wi.mit.edu/primer3/). The primers were designed to be 21–54 bp long. Formation of secondary structures and of dimers was examined in the Oligo Analyzer 1.0.3.0 software. The oligonucleotides were purchased from Macrogen (Seoul, Korea).

To construct stably expressing yeast strains, the expression vector pHO-KanMX4-pGAPDH-α-tabgl1-flag-tGAPDH-HO harbouring the gene encoding TaBgl1 was transformed into four industrial strains of S. cerevisiae with a lithium acetate/single-stranded carrier DNA/PEG method of transformation [32]. The strains used in this study are listed in Table 1. Selection of the yeast transformants was performed on a YPD agar medium containing the antibiotic G418. The resulting recombinant yeast strains harbouring the tabgl1 gene were designated as ATCC 24860-TaBgl1, YB-2625-TaBgl1, Y-1528-TaBgl1, and Y-2034-TaBgl1 (Table 1). To confirm correct integration of the pHO-KanMX4-pGAPDH-α-tabgl1-flag-tGAPDH-HO cassettes into the HO loci, positive G418-resistant transformants from each plate were subjected to colony PCR with combinations of the corresponding target primers with homology to the chromosome that flanks the site of integration (Pr1 and Pr2), and primers specific to the tabgl1 gene (Pr3–Pr4; Fig. 1a and Table 3).

PCR analysis to confirm correct integration of the pHO-KanMX4-pGAPDH-α-tabgl1-flag-tGAPDH-HO cassette at the HO loci. a Integrative vector pHO-KanMX4-pGAPDH-α-tabgl1-flag-tGAPDH-HO contains the tabgl1 gene fused to the glyceraldehyde 3-phosphate dehydrogenase (GAPDH) promoter. The expression cassette shown was flanked by homology regions (HO-R and HO-L) of the S. cerevisiae HO endonuclease gene; these homology regions target integration into the HO locus on chromosome IV. b Agarose gel electrophoresis of the PCR products amplified by means of the Pr1–Pr4 primers. Lane M, GeneRuler 1-kb DNA ladder; lane 1, negative control; lane 2, primers Pr3 and Pr4; lane 3, primers Pr1 and Pr4; lane 4, primers Pr2 and Pr3

PCR amplification was performed in a 25-μL volume containing 12.5 μL of PCR Master Mix (2X) (#K0172, Thermo Fisher Scientific, MA, USA), 0.01 μM of each primer, and 2 μL of yeast DNA. The yeast DNAs were prepared by resuspension of a very small amount of a fresh colony in 10 μL of 0.02 N NaOH in a 0.2-mL PCR tube that was heated for 10 min to 95 °C in a PCR machine [33]. The PCR products were examined on 1.0% w/v agarose gels. A typical example of the results of the PCR analysis of the four recombinant ATCC 24860-TaBgl1, YB-2625-TaBgl1, Y-1528-TaBgl1, and Y-2034-TaBgl1 strains is illustrated in Fig. 1b. Existence of gene tabgl1 in the yeast chromosomes was confirmed by amplification of yeast DNA with gene-specific primers Pr3 and Pr4 (Fig. 1b; lane 2). The PCR products obtained from the various recombinant yeast strains by means of primers Pr1 and Pr4 were ~ 4000 bp in length (Fig. 1b; lane 3). Finally, amplification with primers Pr2 and Pr3 also gave rise to a DNA fragment ~ 6000 bp long for all the recombinant yeast strains tested (Fig. 1b; lane 4); thus, this size matched the calculated cassette-specific sizes predicted for correct integration. Negative control was obtained by the PCR amplification (primers Pr3 and Pr4) of a colony taken from the transformation of the pHO-KanMX4-pGAPDH-eng1-tGAPDH-HO vector (Fig. 1b; lane 1).

Aerobic growth determination

Growth assays were conducted by inoculation of strains in triplicate. Overnight cultures were aerobically pre-cultivated for 24 h in 100-mL Erlenmeyer flasks containing 20 mL of the YPD medium at 30 °C, harvested by centrifugation at 1000×g for 5 min (centrifuge model 5804 R; Eppendorf, Hamburg, Germany), and then washed twice with distilled water. The cells were then resuspended to an initial cell concentration of OD600 0.2 in 100 mL of the YP medium supplemented with 20 g/L cellobiose or glucose in 250-mL Erlenmeyer flasks. These flasks were incubated on rotary shakers (250 rpm) at 30 °C for the duration of the analysis. Samples (200 μL) were diluted (1:10), after which absorbance (A600) readings were taken on a spectrophotometer (spectrophotometer model PD-303UV; Apel, Japan).

Quantification of β-glucosidase activity

β-Glucosidase activity was assayed using the substrate p-nitrophenyl-β-d-glucopyranoside (pNPG) [34]. Cells were centrifuged at 10000×g for 4 min at 10 °C, and 10 μL of the supernatant was incubated with 90 μL of sodium acetate buffer (100 mM, pH 5.0) with 8 mM pNPG at 70 °C for 20 min. After the addition of 2 mL of 10% Na2CO3 to stop the reaction, quantification of the product, p-nitrophenol, was performed on a spectrophotometer (spectrophotometer model PD-303UV; Apel, Japan) at 420 nm using a standard curve for p-nitrophenol as the reference. One unit of the enzymatic activity was defined as the amount of enzyme required to produce 1.0 μmol of p-nitrophenol per millilitre per minute under the assay conditions. Protein concentration was determined by the method of Bradford [35], with bovine serum albumin serving as the standard.

Optimum pH was determined by measuring the β-glucosidase enzymatic activity over a pH range of 3.0 to 8.0 at 70 °C, using 100 mM sodium citrate/NaOH buffer for the pH range 3.0 to 5.0 and sodium phosphate buffer for pH 6.0 to 8.0. The optimum temperature for β-glucosidase was determined over a temperature range of 30 to 80 °C in 100 mM sodium acetate buffer at optimum pH. For evaluation of pH stability, the enzyme was stored for 2 h at 4 °C diluted 5-fold with 100 mM sodium citrate/NaOH buffer for the pH range pH 3.0 to 5.0 and with sodium phosphate buffer for pH 6.0 to 8.0. The remaining activity was measured under standard conditions at optimum pH and temperature. Thermal stability was investigated by incubating the enzyme without a substrate for 4 h, over a temperature range of 30 to 80 °C. After that, aliquots were assayed for residual activities at optimum pH and temperature. The assays were conducted in triplicate.

Deglycosylation of TaBgl1

The TaBgl1 enzymes were deglycosylated using Endoglycosidase H (#P0702L; New England Biolabs, Inc., Ipswich, MA, USA). Deglycosylation reactions were performed as follows: 2 μL of denaturing buffer was added to an 18-μL sample containing approximately 40 μg of precipitated protein and boiled for 10 min. Four microliters of reaction buffer and 1 μL of Endo H (500 U) were added. The reaction mix was incubated at 37 °C for 20 h and stopped by heat inactivation at 75 °C for 10 min.

Protein precipitation from the culture and western blotting

S. cerevisiae transformants were grown at 30 °C with agitation at 250 rpm in 250-mL Erlenmeyer flasks containing 100 mL of the YP medium supplemented with either 2% of cellobiose or 2% of glucose. After 72 h, these cultures were centrifuged for 5 min at 3000×g (centrifuge model 5804 R; Eppendorf, Hamburg, Germany) to separate the culture media from the cell pellet. The culture supernatants were passed through 0.22-μm polyvinylidene difluoride syringe filters (Merck Millipore, MA, USA); then, proteins were precipitated with 20% (w/v) trichloroacetic acid (TCA; final concentration) [36]. One volume of 100% TCA (10 mL) was mixed with four volumes of a yeast culture sample (40 mL) and inverted four times to mix, then vortexed and kept on ice for 1 h overnight and centrifuged at 21000×g for 30 min at 4 °C, and the supernatants were removed. Next, 0.5 mL of ice-cold acetone was added, and the mixture was centrifuged at 21000×g for 15 min at 4 °C (centrifuge model 5910 R; Eppendorf, Hamburg, Germany). The supernatant was discarded, and the pellet was air-dried at room temperature. Finally, the pellet was resuspended in 50 μL of RIPA buffer (1% of Triton X-100, 1 mM EDTA, 1 mM EGTA pH 8.0, 0.2 mM Na3VO4, 10 mM Tris pH 7.4, 150 mM NaCl, and 1 tablet of a Roche protease inhibitor cocktail). The protein concentration was determined with the Coomassie Protein Assay kit (Pierce, USA) and bovine serum albumin as a standard [33]. Absorbance at 595 nm was measured by means of a NanoDrop 2000c spectrophotometer (Thermo Scientific, Waltham, MA, USA). Each measurement was done in triplicate.

The presence of TaBgl1 in the culture supernatants of the transformants was verified by sodium dodecyl sulphate polyacrylamide gel electrophoresis (SDS-PAGE). Western blot analysis of total secreted protein at 72 h was conducted using an anti-FLAG monoclonal antibody (Thermo Fisher) as the primary antibody to detect TaBgl1 and a horseradish peroxidase–conjugated goat anti-rabbit IgG antibody, as a secondary antibody [37]. Precipitated proteins (~ 12 μg of protein) were separated by SDS–polyacrylamide gel electrophoresis in a 10% gel and next electroblotted to a polyvinyl difluoride membrane (Pierce, USA) in a Bio-Rad Mini-Trans-Blot Cell. After the protein transfer, the membrane was gently shaken in a blocking solution consisting of 5% milk and 0.1% Tween 20 in 1× TBS (Tris-buffered saline: 50 mM Tris-HCl pH 7.5, 20 mM NaCl) for 1 h at room temperature. After removal of the blocking solution, this membrane was then incubated in 10 mL of the affinity-purified anti-FLAG antibody (1:1000 dilution in the blocking solution with 0.1% Tween 20) at 4 °C overnight. The membrane was washed five times in 10 mL of wash buffer (1× TBS with 0.1% Tween 20), for 5 min each. After that, the membrane was incubated in 10 mL of the secondary antibody (1:5000 dilution in the blocking solution with 0.1% Tween 20) at room temperature for 1 h. Then, the membrane was washed five times in 10 mL of wash buffer, 5 min each time. The working substrate solution was prepared by mixing an equal volume of a peroxide solution and luminal/enhancer solution and was applied at 0.1 mL/(cm2 blot area). The membrane was then incubated with the working solution in the dark for 2 min, and Kodak X-Omat was exposed to the membrane.

Fermentative generation of ethyl alcohol from cellobiose

To evaluate the fermentation performance with cellobiose, the engineered and parent strains were aerobically pre-cultured for 24 h in 100-mL Erlenmeyer flasks containing 20 mL of YPD medium at 30 °C, harvested by centrifugation at 1000×g for 5 min, and next washed with distilled water twice. The cells were then resuspended to an initial cell concentration corresponding to OD600 0.2 in 20 mL YP medium supplemented with cellobiose at 20 g/L. Ethanol-producing fermentation proceeded at 30 °C for 72 h with mild agitation in 100-mL closed bottles, each with a check valve and siliconized tube (Sanplatec; Osaka, Japan) serving as a CO2 outlet. Fermentation analyses were conducted in triplicate. Cellobiose concentrations were determined by means of a high-performance liquid chromatography (HPLC) system (Sykam, Germany) on a Bio-Rad Aminex HPX-87P column (300 × 7.8 mm). The column temperature was maintained at 85 °C by a S4011 Column Thermo Controller, Sykam. Culture broth was subjected to 10-min centrifugation at 14000×g (centrifuge model 5910 R; Eppendorf, Hamburg, Germany), and the resulting supernatant was passed through a 0.22-μm syringe filter prior to separation on the column. The bound material was eluted with water as a mobile phase (flow rate 0.6 mL/min), and the eluate was monitored using a refractive index detector (Sykam, S3580). Ethanol concentration in the culture supernatant of the broth was determined with an ethanol assay kit (#K-ETOH, Megazyme, Wicklow, Ireland). The procedure outlined by the manufacturer for the Megazyme ethanol assay kit was strictly followed. Ethanol concentration was directly calculated following the specific Megazyme equation based on the measured absorbance values; no additional standard curve or equation was generated for this study.

Stress tolerance assays

The performance (on growth) of the recombinant strains of S. cerevisiae (ATCC 24860-TaBgl1, YB-2625-TaBgl1, Y-1528-TaBgl1, and Y-2034-TaBgl1) under typical stress (acetic acid, furfural, or ethanol or hyper-osmotic stress, oxidative stress, or high temperature) was characterized by a spot dilution growth assay. Cells from overnight culture in the liquid YPD medium were harvested and washed two times with sterile water. The concentration of resuspended cells was normalized to OD600 (optical density at 600 nm) of 1.0. A serial 10-fold dilution of the suspension (100, 10−1, 10−2, and 10−3) was prepared, and 50 μL of each diluted suspension was then spotted on the appropriate solid medium. To evaluate the oxidative stress resistance of the strains, cells of S. cerevisiae were rinsed with 100 μL of sterile water and resuspended. The cell concentration was adjusted to OD600 of 2.0, and these cells were mixed with 20 mL of YPD agar (pre-cooled to ~ 50 °C) and poured immediately into a plate. Then, a filter paper (sterile, 20 mm in diameter) with 40 μL of 30% H2O2 was put in the centre of a plate. The oxidative stress resistance of each strain was characterized by means of the diameter of the growth inhibition zone (mm) after culturing for 2 days at 30 °C. Smaller inhibition zones were interpreted as greater resistance to oxidative stress [38].

To quantitate the growth of yeast strains under stress conditions, the cells were grown in YPD to an OD600 of 0.2. At this point, different stressors were applied. Ethanol stress was imposed by adding ethanol to a final concentration of 10% (v/v). Heat shock was implemented by incubating cultures at 40 °C. Osmotic and inhibitor stressors were imposed by cultivation of cells on YPD containing 1.0 M KCl, 1 g/L furfural, or 5.0 g/L acetic acid, respectively. Distilled water served as the reference. This experiment was conducted under aerobic conditions in 50-mL sterile centrifuge tubes. The tubes were incubated in an orbital incubator at 120 rpm and 30 °C. The maximum specific growth rates were calculated via linear regression of natural logarithmic OD values from the exponential phase of the growth curves. The time of lag phase was defined as the time point where OD was 1.5 times the starting OD [18]. At least 10 consecutive data points were used to determine the specific growth rate μ (h−1), in the exponential growth phase. The results presented are average values from at least three independent cultures, and the average SDs for specific growth rate and lag phase determinations were 7% and 10%, respectively.

Results

A comparison of growth rates among the transformants and measurement enzymatic activity

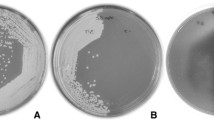

To test the ability of recombinant yeast strains to sustain growth on cellobiose, the strains were streaked onto the YP agar medium containing 2% cellobiose as sole carbon source and incubated at 30 °C for 72 h (Fig. 2). All recombinant strains grew well on cellobiose, suggesting that TaBgl1 was expressed in an active form. Figure 3 illustrates the growth curves of the recombinant yeast strains expressing the tabgl1 gene on glucose and cellobiose under aerobic conditions. The recombinant strains manifested similar growth characteristics during 2% w/w glucose fermentation, as compared with the parent strains (data not shown), indicating that the constitutive expression of the integrated tabgl1 gene had no deleterious effect on the growth capability of the yeast strains tested (Fig. 3a). The ability of the recombinant strains to utilize cellobiose as a carbon and energy source was confirmed by culturing them on the YP medium with 20 g/L cellobiose. None of the parent strains was able to grow on the medium with cellobiose (data not shown). All these recombinant strains were found to aerobically grow on cellobiose, indicating that the integrated tabgl1 gene was functionally expressed (Fig. 3c). The growth data suggested that recombinant yeast strains in 2% cellobiose reached higher OD, in the range of OD600 9.80–10.71, as compared with recombinant yeast strains cultivated in 2% glucose, which yielded a range of OD600 6.21–6.89. When grown at 20 g/L glucose, all recombinant strains reached the stationary phase in 12 h, whereas at 20 g/L cellobiose, they showed slower growth during the first 12 h and reached the stationary phase by hour 46. Of note, at the same time, OD was approximately 1.6-fold higher than the OD in the medium with glucose after 48 h of cultivation.

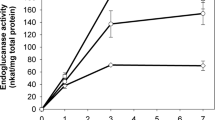

Growth curves of the recombinant yeast strains expressing the tabgl1 gene on glucose (a) and cellobiose (c). Extracellular β-glucosidase activity on glucose (b) and cellobiose (d). Mean values from triplicate experiments are shown, and error bars indicate the standard deviation from the mean (circle, ATCC 24860-TaBgl1 (green); square, YB-2625-TaBgl1 (blue); triangle, Y-1528-TaBgl1 (orange); hexagon, Y-2034-TaBgl1 (violet))

It was interesting whether these differences in yeast cell growth were the result of increased secretion of TaBgl1 by the recombinant strains in the media containing cellobiose. To test this supposition, enzymatic activity was analyzed in a culture medium at different time points ranging from 0 to 12, 24, 48, and 72 h, with 2% glucose or 2% cellobiose as the sole source of carbon (Fig. 3b, d). Despite the low activity of TaBgl1, during the first 12 h, yeast strains Y-2034-TaBgl1 and Y-1528-TaBgl1 in subsequent cultivation periods generated a significantly higher activity of secreted β-glucosidase in a cellobiose-containing medium. Secreted enzyme activity of these two strains was approximately 1.5-fold higher after 72 h of growth on cellobiose in comparison with glucose-fed cells in the same culture period. YB-2625-TaBgl1 strain afforded a low β-glucosidase activity in the YP medium supernatant in the presence of either glucose or cellobiose, whereas ATCC 24860-TaBgl1 strain showed a high activity only in the medium with glucose. It should be noted that YB-2625-TaBgl1 and ATCC 24860-TaBgl1 strains, despite the low level of activity of the secreted TaBgl1, reached approximately the same OD as did the two other strains with a high secretory activity in a YP medium with cellobiose, assuming that this level of enzymatic activity was enough to support rapid growth on cellobiose. No activity was detected in the parental yeast strains harbouring the empty vector (data not shown). Thus, although all the strains grew to almost the same ODs, the extracellular TaBgl1 activity did not correlate with the OD values, despite the same regulatory sequence (GAPDH promoter and terminator), and the same vector backbone (HO) was employed.

Analysis glycosylation features of TaBgl1 synthesized by various recombinant Saccharomyces strains

To investigate potential post-translational modifications of TaBgl1 that could explain the observed enzymatic activity differences, the secreted proteins were precipitated (see “Materials and methods”) from culture supernatants of cells grown with either glucose or cellobiose at 72 h; then, the TaBgl1 protein was analyzed by SDS-PAGE. In all cases, protein bands migrated as a poorly stained, dispersed band, as is characteristic of hyper-glycosylated proteins (data not shown). Western blot analyses with the anti-FLAG antibody confirmed that TaBgl1 was present in the culture supernatant of all the yeast strains under study after 72 h of growth on cellobiose. Nevertheless, the molecular weight of the TaBgl1 secreted by the yeast strains was much higher (above 130 kDa) than the calculated molecular weight of the enzyme (93.6 kDa). After removal of N-linked glycosylation by Endo H treatment, the TaBgl1 band shifted from 130 to 110 kDa. These data suggested that TaBgl1 expressed in yeast strains is hyper-N-glycosylated (Fig. 4a). In contrast, the glycosylation patterns of TaBgl1 in cells grown in the medium with glucose differed significantly among recombinant yeast strains. ATCC 24860-TaBgl1 and YB-2625-TaBgl1 strains yielded a diffuse hyper-glycosylated band, whereas Y-1528-TaBgl1 and Y-2034-TaBgl1 strains gave a protein band very similar to the TaBgl1 (above 130 kDa) expressed in a cellobiose-containing medium. Endo H–treated TaBgl1 from either case showed no difference in size of the protein (Fig. 4a, b), indicating that the difference was caused by the number of mannose residues. These results clearly indicated that the extent of glycosylation of secreted TaBgl1 was greatly influenced not only by the different origin of yeast strains but also by cell growth conditions.

To investigate the correlation between different degrees of glycosylation and enzymatic properties, we compared biochemical properties of β-glucosidase from culture supernatants of cells grown with either glucose or cellobiose at 72 h. The optimal temperature for the enzymatic activity was ~ 70 °C, and the optimal pH was ~ 5.0 (Fig. 5). Thermophilic fungi T. aurantiacus are known to produce thermostable cellulases, including β-glucosidase [13, 39]; therefore, the effect of temperature on TaBgl1 stability was measured at various temperatures ranging from 30 to 80 °C (Fig. 5). Thermal stability analysis revealed that the enzyme was stable in temperature range of 30 to 50 °C and retained more than 40% activity at 60 °C for 4 h. However, the recombinant enzymes from cellobiose-fed cells had a moderately higher stability under the temperature range between 40 and 60 °C, as compared with the enzymes from glucose-fed cells (Fig. 5b). Regardless of the yeast growth conditions (glucose or cellobiose), the TaBgl1 was quite stable over a broad pH range of 4.0–8.0; retained from 70 to 99% of original activity against pNPG but below pH 4.0, the activity was relatively lower. Among all the yeast strains tested, the relative activity of TaBgl1 from Y-2034-TaBgl1 and Y-1528-TaBgl1 yeast strains was retained relatively higher at both acid and alkaline pH conditions as compared with those from other strains.

Effect of temperature (a, b) and pH (c, d) on the activity of recombinant TaBgl1. Stability of enzyme is indicated by a dashed line (circle, ATCC 24860-TaBgl1 (green); square, YB-2625-TaBgl1 (blue); triangle, Y-1528-TaBgl1 (orange); hexagon, Y-2034-TaBgl1 (violet)) and optimum by a solid line (circle, ATCC 24860-TaBgl1 (green); square, YB-2625-TaBgl1 (blue); triangle, Y-1528-TaBgl1 (orange), hexagon, Y-2034-TaBgl1 (violet)). Activity is expressed as a percentage of the highest value. Activity assays were performed in triplicate with the error bars representing the standard deviation

Characterization of recombinant strains in anaerobic cellobiose culture

The characteristics of the strains expressing TaBgl1 and the parental strains were investigated under anaerobic growth conditions with cellobiose as the sole carbon source. Similar to what was found in the aerobic growth experiments, parental strains could not grow on cellobiose (data not shown). All four recombinant strains were able to grow and produce ethanol from cellobiose as the sole carbon source (Fig. 6c). YB-2625-TaBgl1, Y-1528-TaBgl1, and Y-2034-TaBgl1 yeast strains showed faster growth, as indicated by the maximum specific growth rates (Table 4), to eventually reach similar ODs in the stationary phase (Fig. 6a). These three strains consumed 90% cellobiose within 48 h. By contrast, upon further incubation, the remaining 0.2% cellobiose (at the concentration of 2 g/L) was not consumed (Fig. 6b). ATCC 24860-TaBgl1 strain, despite growing much more slowly on cellobiose (μmax of 0.039 h−1), had a cellobiose consumption rate and OD that were essentially the same as those of the other three recombinant strains. The maximum ethanol production for each of these strains coincided with the level of consumption of the substrate (Fig. 6b, c). Ethanol yields are given in Table 4. All the strains grown on cellobiose had similar ethanol yields of ~ 0.40 and 0.43, which correspond to 75.6% and 79.9% of the theoretical ethanol yield (0.538 [g ethanol]/[g sugar consumed]).

Changes in measured parameters of diverse recombinant S. cerevisiae strains during anaerobic batch growth on 20 g/L cellobiose as carbon and energy sources. a OD600, optical density at 600 nm. b Cellobiose consumption. c Ethanol concentration versus time. Wild types are indicated by a dashed line (circle, ATCC 24860-WT (green); square, YB-2625-WT (blue); triangle, Y-1528-WT (orange); hexagon, Y-2034-WT (violet)) and recombinant strains by a solid line (circle, ATCC 24860-TaBgl1 (green); square, YB-2625-TaBgl1 (blue); triangle, Y-1528-TaBgl1 (orange); hexagon, Y-2034-TaBgl1 (violet))

Evaluation of the tolerance of recombinant S. cerevisiae strains to individual stressors

To assay phenotypic differentiation of tolerance capabilities among the recombinant S. cerevisiae strains, their viability was studied under six industrially relevant stress conditions, including high temperatures, high concentration of ethanol, and different concentrations of KCl, acetic acid, furfural, and H2O2. Figure 7a shows that all the strains grew well at temperatures of 30 °C and 37 °C and stopped growing at 42 °C, although only weak growth of the YB-2625-TaBgl1 strain was observed. The hypertonic stress tolerance of all the strains was higher because they grew on plates with 1.0 mol/L KCl (Fig. 7b). YB-2625-TaBgl1 and Y-2034-TaBgl1 strains clearly grew better at 5 g/L acetic acid (Fig. 7c) and showed greater tolerance to ethanol, growing well at 16% ethanol (Fig. 7e). Tolerance to furfural was slightly higher in ATCC 24860-TaBgl1 and Y-2034-TaBgl1 strains than in other strains on plates with 1.0 g/L furfural (Fig. 7d). With regard to resistance to H2O2, all the strains showed good resistance to this oxidant, except for the ATCC 24860-TaBgl1 strain. In contrast to the others, the latter strain was less stable, and its halo diameter was 55 mm, while for the other three strains, the halo diameter was 46.6 mm on average (Fig. 7f).

Although the data obtained by spot plate analysis revealed certain differences among the yeast strains studied, this technique does not provide an accurate indication of growth dynamics, including the lag phase and specific growth rates.

To quantify the growth of these strains under stress conditions, each strain was cultivated in a rich YPD medium with glucose (20 g/L) as well as 10% (v/v) of ethanol, 1 M KCl, 1 g/L furfural, or 5 g/L acetic acid. Haploid laboratory S. cerevisiae strain FF18733 (MATa his7 leu2 lys1 ura3 trpΔ) [29] was used for comparison. Given that most strains did not grow on spot plates at 42 °C, the measurements of growth dynamics were performed at 40 °C. Biomass accumulation levels were determined at 48 h, when maximum cell density for all strains was obtained in the absence of stress factors.

In the absence of stressors, there were only small differences in biomass accumulation levels, specific growth rates, and duration of the lag phase among the strains tested (Fig. 8). OD and the specific growth rate of the slowest growing strain were more than 80% of the value obtained for the strain with the highest growth rate, thus rendering all data statistically similar. In those experiments, the duration of the lag phase was 2–3 h during the growth in the YPD medium. As expected, the growth of strains was directly affected by the indicated concentrations of acetic acid, furfural, and ethanol and by the temperature at 40 °C (Fig. 8b, c). When exposed to 10 mM furfural and 5 g/L acetic acid, all yeast strains showed relative growth values ranging from 61 to 95% of the culture growth achieved in the medium without these stressors. A large reduction in YB-2625-TaBgl1 biomass accumulation was observed in the presence furfural. There was a decrease in the growth rate (12–34%) and an approximately twofold increase in time for the lag phase in the presence furfural, but the response was approximately similar to the one under growth conditions in the absence of this compound for all strains. In the case of acetic acid, ATCC 24860-TaBgl1 and Y-1528-TaBgl1 were the most affected strains (22% and 15%; Fig. 8a), confirming the results obtained in spot plate analysis. ATCC 24860-TaBgl1 had the lowest growth rate and one of the longest lag phases (Fig. 8b, c). The influence of 1 M KCl on the growth of recombinant yeast strains was similar to that of furfural. Only in the presence of KCl, did the final OD strongly diminish for ATCC 24860-TaBgl1 as compared with furfural. The presence of 10% ethanol reduced the final OD slightly but led to a large decrease in the growth rate: by 36 to 57%. In this environment, the lag phase was drastically prolonged for ATCC 24860-TaBgl1 and Y-2034-TaBgl1. In contrast to the above stressors, the inhibitory effect of higher temperature (40 °C) lowered the growth rate and final OD of all yeast strains, as shown in Fig. 8a, b. At 40 °C, the growth rate decreased by more than 50% as compared with the reference medium, without any stressors, and the final OD dropped from 6.0 to 3.44. Of note, in contrast to the aforementioned inhibitory compounds, at the higher temperature, a very slight increase in time for the lag phase was observed for all yeast strains. Apparently, this finding indicates that the inhibitory mechanisms of high temperature and of other stress factors tested in this work are different. Laboratory yeast strains FF18733 was one of the most sensitive strains to the stress conditions when compared with industrial yeast strains analyzed in this study. However, laboratory strain was one of the most resistant strains to the osmotic stress (Fig. 8a–c).

Thus, the results indicated that all recombinant yeast strains were able to grow in the presence stress factors, supporting the previous data obtained by spot plate analysis at the indicated concentrations of stressors (Fig. 7). Three of the four strains tested—Y-1528-TaBgl1, Y-2625-TaBgl1, and Y-2034-TaBgl1—manifested high tolerance towards furfural, acetic acid, temperature, higher concentrations of KCl, and ethanol. This finding could be due to the robustness resulting from their origins of isolation. They will be selected for further strain improvement regarding fermentation of a lignocellulosic biomass hydrolysate. ATCC 24860-TaBgl1 was the least stress-tolerant strain.

Discussion

In this study, the functional expression of the tabgl1 gene encoding β-glucosidase from T. aurantiacus in four industrial strains of S. cerevisiae was investigated. The chosen industrial strains of S. cerevisiae have been isolated from distillery operations; otherwise, these strains have been recommended for lignocellulosic fermentation procedures (Table 1) [19, 40]. In particular, the Y-1528 yeast strain has previously been recommended for fermentation of softwood hydrolysates owing to the rare ability, among yeasts, to co-ferment glucose and galactose [41]. It has been shown that the Y-2034 yeast strain can ferment different sugars commonly present in various raw materials of food waste and ethanol fermentation [42, 43]. The other important factor for the selection of a potential host strain is the presence of an active and efficient pentose phosphate pathway linking the introduced xylose-to-xylulose pathway to glycolysis. S. cerevisiae ATCC 24860 and YB-2625 are supposed to the most efficient xylulose fermenters [44, 45]. It is noteworthy that the YB-2625 natural yeast (isolated from bagasse) features enhanced expression of endogenous genes for xylose metabolism [45]. Furthermore, previously, on the basis of three industrial strains (Y-1528, Y-2034, and YB-2625), recombinant strains have been designed to ferment xylose via stable integration of xylitol dehydrogenase, xylose reductase, and xylulokinase genes and subsequently have been reported as strains holding promise for efficient and cost-effective ethanol production [19]. In the present study, tabgl1 was introduced into the HO locus of four industrial strains of S. cerevisiae to enable the stable expression of this gene under non-selective conditions. The HO endonuclease is not expressed in yeast with high ploidy and is active only in haploid organisms. Deletion of gene HO does not affect the growth rate and viability of yeast [46].

The cDNA of TaBgl1 has been cloned and characterized elsewhere [13]. Previously, recombinant laboratory S. cerevisiae Y294 strain expressing β-glucosidases from Phanerochaete chrysosporium (PcbglB and Pccbgl1) and T. aurantiacus (TaBgl1) under the control of yeast ENO1 promoter was constructed by Njokweni et al. [47]. The S. cerevisiae Y294[Pccbgl1] strain performed best under aerobic and anaerobic conditions, producing 2.6-fold more β-glucosidase activity than S. cerevisiae Y294[SFI] did and an ethanol concentration of 4.8 g/L after 24 h of cultivation on cellobiose as the sole carbohydrate source. However, the recombinant TaBgl1 enzyme activity level in the Y294[Tabgl1] strain was too low to support the growth on cellobiose. In our study, the tabgl1 gene was successfully expressed in industrial ethanol-producing yeast strains. The discrepancy between our results and those of Njokweni et al. [47] may be due to differences between strains and/or promoters used.

The secreted β-glucosidase activity achieved with the Y-1528-TaBgl1 strain (1.2 U/mL) was almost twice as high as that obtained for recombinant S. cerevisiae CICIM Y0086 strains containing at least four copies of the S. fibuligera bgl1 gene [48]. This strain produced a 0.45-U/mL extracellular β-glucosidase activity when grown on cellobiose. Three recombinant S. cerevisiae strains expressing intracellular, secreted, and cell-associated β-glucosidases have been constructed by Guo et al. [49]. Recombinant strains expressing the secreted enzyme were grown on cellobiose and produced a 0.126-U/mg extracellular β-glucosidase activity. Gurgu et al. [50] have reported that S. fibuligera bgl1 gene expression driven by the actin promoter is between 1.6- and 18-fold higher than that obtained with the galactose-inducible promoter. In that study, Saccharomyces strains carrying the actin promoter produced between 0.03- and 0.25-U/mL extracellular BGL activities. These activities are 40- and 4.8-fold lower than the activities achieved by the Y-1528-TaBgl1 strain in our work.

Here, we report for the first time successful expression and secretion of heterologous β-glucosidase from T. aurantiacus in industrial S. cerevisiae strains. Of note, although the same cassette was introduced into all yeast strains and the growth rates of the four industrial strains were approximately identical, the TaBgl1 activity curves differed considerably among the strains (Fig. 3). The maximal extracellular activities of TaBgl1 were attained after 72 h in all four industrial strains in the course of cultivation with either cellobiose or glucose. The activity of heterologous enzymes in descending order was Y-1528-TaBgl1 ≈ Y-2034-TaBgl1 > ATCC 24860-TaBgl1 > YB-2625-TaBgl1 when 20 g/L glucose served as the sole carbon source (Fig. 3b). When cellobiose was used as the sole carbon source, the greatest activity of the heterologous enzyme, as in the case of glucose, was generated by Y-1528-TaBgl1 and Y-2034-TaBgl1 strains.

These differences in the extracellular activity of TaBgl1 in different yeast strains might arise from divergence in cell growth conditions combined with dissimilarity of endogenous factors involved in post-translational events, including protein glycosylation. The correct glycosylation pattern is particularly important with regard to heterologously expressed proteins [51]. Altered glycosylation may affect the stability and half-life of the protein and can change its activity or affinity towards some substrates.

In silico analyses of TaBgl1 amino acid sequences on the NetNGlyC 1.0 server (http://www.cbs.dtu .dk/services/NetNGlyc/) revealed the presence of eight putative N-glycosylation sites on TaBgl1 (Table S1). Deglycosylation of TaBgl1 via Endo H digestion, with subsequent western blot analyses with an anti-FLAG antibody, confirmed that TaBgl1—present in the supernatant after 72 h of growth of all yeast strains—was in a highly glycosylated form. TaBgl1 expressed in ATCC 24860-TaBgl1 and YB-2625-TaBgl1 yeast strains on a glucose-containing medium manifested itself as a broad diffuse band with an apparent molecular weight from 130 to 380 kDa. Nevertheless, the growth of these same yeast strains on a medium with cellobiose significantly reduced the degree of glycosylation of the enzyme (up to 130 kDa). In contrast, Y-1528-TaBgl1 and Y-2034-TaBgl1 strains in both cases yielded a protein band with the same molecular weight (130 kDa), suggesting that these yeast strains may have a unique regulatory pathway responsible for the stable extent of glycosylation regardless of cell growth conditions. In addition, it is important to note that in Y-1528-TaBgl1 and Y-2034-TaBgl1 strains, TaBgl1 seems not to be over-glycosylated because the apparent molecular size of the protein is not larger than that of the native purified enzyme [15]. Endo H–treated TaBgl1 from all yeast strains grown on cellobiose or glucose revealed no differences in size (Fig. 4a, b), indicating that the difference is caused by the number of mannose residues.

Because it has been reported that N-glycosylation renders proteins more thermostable [52, 53], we also investigated the thermostability of these enzymes. The recombinant TaBgl1 showed a maximum activity at 70 °C and pH 5.0. It displayed high thermostability and broad pH stability. The optimum pH and temperatures of TaBgl1 from all tested yeast strains were similar regardless of the yeast growth conditions (glucose or cellobiose).

It is known that the optimum temperature for cellulase enzymes is about 50–60 °C [8], while the optimum growth and fermentation temperature of S. cerevisiae is generally about 30 °C. Therefore, enzymatic hydrolysis remains a major barrier to low-cost production of ethanol. However, the high stability of TaBgl1 under prolonged incubation period at high temperatures makes the enzyme suitable for use in the saccharification procedure with less pre-cooling, thus reducing the risk of contamination and processing time and enhancing fermentation qualities and yield [54]. It is interesting to note that Y-2034-TaBgl1 and Y-1528-TaBgl1 strains outperformed the other yeast strains with regard to thermal and pH stability of TaBgl1. However, TaBgl1 produced in cellobiose-containing media had a higher thermostability, suggesting that proper glycosylation can also be a strong influencing factor.

Altogether, these results clearly indicate that the extent of glycosylation of secreted TaBgl1 depends on the origin of yeast strains and to our surprise, was greatly influenced by cellobiose. This phenomenon seemed to be quite an unusual case of protein glycosylation in that the extent of protein glycosylation is regulated by a culture medium component. Nevertheless, it is known that some cultivation parameters can influence the structure and extent of protein glycosylation [55]. The effect on glycosylation of cultivation parameters such as pH, perfusion rate, and temperature has been investigated for mammalian cells [56, 57]. Glucose limitation has also been observed to lead to decreased γ-interferon glycosylation in CHO cultures [56]. However, to our knowledge, culture-medium component-dependent variations in the glycosylation of recombinant glycoproteins produced in S. cerevisiae have not been reported, although recombinant protein glycosylation changes have been observed in other yeast cells. For example, in methylotrophic yeast Hansenula polymorpha, short-glycosylated forms of heterologous expressed glucose oxidase were found at carbon source starvation state [58]. It was shown that the proteins expressed under actively growing conditions are produced as hyper-glycosylated forms, whereas those under slow or non-growing conditions are as short-glycosylated forms. The specific mechanism for the growth state dependence of glycosylation remains unclear. Studies in S. cerevisiae have shown that carbon starvation results to time-dependent decrease in the expression of early N-glycosylation genes [59].

It should be noted that although cellobiose theoretically provides the same energy and carbon availability to cells as glucose, but it releases glucose only after extracellular hydrolysis by β-glucosidase, accordingly in recombinant S. cerevisiae, the cellobiose consumption is inferior to consumption of glucose in terms of rate and may result to slow cell growth (Fig. 3). Furthermore, a recent study revealed that the plasma membrane ATPase (PMA1) of cellobiose-fermenting S. cerevisiae is in a carbon starvation–like state [60]. Although we unable to exactly pinpoint the cause of the reduced TaBgl1 glycosylation in cellobiose-containing medium, we propose that carbon starvation–like state may be at least in part responsible for that. Further studies are required to elucidate the mechanisms of cellobiose effect on the extent of protein glycosylation.

Growth on a non-native substrate such as cellobiose is a complicated phenomenon that involves β-glucosidase expression, enzymatic action of the corresponding gene product on cellobiose, and subsequent utilization of the resulting glucose by the yeast strains for production of ethanol. In general, it appears that the rate of growth on cellobiose is associated with the magnitude of heterologous expression of the enzyme. However, in our study, a correlation was not detected between the level of tabgl1 gene expression and the rate of cellobiose consumption and ethanol production. In our fermentation tests, all the recombinant yeast strains grew on cellobiose and consumed all available sugar. Recombinant Y-1528-TaBgl1 and Y-2034-TaBgl1 strains expressing TaBgl1 produced ethanol on average with a yield of 77.6% of the theoretical maximum (Table 4). In contrast, ATCC 24860-TaBgl1 and YB-2625-TaBgl1 strains with much less β-glucosidase activity showed relatively similar performance on fermentation of cellobiose, assuming that this level of enzymatic activity is enough to support rapid growth on cellobiose. This finding may indicate that once the synthesis of β-glucosidase exceeds a certain threshold, the transformation of cellobiose into glucose is no longer a rate-limiting step in the fermentation process.

Successful implementation of lignocellulosic ethanol production depends not only on survival and performance of yeast cells under common stress conditions such as ethanol toxicity, osmotic pressure, and high temperature, but also on the ability to tolerate various stressors and growth inhibitory compounds such as furfural, acetic acid, and phenolics. During second-generation ethanol fermentation procedures, yeasts are exposed to inhibitory compounds released by the thermochemical pre-treatment of a lignocellulosic material. In this pre-treatment material, weak acids and furan derivatives are generally recognized as major toxicants. The furan compounds 5-hydroxymethyl-2-furaldehyde (HMF) and furfural are formed by dehydration of hexoses and pentoses, respectively. By contrast, acetic acid is formed by de-acetylation of hemicelluloses [24]. The level of furans and acetic acid varies according to the type of raw material and the pre-treatment procedure. For example, representative amounts of acetic acid in lignocellulosic hydrolysates can vary from 1.6 to 4.4 g/L. HMF concentrations can reach 0.6 g/L in corn stover and 5.9 g/L in spruce hydrolysates. Furfural is usually found in smaller amounts than HMF, but often furfural is still at a high enough concentration (~ 1 g/L) to be inhibitory [61]. Better knowledge of yeast strain behaviour in the presence of toxic compounds would be beneficial for the development of novel yeast strains with increased inhibitor tolerance.

It is important to note that the fermentation and inhibitor resistance characteristics depend on the individual genetic backgrounds of strains, and some studies have explored this phenomenon [62, 63]. Therefore, in the present study, viability of recombinant yeast strains under six industrially relevant stress conditions, including high temperature, high concentration of ethanol, and various concentrations of KCl, acetic acid, furfural, and H2O2 was also tested. All the recombinant yeast strains manifested high resistance to osmo-stress, to varying concentrations of ethanol and furfural, and to high temperatures. It is worth noting that Y-2034-TaBgl1 and YB-2625-TaBgl1 yeast strains showed excellent ethanol (up to 16%) and acetic acid (up to 5 g/L) tolerance as compared with the other strains. Furthermore, no difference in sensitivity to environmental stressors could be detected between the wild-type and recombinant strains (data not shown), suggesting that the recombinant strains constructed in this study could be industrially attractive for lignocellulosic ethanol production.

Conclusion

Four new cellobiose-fermenting Saccharomyces strains were constructed from industrial parental strains. Our results indicate that the activity and extent of glycosylation of secreted TaBgl1 depend on the yeast strain used and are greatly influenced by the carbon source (cellobiose or glucose). In the course of this work, a dramatic reduction in the extent of glycosylation of TaBgl1 was detected when cellobiose was utilized as the sole carbon source. The engineered strains grew on cellobiose, consumed all available sugar, and produced ethanol on average with a yield of 77.6% of the theoretical maximum. These strains thus represent a promising alternative for efficient and cost-effective ethanol production from cellulose.

References

Demirbas A (2008) Biofuels sources, biofuel policy, biofuel economy and global biofuel projections. Energy Convers Manag 49:2106–2116

Jegathese SJP, Farid M (2014) Microalgae as a renewable source of energy: a niche opportunity. Journal of Renewable Energy 2014:10

Jansen MLA, Bracher JM, Papapetridis I, Verhoeven MD, de Bruijn H, de Waal PP, van Maris AJA, Klaassen P, Pronk JT (2017) Saccharomyces cerevisiae strains for second-generation ethanol production: from academic exploration to industrial implementation. FEMS Yeast Res 17:fox044

Hahn-Hagerdal B, Karhumaa K, Jeppsson M, Gorwa-Grauslund MF (2007) Metabolic engineering for pentose utilization in Saccharomyces cerevisiae. Adv Biochem Eng Biotechnol 108:147–177

Wang X, Yang J, Yang S, Jiang Y (2019) Unraveling the genetic basis of fast L-arabinose consumption on top of recombinant xylose-fermenting Saccharomyces cerevisiae. Biotechnol Bioeng 116:283–293

Xiong M, Chen G, Barford J (2011) Alteration of xylose reductase coenzyme preference to improve ethanol production by Saccharomyces cerevisiae from high xylose concentrations. Bioresour Technol 102:9206–9215

Ma TY, Lin TH, Hsu TC, Huang CF, Guo GL, Hwang WS (2012) An improved method of xylose utilization by recombinant Saccharomyces cerevisiae. J Ind Microbiol Biotechnol 39:1477–1486

Kricka W, Fitzpatrick J, Bond U (2014) Metabolic engineering of yeasts by heterologous enzyme production for degradation of cellulose and hemicellulose from biomass: a perspective. Front Microbiol 5:174

Galazka JM, Tian C, Beeson WT, Martinez B, Glass NL, Cate JH (2010) Cellodextrin transport in yeast for improved biofuel production. Science. 330:84–86

Shen Y, Zhang Y, Ma T, Bao X, Du F, Zhuang G, Qu Y (2008) Simultaneous saccharification and fermentation of acid-pretreated corncobs with a recombinant Saccharomyces cerevisiae expressing β-glucosidase. Bioresour Technol 99:5099–5103

da Silva RR, da Conceição PJP, de Menezes CLA, de Oliveira Nascimento CE, Machado Bertelli M, Pessoa Júnior A, de Souza GM, da Silva R, Gomes E (2019) Biochemical characteristics and potential application of a novel ethanol and glucose-tolerant β-glucosidase secreted by Pichia guilliermondii G1.2. J Biotechnol 294:73–80

Brienzo M, Arantes V, Milagres AMF (2008) Enzymology of the thermophilic ascomycetous fungus Thermoascus aurantiacus. Fungal Biology Reviews 22:120–130

Hong J, Tamaki H, Kumagai H (2007) Cloning and functional expression of thermostable β-glucosidase gene from Thermoascus aurantiacus. Appl Microbiol Biotechnol 73:1331–1339

Ríos-Fránquez FJ, González-Bautista E, Ponce-Noyola T, Ramos-Valdivia AC, Poggi-Varaldo HM, García-Mena J, Martinez A (2017) Expression of a codon-optimized β-glucosidase from Cellulomonas flavigena PR-22 in Saccharomyces cerevisiae for bioethanol production from cellobiose. Arch Microbiol 199:605–611

Wilde C, Bawa N, Gold ND, Tambor H, Mougharbel L, Storms R, Martin VJJ (2012) Expression of a library of fungal β-glucosidases in Saccharomyces cerevisiae for the development of a biomass fermenting strain. Appl Microbiol Biotechnol 95:647–659

Van Rooyen R, Hahn-Hägerdal B, La Grange DC, Van Zyl WH (2005) Construction of cellobiose-growing and fermenting Saccharomyces cerevisiae strains. J Biotechnol 120:284–295

Tang H, Hou J, Shen Y, Xu L, Yang H, Fang X, Bao X (2013) High β-glucosidase secretion in Saccharomyces cerevisiae improves the efficiency of cellulase hydrolysis and ethanol production in simultaneous saccharification and fermentation. J Microbiol Biotechnol 23:1577–1585

Albers E, Larsson C (2009) A comparison of stress tolerance in YPD and industrial lignocellulose-based medium among industrial and laboratory yeast strains. J Ind Microbiol Biotechnol 36:1085–1091

Hector RE, Dien BS, Cotta MA, Qureshi N (2011) Engineering industrial Saccharomyces cerevisiae strains for xylose fermentation and comparison for switchgrass conversion. J Ind Microbiol Biotechnol 38:1193–1202

Pajares IG, Elegado FB, Magbanua JPV, Raymundo AK (2009) Selection of high ethanol-producing Saccharomyces cerevisiae strains, their fermentation properties, and genetic differentiation based on rep-PCR and mt rDNA-PCR. Philipp J Sci 138:37–48

Deparis Q, Claes A, Foulquie-Moreno MR, Thevelein JM (2017) Engineering tolerance to industrially relevant stress factors in yeast cell factories. FEMS Yeast Res 17

Larsson S, Palmqvist E, Hahn-Hägerdal B, Tengborg C, Stenberg K, Zacchi G, Nilvebrant NO (1999) The generation of fermentation inhibitors during dilute acid hydrolysis of softwood. Enzyme and Microbial Technology 24:151–159

Larsson S, Quintana-Sainz A, Reimann A, Nilvebrant NO, Jönsson LJ (2000) Influence of lignocellulose-derived aromatic compounds on oxygen-limited growth and ethanolic fermentation by Saccharomyces cerevisiae. Appl Biochem Biotechnol 559:617–632

Li H, Wu M, Xu L, Hou J, Guo T, Bao X, Shen Y (2015) Evaluation of industrial Saccharomyces cerevisiae strains as the chassis cell for second-generation bioethanol production. Microb Biotechnol 8:266–274

De Baetselier A, Vasavada A, Dohet P, Ha-Thi V, De Beukelaer M, Erpicum T, De Clerck L, Hanotier J, Rosenberg S (1991) Fermentation of a yeast producing Aspergillus niger glucose oxidase: scale-up, purification and characterization of the recombinant enzyme. Nat Biotechnol 9:559–561

Ziv N, Siegal ML, Gresham D (2013) Genetic and nongenetic determinants of cell growth variation assessed by high-throughput microscopy. Mol Biol Evol 30:2568–2578

Favaro L, Basaglia M, Trento A, Van Rensburg E, García-Aparicio M, Van Zyl WH, Casella S (2013) Exploring grape marc as trove for new thermotolerant and inhibitor-tolerant Saccharomyces cerevisiae strains for second-generation bioethanol production. Biotechnology for Biofuels 6:168

Idiris A, Tohda H, Kumagai H, Takegawa K (2010) Engineering of protein secretion in yeast: strategies and impact on protein production. Appl Microbiol Biotechnol 86:403–417

Ishchenko AA, Yang XM, Ramotar D, Saparbaev M (2005) The 3′→5′ exonuclease of Apn1 provides an alternative pathway to repair 7,8-dihydro-8-oxodeoxyguanosine in Saccharomyces cerevisiae. Molecular and Cellular Biology 25:6380–6390

Taipakova SM, Smekenov IT, Saparbaev MK, Bissenbaev AK (2015) Characterization of Aspergillus niger endo-1,4-β-glucanase ENG1 secreted from Saccharomyces cerevisiae using different expression vectors. Genetics and Molecular Research online journal 14:39

Bryksin A, Matsumura I (2013) Overlap extension PCR cloning. Methods Mol Biol 1073:31–42

Gietz RD, Woods RA (2006) Yeast transformation by the LiAc/SS carrier DNA/PEG method. Methods Mol Biol 313:107–120

Hong W, Susanne EK, Adrian JC (1996) An improved method for polymerase chain reaction using whole yeast cells. Anal Biochem 237:145–146

Baffi MA, Tobal T, Henrique J, Lago G, Leite RS, Boscolo M, Gomes E, Da-Silva R (2011) A novel β-glucosidase from Sporidiobolus pararoseus: characterization and application in winemaking. J Food Sci 76:997–1002

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Flaugnatti N, Journet L (2017) Identification of effectors: precipitation of supernatant material. Methods in Molecular Biology 1615:459–464

Akishev Z, Taipakova S, Joldybayeva B, Zutterling C, Smekenov I, Ishchenko AA, Zharkov DO, Bissenbaev AK, Saparbaev M (2016) The major Arabidopsis thaliana apurinic/apyrimidinic endonuclease, ARP is involved in the plant nucleotide incision repair pathway. DNA Repair 48:30–42

Liu X, Zhang X, Bao X (2006) Study on the stress resistance of Saccharomyces cerevisiae industrial strains. China Brewing 1:8–11

Gomes I, Gomes J, Gomes DJ, Steiner W (2000) Simultaneous production of high activities of thermostable endoglucanase and beta-glucosidase by the wild thermophilic fungus Thermoascus aurantiacus. Appl Microbiol Biotechnol 53:461–468

Zambare VP, Bhalla A, Muthukumarappan K, Sani RK, Christopher LP (2011) Bioprocessing of agricultural residues to ethanol utilizing a cellulolytic extremophile. Extremophiles 15:611–618

Keating JD, Robinson J, Bothast RJ, Saddler JN, Mansfield SD (2004) Characterization of a unique ethanologenic yeast capable of fermenting galactose. Enzym Microb Technol 35:242–253

Wang M, Wang J, Tan JX, Mou JF (2011) Optimization of ethanol fermentation from sweet sorghum juice using response surface methodology. Energy Sources 33:1139–1146

Phutela UG, Kaur J (2014) Process optimization for ethanol production from sweet sorghum juice using Saccharomyces cerevisiae strain NRRL Y-2034 by response surface methodology. Sugar Tech 16:411–421

Yu S, Jeppsson H, Hahn-Hagerdal B (1995) Xylulose fermentation by Saccharomyces cerevisiae and xylose-fermenting yeast strains. Appl Microbiol Biotechnol 44:314–320

Cheng C, Tang RQ, Xiong L, Hector RE, Bai FW, Zhao XQ (2018) Association of improved oxidative stress tolerance and alleviation of glucose repression with superior xylose-utilization capability by a natural isolate of Saccharomyces cerevisiae. Biotechnology for Biofuels 11:28

Voth WP, Richards JD, Shaw JM, Stillman DJ (2001) Yeast vectors for integration at the HO locus. Nucleic Acids Res 29:E59

Njokweni AP, Rose SH, van Zyl WH (2012) Fungal β-glucosidase expression in Saccharomyces cerevisiae. J Ind Microbiol Biotechnol 39:1445–1452

Zhang L, Guo Z-p, J-h H, Z-y D, Gao Z-q, He Z-m, G-y S (2012) Expressing β-glucosidase from Saccharomycopsis fibuligera in industrial ethanol producing yeast and evaluation of the expressing sufficiency. Ann Microbiol 62:539–544

Guo Z-p, Zhang L, Z-y D, Z-h G, G-y S (2011) Development of an industrial ethanol-producing yeast strain for efficient utilization of cellobiose. Enzym Microb Technol 49:105–112

Gurgu L, Lafraya A, Polaina J, Marin-Navarro J (2011) Fermentation of cellobiose to ethanol by industrial Saccharomyces strains carrying the β-glucosidase gene (BGL1) from Saccharomycopsis fibuligera. Bioresour Technol 102:5229–5236

Kruszewska JS, Perlińska-Lenart U, Górka-Nieć W, Orłowski J, Zembek P, Palamarczyk G (2008) Alterations in protein secretion caused by metabolic engineering of glycosylation pathways in fungi. Acta Biochim Pol 55:447–456

Sola RJ, Griebenow K (2009) Effects of glycosylation on the stability of protein pharmaceuticals. J Pharm Sci 98:1223–1245

Bretthauer RK, Castellino FJ (1999) Glycosylation of Pichia pastoris-derived proteins. Biotechnol Appl Biochem 30:193–200

Olajuyigbe M, Nlekerem CM, Ogunyewo OA (2016) Production and characterization of highly thermostable β-glucosidase during the biodegradation of methyl cellulose by Fusarium oxysporum. Biochem Res Int 1:1–8

Goochee CF, Monica T (1990) Environmental-effects on protein glycosylation. Biotechnology 8:421–427

Andersen DC, Bridges T, Gawlitzek M, Hoy C (2000) Multiple cell culture factors can affect the glycosylation of Asn-184 in CHO-produced tissue-type plasminogen activator. Biotechnol Bioeng 70:25–31

Yuen CT, Storring PL, Tiplady RJ, Izquierdo M, Wait R, Gee CK, Gerson P, Lloyd P, Cremata JA (2003) Relationships between the N-glycan structures and biological activities of recombinant human erythropoietins produced using different culture conditions and purification procedures. Brit J Haematol 121:511–526

Kim S-Y, Sohn J-H, Pyun Y-R, Choi E-S (2007) Variations in protein glycosylation in Hansenula polymorpha depending on cell culture stage. J. Microbiol. Biotechnol. 17:1949–1954

Kukuruzinska MA, Lennon K (1994) Growth-related coordinate regulation of the early N-glycosylation genes in yeast. Glycobiology 4:437–443

Chomvong K, Benjamin DI, Nomura DK, Cate JHD (2017) Cellobiose consumption uncouples extracellular glucose sensing and glucose metabolism in Saccharomyces cerevisiae. mBio 8:e00855–e00817

Almeida J, Modig T, Petersson A, Hahn-Hägerdal B, Lidén G, Gorwa-Grauslund MF (2007) Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. J Chem Technol Biotechnol 82:340–349

Lopes DD, Rosa CA, Hector RE, Dien BS, Mertens JA, Ayub MAZ (2017) Influence of genetic background of engineered xylose-fermenting industrial Saccharomyces cerevisiae strains for ethanol production from lignocellulosic hydrolysates. J Ind Microbiol Biotechnol 44:1575–1588

Romanh A, Pereira F, Johansson B, Domingues L (2015) Metabolic engineering of Saccharomyces cerevisiae ethanol strains PE-2 and CAT-1 for efficient lignocellulosic fermentation. Bioresour Technol 179:150–158

Funding

This study was funded by the Science Committee of the Ministry of Education and Science of the Republic of Kazakhstan (grant no. AP05131569).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Responsible Editor: Eleni Gomes.

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(PDF 456 kb)

Rights and permissions

About this article

Cite this article

Smekenov, I., Bakhtambayeva, M., Bissenbayev, K. et al. Heterologous secretory expression of β-glucosidase from Thermoascus aurantiacus in industrial Saccharomyces cerevisiae strains. Braz J Microbiol 51, 107–123 (2020). https://doi.org/10.1007/s42770-019-00192-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42770-019-00192-1