Abstract

Starch is one of the most abundant renewable carbohydrate reserves of higher plants. It can be used to produce many valuable food products in the food processing industry. Furthermore, starch is also used as an important feedstock in the fermentation industry to produce value-added products. Lignocellulosic materials such as agriculture and forestry wastes are considered as a renewable feedstock for bioenergy production through a biochemical conversion process. Converting lignocellulosic biomass into fuels and chemicals entail a physicochemical pretreatment of the biomass, followed by enzymatic hydrolysis of the polysaccharide components such as cellulose and hemicellulose into monomeric sugars. These sugars can then be further fermented into other desired compounds of interest. During the deconstruction processes, various inhibitory compounds are released due to the partial over-degradation of lignocellulose biomass, which inhibits the cell growth and metabolic capacity of fermenting strains. Cellulosic materials such as waste paper in large quantities can also be used as potentially cheap feedstock for sustainable production of value-added products. The present investigation is mainly focused on the utility of starchy hydrolysates (wheat, potato, and rice) and lignocellulosics hydrolysates (bagasse and wheat straw) in cellulase production under liquid state fermentation. It also depicts the potential of cellulosic hydrolysate (waste newspaper) in product formation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bioconversion of lignocellulosic and starchy waste biomass is still a significant area of research. It holds tremendous potential for sustainable product formation to meet the increasing worldwide demand. The large quantities of byproducts generated during the processing of plant food involve economic and environmental problems due to their high volumes and disposal costs. Agricultural wastes are important feedstocks under such categories as this can be converted into commercially important and valuable products such as ethanol, glucose, enzymes, and single-cell proteins [1,2,3,4]. Cellulases are the main industrial enzyme used to depolymerize plant biomass into simple sugars.

Starch is a polymer of glucose and mainly consists of amylose and amylopectin [5]. Wheat starch is comprised of around 1/4th amylose and around 3/4th amylopectin with little proportions of protein (0.8%) and lipid degradations (0.2%). It consists of a large number of glucose units joined by glycosidic bonds [6]. Amylose (16–30%) is essentially a linear polymer in which the glucose residues are connected by the α-1, 4 linkages while the other main component of starch is amylopectin (65–85%), which is a larger and branched molecule having both α-1, 4 and α-1, 6 linkages [7, 8]. Acid treatment of various starches showed a decrement in amylopectin fraction and increment in amylose fraction. During the initial stages of hydrolysis, the branching point of amylopectin was degraded and further both alpha 1 → 4 and1 → 6 linkages were hydrolyzed [9]. Luo et al.(2018) [10] reported the feasibility of butanol production from wheat starch wastewater by Clostridium acetobutylicum. Soluble inducers derived from starch were investigated for cellulase production by T. reesei. Acid-hydrolysed starch was found to be most effective [11]. Izmirlioglu and Demirci (2015) [12] reported the enhanced bioethanol production from industrial potato waste. Acid hydrolysis of potato tuber-based starch at different ratios of plant material to the acid solution was investigated and found that final reducing sugars concentration in the hydrolyzates mostly depends upon the type and concentration of acid but not on the type of potato. The treatment ratio of plant material to acid solution also plays a significant role in hydrolysis [13]. Sulfuric acid-based hydrolysis of rotten potato produced a significant amount of reducing sugar [14]. Acid hydrolysis of the granular potato starch decreased the molecular mass of amylose and amylopectin [15]. Miao et al. (2011) [16] investigated the structure and digestion properties of waxy maize starch by mild acid hydrolysis. The results demonstrated that the amorphous regions of starch granules are preferentially hydrolyzed first. Moniruzzaman and Ingram (1998) [17] investigated the ethanol production from dilute acid hydrolysate of rice hulls using genetically engineered Escherichia coli. As the literature suggested that the water-soluble acid hydrolyzed starch is an excellent inducer for growth and cellulase production, which induces the enzymes to the same extent as pure cellulose [18, 19].

Fermentation performances of different microorganisms in lignocellulosic hydrolysates are different, which are strongly associated with inhibitory compounds generated from diversified feedstock and pretreatment approaches [20]. During pretreatment processes, various inhibitory compounds are generated because of the partial over-degradation of lignocellulose, which effects cell growth and metabolic capacity of fermenting strains [21]. It has also been reported that hemicellulose depolymerized into its monomeric constituents, mainly xylose and their subsequent conversion into value-added products via microbial fermentation. Dilute acid hydrolysis is a well- established process for hemicellulose depolymerization [22]. Sugarcane bagasse can be hydrolyzed using dilute acid to obtain a mixture of sugars with xylose as the major component [23, 24]. The composition of the different phenolic compounds-formed during pretreatment varies and depends on plant source as well as pre-treatment method. Generally, it is made up of phenolic acids, phenolic aldehydes, phenolic alcohols, and phenolic ketones, all of which are inhibitory to cells [25, 26]. Dilute acid pretreatment targets the hemicellulose fraction of biomass thereby liberating pentose sugars and also redistributing lignin as well as disrupting the crystalline structure of cellulose fibrils thereby increment in porosity and overall surface area of the treated material [27].

Furan aldehydes, 2-furylaldehyde (furfural) and 5-hydroxymethyl-2-furaldehyde (HMF) produced by the dehydration of pentose and hexose sugars, respectively. Aliphatic carboxylic acids, especially acetic acid produced by the deacetylation of hemicellulose and lignin whereas formic acid produced by the degradation of furans [28, 29]. 2,6-Dimethoxyhydroquinone has been reported a recent inhibitor in a hemicellulose hydrolysate [30]. Reaction time influences xylose and furan derivatives concentrations in hydrolysates but not phenolics or acetic acid content [31]. The pretreatment with H2SO4 is one of the widely employed procedures for structural plant cell wall depolymerization and solubilization of its sugars forming mainly xylose in the hemicellulosic fraction and cellulignin [32]. Hydrolysis of wheat straw hemicellulose generally produced xylitol. It has been performed using a mixed solution of formic and hydrochloric acid under which xylan can be hydrolyzed effectively [33, 34]. Marđetko et al. (2018) [35] reported bioethanol production from dilute-acid treated wheat straw liquor hydrolysate by genetically engineered Saccharomyces cerevisiae.

Fermentability of lignocellulosic hydrolyzate decreases by retarding microbial fermentation due to the presence of inhibitors released during hydrolysis. These inhibitors can be removed by applying the proper detoxification process [36]. Several detoxification methods such as neutralization, overliming with calcium hydroxide, adsorption with activated carbon, ion exchange resins, laccase enzyme [37,38,39,40] are known for removing various inhibitory compounds from lignocellulosic hydrolysates.

Removal of volatile inhibitory compounds such as furfural and hydroxymethyl furfural (HMF) has been achieved overliming process [41]. The effects of overliming and activated carbon (AC) detoxification on the removal of inhibitors and butanol fermentation of the poplar hydrolysates were investigated. Overliming removed 75.6% of furan derivatives and 68.1% of aromatic monomers. It also removed 2,5-furandicarboxyaldehyde, 5-ethylfuran-2-carbaldehyde and 2,5-hexanedione [42].The most significant effect of overliming was a sharp decrease in the concentration of furfural and hydroxymethylfurfural, whereas the concentration of acetic acid remained unchanged along with these, decrement in the total phenolic compounds were also observed [43]. Detoxification with calcium hydroxide and ammonia resulted in better fermentability. The treatment of dilute acid lignocellulosics hydrolysates with calcium hydroxide or carbonate (overliming) is known to improve the fermentability of carbohydrate-rich hydrolyzate streams [44, 45]. Multiple contaminants removed by the overliming treatment were also identified [46]. Toxins generated during acid hydrolysis of rice hulls were mitigated with Ca(OH)2. The treated hydrolysate was fermented with Escherichia coli KO11 to produce ethanol with 92% of theoretical yield [17]. It has also been reported that phenol removal from urban drinking water with powdered eggshell. The main component of eggshell powder is calcium carbonate (CaCO3) [47].

Waste paper sludge is a residue material originating from pulp mills. Paper sludge consists of mainly cellulose and hemicellulose. Paper sludge, is believed to be one of the most promising feedstocks for the production of bio-ethanol and value-added chemicals [48, 49]. The newspaper contains almost 61% cellulose and 16% hemicelluloses whereas office paper contains around 90% cellulose [50]. The enzymatic hydrolysate of wastepaper was evaluated for its cellulase-inducing capability. The wastepaper hydrolysate was found to have cellulase inducing strength and to induce a complete set of cellulase components. The hydrolysate was also concluded to be a better soluble inducer than sophorose [51]. Acid hydrolysis of cellulose can be combined with hydrogenation to produce sorbitol and mannitol [52]. Dilute acid hydrolysis produced “hydro-cellulose,” a product with a reduced degree of polymerization in cellulosic components. It is known that strong mineral acids hydrolyze cellulose more effectively than weak acids [53]. Franceschin et al. (2010) [54] investigated the hot water pretreated waste paper as a carbohydrate source for biofuel production. The present paper describes the utilization of various hydrolysates as carbon sources such as starchy (Wheat, Potato, and Rice), Lignocellulosic (Boiled baggase, bagasse, wheat straw) and cellulose based (waste newspaper hydrolysate) under liquid state fermentation by fungal strains.

Experimental section

Materials

All the chemicals and reagents used to perform the experimental work were of Himedia, Sigma Aldrich, and Merck make. Trichoderma reesei NCIM 1186, Neurospora crassa NCIM 1021 and Aspergillus niger 777 were procured from National Chemical Laboratory, Pune. Separate sets of batch experiments were carried out in 250 mL Erlenmeyer flasks containing following production media in (g/L) Urea, 0.3; (NH4)2SO4, 1.4; KH2PO4, 2.0; MgSO4.7H2O, 0.3; Peptone, 1.0; Tween 80, 0.2; FeSO4.7H2O, 0.005; MnSO4.7H2O, 0.0016; ZnSO4.7H2O; 0.0014; CaCl2.2H2O; CoCl2.6H2O, 0.02; acid hydrolysates solution. Production media were autoclaved and then inoculated with specific volume (g/L cell dry weight) of potato dextrose and M2 broth culture solution of Trichoderma reesei, Aspergillus niger and Neurospora crassa, respectively. A separate set of batch experiments were performed to investigate the effect of boiled baggase, bagasse, wheat straw, waste newspaper, and starch hydrolysate. All the hydrolysates containing production flasks inoculated with culture solution were placed in an incubator shaker at 30 °C with 180 rpm for 5 days.

Methodology

Preparation of bagasse and wheat straw hydrolysates

Raw materials were collected from the local market. Chopped and grounded bagasse and wheat straw of definite particle size (850 μm) were used for the acid pretreatment. Acid treatment of raw materials has been performed using 5, 10 and 20% H2SO4 (v/v) solution with maintaining solid to liquid ratio of about 1:20. Further, these solutions were kept at room temperature for 1 h and then subjected to steam treatment under pressure of 15 lb at 121 °C for 1 h duration. After steam treatment solutions, were cooled out and filtered with muslin cloth. Due to acid treatment at a higher temperature several toxic components were released in the hydrolysates. To minimize the effect of toxic substances, overliming process has been conducted. Calcium salt solution was used to perform overliming process. The hydrolysates were added into calcium salt solution and boiled for 1 h and kept it at room temperature for further an hour. The resulting detoxified hydrolysates suspension was diluted to 100 mL with distilled water and make up the resulting solution pH at 7.0 with dilute NaOH solution. The resulting solution which has been obtained under these treatments was used in the production medium.

Preparation of waste news paper hydrolysates

The hydrolysates of waste newspaper were prepared by acid digestion. Old newspapers (Times of India) were collected from the local market. Before acid pretreatment, the deinking process of the chopped and grounded waste newspaper has been performed using effective chemicals and surfactants (Tween-80). Deinked waste newspapers were further used for the acid pretreatment. Acid treatment of WNP (waste newspaper) has been performed using a 20–70% H2SO4 (v/v) solution with maintaining the definite solid to liquid ratio. Waste newspaper was soaked in an acid solution at room temperature for an hour. These solutions were cooled out, filtered and make up the resulting solution pH at 7.0 by dilute NaOH solution. The resulting hydrolyzates were used in the production medium.

Preparation of starch hydrolysates

Acid pretreatment of starches was carried out using a 2% and 5% HCl (v/v) solution. 10 g of wheat, potato, and rice starch powdered biomass were taken separately; further 40 mL of diluted HCl solution with specific strength was added to maintain the slurry of about 25%. Afterward, starch slurries were subjected to steam treatment under a pressure of 15 psi at 121 °C for 1 and 3 h time duration separately. The treated starch slurries were used in the production medium as pure hydrolyzates.

Inoculum development

For inoculum development separate experiment was performed in 250 mL Erlenmeyer flasks containing 100 mL of potato dextrose broth (PDB) medium (In g/L peeled potato, 200; dextrose, 20; and yeast extract, 0.1) and M2 broth medium (In g/L Glucose, 10; Glycerine, 10; Yeast extract, 5; KH2PO4, 0.3; MgSO4.7H2O, 0.1) each, in which five loopfull cultures of mycelial conidia were added and shaken at 180 rpm at 30 °C in an incubator shaker for 3–4 days [55]. A definite volume of prepared cultures in broth suspension was used as inoculum for further production studies.

Dry weight determination

5.0 mL of culture solution was taken from potato dextrose and M2 broth medium. It was then filtered on a dried and preweighed Whatman filter paper No 1. Further, the solids collected were washed thoroughly with cold distilled water and subsequently with 5.0 mL of 0.9% sterile saline solution. The filter containing mycelium residue was then dried for 24 h at 105 °C until attainment of constant weight and weighed. The determination of fungal growth by cell dry weight was expressed as the mean of three independent readings.

Preparation of production media

Four types of production medium were used for production studies. (I) Normal basal salt media was used for production studies having the following constituents (g/L): urea, 0.3; (NH4)2SO4, 1.4; KH2PO4, 2.0; MgSO4.7H2O, 0.3; peptone, 1.0; Tween 80, 0.2; FeSO4.7H2O, 0.005; MnSO4.7H2O, 0.0016; ZnSO4.7H2O; 0.0014; CaCl2.2H2O; CoCl2.6H2O, 0.02. (II) Modified basal salt media, in which 5% (w/v) untreated starch were incorporated in the earlier described production media separately. (III) Modified basal salt media, in which 50% (v/v) dosages of boiled bagasse, bagasse hydrolysate, wheat straw hydrolysate, and waste newspaper hydrolysate solution were incorporated in the earlier described production media separately. (IV) Modified basal salt media, in which 10% (v/v) dosages of potato, wheat, and rice starch hydrolysate solution were incorporated in the earlier described production media separately.

Submerged fermentation

Separate set of batch experiments were carried out in 250 ml Erlenmeyer flasks containing 100 ml of production media having components in (g/L) Urea, 0.3; (NH4)2SO4, 1.4; KH2PO4, 2.0; MgSO4.7H2O,0.3; Peptone, 1.0; Tween80, 0.2; FeSO4.7H2O, 0.005; MnSO4.7H2O, 0.0016; ZnSO4.7H2O; 0.0014; CaCl2.2H2O; CoCl2.6H2O, 0.02; hydrolysates solution (v/v). Flasks containing production media were autoclaved, cooled and then inoculated with specific volume having (0.56 g/L cell dry weight) of Potato dextrose and M2 broth culture solution of respective strains. The autoclaved and inoculated flasks were placed in incubator shaker at 30 °C with 180 rpm for 5 days.

Extraction of enzyme

The fermented sample was then filtered and the crude extract obtained was centrifuged at 6000 rpm. The resulting supernatant was stored and used as an enzyme source. All extractions were conducted in duplicate.

Filter paper activity (FPA)

Filter paper activity (FPA) was determined by the method recommended by Ghose (1987) [56]. As follows: 0.5 mL of culture supernatant was added to 1 mL of 0.05 M citrate buffer, pH 4.8 and filter paper (50 mg, Whatman filter paper no#1), mix well and incubated at 50 °C for 60 min. The enzymatic reaction was terminated by the addition of 3 mL dinitrosalicylic acid reagent (DNSA). All reducing sugar determinations were performed by the 3,5-dinitrosalicylic (DNS) method at 540 nm. One unit of enzyme activity was defined as the amount of enzyme that released 1 μmol of reducing sugar equivalent to glucose/min under the assay conditions.

Carboxymethyl cellulase activity (CMCase)

Carboxymethyl cellulase activity was determined by the method recommended by Ghose (1987) [56], as follows 0.5 mL of culture supernatant, diluted with citrate buffer was added to 1 mL 2% carboxymethyl cellulose solution prepared in 0.05 M citrate buffer, pH 4.8, mix well and incubated at 500 °C for 30 min. The enzymatic reaction was terminated by the addition of 3 mL dinitrosalicylic acid reagent (DNSA). All reducing sugar determinations were performed by the 3,5-dinitrosalicylic (DNS) method at 540 nm.

Results and discussions

Effect of starch hydrolysates on the growth of fungal strains under submerged cultivation

To investigate the role of starch hydrolysates in cellulase production, a separate set of experiments was performed. Pretreatment of starches was performed by taking 2% and 5% HCl with varying pretreatment time of 1 and 3 h. From the above experimental observation, we found that after hydrolysis potato and wheat starch becomes more soluble than rice starch. 2% HCl treatment was more favorable than 5% HCl for starch hydrolysis.

Under 5% HCl treatment overhydrolysis of starch molecules occurred, upon increasing the pretreatment time, the condition becomes more extreme and unfavorable for a microbial system, as the essential components or sugars present in the starch solution were destroyed or burnt out. Pretreatment of wheat starch with 2% HCl having pretreatment time of 1 h was found most suitable for the microbial growth in comparison to higher acid dosages with higher pretreatment time. Therefore, 5% HCl treated starch with 3 h pretreatment time was unsuitable for the microbial growth as has been observed from Table 1.

Effect of starch hydrolysates on cellulase production under submerged fermentation

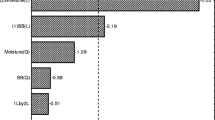

Individual sets of batch experiments have been performed to study the effect of untreated as well as 2% and 5% HCl treated wheat starch hydrolysate as carbon source on cellulase production by various fungal strains under submerged cultivation at 180 rpm. Maximum cellulase activities (IU/mL) in terms of FPA and CMCase attained by T.reesei, N.crassa and A.niger were 1.40, 1.24; 0.184, 0.375; 0.118, 0.849, respectively, under 2% wheat starch hydrolysate-based fermentation medium. It was observed from Figs. 1 and 2 that fungal strains produce significantly higher cellulase activities under 2% HCl treated wheat starch hydrolysate-based fermentation medium as compared to untreated and 5% HCl treated one. This may be presumably due to the release of some dimeric sugars (sophrose) in the hydrolyzates, which induces more cellulase production rather than growth enhancement. The inducing ability of the acid-hydrolyzed starch may be attributed to the reversion product of glucose. By increasing the acid strength, resulting in more reversion products of glucose in the hydrolyzates, which are responsible for the induction capability of the starch. But when the starch is over hydrolyzed, other byproducts may be generated, which might have served as inhibitors for cellulase production [11, 57]. When compared, the effectiveness of wheat starch hydrolysates for various used fungal strains than it has been observed that T.reesei and A. niger performed much better in terms of cellulase activity under wheat starch hydrolysate-based fermentation medium as compared to N.crassa fungal strain. Wheat hydrolysate contained a glucose-rich solution with potential nutrients, therefore, it is a prospective supplement for the bioconversion process [58].

FPA (IU/mL) activity achieved by various fungal strains under acid treated starch hydrolysate-based fermentation medium at 30 °C and pH 5.0. WSH wheat starch hydrolysate, UTR untreated, HYL hydrolysate, UTWS untreated wheat starch, UTPS untreated potato starch, UTRS untreated rice starch, Actr acid treated

On the other hand maximum cellulase activities (IU/mL) in terms of FPA and CMCase attained by T.reesei, N.crassa and A.niger were 0.802, 0.670; 0.275, 0.543; 0.121, 0.567, respectively, under 2% potato starch hydrolysate-based fermentation medium. It has been observed from Figs. 1 and 2 that N.crassa showed higher cellulase activities under potato starch-based fermentation medium compared to wheat starch-based medium, whereas T.reesei and A. niger showed somewhat lower cellulase activity under potato starch hydrolysate-based medium as observed from which might be due to the fact sugars released after hydrolysis are growth-inducing nature rather than cellulase induction for T.reesei and A. niger system.

Maximum cellulase activities (IU/mL) in terms of FPA and CMCase attained by T.reesei, N.crassa and A.niger were 1.01, 0.797; 0.186, 0.390; 0.174, 0.895, respectively, under 2% rice starch hydrolysate-based fermentation medium as shown by Figs. 1 and 2. A. niger showed higher cellulase activities under rice starch hydrolysate-based fermentation medium compared to wheat and potato starch hydrolysate, whereas N.crassa showed somewhat lower cellulase activity under rice starch hydrolysate-based medium.

Effect of bagasse and wheat straw hydrolysates on the growth of fungal strains under submerged cultivation

To study the effects of bagasse and wheat straw hydrolysates on the growth and production system of fungal strains, acid pretreatment of bagasse and wheat straw have been performed with 5%, 10% and 20% H2SO4 (v/v) solution with maintaining the solid–liquid ratio of 1:25 and 1:20, respectively. Detoxification of acid hydrolysates was performed by overliming process. Over-liming, considered as a promising detoxification method for dilute sulfuric acid-pretreated hydrolysate of lignocellulosic biomass [59].The resulting detoxified hydrolyzates were used in the production medium as pure hydrolyzates. Growth of Trichoderma reesei has been observed in the form of tiny and minute filament under pure hydrolyzate system as evident from Table 2. Distinctly longer lag phase ~ 20 h were observed in the cell growth under hydrolysate-based medium presumably because of the presence of hydrolysis by-products. On the other hand growth of A.niger was observed in the form of smaller round shaped beads, whereas N.crassa showed diminished growth under hydrolysate-based production medium. 20% H2SO4 treated wheat straw and 10% H2SO4 treated bagasse was found quite unsuitable for the growth as compared to lower acid dosages as observed from Table 2.

Effect of boiled bagasse syrup on cellulase production under submerged fermentation

Individual sets of batch experiments have been performed to study the effect of boiled bagasse syrup a carbon source on cellulase production by various fungal strains under submerged cultivation at 180 rpm. Maximum cellulase activities (IU/mL) in terms of FPA and CMCase attained by T.reesei, N.crassa and A.niger were 0.841, 0.709; 0.142, 0.187; 0.080, 0.298, respectively, under boiled bagasse syrup-based fermentation medium. It was observed from Figs. 3 and 4 that Trichoderma reesei produces significantly higher cellulase activities as compared to N.crassa and A.niger under boiled bagasse syrup-based fermentation medium. This might be due to the release of superficial sugars such as sucrose in the medium, which induces the cellulase production as well as growth enhancement. Autohydrolysis or hot water extraction mainly focused on the removal of the hemicellulose barrier. It also allows the recovery of a significant portion of hemicellulose as sugars. It also produces a cellulose‐rich solid with increased digestibility [60].

Effect of bagasse hydrolysates on cellulase production under submerged fermentation

An individual set of batch experiments have been performed to study the effect of bagasse hydrolysates used separately as pure hydrolysate (carbon source) on cellulase production by various fungal strains under submerged cultivation at 180 rpm. Maximum cellulase activities (IU/mL) in terms of FPA and CMCase attained by T.reesei, N.crassa and A.niger were 0.813, 0.601; 0.125, 0.146; 0.059, 0.306, respectively, under 10% acid-treated bagasse hydrolysates-based fermentation medium. It was observed from Figs. 3 and 4. that Trichoderma reesei produces significantly higher cellulase activities as compared to N.crassa and A.niger under bagasse hydrolysates-based fermentation medium. This might be because acid hydrolysis of bagasse may release C-6 and C-5 sugars such as glucose, xylose, arabinose, mannose, galactose, as well as few dimers (cellobiose) and oligosaccharides. In all the released sugars, few ones are involved in the enhancement of fungal growth as well as others can induce fungal system for cellulase production. In bagasse hydrolysate, there may be the possibility of releasing more hemicellulose degradation products such as xylose and arabinose as compared to others, which ultimately affects the fungal growth and cellulase production system of different fungal strains. Xylose is also known to induce cellulase synthesis, although not as effectively as cellulose. The nonglucose sugars present in the hydrolysates also facilitated the induction of cellulase synthesis. Available literature shows that acid attacks especially on hemicelluloses portion of raw materials than cellulose and lignin. Hydrolysates with less than 20% of oligomers supported active cellulase biosynthesis [61, 62].

Effect of wheat straw hydrolysates as carbon source on cellulase production under submerged fermentation

Individual sets of batch experiments have been performed to study the effect of wheat straw hydrolysate used separately as a carbon source for cellulase production by various fungal strains under submerged cultivation at 180 rpm. Maximum cellulase activities (IU/mL) in terms of FPA and CMCase attained by T.reesei, N.crassa and A.niger were 0.568, 0.522; 0.045, 0.091; 0.047, 0.257, respectively, under 5% acid-treated wheat straw hydrolysates-based fermentation medium. It was observed from Figs. 3 and 4 that Trichoderma reesei produces significantly higher cellulase activities as compared to N.crassa and A.niger under bagasse hydrolysates-based fermentation medium. The decremental rate of enzyme activities was somewhat higher in the case of N.crassa followed by A. niger under wheat straw hydrolysate-based fermentation medium.

When compared to the enzyme activities attained by fungal strains under wheat straw and bagasse hydrolysate-based fermentation medium, it has been observed that bagasse hydrolysate-based medium was found much suitable for growth and production system of fungal strain compared to wheat straw hydrolysate. 20% H2SO4 treated wheat straw and 10% H2SO4 treated bagasse were found quite unsuitable for the growth and cellulase production by fungal strains, which might be due to the fact that under higher acid dosages overhydrolysis of monomers, dimmers, and oligomeric sugars are taking place which discharges certain inhibitory, toxic, noxious and lethal components. In conclusion, despite the potentially inhibitory effects, the hydrolysates supported cell growth and induced active cellulase biosynthesis.

Effect of waste newspaper hydrolysates as carbon source on cellulase production under submerged fermentation

To investigate the effect of waste newspaper hydrolysates as carbon source on cellulase production under submerged fermentation separate set of experiments have been performed with utilizing 20, 30, 40, 50 and 70% acid (H2SO4) treated waste newspaper hydrolysate. Newspaper was the second inducer of cellulase enzyme and found to be the best for releasing maximum reducing sugar and saccharification [50]. Carbohydrates, organic acids, furfural, and 5-HMF were not detected in the liquid fraction after acid pretreatment, probably due to the moderate conditions in this step (50 °C, 150 rpm, duration 3 h).

It has been observed from Figs. 5 and 6 that 40% acid-treated waste newspaper was found much more suitable for cellulase production by fungal strains as compared to higher acid dosages. Maximum cellulase activities (IU/mL) in terms of FPA and CMCase attained by T.reesei, N.crassa and A.niger were 0.986, 1.04; 0.216, 0.390; 0.121, 0.605, respectively, under 40% acid-treated waste newspaper hydrolysates-based fermentation medium. Trichoderma reesei showed higher cellulase activities followed by N.crassa under such fermentation medium this might be because acid hydrolysis of waste newspapers released sophrose, cellobiose, xylose, glucose, etc., which may induce the cellulase production by fungal strains. Inducers derived from the waste newspaper (or discarded office paper) were investigated for their use in cellulase production by T. reesei. Partially enzymatically saccharified newspaper was found to be most effective [63, 64].

Conclusion

Acid-hydrolysed starch was found to be the most effective for cellulase production. Waste papers are also suitable and potentially cheap resources for sustainable production of value-added products. Utilization of bagasse and wheat straw hydrolyzates for growth and production is a better approach for the complete utilization of waste raw material. As the pretreated solid waste biomass used as solid bed under solid-state fermentation and on the other hand remaining liquid residue in terms of hydrolyzates can also be used for cellulase production under submerged fermentation system, which revealed the complete utilization of sugars present in the waste lignocellulosic biomass. 2% acid-treated starch hydrolysate was found a quite effective inducer for cellulase production by most of the fungal strain, in between starch hydrolysates wheat starch hydrolysate was found quite effective for cellulase production followed by rice starch hydrolysate. When compared the cellulase activity produced by fungal strains under lignocellulosic hydrolysate, boiled bagasse syrup, as well as bagasse hydrolysate were found much effective for cellulase production as compared to wheat straw hydrolysate. 40% acid-treated waste newspaper hydrolysate was found quite effective for cellulase production as compared to other treatment dosages under liquid state fermentation.

Change history

27 August 2021

A Correction to this paper has been published: https://doi.org/10.1007/s42768-021-00078-9

References

Ali N, Athar MA, Khan YH, et al. Regulation and improvement of cellulase production: recent advances. Nat Res. 2014;5:857–63.

Oszust K, Pawlik A, Siczek A, et al. Efficient cellulases production by Trichoderma atroviride G79/11 in submerged culture based on soy flour-cellulose-lactose. BioRes. 2017;12(4):8468–89.

Adelabu BA, Kareem SO, Oluwafemi F, et al. Bioconversion of corn straw to ethanol by cellulolytic yeasts immobilized in Mucuna urens matrix. J King Saud Univ Sci. 2017;31:136.

Verma N, Bansal MC, Kumar V. Utility of Luffa cylindrica and Litchi chinensis peel, an agricultural waste biomass in cellulase production by Trichoderma reesei under solid state cultivation. Biocatal Agric Biotechnol. 2018;16:483–92.

Carvalho JFA. Starch: major sources, properties and applications as thermoplastic materials, handbook of biopolymers and biodegradable plastics. Boston: William Andrew Publishing; 2013.

Razdan N, Kocher GS. Utilization of damaged and spoiled wheat grains for bioethanol production. Biosci Biotech Res Comm. 2018;11(4):658–73.

Perez S, Bertoft E. The molecular structures of starch components and their contribution to the architecture of starch granules: a comprehensive review. Starch-Starke. 2010;62(8):389–420.

Miao M, Jiang B, Jin Z, et al. Microbial starch-converting enzymes: recent insights and perspectives. Compr Rev Food Sci Food Saf. 2018;17(15):1238–60.

Singh SV, Ali SZ. Properties of starches modified by different acid. Int J Food Prop. 2008;11:495–507.

Luo W, Zhao Z, Pan H, et al. Feasibility of butanol production from wheat starch wastewater by Clostridium acetobutylicum. Energy. 2018;154:240–8.

Chen S, Wayman M. Novel inducers derived from starch for cellulase production by Trichoderma reesei. Process Biochem. 1992;27:327–34.

Izmirlioglu G, Demirci A. Enhanced bio-ethanol production from industrial potato waste by statistical medium optimization. Int J Mol Sci. 2015;16(10):24490–505.

Tasić MB, Konstantinović BV, Lazic ML, et al. The acid hydrolysis of potato tuber mash in bioethanol production. Biochem Eng J. 2009;43(2):208–11.

Yadav P, Majumder CB. Production of glucose syrup by the hydrolysis of starch made from rotten potato. J Integr Sci Technol. 2017;5(1):19–22.

Soest JJGV, Benes K, Wit DD. The influence of acid hydrolysis of potato starch on the stress-strain properties of thermoplastic starch. Starch. 1995;47(11):429–34.

Miao M, Jiang B, Zhang T, et al. Impact of mild acid hydrolysis on structure and digestion properties of waxy maize starch. Food Chem. 2011;126(2):506–13.

Moniruzzaman M, Ingram LO. Ethanol production from dilute acid hydrolysate of rice hulls using genetically engineered Escherichia coli. Biotechnol Lett. 1998;20(10):943–7.

Wang CH, Hseu TH, Huang CM. Induction of cellulases by cellooligosaccharides in Trichoderma koninghii G-39. J Biotechnol. 1998;9:47–60.

Wayman M, Chen S. Cellulase production by Trichodermma reesei using whole wheat flour as a carbon source. Enzyme Microbial Technol. 1992;14:825–31.

Yang Y, Hu M, Tang Y, et al. Progress and perspective on lignocellulosic hydrolysate inhibitor tolerance improvement in Zymomonas mobilis. Biores Bioprocess. 2018;5:6.

Jönsson LJ, Alriksson B, Nilvebrant NO. Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol Biofuels. 2013;6:16.

Canilha L, Rodrigues RDCLB, Antunes FAF, et al. Bioconversion of sugarcane biomass into ethanol: an overview about composition, pretreatment methods, detoxification of hydrolysates, enzymatic saccharification and ethanol fermentation. J Biomed Biotechnol. 2012;2012:15.

Pessoa A Jr, Mancilha IM, Sato S. Acid hydrolysis of hemicellulose from sugarcane bagasse. Brazil J Chem Eng. 1997;14:3.

Lavarack BP, Griffin GJ, Rodman D. The acid hydrolysis of sugarcane bagasse hemicellulose to produce xylose, arabinose, glucose and other products. Biomass Bioenergy. 2002;23(5):367–80.

Larsson S, Palmqvist E, Hahn-Hagerdal B, et al. The generation of fermentation inhibitors during dilute acid hydrolysis of softwood. Enzym Microb Technol. 1999;24:151–9.

Adeboye PT, Bettiga M, Olsson L. The chemical nature of phenolic compounds determines their toxicity and induces distinct physiological responses in Saccharomyces cerevisiae in lignocellulose hydrolysates. AMB Express. 2014;4:46.

Paniagua AI, Diez-Antolinez R, Hijosa-Valsero M, et al. Response surface optimization of dilute sulfuric acid pretreatment of switchgrass (Panicum virgatum l.) for fermentable sugars production. Chem Eng Trans. 2016;49:223–8.

Sritrakul N, Nitisinprasert S, Keawsompong S. Evaluation of dilute acid pretreatment for bioethanol fermentation from sugarcane bagasse pith. Agric Nat Res. 2017;51(6):512–9.

Luo Y, Li Z, Li X, et al. The production of furfural directly from hemicellulose in lignocellulosic biomass: a review. Catal Today. 2019;319:14–24.

Stagge S, Adnan Cavka A, Jönsson LJ. Identification of benzoquinones in pretreated lignocellulosic feedstocks and inhibitory effects on yeast. AMB Express. 2015;5:62.

Luís C, DuarteL C, Silva-Fernandes T, et al. Dilute acid hydrolysis of wheat straw oligosaccharides. Appl Biochem Biotechnol. 2009;153:116.

Dussan KJ, Silva DDV, Moraes EJC, et al. Dilute-acid hydrolysis of cellulose to glucose from sugarcane bagasse. Chem Eng Trans. 2014;38:433–8.

Zhuang J, Liu Y, Wu Z, et al. Hydrolysis of wheat straw hemicellulose and detoxification of the hydrolysate for xylitol production. BioResources. 2009;4(2):674–86.

Guerra-Rodríguez E, Portilla-RiveraO M, Jarquín-Enríquez L, et al. Acid hydrolysis of wheat straw: a kinetic study. Biomass Bioenergy. 2012;36:346–55.

Marđetko N, Novak M, Trontel A, et al. Bioethanol production from dilute-acid pre-treated wheat straw liquor hydrolysate by genetically engineered Saccharomyces cerevisiae. Chem Biochem Eng Q. 2018;32(4):483–99.

Baig MZ, Dharmadhikari SM. Optimization of detoxification with over liming and charcoal treatment for increasing the fermentability of cotton stalk hydrolyzate. Microbiology. 2014;4(7):8–10.

Carvalheiro F, Duarte LC, Lopes S, et al. Evaluation of the detoxification of brewery’s spent grain hydrolysate for xylitol production by Debaryomyces hansenii CCMI 941. Process Biochem. 2005;40:1215–23.

Pattra S, Sangyoka S, Boonmee M, et al. Bio-hydrogen production from the fermentation of sugarcane bagasse hydrolysate by Clostridium butyricum. Int J Hydrogen Energy. 2008;33:5256–65.

Llano T, Quijorna N, Coz A. Detoxification of a lignocellulosic waste from a pulp mill to enhance its fermentation prospects. Energies. 2017;10(3):348.

Bahiru TB, Balomajumder C, Roy P. Microbial delignification and hydrolysis of lignocellulosic biomass to enhance biofuel production: an overview and future prospect. Bull Natl Res Centre. 2019;43:51.

Chandel AK, Silva SSRD, Singh O (2011) Detoxification of lignocellulosic hydrolysatesfor improved bioethanol production. In: MarcoAurelio Dos Santos Bernardes (Ed.) Biofuel production-recent developments and prospects, InTech, (ISBN: 978-953-307- 478-8).

Mingming LM, Tu M. Effect of overliming and activated carbon detoxification on inhibitors removal and butanol fermentation of poplar prehydrolysates. Biotechnol Biofuels. 2018;11:178.

Millati R, Niklasson C, Taherzadeh MJ. Effect of pH, time and temperature of overliming on detoxification of dilute-acid hydrolyzates for fermentation by Saccharomyces cerevisiae. Process Biochem. 2002;38(4):515–22.

Ranatunga TD, Jervis J, Helm RF, et al. The effect of overliming on the toxicity of dilute acid pretreated lignocellulosics: the role of inorganics, uronic acids and ether-soluble organics. Enzyme Microb Technol. 2000;27(3–5):240–7.

Persson P, Andersson J, Gorton L, et al. Effect of different forms of alkali treatment on specific fermentation inhibitors and on the fermentability of lignocellulose hydrolysates for production of fuel ethanol. J Agric Food Chem. 2012;50:5318.

Chi Z, Rover M, Jun E, et al. Overliming detoxification of pyrolytic sugar syrup fordirect fermentation of levoglucosan to ethanol. Biores Technol. 2013;150:220–7.

Kashi G. On the analysis of phenol removal from drinking water by batch reactor using powdered eggshell. Biosci Biotech Res Comm. 2017;10(2):287–96.

Cavka A, Guo X, Tang S-J, et al. Production of bacterial cellulose and enzyme from waste fiber sludge. Biotechnol Biofuels. 2013;6:25.

Pecar D, Gorsek A. Enzymatic treatment of paper sludge. Chem Eng Trans. 2015;43:631–6.

Varotkar P, Tumane PM, Wasnik DD. Bioconversion of waste paper into bio-ethanol by co-culture of fungi isolated from lignocellulosic waste. J Pure App Biosci. 2016;4(4):264–74.

Ju LK, Afolabi OA. Waste paper hydrolysate as soluble inducing substrate for cellulase production in continuous culture of Trichoderma reesei. Biotechnol Progg. 1999;5:91–7.

Balagurumurthy B, Singh R, Bhaskar T. Catalysts for thermochemical conversion of biomass. Recent Adv Thermo-Chem Conv Biomass. 2015;2015:109–32.

Joksimovic G, Markovic Z. Investigation of the mechanism of acidic hydrolysis of cellulose. Acta Agric Serbica. 2007;12(24):51.

Franceschin G, Favaron C, Bertucco A. Waste paper as carbohydrate source for biofuel production: an experimental investigation. Chem Engg Trans. 2010;20:279–84.

Domingues FC, Queinoz JA, Cabral JMS, et al. The influence of culture conditions on mycelial structure and cellulase production by Trichoderma reesei RUT C 30. Enzyme Microb Technol. 2004;26:394.

Ghose TK. Measurement of cellulase activities. Pure Appl Chem. 1987;59(2):257–68.

Chen S, Wayman M. Use of sorbose to enhance cellobiose activity in a Trichoderma reesei cellulase system produced on wheat hydrolysates. Biotechnol Technique. 1993;7:345–50.

Cornejo-Ramírez YI, Martínez-Cruz O, Toro-Sánchez CLD, et al. The structural characteristics of starches and their functional properties. CyTA J Food. 2018;16(1):1003–17.

Chandel AK, Kapoor RK, Singh A, et al. Detoxification of sugarcane bagasse hydrolysate improves ethanol production by Candida shehatae NCIM3501. Biores Technol. 2007;98:1947–50.

Nitsos CK, Lazaridis PA, Mach-Aigner A, et al. Enhancing lignocellulosic biomass hydrolysis by hydrothermal pretreatment, extraction of surface lignin, wet milling and production of cellulolytic enzymes. ChemSusChem. 2019;12(6):1179–95.

Talebnia F, Karakashev D, Angelidaki I. Production of bioethanol from wheat straw: an overview on pretreatment, hydrolysis and fermentation. Biores Technol. 2010;101:4744–53.

Cardona CA, Quintero JA, Paz IC. Production of bioethanol from sugarcane bagasse: status and perspectives. Biores Technol. 2010;101:4754–66.

Chansoliya PR, Anand R, Sharma S. Analysis of Bioethanol production from Newspaper by Saccharomyces cerevisiae and Zymomonas mobilis. Int J Eng Develop Res. 2016;4(3):517.

Wyman M, Chen S. Cellulase production induced by carbon source derived from waste news paper. Process Biochem. 1991;26:93–100.

Acknowledgement

Authors gratefully acknowledged the ministry of human resource and development, India for providing fellowship to carry out present research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Verma, N., Kumar, V. & Bansal, M.C. Utility of starchy, lignocellulosics and cellulosics hydrolysates on cellulase production under liquid state fermentation. Waste Dispos. Sustain. Energy 1, 289–299 (2019). https://doi.org/10.1007/s42768-019-00019-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42768-019-00019-7