Abstract

This study aimed to determine the effect of foliar (Si) spraying of silicon using different sources on leaf Si concentration, photosynthetic parameters, and yield in soybean, cotton, and maize. Three experiments were carried out in the 2016/2017 growing season (Study 1), and three experiments were carried out in the 2017/2018 season (Study 2). Study 1 was arranged using a randomized block design in a 4 × 4 factorial scheme consisting of four sources of Si: sorbitol-stabilized sodium and potassium silicate (SiAl), PEG-400-stabilized monosilicic acid (SiAc), nanosilica (Nano), and potassium silicate without stabilizers (SiK), and four silicon concentrations: (0.0, 0.25, 0.50, and 1.0 g L−1), with three replicates. Study 2 was arranged in a randomized block design consisting of a treatment without Si (0 g L−1) and treatments with three sprayings of SiK (0.6 g L−1) or SiAl (0.6 g L−1), with seven replicates. In Study 1, all Si sources studied increased the leaf Si concentration. In addition, increasing Si concentrations also increased the photosynthetic variables and yield of soybean, maize, and cotton plants, with SiAl at the concentrations of 0.5 and 1.0 g L−1 being superior to the other sources, promoting greater yield. In Study 2, SiAl and SiK increased the leaf Si concentration, photosynthetic variables, and yield in soybeans, cotton, and maize plants. It is concluded that stabilized potassium silicate can be used as a new option in relation to the conventional source, potassium silicate for fertilization in annual crops. Our study proposes the use of this Si source for foliar spraying at a concentration between 0.6 and 0.8 g L−1 for soybean, cotton, and maize crops, especially when the leaf Si contents are below 2.0, 5.5, and 26.6 g kg−1, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Silicon (Si) is considered as a beneficial element that can increase the yield of crops submitted to biotic or abiotic stress (Bakhat et al. 2018; Campos et al. 2020; Coskun et al. 2019; Silva and Prado 2021) or under adequate conditions (Barros et al. 2018, 2019; Flores et al. 2019). Silicon absorption varies among species. Fabales such as soybean (Glycine max) show a low leaf Si concentration, while Poales such as maize (Zea mays) show a high leaf Si concentration, and Malvales such as cotton (Gossypium hirsutum) show an intermediate leaf Si concentration (Deshmukh et al. 2020).

Silicon can be applied to crops in the soil or in leaves (Santos Sarah et al. 2021; Souza Junior et al. 2019); however, in plants that exhibit low or intermediate Si concentrations (such as soybean and cotton, respectively), the root Si uptake capacity is favored by the foliar application of the element (Flores et al. 2019; Hurtado et al. 2021; Souza Junior et al. 2019, 2020, 2022). For foliar Si application, potassium silicate (SiK) has been the predominant source in agriculture (Laane 2018); however, studies on the ideal Si concentration for leaf application, taking into consideration 2 years of field production, are scarce in the literature. In one study involving maize in two growing seasons, the authors were unable to determine the optimal concentration of Si in the form of potassium silicate, only indicating that it was above 0.056 g L−1 (Ibrahim et al. 2020). Other studies were performed in crops under stress (Oliveira et al. 2019a; Oliveira Rocha et al. 2022; Rodrigues et al. 2009; Santos Sarah et al. 2021; Souza Junior et al. 2019) and cannot be applied to their stress-free counterparts. Thus, the effect of the foliar spraying of Si in plants under adequate conditions needs to be studied.

A number of studies conducted under greenhouse conditions indicated that the ideal Si concentration in the form of potassium silicate in the leaf spray solution is 0.80 g L−1 and 1.47 g L−1 for cotton (Souza Junior et al. 2019) and soybean (Felisberto et al. 2020), respectively. Although these results were obtained in pots and cannot be extrapolated to the field, they indicate that optimal Si concentrations in the spray solution differ among crops. As the leaf surface and cuticle thickness vary according to plant species (Chacalis et al. 2001; Monquero et al. 2004), they may induce differences in Si absorption, consequently generating differences in the ideal concentrations of this element in the spray solution. Thus, the optimal Si concentration in different field crops remains unknown.

The few field experiments with Si in annual crops used only potassium silicate without stabilizers, which is the source that continues to predominate in the agricultural market. As such, new sources of this element have emerged, such as silicon oxide nanoparticles and other soluble sources, such as sorbitol-stabilized sodium and potassium silicate and PEG-400-stabilized monosilicic acid. The nanoparticle source consists of SiO2 in colloidal dispersion, measuring between 1 and 10 nm (Ball 2002; Roco 2003), which changes its chemical properties in relation to microparticles (Bell 2003), increasing the leaf absorption of Si by plants, as reported for sorghum (Oliveira et al. 2019b) grown in a greenhouse. Soluble sources contain stabilizers that prevent polymer formation and increase the leaf absorption of Si by plants. In this case, once absorbed, Si may favor the basic aspects of the physiology of photosynthesis, resulting in increased plant development, as observed for cotton (Souza Junior et al. 2019, 2020), maize (Santos Sarah et al. 2021), and soybean (Shwethakumari and Prakash 2018) grown in a greenhouse. These results indicate the promising potential of soluble Si sources, although needing to be confirmed by analyzing the yield data of crops under field conditions. Differences in the stability of Si in solution as a function of the source (Souza Junior et al. 2020) may affect the optimal Si concentration for foliar application.

We hypothesize that (a) innovative sources of Si, such as SiO2 nanoparticles and soluble sources of silicon (such as PEG-400-stabilized monosilicic acid and sorbitol-stabilized sodium and potassium silicate) applied to leaves, are efficient in supplying Si, being alternatives to the standard source, potassium silicate; (b) once absorbed, Si should favor photosynthetic variables, underscoring an innovative source of the element that is able to promote greater increases in cotton, maize, and soybean yields over two consecutive growing seasons, depending on the Si concentration in the spray solution.

If confirmed, this hypothesis would contribute to broaden the possibilities of alternative Si sources and to determine the optimal Si concentrations in solution for leaf spraying in annual crops, which may optimize yields and favor the sustainability of these crops.

Therefore, the present study aimed to determine the effect of foliar Si application using innovative sources on leaf Si concentration, photosynthetic parameters, and yield in soybean (Glycine max), cotton (Gossypium hirsutum), and maize plants (Zea mays).

2 Material and Methods

2.1 Growth Condition and Field Characterization

Six experiments were conducted under field conditions, as follows: three experiments (soybean, cotton, and maize) were carried out in the 2016/2017 growing season (Study 1), and three experiments were carried out with the same crops in the 2017/2018 growing season (Study 2). The experiments were carried out at the Agricultural Research Support Foundation of Chapadão (18°41′33″ S and 52°40′45″ W) in the municipality of Chapadão do Sul, Mato Grosso do Sul state, Brazil.

The soil was classified as a Dystrophic Red Latosol (Embrapa 2018). Before the experiment, chemical analysis of the soil at a depth of 0.00–0.20 cm was carried out according to the methodology described by Raij et al. (2001), obtaining the following results for Study 1 and 2, respectively: pH (CaCl2): 5.4 and 4.9; P (resin): 55.3 and 29.7 mg dm−3; organic matter: 29.1 and 28.8 g dm−3; K: 147 and 185 mg dm−3; Ca: 4.4 and 2.7 cmolc dm−3; Mg: 1.7 and 1.0 cmolc dm−3; S: 10.3 and 3.8 mg dm−3; H + Al: 3.1 and 6.3 cmolc dm−3; Al: 0.02 and 0.05 cmolc dm−3; B: 0.12 and 0.08 mg dm−3; Cu: 2.0 and 0.95 mg dm−3; Fe: 59.0 and 30.5 mg dm−3; Mn: 32.30 and 12.05 mg dm−3; and Zn: 16.3 and 5.85 mg dm−3.

The climate in the region, according to the Köppen classification, is Aw (tropical wet), with rainy summers and dry winters. Rainfall (mm) and minimum and maximum temperatures (°C) were recorded during the experimental period (Fig. 1).

Study 1 was conducted with the soybean cultivar BRX Bonus IPRO®, from October 2016 to February 2017, with cotton cultivar FM 975 WS®, from February to June 2017, and with the maize hybrid 2B633PW, from February to March 2017. The soybean cultivar BRX Bonus IPRO® belongs to the 7.9 maturation group, with indeterminate growth, moderate soil fertility requirement, and moderate lodging resistance; the cotton cultivar FM 975 WS® presents high yield potential, a medium-late maturing cycle of 160 to 190 days, and presents the WideStrike® technology, which provides resistance to bacteriosis and viruses; and the hybrid maize variety 2B633PW presents high rusticity and productive stability, with an early maturing cycle, being highly indicated for production systems with high to medium investments. Study 2 was conducted with the soybean cultivar BRX Desafio RR®, from October 2017 to January 2018, cotton cultivar FM 983 GLT®, between January and July 2018, and maize genotype P30F35, between February and April 2018. The soybean cultivar BRX Desafio RR® belongs to the 7.4 maturation group, with indeterminate growth, high soil fertility requirements, and high lodging resistance; the cotton cultivar FM 983 GLT® presents a late maturing cycle of 180 to 200 days, presenting the GLT® technology, which provides resistance to bacteriosis and viruses; the maize genotype P30F35 presents a hyper-early cycle and high yield, being indicated for planting systems with high investment.

The soil was prepared conventionally by plowing and two harrowings 60 days before crop planting, with another harrowing 2 days before planting in both studies. In Study 1, there was no need for soil correction. In Study 2, 2 t ha−1 of lime (CaO 35%; MgO 12%; total neutralizing power of 85%) and 2.5 t ha−1 of gypsum were applied.

The fertilizer was applied based on the recommendations by Souza and Lobato (2004), with the soil being subsequently analyzed. In both studies, a base dressing of 150, 250, and 270 kg ha−1 monoammonium phosphate (11–52-00) was used for soybean, cotton, and maize, respectively, and 150 kg ha−1 KCl (60% K2O) was also used for cotton. Topdressing was performed with 150 kg ha−1 of KCl (60% K2O) in the V3 growth stage (third node, second trefoil completely open) for soybean; with 260 kg ha−1 of urea distributed into half of the dose in stage B1 (first flower bud in the first reproductive node) and the rest of the dose in F1 (first flower in the first reproductive node) for cotton; and with 150 kg ha−1 of N in the form of urea (45% of N) distributed into half of the dose in V2 (second fully developed leaf) and the rest of the dose in V4 (fourth fully developed leaf) for maize.

2.2 Experimental Design and Experimental Plots

Study 1 was arranged using a randomized blocks in a 4 × 4 factorial scheme consisting of four sources of Si: sorbitol-stabilized sodium and potassium silicate (SiAl—107 g L−1 Si; 14.9 g L−1 Cu; 28.4 g L−1 K2O; 100 mL L−1 sorbitol; and pH 11.8); PEG-400-stabilized monosilicic acid (SiAc—13.8 g L−1 Si and pH 1.6); nanosilica (Bindzil®) (Nano—77 g L−1 Si, mean diameter of 4 nm, specific surface area of 750 cm2 g−1, and pH 10.5); and potassium silicate without stabilizer (SiK—128 g L−1 Si; 126.5 g L−1 K2O, and pH 12.0); and four Si concentrations: 0.0; 0.25; 0.50; and 1.0 g L−1 Si, with three replicates. Treatments with SiAl and SiK contained potassium and copper, nutrients that were balanced in all treatments using potassium chloride and copper sulfate, respectively.

The results of Study 1, which indicated the best innovative source of Si and the best concentration in the spray solution for the crops studied, were compared in the subsequent growing season with the results obtained using the standard source (potassium silicate), in order to determine whether the innovative source would be stable over at least two consecutive seasons. Study 2 was carried out using three experiments with maize, soybean, and cotton crops, being arranged in randomized blocks with three treatments: without Si (0 g L−1); SiK (0.6 g L−1); and SiAl (0.6 g L−1), with seven replicates. K and Cu were balanced in all treatments using potassium chloride and copper sulfate.

In both studies, the experimental plots for soybean and maize consisted of seven rows, 5.5-m-long spaced 0.45 cm apart, with the study area consisting of the two central rows and being 3 m long (4.05 m2). The experimental plot for cotton consisted of four rows, 5.5 m long spaced 0.9 m apart, with the study area consisting of the two central rows and being 3 m long (4.05 m2).

2.3 Treatments

The silicate solution for foliar spraying was prepared using the different treatments in both studies, and the pH was adjusted to 7.0 ± 0.3. Foliar Si application was performed immediately after the spray solution was prepared using a CO2-pressurized sprayer with a flow rate of 150 L ha−1 at 2 bar pressure and 6 nozzles spaced 0.50 m apart for studies with soybean and maize; and with a flow rate of 150 L ha−1 at 2.5 bar pressure and 6 nozzles spaced 0.45 m apart for studies with cotton.

In Study 1, four foliar applications were performed in soybean: in V4 (fourth node, 3rd open trefoil), R1 (start of flowering), R3 (end of flowering, beginning pod), and R5 (beginning seed fill, at 10% seed development), and in cotton: in B5 (five fully developed flower buds), F5 (five fully developed flowers), C1 (first open boll), and C3 (third open boll); while three foliar applications were performed in maize: in V7 (seven fully expanded leaves), VT (bolting), and in R3 (milky grain).

In Study 2, three foliar applications were performed in soybean: in V4 (fourth node, 3rd open trefoil), R2 (complete flowering) and R5.1 (noticeable grains, at 10% germination), in maize: in V6 (sixth fully developed leaf), V9 (ninth developed leaf), and VT (bolting), and in cotton: in B3 (third flower bud in the first reproductive node), F1 (first flower in the first reproductive node), and F3 (third flower in the first reproductive node).

The climate conditions for all foliar applications in the experiments were adequate, since there was no rainfall in the first 48 h after sprayings, the temperature ranged from 20 to 24 °C, the relative humidity was above 72%, and the wind speed was below 7 km h−1.

2.4 Specific Analyses

Photosynthetic rate, stomatal conductance, internal CO2 concentration, and transpiration were evaluated using a portable gas analyzer (Li-COR-6400 XT®), regulated for an irradiance of 1000 µmol m−2 s−1 of photons, leaf carbon assimilation rate of 380 µmol m−2 s−1 CO2, and flow rate of 500 µmol m−2 s−1. Analyses were carried out between 9:00 and 10:00 am 1 week after the third application, with fully flowered plants being measured in the soybean plants in Studies 1 and 2 in the central trefoil of the first fully expanded leaf. Due to excessive cloud cover, photosynthetic analyses were conducted in the cotton plants only in Study 1, in the fifth leaf from the apex of the main stem; and in maize plants only in Study 2, in the opposite leaf below the spike.

In all the experiments, 30 leaves of fully flowered plants were sampled. For soybean plants, the central trefoil of the first fully expanded leaf was collected; for cotton plants, the fifth leaf from the apex of the main stem was collected; and for maize plants, the third basal leaf opposite and below the spike (upper) was collected.

Leaf samples were decontaminated with water, followed by a neutral detergent solution (1%), HCl solution (1%), and deionized water, being dried in a forced air ventilation oven at 65 ± 5 °C until reaching constant mass. Later, samples were ground in a Wiley mill. Then, the leaves were chemically analyzed to determine the Si content from alkaline digestion with H2O2 and NaOH, and the colorimetric reaction with ammonium molybdate was conducted for colorimetric reading in a spectrophotometer, according to the methodology described by Kondörfer et al. (2004).

Soybean, maize, and cotton yield were analyzed in both studies. For this, plants in the study area (4.05 m2) were collected manually in R7 for soybean and R6 for maize plants. Next, the pods and the spikes were threshed, passed through sieves, dried under natural conditions, and weighed, being corrected for 13% moisture and converted into kg ha−1. When cotton plants were in the physiological stage C5, the bolls were collected in the study area (4.05 m2), and the cotton fiber + cotton seed yield was calculated.

2.5 Statistical Analysis

The data obtained were submitted to analysis of variance (F-test). When significant, the data were analyzed using Tukey’s test at 5% probability for the different sources in Study 1 and treatments in Study 2. The different concentrations analyzed in Study 1 were studied using polynomial regression. The model significant at 5% probability was selected by the t test. All statistical analyses were conducted using the software Sisvar® (Ferreira 2014).

3 Results

3.1 Study 1—Innovative Silicon Source for Foliar Application in Cotton, Soybean, and Maize

3.1.1 Leaf Silicon Concentration

In soybean (Fig. 2a), SiAl, SiAc, and Nano at concentrations of 0.25 and 0.50 g L−1 showed the same efficiency to increase the leaf Si concentration in the crops; however, at the highest concentration studied (1.00 g L−1 Si), SiAl was more efficient. SiK showed lower efficiency in increasing the leaf Si concentration of soybean plants in all concentrations studied compared to the other sources. The increase in the Si concentrations applied resulted in a quadratic increase in the leaf Si content, reaching the maximum contents of 2.00, 1.72, 1.71, and 1.57 g kg−1 with SiAl, SiAc, Nano, and SiK, respectively. In addition, the leaf Si content increased with all Si sources, peaking at Si the concentrations of 0.77, 0.58, 0.69, and 0.96 g L−1 for SiAl, SiAc, Nano, and SiK, respectively.

Leaf silicon (Si) content in soybean (a), cotton (b), and maize (c) cultivated with different foliar-applied sources (S): sodium and potassium stabilized with sorbitol (SiAl); monosilicic acid stabilized with PEG400 (SiAc); nanosilica Bindzil® (Nano); and potassium silicate without stabilizer (SiK); and different concentrations (c) of Si (Season 2016/17). Different letters indicate a different source at the same Si concentration according to Tukey’s test at 5% probability. ** significant at 1% probability according to the F-test

In cotton plants (Fig. 2b), SiAl was the most efficient source to increase the leaf Si content in all sources studied. In the application of Si at concentrations equal to 0.25 and 0.50 g L−1, SiAc and Nano were more efficient to increase the leaf Si content compared to SiK, without differing between them, and at the concentration of 1.0 g L−1 Si, the SiAc was more efficient in increasing the leaf Si content compared to Nano and SiK, which did not differ from each other. The increase in the Si concentration applied increased the leaf Si content in cotton plants. The leaf Si content increased linearly, reaching 5.7 g L−1 at the highest Si concentration (1.00 g L−1) with the use of SiAc. The other Si sources presented quadratic adjustment as a function of the increase in the Si concentration applied, reaching the maximum points at concentrations of 0.97, 0.71, and 0.93 g L−1 Si, which obtained contents of 6.70, 3.61, and 3.00 g kg−1 for SiAl, Nano, and SiK, respectively. The foliar spraying of Si in cotton plants promoted an increase in leaf Si content, with the maximum values obtained at the concentrations of 0.97, 0.71, and 0.93 g L−1 Si with SiAl, Nano, and SiK, respectively (Fig. 2b).

In maize, SiAl, SiAc, and Nano were more efficient in comparison to SiK in increasing the leaf Si content in all studied concentrations. The increase in the Si concentration applied resulted in an increase with quadratic adjustment in the leaf Si content, reaching a maximum point at Si concentrations up to 0.70, 0.72, 0.73, and 0.71 g L−1, which obtained contents of 26.7, 26.0, 25.4, and 22.4 for SiAl, SiAc, Nano, and Sik, respectively (Fig. 2a).

3.1.2 Photosynthetic Variables

In soybean, there were no differences between Si sources for transpiration (Fig. 3a), stomatal conductance (Fig. 3c), and photosynthetic rate (Fig. 3e). However, the increase in the Si concentrations increased transpiration, stomatal conductance, and photosynthetic rate with quadratic adjustment, peaking at 13.5, 0.99, and 31.0 mmol m−2 s−1 at 0.65, 0.66, and 0.61 g L−1 Si for transpiration (Fig. 3a), stomatal conductance (Fig. 3c), and photosynthetic rate (Fig. 3e), respectively.

Transpiration (a, b), stomatal conductance (c, d), and photosynthetic rate (e, f) in soybean and cotton grown under different foliar-applied sources (S): sodium and potassium stabilized with sorbitol (SiAl); monosilicic acid stabilized with PEG400 (SiAc); nanosilica Bindzil® (Nano); and potassium silicate without stabilizer (SiK); and different concentrations (c) of Si (2016/17 growing season). Different letters indicate a different source at the same Si concentration according to Tukey’s test at 5% probability; ** e ns—significant at 1% probability and non-significant according to the F-test, respectively

In cotton, the application of Si using SiAc stood out from the other Si sources at the concentrations of 0.25 and 0.50 g L−1, promoting higher transpiration rates, with no difference being observed between the other sources at these concentrations. At the concentration of 1.00 g L−1, Si sources did not differ among them for the transpiration variable. The increase in Si contents increased transpiration with quadratic adjustment, reaching a maximum point of 9.79, 11.14, 9.09, and 9.70 mmol m−2 s−1 with the application of 0.59, 0.51, 0.55, and 0.51 g L−1 Si for SiAl, SiAc, Nano, and SiK, respectively (Fig. 3b).

The application of Si as SiAc at concentrations of 0.50 and 1.00 g L−1 Si also resulted in the highest stomatal conductance for cotton plants, with no difference being observed between the other Si sources at these Si concentrations. At the Si concentration equal to 0.25 g L−1, Si sources did not differ between them for the transpiration variable. The stomatal conductance increased as a function of the increase in the Si concentration applied, reaching 0.57, 0.73, 0.55, and 0.59 mmol m−2 s−1 at 0.67, 0.64, 0.56, and 0.65 g L−1 Si for SiAl, SiAc, Nano, and SiK, respectively.

The application of SiAc also resulted in the highest photosynthetic rate at the concentration of 0.25 g L−1 Si, not differing from SiAl and SiK, while the application of Si in the Nano form resulted in the lowest photosynthetic rate, without differing from the SiAl and SiK sources. At Si concentrations equal to 0.50 and 1.00 g L−1, the use of SiAc and SiK resulted in the highest photosynthetic rate, without differing between Si sources, while the application of Nano and SiAl presented the opposite effect, promoting the lowest photosynthetic rates, without differences between them. The increase in the Si concentration applied resulted in an increase in the photosynthetic rate with quadratic adjustment, reaching a maximum point of 26.7, 29.8, 24.4, and 28.8 mmol m−2 s−1 at the concentrations of 0.59, 0.60, 0.63, and 0.65 g L−1 Si for SiAl, SiAc, Nano, and SiK, respectively (Fig. 3f).

3.1.3 Yield

In soybean, the application of SiAl and SiAc resulted in the greatest increase in grain yield when applied at a concentration of 0.25 g L−1 Si, without differing between them. However, when used at concentrations of 0.5 and 1.00 g L−1 Si, SiAl stood out, presenting higher yield, followed by SiAc, Nano, and SiK, which did not present differences between them. The increase in the Si concentration increased soybean yield until the concentration of 0.67, 0.53, 0.56, and 0.60 g L−1 Si, with total grain yields of 82.2, 71.9, 70.51, and 74.5 kg ha−1 for SiAl, SiAc, Nano, and SiK, respectively (Fig. 4a).

Yield of soybean (a), cotton (b), and maize (c) cultivated with different foliar-applied sources (S): sodium and potassium stabilized with sorbitol (SiAl); monosilicic acid stabilized with PEG400 (SiAc); nanosilica Bindzil® (Nano); and potassium silicate without stabilizer (SiK); and different Si concentrations (c) (2016/17 growing season). Different letters indicate a different source at the same Si concentration according to Tukey’s test at 5% probability; ** e ns—significant at 1% probability and non-significant according to the F-test, respectively

In cotton, fiber + seeds yield was higher in plants that received Si at a concentration of 0.25 g L−1 using SiAl, without differences from SiAc and SiK. In addition, at this Si concentration, the Nano source provided the lowest value and presented the lowest fiber + seeds yield, without differing from SiAc and SiK. At the Si concentration of 0.50 g L−1, SiAl showed the highest fibers + seeds yield, followed by Nano and SiAc, which did not present differences between them, while SiK presented the lowest yield. At the highest Si concentration studied, 1.00 g L−1, SiAl obtained the greatest yield increase, followed by the other sources, which did not differ from each other. The increase in the Si concentration increased the fiber + seeds yield with quadratic adjustment, obtaining the maximum point at concentrations of 0.56, 0.51, 0.54, and 0.52 g L−1 Si, with yields of 2298.3, 2568.8, 2593.7, and 2566.4 kg ha−1 for SiAl, SiAc, Nano, and SiK, respectively (Fig. 4c).

The application of Si at a concentration of 0.25 g L−1, in the form of SiK, resulted in the highest yield for maize plants, followed by SiAc, SiAl, and Nano, which did not differ from each other. However, the Si concentrations of 0.50 and 1.00 g L−1 using SiAl resulted in the highest yield, followed by SiAc and SiK, without differences between them, and Nano. The yield of maize grains increased as the Si concentration increased up to the concentrations of 0.77, 0.62, 0.63, and 0.65 g L−1, with yields of 6284.8, 6143.7, 5427.7, and 6160.3 kg ha−1, for SiAl, SiAc, Nano, and SiK, respectively.

3.2 Study 2—Sorbitol-Stabilized Sodium and Potassium Silicate and Potassium Silicate for Foliar Application Increase Cotton, Soybean, and Maize Yield

3.2.1 Leaf Silicon Concentration

In soybean plants, there was no difference between the Si sources applied, although both SiK and SiAl provided higher leaf Si contents compared to the control treatment; in maize and cotton plants, the application of Si in the form of SiAl resulted in a greater increase in the leaf Si content, followed by the application of Si using SiK and by the control plants (Fig. 5a).

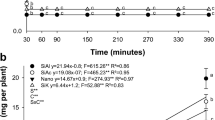

Leaf Si content in soybean, cotton, and maize (a) and transpiration (b), stomatal conductance (c), and photosynthetic rate (d) in soybean and maize plants with no leaf Si application (No Si) and application of 0.6 g L−1 of Si in the form of SiK and SiAl (2017/18 growing season). Different letters indicate a different source in the same crop studied

3.2.2 Photosynthetic Variables

In soybean plants, leaf Si application in the form of SiK and SiAl increased transpiration (Fig. 5b), stomatal conductance (Fig. 5c), and photosynthesis (Fig. 5d) when compared to the control treatments, with no difference between Si sources. In maize plants, Si application in the form of SiAl promoted higher transpiration (Fig. 5b), stomatal conductance (Fig. 5c), and photosynthetic rates (Fig. 5d) compared with SiK, although both sources differed from the control treatment (without Si).

3.2.3 Yield

Foliar spraying of Si in the form of SiAl was superior to the spraying of SiK for soybean, cotton, and maize yields (Fig. 6). In soybean, the application of SiAl increased yield by 39% (119.9 kg ha−1), while the application of Si K increased yield by 22% (104.8 kg ha−1) compared to the control (86 kg ha−1); in cotton, the application of SiAl increased yield by 39% (2843.5 kg ha−1), while the application of SiK increased yield by 16% (2378.9 kg ha−1) in relation to the control treatment (2043.8y kg ha−1). In maize, the application of SiAl increased yield by 42% (6994.4 kg ha−1), while the application of SiK increased yield by 15% (5611.8 kg ha−1) in relation to the control treatment (4904.4 kg ha−1).

Yield of soybean (a), cotton and maize (b) cultivated with no foliar Si application (No Si) and application of 0.6 g L−1 of Si in the form of potassium silicate without stabilizer and sodium and potassium silicate stabilized with sorbitol (SiAl). Different letters indicate a different source in the same crop studied

4 Discussion

The efficiency of the foliar application of Si depends on the source and concentration of Si applied (Souza Junior et al. 2020), and despite SiK being the main Si source for foliar application in crops (Laane et al. 2018), innovative sources of Si such as SiAl, SiAc, and Nano promote higher leaf Si contents for soybean, maize, and cotton plants. The greater efficiency of innovative sources such as SiAc and SiAl may be due to the greater stability of the monomeric species of Si in solution in these sources, which is promoted by the presence of stabilizers, such as PEG400 or sorbitol, respectively (Souza Junior et al. 2020). Sorbitol is a polyalcohol that provides greater solution stability, decreasing the polymerization rate of monosilicic acid in solution and lowering the deliquescence point of the solution on the leaf surface (Kubicki and Heaney 2003), while PEG400 may decrease the clustering of monomeric Si species and the polymerization process, as well as increasing viscosity, decreasing water evaporation on the leaf surface (D’souza and Shegokar 2016). Si nanoparticles do not have stabilizers. However, Nano was superior to SiK in increasing the leaf silicon content of soybean, cotton, and maize, as Nano-SiO2 is a material that exhibits particles in a nanomeric scale (Le et al. 2014), thereby facilitating the leaf absorption process (Oliveira et al. 2019b).

It is important to highlight that despite being less efficient than the innovative sources of Si, SiK was also efficient in increasing the leaf Si content in soybean, cotton, and maize in relation to the control treatment, thus being also an efficient source for foliar application. Once absorbed, Si is deposited in the cells of the leaf epidermis and in guard cells of the stomata, forming a Cuticle-Si double layer (Keller et al. 2015), which may affect gas exchanges. In the literature, information on the effect of Si on gas exchange is contradictory, as while some studies have found that Si decreases gas exchanges (Ahmed et al. 2020; Barros et al. 2018; Hussain et al. 2020), other studies have shown that the application of Si increases gas exchanges (Flores et al. 2018; Liu et al. 2014). Chen et al. (2018) underscored that these conflicting results are caused by the variation in the species studied, with a tendency for Si to reduce transpiration in plants that received a high concentration of the element. This may occur due to Si polymerization on the leaf surface, forming a crust and decreasing gas exchanges, as according to Haynes (2019), the increased concentration of this element in the solution increases the risks of the formation of polysilicic acid and silica gel.

Studies with foliar spraying of Si in annual crops do not explore the importance of Si sources and the relationship of foliar contents with crop yield, making it difficult to use foliar analysis to guide the use or management of Si application in the field. The beneficial effect of the foliar Si application was confirmed by the increase in yield, particularly for SiAl at the intermediate dose, since it promoted high contents of the element in the leaves of the crops studied. It is important to underscore that the ideal Si concentration in the leaf spray solution varied between crops. This may be due to the difference in Si absorption by leaves, since plant tissues differ between species (Chacalis et al. 2001; Monquero et al. 2004). The positive effect of the foliar spraying of Si on the basic physiology of plants, increasing transpiration, stomatal conductance, and photosynthesis, which was also observed in the present study, has been reported in the literature for soybean (Barros et al. 2018; Hussain et al. 2021; Shwethakumari and Prakash 2018), cotton (Barros et al. 2019; Leal et al. 2021; Souza Junior et al. 2019, 2020), and maize plants (Galindo et al. 2020; Hosseini et al. 2019; Ibrahim et al. 2020). Another important aspect that contributed to favor the benefits of Si on crop yield may be the fact that three or four sprayings were performed in all the experiments. This may have enriched a larger number of leaves with Si in the plants, favoring its biological effect, as according to Moreira et al. (2010), foliar sprayings of Si only increase the yield of annual crops with at least three applications.

In the literature, it is indicated that the responses of crops to the supply of Si predominate especially under stress conditions (Prado 2021). However, in this study, the response of annual crops under nutritional sufficiency was observed, and the number of studies addressing plants under nutritional sufficiency is restricted; hence, it is important to expand the research in stress-free field crops. It was shown that the optimal leaf Si contents associated with maximum yield varied according with the crop and source used. In the soybean crop that had Si applied as SiK, the optimal Si concentration in the foliar spray solution is similar to that indicated by Felisberto et al. (2020) in soybean using the same source (1.47 g L−1) and lower than that of other species, since this plant does not accumulate Si. The highest optimal leaf Si contents were recorded for the maize crop, as according to Deshmukh et al. (2020), this crop displays a high Si absorption capacity, being an accumulator of this element in the leaves. For the first time, the optimal Si concentrations in the solution were established according to the Si source used in foliar spraying for three important annual crops: soybean, cotton, and maize. This finding has other practical implications as soybean, cotton, and maize crops, which have relatively low leaf Si contents, that is, lower than the optimal concentrations indicated above, may present positives responses to foliar Si application. This unprecedented information could be used to make a decision regarding the indication of foliar spraying, contributing to ensure greater efficiency in the use of Si in agriculture for these three species, using foliar analysis as a criterion to indicate the use of Si.

Thus, we can accept the hypotheses tested, indicating that innovative sources of Si for foliar application are efficient in providing the beneficial element to soybean, cotton, and maize crops due to presenting greater increases in leaf Si concentration than SiK. We proved that after absorption, Si favors physiological aspects, and the innovative source of Si SiAl stood out for achieving the highest yield for the three crops over two growing seasons.

5 Conclusions

The stabilized sodium and potassium silicate is a new option in relation to the conventional source, potassium silicate, for foliar fertilization with silicon in annual crops. Our study proposes the use of this source for the foliar spraying of Si at a concentration between 0.6 and 0.8 g L−1, for soybean, cotton, and maize crops, especially when the foliar contents of the element are below 2.0, 5.5, and 26.6 g kg−1, respectively. The perspective is that the foliar spraying of Si will be used even in stress-free field crops and, when supported by adequate recommendation, should contribute to the efficient use of the foliar spraying of Si, strengthening the sustainability of annual crops, as it is known that the contents used are relatively low when compared to soil applications, not posing risks to the environment.

References

Ahmed M, Qadeer U, Fayayz-ul-Hassan FS, Naseem W, Duangpan S, Ahmad S (2020) Abiotic stress tolerance in wheat and the role of silicon: an experimental evidence. Agron Crops. https://doi.org/10.1007/978-981-15-0025-1_22

Bakhat HF, Bibi N, Zia Z, Abbas S, Hammad HM, Fahad S, Ashraf MR, Shah GM, Rabbani F, Saeed S (2018) Silicon mitigates biotic stresses in crop plants: a review. Crop Prot. https://doi.org/10.1016/j.cropo.2017.10.008

Ball P (2002) Natural strategies for the molecular engineer. Nanotechnology. https://doi.org/10.1088/0957-4484/13/5/201

Barros TC, De Mello PR, Garcia Roque C, RibeiroBarzotto G, Roberto Wassolowski C (2018) Silicon and salicylic acid promote different responses in legume plants. J Plant Nutr. https://doi.org/10.1080/01904167.2018.1497177

Barros TC, de Mello PR, Roque CG, Arf MV, Vilela RG (2019) Silicon and salicylic acid in the physiology and yield of cotton. J Plant Nutr. https://doi.org/10.1080/01904167.2019.1567765

Bell AT (2003) The impact of nanoscience on heterogeneous catalysis. Science. https://doi.org/10.1126/science.1083671

Campos CNS, da Silva Júnior GB, de Mello Prado R, de David CHO, de Souza Junior JP, Teodoro PE (2020) Silicon mitigates ammonium toxicity in plants. Agron J. https://doi.org/10.1002/agj2.20069

Chacalis D, Reddy K, Elmore C (2001) Characterization of leaf surgace, wax composition, and control of redvine and trumpetcreeper with glyphosate. Weed Sci. https://doi.org/10.1086/337823

Chen D, Wang S, Yin L, Deng X (2018) How does silicon mediate plant water uptake and loss under water deficiency? Front Plant Sci. https://doi.org/10.3389/fpls.2018.00281

Coskun D, Deshmukh R, Sonah H, Menzies JG, Reynolds O, Ma JF, Kronzucker HJ, Bélanger RR (2019) The controversies of silicon’s role in plant biology. New Phytol. https://doi.org/10.1111/nph.15343

de Mello Prado R (2021) Mineral nutrition of tropical plants. Springer Nature, Switzerland

de Souza Junior JP, de Mello Prado R, dos Santos Sarah MM, Felisberto G (2019) Silicon mitigates boron deficiency and toxicity in cotton cultivated in nutrient solution. J Plant Nutr Soil Sci. https://doi.org/10.1002/jpln.201800398

Deshmukh R, Sonah H, Belanger R (2020) New evidence defining the evolutionary path of aquaporins regulating silicon uptake in land plants. J Exp Bot. https://doi.org/10.1093/jxb/eraa342

D’souza AA, Shegokar R (2016) Polyethylene glycol (PEG): a versatile polymer for pharmaceutical applications. Expert opin drug deliv 13(9):1257–1275. https://doi.org/10.1080/17425247.2016.1182485

Embrapa (2018) Sistema brasileiro de classificação de solo [Portuguese]. Embrapa, Brasília

Felisberto G, de Mello PR, de Oliveira RLL, de Carvalho Felisberto PA (2020) Are nanosilica, potassium silicate and new soluble sources of silicon effective for silicon foliar application to soybean and rice plants? Silicon. https://doi.org/10.1007/s12633-020-00668-y

Ferreira DF (2014) Sisvar: a guide for its bootstrap procedures in multiple comparisons. Cienc e Agrotec. https://doi.org/10.1590/S1413-70542014000200001

Flores RA, Martins Arruda E, Damin V, Pereira Souza Junior J, Diego Carvalho Maranhão D, André RibeiroCorreia M, de Mello Prado R (2018) Physiological quality and dry mass production of Sorghum bicolor following silicon (Si) foliar application. Aust J Crop Sci. https://doi.org/10.21475/ajcs.18.12.04.pne967

Flores RA, Arruda EM, de Souza Junior JP, de Mello Prado R, dos Santos ACA, Aragão AS, Pedreira NG, da Costa CF (2019) Nutrition and production of Helianthus annuus in a function of application of leaf silicon. J Plant Nutr. https://doi.org/10.1080/01904167.2018.1549678

Galindo FS, Pagliari PH, Rodrigues WL, de Azambuja Pereira MR, Buzetti S, Teixeira Filho MCM (2020) Investigation of Azospirillum brasilense inoculation and silicon application on corn yield responses. J Soil Sci Plant Nutr. https://doi.org/10.1007/s42729-020-00306-x

Haynes RJ (2019) What effect does liming have on silicon availability in agricultural soils? Geoderma. https://doi.org/10.1016/j.geoderma.2018.09.026

Hosseini SA, Rad SN, Ali N, Yvin J-C (2019) The ameliorative effect of silicon on maize plants grown in Mg-deficient conditions. Int J Mol Sci. https://doi.org/10.3390/ijms20040969

Hurtado AC, Chiconato DA, de Mello PR, Souza Júnior JS, Viciedo DO, Díaz YP, Calzada KP, Gratão PL (2021) Silicon alleviates sodium toxicity in sorghum and sunflower plants by enhancing ionic homeostasis in roots and shoots and increasing dry matter accumulation. Silicon. https://doi.org/10.1007/s12633-020-00449-7

Hussain S, Shuxian L, Mumtaz M et al (2020) Foliar application of silicon improves stem strength under low light stress by regulating lignin biosynthesis genes in soybean (Glycine max (L.) Merr.). J Hazard Mater. https://doi.org/10.1016/j.jhazmat.2020.123256

Hussain S, Mumtaz M, Manzoor S, Shuxian L, Ahmed I, Skalicky M, Brestic M, Rastogi A, Ulhassan Z, Shafiq I, Allakhverdiev SI, Khurshid H, Yang W, Liu W (2021) Foliar application of silicon improves growth of soybean by enhancing carbon metabolism under shading conditions. Plant Physiol Biochem. https://doi.org/10.1016/j.plaphy.2020.11.053

Ibrahim MFM, El-Samad GA, Ashour H, El-Sawy AM, Hikal M, Elkelish A, El-Gawad HA, El-Yazied AA, Hozzein WN, Farag R (2020) Regulation of agronomic traits, nutrient uptake, osmolytes and antioxidants of maize as influenced by exogenous potassium silicate under deficit irrigation and semiarid conditions. Agron. https://doi.org/10.3390/AGRONOMY10081212

Keller C, Rizwan M, Davidian JC, Pokrovsky OS, Bovet N, Chaurand P, Meunier JD (2015) Effect of silicon on wheat seedlings (Triticum turgidum L.) grown in hydroponics and exposed to 0 to 30 μM Cu. Planta 241(4):847–860. https://doi.org/10.1007/s00425-014-2220-1

Kondörfer GH, Pereira HS, Nola A (2004) Análise de silício: solo, planta e fertilizante [Portuguese]. UFU, Uberlândia

Kubicki JD, Heaney PJ (2003) Molecular orbital modeling of aqueous organosilicon complexes: Implications for silica biomineralization. Geochimica et Cosmochimica Acta, 67(21):4113–4121. https://doi.org/10.1016/S0016-7037(03)00093-0

Laane H-M (2018) The effects of foliar sprays with different silicon compounds. Plants. https://doi.org/10.3390/plants7020045

Le VN, Rui Y, Gui X, Li X, Liu S, Han Y (2014) Uptake, transport, distribution and bio effects of SiO2 nano particles in Bt-transgenic cotton. Journal of nano biotechnology 12(1):1–15. https://doi.org/10.1186/s12951-014-0050-8

Leal AJF, Barreto RF, Mello Prado R, Silva Junior GB, Barreto CF, dos Santos LCN, Campos CNS (2021) Silicon attenuates abiotic stress caused by ammonium toxicity but not nitrogen deficiency in cotton plants. J Agron Crop Sci. https://doi.org/10.1111/jac.12499

Liu P, Yin L, Deng X, Wang S, Tanaka K, Zhang S (2014) Aquaporin-mediated increase in root hydraulic conductance is involved in silicon-induced improved root water uptake under osmotic stress in Sorghum bicolor L. J Exp Bot. https://doi.org/10.1093/jxb/eru220

Monquero PA, Christoffoleti PJ, Matas JA, Heredia A (2004) Caracterização da superfície foliar e das ceras epicuticulares em Commelina benghalensis, Ipomoea grandifolia e Amaranthus hybridus [Portuguese]. Planta Daninha. https://doi.org/10.1590/S0100-83582004000200005

Moreira AR, Fagan EB, Martins KV, Souza CHE (2010) Resposta da cultura de soja a aplicação de silício foliar [Portuguese]. Biosci J 26:413–423

Oliveira RLL, de Mello PR, Felisberto G, Checchio MV, Gratão PL (2019a) Silicon mitigates manganese deficiency stress by regulating the physiology and activity of antioxidant enzymes in sorghum plants. J Soil Sci Plant Nutr. https://doi.org/10.1007/s42729-019-00051-w

Oliveira RLL, de Mello PR, Felisberto G, Cruz FJR (2019b) Different sources of silicon by foliar spraying on the growth and gas exchange in sorghum. J Soil Sci Plant Nutr. https://doi.org/10.1007/s42729-019-00092-1

Oliveira Rocha IL, de Mello PR, Oliveira KS, da Silva DL, Abreu-Junior CH (2022) Foliar spraying of Mn with addition of Si increases phenolic compound, photosynthetic efficiency, productivity and the protein content of the soybean crop. J Soil Sci Plant Nutr. https://doi.org/10.1007/s42729-022-00780-5

Roco MC (2003) Broader societal issues of nanotechnology. J Nanoparticle Res. https://doi.org/10.1023/A:1025548512438

Rodrigues FA, Duarte HSS, Domiciano GP, Souza CA, Korndörfer GH, Zambolim L (2009) Foliar application of potassium silicate reduces the intensity of soybean rust. Australas Plant Pathol. https://doi.org/10.1071/AP09010

Santos Sarah MM, de Mello PR, Teixeira GCM, de Souza Júnior JP, de Medeiros RLS, Barreto RF (2021) Silicon supplied via roots or leaves relieves potassium deficiency in maize plants. Silicon. https://doi.org/10.1007/s12633-020-00908-1

Shwethakumari U, Prakash NB (2018) Effect of foliar application of silicic acid on soybean yield and seed quality under field conditions. J Indian Soc Soil Sci. https://doi.org/10.5958/0974-0228.2018.00051.8

Silva JLF (2021) Elucidating the action mechanisms of silicon in the mitigation of phosphorus deficiency and enhancement of its response in sorghum plants. J Plant Nutr. https://doi.org/10.1080/01904167.2021.1918155

Souza Junior JP, de Mello PR, Soares MB, da Silva JLF, de Farias Guedes VH, dos Santos Sarah MM, Cazetta JO (2020) Effect of different foliar silicon sources on cotton plants. J Soil Sci Plant Nutr. https://doi.org/10.1007/s42729-020-00345-4

Souza Junior JP, de Mello PR, Campos CNS, Oliveira DF, Cazetta JO, Detoni JA (2022) Silicon foliar spraying in the reproductive stage of cotton plays an equivalent role to boron in increasing yield, and combined boron-silicon application, without polymerization, increases fiber quality. Ind Crops Prod. https://doi.org/10.1016/j.indcrop.2022.114888

Souza DMG, Lobato E (2004) Cerrado: correção do solo e adubação [Portuguese]. Embrapa, Brasília

Van Raij B, Andrade JC, Cantarella H, Quaggio JA (2001) Análise química para availação da fertilidade de solos tropicais [Portuguese]. Instituto Agronômico de Campinas, Campinas

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Souza Júnior, J.P., de Mello Prado, R., Ferreira Diniz, J. et al. Foliar Application of Innovative Sources of Silicon in Soybean, Cotton, and Maize. J Soil Sci Plant Nutr 22, 3200–3211 (2022). https://doi.org/10.1007/s42729-022-00878-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42729-022-00878-w