Abstract

Background

This paper proposes the study of the visco-hyperelastic behavior of a rubber sample. This rubber, coded as the BX rubber sample, is simultaneously loaded and subjected to linear vibrations.

Methods

A multiplicative non-separable variables law of the Nashif has been used to model the behavior that depends on both stretch and frequency. This method allows splitting the intricately combined test performed jointly on both stretch and frequency. On the one hand, we use Young’s complex modulus \(E^*({\omega })\) calculated from the experimental data, and on the other hand, the hyperelastic characteristics \(E({\lambda })\) of the same material obtained from the experimental tensile curve. The hyperelastic phenomenological Gent–Thomas model and the hyperelastic molecular Flory–Erman model are used to evaluate the combined complex modulus \(E^*({\lambda },{\omega })\).

Results

We obtain results that go in the physical sense, i.e, Young’s modulus increases when the material is stretched, while the damping decreases.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The elastomers belong to the great family of polymers and indicate today generally all rubbers, natural or synthetic. Because of their energy-dissipating nature, these materials are used more in the field of the vibration mechanics [1,2,3,4,5,6] and large deformation [7,8,9,10,11,12], more specifically in the suppression of noise and vibrations and also in the calculations of structures using elastomers. Generally, the mechanical behavior of rubber-like materials depends either on the frequency or the temperature, or even on the stress applied. Thus, the behavior law is sometimes defined in quasi-static mode or the dynamic mode. In quasi-static mode, these materials can undergo large deformations and return to their initial form without permanent deformation [13,14,15,16]. In dynamics, elastomeric materials exhibit a frequency and time behavior having the characteristics of a spring [17]. The study of elastomer’s behavior in large deformations under a dynamics regime remains less known and developed. The most well-known and cited research works in this area are the works of [1, 18, 19]. The expression of the constitutive law of this complex study is defined by two approaches. The first approach is given by Padovan [18]. It is a theory based on the summation of the effects of the various deformations, i.e., Small vibrations and hyperelasticity. The second approach is that given by Nashif, Jones, and Henderson [1]. This approach consists of separating the variables, i.e., separating the frequencies of the extensions. Tibi Beda et al. [20] used the second approach to study the linear vibrations of a structure subjected to large static deformation. In their work, they used in the constitutive law the two following strain energy models: Mooney energy [21] and Gent–Thomas energy [22]. In their results, they showed that the preload stiffens the elastomer materials but reduces their damping property. However, this result gives no information on the molecular behavior of the chain network of the material used. Moreover, these two phenomenological models used do not study the displacement of the junction points between the chains during the applied stresses.

To complete the previous results given by [20], we use the molecular Flory–Erman model [23] to Characterize the loaded rubber-like materials subjected to linear vibrations. After recalling the behavior laws in linear viscoelasticity for the determination of the Young complex modulus and the loss factor, the formulation of the constitutive hyperelastic models used are given in the next section; the equations of the hyperelastic behavior are briefly summarized under the title hyperelastic uniaxial behavior; under the title behavior laws for the combined complex modulus and combined loss factor, the equations of linear viscoelasticity coupled with the hyperelastic models are detailed; in the section identification of the mechanical parameters, the least square method for identification of the material parameters is described; afterward, the results; finally, the conclusion summarizes the concluding remarks.

Linear Vibration Behavior Law: Expression of the Modulus \(E(\omega )\) and Loss Factor \({\eta (\omega )}\)

In the representation of the behavior of the viscoelastic material, the history of the loading is taken into account from the earliest to the present moment. In the case of short-memory viscoelastic materials, only the short time interval between the time of observation and the time of loading is taken into account. The modeling of the linear behavior viscoelastic of elastomers by the fractional operators with derivative is an approach that interests the rheologists more and more, because it requires a low number of parameters [2,3,4,5,6]. Thus, the formulation of the Complex modulus and loss factor can be done by using the real parameters. This is how Bagley and Torvik [2] proposed the model below defined by Eq. 1:

With \({\tau _o}=\frac{1}{\omega _o}\) and \({\tau _1}=\frac{1}{\omega _1}\)

\({\omega _o}\) and \({\omega _o}\) represent the cutoff frequencies. \(E_{o},\) \(\tau _o,\) \(\tau _1\), \(\alpha\) and \(\beta\) represents the rheological parameters. Tibi Beda and Yvone Chevalier [24] propose that \(\alpha =\beta\), because:

-

if \(\alpha >\beta\):

$$\begin{aligned} \lim _{{\omega } \rightarrow \infty }E^*({\omega })={E_{o}}\frac{1+(i\tau _o\omega )^{\alpha }}{1+(i\tau _1\omega )^{\beta }}=+\infty , \end{aligned}$$this has no sense in physics.

-

if \(\alpha <\beta\):

$$\begin{aligned} \lim _{{\omega } \rightarrow \infty }E^*({\omega })={E_{o}}\frac{1+(i\tau _o\omega )^{\alpha }}{1+(i\tau _1\omega )^{\beta }}=0, \end{aligned}$$this has also no sense in physics.

-

if \(\alpha =\beta\):

$$\begin{aligned} \lim _{{\omega } \rightarrow \infty }E^*({\omega })={E_{o}}\frac{1+(i\tau _o\omega )^{\alpha }}{1+(i\tau _1\omega )^{\alpha }} ={E_{o}}(\frac{\tau _o}{\tau _1})^{\alpha }, \end{aligned}$$this a real number, which physically has a sense.

Therefore, Eq. 1 then becomes

let us put

With \((i)^{\alpha }=cos(\frac{{\alpha }{\pi }}{2})+isin(\frac{{\alpha }{\pi }}{2})\), we obtain

By developing equation above, we get:

From Eq. 3, we obtains the modulus:

Within the framework of this work, we will use the data estimate from discrete function of Young modulus and the loss factor on rubber sample BX [25].

Constitutive Hyperelastic Models

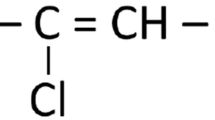

Phenomenological Gent–Thomas Model

Gent and Thomas [22] proposed the following empirical strain energy function which involves only two material parameters:

Where \(K_{1}\) and \(K_2\) represents the material parameters, and \(I_1\) and \(I_2\) the invariants defined by:

and

Molecular Flory–Erman Model

Flory and Erman [23] developed a model based on junction points between chains are constrained to move in a restricted neighborhood due to other chains. Thus, this constrained chain model is given by Eq. 9

Where

k is a measure of the strengths of the constraints and \(\eta\) is the cyclic rank of a network, K the Boltzmann’s constant, T is the absolute temperature and N is the chain density.

Hyperelastic Uniaxial Behavior

The uniaxial behavior of rubber-like materials is given by the Eq. 13:

Where W is the strain energy function, \(\sigma _n\) the nominal stress and \(\lambda\) the stretch; \({\lambda _1}={\lambda }\), and \({\lambda _2}={\lambda _3}=\frac{1}{\sqrt{\lambda }}\). This law can be rewritten in the strain invariants-based by Eq. 14:

In uniaxial traction, the expressions of the invariants \({I_1}\) and \({I_2}\) become: \({I_1}=\lambda ^2+\frac{2}{\lambda }\) and \({I_2}=2\lambda +\frac{1}{\lambda ^2}\).

The relative uniaxial behavior law can be rewritten with Gent–Thomas model and Flory–Erman model.

Using the Phenomenological Gent–Thomas Model

Using the Molecular Flory–Erman Model

With

To simplify the calculations, we set in the following

Combined Modulus \(E({\lambda },{\omega })\) and Combined Loss Factor \(\eta (\lambda ,\omega )\)

To determine the combined complex modulus, we will base the study on three independent experiments: uniaxial tension test to evaluate material tangent modulus \(E(\lambda )\), linear uniaxial vibrations test to determine the dynamic modulus \(E({\omega })\) and loss factor \(\eta (\omega )\). Thus, we consider the multiplicative law and center our study on incompressible materials under simple tension. These independent experiences and results will allow the evaluation of the combined modulus \(E({\lambda },\omega )\) and combined loss factor \(\eta (\lambda ,\omega )\) dependent on both frequency and stretch. These equations are required for comparing the theoretical model with experimental data.

Expression of the Tangent Modulus \(E(\lambda )\)

The logarithmic definition of the Hencky’s variations [26] leads to relation:

Where, \(\lambda\) represent stretch and \(\varepsilon\) the linear deformation.

The Young modulus E (tangent) is equal to:

where \({\sigma }\) is the stress (see Hooke’s law).

For a fixed frequency \(\omega\), one obtains the tangent Young modulus by the relation:

This quantity depends on both the stretch \(\lambda\) and the frequency \(\omega\), so \(E{\equiv }E(\lambda ,\omega )\)

Expression of the Combined Modulus \(E({\lambda },{\omega })\)

The constitutive law taking in account both \(\lambda\) and \(\omega\) is proposed by Nashif [1] This theory stipulates that: if a sample of preloaded elastomer is vibrated linearly (subjected to a large static deformation: extension), the stress can be factored into a function of vibration frequency and a function of the extension. Considering Ferry’s hypothesis [1] separating the variables \(\lambda\) and \(\omega\), and taking advantage of the study of combined statistical and dynamic characteristics Nashif, Jones and Henderson adopted as a law of behavior:

Therefore

where \(\omega\) is the linear vibration frequency and \(\lambda\) the extension caused by the preload. \(F(\lambda )\) is a function to be determined, which depends on the hyperelastic model used and \(G(\omega )\) a function which depends on the vibration frequencies.

\(E({\lambda },{\omega })\) and \(\eta (\lambda ,\omega )\) Expressed with Gent–Thomas Model

Using the

Gent–Thomas strain energy, Nashif’s law is written in unidirectional traction:

Substituting Eq. 25 into Eq. 24, the expression for Young’s modulus is

Let’s put:

and

Eq. 26 is then written

Applying the correspondence principle [17], we obtains:

and

In Eq. 31, the term \(\eta _1({\omega })\) can be neglected by the assumptions of Ferry [17] and Nashif [1]. Indeed, by removing the static load, i.e by making the extension tend towards unity, we must be able to find the characteristics in the linear dynamic regime of the material. Which means, see [20]

and

From Eqs. 27, 28, 29, 30, 31, 32, and 33 we deduce

The combined Young modulus and loss factor using the Gent–Thomas model are then the following:

\(E({\lambda },{\omega })\) and \(\eta (\lambda ,\omega )\) Expressed with Flory–Erman Model

Using the Flory Erman strain energy, Nashif’s law is written in unidirectional traction

Substituting Eq. 40 into equation Eq. 24, the expression for Young’s modulus is:

With

Applying the correspondence principle [17], we obtain:

and

Neglecting expression \(\eta _1({\omega })\), Eq. 44 becomes

By calculating the limits of \({E(\lambda ,\omega )}\) and \({\eta (\lambda ,\omega )}\) when \(\lambda\) tends to 1, we deduce

The characteristics combined using the Flory–Erman model are then the following:

Identification of the Mechanical Parameters

We use experimental data from a rubber sample referenced by BX [25]. This data allows us to evaluate the characteristics of hyperelastic models using the least squares method, and these models allow building the combined modulus and combined loss factor. The procedure of the identification consists in making coincide a theoretical solution \(\sigma _n\) resulting from a model with the experimental data of sample BX rubber in simple tension represent by the couple of the point \((\lambda _{exp},\sigma _{exp})\). The least squares methods takes into account the particular form of the reduced stress \(\phi\). Thus, we mention in equations 52 and 53 below, the different expressions of \(\phi\) obtained from the different nominal stresses:

where \(\phi _{G-T}\) is the reduced stress according to the phenomenological Gent–Thomas model, and \(\phi _{F-E}\) the reduced stress according to the molecular Flory–Erman model.

Identification of Gent–Thomas Model Parameters

Applying the least squares method to the Gent–Thomas model, we have:

With, \(<P_2(\lambda )>\) the base of approximation and \(\langle \psi _1(\lambda )\rangle\), \(\langle \psi _2(\lambda )\rangle\) the generating function. Consequently, the parameters \(k_{1}\) and \(k_{2}\) are then given by the relation below:

While posing

We obtains

The estimated parameters of the Gent–Thomas model are recorded in Table 1

Identification of Flory–Erman Model Parameters

Applying

the least squares method to the Flory–Erman model, we have:

With, \(<P_3(\lambda )>\) the base of approximation and \(\langle \chi _1(\lambda )\rangle\) the generating function. We summarize the different parameters identified on the sample BX tests data by the least squares method in Table 1.

Result

Hyperelastic Behavior Modeling

The various values mentioned in Table 1, enable us to obtain Fig. 1.

In Fig. 1, one sees that all the two models present a very good accuracy with the uniaxial tensile data, the deformation being moderate, lower than \(200\%\) [27]. The two models give similar results [28], the Gent–Thomas is a phenomenological model while the Flory–Erman is a molecular one.

Combined Modulus

2D Representation

Figure 2a, b shows predicted combined complex modulus of BX sample for different values of stretch in a large range of frequencies from about 100 Hz to 100 KHz. One remark that the combined complex modulus increase when stretch increase.

This result makes it possible to note that:when one makes linearly vibrate a sample BX of elastomer subjected to a great static deformation (extension), the combined elasticity modulus increases if the stretch \(\lambda\) increases.

3D Representation

Figure 3a, b shows the storage modulus as continuous double variables function of stretch and frequency.

In Fig. 3, one notes simultaneously the influence of the frequency and extension \(\lambda\) on the modulus of elasticity \(E(\lambda , \omega )\). This module increases way continues and at the end one observes a strong rigidification of material BX.

Combined Loss Factor Modulus

2D Representation

Figure 4a, b shows predicted combined loss factor modulus of BX sample for different values of stretch in a large range of frequencies from about 100 Hz to 100 kHz.

One remark that, when one makes linearly vibrate a sample BX of elastomer subjected to a great static deformation (extension), the combined combined loss factor decrease if the stretch \(\lambda\) increases.

3D Representation

Figure 5a, b shows the loss factor as continuous double variables function of stretch and frequency.

In Fig. 5, one notes simultaneously the influence of the frequency and extension \(\lambda\) on the damping. damping decreases and material BX becomes less resilient.

Conclusion

We showed in this paper, the influence of the frequency of the linear vibrations and the nonlinear extension due to a static load on the combined characteristics of the sample BX elastomer. this study made it possible to show that when a sample of elastomer subjected to a hyperelastic deformation vibrates linearly its modulus of elasticity increases whereas its damping decreases. The phenomenological Gent–Thomas model and the molecular Flory–Erman model give the identical results in characterizing the combined Young modulus and the loss factor. Moreover, the second originality of this work, is that it uses a law of behavior which saves the experimenter of the problems involved in the instrumental and experimental realization of the simultaneous tests in statics and dynamics.

Data availability

All relevant data are within the paper.

References

Nashif Ahid D, Jones David IG, Henderson John P (1975) Vibration damping. John & Wiley Sons, New York

Bagley Ronald L, Torvik Peter J (1983) Fractional calculus: a different approach to the analysis of viscoelastic damped structures. AIAA J 21:741–748. https://doi.org/10.2514/3.8142

Bagley Ronald L, Torvik Peter J (1983) A theoretical basis for the application of fractional calculus to viscoelasticity. J Rheol 27:201–210. https://doi.org/10.1122/1.549724

Koeller RC (1984) Application of fractional calculus to the theory of viscoelasticity. J Appl Mech 51:299–307. https://doi.org/10.1115/1.3167616

Bagley Ronald L, Torvik Peter J (1985) Fractional calculus in the transient analysis of viscoelastically damped structures. AIAA J 23:918–925. https://doi.org/10.2514/3.9007

Beda T, Chevalier Y (2004) Identification of viscoelastic fractional complex modulus. AIAA J 42:1450–1456. https://doi.org/10.2514/1.11883

Rivlin RS (1948) Large elastic deformations of isotropic materials: fundamental concepts. R Soc 240:459–490. https://doi.org/10.1098/rsta.1948.0002

Raymond William Ogden (1972) Large deformation isotropic elasticity: on the correlation of theory and experiment for compressible rubberlike solids. R Soc A 328:567–583. https://doi.org/10.1098/rspa.1972.0026

Arruda E, Boyce M (1993) A three-dimensional constitutive model for the large stretch behavior of rubber elastic materials. J Mech Phys Solids 41:389–412. https://doi.org/10.1016/0022-5096(93)90013-6

Beda Tibi (2005) Optimizing the ogden strain energy expression of rubber materials. J Eng Mater Technol 127:351–353. https://doi.org/10.1115/1.1925282

Beda Tibi (2007) Modeling hyperelastic behavior of rubber: a novel invariant-based and a review of constitutive models. J Polym Sci Part B Polym Phys 45:1713–1732. https://doi.org/10.1002/polb.20928

Baidi Blaise Bale, Bien-aimé Liman Kaoye Madahan, Betchewe Gambo, Marckman Gilles, Beda Tibi (2020) A phenomenological expression of strain energy in large elastic deformations of isotropic materials. Iran Polym J 29:525–533. https://doi.org/10.1007/s13726-020-00816-6

James AG, Green A, Simpson GM (1975) Strain energy functions of rubber I characterization of gum vulcanizates. J Appl Polym Sci 19:2033–2058. https://doi.org/10.1002/app.1975.070190723

Green AE, Adkins JE (1960) Large elastic deformation and nonlinear continum mechanics. Clarendon Press Oxford. https://doi.org/10.2307/3613144

Ian Macmillan Ward (1979) Mechanical properties of solid polymers. John Wiley & Sons, New york

Beda Tibi (2014) An approach for hyperelastic model-building and parameters estimation a review of constitutive models. Eur Polym J 50:97–108. https://doi.org/10.1016/j.eurpolymj.2013.10.006

John Ferry D (1980) Viscoelastic properties of polymers, 3rd edn. John Wiley & Sons, New York, p 1980

Padovan Joe (1987) Finite element analysis of steady and transienly Moving/Rolling nonlinear viscoelastic structure-I theory. Computer Struct 27:249–257. https://doi.org/10.1016/0045-7949(87)90093-9

Morman KN, Nagtegaal JC (1983) Finite element analysis of sinusoidal small-amplitude vibrations in deformed viscoelastic solids. Part I: theoretical development. Int J Numer Methods Eng 19:1079–1103. https://doi.org/10.1002/nme.1620190712

Tibi Beda JB, Casimir KE, Atcholi Y Chevalier (2014) Loaded rubber-like materials subjected to small-amplitude vibrations. Chin J Polym Sci 32:620–632. https://doi.org/10.1007/s10118-014-1437-6

Mooney MA (1940) Theory of large elastic deformation. J Appl Phys 11:582–592. https://doi.org/10.1063/1.1712836

Gent AN, Thomas AG (1958) Forms for the stored (strain) energy function for vulcanized rubber. J Polym Sci 28:625–637. https://doi.org/10.1002/pol.1958.1202811814

Flory Paul J, Erman Burak (1982) Theory of elasticity of polymer networks. 3. Macromolecules 15:800–806. https://doi.org/10.1021/ma.00231a022

Beda Tibi, Chevalier Yvone (2004) New methods for identifying rheological parameter for fractional derivative modeling of viscoelastic behavior. Mech Time Depend Mater 8:105–118. https://doi.org/10.1023/B:MTDM.0000027671.75739.10

Tibi Beda (1990) Modules complexes des matériaux viscoélastiques par essais dynamiques sur tiges-Petites et grandes déformations (Dynamic testing of complex moduli of viscoelastic beams-Small and large strain). Ph.D. Thesis. CNAM. Paris [in French]

Hencky H (1931) The law of elasticity for isotropic and quasi-isotropic substances by finite deformations. J Rheol 2:169–176. https://doi.org/10.1122/1.2116361

Marckmann Gilles, Verron Erwan (2006) Comparison of hyperelastic models for rubber like materials. Rubber Chem Technol 79:835–858. https://doi.org/10.5254/1.3547969

Beda T, Gacem H, Chevalier Y, Mbarga P (2008) Domain of validity and fit of Gent-Thomas and Flory-Erman rubber models to data. Express Polym Lett 2(9):615–622. https://doi.org/10.3144/expresspolymlett.2008.74

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Blaise, B.B., Kaoye, L., Samon, B. et al. Characterization of the Preloaded Hyperelastic Materials Subjected to Linear Vibrations. J. Vib. Eng. Technol. 12, 6031–6041 (2024). https://doi.org/10.1007/s42417-023-01234-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42417-023-01234-7