Abstract

Membrane technology, based on a different kind of polymeric membranes, is among the most recognized and crucial technologies for the treatment of wastewater. Polymer Inclusion Membranes (PIMs) were used in selective and facilitated transport of different heavy metals from acidic media. The motivation of this study is to synthesize novel PVC-based polymer inclusion membranes (PIMs) with specific percentages of plasticizer and carrier to transport and separate Zn(II) ions under particular conditions. In the synthesis of these membranes, the efforts are directed towards minimizing the quantities of organic solvents employed as plasticizing and carrier agents. This reduction not only contributes to environmental sustainability but also enhances health and economic aspects. These findings align with the ongoing commitment to advancing environmentally conscious practices in membrane synthesis. Polymer inclusion membranes consisting of poly (vinyl chloride) (PVC) as base polymer, 2-nitrophenyl octyl ether (NPOE) as a plasticizer (10 wt. %), and D2EHPA as a carrier (30 wt. %) were prepared. The membranes were characterized by attenuated total reflectance-fourier transformed infrared (ATR-FTIR), scanning electron microscopy (SEM), and thermogravimetric analysis (TGA) to collect information on their morphology and composition. Mechanical properties and hydrophobicity of the PIMs were determined by the tensile strength and the contact angle measurements. To further verify the feasibility of the new composition of the membranes, the PVC/NPOE/D2EHPA PIM was used to evaluate the effect of the pH of the feed phase on zinc transport ([Zn2+] = 30 mg.L−1, pH range varied from 2 to 5). At optimal pH equal to 5, zinc ions were completely transported through the selected PIM after only 4 h by using 1 M of sulfuric acid as a receiving phase. The stability of the studied PIM was also examined. We note that Zn(II) flux through this membrane decreases slightly after six extraction cycles. Moreover, the selectivity coefficient revealed that the PIM is more selective towards Zn(II) than Ni(II) cations. The performances of the PIM system for zinc, nickel and copper separation were evaluated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Many aqueous industrial releases are loaded by heavy metal ions. Pollution of water by these toxic ions is among of the most alarming problems of environment over the world because of their elevated toxicity and carcinogenic effect on plants [1], humans [2] and animals [3] amplified by the accumulation effects. Recovery and separation of heavy metals ions from liquid wastes has attracted a lot of attention for environmental and even economic reasons. That is why various processes have been developed and used to transport and recover heavy metal ions [4,5,6]. We can distinguish two main types of the processes: those based on chemical reactions designed to react metal ions with other substances in order to precipitate them (chemical precipitation), extract them (liquid–liquid extraction), adsorb them through a support (absorption by bio-composites, or ion exchange), and those based on the use of fine barriers, known as membranes, enabling the selective passage of these ions. Membranes technologies have played a very important role in the removal and recovery of heavy metal ions [7,8,9]. Table 1 presents various membrane techniques applied for metal ions removal.

If we take the main disadvantages into account, we can say that chemical processes need large amounts of an organic solvent and generate secondary sludge to be treated, while some membrane processes have low fluxes due to the density of the membrane materials, worsened by the appearance of fouling after a certain period of time [18]. Liquid membrane technology has demonstrated its usefulness in separation and recovery of metal ions. In this context, supported liquid membranes (SLMs) has been tested. This separation system consists of a microporous polymer support that acts as a barrier between an aqueous source phase and an aqueous receiving phase. This support is impregnated with an organic membrane liquid containing a carrier dissolved in an organic solvent [19].

Nonetheless, SLMs suffer from the lack of stability in long-term. Thus, polymer inclusion membranes have been used as an attractive solution because they are considered as the most selected liquid membranes for separation and extraction techniques due to their improved stability and flexibility [20]. These membranes have been the topic of several studies in these recent decades. They have shown an efficiency of metal ions transport comparable to that of supported liquid membranes with a greater stability. This technique is based on the properties of a support that separates two phases and allows the selective transfer of certain species from one phase to another.

Zulkefeli et al. [21], Zawierucha et al. [22] and Pyszka et al. [23] used PIMs to extract and separate heavy metals from aqueous solutions. PIMs prepared by Nowik-Zajac et al. [24] and containing o-NPPE as a plasticizer, carboxyl calixpyrolles and methyl calixpyrolles groups, as carriers and CTA as polymer have shown effective separation of silver ions from silver nitrate aqueous solution. PIMs have been promisingly applied for the determination and separation of small organic mixtures (e.g., acetaldehyde, acetone and methane) [25], rare earth elements (e.g., lutetium(III)) [26], metals ions(e.g., mercury(Hg(II)), cadmium (Cd(II)) and lead (Pb(II))) [27]. They allow fast transport of metal ions and elevated selectivity [28], as well as simple design of operation and installation [29]. PIMs are thin membranes easily synthesized by casting a solution of organic solvent containing a base polymer, a plasticizer and a carrier.

The base polymer has an important role in promoting the mechanical properties of the membrane. PVDF [30], PVC [31] and CTA [32] are the major polymers used in studies concerning PIMs carried out to date. They are used with a mass percentage varying from 15 wt. %. [33] to 70 wt. %. [8].

The plasticizer is one of the most important components for the synthesis of polymer inclusion membranes. Its nature has a significant influence on the properties of the membrane on the one hand and the extraction of heavy metals on the other hand. It is introduced into the polymer matrix in order to raise the distance between the molecules of the polymer matrix, thus it reduces the intensity of intermolecular forces existing between its chains and improves its elasticity [34]. 2-Nitrophenyl octyl ether (NPOE) is the most frequently used plasticizer with a mass percentage ranging from 10 wt. %. [31] to 32 wt. %. [33]. The NPOE has an average viscosity and a higher dielectric constant, which facilitates the transfer of the complexes metal ion-D2EHPA formed from the feed phase to the receiving phase. Numerous studies have demonstrated that PIMs containing this plasticizer exhibited higher initial flux values [35].

The extractant ensures molecular recognition and facilitated transport of ions. It is retained in the membrane via the capillary forces in the micropores of a polymeric support as in SLMs [36], therefore inhibiting leaching of the support. For this reason, PIMs have a greater stability and a longer lifetime than SLMs with regard to the loss of the liquid membrane phase [25]. PIMs, composed of commonly used polymers, extractants, and possibly plasticizers, have been gradually figured as an alternative to separation and extraction technologies. Over the two last decades, the importance of these membranes has risen considerably which implicates the exponentially increase of the number of research papers [16, 37].

Zinc is among the heavy metals of greatest concern because it is widely present in effluents generated by industrial processes such as plating [38], mining activities [39], and structural engineering of cathodes [40]. Radzyminska‐Lenarcik et al. [41] focused on the preparation of PIMs based on CTA and doped with ethylenodiamino‐bis‐acetylacetone as carrier to separate zinc ions from nitrate aqueous feed phase. In another study, Smail et al. [42] studied the transport and separation of Zn(II) and Ni(II) from nitrate solutions across CTA plasticized PIMs. However, a few studies have investigated the transport and separation of zinc and nickel by PIMs based on PVC which resist to acidic solutions more than PIMs based on CTA [43].

D2EHPA is the acidic extractant frequently used to extract metal ions. This carrier presents 30 wt.% [44] to 50 wt. %. [17] of the total mass of the membrane. It demonstrates important selectivity for the separation of Zn(II) ions present in aqueous phase with various heavy metals. The transport of metal cations with D2EHPA is controlled by the diffusion of the complex metal-carrier through the PIM. This owes to the fact that as the carrier concentration in the polymer increases the liquid micro-domains, the carrier molecules are solvated under the effect of the plasticizer, merging together to form a sort of network of continuous paths that link the two sides of the membrane [45].

The aim of this manuscript is to investigate the performance of a lab-scale method using a PIM to meet industrial needs. Therefore, novel PVC-based PIMs were prepared using PVC as base polymer, NPOE as a plasticizer and D2EHPA as a carrier. The plasticizer and carrier were used with low percentages. The influence of NPOE on microstructures of PIMs was investigated. The transport and separation of zinc ions through PVC/NPOE/D2EHPA membrane were evaluated under the conditions of using NPOE as plasticizer and pH of feed solution. Then, the stability of the latter was evaluated. Finally, the performance of this membrane to separate Zn(II), Ni(II) and Cu(II) ions was evaluated.

2 Materials and Methods

2.1 Chemicals and Solutions

High molecular weight Poly (vinyl chloride), 2-nitrophenyl octyl ether were provided by Sigma Aldrich (switzerland) and di(2-ethylhexyl) phosphoric acid was obtained from Sigma Aldrich (United states). The solvent tetrahydrofuran (MW = 72.11 g.mol.−1) was acquired from Scharlau (Spain).Table 2

2.2 Polymer Inclusion Membranes Preparation

The polymer inclusion membranes were prepared according to the solvent evaporation method [46]. The compositions of the PIMs are summarized in Table 3. Typically, 0.2 g of membrane components was dissolved in 20 mL of THF by stirring at room temperature. The obtained solutions were spread over a glass Petri dish with a diameter of 8.0 cm and partially covered to slowly evaporate the solvent, and to obtain transparent and flexible membranes. Then, the obtained membranes were peeled off carefully from the dishes.

The membrane composition was inspired by previous works [47,48,49,50] which showed that a high percentage of the plasticizer (30 wt. %) results in a marked reduction in transport, and a moderate percentage of carrier could achieve acceptable transport efficiency. It should be noted that a percentage of plasticizer over 10 wt. % results in the non-cohesion of the various constituents of the mixture, and an excess of plasticizer (oily layer) was observed on the PIMs surface. Similar behavior was observed by Nghiem et al. [25]. An excess of plasticizer results in the formation of a film on the membrane surface and causes a supplementary barrier to zinc transport.

2.3 Membranes Analysis

2.3.1 Attenuated Total Reflectance-Fourier Transformed Infrared (ATR-FTIR) Spectroscopy

The infrared spectroscopy is very useful in the identification and structure analysis of a variety of substances. Based on this, it is possible to find out the membrane’s compositions and the nature of the possible interactions established between their components. (ATR-FTIR) spectra of various studied membranes were registered using Bruker FTIR spectrometer model Tensor 27 (Spectralab, Canada), which is equipped with a crystal of ATR. 32 scans were collected in the mode of transmission for every measurement over the spectral range of 600–4000 cm−1 with a resolution of 2 cm−1.

2.3.2 Scanning Electron Microscopy (SEM)

Scanning Electron Microscopy (SEM) was utilized to analyze the membrane morphology. The sample was mounted on the specimen holder of SEM and the analysis of the image was executed in the environmental mode by an electron microscope manufactured by Carl Zeiss (Germany). All samples were sputter-coated with a nanometric palladium layer.

2.3.3 Contact Angle

The measurement of the contact angle of PIMs was determined by a contact angle system FM 40 Easy drop (KRUSS, Germany) under ambient conditions using the sessile drop method. Ten independent measurements were carried out to calculate the contact angle of the membranes.

2.3.4 Thermogravimetric Analysis (TGA)

The thermal stability of PIMs was evaluated by a thermos gravimetric analyzer Setsys Evolution 16 from SETARAM (Romania). A sample of about 20 mg of each PIM was heated from room temperature to 800 °C with a heating rate of 20 °C.min−1 under argon atmosphere.

2.3.5 Mechanical Properties

To examine the mechanical characteristics of the membranes, Young’s modulus, elongation at break and tensile strength of the membranes were measured using tensile tester INSTRON model 5965L2806 (United states) under ambient conditions (20 ± 2 °C). The membranes were cut into a strip of 0.012 m wide and 0.07 cm long. The tensile tests were repeated 10 times.

2.4 Ion Permeability Measurement

Polymer inclusion membranes are composed of a polymer, a plasticizer and a carrier. The polymer encapsulates the liquid phase between its entangled chains. The extractant is used for binding the solute to produce a complex or an ion pair as in liquid–liquid extraction. PIMs were used to the separation of source and receiving phases. The source phase contains the solution of metal ions (Zn(II) or/and Ni(II)) and the receiving phase contains the acidic stripping solution. This configuration permits the extraction of the metal ions from the source phase to the receiving phase by simultaneous extraction and back-extraction at the two interfaces of the membrane [30]. The reaction of the complexation of D2EHPA with Zn(II) cations is described as follows:

The indexes aq and org refer to aqueous and organic solutions, respectively, (HR)2 is the dimeric form of di(2-ethylhexyl) phosphoric acid in tetrahydrofuran, and R is (C8H17O)2P(O)O−.

The complex formed is transported by diffusion under the effect of the gradient of pH between the feed phase (high pH) and the receiving phase (low pH). Variations in pH values generate flows of protons, which make it possible to pump the ions against their concentration gradient (pH pump). D2EHPA creates complexes with metal cations by the mechanism of cation-exchange at the first interface feed phase-membrane. The hydrophobic groups of carriers help the formed complexes to diffuse from the feed phase to the receiving phase. At the second interface membrane-stripping phase, the complexes release the metal ions into the receiving solution by cation-exchange. The complexes are dissociated, and the metals tied to carrier are exchanged with proton ions from the strip solution. Thus, the carrier is regenerated to form other complexes.

The metal ions permeability measurement was carried out at room temperature in a permeation cell made of Teflon containing two-compartment with a capacity of 100 mL. These two compartments have on one of their faces a circular opening of contact with an area of 7.1 cm2 on which immobilized the synthesized membranes [30]. Both aqueous solutions were magnetically stirred at 700 rpm to avoid polarization conditions of the concentration at the membrane interfaces. The pH of both source and feed solutions was measured using a pH meter (Jeulin pH 211 J-SA). The samples were collected at accurate intervals of time of one hour from each aqueous phase for 24 h. To determine the concentration of metal ions in the two aqueous phases, an atomic absorption spectrophotometer (Analytic Jenna model NoVAA400) was used.

The kinetic transport parameter of metal cations through the PIMs was calculated according to Danesi [51] as follows:

where Ct refers to the concentration of metal ions in the source phase at a given time, C0 refers to the concentration of metal ions in the receiving phase, k refers to the rate constant, and t refers to the time of transport.

The initial flux Ji (mol.m−2.s−1) was determined using [52]:

The percentage of extraction of metal ions was calculated according to:

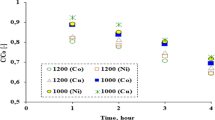

Note that for the determination of the ion’s permeability, we repeated the measurements 3 times. From these 3 measurements, we calculated a mean value and an enlarged uncertainty (Fig. 1).

3 Results and Discussions

3.1 PIMs Characterization

3.1.1 ATR-FTIR Spectra

The synthesized PIMs, analyzed by infrared spectroscopy, allowed to determine their compositions and the interactions type formed between the different components. Figure 2 shows FTIR spectra characteristic of the four PIMs, and, more specifically, the two membranes of extreme composition, PVC and PVC/NPOE/D2EHPA. The band assignments for pure PVC were similar to those reported in the previous works for this polymer [53]. Thus, in the PVC-based membrane spectra, the C–Cl stretching mode was detected at 698 cm−1. The peaks at 2926 cm−1 and 2981 cm−1 are attributed to the stretching modes of the C–H2 and C–H bonds, respectively. The peaks at 1336 cm−1 and 1435 cm−1 were recorded for C–H2 twisting and scissors, respectively. The C–H wagging modes was detected at 970 cm−1 (Trans C–H wagging) and 613 cm−1 (cis C–H wagging), respectively. From the spectrum of the membrane containing the plasticizer (NPOE) and the transporter (D2EHPA), we can notice the appearance of new peaks characteristic of NPOE and D2EHPA (Table 4). The peak at 1531 cm−1 is assigned to the asymmetric vibrations of the C–N bonds of NPOE. The peaks at 1029–1249 cm−1 correspond to the stretching modes P–O–C / P–O–H and P = O of D2EHPA, respectively.

Figure 2 shows the existence of a new peak located at 771 cm−1. This peak indicates that PVC could bind with NPOE [47]. This new interaction was confirmed by the FTIR spectrum of the membrane prepared with PVC and NPOE only. These results confirm the existence of the plasticizer and the carrier in the membrane and the presence of chemical interactions between PVC and NPOE.

3.1.2 Scanning Electron Microscopy (SEM)

The surface and section images of the four tested PIMs are represented in Table 5. This table shows that the PIM based on PVC (Figure a) has a homogeneous, uniform surface with no apparent porosity. Same result was found by Meng et al. [54] which revealed that the surface of the membrane based on PVC looks dense and smooth. SEM images show that the surface structures of both PVC and PVC/NPOE (Figure b) membranes are significantly comparable. This result shows that PVC and NPOE are miscible, and that there is good adhesion and uniformity between the polymer and the plasticizer. However, the PVC/D2EHPA and PVC/NPOE/D2EHPA membranes (Figures c and d respectively) have a relatively rough surface presenting nodular structure without any pore. This result is similar to the result observed by Ounissa et al. [55] who used CTA as the base polymer. They demonstrated that the surface of the pure CTA was smooth, and the addition of NPOE and D2EHPA make the surface rough due to the nodular structure of the PIM containing D2EHPA. These results are in accordance with those found by Wang et al. [47] which demonstrate that PVC-D2EHPA PIM present haystacks on their surfaces. The section images (Figures e, f, g and h) demonstrated that all the membranes have a dense structure (no apparent porosity). Similar results have already been presented in the literature [55].

3.1.3 Contact Angle

Table 6 summarizes the values of the measurements of contact angle. As shown in this table, we can conclude that the PVC-based membrane presents a hydrophobic character (contact angle of θ = 74.1 ± 3.7°). The inclusion of NPOE decreased the contact angle to reach 70.6 ± 3.5° which implied a slightly decrease of the hydrophobicity of the PIM. However, the addition of D2EHPA in the membrane caused a greater decline in its contact angle. This is observed for the two membranes PVC/D2EHPA and PVC/NPOE/D2EHPA.These results reveal the adsorption of the carrier molecules at the interface between the liquid domains and the air, as well as the orientation of the hydrophilic region of the molecule towards the interface of PIM as expected. D2EHPA molecules decreased the resistance against the movement of the water droplet on the membrane surface [18]. These findings are in accordance with the contact angle values founded by other authors in a previous work [56].

3.1.4 TGA

The thermal behavior of PVC is illustrated in Fig. 3. The general shape of the ATG thermogram is characterized by two major stages of degradation (loss of mass). Indeed, the sample is thermally stable below 180 °C. Between 180 and 350 °C, the variation of loss of mass seems to be insignificant for all studied PIMs in the average value of about 38.74%. This loss of mass is due to the dehydrochlorination which causes the formation of polyenes [57]. This phenomenon can be explained by considering the reaction between the hydrogen in the C-H group and the chlorine radical produced from the cleavage of the C–Cl chain. This reaction leads to the formation of a covalent bond H-Cl, resulting in the creation of a polyenes throughout the polymer chains [58]. When adding the NPOE or D2EHPA, the appearance of the PIMs thermogram is the same as that of the PVC-based membrane except that the mass degradation begin at lower temperatures. This can be explained by the boiling points of NPOE and D2EHPA (197–198 and 155 °C respectively) and the effect of the presence of organic molecules in their structures. Between temperatures of 350 and 400 °C, no mass loss is recorded. The sample becomes thermally stable. This is attributed to the training of a new polymer more thermally stable than PVC.

A second stage of decomposition, noted in temperature domain from 400 to 655 °C, corresponds to the degradation of the polyenes formed during the first stage of decomposition (scission of covalent and multiple bonds) [59]. Above 655 °C, a total residue of 6.68% was observed, which is due to the formation of infusible reticulates originating from the polyenes. The use of extractant (D2EHPA) results a total residue of 15.25% for PVC/NPOE/D2EHPA PIM at 798 °C. Similar results were recorded by Yadav et al. [60] during the separation of rare earths from aqueous solution using D2EHPA.

3.1.5 Mechanical Properties

The mechanical characteristics of synthetic PIMs were evaluated using tensile tests. According to the literature, PVC is known as a glassy polymer [46, 61,62,63]. The function of the plasticizer is to ameliorate the mechanical strength and the elasticity of PIMs [63]. The effect of adding the plasticizer and the transporter to the membranes on the mechanical properties has been demonstrated. The incorporation of the plasticizer and the carrier modifies the strength and the behavior of the membranes considerably. Young’s Modulus, strength at break and elongation at break for PVC/D2EHPA, PVC/NPOE and PVC/NPOE/D2EHPA membranes are shown in Table 7. The results demonstrate that after the plasticizer addition, the strength at break of the PVC/NPOE membrane is 13.6 ± 1.3 MPa. This value continues to decrease with the addition of D2EHPA to reach 7.1 ± 1.0 MPa. The evolution of the elongation at break shows that the deformation of the PIM increases gradually when adding the NPOE and rapidly with the addition of D2EHPA. These results show that D2EHPA also played the role of a plasticizer in the membrane. This can be explained by the increased mobility of the PVC chains in the presence of plasticizer and the transporter which make the membrane more flexible. The plasticizer infiltrates between the polymer chains to reduce the intermolecular forces [63]. In addition, the increase of the free volume decreases the young’s modulus and the strength at break [64]. The elongation at break increased from 6.2 ± 3.0% for the PVC/NPOE membrane to 120.2 ± 4.0% for the PVC/NPOE/D2EHPA membrane. It was found out that Young’s modulus decreased from 289.8 ± 4.9 MPa to 166.0 ± 5.0 MPa after the addition of D2EHPA. The obtained results are in accordance with those obtained in another previous study [18, 56, 59, 61].

3.2 Recovery of Zn(II)ions and Membrane Stability

3.2.1 Passive Transport

The passive transport of Zinc ions between the two aqueous phases implicates only the membrane properties, and the transport is governed by the gradient of concentration. The current study was carried out with a PIM containing only PVC as polymer and the NPOE as plasticizer.

The obtained results revealed that no transport of Zinc ions across the membrane was observed. The concentration of the feed phase remained almost constant and the recovery of Zn(II) ions was 0%. This result could be attributed to the homogeneous and uniform surface with no apparent porosity of the PIM revealed by SEM images (Table 5). Thus, we can conclude that the absence of carrier makes the membrane as real barrier for metal ions transport. The presence of the carrier is therefore necessary to achieve the extraction.

3.2.2 Recovery of Zn(II) ions

3.2.2.1 Effect of the Plasticizer Addition on Zn(II) Transport

To better understand the importance of using NPOE as plasticizer in the extraction of Zn(II) ions, a PVC–based membrane containing only the D2EHPA as carrier was tested. The percentages of zinc extraction are shown in the Table 8.

After 4 h, zinc ions were completely transported through the PVC/NPOE/D2EHPA membrane, but in the case of PVC/D2EHPA one, only 81% was transported. This result is currently explained by the creation of liquid micro-domains where the D2EHPA molecules become solvated by the NPOE coalescing to form a kind of network of continuous paths which manage to join the two PIM interfaces to facilitate the Zn(II) transport [45]. That is why PVC/NPOE/D2EHPA membrane was chosen for the rest of this study.

3.2.2.2 Effect of pH

pH difference between source and receiving phases presents a great magnitude on metal ion permeation. To determine the optimal pH for Zn(II) extraction with D2EHPA across the PVC/NPOE/D2EHPA membrane, various transport experiments were carried out with varying the initial pH of the feed solution. The studied pH range from 2 to 5 was chosen to ovoid zinc hydroxide precipitation. The feed solution was 0.46 mmol.L−1 of Zn(II). The stripping solution was a sulfuric acid solution (1M), which was the best solution for the recovery of zinc according to literature [37]. Extraction (E(%)) and initial flux (Ji) are summarized in Table 9. Figure 4 reveals that the removal efficiency yield of Zn(II) ions varies between 22 and 100% for tested values of pH. A total recovery of Zn(II) ions was obtained from pH = 3 and pH = 5 with an extraction time of 24 and 4 h, respectively. The experimental results reveal that the quantity of transported ions is all the more important, while the difference in pH between the two aqueous phases is greater. This pH difference on either side of the PIM generates proton flows that pump metal cations against their concentration gradient (pH pump). The driving force here is the H+ ion concentration gradient between the source phase (low H+ concentration) and the receiving phase (high H+ concentration). Hoque et al. [32] found similar results by cross-linking PVC-based PIMs. Table 9 shows that the value of initial flux of Zn(II) increased with the increase of pH.

Referring to Table 9, pH = 5 seems to be the optimal pH value for Zn(II) ions extraction. The results seem to agree with different works summarized in the table below. The slight differences are linked to the nature of base polymer, the type of carrier and the initial concentration of metal.Table 10.

After having optimized the pH of Zn(II) transport through the PVC/NPOE/D2EHPA membrane, the variation of the concentrations of metal cation as function of time in the three phases: source, receiving and membrane phase was recorded. The concentration of Zn(II) ions in the membrane phase was calculated according to:

The results are grouped in Fig. 5. The quantity of zinc ions inside the membrane phase increases during the first hour, then it gradually decreases to reach a constant level after 7 h of transport due to the discharge of Zn(II) into the receiving phase. Similar result was reported by Ncib et al. [18], Kebiche-Senhadji et al. [17] and Resina et al. [66]. After 4 h, zinc ions was completely transported from the feed phase. A low accumulation of Zn(II) ions in the pores of the membrane was observed.

It’s worth noting that Kazemi et al. [67] recently prepared a PIM (50 wt. % PVC and 50 wt. % D2EHPA, but without NPOE) similar to the PVC/NPOE/D2EHPA PIM, with a thin thickness (14 µm), and used it to recover bismuth (III) from sulfate solutions. With a pH of 1.3, a starting concentration of 20 mg.L−1 of Bi(III) and stirring at 550 rpm, they succeeded in recovering just over 95% of Bi(III) and achieving fluxes of 1.03 × 10–6 mol.m−2.s−1, almost an order of magnitude lower than what we obtained for Zn(II). This is certainly due to the smaller size (or weight) of Zn compared with Bi.

3.2.3 Membrane Stability

To evaluate the stability of PIMs and the long-term durability in an acidic solution, the performance of the PVC/NPOE/D2EHPA membrane in a continuous way was examined. After each cycle of 8 h, the source and receiving phase were replaced by new solutions with the same concentrations and initial pH. The zinc flux was measured for every cycle. The results are illustrated in Fig. 6.

This figure shows that the membrane works well and provides efficient transport of Zn(II) ions until the sixth use. The obtained results show that an average zinc flux of 1.62 ± 0.05 × 10−5 mol.m−2.s−1 was recorded during the six cycles of transport. After the sixth use, this flux decreases slightly until the value of 1.18 ± 0.06 × 10−5 mol.m−2.s−1. After that, the more the membrane is reused, the more its ability to transport zinc ions decreases significantly. This might be attributed to PIM organic phase loss (carrier and/or plasticizer). PIM’s stability depends on an aqueous medium and membrane composition [66]. Also, when the aqueous solution is renewed, the stability and shelf life of D2EHPA-based PIMs containing NPOE are reduced.

Similar results were found by Saka et al. [68] when using a PVC-based membrane containing dibenzyl ether (DBE) as a plasticizer and 4% co-EDVB as a carrier. They found that the membrane works well and gives effective phenol transport until 72 h. After that, the percentage of phenol transported tended toward 0%.

3.3 Separation of Zn(II) and Ni(II) ions

In acidic leaching process, nickel and zinc are leached into the solution. Prior neutralization and/or precipitation at appropriate pH is usually used to remove other concomitant impurities such as ferrum, aluminum, chromium and copper and meanwhile prevent nickel loss, despite the fact that zinc is barely precipitated. PIM system is adapted to selective Zn remove and/or recovery. In order to study the selectivity of the PVC/NPOE/D2EHPA membrane towards Zn(II) ions, a mixture solution containing Zn(II) and Ni(II) with the same initial concentration of 0.46 mmol.L−1 was prepared. The pH of the feed phase was adjusted to 5 and the stripping solution consisted of a hydrochloric acid solution (1 M). Figure 7 shows the removal efficiency of Zn(II), Ni(II) from single solutions and Zn*(II), Ni*(II)from binary solutions. The value of the zinc ions separation coefficients (SZn/Ni) was calculated according to the following formula:

The same transport selectivity is observed in comparison to that obtained during the individual transport of the two metals (Zn > Ni). Several works reported that D2EHPA is one of the mainly common extractants used in zinc separation [66, 69,70,71,72,73]. At pH values of 2, and using D2EHPA as extractant, Owusu et al. [73] demonstrated that selectivity toward Zn over Cd, Co and Ni is very high. To the best of the knowledge, the only explanation for this high selectivity is given by Resina et al. [66] who attribute this to a high affinity between D2EHPA and Zn(II).

The extraction percentage after 24 h of zinc and nickel ions from competitive transport was 62 and 26%, respectively. Table 11 demonstrates that the percentage of extraction of Zn(II) from mixture solution was not be total; besides it achieved a decrease of 38%. This observation could be explained by the crowding effect (the co-transport of Ni(II) with Zn(II) decreases the D2EHPA concentration in the membrane). For the transport of nickel, the coexistence of Zn(II) ions decreased slightly the extraction percentage values (E (%) varies from 31 to 26%). The same behavior was observed by several authors [71] for Zn and Ni separation. The selectivity coefficient summarized in Table 11 revealed that the PIM is more selective towards Zn(II)than Ni(II) ions.

3.4 Analytical Application

The performances of the PIM system for zinc, copper and nickel separation were evaluated. The results are presented in Table 12.

In ternary mixture, the membrane PVC/NPOE/D2EHPA showed a better affinity toward Zn(II) than Cu(II) and Ni(II) ions. After 6 h of transport, the percentages of extraction of copper and nickel were 32% and 15%, respectively. This result may be attributed to the size of the hydrated ions. The radius of the hydrated Cu(II) (i.e., 0.206 nm) is smaller compared to the radius of the hydrated Ni(II) (i.e., 0.302 nm). For this reason, Ni(II) ions are encircled by a greater number of H2O molecules than Cu(II) ions, which facilitate the interaction between the carrier and Cu(II) ions (Cu(II) ions are more hydrophobic than Ni(II) ions). Similar findings were observed by NCIB et al. [48] for copper and nickel separation.

4 Conclusion

This paper focused on the validation of a lab-scale method that allows prediction of the performances of a new PIM system to meet industrial needs as effectively as possible. The PIMs based on PVC were prepared using NPOE as a plasticizer and D2EHPA as a carrier. The SEM images and ATR-FTIR spectra reveal that all the components are well dispersed in the polymer matrix with the presence of interactions established between PVC and NPOE. The addition of NPOE and D2EHPA decreased the rigidity, the hydrophobicity and the thermal stability of the PVC. The PVC/NPOE/D2EHPA PIM was used for Zn(II) ions transport and separation. At pH = 5, total recovery of Zn(II) ions was obtained and the highest initial flux was recorded. The performance of the PIM system can be explained by two important factors: the pH of the source phase and the use of H2SO4 (1 M).

In the case of binary Zn/Ni solution, the extraction percentages of 62% and 26% were registered for Zn(II) and Ni(II) ions, respectively. This PIM shows a good stability during 6 cycles of transport and the flux decreases slightly after the sixth use. The PVC/NPOE/D2EHPA PIM is more selective towards Zn(II) than Ni(II) ions. In ternary mixture, the percentages of extraction were in the order of zinc > copper > nickel. Thus, this investigation proposes an effective wastewater treatment and a promising separation method for heavy metals removal and/or recovery.

Data availability

All data cited in the article are available from the corresponding author on reasonable request.

Abbreviations

- ATR-FTIR:

-

Attenuated total reflectance-Fourier transformed infrared

- CTA:

-

Cellulose triacetate

- D2EHPA:

-

Di(2-ethylhexyl) phosphoric acid

- DBE:

-

Dibenzyl ether

- EDTA:

-

Ethylenediaminetetraacetic acid

- FTIR:

-

Fourier Transform Infrared

- NPOE:

-

2-Nitrophenyl octyl ether

- OHA:

-

Octylhydroxamic acid

- o-NPPE:

-

O-nitrophenyl pentyl ether

- PIM:

-

Polymer Inclusion Membrane

- PVC:

-

Poly (vinyl chloride)

- PVDF:

-

Polyvinylidene difluoride

- RILs:

-

Reactive ionic liquids

- RO:

-

Reverse osmosis

- SEM:

-

Scanning electron microscopy

- SLM:

-

Supported liquid membrane

- TGA:

-

Thermogravimetric analysis

References

Taghipour M, Jalali M (2019) Ecotoxicol Environ Saf 182:109347

Balali-Mood M, Naseri K, Tahergorabi Z, Khazdair M, Sadeghi M (2021) Front Pharmacol 12:643972

Rajput VD, Minkina TM, Behal A, Sushkova SN, Mandzhieva S, Singh R, Gorovtsov A, Tsitsuashvili VS, Purvis WO, Ghazaryan KA, Movsesyan HS (2018) Environ Nanotechnol Monit Manag 9:76–84

Abdullah N, Yusof N, Lau WJ, Jaafar J, Ismail AF (2019) J Ind Eng Chem 76:17–38

Kumar V, Dwivedi SK (2021) J Clean Prod 295:126229

El Batouti M, Al-Harby NF, Elewa MM (2021) Water 13:3241

Xiang H, Min X, Tang C-J, Sillanpää M, Zhao F (2022) J Water Process Eng 49:103023

Maiphetlho K, Chimuka L, Tutu H, Richards H (2021) Sci Total Environ 799:149483

Ocaña-González JA, Aranda-Merino N, Pérez-Bernal JL, Ramos-Payán M (2023) J Chromatogr 1691:463825

Basaran G, Kavak D, Dizge N, Asci Y, Solener M, Ozbey B (2016) Desalination. Water Treat 57:21870–21880

Ennigrou DJ, Ali MBS, Dhahbi M, Mokhtar F (2014) Membr. Water Treat 5:183–195

Hosseini SS, Khodakarami AH, Nxumalo EN (2020) Polym Eng Sci 60:1795–1811

Hosseini SS, Nazif A, Alaei Shahmirzadi MA, Ortiz I (2017) Sep Purif Technol 187:46–59

Lech M, Gala O, Helińska K, Kołodzińska K, Konczak H, Mroczyński Ł, Siarka E (2023) Waste 1:482–496

Fradler KR, Michie I, Dinsdale RM, Guwy AJ, Premier GC (2014) Water Res 55:115–125

Almeida M, Cattrall RW, Kolev SD (2012) J Membr Sci 415–416:9–23

Kebiche-Senhadji O, Mansouri L, Tingry S, Seta P, Benamor M (2008) J Membr Sci 310:438–445

Ncib S, Barhoumi A, Bouguerra W, Larchet C, Dammak L, Hamrouni B, Elaloui E (2018) Desalin Water Treatm 104:263–272

Othmen K, Ncib S, Barhoumi A, Dammak L, Bouguerra W (2021) Desalination. Water Treat 225:422–429

Almeida M, Cattrall RW, Kolev SD (2017) Anal Chim Acta 987:1–14

Zulkefeli N.S.W., Weng S.K., Abdul Halim N.S., (2018) Curr. Pollut. Rep., 4:84–92.

Zawierucha I, Nowik-Zajac A, Kozlowski C (2019) Polymers 11:2111

Pyszka I, Radzyminska-Lenarcik E (2020) Membranes 10:385

Nowik-Zajac A, Zawierucha I, Kozlowski C (2019) RSC Adv 9:31122–31132

Nghiem LD, Mornane P, Potter ID, Perera JM, Cattrall RW, Kolev SD (2006) J Membr Sci 281:7–41

Huang S, Chen J, Zou D (2021) J Rare Earths 39:1256–1263

Sgarlata C, Arena G, Longo E, Zhang D, Yang Y, Bartsch RA (2008) J Membr Sci 323:444–451

Sun C, Zhou C, Zhang D, Shen S (2020) J Chin Chem Soc 67:478–483

Almeida MI, Cattrall RW, Kolev S (2012) Procedia Eng 44:681–682

Wang D, Cattrall RW, Li J, Almeida M, Stevens GW, Kolev SD (2017) J Membr Sci 542:272–279

Meng X, Wang C, Ren T, Wang L, Wang X (2018) Chem Eng J 346:506–514

Hoque B, Almeida M, Cattrall RW, Gopakumar TG, Kolev SD (2019) J Membr Sci 589:117256

Szczepański P, Guo H, Dzieszkowski K, Rafiński Z, Wolan A, Fatyeyeva K, Kujawa J, Kujawski W (2021) J Membr Sci 638:119674

Sellami F, Kebiche-Senhadji O, Marais S, Couvrat N, Fatyeyeva K (2019) React Funct Polym 139:120–132

Iben NI, El Haj I, Amor F, Donato L, Algieri C, Garofalo A, Drioli E, Ahmed C (2016) Chem Eng J 295:207–217

Parhi P.K., (2013) J. Chem. 2013 https://doi.org/10.1155/2013/618236.

Wang D, Liu J, Chen J, Liu Q, Zeng H (2020) Chem Eng Sci 220:115620

Lin C, Liu Y, Zhang X, Miao X, Chen Y, Chen S, Zhang Y (2022) J Power Sources 549:232078

Gyamfi E, Appiah-Adjei EK, Adjei KA (2019) Groundw Sustain Dev 8:450–456

Huang J, Li Y, Xie R, Li J, Tian Z, Chai G, Zhang Y, Lai F, He G, Liu C, Liu T, Brett DJL (2021) J Energy Chem 58:147–155

Radzyminska-Lenarcik E, Pyszka I, Ulewicz M (2020) Membranes 10:88

Smail F, Arous O, Amara M, Kerdjoudj H (2013) Comptes Rendus Chim 16:605–612

Kolev SD, Baba Y, Cattrall RW, Tasaki T, Pereira N, Perera JM, Stevens GW (2009) Talanta 78:795–799

Makowka A, Pospiech B (2019) Autex Res J 19:288–292

Fontàs C, Tayeb R, Dhahbi M, Gaudichet E, Thominette F, Roy P, Steenkeste K, Fontaine-Aupart M-P, Tingry S, Tronel-Peyroz E, Seta P (2007) J Membr Sci 290:62–72

Kazemi D, Yaftian MR, Kolev SD (2021) React Funct Polym 164:104935

Wang D, Hu J, Li Y, Fu M, Liu D, Chen Q (2016) J Membr Sci 501:228–235

Ncib S., Chibani A., Barhoumi A., Larchet C., Dammak L., Elaloui E., Bouguerra W., (2022) Polym Bull https://doi.org/10.1007/s00289-022-04634-z

Alcalde B, Anticó E, Fontàs C (2021) Appl Sci 11:10404

Vera R, Fontas C, Galceran J, Serra O, Anticó E (2017) Sci Total Environ 622:316–324

Danesi PR (1984) Sep Sci Technol 19:857–894

Chen L, Dong H, Pan W, Dai J, Dai X, Pan J (2021) Chem Eng J426:131305

Alsalhy Q (2020) Membranes 77:1–22

Meng X, Wang C, Zhou P, Xin X, Wang L (2017) FrontEnviron Sci Eng 11:1–10

Ounissa S, Mansouri L, Benamor M (2015) Int Proc Chem Biol Environ Eng 83:169

Wang D, Liu F, Zhang X, Wu M, Wang F, Liu J, Wang J, Liu Q, Zeng H (2021) J Membr Sci 626:119183

Liu R, Liu M, Wu S, Che X, Dong J, Yang J (2020) Eur Polym J 137:109948

Jia P, Zhang M, Hu L, Feng G, Bo C, Zhou Y (2015) ACS Sustain Chem Eng 3:2187–2193

Soudais Y, Moga L, Blazek J, Lemort F (2007) J Anal Appl Pyrolysis 78:46–57

Yadav KK, Singh DK, Anitha M, Varshney L, Singh H (2013) Sep Purif Technol 118:350–358

Sellami .F, Kebiche-Senhadji O., Marais S., Fatyeyeva K., (2022) J Hazard Mater 436:129069.

Yin B, Hakkarainen M (2011) J Appl Polym Sci 119:2400–2407

Witt K., Radzyminska-Lenarcik E., Kościuszko A., Gierszewska M., Ziuziakowski K., (2018) Polymers 10:https://doi.org/10.3390/polym10020134.

Najafi V, Abdollahi H (2020) Eur Polym J 128:109620

Li C, Jia Y, Lu X, Chen H (2023) Chemw Eng J 452:139288

Resina M, Macanás J, de Gyves J, Muñoz M (2006) J Membr Sci 268:57–64

Kazemi D, Yaftian MR (2022) Sep Purif Technol 285:120375

Saka C., Kiswandono A.A., Hadi S., Poll. Res. 39:1009–1016.

Zhang LL, Cattrall RW, Kolev SD (2011) Talanta 84:1278–1283

Ershad M, Almeida M, Spassov TG, Cattrall RW, Kolev SD (2018) Sep Purif Technol 195:446–452

Radzyminska-Lenarcik E, Pyszka I, Urbaniak W (2021) Polymers 13:1424

Dong Z, He F, Miao Z, Zhang Y (2021) Sep Purif Technol 267:118564

Owusu G (1998) Hydrometallurgy 47:205–215

Acknowledgements

The researchers would like to thank the Deanship of Scientific Research, Qassim University for funding the publication of this project.

Author information

Authors and Affiliations

Contributions

Conceptualization, H.M., S.N., W.B. and L.A.; methodology, S.N., L.D., and W.B.; validation, W.B., S.A., L.D. and L.A.; formal analysis, H.M., S.N. and K.O.; investigation, L.D., S.A., W.B., S.N. and L.A.; resources, W.B. and L.D.; data curation, H.M., K.O., S.N., W.B. and L.D.; writing—original draft preparation, H.M., K.O. and S.N.; writing—review and editing, S.N., W.B., S.A., L.D. and L.A.; supervision, L.A. and W.B.; project administration, W.B. and L.D.. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mahmoud, H., Ncib, S., Othmen, K. et al. Evaluation of Poly (Vinyl Chloride)/2-Nitrophenyl Octyl Ether/Di(2-Ethylhexyl) Phosphoric Acid Polymer Inclusion Membrane Performance for Zinc Recovery and Separation. Chemistry Africa 7, 2125–2137 (2024). https://doi.org/10.1007/s42250-023-00853-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42250-023-00853-7