Abstract

Intermediate-temperature solid oxide fuel cell (IT-SOFC) work at moderate temperature range (600—800 ℃), thereby eliminating the issue of thermal degradation of electrode materials, reduce operational cost, increase flexibility of material selections, and enhance electrochemical stability of cell components. At intermediate-temperature range, there exists sluggish cathodic reaction, high activation energy and slow oxygen reduction reaction (ORR) at the cathode. Several cobalt-containing cathode perovskite materials with mixed ionic and electronic properties have been developed, which has helped in resolving sluggish ORR and enhances cathodic reaction, thereby increasing the overall performance of IT-SOFC. The expensive nature of cobalt, high evaporation rate and poor thermal expansion coefficient (TEC) means cobalt-free cathode materials need to be investigated. The present study gives an insight into the current trends of cobalt-free cathode materials development in IT-SOFC. Literature reviewed showed composite La0.65Ca0.35FeO3-δ-Gd0.2Ce0.8O2-δ (LCF-GDC), and La0.7Sr0.3Cu0.15Fe0.85O3-δ cathode materials has good polarisation resistance of 0.28 Ωcm2 at 750 ℃, and 0.0153 Ωcm2 at 700 ℃, respectively. Limitations, challenges, gaps were identified, and possible future research direction was recommended. The study also analysed the use of symmetrical electrodes, as it will help resolve the complexity of developing different electrode materials for cathode and anode in IT-SOFC. Holistic efforts were devoted to ensuring that the literature reviewed was recent (within the last 4yrs), and relevant to the current constraints impeding cathode materials use in IT-SOFC. This review study is meant to serve as a reference material to related researchers, and industry experts looking for the most recent accomplishments in cobalt-free cathode materials development.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Global warming, depletion of the ozone layers and environmental concerns have led to the continued search for a more clean, sustainable, and affordable means of energy generation. Solid oxide fuel cells (SOFCs) are electrochemical devices that convert the chemical energy of fuels directly into electricity [1]. The absence of a combustion chamber in SOFCs means that there are no toxic or harmful emissions of gases, and thus are reliable and clean sources of energy. In comparison to other fuel cell technologies, SOFC has high energy and power densities (around 60%), fuel flexibility, long-term stability, and relatively low cost [2]. SOFCs work at high temperatures (800 – 1000 ℃), which causes some challenges such as degradation of electrode materials, high maintenance cost, limited materials selection, reactivity with cell interconnects and carbon dioxide poisoning [3, 4]. To mitigate some of these constraints, researchers have been able to invent intermediate-temperature solid oxide fuel cells (IT-SOFCs), which work in intermediate-temperature range (600 – 800 ℃) [5, 6]. At intermediate-temperatures range, there exist several demerits such as slow oxygen reduction reaction (ORR) rate, material stability, high activation energy requirements of the electrochemical process, sluggish cathodic reactions, incomplete fuel conversion, and redox stability. However, cobalt-containing perovskite cathode materials with mixed ionic and electronic properties have been developed, which has helped in resolving some of these challenges and enhances cathodic reaction, thereby increasing the overall performance of IT-SOFCs [7, 8]. Figure 1 shows the conventional SOFC and its various components.

The primary role of cathode in IT-SOFC is to facilitate ORR by catalysing the conversion of oxygen molecules (O2) into oxygen ions (O2−) at the cathode-electrolyte interface. Typically, cathode consists of mixed ionic-electronic conducting materials, which promote the migration of both electrons and oxygen ions [9, 10]. This redox process allows the release of energy and the generation of electrical current. Thus, cathode materials must ensure smooth transport of oxygen ions from the cathode-electrolyte interface to the anode-electrolyte interface through the electrolyte. This transport process is essential for the continuous flow of ions within the IT-SOFC, ensuring a steady electrochemical reaction. Efficient functioning of the cathode relies on maximizing the triple phase boundary (TPB) length, which is the region where the cathode, electrolyte, and fuel (usually hydrogen) meet [11]. Key to ensuring TPB effectiveness include optimized electrode design, high catalyst activity, adequate ionic-electronic conductivity, efficient thermal management, optimized gas composition, and electrode stability [12, 13]. Hence, cathode materials with a large TPB surface area are desirable to promote ORR and improve overall cell efficiency.

Conventionally, lanthanum strontium cobalt ferrite (LSCF) has been widely employed as the cathode material in IT-SOFCs [14,15,16]. While LSCF exhibits excellent electrochemical activity and conductivity, it suffers from some inherent limitations, such as high material cost, limited stability under reducing atmospheres, and dependency on scarce cobalt resources. These challenges have motivated researchers to explore alternative cathode materials that offer comparable or improved performance and are devoid of cobalt, thus addressing sustainability concerns. SrFeO3-δ perovskite oxide series are among the first group of cobalt-free cathode materials developed [17, 18]. With its mixed ionic and electronic properties, this group of perovskite oxides showed excellent and promising prospects for IT-SOCFs, oxygen permeation membranes, and oxygen sensor applications. However, its crystal structure and defect properties can vary depending on the oxygen vacancy content (δ), which can lead to a structural phase shift from cubic to brownmillerite at temperature < 870 ℃ [19, 20]. The resulting long-range ordering in oxygen vacancies reduces the electrical conductivity of this material, highlighting the urgent need to repress orthorhombic to brownmillerite phase at low temperatures to retain the superior electrical conductivity of the cubic phase. In order to address this limitation, researchers have attempted to stabilize cubic perovskite structure through fractional replacement of Fe sites with other elements such as La, Pr, Sm, Cr, Mo, Sb, Ce, and Nb [21,22,23]. Several perovskite oxides, which include Sr2Ti0.9FeNi0.1O6, Pr1.90−xCe0.1CuO4, YBaCo2O5+δ, and La0.54Sr0.46Zn0.20Fe0.80O3−δ, have been studied as possible cathode materials for IT-SOFCs [24,25,26]. Other series of cobalt-free cathode materials have also been investigated for IT-SOFC application [27, 28]. Figure 2 gives an overview of the topics treated in the present study.

The main goal of this study is to provide an overview of the recent progress in cobalt-free cathode materials development for IT-SOFCs. Efforts were dedicated to ensuring that the literature reviewed is recent (within the last 4yrs), and relevant to the current challenges limiting the wide use of cobalt-free cathode materials. Figure 3 shows the methodology adopted in this study, and the credibility of sources used. A systematic literature review was carried out to highlight the gaps, challenges, and limitations facing the practical application of cobalt-free cathode materials. Future research directions and possible solutions were recommended in addressing the key challenges identified by the present study. A vast number of review studies related to IT-SOFCs have been published in the last five years, but none was dedicated to addressing the constraints faced by cobalt-free cathode materials and cobalt-free symmetrical electrodes. Most of the existing studies are dedicated to addressing the challenges of the traditional solid oxide fuel cell, which operates at 800 to 1000 ℃. Thus, the present study will serve as a reference to energy experts and related researchers looking for recent accomplishments in the field of IT-SOFCs cobalt-free cathode material development. Table 1 provides an overview of previous related review studies on cobalt-free cathode material development for solid oxide fuel cells. Recent review studies on cobalt-free cathode materials for traditional SOFC have highlighted advancements in nickel, manganese, and iron-based compositions, emphasizing their potential for mitigating cobalt’s cost and toxicity concerns based on the information in Table 1. However, the need to lower the operation temperature of SOFC to the intermediate-temperature range necessitates a fresh review to assess emerging cobalt-free cathode materials and performance.

2 Overview of cathode reaction mechanism in IT-SOFC

Cathode in IT-SOFC is responsible for facilitating ORR, where oxygen molecules from air are electrochemically reduced to oxide ions. This reaction is crucial as it balances the charges produced during fuel oxidation at the anode, thereby enabling the flow of electrical current through the external circuit. Oxygen reduction reaction is typically the slowest step in the electrochemical process, imposing limitations on cell performance [37, 38]. Figure 4 shows the schematic region between the electrolyte and cathode where TPB exist. Equation (1) gives the overall cathode reaction in IT-SOFC [39]. The cathode reaction mechanism involves multiple steps, which include adsorption of oxygen molecules, dissociation into oxygen ions at TPB, diffusion of ions through the electrolyte, and incorporation into electrolyte lattice [40]. The rate-limiting step often occurs at the TPB, where the oxygen molecules need to overcome activation barriers for adsorption and dissociation. Therefore, catalytic materials that can lower the activation barriers are essential for enhancing cathode kinetics. The \(\frac{1}{2}{O}_{2}\) in Fig. 4 represents half a molecule of oxygen, and the \({2e}^{-}\) represents two electrons involved in the reduction process. The two oxygen vacancies on the surface of the cathode are denoted as \({2VO}^{**}\), and the oxygen vacancy left behind after the oxygen reduction \({VO}_{0}\).

The microstructure of cathode materials is crucial for promoting effective diffusion of oxygen and surface interactions. Nanostructuring and controlling the grain boundaries can enhance TPB density and facilitate faster oxygen incorporation into electrolytes [41, 42]. Moreover, proper electrode–electrolyte contact is essential for minimizing polarization losses. Techniques such as infiltration, co-firing, and advanced deposition methods are currently being investigated to engineer well-defined microstructures in cathode materials [43, 44]. Figure 5 shows the schematics of possible oxygen incorporation pathways for a mixed ionic and electronic conductor. Thus, the process involved in oxygen surface exchange can be described by the following steps:

-

Step 1: Oxygen adsorption and dissociation

$${{\text{O}}}_{2}+4{{\text{e}}}^{-}+2\mathrm{ vacancies}\to 2{{\text{O}}}^{2-}$$(2) -

Step 2: Oxygen incorporation

$${{\text{O}}}^{2-}+{\text{vacancies}}\to {{\text{O}}}^{2-}\mathrm{ vacancy complex}\to {{\text{O}}}^{2-}\mathrm{incorporation intocathode lattice}$$(3)

Perovskite oxides, particularly those with mixed ionic-electronic conducting properties, have shown great potential as cathode materials in IT-SOFCs. Materials such as La0.6Sr0.4Co0.2Fe0.8O3-δ (LSCF) and La0.8Sr0.2MnO3 (LSM) exhibit favourable oxygen transport properties and offer efficient pathways for charge transfer [45, 46]. These materials also exhibit excellent stability under operating conditions and possess reasonable catalytic activity for ORR. Advanced characterization techniques such as in-situ spectroscopy, electron microscopy, and computational modelling have provided more valuable insights into cathode reaction mechanism [47, 48]. These techniques allow researchers to directly observe the oxygen exchange processes, surface interactions, and defect chemistry, aiding in the design of improved cathode materials and structures.

3 IT-SOFC cathode materials

Several cathode materials have been investigated for IT-SOFC applications, each with its own advantages and limitations [49, 50]. Cathode materials should exhibit rapid and efficient ORR kinetics to minimize polarization losses and enhance overall cell efficiency. Operating at intermediate temperatures implies that cathode materials must have good thermal stability to prevent degradation and ensure prolonged cell lifespan. This involves resistance to sintering, phase transitions, and chemical interactions with other cell components. Lanthanum strontium manganite (LSM) is a widely studied cathode material due to its high electronic conductivity and good catalytic activity [51, 52]. However, it may suffer from strontium segregation at the cathode-electrolyte interface under certain conditions, leading to performance degradation. Li et al. [53] synthesized novel La0.7Sr0.3Co0.25Fe0.25Ni0.25Mn0.25O3-δ (LSCFNM73) perovskite oxide via a one-pot combustion method. Findings from their investigations showed that the substitution of Sr2+ with La3+ increased the electrical conductivity, thermal expansion coefficient, oxygen vacancy concentration, and oxygen adsorption. The LSCFNM73 cathode material exhibited a high conductivity of 464 S/cm at 800 ℃. The NiO-YSZ|YSZ|GDC|LSCFNM73-GDC fuel cell achieved a maximum power density of 1088 mWcm2 at 800 ℃, and demonstrated good thermal stability. Though LSCFNM73 appears to have excellent cathode potential, the effect of cobalt on the B-site was not investigated. A comprehensive study is needed to determine the effect of cobalt poisoning, stability, and degradation over a long period of time. Klyndyuk et al. [54] investigated NdBa(Fe,Co,Cu)2O5+δ (NBCC2) as cathode material for SOFC application. Their result showed that Cu- and Fe-doped variants show compatibility with commonly used electrolytes (GDC and YSZ), low thermal expansion coefficient (TEC), and high electrical conductivity. They reported that NBCC2 with slight Cu substitution exhibits the best performance, offering enhanced conductivity, stability, and electrochemical benefits, making it a promising cathode material for IT-SOFCs. While the results of their findings are exciting, further investigations are needed to understand the activation energy (Ea) of the system. The Ea is an important factor in determining how fast the electrochemical reduction of oxygen will be achieved. As large Ea values will mean sluggish cathodic reaction, thereby reducing the overall cell performance. Costilla-Aguilar et al. [55] synthesized La1.8Sr0.2FeCoO5+δ (DP-LSCF) double perovskite oxide via modified sol–gel technique and evaluated its performance as cathode material for IT-SOFCs. The new compound displayed a stable rhombohedral structure (space group \(R\overline{3 }c\)) and good compatibility with GDC electrolyte. Raman analysis confirmed the double perovskite structure, while XPS showed mixed Co2+/Co3+ and Fe3+/Fe4+ states. Substituting Fe for Co lowered the thermal expansion coefficient value to 19.4 × 10–6 K−1 and reduced the electrical conductivity from 9 to 50 S/cm at 300 – 900 ℃. They obtained a favorable area-specific resistance (ASR) value of 0.42 Ω cm2 at 800 ℃. Their electrochemical impedance spectrometer (EIS) analysis highlighted DP-LSCF as an excellent cathode material for IT-SOFCs. Figure 6 illustrates the electrical conductivity and TEC profile of their experiment.

(a) Electrical conductivity of DP-LSCF in air at 300 – 900 ℃; (b) Thermal elongation measurement of DP-LSCF [55]. (This result was reproduced with copyright permission from Elsevier)

Based on the profile analysis of DP-LSCF in Fig. 6(a), it’s obvious that an increase in temperature results in a corresponding increase in electrical conductivity. This is very true for cathode materials when their electrical conductivity is measured in air. Perovskite oxides often exhibit mixed ionic and electronic conductivity. At lower temperatures, ionic mobility might dominate, which can impede electronic conduction. As the temperature increases, ionic mobility becomes more significant, allowing ions to move more freely within the material. The increase in ionic mobility can lead to higher electronic conductivity by facilitating fast charge movement. However, in the study, the electrical conductivity of DP-LSCF under an oxidizing environment (5%H2/95%Ar) wasn’t investigated. Exposing DP-LSCF to an oxidizing environment will trigger various degradation mechanisms, such as chemical reactions, phase changes, and microstructural alterations. These mechanisms can negatively impact the cathode’s electrical conductivity over time. Further study should be conducted to understand the influence of oxidizing environment on DP-LSCF, so that more useful insights can be gained on the degradation mechanisms, and work towards mitigating it.

Liu et al. [56] investigated Ca-doped layered double perovskite Sm1–xCaxBaCo2O5+δ (x = 0–0.4; SCBC) oxides as cathodes for IT-SOFCs. The SCBC cathodes demonstrated good chemical compatibility with CeO2-based electrolytes at high temperatures, with Co3+ and Co4+ coexisting in the lattice due to Ca doping, promoting oxygen vacancies. They also reported that SCBC2 showed superior conductivity, catalytic activity, and CO2 durability, suggesting potential use as cathode in IT-SOFC. The authors demonstrated the influence of calcium doping in enhancing the catalytic performance of SCBC cathode materials, but little was known about the thermal compatibility of these materials with the two commonly used electrolytes (YSZ and GDC). Further studies are needed to determine the appropriate thermal elongation of these materials under the influence of varying temperatures. Table 2 gives an overview of some recent findings in cathode materials development for IT-SOFC.

A critical and comparative analysis of Table 2 shows that composite cathode material Ba0.5Sr0.5Co0.8Fe0.2O3−δ-Sm0.2Ce0.8O1.9 has good thermal elongation of 12.4 × 10–6 K−1 at 30 to 600 ℃. The good thermal expansion coefficient noticed in the composite cathode can be attributed to synergistic effects that lead to desirable properties. The interactions between the different constituents can result in composite cathode material with a more controlled and balanced thermal expansion behaviour. It’s important to note that while composite cathode materials generally offer advantages in terms of thermal expansion coefficient, they also need to fulfil other requirements such as electrical conductivity, oxygen reduction kinetics, and chemical compatibility with the fuel cell environment. Another obvious fact is that most of the studies in Table 2 contain cobalt, this can be attributed to the fact that cobalt-containing materials are less prone to sintering at intermediate temperatures compared to other cathode materials. Despite all the unique properties of cobalt-containing cathode materials used in IT-SOFC, its effectiveness is being hampered by the diffusive nature of cobalt which results in cell losses. The expensive nature of cobalt, high evaporation rate and poor thermal expansion coefficient (TEC) means other cobalt-free cathode materials need to be investigated.

4 IT-SOFC cobalt-free cathode materials

Traditional cathode materials often contain cobalt, and pose challenges due to their limited availability, high cost, and susceptibility to performance degradation. Thus, investigating alternative cobalt-free cathode materials will address these limitations and enhance the overall viability of IT-SOFC technology. Materials belonging to the Ruddlesden-Popper phase, such as La2NiO4 (LNO) are being investigated as potential substitutes for cobalt-containing perovskite oxides [65, 66]. This is due to their mixed ionic-electronic conductivity and good chemical compatibility, making them potential candidates for advanced IT-SOFC cathodes. Recent studies also showed that Ruddlesden-Popper phase containing cobalt has better thermal stability under increasing temperature than its perovskite oxide counterpart [67, 68]. Ghorbani-Moghadam et al. [69] successfully synthesized La0.7Sr1.3Co1-xFexO4 Ruddlesden-Popper oxides (x = 0, 0.1, 0.3, 0.5) via modified sol–gel method for IT-SOFC cathodes. Structural analysis displayed a tetragonal phase with expanded lattice parameters due to Fe substitution in Co sites. Electrical conductivity decreased with Fe substitution, yet oxygen reduction reaction activity improved, leading to enhanced electrochemical performance with lower area-specific resistance, making La0.7Sr1.3Co1-xFexO4 a promising cathode materials. Challenges associated with some Ruddlesden-Popper oxides are phase transitions, chemical degradation, or structural changes at intermediate-temperature. These issues can lead to cathode instability, reduced performance, and a shorter operational lifespan. Also, synthesizing Ruddlesden-Popper oxides can involve complex procedures, potentially leading to higher production costs. Developing scalable and cost-effective synthesis routes is important for practical implementation.

Qi et al. [70] investigated self-assembled cobalt-free Ba0.5A0.5Fe0.8Zr0.2O3-δ (A = Sr2+/Sm3+, BSrFZ/BSmFZ) iron-based composite oxides, with Sr2+ and Sm3+ ions compared for enhanced ORR activity. Both composites showed uniform nanoparticle size, benefiting from multi-phase interactions during self-assembly. The BSrFZ composite exhibited superior oxygen vacancy content, adsorption, and redox activity, resulting in a high-power density of 1.64 mW/cm2 at 750 ℃. Their work showed BSrFZ as a potential cathode for IT-SOFC, with improved electrochemical performance. Wang et al. [71] synthesized BaFe0.9Nb0.1O3-δ (BFNb) with 10 mol.% Nb5+ doped BF oxide as cathode material for IT-SOFCs application. The cubic phase in BFNb synthesized at 1000 ℃ facilitated disordered oxygen vacancies, and thus enhancing oxygen vacancy concentration. Favourable electrochemical performance and stability showed BFNb as a potential cathode in IT-SOFC. La0.8Sr0.2Fe1-xCuxO3-δ (LSFCux, x = 0.0 – 0.3) nanofiber cathodes doped with Cu at the B site were synthesized via electrospinning [72]. The calcination of the samples at 800 ℃ yielded perovskite-based structures with high crystallinity. Doping with copper increased the oxygen vacancy concentration and shifted the rate-limiting step to cathode charge transfer. Thus, demonstrating outstanding electrochemical properties. The study reported that LSFCu2 achieved a polarization resistance of 0.674 Ωcm2 at 650 ℃, while Ni-SDC/SDC/LSFCu2 single cell exhibited a stable power density of 362 mW/cm2 at 600 °C for 50 h. Figure 7 shows the result profiles of their investigation.

SEM images of La0.8Sr0.2Fe1-xCuxO3-δ (LSFCux, x = 0.0–0.3) nanofibers fired at 800 ℃ and distributions of fibre diameters. (a)x = 0.0, (b) = 0.1, (c) = 0.2, (d) = 0.3; (e) Electrochemical impedance spectroscopies of the single cell with LSFCu2 cathodes at 500–650 ℃, (f) performance output curve for NiO-SDC/SDC/LSFCu2 anode-supported single cell at 500–650 ℃ [72]. (This result was reproduced with copyright permission from Elsevier)

Based on the result profiles in Fig. 7 (a – d), it’s evident that LSFCux is a highly porous cathode material, with what appears to be an even distribution of nanofibers. Porous LSFCux will aid in providing pathways for reactant gases (oxygen and fuel) to diffuse within the cathode material. This will promote efficient gas-phase reactions at the electrode–electrolyte interface, enhancing overall cell performance. The excellent interchange at electrode–electrolyte interface is collaborated by the result profiles in Fig. 7 (e, f). Belotti et al. [73] explored A-site deficiency effects in (Ba0.95La0.05)1-xFeO3-δ perovskite oxides. Density functional theory (DFT) computations revealed charge effects enhancing p-type conductivity via lowered oxygen vacancy and increased ligand holes. Experimental validation showed improved electrical conductivity and catalytic performance at intermediate temperatures. Moderate deficiency of up to 10% yields stable power output, while excess deficiency of more than 20% results in the formation of secondary phases. The insights from their work can be used as a template for analyzing the limitation and effects of A-site deficiency in other cobalt-free oxides, and can also be used as a tool in the rational design of IT-SOFC’s cathodes. Table 3 gives an overview of some recent findings on cobalt-free cathode materials for IT-SOFC applications.

Comparative analysis of Table 3 shows that cobalt-free cathode materials have good polarization resistance, with La0.7Sr0.3Cu0.15Fe0.85O3-δ having the least value of 0.0153 Ω cm2 at 700 ℃. Low polarization resistance is vital for cathode materials in IT-SOFCs because it directly impacts the cell’s efficiency, power output, voltage losses, stability, and compatibility at intermediate-temperatures. Materials with low polarization resistance facilitate faster electrochemical reactions, reduce overpotential, and contribute to overall improved cell performance. Though, while La0.7Sr0.3Cu0.15Fe0.85O3-δ has low polarization resistance at 700 ℃, it’s also obvious that this material has low electrical conductivity of 1.54 S/cm in air at 700 ℃ compared to composite La0.65Ca0.35FeO3-δ-Gd0.2Ce0.8O2-δ (LCF-GDC), which has a good electrical conductivity of 100 S/cm in air at a lower temperature of 650 ℃. Higher electrical conductivity reduces cathodic overpotential, allowing the cell to operate at lower temperatures with reduced energy losses. This is particularly important for IT-SOFCs that operate at intermediate temperatures (600 – 800 ℃) compared to traditional high-temperature SOFCs. Thus, there is a need to enhance the electrical conductivity of cobalt-free cathode materials to be able to compete fairly with those of cobalt-containing counterparts. Most recent studies on cobalt-free cathode materials showed good activation energy, which is the minimum energy required to kickstart an electrochemical reaction occurring at the cathode-electrolyte interface [81, 82]. This reaction is essential for the overall operation of the fuel cell, as it generates electrons that flow through the external circuit to produce electric power. The activation energy of the cathode materials plays a significant role in determining the speed at which this electrochemical reaction occurs.

Lach et al. [82] synthesized La1-xSrxNi0.75Cu0.25O3-δ and La1-xSrxNi0.5Cu0.5O3-δ perovskites via the soft chemistry technique. They observed a transition from R-3c to Pm-3 m crystal structure at high temperatures. The doping with Sr reduced the phase transition temperatures, with La1-xSrxNi0.5Cu0.5O3-δ-series showing the lowest at 450 ℃. The study concludes that Sr-doping increased oxygen non-stoichiometry and thermal expansion coefficients, similar to solid electrolytes. Both samples showed good stability and chemical compatibility with GDC-electrolyte. However, the samples were not compatible with YSZ electrolyte. La1-xSrxNi0.5Cu0.5O3-δ-series demonstrated promising performance in anode-supported IT-SOFCs, achieving a power density of 445 mWcm−2 at 650 ℃ in a humidified H2 environment, indicating its potential as a high-performance cathode material for intermediate-temperature SOFCs. Figure 8 shows the excellent electrochemical performance of La0.95Sr0.05Ni0.5Cu0.5O3-δ -based cathode. Based on the result profile, we can conclude that the La0.95Sr0.05Ni0.5Cu0.5O3-δ -based cathode has good power density at 600 and 650 ℃. While the electrochemical impedance analysis was impressive, the values of nearly 0.7 and 1.6 Ωcm2 seen on the EIS plot for polarization resistance at 650 and 600 ℃ are a bit high compared to those reported in the literature [83,84,85,86]. Thus, there is a need to further enhance the performance of this material with the addition of an electrocatalyst.

(a) Voltage and power density as a function of current density and (b) impedance spectra for anode-supported SOFC with La0.95Sr0.05Ni0.5Cu0.5O3-δ-based cathode [82]. (This result was reproduced from MDPI open access journal, no copyright permission is required)

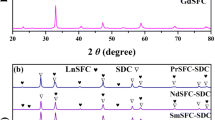

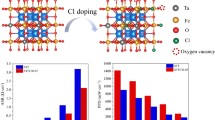

Dengjie Chen et al. [87] investigated the influence of rare earth metals on various properties of composite oxides LnBaFe2O5+δ. The study found that rare earth metals influence phase structure, oxygen content, conductivity, thermal expansion behaviour, microstructure, and electrochemical performance of the oxides. Electronic conductivity decreased with decreasing ionic radius of Ln3+, while oxygen desorption temperature and thermal expansion coefficient showed opposing trends. SmBaFe2O5+δ exhibited the best electrocatalytic activity for oxygen reduction reaction (ORR), achieving peak power densities at different temperatures. Additionally, cathodic polarization was found to enhance the ORR performance of LnBaFe2O5+δ cathodes. Metallic nanoparticle-decorated with ceramic anodes were synthesized via in-situ reduction of Sr2FeMo0.65Ni0.35O6-δ (SFMNi) in H2 environment at 850 ℃ [88]. The reduction induced a phase transformation, resulting in the formation of mixed phases, including the Ruddlesden–Popper Sr3FeMoO7-δ, perovskite Sr(FeMo)O3-δ, and FeNi3 bimetallic alloy nanoparticle catalysts. It was observed that the resulting materials exhibited a unique structure with a homogeneous distribution of metallic nanoparticle catalysts on the ceramic surface. Furthermore, incorporating metallic nanoparticle catalysts onto the SFMNi ceramic anode led to a significant enhancement in electrochemical performance. This improvement can be attributed to the catalytic activity of the exsolved Fe–Ni alloy nanoparticle catalysts, which facilitated the electrochemical reactions at the anode-electrolyte interface. While most of the studies reviewed on cobalt-free cathode materials development for IT-SOFC provided valuable insight on strontium-doping and in-situ reduction in H2 environment for enhanced ORR rate and linear thermal elongation, more investigation is needed to understand the chemical compatibility of these materials with YSZ and GDC electrolytes. Mixed ionic and electronic conduction (MIEC) in composite cathodes also show promise for enhancing ORR at lower temperatures. Fe-based cobalt-free perovskite emerges as a favourable cathode material owing to its catalytic activity, stability, and cost-effectiveness [89, 90]. Table 4 gives an overview of recently developed Fe-based perovskite cathode materials for IT-SOFCs.

Comparative analysis of Table 4 shows that cobalt-free iron-based LaBaFe1.8Zn0.2O5+δ has the best electrochemical performance with polarization resistance of 0.014 Ωcm2 at 800 ℃, and an average linear thermal expansion coefficient of 11.4 × 10–6 K−1 at 30 to 750 ℃. Despite the good electrochemical properties of LaBaFe1.8Zn0.2O5+δ, Fe-based cathode materials often suffer from chemical instability under operating conditions, leading to degradation and reduced cell performance. This instability can result from reactions with the electrolyte or other cell components.

Traditionally, the intermediate-temperature solid oxide fuel cell (IT-SOFC) has distinct electrode materials for the cathode and anode. However, efforts have been directed toward the development of electrodes for symmetrical configuration. This will help reduce material costs and effectively ensure homogeneity in electrode material development investigations. Nevertheless, there remains inadequate information regarding which materials can effectively serve as symmetrical electrodes. Novel Sr-doped PrBa0.5Sr0.5Fe2O5+δ (PBSF) symmetrical electrode was synthesized via a conventional sol–gel technique [97]. A cubic structure was reported for PBSF after calcination in air for 1000 ℃. The PBSF demonstrated robust structural integrity when exposed to a CO2 atmosphere and showed compatibility with the LSGM electrolyte. In comparison to the original PBF, the polarization resistance of PBSF decreased significantly by 75% in air and 61% in H2. Furthermore, PBSF electrode showed resilience against CO2 poisoning and maintained short-term stability. The study reported that in a single cell configuration with a 300 μm-thick LSGM electrolyte supporting PBSF/LSGM/PBSF, the maximum power output (Pmax) reached 1067 mWcm−2 at 850 ℃ using humidified hydrogen fuel and 535 mWcm−2 using propane fuel at 800 ℃. Additionally, effective electrolysis of CO2 was accomplished using PBSF as a symmetrical electrode. The PBSF electrode demonstrated consistent stability in both fuel cell and electrolytic cell operations. Their findings strongly indicate that PBSF is a promising symmetrical electrode material for IT-SOFC applications. Figure 9 shows the structural integrity of Sr-doped PrBa0.5Sr0.5Fe2O5+δ (PBSF) and its chemical compatibility with commonly used electrolyte. Table 5 illustrates recent findings on electrode materials for symmetrical solid oxide fuel cell operating at intermediate temperatures.

(a) XRD profile of PBF and PBSF samples and PBSF sample was reduced at 5%H2/Ar at 800 ℃ for 10 h and then oxidized at 800 °C for 10 h in air; (b) An enlarged view of (110) peak of PBF and PBSF samples; (c) Chemical compatibility between PBSF and LSGM electrolyte; (d) XRD patterns of PBSF fired at 800 °C for 10 h at 6% CO2 and annealed at 800 ℃ for 10 h at 100% CO2 [97]. (This result was reproduced with copyright permission from Elsevier)

A critical overview of the recently developed electrode materials for symmetrical solid oxide fuel cell in Table 5 shows that the polarization resistance values in air are higher compared to traditional intermediate-temperature solid oxide fuel cells cathode materials. Realistically, it’s difficult to synthesize electrode materials with excellent electrochemical properties for both fuel oxidation and oxygen reduction reactions. Thus, there is a need to control the microstructure of this type of electrode material to minimize grain boundaries and maximize the percolation pathways for charge carriers. This can be achieved through careful optimization of sintering conditions, grain size control, and the addition of pore formers. The study on identical electrodes for symmetrical configuration is mainly restricted to polarization resistance measurement in air, because our concern is mainly on cobalt-free cathode materials development for IT-SOFC applications.

5 Challenges and future research recommendations on cobalt-free cathode materials for IT-SOFC

Despite advancements in cobalt-free cathode materials, many still face challenges related to performance and stability. Lower electrical conductivity, sluggish oxygen reduction kinetics, and susceptibility to chemical and thermal degradation can hinder the overall efficiency and long-term stability of IT-SOFC as evident from the reviewed literature. A significant limitation lies in the incomplete understanding of the fundamental mechanisms governing the performance of cobalt-free cathode materials [103]. This has hampered the ability to design and optimize materials with targeted properties, hindering progress in achieving high-efficiency IT-SOFC. The integration of cobalt-free cathode materials with other cell components, such as electrolytes and anodes, can lead to compatibility issues and performance degradation. Thus, interactions at the interfaces between different materials need further investigation to ensure overall system stability. Moving from laboratory-scale synthesis to large-scale manufacturing of cobalt-free cathode materials presents challenges related to cost-effectiveness, reproducibility and maintaining consistent performance [104]. Hence, innovative approaches are needed to address these hurdles and enable practical commercialization. The pool of suitable cobalt-free cathode materials is still limited compared to traditional cobalt-containing counterparts. Exploring and identifying new materials with improved properties is crucial to broadening the range of options for IT-SOFC development. Below are the specific future research recommendations on cobalt-free cathode materials development for IT-SFOC applications:

-

There is a need to conduct a comprehensive study to understand the oxygen reduction kinetics and mechanisms in cobalt-free cathode materials. Advanced computational modelling and experimental techniques can provide insights into surface reactions, charge transfer processes, and diffusion mechanisms, aiding in material design.

-

Research efforts should focus on developing scalable synthesis routes for cobalt-free cathode materials that ensure consistent properties. Comprehensive characterization techniques should be employed to correlate material structure, composition, and performance, enabling targeted improvements.

-

Investigating the interactions between cobalt-free cathode materials and other cell components is vital. Interface engineering strategies can be explored to enhance compatibility and mitigate performance degradation in multi-component IT-SOFC systems.

-

Rigorous electrochemical testing, including impedance spectroscopy and electrochemical performance under relevant operating conditions, can provide valuable insights into the limitations of cobalt-free cathode materials and guide their optimization.

-

Long-term stability assessments under realistic operating conditions are essential to evaluate the performance and durability of cobalt-free cathode materials. These studies can guide improvements and provide insights into degradation mechanisms.

-

More research effort is needed on the development of cobalt-free electrode materials for symmetrical solid oxide fuel cells working at intermediate-temperature range, as existing studies are not sufficient.

-

Future studies should consider investigating agricultural waste, such as rice-husk crop residues, weeds, leaf litter, sawdust, forest waste, and livestock waste, as possible cathode materials in IT-SOFC. This will go a long way in addressing the high cost associated with traditional cobalt-containing cathode materials, and any environmental concerns.

Cobalt-free cathode materials hold great prospects for enhancing the efficiency and sustainability of IT-SOFCs, several limitations must be addressed through tailored research efforts. A deep understanding of material properties, interfaces, and performance mechanisms will pave the way for the development of advanced cobalt-free cathode materials that enable practical implementation.

6 Conclusion

In the present study, we have discussed a range of cobalt-free cathode materials, which include perovskites, pyrochlores, Ruddlesden-Popper, spinels, and double perovskites. Literature reviewed showed that these materials exhibit promising electrochemical performance, thermal stability, and compatibility with IT-SOFC operating conditions. However, it is evident that the development of cobalt-free cathode materials is not without its challenges. Issues such as chemical stability, conductivity, and thermal compatibility with commonly used electrolytes (YSZ and GDC) in IT-SOFC must be addressed to ensure long-term reliability and efficiency. Mixed ionic conducting cobalt-free LaBa0.5Sr0.5Fe2O5.875-δF0.125 showed good electrical conductivity of 45 S/cm at 800 ℃, and a favourable polarisation resistance of 0.089 Ωcm2 at 750 ℃. Hence, optimizing, and enhancing this group of materials could yield more desirable electrochemical properties for oxygen reduction reaction. Furthermore, the transition from laboratory-scale studies to practical-based IT-SOFC applications requires careful consideration of several factors such as stability, scalability, and long-term performance. The potential benefits of reduced degradation, cost affordability and improved durability offered by some cobalt-free cathode materials need continued investigation under realistic operating conditions. Despite the significant progress made in the field, cobalt-free cathode materials are not the only solution to the challenges associated with cobalt-containing counterparts. Different operating conditions, desired performance metrics, and cell configurations will dictate the optimal choice of materials. Thus, continued research in the field to explore new materials, optimize existing ones, and bridge the gap between fundamental understanding and practical implementation is necessary.

Data availability

The data and materials that have been used are embedded in the body of the manuscript.

Code availability

Not applicable.

References

S. Seyam, I. Dincer, M. Agelin-Chaab, Investigation of a hybridized combined cycle engine with SOFC system for marine applications. J. Therm. Anal. Calorim. 148, 8323–8344 (2023). https://doi.org/10.1007/s10973-022-11765-y

Md.M. Rahman, A.M. Abdalla, L.A. Omeiza, V. Raj, S. Afroze, Md.S. Reza et al., Numerical Modeling of Ammonia-Fueled Protonic-Ion Conducting Electrolyte-Supported Solid Oxide Fuel Cell (H-SOFC): A Brief Review. Processes 11, 2728 (2023)

T. Chen, Y. Xie, Z. Lu, L. Wang, Z. Chen, X. Zhong et al., La0.75Sr0.25Cr0.5Mn0.5O3−δ-Ce0.8Gd0.2O1.9 composite electrodes as anodes in LaGaO3-based direct carbon solid oxide fuel cells. J Cent South Univ 29, 1788–98 (2022). https://doi.org/10.1007/s11771-022-5045-2

Li Y, Yu S, Dai H, Xu Y, Bi L. TiO2-induced electronic change in traditional La0.5Sr0.5MnO3−δ cathode allows high performance of proton-conducting solid oxide fuel cells. Sci. China Mater. (2023). https://doi.org/10.1007/s40843-023-2519-9.

Mandal R, Behera SK, Pratihar SK. Effect of oxygen nonstoichiometry on electrical conductivity and oxygen transport parameters of Cu-substituted La0.5Sr0.5Co0.8Fe0.2O3-δ perovskite oxides. J. Solid State Electrochem. (2023). https://doi.org/10.1007/s10008-023-05578-8.

S. Amira, M. Ferkhi, F. Mauvy, S. Fourcade, J.M. Bassat, J.C. Grenier, A La1.5Nd0.3Pr0.2NiO4.16: A New Cathode Material for IT-Solid Oxide Fuel Cells. Electrocatalysis 14, 546–60 (2023). https://doi.org/10.1007/s12678-023-00818-x

A.P. Khandale, R.V. Kumar, S.S. Bhoga, Effect of synthesis route on electrochemical performance of PrBaCo2O5+δ cathode for IT-SOFC application. Bull. Mater. Sci. 46, 119 (2023). https://doi.org/10.1007/s12034-023-02949-9

M. Kiani, M.H. Paydar, SrCo0.8Fe0.1Ga0.1O3−δ (SCFG) cathodes incorporated with Sm0.2Ce0.8O1.9 (SDC) for IT-SOFCs application. J Mater Sci Mater Electr 34, 1366 (2023). https://doi.org/10.1007/s10854-023-10773-4

D. Sikstrom, A. Javed, S. Muhammad, V. Thangadurai, Perovskite-type Nd0.75Ba0.25Co0.8Fe0.2O3-δ cathode for intermediate temperature solid oxide fuel cells. Ionics (Kiel) 29, 1507–14 (2023). https://doi.org/10.1007/s11581-023-04901-7

L.A. Omeiza, A.M. Abdalla, B. Wei, A. Dhanasekaran, Y. Subramanian, S. Afroze et al., Nanostructured Electrocatalysts for Advanced Applications in Fuel Cells. Energies (Basel) 16, 1876 (2023). https://doi.org/10.3390/en16041876

H.S. Yoo, S. Ju Kim, Y.T. Megra, J. Lee, J.W. Suk, W. Lee, Interface engineering to improve electrochemical performance of intermediate-temperature solid oxide fuel cells. Appl. Surf. Sci. 639, 158188 (2023). https://doi.org/10.1016/j.apsusc.2023.158188

C. Ampelli, F. Tavella, D. Giusi, A.M. Ronsisvalle, S. Perathoner, G. Centi, Electrode and cell design for CO2 reduction: A viewpoint. Catal. Today 421, 114217 (2023). https://doi.org/10.1016/j.cattod.2023.114217

Fu S, Ye L. Global self-optimizing control of a solid oxide fuel cell. 2023 IEEE 12th Data Driven Control and Learning Systems Conference (DDCLS), (IEEE; 2023) 1865–70. https://doi.org/10.1109/DDCLS58216.2023.10166897.

A.P. Panunzi, L. Duranti, I. Luisetto, N. Lisi, M. Marelli, E. Di Bartolomeo, Triggering electrode multi-catalytic activity for reversible symmetric solid oxide cells by Pt-doping lanthanum strontium ferrite. Chem. Eng. J. 471, 144448 (2023). https://doi.org/10.1016/j.cej.2023.144448

M. Geofrey Sahini, L.S. Daud, Perspective and control of cation interdiffusion and interface reactions in solid oxide fuel cells (SOFCs). Mater. Sci. Eng., B 292, 116415 (2023). https://doi.org/10.1016/j.mseb.2023.116415

A.M. Mehdi, A. Hussain, R.H. Song, T.-H. Lim, W.W. Kazmi, H.A. Ishfaq et al., Improving the durability of cobaltite cathode of solid oxide fuel cells – a review. RSC Adv. 13, 25029–25053 (2023). https://doi.org/10.1039/D3RA02571C

L. Zhang, D. Huan, K. Zhu, P. Dai, R. Peng, C. Xia, Tuning the Phase Transition of SrFeO 3−δ by Mn toward Enhanced Catalytic Activity and CO 2 Resistance for the Oxygen Reduction Reaction. ACS Appl. Mater. Interfaces 14, 17358–17368 (2022). https://doi.org/10.1021/acsami.2c01339

M.L. Tummino, SrFeO3 peculiarities and exploitation in decontamination processes and environmentally-friendly energy applications. Curr Res Green Sustain Chem 5, 100339 (2022). https://doi.org/10.1016/j.crgsc.2022.100339

E.K. Abdel-Khalek, M.A. Motawea, M.A. Aboelnasr, H.H. El-Bahnasawy, Study the oxygen vacancies and Fe oxidation states in CaFeO3-δ perovskite nanomaterial. Physica B Condens Matter 624, 413415 (2022). https://doi.org/10.1016/j.physb.2021.413415

M.G. Sahini, B.S. Mwankemwa, N. Kanas, BaxSr1-xCoyFe1-yO3-δ (BSCF) mixed ionic-electronic conducting (MIEC) materials for oxygen separation membrane and SOFC applications: Insights into processing, stability, and functional properties. Ceram. Int. 48, 2948–2964 (2022). https://doi.org/10.1016/j.ceramint.2021.10.189

A. Ndubuisi, S. Abouali, K. Singh, V. Thangadurai, Recent advances, practical challenges, and perspectives of intermediate temperature solid oxide fuel cell cathodes. J Mater Chem A Mater 10, 2196–2227 (2022). https://doi.org/10.1039/D1TA08475E

D. Liu, Y. Dou, T. Xia, Q. Li, L. Sun, L. Huo et al., B-site La, Ce, and Pr-doped Ba0.5Sr0.5Co0.7Fe0.3O3- perovskite cathodes for intermediate-temperature solid oxide fuel cells: Effectively promoted oxygen reduction activity and operating stability. J Power Sources 494, 229778 (2021). https://doi.org/10.1016/j.jpowsour.2021.229778

I. Jang, J. Kwon, C. Kim, H. Lee, S. Kim, H. Yoon et al., Boosted Oxygen Reduction Reaction Activity by Ordering Cations in the A-Site of a Perovskite Catalyst. ACS Sustain Chem Eng 11, 4623–4632 (2023). https://doi.org/10.1021/acssuschemeng.2c06381

H. Wang, J. Xu, Z. Song, X. Su, D. Wu, L. Zhang, Characterisation of Bi doped YBaCo<SUB align="right">2O<SUB align="right">5+δ layered perovskite oxide as a cathode for Intermediate-temperature solid oxide fuel cell. Int. J. Comput. Mater. Sci. Surf. Eng. 10, 88 (2021). https://doi.org/10.1504/IJCMSSE.2021.118499

J. Teng, T. Xia, Q. Li, L. Sun, H. Zhao, Advanced electrocatalytic activity of praseodymium-deficient copper-based oxygen electrodes for solid oxide fuel cells. Int. J. Hydrogen Energy 48, 27361–27370 (2023). https://doi.org/10.1016/j.ijhydene.2023.03.390

Qian B, Wang S, Zheng Y, Yin B, He S, Chen H, et al. Cobalt-free double-perovskite oxide Sr2Ti0.9FeNi0.1O6 as a promising electrode for symmetric solid oxide electrolysis cells. J. Eur. Ceram. Soc. (2023). https://doi.org/10.1016/j.jeurceramsoc.2023.08.006.

M. Wu, H. Cai, F. Jin, N. Sun, J. Xu, L. Zhang et al., Assessment of cobalt–free ferrite–based perovskite Ln0.5Sr0.5Fe0.9Mo0.1O3–δ (Ln = lanthanide) as cathodes for IT-SOFCs. J Eur Ceram Soc 41, 2682–90 (2021). https://doi.org/10.1016/j.jeurceramsoc.2020.11.035

M. Hussain, M. Muneer, R. Raza, M.A. Jamal, M.K. Khosa, Evaluation of La x Sr 1− x Zn y Fe 1− y O 3− δ ( x = 0.54, 0.8, y = 0.2, 0.4) as a promising cobalt free composite cathode for SOFCs. New J Chem 46, 21695–703 (2022). https://doi.org/10.1039/D2NJ04295A

S. Akkurt, C. Sindirac, T. Özmenegesoy, E. Ergen, A review on new cobalt-free cathode materials for reversible solid oxide fuel cells. J Metals, Mater Min 33, 1654 (2023). https://doi.org/10.55713/jmmm.v33i3.1654

P. Kaur, K. Singh, Perovskite-structured cobalt-free cathode materials for solid oxide fuel cells, in Recent Advances in Renewable Energy Technologies. (Elsevier, 2022), pp.357–73. https://doi.org/10.1016/B978-0-12-823532-4.00009-4

N.A. Baharuddin, A. Muchtar, M.R. Somalu, Short review on cobalt-free cathodes for solid oxide fuel cells. Int. J. Hydrogen Energy 42, 9149–9155 (2017). https://doi.org/10.1016/j.ijhydene.2016.04.097

M.A. Morales-Zapata, A. Larrea, M.A. Laguna-Bercero, Lanthanide nickelates for their application on Solid Oxide Cells. Electrochim. Acta 444, 141970 (2023). https://doi.org/10.1016/j.electacta.2023.141970

Zhao H, Lam WA, Sheng L, Wang L, Bai P, Yang Y, et al. Cobalt‐Free Cathode Materials: Families and their Prospects. Adv. Energy. Mater. 12 (2022) https://doi.org/10.1002/aenm.202103894.

N. Shah, X. Xu, J. Love, H. Wang, Z. Zhu, L. Ge, Mitigating thermal expansion effects in solid oxide fuel cell cathodes: A critical review. J. Power. Sources 599, 234211 (2024). https://doi.org/10.1016/j.jpowsour.2024.234211

S.S. Hashim, F. Liang, W. Zhou, J. Sunarso, Cobalt-Free Perovskite Cathodes for Solid Oxide Fuel Cells. ChemElectroChem 6, 3549–3569 (2019). https://doi.org/10.1002/celc.201900391

A.K. Yadav, S. Sinha, A. Kumar, Advancements in composite cathodes for intermediate-temperature solid oxide fuel cells: A comprehensive review. Int. J. Hydrogen Energy 59, 1080–1093 (2024). https://doi.org/10.1016/j.ijhydene.2024.02.124

Y. Dong, J. Li, Oxide Cathodes: Functions, Instabilities, Self Healing, and Degradation Mitigations. Chem. Rev. 123, 811–833 (2023). https://doi.org/10.1021/acs.chemrev.2c00251

T. Wang, A. Chutia, D.J.L. Brett, P.R. Shearing, G. He, G. Chai et al., Palladium alloys used as electrocatalysts for the oxygen reduction reaction. Energy Environ. Sci. 14, 2639–2669 (2021). https://doi.org/10.1039/D0EE03915B

M. Irshad, R. Idrees, K. Siraj, I. Shakir, M. Rafique, Ain Qul et al., Electrochemical evaluation of mixed ionic electronic perovskite cathode LaNi1-xCoxO3-δ for IT-SOFC synthesized by high temperature decomposition. Int J Hydrogen Energy 46, 10448–56 (2021). https://doi.org/10.1016/j.ijhydene.2020.09.180

S. Lee, M. Kim, K.T. Lee, J.T.S. Irvine, T.H. Shin, Enhancing Electrochemical CO 2 Reduction using Ce(Mn, Fe)O2 with La(Sr)Cr(Mn)O3 Cathode for High-Temperature Solid Oxide Electrolysis Cells. Adv. Energy Mater. 11, 2100339 (2021). https://doi.org/10.1002/aenm.202100339

S. Rauf, B. Zhu, M.A.K.Y. Shah, C. Xia, Z. Tayyab, N. Ali et al., Tailoring triple charge conduction in BaCo0.2Fe0.1Ce0.2Tm0.1Zr0.3Y0.1O3−δ semiconductor electrolyte for boosting solid oxide fuel cell performance. Renew Energy 172, 336–49 (2021). https://doi.org/10.1016/j.renene.2021.03.031

Sirvent J de D, Buzi F, Baiutti F, Tarancón A. Advances in nanoengineered air electrodes: towards high-performance solid oxide cells. Nanoengineered Materials for Solid Oxide Cells, (IOP Publishing 2023), p. 1–1–1–35. https://doi.org/10.1088/978-0-7503-4064-9ch1.

S. He, S.P. Jiang, Electrode/electrolyte interface and interface reactions of solid oxide cells: Recent development and advances. Progr Nat Sci : Mater Intl 31, 341–372 (2021). https://doi.org/10.1016/j.pnsc.2021.03.002

L. dos Santos-Gómez, J. Zamudio-García, J.M. Porras-Vázquez, E.R. Losilla, D. Marrero-López, Recent progress in nanostructured electrodes for solid oxide fuel cells deposited by spray pyrolysis. J. Power. Sources 507, 230277 (2021). https://doi.org/10.1016/j.jpowsour.2021.230277

O.Y. Akduman, A.M. Soydan, Fabrication and characterization of micro-tubular solid oxide fuel cells with yttria stabilized zirconia and Hafnia-Erbia co-doped bismuth oxide bilayer electrolyte. Int. J. Hydrogen Energy (2022). https://doi.org/10.1016/j.ijhydene.2022.04.268

Shaikh Abdul MA, Muchtar A, Raharjo J, Khaerudini DS. A Review on the Process-Structure-Performance of Lanthanum Strontium Cobalt Ferrite Oxide for Solid Oxide Fuel Cells Cathodes. Intl J Integr Eng 14 (2022). https://doi.org/10.30880/ijie.2022.14.02.017.

C. Yang, L. Chen, H. Hou, G. Zou, X. Ji, Z. Wu, Advanced Characterization Techniques and Theoretical Calculation. Sodium‐Ion Batteries (Wiley, 2024), pp.247–309. https://doi.org/10.1002/9783527841684.ch6

A.C.M. Loy, W.L. Ng, S. Bhattacharya, Advanced characterization techniques for the development of Subatomic scale catalysts: One step closer to industrial scale fabrication. Mater Today Catal 4, 100033 (2024). https://doi.org/10.1016/j.mtcata.2023.100033

S.H. Woo, K.E. Song, S.-W. Baek, H. Kang, W. Choi, T.H. Shin et al., Pr- and Sm-Substituted Layered Perovskite Oxide Systems for IT-SOFC Cathodes. Energies (Basel) 14, 6739 (2021). https://doi.org/10.3390/en14206739

S. Farhan, M. Mohsin, A.H. Raza, R. Anwar, B. Ahmad, R. Raza, Co-doped cerium oxide Fe0.25-xMnxCe0.75O2-δ as a composite cathode material for IT-SOFC. J Alloys Compd 906, 164319 (2022). https://doi.org/10.1016/j.jallcom.2022.164319

S. Wang, J. Zan, W. Qiu, D. Zheng, F. Li, W. Chen et al., Evaluation of perovskite oxides LnBaCo2O5+δ (Ln = La, Pr, Nd and Sm) as cathode materials for IT-SOFC. J. Electroanal. Chem. 886, 115144 (2021). https://doi.org/10.1016/j.jelechem.2021.115144

J. Zan, S. Wang, D. Zheng, F. Li, W. Chen, Q. Pei et al., Characterization and functional application of PrBa0.5Sr0.5Co1.5Fe0.5O5+ cathode material for IT-SOFC. Mater Res Bull 137, 111173 (2021). https://doi.org/10.1016/j.materresbull.2020.111173

X. Li, C. Shi, G. Zhang, G. Zheng, Z. Huang, X. Shen et al., A medium-entropy perovskite oxide La0.7Sr0.3Co0.25Fe0.25Ni0.25Mn0.25O3-δ as intermediate temperature solid oxide fuel cells cathode material. Ceram Int 49, 30187–95 (2023). https://doi.org/10.1016/j.ceramint.2023.06.275

A.I. Klyndyuk, D.S. Kharytonau, M. Mosiałek, E.A. Chizhova, A. Komenda, R.P. Socha et al., Double substituted NdBa(Fe Co, Cu)2O5+δ layered perovskites as cathode materials for intermediate-temperature solid oxide fuel cells – correlation between structure and electrochemical properties. Electrochim. Acta 411, 140062 (2022). https://doi.org/10.1016/j.electacta.2022.140062

S.U. Costilla-Aguilar, M.J. Escudero, R.F. Cienfuegos-Pelaes, J.A. Aguilar-Martínez, Double perovskite La1.8Sr0.2CoFeO5+δ as a cathode material for intermediate temperature solid oxide fuel cells. J Alloys Compd 862, 158025 (2021). https://doi.org/10.1016/j.jallcom.2020.158025

X. Liu, F. Jin, X. Liu, N. Sun, J. Li, Y. Shen et al., Effect of calcium doping on Sm1–Ca BaCo2O5+ cathode materials for intermediate-temperature solid oxide fuel cells. Electrochim. Acta 390, 138830 (2021). https://doi.org/10.1016/j.electacta.2021.138830

M. Rafaqat, G. Ali, N. Ahmad, S.H.M. Jafri, S. Atiq, G. Abbas et al., The substitution of La and Ba in X0.5Sr0.5Co0.8Mn0.2O3 as a perovskite cathode for low temperature solid oxide fuel cells. J Alloys Compd 937, 168214 (2023). https://doi.org/10.1016/j.jallcom.2022.168214

Guo D, Li A, Lu C, Qiu D, Niu B, Wang B. High activity and stability of cobalt-free SmBa0.5Sr0.5Fe2O5+δ perovskite oxide as cathode material for solid oxide fuel cells. Ceram. Int. 2023. https://doi.org/10.1016/j.ceramint.2023.08.145.

S.U. Rehman, M.H. Hassan, S.Y. Batool, H.-S. Kim, R.-H. Song, T.-H. Lim et al., A highly stable Co3O4-GDC nanocomposite cathode for intermediate temperature solid oxide fuel cells. Int. J. Hydrogen Energy (2023). https://doi.org/10.1016/j.ijhydene.2023.03.341

X. Bao, X. Su, S. Wang, B. Pan, L. Wang, L. Zhang et al., Effects of Bi-doping on structure and properties of YBaCo2O5+ layered perovskite cathode for intermediate-temperature solid oxide fuel cells. J. Alloys Compd. 965, 171391 (2023). https://doi.org/10.1016/j.jallcom.2023.171391

K.H. Tan, H.A. Rahman, M.S. Azami, U.A. Yusop, N.A. Baharuddin, M.I.N. Ma’arof, Electrochemical and material characteristics of Ba0.5Sr0.5Co0.8Fe0.2O3−δ-Sm0.2Ce0.8O1.9 carbonate perovskite cathode composite for low-temperature solid oxide fuel cell. Ceram Int 48, 34258–64 (2022). https://doi.org/10.1016/j.ceramint.2022.07.325

N. Li, L. Sun, Q. Li, T. Xia, L. Huo, H. Zhao, Electrode properties of CuBi2O4 spinel oxide as a new and potential cathode material for solid oxide fuel cells. J. Power. Sources 511, 230447 (2021). https://doi.org/10.1016/j.jpowsour.2021.230447

F. Bu, F. Yang, Y. He, M. Wang, Y. Li, Q. Zhou, double perovskite oxide as a novel cathode for intermediate-temperature solid oxide fuel cell. Mater Res Bull 146, 111624 (2022). https://doi.org/10.1016/j.materresbull.2021.111624

W. Yi, Y. Tian, C. Lu, B. Wang, Y. Liu, S. Gao et al., Highly active and stable BaCo0.8Zr0.1Y0.1O3-δ cathode for intermediate temperature solid oxide fuel cells. J Eur Ceram Soc 42, 2860–9 (2022). https://doi.org/10.1016/j.jeurceramsoc.2022.01.057

S. Peng, S. Lei, S. Wen, J. Xue, H. Wang, A Ruddlesden-Popper oxide as a carbon dioxide tolerant cathode for solid oxide fuel cells that operate at intermediate temperatures. Chin. J. Chem. Eng. 56, 25–32 (2023). https://doi.org/10.1016/j.cjche.2022.08.023

C. Yao, J. Yang, H. Zhang, S. Chen, J. Meng, K. Cai, Evaluation of bismuth doped La2-Bi NiO4+ (x = 0, 0.02 and 0.04) as cathode materials for solid oxide fuel cells. Ceram Int 47, 24589–96 (2021). https://doi.org/10.1016/j.ceramint.2021.05.179

T. Ma, T. Xia, Q. Li, L. Sun, L. Huo, H. Zhao, Highly electrocatalytic activity Ruddlesden−Popper type electrode materials for solid oxide fuel cells. J. Eur. Ceram. Soc. 42, 490–498 (2022). https://doi.org/10.1016/j.jeurceramsoc.2021.10.028

D. Muñoz Gil, K. Boulahya, M. Santamaria Santoyo, M.T. Azcondo, U. Amador, Superior Performance as Cathode Material for Intermediate-Temperature Solid Oxide Fuel Cells of the Ruddlesden–Popper n = 2 Member Eu 2 SrCo 0.50 Fe 1.50 O 7−δ with Low Cobalt Content. Inorg Chem 60, 3094–105 (2021). https://doi.org/10.1021/acs.inorgchem.0c03391

T. Ghorbani-Moghadam, A. Kompany, M. Golmohammad, Study of structural, electrical and electrochemical properties of La0.7Sr1.3Co1−xFexO4 (x = 0, 0.1, 0.3, 0.5) Ruddlesden-Popper oxides as promising cathode for intermediate solid oxide fuel cells. J Alloys Compd 900, 163382 (2022). https://doi.org/10.1016/j.jallcom.2021.163382

H. Qi, P. Qiu, T. Zhang, D. Liu, M. Cheng, B. Tu, Self-assembled, high-performing cobalt-free Ba0.5A0.5Fe0.8Zr0.2O3-δ (A=Sr2+/Sm3+) composite cathode for intermediate-temperature solid oxide fuel cells. Ceram Int 48, 28669–77 (2022). https://doi.org/10.1016/j.ceramint.2022.06.181

S. Wang, J. Xu, M. Wu, Z. Song, L. Wang, L. Zhang et al., Cobalt–free perovskite cathode BaFe0.9Nb0.1O3– for intermediate–temperature solid oxide fuel cell. J Alloys Compd 872, 159701 (2021). https://doi.org/10.1016/j.jallcom.2021.159701

G. Xue, X. Zhang, L. Wang, Y. Hao, J. Li, H. Sun et al., Synthesis and characterization of fibrous La0.8Sr0.2Fe1-xCuxO3-δ cathode for intermediate-temperature solid oxide fuel cells. Ceram Int 48, 25940–8 (2022). https://doi.org/10.1016/j.ceramint.2022.05.272

A. Belotti, Y. Wang, A. Curcio, J. Liu, E. Quattrocchi, S. Pepe et al., The influence of A-site deficiency on the electrochemical properties of (Ba0.95La0.05)1-xFeO3-δ as an intermediate temperature solid oxide fuel cell cathode. Int J Hydrogen Energy 47, 1229–40 (2022). https://doi.org/10.1016/j.ijhydene.2021.10.098

H. Li, Z. Lü, High-performance fluorine-doped cobalt-free oxide as a potential cathode material for solid oxide fuel cells. Int. J. Hydrogen Energy 46, 2503–2510 (2021). https://doi.org/10.1016/j.ijhydene.2020.10.074

H.G. Desta, D. Tian, Q. Yang, S. Zhu, K. Song, Y. Chen et al., Developing a new Sr and Co-free composite cathode of solid oxide fuel cells with high performance. Chem. Phys. Lett. 806, 140037 (2022). https://doi.org/10.1016/j.cplett.2022.140037

Q. Yang, J. Lu, C. Li, D. Tian, Y. Ding, X. Lu et al., Tailoring the electrochemical reduction kinetics of dual-phase BaCe0.5Fe0.5O cathode via incorporating Mo for IT-SOFCs. J Eur Ceram Soc 43, 6180–8 (2023). https://doi.org/10.1016/j.jeurceramsoc.2023.06.006

D. Cademartori, A. Maria Asensio, D. Clematis, J.F. Basbus, M. Viviani, S. Presto et al., A high-performance Co-free electrode for solid oxide cells: La0.7Sr0.3Cu0.15Fe0.85O3-δ synthesis and characterisation. J Alloys Compd 965, 171334 (2023). https://doi.org/10.1016/j.jallcom.2023.171334

L. Gao, M. Zhu, T. Xia, Q. Li, T. Li, H. Zhao, Ni-doped BaFeO3− perovskite oxide as highly active cathode electrocatalyst for intermediate-temperature solid oxide fuel cells. Electrochim. Acta 289, 428–436 (2018). https://doi.org/10.1016/j.electacta.2018.09.096

J. Gao, Q. Li, Z. Zhang, Z. Lü, B. Wei, A cobalt-free bismuth ferrite-based cathode for intermediate temperature solid oxide fuel cells. Electrochem. Commun. 125, 106978 (2021). https://doi.org/10.1016/j.elecom.2021.106978

J. Gao, Q. Li, L. Sun, L. Huo, H. Zhao, Enhanced electrocatalytic activity and CO2 tolerant Bi0.5Sr0.5Fe1-Ta O3- as cobalt-free cathode for intermediate-temperature solid oxide fuel cells. Ceram Int 45, 20226–33 (2019). https://doi.org/10.1016/j.ceramint.2019.06.295

Z. Ma, L. Li, Q. Ye, B. Dongyang, W. Yang, F. Dong et al., Facile Approach to Enhance Activity and CO 2 Resistance of a Novel Cobalt-Free Perovskite Cathode for Solid Oxide Fuel Cells. ACS Appl. Mater. Interfaces 14, 30881–30888 (2022). https://doi.org/10.1021/acsami.2c06998

J. Lach, K. Zheng, R. Kluczowski, A. Niemczyk, H. Zhao, M. Chen, Tuning Cu-Content La1−xSrxNi1−yCuyO3−δ with Strontium Doping as Cobalt-Free Cathode Materials for High-Performance Anode-Supported IT-SOFCs. Materials 15, 8737 (2022). https://doi.org/10.3390/ma15248737

H. Gong, D. Zhou, X. Zhu, N. Wang, J. Bai, L. Hu et al., Characterization of B‐Site Sc‐doped La2Ni1-xScxO4+δ (x=0, 0.05, 0.10, and 0.15) perovskites as cathode materials for IT-SOFCs. Int J Hydrogen Energy 50, 1492–502 (2024). https://doi.org/10.1016/j.ijhydene.2023.11.010

B. Admasu Beshiwork, X. Wan, M. Xu, H. Guo, B. Sirak Teketel, Y. Chen et al., A defective iron-based perovskite cathode for high-performance IT-SOFCs: Tailoring the oxygen vacancies using Nb/Ta co-doping. J. Energy Chem. 88, 306–316 (2024). https://doi.org/10.1016/j.jechem.2023.09.015

I. Bhasin, K.K. Mohan, Development of conducting composite cathodes for IT-SOFCs. Mater. Lett. 354, 135344 (2024). https://doi.org/10.1016/j.matlet.2023.135344

A. Ghani Harzand, M. Golmohammad, S.A. Zargar, A.M. Khachatourian, A. Nemati, Study of structural, electrical, and electrochemical properties of Sr3-xPrxFe1.8Co0.2O7-δ cathode for IT-SOFCs. Solid State Ion 404, 116421 (2024). https://doi.org/10.1016/j.ssi.2023.116421

D. Chen, F. Wang, H. Shi, R. Ran, Z. Shao, Systematic evaluation of Co-free LnBaFe2O5+δ (Ln=Lanthanides or Y) oxides towards the application as cathodes for intermediate-temperature solid oxide fuel cells. Electrochim. Acta 78, 466–474 (2012). https://doi.org/10.1016/j.electacta.2012.06.073

Z. Du, H. Zhao, S. Yi, Q. Xia, Y. Gong, Y. Zhang et al., High-Performance Anode Material Sr 2 FeMo 0.65 Ni 0.35 O 6−δ with In Situ Exsolved Nanoparticle Catalyst. ACS Nano 10, 8660–9 (2016). https://doi.org/10.1021/acsnano.6b03979

C. Wang, H. Miao, X. Zhang, J. Huang, J. Yuan, On Fe-based perovskite electrodes for symmetrical reversible solid oxide cells – A review. J. Power. Sources 596, 234112 (2024). https://doi.org/10.1016/j.jpowsour.2024.234112

Z. Yu, X. Zhang, Z. Lü, H. Li, Boosting the electrochemical performance of cobalt-free Fe-based cathodes by calcium-doping for solid oxide fuel cells. J. Alloys Compd. 980, 173646 (2024). https://doi.org/10.1016/j.jallcom.2024.173646

L.-M. Xue, S.-B. Li, S.-L. An, N. Li, H.-P. Ma, M.-X. Li, Fe-based double perovskite with Zn doping for enhanced electrochemical performance as intermediate-temperature solid oxide fuel cell cathode material. RSC Adv. 13, 30606–30614 (2023). https://doi.org/10.1039/D3RA04991D

J. Bai, D. Zhou, X. Zhu, N. Wang, Q. Liang, R. Chen et al., Bi0.5Sr0.5FeO3-δ perovskite B-site doped Ln (Nd, Sm) as cathode for high performance Co-free intermediate temperature solid oxide fuel cell. Ceram Int 49, 28682–92 (2023). https://doi.org/10.1016/j.ceramint.2023.06.124

J. Gao, D. Ma, H. Zhao, Q. Li, Z. Lü, B. Wei, Synergistically improving electrocatalytic performance and CO2 tolerance of Fe-based cathode catalysts for solid oxide fuel cells. Energy 252, 124050 (2022). https://doi.org/10.1016/j.energy.2022.124050

H.-X. Zhang, J.-X. Yang, P.-F. Wang, C.-G. Yao, X.-D. Yu, F.-N. Shi, Novel cobalt-free perovskite PrBaFe1.9Mo0.1O5+ as a cathode material for solid oxide fuel cells. Solid State Ion 391, 116144 (2023). https://doi.org/10.1016/j.ssi.2023.116144

S. Lü, Y. Zhu, X. Fu, R. Huang, Y. Guo, W. Zhang et al., A-site deficient Fe-based double perovskite oxides PrxBaFe2O5+δ as cathodes for solid oxide fuel cells. J. Alloys Compd. 911, 165002 (2022). https://doi.org/10.1016/j.jallcom.2022.165002

D. Guo, A. Li, C. Lu, D. Qiu, B. Niu, B. Wang, High activity and stability of cobalt-free SmBa0.5Sr0.5Fe2O5+δ perovskite oxide as cathode material for solid oxide fuel cells. Ceram Int 49, 34277–90 (2023). https://doi.org/10.1016/j.ceramint.2023.08.145

C. Wen, K. Chen, D. Guo, W. Yang, S. Gao, C. Lu et al., High performance and stability of PrBa0.5Sr0.5Fe2O5+δ symmetrical electrode for intermediate temperature solid oxide fuel cells. Solid State Ion 386, 116048 (2022). https://doi.org/10.1016/j.ssi.2022.116048

S. Kumar, A. Das, S. Omar, Electrochemical Performance of SrFeO 3−δ for Application as a Symmetric Electrode in Solid Oxide Fuel Cells. ACS Appl Energy Mater 6, 2049–2062 (2023). https://doi.org/10.1021/acsaem.2c04034

J. Zamudio-García, J.M. Porras-Vázquez, E.R. Losilla, D. Marrero-López, LaCrO 3 –CeO 2 -Based Nanocomposite Electrodes for Efficient Symmetrical Solid Oxide Fuel Cells. ACS Appl Energy Mater 5, 4536–4546 (2022). https://doi.org/10.1021/acsaem.1c04116

Q. Yang, M. Chen, B.S. Teketel, D. Tian, Y. Ding, X. Lu et al., Influences of equal A-site rare-deficiency or B-site high-valent metal doping on NdBaFe2O employed as the symmetrical electrode for solid oxide fuel cells. J. Alloys Compd. 918, 165368 (2022). https://doi.org/10.1016/j.jallcom.2022.165368

C. Sun, L. Bian, W. Yu, Y. Hou, L. Wang, L. Xing et al., Electrochemical performance of Sr1.9La0.1Fe1.5Mo0.5O6-δ symmetric electrode for solid oxide fuel cells with carbon-based fuels. Int J Hydrogen Energy 47, 565–74 (2022). https://doi.org/10.1016/j.ijhydene.2021.10.038

C. Liu, F. Wang, Y. Ni, S. Wang, B. Qian, Q. Ni et al., Ta-doped PrBaFe2O5+δ double perovskite as a high-performance electrode material for symmetrical solid oxide fuel cells. Int. J. Hydrogen Energy 48, 9812–9822 (2023). https://doi.org/10.1016/j.ijhydene.2022.11.237

L.A. Omeiza, M.D.M. Rahman, K.A. Kuterbekov, A. Kabyshev, K. Bekmyrza, M. Kubenova et al., Novel sr-doped NdMn0.5Cr0.5O3-δ electrodes for symmetrical solid oxide fuel cell. Electrochem Commun 164, 107730 (2024). https://doi.org/10.1016/j.elecom.2024.107730

Omeiza LA, Mamudu U, Subramanian Y, Dhanasekaran A, Rahman MdM, Bakar SA, et al. Structure and Electrochemical Characterization of Nd0.5Ba0.5Zr0.8Fe0.2O3+δ Cobalt-Free Cathode Material for Intermediate-Temperature Solid Oxide Fuel Cells: An Experimental Investigation. Johnson Matthey Technol Rev. 2024 https://doi.org/10.1595/205651324X17048121572464.

Funding

This study was supported by the grant with reference number BR21882359, provided by the Ministry of Science and Higher Education of Kazakhstan.

Author information

Authors and Affiliations

Contributions

Lukman Ahmed Omeiza and Asset Kabyshev: Formal analysis, Writing – original draft. Lukman Ahmed Omieza: Writing – review & editing, Conceptualization, Investigation, Resources, Supervision. Abul Kalam Azad: Formal analysis, Writing – original draft. Kenzhebatyr Bekmyrza: Validation, Investigation, Methodology, Writing – review & editing. Marzhan Kubenova and Shammya Afroze: Formal analysis, Writing – original draft. Kenzhebatyr Bekmyrza and Asset Kabyshev: Writing – review & editing. Saifullah Abu Bakar: Writing – original draft. Lukman Ahmed Omieza: Writing – review & editing. Kairat A Kuterbekov and Abul Kalam Azad: Resources.

Corresponding authors

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Content for publication

Not applicable.

Conflict of interest

The authors affirm that there is no conflict of interest to declare, given that all sources of information used have been appropriately cited and attributed.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Omeiza, L.A., Kuterbekov, K.A., Kabyshev, A. et al. Limitations and trends on cobalt-free cathode materials development for intermediate-temperature solid oxide fuel cell- an updated technical review. emergent mater. (2024). https://doi.org/10.1007/s42247-024-00737-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42247-024-00737-7