Abstract

In an epoch defined by an increasing emphasis on environmental sustainability, the construction industry stands at a crucial juncture, where innovation and informed decision-making are imperative. This study investigates the intricate interplay between structural design parameters and environmental sustainability in concrete slab construction. Focusing on span length, live load variations, and the inclusion of secondary beams, this study seeks to establish a delicate equilibrium for achieving optimal structural efficiency while minimising the environmental impact. Analysis of span length reveals, as would be expected, that the minimum slab thickness meeting the deflection criteria increases proportionally with span length, demanding careful consideration in project-specific scenarios. Live load investigations highlight the sensitivity of slab design to external loading conditions, with increased live loads correlating with greater demand for steel reinforcement, deflection, and minimum slab thickness. The inclusion of secondary beams, while consistently reducing the required reinforcement and enhancing the deflection performance, has a marginal impact on the embodied carbon. This research contributes to the growing knowledge at the intersection of structural engineering and sustainability, guiding decision-makers toward informed choices for optimised, environmentally conscious structural solutions in the construction industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the face of formidable challenges confronting society, including the pressing issues of climate change and resource scarcity, the research community plays a vital role in seeking solutions that lay the groundwork for sustainable societal development. The consensus in sustainability discourse underscores the need to holistically address the interconnected triad of society, economy, and the environment (David & Ayyub, 2017). The heart of this triad lies in the construction sector, a linchpin of societal progress. This sector not only shapes the physical landscape of infrastructure and buildings, which in turn underpin our daily activities, but also has substantial economic influence, with global annual expenditures exceeding $10 trillion in construction-related goods and services (McKinsey, 2017). However, alongside its societal and economic significance, the construction sector generates significant environmental concerns (Sjostrom & Bakens, 1999).

Among these concerns, the emission of greenhouse gases and their contribution to global warming are of paramount importance. Recent estimates suggest that the construction sector accounts for more than 20% of total CO2 emissions attributed to global economic activities (Huang et al., 2018). Approximately half of this proportion is associated with building construction (GABC, 2020). In light of the Paris Agreement on Climate Change, which calls for limiting global warming to 2°C compared to preindustrial levels, there is a limited carbon budget for the twenty-first century, equivalent to less than 30 years of current global emissions (Kriegler et al., 2014), and approximately 35% of the emission budget required for building essential infrastructure in developing countries (Müller et al., 2013). To align the global construction sector with the goals of this agreement, worldwide commitments to decarbonize buildings and infrastructure must increase both in scale and pace.

This commitment extends to the structural engineering profession, which plays a pivotal role in shaping the built environment’s environmental footprint. Over the past decades, numerous strategies, methods, and tools have emerged to assess the environmental sustainability of structures (Ding, 2008; Pomponi & Moncaster, 2016; Eberhardt et al., 2019; KC and Gautam, 2021), often grounded in Life Cycle Assessment (LCA). Despite substantial standardization efforts, such as those by CEN (2010), and the availability of Environmental Product Declarations (EPD), practical doubts persist regarding the implementation of LCA procedures and associated uncertainties (De Wolf et al., 2017; Dong et al., 2018; Hawkins et al., 2021; Saxe et al., 2020). These doubts have hindered the broader acceptance and application of LCA. Embodied carbon emissions encompass an all-encompassing quantification of the environmental impacts spanning various phases of construction, from raw material extraction and manufacturing to transportation, construction, ongoing upkeep, and ultimate decommissioning and disposal stages (Hammond & Jones, 2008; Gibbon et al., 2022).

Numerous research endeavours have focused on mitigating embodied carbon in reinforced concrete slabs, with numerous studies investigating methods to optimize costs and embodied energy. Sahab et al., (2005) conducted a comprehensive study on cost optimization in flat slabs, considering three critical variables: column layout, slab thickness, and reinforcement design. Their research underscored the pivotal role of optimizing column layout, which could yield substantial cost savings. Additionally, their work emphasized the feasibility of increasing reinforcement ratios to reduce slab thickness, particularly in designs governed by deflection criteria, resulting in an overall cost reduction.

Goodchild et al., (2009) developed a set of design charts for slabs and other reinforced concrete frame elements, offering insights into the minimum cost considerations for various spans. The charts were generated using a series of parametric designs. In their research, they meticulously controlled deflections according to the Eurocode 2 guidelines (CEN, 2014), thereby establishing adjusted span-to-depth ratios. Notably, their findings indicated that increasing the reinforcement to further reduce the allowable slab thickness could contribute to overall cost reduction. Ferreiro-Cabello et al., (2016) embarked on a study involving flat slabs with varying thickness for different column grids. Their research highlighted the significance of reducing spans as a means of minimising embodied carbon. Moreover, their work demonstrated that designs with the lowest embodied carbon approached the minimum feasible slab thickness, indicating a delicate trade-off between slab depth and reinforcement content. Eleftheriadis et al., (2018) employed a BIM-based genetic algorithm to optimize flat slabs, wherein they systematically varied the dimensions and reinforcement of slabs and columns, along with the column layout. Their investigation led to the conclusion that designs with the least embodied carbon leaned towards shorter column spacing and thinner slabs. This study also observed that increasing the slab thickness to reduce the reinforcement ratio could effectively diminish the overall embodied carbon content.

Bechmann and Weidner, (2021) compared a standard multi-storey concrete building with optimized concrete and a hybrid timber tower, each with 29 floors. The optimized concrete building included a specific concrete mix, specifically adjusted structural systems, and material manufacturing. The hybrid timber building was designed with a foundation, underground levels, and a stiffening core made of concrete, while the slabs of all upper floors featured 200 mm timber panels with 100 mm concrete topping slabs. The results of this study revealed the potential for substantial reductions in carbon emissions, with the selection of hybrid timber over conventional concrete design leading to emissions reductions of up to 78%. Additionally, it was observed that a concrete optimization approach could considerably reduce carbon emissions by 47%.

The evaluation of construction sustainability necessitates a comprehensive examination of its environmental impact throughout the various stages of its life cycle, as standardized by BS EN 15978(2011). According to this norm, stages A1–A3, collectively referred to as 'cradle-to-gate,' encompass the Product stage, involving activities such as raw material procurement, material transportation, and manufacturing (Gibbon et al., 2022). Notably, the London Energy Transformation Initiative, (2020) underscores a substantial proportion of embodied carbon, often accounting for up to 50% of the entire life cycle carbon footprint, in contrast to the relatively smaller contribution of the construction phase, which typically constitutes approximately 5% of the total. Researchers including Sansom and Pope, (2012), Wen et al., (2015), and Gan et al., (2017), also explored embodied carbon across the life cycle in various case studies and, consistently found that transportation and construction activities collectively account for a contribution within the range of 1–15%. Thus, ‘cradle-to-gate’ embodied carbon serves as a performance indicator, allowing a focused examination of the environmental implications associated with variations in concrete grade and slab thickness while maintaining a constant construction method.

Despite the increasing importance of sustainable construction practices, there remains a limited body of literature specifically addressing the embodied carbon implications in concrete slabs, especially when secondary beams are introduced. The majority of existing studies often generalize their findings to broader structural elements or focus on isolated aspects of construction materials. This research, however, homes in on the nuanced environmental impact of concrete slabs, considering various parameters such as span variations, live loads, and the incorporation of secondary beams. This specificity allows for a more detailed and targeted analysis of the factors influencing embodied carbon in concrete slabs, contributing a unique perspective to the existing body of knowledge. This study aims to contribute to the development of more sustainable construction practices in the structural engineering field. This study not only seeks to identify carbon-efficient choices for concrete slabs, but also provides insights into the broader discourse on sustainable building design and construction within the context of a rapidly changing world.

Methodology

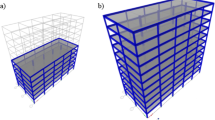

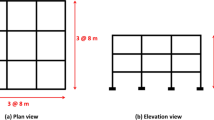

Two-way concrete slabs were designed on beams configured as 3 × 3 bays, as shown in Fig. 1. The design simulations adhered to the specific parameter characteristics of the office building context. Gravity loads were considered according to the guidelines provided by ASCE/SEI 7-16 (ASCE, 2016). This encompassed accounting for the dead load, which includes the self-weight of the structure and a superimposed dead load of 2 kN/m2, along with a live load of 2.5 kN/m2. The structural analysis employed the ultimate combination, incorporating a load factor of 1.2 for the dead load and 1.6 for the live load, utilizing the well-established commercial finite element software package ETABS(CSI, 2023).

A concrete grade of K350, characterised by a compressive strength of 28 MPa was used. The steel reinforcement followed the specifications of BjTS 420A, featuring a yield strength of 420 MPa. This study established a range for the slab thickness, varying between a minimum of 120 mm and a maximum of 210 mm. This variation enabled a comprehensive analysis of the embodied carbon in reinforced concrete slabs of different thicknesses. Once the slab thickness was set within the specified range, the reinforcement was determined based on flexure and aligned with the guidelines provided by ACI 318-19 (ACI, 2019). The designs for both the bottom and top reinforcements were consistent. This alignment with industry standards maintains the structural integrity, reflecting practical construction scenarios.

The design process involves a meticulous assessment of the structural components and anticipated loads, ensuring that the designed slabs satisfy the specified long-term deflection limits (ACI, 2019). Compliance with the L/240 limit, where “L” represents the span of the slab, is essential not only for structural stability but also for meeting occupant comfort and serviceability requirements. The long-term deflection analysis incorporates the impact of cracking and the presence of reinforcement on the stiffness of the structural members. The effective moment of inertia, Ie is determined using Equation 1.

where Ma represents maximum moment due to service load, Ig is the moment of inertia of gross section, Icr is the moment of inertia of cracked section (assumed as 0.25Ig), and Mcr is cracking moment obtained from Equation 2.

where fr signifies the modulus of rupture of concrete and yt is the distance from centroidal axis of gross section. Additionally, the time-dependent deflection resulting due to creep and shrinkage is determined as the product of the immediate deflection caused by sustained load and the factor, λΔ.

where ξ is considered as 2, and ρ’ represents ratio of compression reinforcement at midspan.

This study comprehensively investigated the embodied carbon in concrete slabs, emphasizing diverse layout configurations and considering the influence of secondary beams. The distribution of columns within the structural framework adhered to a grid pattern with dimensions of 10 x 10, 8 × 8, and 6 x 6 m. These grid layouts were deliberately chosen to align with common column arrangements encountered in practical construction scenarios. Additionally, this study introduces an additional variation by exploring the impact of different live load values on the structural design. Three distinct live load scenarios were considered: 2.5 kN/m2, 5 kN/m2, and 7.5 kN/m2. This variation aims to assess how varying live loads contribute to changes in structural performance and embodied carbon, thereby providing valuable insights into the adaptability of slab designs to different usage conditions. Furthermore, the investigation extends to the presence or absence of secondary beams in the structural design. The inclusion of this factor allows for a thorough examination of its effects on both the structural performance and embodied carbon footprint of the concrete slabs. A comprehensive exploration of these variations will contribute to a holistic understanding of the factors influencing embodied carbon in concrete slabs, offering valuable insights for sustainable and efficient design practices in the construction industry.

The estimation of embodied carbon in reinforced concrete slabs follows the 'cradle-to-gate’ framework, spanning stages A1–A3, as per BS EN 15978 (2011). This approach thoroughly evaluates the environmental impact throughout the life cycle of concrete slabs, from the raw material extraction (cradle) to the factory gate (gate). Equation 4 was adopted to determine the quantity of the embodied carbon in kgCO2e.

The carbon factors used for this assessment are obtained from an inventory of carbon and energy using circular ecology, as outlined by Hammond and Jones, (2008). The following representative values for environmental impact were adopted:

-

Reinforcing steel: 1.99 kg CO2e/kg

-

Concrete grade K350: 0.126 kg CO2e/kg

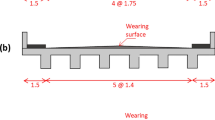

These factors form the basis for quantitatively evaluating embodied carbon in concrete slabs, providing insights into the environmental implications of the selected materials and design parameters. The utilization of recognized data sources ensures the reliability and relevance of assessments within the broader context of sustainability considerations in construction. To enhance the clarity of our methodology, a graphical representation is provided in Fig. 2, illustrating the key steps and parameters involved in our adopted approach.

Results and discussion

Span length effect on embodied carbon

This section examines the impact of span variations on the performance and embodied carbon of concrete slabs, with a particular focus on the real-world applicability of the design results. Figure 3 presents the results for required steel reinforcements at different spans, offering a detailed analysis of the corresponding reinforcement values measured in kilograms per cubic meter (kg/m3). This comprehensive examination provides valuable insights into both structural considerations and environmental implications.

The examination of concrete slabs with varying thicknesses across different spans revealed a consistent and significant inverse relationship between slab thickness and required steel reinforcement. This finding holds true for spans of 6 m, 8 m, and 10 m, aligning with established principles in structural engineering. As slabs become thicker, the demand for reinforcing steel decreases proportionally, thereby showcasing the inherent load-bearing capacity of thicker slabs. The coherence between the design results and established engineering principles affirms the real-world applicability of our approach. This also serves as an implicit validation, reinforcing the reliability and practical utility of our design configurations within the broader context of structural engineering.

The influence of span length on structural design is further emphasized by the observed variation in required steel reinforcement density. Longer spans showcase a decreasing trend in reinforcement density, indicating an opportunity for designers to optimize material usage in larger structures. This valuable insight not only contributes to structural efficiency but also underscores the potential for minimizing the environmental and economic impact associated with steel reinforcement in real-world construction scenarios.

The examination of long-term deflection for concrete slabs with varying spans and thicknesses provides critical insights into the structural behaviour and performance of these elements. Figure 4 shows the nuanced relationship between slab characteristics and deflection. Similarly, there is a clear inverse relationship between slab thickness and long-term deflection across all spans (6 m, 8 m, and 10 m). Thicker slabs consistently exhibited lower deflection values, emphasizing the importance of slab thickness in controlling long-term deflection.

The influence of span length on deflection was evident. Longer spans generally result in higher deflections, highlighting the importance of considering span length in the design process. The observed trends underscore the need for careful consideration of the structural requirements and appropriate design measures for longer spans. The deflection values were compared against the specified deflection limits (25 mm, 29 mm, and 33 mm for spans 6 m, 8 m, and 10 m, respectively). The analysis of various span lengths revealed critical observations regarding the deflection criteria. For a span of 6 m, the study indicated that a minimum slab thickness of 140 mm is necessary to ensure that the deflection remains within the acceptable limit. Similarly, for spans of 8 m and 10 m, the identified minimum slab thicknesses were 160 mm and 200 mm, respectively. These findings emphasize the direct relationship between span length and structural demands placed the on slab thickness.

Figure 5 shows a discernible relationship between the slab thickness and embodied carbon for all spans. It can be seen that thicker slabs are generally associated with higher embodied carbon values, despite a reduction in the required steel, highlighting the crucial role of concrete slabs in influencing the overall environmental impact of structural systems. The data indicated that the embodied carbon in concrete slabs is a significant contributor to the overall environmental impact of the structural system. While the reduction in the required steel in thicker slabs is advantageous from a material use perspective, the increased concrete volume contributes substantially to the overall embodied carbon. This phenomenon underscores the complexity of the relationship between structural elements and embodied carbon, which necessitates a nuanced understanding of sustainable design considerations.

Variations in embodied carbon were observed across all three spans (6 m, 8 m, and 10 m). While there is no consistent trend across all thicknesses, the data suggest that span length may influence embodied carbon, indicating a need for careful consideration of environmental impact alongside structural design decisions. Substantial differences in embodied carbon can be seen for thinner slabs. With reduced concrete volume, alterations in the composition of materials, such as cement content and steel reinforcement, can lead to more pronounced variations in embodied carbon. Conversely, the observed similarity in the embodied carbon values for thicker slabs suggests a potential convergence of environmental impact as the concrete volume increases. This is possibly due to a saturation point where the incremental increase in concrete volume has a diminishing effect on the overall embodied carbon.

Live load impact on embodied carbon

In this section, the impact of live load (LL) is investigated on concrete slabs with a span of 8 m. The analysis of the impact of different live loads on the required steel reinforcement offers insightful observations that can inform structural engineering practices. Notably, there is a consistent trend across varying live loads—2.5 kN/m2, 5 kN/m2, and 7.5 kN/m2—indicating a uniform influence on steel requirements for each slab thickness category as shown in Figure 6. This suggests the robustness of the relationship between the live load and steel demand within the studied variations.

It can be seen that thicker slabs consistently exhibit lower demands for steel, while thinner slabs require a higher steel content to meet the structural requirements. This finding aligns with established engineering principles and reinforces the importance of considering the slab thickness as a critical factor in design optimization. As the live load magnitude increased, the study revealed a corresponding trend of higher steel requirements across all slab thicknesses. This aligns with engineering expectations because increased live loads typically induce higher stresses on the structure, necessitating additional reinforcement for structural integrity.

Figure 7 shows a clear correlation between the increasing live loads and higher deflections across all slab thicknesses. The results consistently demonstrated that as the live load increases, the deflections of the concrete slabs also increased. The results also highlight the direct impact of live load on the minimum slab thickness required to meet deflection criteria. As the magnitude of live load increases, the minimum acceptable slab thickness also increases. For instance, with a live load of 2.5 kN/m2, a minimum thickness of 160 mm was sufficient to meet the deflection limits. However, for a live load of 5 kN/m2, the minimum thickness increased to 170 mm, and further increased to 190 mm for a live load of 7.5 kN/m2.

The impact of varying live loads on the embodied carbon of the concrete slabs is shown in Figure 8. A discernible pattern emerges as the live load magnitude increases from 2.5 to 7.5 kN/m2, revealing a consistent rise in embodied carbon across different slab thicknesses. This correlation underscores the direct influence of the live load on the environmental impact of the structure. While live loads are conventionally considered in structural design, this emphasizes the broader implications for sustainability.

The results highlight a crucial dual consideration in engineering design: live loads that not only dictate structural requirements but also contribute significantly to the embodied carbon of the structure. This dual impact necessitates an integrated design approach, in which structural performance and environmental sustainability are carefully balanced. Engineers must be cognizant of the environmental consequences associated with higher live loads, fostering a paradigm shift towards holistic and sustainable design practices.

These findings have implications for the broader discourse on sustainable construction. The observed increase in embodied carbon with higher live loads prompted a reconsideration of design strategies. Engineers are encouraged to explore alternative materials, innovative structural systems, and advanced construction methodologies to mitigate their environmental impacts. This approach aligns with contemporary sustainability goals, encouraging a comprehensive view of structural engineering that prioritizes both performance and environmental responsibility.

Secondary beam impact on embodied carbon

This section focuses on exploring the effects of the presence or absence of secondary beams on both structural performance and embodied carbon. In this study, a span length of 8 m was selected as a representative value commonly encountered in practical construction scenarios. A single secondary beam measuring 30 cm by 60 cm was placed at the midpoint of each direction, resulting 4 m by 4 m slab panels. This configuration allowed for systematic examination of how the introduction of secondary beams influences the structural performance and environmental footprint of the concrete slabs.

The examination of the required rebar for different slab thicknesses, both with and without secondary beams, as shown in Figure 9, provides valuable insights into the structural behaviour and efficiency of concrete slabs. Across various thicknesses, the inclusion of secondary beams consistently led to a substantial reduction in the required amount of reinforcement, ranging from approximately 50 to 70%. It can be observed that the secondary beams significantly contribute to the load distribution and overall stability. This improvement in structural efficiency can be attributed to the effective load-carrying capacity of the slab when the secondary beams are integrated. Consequently, the reduced need for additional reinforcement indicates a structural system that efficiently distributes loads.

The disparities in the required reinforcement between slabs with and without secondary beams were more pronounced in thinner slabs, whereas the differences diminished as the slab thickness increased. For thinner slabs, the impact of secondary beams on the required rebar is substantial. The inclusion of the secondary beams led to a significant reduction in the amount of reinforcement required. This phenomenon can be attributed to the enhanced load distribution capabilities of the secondary beams. The beams effectively contribute to the load-carrying capacity of the slab, resulting in reduced stress on the individual elements and, consequently, a diminished need for additional reinforcement. Conversely, as the slab thickness increased, the influence of the secondary beams on the required rebar became less pronounced. The diminishing effect suggests that for thicker slabs, the inherent structural strength and stiffness of the slab itself play a more dominant role in determining the required reinforcement. In these cases, the contribution of secondary beams to the load distribution becomes relatively less significant compared to the overall capacity of the thicker slab.

Furthermore, the inclusion of secondary beams had a profound effect on the deflection behaviour of the slabs. The deflection decreased significantly when the secondary beams were introduced into the structural system, as shown in Fig. 10. This reduction is particularly noteworthy because it results in all slab thicknesses satisfying the specified deflection limit. The improved deflection performance of secondary beams indicates their crucial role in enhancing the overall structural stability and serviceability of concrete slabs.

Figure 11 presents valuable insights into the influence of the secondary beams on the embodied carbon of concrete slabs of various thicknesses. The results indicate a striking similarity in the embodied carbon values between designs with and without secondary beams. Across various slab thicknesses, the impact of secondary beams on embodied carbon appeared to be marginal, suggesting that their inclusion may not significantly influence the overall environmental footprint.

The close resemblance in embodied carbon values prompts consideration of potential implications for design decisions. While secondary beams contribute to structural stability, the observed similarity implies that their environmental impact might be outweighed by other factors, such as the overall material composition or construction processes. The near equivalence in embodied carbon between designs with and without secondary beams raises intriguing questions regarding their necessity in the context of environmental sustainability. This observation prompts a re-evaluation of design priorities and the need for a nuanced, context-specific approach to achieve optimal outcomes.

Conclusions

This study has undertaken a comprehensive exploration of the environmental implications embedded in the design choices of two-way concrete slabs, shedding light on the key considerations for sustainable structural engineering. The investigation of span length, live load, and the inclusion of secondary beams yielded nuanced results that have implications for both engineering and environmental considerations.

The following conclusions can be drawn from this study.

-

The impact of the span length on slab design is evident, with thicker slabs generally requiring less steel reinforcement and exhibiting lower deflections. However, it is noteworthy that the minimum slab thickness to meet the deflection criteria increases with the span length—140 mm for 6 m span, 160 mm for 8 m span, and 200 mm for 10 m span. This emphasizes the importance of tailoring the slab thickness to specific project requirements, striking a balance between structural efficiency and material use.

-

Live load considerations highlight the sensitivity of slab design to external loading conditions. As the live load increases, so does the required steel reinforcement and deflection. The minimum slab thickness also rises with higher live loads—160 mm for 2.5 kN/m2, 170 mm for 5 kN/m2, and 190 mm for 7.5 kN/m2. This highlights the need for meticulous load analysis and consideration of intended use when designing concrete slabs

-

The inclusion of secondary beams presents a compelling trade-off between the structural efficiency and embodied carbon. Although secondary beams consistently lead to a substantial reduction in the required reinforcement and improvements in deflection performance, the impact on embodied carbon is marginal. This finding suggests that from an environmental standpoint, the inclusion of secondary beams may not significantly influence the overall carbon footprint of concrete structures.

This study contributes to the growing body of knowledge on the intersection of structural engineering and sustainability. This underscores the need for a holistic approach to concrete slab design that consider not only structural efficiency but also environmental impact. As the construction industry strives for more sustainable practices, these findings serve as a foundation for future research and guide decision makers in making informed choices for optimized and environmentally conscious structural design.

Data availability

No datasets were generated or analysed during the current study.

References

ACI (2019) Building code requirements for structural concrete (ACI 318-19). Available at: https://www.concrete.org/publications/internationalconcreteabstractsportal.aspx?m=details&ID=51716937.

ASCE (2016) ASCE/SEI 7-16 Minimum design loads for Buildings and other structures

Bechmann, R., & Weidner, S. (2021). Reducing the carbon emissions of high-rise structures from the very beginning. CTBUH Journal, 4, 30–35.

BS 15978: 2011 (2011) Sustainability of construkction works - assessment of environmental performance of buildings - calculation method

CEN (2010) EN 15643-1:2010 Sustainability of construction works - sustainability assessment of buildings - part 1: general framework

CEN (2014) Eurocode 2: Design of concrete structures - Part 1–1: General rules and rules for buildings’, British Standard Institute, London, UK, 3.

CSI (2023) ETABS analysis design and building systems

David, W., & Ayyub, B. M. (2017). Sustainability quantification and valuation. I: definitions, metrics, and valuations for decision making. ASCE-ASME Journal of Risk and Uncertainty in Engineering Systems Part a: Civil Engineering., 3(3), 44016001. https://doi.org/10.1061/AJRUA6.0000893

De Wolf, C., Pomponi, F., & Moncaster, A. (2017). Measuring embodied carbon dioxide equivalent of buildings: A review and critique of current industry practice. Energy and Buildings, 140, 68–80. https://doi.org/10.1016/j.enbuild.2017.01.075

Ding, G. K. C. (2008). Sustainable construction-the role of environmental assessment tools. Journal of Environmental Management, 86(3), 451–464. https://doi.org/10.1016/j.jenvman.2006.12.025

Dong, Y., Miraglia, S., Manzo, S., Georgiadis, S., Sørup, H. J. D., Boriani, E., Hald, T., Thöns, S., & Hauschild, M. Z. (2018). Environmental sustainable decision making– The need and obstacles for integration of LCA into decision analysis. Environmental Science & Policy, 87, 33–44. https://doi.org/10.1016/j.envsci.2018.05.018

Eberhardt, L. C. M., Birgisdóttir, H., & Birkved, M. (2019). Life cycle assessment of a Danish office building designed for disassembly. Building Research and Information, 47(6), 666–680. https://doi.org/10.1080/09613218.2018.1517458

Eleftheriadis, S., Duffour, P., Greening, P., James, J., Stephenson, B., & Mumovic, D. (2018). Investigating relationships between cost and CO2 emissions in reinforced concrete structures using a BIM-based design optimisation approach. Energy and Buildings, 166, 330–346. https://doi.org/10.1016/j.enbuild.2018.01.059

Ferreiro-Cabello, J., Fraile-Garcia, E., de Pison, A., Eduardo, M., de Pison, A., & Francisco, J. M. (2016). Minimizing greenhouse gas emissions and costs for structures with flat slabs. Journal of Cleaner Production., 137, 922–930. https://doi.org/10.1016/j.jclepro.2016.07.153

GABC (2020) 2020 Global status report for buildings and construction, pp. 9–10.

Gan, V. J. L., Chan, C. M., Tse, K. T., Lo, I. M. C., & Cheng, J. C. P. (2017). A comparative analysis of embodied carbon in high-rise buildings regarding different design parameters. Journal of Cleaner Production, 161, 663–675. https://doi.org/10.1016/j.jclepro.2017.05.156

Gibbon, O. P., Orr, J. J., Archer-Jones, C., Arnold, W., Green, D. (2022). How to calculate embodied carbon. The institution of structural engineers. Available at: https://www.istructe.org/resources/guidance/how-to-calculate-embodied-carbon/.

Goodchild, C. H., Webster, R. M. and Elliott, K. S. (2009) Economic concrete frame elements to eurocode 2, p. 192. Available at: www.concretecentre.com.

Hammond, G. P., & Jones, C. I. (2008). Embodied energy and carbon in construction materials. Proceedings of Institution of Civil Engineers: Energy, 161(2), 87–98. https://doi.org/10.1680/ener.2008.161.2.87

Hawkins, W., Cooper, S., Allen, S., Roynon, J., & Ibell, T. (2021). Embodied carbon assessment using a dynamic climate model: Case-study comparison of a concrete, steel and timber building structure. Structures, 33, 90–98. https://doi.org/10.1016/j.istruc.2020.12.013

Huang, L., Krigsvoll, G., Johansen, F., Liu, Y., & Zhang, X. (2018). Carbon emission of global construction sector. Renewable and Sustainable Energy Reviews, 81, 1906–1916. https://doi.org/10.1016/j.rser.2017.06.001

Jia Wen, T., Chin Siong, H., & Noor, Z. Z. (2015). Assessment of embodied energy and global warming potential of building construction using life cycle analysis approach: Case studies of residential buildings in Iskandar Malaysia. Energy and Buildings, 93, 295–302. https://doi.org/10.1016/j.enbuild.2014.12.002

KC, S., & Gautam, D. (2021). Progress in sustainable structural engineering: a review. Innovative Infrastructure Solutions. https://doi.org/10.1007/s41062-020-00419-3

Kriegler, E., Riahi, K., Petermann, N., Bosetti, V., Capros, P., van Vuuren, D. P., Criqui, P., Egenhofer, C., Fragkos, P., & Johnson, N. (2014) Assessing pathways toward ambitious climate targets at the global and european levels: A synthesis of results from the AMPERE project’. Available at: http://ampere-project.eu/web/images/Final_Conference/ampere_synthesis_5-2014-compact.pdf.

London Energy Transformation Initiative (2020) ‘Embodied Carbon Primer’. Available at: https://www.leti.london/ecp.

McKinsey (2017) Reinventing construction: a route to higher productivity. McKinsey Global Institute, p 168. Available at: http://www.mckinsey.com/industries/capital-projects-and-infrastructure/our-insights/reinventing-construction-through-a-productivity-revolution

Müller, D. B., Liu, G., Løvik, A. N., Modaresi, R., Pauliuk, S., Steinhoff, F. S., & Brattebø, H. (2013). Carbon emissions of infrastructure development. Environmental Science & Technology, 47(20), 11739–11746. https://doi.org/10.1021/es402618m

Pomponi, F., & Moncaster, A. (2016). Embodied carbon mitigation and reduction in the built environment – What does the evidence say? Journal of Environmental Management, 181, 687–700. https://doi.org/10.1016/j.jenvman.2016.08.036

Sahab, M. G., Ashour, A. F., & Toropov, V. V. (2005). Cost optimisation of reinforced concrete flat slab buildings. Engineering Structures, 27(3), 313–322. https://doi.org/10.1016/j.engstruct.2004.10.002

Sansom, M., & Pope, R. J. (2012). A comparative embodied carbon assessment of commercial buildings. Structural Engineer, 90(10), 38–49.

Saxe, S., Guven, G., Pereira, L., Arrigoni, A., Opher, T., Roy, A., Arceo, A., Von Raesfeld, S. S., Duhamel, M., McCabe, B., Panesar, D. K., MacLean, H. L., & Posen, I. D. (2020). Taxonomy of uncertainty in environmental life cycle assessment of infrastructure projects. Environmental Research Letters. https://doi.org/10.1088/1748-9326/ab85f8

Sjostrom, C., & Bakens, W. (1999). CIB Agenda 21 for sustainable construction: Why, how and what. Building Research & Information. Routledge, 27(6), 347–353. https://doi.org/10.1080/096132199369174

Funding

This work was supported by the Directorate General of Higher Education, Research and Technology, Ministry of Education, Culture, Research and Technology as a part of Penelitian Dasar Unggulan Perguruan Tinggi Research Grant to Binus University entitled “Konstrukti Hijau Untuk Masa Depan: Upaya Mengurangi Embodied Carbon Pada Proyek Gedung Bertingkat” with contract number 179/E5/ PG.02.00/PL/2023; 1402/LL3/AL.04/2023; 149/VR.RTT/VII/2023).

Author information

Authors and Affiliations

Contributions

RS prepare the initial draft of the paper LC check and review the draft MK calculate the slab design MS check and review the draft

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Suwondo, R., Cunningham, L., Keintjem, M. et al. Evaluating environmental sustainability in concrete slabs: a comparative study of embodied carbon for different design approaches. Asian J Civ Eng 25, 3655–3664 (2024). https://doi.org/10.1007/s42107-024-01002-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42107-024-01002-2