Abstract

The substantial contribution of the global construction sector to greenhouse gas emissions underscores the urgency of mitigating its environmental impact. This study addresses the pressing need for sustainable practices in the construction sector, focusing on the intricate relationship between concrete grade selection, bridge span length, embodied carbon, and construction costs within a concrete T-girder highway bridge design. By examining various girder spacings, concrete grades, and bridge spans, this study aims to provide holistic insights into material optimisation for structural efficiency, sustainability, and economic viability. Notably, the findings reveal a nuanced understanding of design parameters, with shorter spans exhibiting minimal sensitivity to girder spacing and concrete grade, whereas longer spans highlight their significant role in shaping embodied carbon and cost. The results also show a remarkable similarity between the C25/30 and C32/40 concrete grades, emphasizing the need for a strategic balance between environmental and financial performance. This study underscores scientific rigour and methodological robustness, providing useful contributions to the field of sustainable construction practices. In conclusion, this research advocates a balanced approach that integrates concrete grade, girder spacing, and span length considerations to optimise sustainability and economic feasibility in concrete T-girder bridge designs. These insights facilitate informed decision-making, aligning with evolving trends towards environmentally conscious infrastructure development.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The building and construction sector is a primary contributor to the prevailing environmental and climate crises. In 2022, 37% of the global greenhouse gas emissions resulting from human activities were attributed to the construction and maintenance of buildings and infrastructure [1]. Notably, the construction sector accounted for 20% of the total energy-related CO2 emissions in 2020, and without preventive measures, this percentage is anticipated to escalate in the coming years [2]. Consequently, prominent global institutions are urgently pursuing actions to achieve a 78% reduction in emissions by 2035, a crucial milestone in the planned transition to net zero by 2050.

Carbon emissions linked to buildings can be categorised into two primary components: operational and embodied carbon. Operational carbon pertains to the emissions linked to energy consumption during the ongoing operation of a building or infrastructure, encompassing activities such as heating, cooling, and lighting. Embodied carbon encompasses the residual emissions related to the materials used and the construction processes involved. The impact of embodied carbon on the overall carbon emissions of buildings is intricately linked to the energy efficiency of the building itself, as highlighted by Chaudhary and Piracha [3]. A comprehensive examination of various studies, including those conducted by Eaton and Amato [4], Dimoudi and Tompa [5], Al-Omari et al [6], and Santoro et al. [7] indicates noticeable variation. The contribution of embodied carbon to the total emissions of buildings ranged from 30 to 80%, underscoring the diverse factors influencing this relationship. Understanding these dynamics is crucial for developing effective strategies to address and mitigate the environmental impacts of building construction and use [8, 9].

Numerous studies have attempted to minimise embodied carbon in buildings and construction. Mak and Less [10] explored an innovative method for improving both the environmental and mechanical aspects of reinforced concrete construction. Their investigation specifically addressed shear-critical elements by employing a distinctive approach that integrated functionally graded concrete and voids to activate a preferential internal resistance mechanism based on internal arch action. The study, conducted through comprehensive failure testing, showed significant enhancements in the performance of the specimens when compared to conventional designs. These improvements included heightened resistance and a reduction in embodied carbon, marking a promising stride towards more sustainable and efficient reinforced concrete structures.

Bechman and Weidner [11] conducted a comparative analysis encompassing a standard 29-floor multi-storey concrete building, an optimised concrete structure, and a hybrid timber tower of similar height. The optimised concrete building underwent specific modifications, including a customised concrete mix, optimised structural systems, and refined material manufacturing processes. In contrast, the hybrid timber tower featured a foundation, underground levels, and a rigid concrete core, while its upper floors incorporated 200-millimetre thick timber panels with 100-millimetre thick concrete topping slabs. The results revealed a substantial potential for reducing carbon emissions. The adoption of a hybrid timber design resulted in an impressive emission reduction of up to 78% when compared to conventional concrete structures. Additionally, the investigation highlighted that an optimised concrete approach could yield significant carbon emission reductions of 47%. These insights underscore the promising avenues available for environmentally conscious design and construction practices for multi-storey buildings.

Goodchild et al. [12] developed a series of design charts specifically tailored for reinforced concrete frame elements, with a focus on slabs. Their work delved into optimal cost considerations for a range of spans, employing a series of parametric designs that rigorously adhered to deflection controls based on Eurocode 2 guidelines [13]. Through this meticulous approach, researchers established adjusted span-to-depth ratios, revealing that reinforcing structures to achieve a reduction in allowable slab thickness could effectively contribute to an overall cost reduction. In addition to this body of knowledge, Ferreiro-Cabello et al. [14] investigated flat slabs with varying thicknesses across different column grids. Their study emphasized the significance of minimising embodied carbon by reducing spans. Furthermore, their research highlighted that designs with the lowest embodied carbon tended to approach the minimum feasible slab thickness, revealing a nuanced trade-off between the slab depth and reinforcement content.

Alternatively, Eleftheriadis et al. [15] employed a building information modelling (BIM)-based genetic algorithm to optimise flat slabs. By systematically manipulating the dimensions, reinforcement, and column layout, they identified designs with the least embodied carbon, showing a preference for shorter column spacing and thinner slabs. Notably, the study revealed that increasing the slab thickness to achieve a reduction in reinforcement ratios is an effective strategy for diminishing the overall embodied carbon content. These findings collectively provide valuable insights into optimising structural elements to enhance sustainability in construction practices.

Previous studies have primarily focused on buildings, yet there exists an untapped potential for savings in embodied carbon within infrastructure. In particular, bridges can be considered as promising candidates for carbon reduction due to their widespread presence and the substantial proportion of structural materials they typically entail [16]. However, there is a limited amount of work that systematically investigates the embodied carbon in bridge structures. Gervasio and Silva [17] conducted a life cycle analysis encompassing environmental and cost considerations of two alternative structural solutions: concrete and steel composite bridges. While the concrete solution exhibited a clear cost advantage, being 20% cheaper, the environmental life cycle analysis revealed a potential inversion of this result in favour of the steel solution. Zhang et al. [18] compared the environmental impact, specifically in terms of carbon emissions, of employing a fibre-reinforced polymer (FRP) bridge decking system versus a conventional prestressed concrete beam and deck system for a highway bridge deck replacement project in the UK. Their findings indicated similar life cycle carbon dioxide emissions for both options, suggesting that the FRP decking system could offer environmental competitiveness and even advantages over conventional materials for the considered bridge project. Notably, the study identified construction stage emissions as the most controllable, with material supply for the FRP option contributing to 83.6% of construction carbon emissions whilst traffic diversions for the prestressed concrete option contributed to 83.5% of construction carbon emissions.

However, despite these advancements, there remains a notable gap in the systematic analysis of embodied carbon in bridge structures. The present work endeavours to address a critical knowledge gap by conducting an in-depth investigation into the potential of minimising the embodied carbon in concrete T-girder bridges. This study aimed to systematically examine and compare the environmental implications and financial costs associated with the construction of concrete T-girder bridges, specifically focusing on the variable parameters of girder spacing and concrete grade. Through this comprehensive exploration, this study seeks to provide useful insights into the effectiveness of design strategies for reducing the carbon footprint of concrete T-girder bridges. The overarching objective is to contribute to sustainable construction practices by identifying optimal design considerations that enhance structural performance, minimise embodied carbon, and ensure economic viability. Through a holistic approach, this study aims to optimise material usage in concrete T-girder bridges, balancing structural integrity, environmental sustainability, and cost-effectiveness.

Methodology

Bridge information

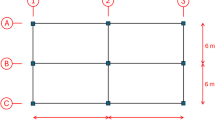

This study investigated highway bridges with spans ranging from 10 to 40 m while maintaining a standardised width of 10 m. This configuration aligns with typical simply supported bridge designs and allows for comprehensive exploration of the design parameters. The investigation involved varying the girder spacing. As shown in Fig. 1, three distinct design configurations are explored, each featuring a different number of girders: four, five, and six.

Additionally, a 50-mm thick asphalt wearing surface was uniformly applied, contributing to the overall durability and functionality of the bridges. The girder specifications included a specified yield strength (fy) for the steel reinforcement set at 420 MPa and a specified concrete strength (fc’) of 32 MPa (C32/40). These parameters establish a clear framework for the experimental conditions, ensuring precision and repeatability in the examination of the environmental and financial aspects of concrete T-girder bridges.

In this study, a comprehensive consideration of various loads was essential for a rigorous analysis of the focused bridges. The loads acting on the bridge were determined in accordance with the specifications outlined in Indonesian Standard SNI 1725-2016 [19], ensuring that the study adhered to established and region-specific guidelines for load determination in bridge design. The loads considered were classified as follows:

(1) Permanent load

The permanent load comprises both the dead load of the structural components (DD) and that of the wearing surface (DW). The unit weight of the concrete, representing the structural component dead load, was established as 25 kN/m3. Additionally, the dead load of the asphalt wearing surface was characterised by a unit weight of 22.4 kN/m3.

(2) Transient load (TL)

The transient load is ascertained through rigorous evaluation, considering the most critical condition between the design truck load and lane load.

(a) Truck load

The truck load, which is a dynamic and pivotal factor in bridge analysis, is characterised by the weights and spacings of the axles and wheels, as illustrated in Fig. 2. This load scenario represents the actual conditions, considering the impact of vehicular traffic on the structural integrity of a concrete T-girder bridge.

(b) Lane load

The designed lane load is defined as a composite load that incorporates both a uniformly distributed load (UDL) and a transverse line load. The UDL, quantified as 9 kN/m2, is representative of the evenly distributed forces exerted across the lane by vehicular traffic. Simultaneously, a transverse line load of 49 kN/m, often referred to as knife-edge load, was applied to emulate the concentrated forces acting in a specific direction, as illustrated in Fig. 3.

The factored load combination of (1.3DD + 2.0DW + 1.8TL), is the design limit state as defined by the Indonesian Standard SNI 1725-2016 [19]. This approach aligns with established engineering principles, ensuring that the concrete T-girder bridge design is evaluated under a comprehensive set of conditions, including both static and dynamic loading scenarios. The detailed load specifications and configurations ensure a realistic and robust simulation for meaningful analysis and interpretation of research findings.

Bridge deck and T-girder design

The primary focus of this investigation is the examination and optimisation of the main structural elements, bridge deck, and T-girder. Adhering to the rigorous standards set forth in AASHTO [20] ensures that the structural design is not only in compliance with industry-recognised codes but also adheres to established principles and practices governing the design of concrete elements. This methodological approach ensures the reliability, safety, and structural integrity of the examined elements, thereby enhancing the robustness and scientific rigour of the research.

To determine the structural dimensions of the bridge components, specific criteria were applied to ascertain their minimum depth and effective flange width. The minimum depth of the deck slab (ts) is calculated using the following equation:

where S is the distance between the girders.

The minimum depth of the T-girder (h) was established as follows:

where L denotes the bridge span. This criterion serves as a foundational parameter in designing a T-girder structure, providing a baseline for the overall dimensions of this primary bridge element. Additionally, the effective flange width, bef, was determined using the following equations:

where L is the bridge span and bw is the width of the beam.

The design of concrete structures requires evaluation of the flexural strength and shear strength. The flexural strength of the reinforced concrete beam section depends on the position of the neutral axis. There are two conditions for the neutral axis position: first, when it is in the concrete slab, the beam is designed as a square beam; and second, when it is in the web of the beam, the beam is designed as a T-beam. The determination of the neutral axis position plays a critical role in shaping the structural configuration, defining whether the beam assumes a square or T-beam design. A detailed step-by-step illustration of the flexural strength design process for both conditions is shown in Fig. 4.

Shear reinforcement is essential for resisting factored shear forces acting on the beams. Shear damage represents a critical failure mode in the design of reinforced concrete structural elements, often resulting in catastrophic consequences [21, 22]. The nominal shear strength Vn was determined using the following equations:

where Vc is nominal shear strength provided by concrete and Vs is nominal shear strength provided by shear reinforcement, Av and s is the area and spacing respectively of the shear reinforcement.

Embodied carbon and cost analysis

The evaluation of construction sustainability necessitates a comprehensive exploration of its environmental impact across distinct life cycle stages, as defined by BS EN 15978 [23]. This standard delineates stages A1–A3 collectively as the 'cradle-to-gate' phase, referred to as the product stage. This phase encompasses activities ranging from raw material extraction and transportation to manufacturing [24]. Significantly, the London Energy Transformation Initiative (LETI) [25] underscores the notable contribution of embodied carbon in this phase, often constituting up to 50% of the entire life cycle carbon footprint. This is in contrast to the comparatively smaller share in the construction phase, typically approximately 5% of the total. Case studies conducted by researchers such as Sansom and Pope [26], Wen et al. [27], and Gan et al. [28] consistently revealed that transportation and construction activities collectively contribute within the range of 1–15%. Therefore, employing 'cradle-to-gate' embodied carbon as a performance indicator is rational, allowing a focused examination of the environmental implications associated with variations in concrete grade and slab thickness while maintaining consistent construction methods. Total embodied carbon (EC) was calculated using the following equation:

where C represents the quantity of materials utilised and CF signifies the carbon factor, denoting the quantity of carbon per unit weight or volume. This methodological approach aligns with recognised standards, enabling a comprehensive evaluation of the carbon footprint attributed to concrete structures. The specific carbon factors for various materials obtained from the Inventory of Carbon and Energy (ICE) [29] are listed in Table 1. This table serves as a valuable reference for assessing the environmental impacts of the materials used in the analysis.

In terms of cost considerations, the analysis incorporated typical construction costs relevant to Indonesia, as outlined in Table 2. These costs were derived from a unit cost analysis conducted in accordance with the Ministry of Public Works and Housing guidelines [30]. Aligning the study with local construction cost data ensures that the findings are not only environmentally relevant but also economically practical within the context of the study area.

Results and discussion

The investigation into embodied carbon and financial costs, conducted through a systematic variation of layout parameters, has yielded insightful findings with direct implications for sustainable construction practices. The methodical exploration of girder spacing and variations in concrete grade has uncovered discernible trends in the overall embodied carbon and cost of concrete T-girder bridges.

This section is structured into two sections, each dedicated to scrutinising the specific aspects of the geometric layout variations. The first section examines the impact of girder spacing on embodied carbon and cost, while the second section determines the effect of varying concrete grade. Both sections extend their exploration across a range of bridge spans varying from 10 to 40 m. This dual focus allows for a more nuanced understanding of how individual layout parameters contribute to the overall embodied carbon and cost in concrete T-girder bridges, thereby providing valuable insights into optimising these elements for enhanced sustainability.

Effect of girder spacing

This section specifically investigates the impact of varying the girder spacing on the total embodied carbon and cost. It examines how alterations in girder spacing contribute to variations not only in the environmental impact, but also in the associated economic implications across different bridge spans. The study encompasses three distinct girder spacings: −1.75, 1.40, and 1.17 m, as illustrated in Fig. 1. This comprehensive exploration aims to elucidate the nuanced relationship between changes in girder spacing and their corresponding effects on both the environmental impact and financial cost, providing a thorough understanding of these critical aspects within varying bridge spans. The result of the bridge design with various girder spacing is presented in Appendix 1.

Figure 5 shows the variation in the embodied carbon across the bridge for different spans and girder spacings, with the results expressed in kilograms per meter of bridge span. As expected, a noticeable trend emerged, revealing that total embodied carbon consistently increased with the expansion of the bridge span. This observation aligns with the anticipated outcomes, reflecting an intuitive understanding that larger spans inherently require more materials, leading to a proportional increase in embodied carbon. This correlation underscores the significance of considering the bridge span dimensions in the assessment of embodied carbon, emphasizing the environmental implications associated with varying spatial configurations.

It is noteworthy that from 10 to 20 m, the embodied carbon increases gradually. However, beyond the 20 m mark, there was an exponential surge in embodied carbon. The gradual increase in embodied carbon from 10 to 20 m spans suggests a relatively linear relationship between span length and environmental impact. However, beyond the 20 m mark, the rate of increase in embodied carbon accelerates, indicating a nonlinear relationship between span dimensions and environmental impact. By identifying this critical threshold and understanding the corresponding shift in environmental impact, engineers and designers can make informed decisions when optimising sustainability in bridge design.

In the context of shorter spans, it was observed that girder spacing had minimal impact on the total embodied carbon. In these cases, other design factors may play a dominant role in determining environmental impact. However, as the bridge span increased, the effect of girder spacing became more noticeable. Larger spans inherently require more materials; therefore, variations in girder spacing have a more significant effect on the total embodied carbon. This heightened sensitivity underscores the importance of carefully considering girder spacing, particularly in the context of longer spans, where even small adjustments can lead to noticeable changes in the environmental implications.

To achieve harmonious integration of structural efficiency, environmental sustainability, and financial considerations, this study meticulously explored the cost implications of each bridge design. As shown in Fig. 6, the total cost of the bridge is evaluated for various girder spacings and bridge spans. In similarity with the embodied carbon analysis, the influence of girder spacing on cost variation was observed to be inconsequential for shorter spans. However, as the bridge span increases, the impact of girder spacing on cost variation becomes more pronounced and significant.

The comprehensive evaluation of both environmental and financial implications in this study provides a holistic perspective that is crucial for informed decision-making in bridge design. For shorter spans, where the overall material quantity is inherently less substantial, the observed minimal impact of girder spacing on both embodied carbon and cost suggests that other design considerations may play a more dominant role. As the bridge span increases, the intricate relationship between girder spacing and both the environmental and financial aspects becomes more evident. Larger spans necessitate a greater quantity of materials, and variations in girder spacing become a more critical factor influencing not only the embodied carbon, but also the overall cost of the bridge.

This nuanced understanding emphasizes the interconnected nature of the design parameters, highlighting the need for a tailored approach based on the specific characteristics of the bridge, such as its span length. Striking a balance between structural efficiency, environmental sustainability, and financial viability requires careful consideration of the interplay between girder spacing and bridge span, particularly as projects move towards longer spans. Designers can make informed decisions that optimise both environmental and financial performance, ultimately contributing to the overarching goal of achieving balanced and sustainable bridge design practices.

Effect of concrete grade

This section investigates the impact of varying concrete grades on both the total embodied carbon and financial costs. It delves into how changes in the concrete grade contribute to variations in the environmental impact and economic considerations across different bridge spans. The study encompasses three distinct concrete grades, C25/30, C32/40, and C40/50, providing a comprehensive exploration of how alterations in the concrete grade influence both the environmental and financial aspects of the bridge. The detailed results of the bridge design with various concrete grades are presented in Appendix 2, which offers a thorough examination of the specific outcomes and implications associated with each concrete grade considered in the study.

Figure 7 provides a comprehensive insight into the impact of varying concrete grades on the total embodied carbon across different spans in the concrete T-girder bridge design. Across all spans, there is a clear and expected pattern: as the concrete grade increases from C25/30 to C40/50, the total embodied carbon increases consistently. This correlation is intuitive, aligning with the conventional understanding that higher concrete grades typically entail a greater carbon footprint owing to increased cement contents and production processes.

For shorter spans, the differences in total embodied carbon between various concrete grades were comparatively modest. This suggests that in the context of shorter spans, the influence of concrete grade on the overall environmental impact is relatively limited. In contrast, as the span length increased, the effect of the concrete grade on the total embodied carbon became more substantial. The data indicate a progressively larger impact on embodied carbon with higher concrete grades, emphasizing the need for careful consideration of material selection in longer-span bridge designs.

The presented cost analysis, as shown in Fig. 8, in conjunction with varying concrete grades and spans in the concrete T-girder bridge design, offers valuable insights into the financial implications of material selection. Notably, the data reveals a noteworthy similarity between the C25/30 and C32/40 concrete grades in terms of both total embodied carbon and cost across various span lengths. The observed similarity in the outcomes between C25/30 and C32/40 prompted a closer examination of the trade-offs associated with these concrete grades. Designers may find that opting for C25/30, which often comes with lower production costs, could provide a viable alternative to C32/40 without significant compromise in environmental or financial performance. In essence, this suggests that while C25/30 may have lower initial production costs, it can still deliver comparable environmental and financial outcomes to slightly higher-grade C32/40 concrete.

The results also reveal a consistent trend wherein the C40/50 concrete grade incurs higher costs than its counterparts (C25/30 and C32/40) across various span lengths. This observation underscores the financial implications associated with opting for higher-grade concrete, signalling a potential trade-off between enhanced structural properties and increased construction expenses. The elevated cost of C40/50 concrete emphasizes the need for a balanced approach that considers both sustainability and economic viability. Although higher-grade concrete may contribute to enhanced structural performance, its cost implications may not always align with the project's financial constraints. This prompts a strategic assessment of whether incremental benefits justify added expenses in the pursuit of sustainability.

This study provides a nuanced understanding of the intricate relationship between the concrete grade, span length, and construction cost in concrete T-girder bridge design. This knowledge can guide informed decision-making, allowing designers to optimise material choices based on project-specific requirements, and contribute to the overarching goal of achieving both structural efficiency and economic sustainability in bridge construction.

Conclusion

This research endeavours to shed light on the intricate relationship between concrete grade selection, bridge span length, embodied carbon, and construction costs in the context of concrete T-girder bridge design. The key findings and implications of this study provide valuable insights into the fields of structural engineering, environmental sustainability, and construction economics.

This investigation underscores the following key points:

(1) Girder spacing impact: A meticulous investigation into girder spacing revealed a notable finding: larger girder spacing correlates with reduced embodied carbon and cost. This result provides an opportunity for designers to optimise sustainability and economic considerations by carefully selecting the girder spacing.

(2) Concrete Grade Impact: Comprehensive exploration of the concrete grade reaffirmed the expected pattern, with higher concrete grades associated with increased embodied carbon. Notably, a closer examination revealed similarities between C25/30 and C32/40, emphasizing the need for designers to strategically balance environmental and financial performance.

(3) The integrated approach of this study sheds light on the interconnected nature of the design parameters. While shorter spans exhibited minimal sensitivity to girder spacing and concrete grade, longer spans showcased the significant role these parameters played in shaping both embodied carbon and cost.

(4) A critical threshold in span dimensions was observed, whereby a transition beyond the 20 m mark led to an exponential surge in embodied carbon. This nuanced understanding emphasizes the importance of tailored approaches based on span length, urging designers to focus on optimising sustainability, particularly over longer spans.

In the broader context of sustainable construction practices, this study contributes to the ongoing discourse on optimising material selection in bridge design. The insights gained can inform decision makers, engineers, and policymakers in making informed choices that align with both structural requirements and the imperative of reducing the environmental footprint of infrastructure projects. As the construction industry continues to evolve towards more sustainable practices, this study provides a valuable foundation for future research and innovation in the pursuit of environmentally conscious and economically viable bridge design solutions. However, this study primarily examined the influence of girder spacing and concrete grade on embodied carbon and costs. Other design parameters, such as bridge geometry, foundation types, alternative concrete constituents and construction methods, were not explicitly considered but may also play significant roles in determining environmental and economic outcomes. Future research should address these limitations by adopting a more comprehensive and integrated approach to bridge design that considers a wider range of design variables and objectives.

Data availability

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Abbreviations

- A :

-

Depth of equivalent rectangular stress block

- A req :

-

Required area of steel reinforcement

- A sf :

-

Total area of steel reinforcement at flange

- A sw :

-

Total area of steel reinforcement at web

- A used :

-

Used area of steel reinforcement

- A v :

-

Area of shear reinforcement

- b ef :

-

Effective flange width

- b w :

-

Width of the beam

- c :

-

Distance from compression fibre to neutral axis

- C :

-

Quantity of materials

- CF:

-

Carbon factor

- d e :

-

Effective depth of beam

- DD:

-

Dead load of structural component

- DW:

-

Dead load of wearing surface

- f c ’ :

-

Compressive strength of concrete

- f r :

-

Modulus of rupture of concrete

- f y :

-

Yield strength of steel reinforcement

- h :

-

Depth of the T-girder

- I g :

-

Moment of inertia of gross section

- L :

-

Bridge span

- M cr :

-

Cracking moment

- M n :

-

Total nominal flexural strength

- M nf :

-

Nominal flexural strength provided by flange section

- M nw :

-

Nominal flexural strength provided by web section

- M r :

-

Allowable flexural strength

- M u :

-

Factored moment obtained from analysis

- S :

-

Distance between girders

- t s :

-

Minimum depth of the deck slab

- TL:

-

Transient load

- UDL:

-

Uniformly distributed load

- V c :

-

Nominal shear strength provided by concrete

- V n :

-

Total nominal shear strength

- V s :

-

Nominal shear strength provided by steel reinforcement

- ε c :

-

Compressive strain of concrete

- ε s :

-

Tensile strain of steel

References

UNEP (2022) Global status report for buildings and construction: towards a zero‐emission, efficient and resilient buildings and construction sector. Nairobi Effic Resilient Build Constr Sect

UNEP (2021) Global status report for buildings and construction: towards a zero-emission, efficient and resilient buildings and construction sector. Nairobi Effic Resilient Build Constr Sect 2021:1–105

Chaudhary T, Piracha A (2013) Effective contribution of structural engineers to green buildings and sustainability. Can J Civ Eng 40:97–100. https://doi.org/10.1139/cjce-2012-0154

Eaton KJ, Amato A (1998) A comparative life cycle assessment of steel and concrete framed office buildings. J Constr Steel Res 46:286–287. https://doi.org/10.1016/S0143-974X(98)00074-1

Dimoudi A, Tompa C (2008) Energy and environmental indicators related to construction of office buildings. Resour Conserv Recycl 53:86–95. https://doi.org/10.1016/j.resconrec.2008.09.008

Al-Omari O, Alkhdor A, Al-Rawashdeh MA, Al-Ruwaishedi MR, Al-Rawashdeh SB (2023) Evaluating carbon footprint in the life cycle design of residential concrete structures in Jordan. Civ Eng J 9:1646–1659. https://doi.org/10.28991/CEJ-2023-09-07-07

Santoro JF, Kripka M (2024) Evaluation of CO2 emissions in RC structures considering local and global databases. Innov Infrastruct Solut 9:33. https://doi.org/10.1007/s41062-023-01345-w

Kryeziu D, Selmani F, Mujaj A, Kondi I (2023) Recycled concrete aggregates: a promising and sustainable option for the construction industry. J Human Earth Futur 4:166–180. https://doi.org/10.28991/HEF-2023-04-02-03

Husin AE, Prawina RS, Priyawan P, Pangestu R, Kusumadiadewi BD (2023) Optimizing time performance in implementing green retrofitting on high-rise residential by using dynamic systems and M-pert. Civ Eng J 10:3060–3074

Mak MWT, Lees JM (2023) Carbon reduction and strength enhancement in functionally graded reinforced concrete beams. Eng Struct. https://doi.org/10.1016/j.engstruct.2022.115358

Bechmann R, Weidner S (2021) Reducing the carbon emissions of high-rise structures from the very beginning. Ctbuh J 2021:30–35

Goodchild CH, Webster RM, Elliott KS (2009) Economic concrete frame elements to Eurocode 2, 192. www.concretecentre.com.

CEN (2014) Eurocode 2: design of concrete structures - Part 1–1: general rules and rules for buildings. Br. Stand. Institute, London, UK

Ferreiro-Cabello J, Fraile-Garcia E, de PisonAscacibar EM, de PisonAscacibar FJM (2016) Minimizing greenhouse gas emissions and costs for structures with flat slabs. J Clean Prod 137:922–930. https://doi.org/10.1016/j.jclepro.2016.07.153

Eleftheriadis S, Duffour P, Greening P, James J, Stephenson B, Mumovic D (2018) Investigating relationships between cost and CO2 emissions in reinforced concrete structures using a BIM-based design optimisation approach. Energy Build 166:330–346. https://doi.org/10.1016/j.enbuild.2018.01.059

Arıoğlu Akan MÖ, Dhavale DG, Sarkis J (2017) Greenhouse gas emissions in the construction industry: an analysis and evaluation of a concrete supply chain. J Clean Prod 167:1195–1207. https://doi.org/10.1016/j.jclepro.2017.07.225

Gervásio H, da Silva LS (2008) Comparative life-cycle analysis of steel-concrete composite bridges. Struct Infrastruct Eng 4:251–269. https://doi.org/10.1080/15732470600627325

Zhang C, Amaduddin M, Canning L (2011) Carbon dioxide evaluation in a typical bridge deck replacement project. In: Proceedings of the institution of civil engineers-energy. 164: 183–194. Doi: https://doi.org/10.1680/ener.2011.164.4.183.

BSN (2016) SNI 1725–2016 Pembebanan untuk Jembatan. Badan Stand Nas, Indones, pp 1–63

AASHTO (2020) LRFD bridge design specification

Özkılıç YO, Karalar M, Aksoylu C, Beskopylny AN, Stel’makh SA, Shcherban EM, Qaidi S, da Pereira SA, Monteiro SN, Azevedo ARG (2023) Shear performance of reinforced expansive concrete beams utilizing aluminium waste. J Mater Res Technol 24:5433–5448. https://doi.org/10.1016/j.jmrt.2023.04.120

Aksoylu C, Özkılıç YO, Hadzima-Nyarko M, Işık E, Arslan MH (2022) Investigation on improvement in shear performance of reinforced-concrete beams produced with recycled steel wires from waste tires. Sustain. https://doi.org/10.3390/su142013360

BS 15978 (2011) Sustainability of construction works - assessment of environmental performance of buildings - calculation method

Gibbon OP, Orr JJ, Archer-Jones C, Green D (2022) How to calculate embodied carbon. The institution of structural engineers. https://www.istructe.org/resources/guidance/how-to-calculate-embodied-carbon/.

London energy transformation initiative (2020) Embodied carbon primer. https://www.leti.london/ecp.

Sansom M, Pope RJ (2012) A comparative embodied carbon assessment of commercial buildings. Struct Eng 90:38–49

Jia Wen T, Chin Siong H, Noor ZZ (2015) Assessment of embodied energy and global warming potential of building construction using life cycle analysis approach: case studies of residential buildings in Iskandar Malaysia. Energy Build. 93:295–302. https://doi.org/10.1016/j.enbuild.2014.12.002

Gan VJL, Chan CM, Tse KT, Lo IMC, Cheng JCP (2017) A comparative analysis of embodied carbon in high-rise buildings regarding different design parameters. J Clean Prod 161:663–675. https://doi.org/10.1016/j.jclepro.2017.05.156

Hammond G, Jones C (2008) Inventory of carbon & energy (ICE)

Ministry of public works and housing (2022) Analisa Harga Satuan Pekerjaan Bidang Umum

Acknowledgements

The authors acknowledge the support of Civil Engineering Department, Bina Nusantara University and Department of Mechanical, Aerospace and Civil Engineering, The University of Manchester.

Funding

Directorate General of Higher Education, Research and Technology, Ministry of Education, Culture, Research and Technology as a part of the Penelitian Dasar Unggulan Perguruan Tinggi Tahun 2024 entitle "Konstruksi Hijau Untuk Masa Depan: Upaya Mengurangi Embodied Carbon pada Proyek Gedung Bertingkat".

Author information

Authors and Affiliations

Contributions

RS contributed to conception; MK done analysis: MS helped in supervision; LC done editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare.

Ethical approval

The paper is neither published nor under review elsewhere. There are no human or animal participants involved in the conducted study.

Informed consent

All authors are aware of the paper.

Appendices

Appendix 1 Concrete T-girder bridge design with different girder spacing

Girder spacing (m) | Span (m) | Deck | T Girder | ||

|---|---|---|---|---|---|

Thickness (mm) | Reinforcement | Dimension (mm) | Reinforcement | ||

1750 | 10 | 200 | 16D-150 | 500 × 700 | 7D32 Bottom and 4D22 Top D16-150 transv |

1750 | 15 | 200 | 16D-150 | 500 × 1100 | 9D32 Bottom and 6D22 Top D16-250 transv |

1750 | 20 | 200 | 16D-150 | 500 × 1400 | 12D32 Bottom and 8D22 Top D16-250 transv |

1750 | 25 | 200 | 16D-150 | 600 × 1750 | 16D32 Bottom and 10D22 Top D16-350 transv |

1750 | 30 | 200 | 16D-150 | 700 × 2100 | 22D32 Bottom and 13D22 Top D16-400 transv |

1750 | 35 | 200 | 16D-150 | 900 × 2500 | 30D32 Bottom and 19D22 Top D16-400 transv |

1750 | 40 | 200 | 16D-150 | 1100 × 2800 | 40D32 Bottom and 24D22 Top D16-300 transv |

1400 | 10 | 200 | 16D-200 | 500 × 700 | 6D32 Bottom and 4D22 Top D16-200 transv |

1400 | 15 | 200 | 16D-200 | 500 × 1100 | 7D32 Bottom and 6D22 Top D16-300 transv |

1400 | 20 | 200 | 16D-200 | 500 × 1400 | 10D32 Bottom and 7D22 Top D16-350 transv |

1400 | 25 | 200 | 16D-200 | 600 × 1750 | 13D32 Bottom and 10D22 Top D16-450 transv |

1400 | 30 | 200 | 16D-200 | 700 × 2100 | 18D32 Bottom and 13D22 Top D16-500 transv |

1400 | 35 | 200 | 16D-200 | 900 × 2500 | 25D32 Bottom and 18D22 Top D16-500 transv |

1400 | 40 | 200 | 16D-200 | 1100 × 2800 | 35D32 Bottom and 23D22 Top D16-500 transv |

1170 | 10 | 200 | 16D-250 | 500 × 700 | 5D32 Bottom and 4D22 Top D16-200 transv |

1170 | 15 | 200 | 16D-250 | 500 × 1100 | 7D32 Bottom and 6D22 Top D16-350 transv |

1170 | 20 | 200 | 16D-250 | 500 × 1400 | 9D32 Bottom and 7D22 Top D16-400 transv |

1170 | 25 | 200 | 16D-250 | 600 × 1750 | 13D32 Bottom and 10D22 Top D16-500 transv |

1170 | 30 | 200 | 16D-250 | 700 × 2100 | 17D32 Bottom and 13D22 Top D16-500 transv |

1170 | 35 | 200 | 16D-250 | 900 × 2500 | 25D32 Bottom and 18D22 Top D16-500 transv |

1170 | 40 | 200 | 16D-250 | 1100 × 2800 | 35D32 Bottom and 23D22 Top D16-500 transv |

Appendix 2 Concrete T-girder bridge design with different concrete grade

Concrete grade | Span (m) | Deck | T Girder | ||

|---|---|---|---|---|---|

Thickness (mm) | Reinforcement | Dimension (mm) | Reinforcement | ||

C25/30 | 10 | 200 | 16D-200 | 500 × 700 | 6D32 Bottom and 4D22 Top D16-150 transv |

C25/30 | 15 | 200 | 16D-200 | 500 × 1100 | 8D32 Bottom and 5D22 Top D16-250 transv |

C25/30 | 20 | 200 | 16D-200 | 500 × 1400 | 10D32 Bottom and 6D22 Top D16-300 transv |

C25/30 | 25 | 200 | 16D-200 | 600 × 1750 | 13D32 Bottom and 9D22 Top D16-400 transv |

C25/30 | 30 | 200 | 16D-200 | 700 × 2100 | 18D32 Bottom and 11D22 Top D16-400 transv |

C25/30 | 35 | 200 | 16D-200 | 900 × 2500 | 25D32 Bottom and 16D22 Top D16-400 transv |

C25/30 | 40 | 200 | 16D-200 | 1100 × 2800 | 36D32 Bottom and 21D22 Top D16-300 transv |

C32/40 | 10 | 200 | 16D-200 | 500 × 700 | 6D32 Bottom and 4D22 Top D16-200 transv |

C32/40 | 15 | 200 | 16D-200 | 500 × 1100 | 7D32 Bottom and 6D22 Top D16-300 transv |

C32/40 | 20 | 200 | 16D-200 | 500 × 1400 | 10D32 Bottom and 7D22 Top D16-350 transv |

C32/40 | 25 | 200 | 16D-200 | 600 × 1750 | 13D32 Bottom and 10D22 Top D16-450 transv |

C32/40 | 30 | 200 | 16D-200 | 700 × 2100 | 18D32 Bottom and 13D22 Top D16-500 transv |

C32/40 | 35 | 200 | 16D-200 | 900 × 2500 | 25D32 Bottom and 18D22 Top D16-500 transv |

C32/40 | 40 | 200 | 16D-200 | 1100 × 2800 | 35D32 Bottom and 23D22 Top D16-500 transv |

C40/50 | 10 | 200 | 16D-200 | 500 × 700 | 6D32 Bottom and 4D22 Top D16-200 transv |

C40/50 | 15 | 200 | 16D-200 | 500 × 1100 | 7D32 Bottom and 6D22 Top D16-350 transv |

C40/50 | 20 | 200 | 16D-200 | 500 × 1400 | 10D32 Bottom and 8D22 Top D16-400 transv |

C40/50 | 25 | 200 | 16D-200 | 600 × 1750 | 13D32 Bottom and 11D22 Top D16-500 transv |

C40/50 | 30 | 200 | 16D-200 | 700 × 2100 | 18D32 Bottom and 14D22 Top D16-500 transv |

C40/50 | 35 | 200 | 16D-200 | 900 × 2500 | 25D32 Bottom and 20D22 Top D16-500 transv |

C40/50 | 40 | 200 | 16D-200 | 1100 × 2800 | 35D32 Bottom and 26D22 Top D16-500 transv |

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Suwondo, R., Keintjem, M., Suangga, M. et al. Assessing embodied carbon and financial implications in concrete T-girder bridge design for cost-effective sustainability. Innov. Infrastruct. Solut. 9, 136 (2024). https://doi.org/10.1007/s41062-024-01436-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-024-01436-2