Abstract

Masonry is a prevalent human chronicle substance used all over the globe as it offers significant advantages concerning building execution time, consumption, and costs despite being an engineered material manufactured using naturally occurring resources. In burgeoning countries, in particular India, most of the constructions are forged using masonry materials. As this system is in wide usage around the globe, it is cardinal to have cognition about the emergence of the material and the praxis of the same. The purpose of this paper was to review the evolution of masonry and brick masonry from the Stone Age (4000 BCE and 2000 BCE) to the Meghalayan Age and to discuss the details related to the manufacturing processes, composition, classification, and performance of brick masonry under various conditions including those materials that are in use along with the masonry. An efficient survey conducted concentrating on the significant discoveries and perceptions made by each researcher is introduced. A table contains insights about the strengthening process used, and parameters considered results and main observations for every method.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Masonry-infilled reinforced concrete (RC) frames are one of the most commonly used structural systems worldwide. These structural forms are used for low-to-medium rise structures around the world mainly in developing countries, such as India. For infilled frame buildings, infill panels are used as partitions, whereas the bounding frame is designed as a structural skeleton to withstand vertical and lateral loading. When designing such structural systems against seismic actions, it is common practice not to include the infill walls in the numerical models used for practical structural analysis and design purposes, as these elements are considered to be non-load bearing Elouali (2008). In doing so, their stiffness and strength contribution, as well as their interaction with the load-bearing elements of the frame (i.e. beams, columns, and walls), are fully neglected. Thus, the actual performance of infilled RC frames will differ from the expected performance based on the structural analyses Singh and Verma (2015). The effect of infill walls is usually considered only through the interaction of the frame and infill along the interfaces between the surrounding frame and the infill walls by which it adds stiffness to the whole frame. From the available published experimental and numerical data, it can be observed that masonry infill walls can have a significant effect on the structural performance of RC frames under seismic actions. Even light to moderate earthquake shaking/acceleration or drift levels can cause damage to the infill walls and this damage may result in life safety hazards, immediate evacuation and loss of function of buildings, limiting the use of internal spaces. In many cases, the influence of the infill panels showed to be the reason for extensive damages or even the buildings collapses. Based on the above, it is not surprising that, over the past decade, an increasing interest has been observed concerning the investigation of the effect of infill walls on the seismic performance of infilled frames Mosalam and Günay (2017).

Vulnerability studies are very important to evaluate the seismic risk and its application is particularly interesting in urban areas located in low to moderate seismic hazard regions where the increase of the population and the absence of adequate seismic-resistant prescriptions for buildings increment the seismic risk. Very often, in these areas, a large number of RC frame structures have been designed mainly for gravity loads, or their lateral resistance has been determined without adequate seismic-resistant considerations or according to old seismic codes, in which ductile detailing is not explicitly required. It is very likely that these buildings, when subjected to a maximum credible seismic event, suffer more damage than reasonable. Therefore, it became a must job for earthquake engineers to design earthquake-resistant buildings in such a way that the whole structure contributes to the seismic safety.

Material used for construction

The construction processes of dwellings from ancient times have evolved over the period undergoing various stages if explained in chronological order, starting from the Stone Age, ultimately reaching where we are up to the present day.

As we delve into the past, the period from 7000 to 6000 BC was named the Stone Age or Neolithic age. The materials used for the building included bones and skins of animals, bamboo, metals, etc. The tools used to construct these were axe and chopper, made up of stones, rope, grass, etc. Most of the shelter for living was natural and manufactured caves. Next comes the invention of the arches in the Copper and the Bronze Age around 5000 B.C. and 3000 B.C., respectively “The history of bricks and brickmaking” (2017). During the Iron Age, between 1200 B.C. and 50 B.C, carbon and iron form steel. Large palaces and temples were built in this period in which some of them still survive to this date. The significant material used to construct these structures was mudbrick. The manufacture of bricks took place in various shapes and sizes, which were named adobe bricks. The pyramids are live examples of the big feat achieved by the Ancient Egyptians. Roman Builders used volcanic tuff found near Pozzuoli village near Mount Vesuvius in Italy. This volcanic tuff or volcanic ash is siliceous mainly in nature, thus possessing the name Pozzolana. Romans also initiated using glass as a construction material for architectural and aesthetic purposes.

In the seventh century, the Chinese built the most famous Great Wall of China using stones, bricks with lime mortar. They built temples typically consisting of timber standing on a basement carved out of larger stones. The extinction of Roman Civilization began with the rising of the Middle Ages (fifth century A.D.–fifteenth century A.D.), during which castles and cathedrals were considered the most prestigious constructions. Bricks were the most used construction material during this period, even though timber was more popular to construct the superstructure part of the buildings. The seventeenth century witnessed the birth and growth of modern science, which highly impacted building construction and the forthcoming millennia. The path-breaking achievement was due to the invention of the glass manufacturing technique “Evolution of glass as an architectural material,” (2017). The construction industry was in recognition as a prestigious profession. Cast iron and wrought iron were popular materials for building structures. The Iron Bridge at Coalbrookdale, constructed around 1779–1780, is the best example, shown in Fig. 1 “The Iron Bridge” (construction started in 1777, ended in 1781). The industrial revolution began in the nineteenth century, which brought up drastic change globally almost in every field, displaying a significant impact on the construction industries such as railways, canals, roadways. Steel became the primary construction material during the mid-nineteenth century. The second industrial revolution occurred in the twentieth century, during which exceptional developments such as elevators, cranes, tall buildings, skyscrapers, and heavier equipment reduced the burden on man by saving time and energy.

Iron Bridge at Coalbrookdale (“The Iron Bridge” construction started in 1777, ended in 1781)

Methodology of the review

Related studies were recognised through various bibliographies such as Science Direct, ASCE, Earthquake Spectra, Wiley, Taylor and Francis to conduct an organised review, published from 1988 till 2020. References for this article were selected if they (a) performed the material and mechanical property tests; (b) provided the details of the strengthening materials. Indeed, it was considered suitable to incorporate these works because of the profoundly important and various data on this subject. All these records were segregated using Mendeley Desktop (version 1.19.4). Following this task, titles and year of publication of the articles were filtered to eliminate the irrelevant papers. The tags of each piece were read with utmost care and are categorised based on the type of work carried out by the authors. Initially, they were segregated based on the type of loading, i.e., out-of-plane (OOP) and in-plane (IP) load. Later, it was even more segregated based on the work done by the authors, whether it is numerical or experimental. Full articles related to the selected titles/work were scrutinised thoroughly and complemented the mentioned criterion in the ultimate bibliography. This review paper pertains to the experimental, numerical and analytical work on MIW subjected to IP and OOP.

A total data set inquiry brought about 485 papers. Out of these, 250 documents were eliminated, from which 235 articles were left out to be filtered. Of these, 60 articles were not relevant to this topic. They were rejected because few reasons, like the papers, contain numerical modelling of confined masonry walls, analytical work, and experimental works on masonry walls surrounded by steel frames.

The parameters considered while gathering the information regarding the methods of strengthening and retrofitting of MIW were (a) technical parameters of the strengthening material, (b) specifications regarding strengthening strategies of MIW, (c) failure pattern of strengthened MIW and (d) effect of strengthening material on MIW. As this research topic consists of several parameters, systematic evaluation was contemplated as the appropriate practice as far as this topic is concerned.

Although most of the literature concludes that infills increase the overall lateral stiffness of the whole structure, something is holding back researchers and scientists in considering the infills in the seismic design of RCC structures. In few cases, a small gap pertains between the infill wall and the bounding structural system, and in the remaining cases, innovative strengthening methods of MIW are practices. Contrastingly, strengthening existing MIW constructions is a bit complicated due to the absence of the technical details of the structure, such as the type of masonry units used for building the wall, which leads to the unpredictability of selecting a suitable strengthening technique to adopt for the masonry structure.

Several researchers have carried out and performed studies on masonry infill walls for decades. Studies showed that masonry infill walls contribute to the resistance of lateral forces such as seismic actions. Hence, the presence of infills has the purpose of the overall structure. The masonry infills can also be strengthened with various materials to increase the tensile behaviour as the material is brittle. The research on MIW is divided into three categories, i.e., experimental work, numerical work and analytical work, as discussed in the following sections.

Walls

Masonry infill wall

Brickwork is regularly framed by spreading various interlocking units bound together by mortar. The dry set masonry depends on the friction between the units to forestall movement and does not need mortar. Brick masonry is vital in compression, however less viable at opposing horizontal loading or tension forces.

Types of walls

The wall is a construction characterising an accurate region and giving security and haven. There are different sorts of walls utilised in the development of structures shown underneath.

-

a)

Load Bearing—the walls that carry the imposed load and their self-weight are the load-bearing walls. These walls can be classified as exterior or enclosing walls.

-

b)

Non-Load Bearing—the walls that do not carry the imposed load instead of the gravity load are named the non-bearing wall. An example is partition walls.

-

c)

Masonry walls—the wall constructed using all those building units such as bricks, blocks, stones, tiles, generally horizontal in direction bonded with mortar.

Wall openings

The critical parameter that alters the performance of a wall under lateral loads is the openings provided in the wall. Therefore, the consideration of openings in the design of barriers is of utmost importance. The different types of wall opening available are doors, windows and ventilators. Many researchers study the performance of walls subjected to lateral loads with and without openings. Figure 2 shows some examples of walls with openings.

Filled frames with unreinforced masonry (A); filled frames with reinforced masonry (RM) (B); partially RM filled the frame with the opening (C); partially RM filled the frame with door and lintel (D). da Porto et al. (2020)

Building materials

Bricks

Brick is one of the oldest building materials used for construction purposes—bricks for constructing shelter dates back to 7000 B.C. Since then, bricks have been the most famous building material till today. Bricks (Fig. 3) the material manufactured artificially using natural resources such as clay heated and moulded in uniform shape and size “Bricks and blocks,” (2019).

The brick consists of a small cavity on one of its surfaces called the frog, whose depth is about 10 mm, provided for the excellent binding with the mortar. There are four classes of bricks based on the water absorption capacity and its strength. The details of these classes of bricks are as follows. A summary table (Table 1) for the same is prepared to comprise the elements apropos the classification of bricks (Fig. 4).

Composition of bricks

Bricks are not naturally available material. The manufacturing takes place artificially, either manually or mechanically. Later, fire bricks were invented in 3500 B.C by Romans. They just eliminated the long and tedious process of hardening the bricks under warm temperatures and manufactured bricks in different shapes according to the requirement in wooden moulds. In the medieval period, clay became the most crucial ingredient in the making of bricks. In 1666, the city of London was majorly decorated with brickwork structures. The majority of the skyscrapers in the United States of America use bricks or terracotta, “Bricks and blocks,” (2019).

The bricks consist of primarily five constituents, namely silica, alumina, lime, iron oxide and magnesia in different proportions. Each component has another purpose that forms the end product brick. Hence, it can be a great brick if its excellent properties such as the shape and size of the brick are uniform with straight and sharp edges, deep red with the surface texture being rough so that binding action with the mortar will be proper. The hardness should be so that no mark should be visible if nails scratch the brick, and it should make a clear metallic sound it pounded on each other, which indicates the soundness of the brick. Most importantly, the brick should not contain any impurities in the form of stones or grits, etc (Fig. 5).

Porotherm clay hollow blocks (“Bricks & blocks”, 2019)

Special types of bricks

The most common type of bricks for construction purposes are burnt clay bricks. Other types include fly ash bricks, solid concrete blocks, hollow blocks, heavy-duty bricks, perforated bricks, lightweight bricks and refractory bricks. The application of these bricks includes abutments, construction of bridges, heavy types of equipment works, etc. “The history of bricks and brickmaking,” (2017).

Porotherm clay hollow blocks are easy to use to construct partition walls or mainly for masonry infill walls consisting of clay, concrete, and coarse aggregates as components. Its crushing strength is about 4 N/mm2. It is available in different dimensions ranging from 4 to 8 inches. Compared to solid concrete blocks, Porotherm blocks are of 60% less weight and provide superior thermal insulation, BIS (1988).

Masonry construction

Masonry is a process of construction that utilises singular units, similar to brick and stone, bound along with mortar. Even though it is amazingly durable, masonry does, in any case, wear out after some time and is regularly needing repair or restoration.

Types of masonry construction

Masonry wall construction is of two types based on their function. They are load-bearing walls and non-load bearing walls. The walls that support no imposed load, i.e., vertical load except gravity loads, are called non-load bearing walls primarily used as interior partition walls (Fig. 6a). The walls designed to carry the superimposed load, including their self-weight, i.e., dead load, are load-bearing walls. These walls are generally helpful as exterior walls (Fig. 6b).

Functional requirement

A wall is used to enclose a space to provide privacy and good communication inside a house. Along with this, their secondary purposes include supporting the weight of the top storeys, providing security and protection against the weather. Walls can be classified based on their functions and placement in a building. Depending on the motor mix materials, there are various types of masonry walls used in building constructions as follows:

-

a)

Load-bearing masonry wall.

-

b)

Reinforced masonry wall.

-

c)

Hollow/Cavity masonry wall.

-

d)

Composite masonry wall.

-

e)

Post-tensioned masonry wall.

However, not going deep inside these details, the typical primary concern regarding any wall might be the failure under different loading conditions. The primary function of a non-load bearing wall is to carry the gravity loads, but instances occur where lateral loads act on these walls. In such circumstances, the walls will become vulnerable and might collapse drastically. As discussed in the following sections, the walls can be seismically strengthening or protected against lateral loads to prevent the walls from these failures.

Prevention of failures

The fundamental purpose of seismic strengthening is to enhance the overall structural performance and increase the resistance to deformation when subjected to lateral loadings. There are two safeguarding strategies for the masonry system against the effect of the earthquake. One is to protect the structure from the seismic forces, and the other is to enhance the strength of the existing systems to withstand seismic loads. The two ways of retrofitting a structure are by using additional components and additional adhesives.

Seismic analysis of the existing structure is proper if the soil under the construction is solid and stiff enough; then only, fewer seismic forces will transfer to the network.

Estimating the capacity of structure for strengthening is estimated by the structural engineers by considering the type of construction materials, loads acting on the structure and the geometric aspects of deteriorated structures. All kinds of failure modes must be in consideration during the strengthening process.

The selection of strengthening technique should be according to the design and condition of the existing structure, knowing the overall characteristics of the system in detail for the selection process of a particular strengthening method. The basic parameters such as deformation capacity, dissipating energy capacity, shear capacity, stiffness and strength properties are considered.

In addition to all these mentioned, other details include the foundation design, seismic zone and earthquake records in that zone.

Seismically strengthen the structure

Seismically strengthening the structure represents improving each member's strength, such as beam, columns and walls individually. There are various techniques to retrofit these members. The strengthening methods are two types based on the location of the strengthening material on the MIW: intrinsic and extrinsic. The former consists of dowel bars, vertical and horizontal reinforcement, and the centre core technique. In contrast, the latter consists of various methods such as Welded Wire Mesh (WWM), Fibre Reinforced Polymer (FRP) jacketing, Steel Bracing and Textile Reinforced Concrete (TRC). In this paper, retrofitting techniques for infill walls are discussed. The methods involved in retrofitting walls include structural fuse, repointing technique, centre core technique, Fibre Reinforced Polymer (FRP) and Textile Reinforced Mortar (TRM).

Repointing technique

This repointing technique is the most popular in the masonry wall field among the available traditional retrofitting infill walls. This method's general procedure follows to eradicate the defective portion and substitute those with similar elements to rehabilitate the previously lost strength of the wall. In such cases, this method is more productive when the mortar gets eroded over time or notches included in the bonds, Jaime et al. (2019).

The filling of the bed joint between the bricks in a brick wall is called the pointing method. This method accomplishes the ongoing work by disseminating the mortar in the bed joint with the masonry wall face or separately when the exterior part of the mortar in the bed joint was left broken. The primary factor contributing to the brick wall's aesthetic appearance is the pattern of the mortar joints, uniformity and the sequence of laying, significantly when the sizes of the bricks vary. The mortar joint contributes to the aesthetic aspect of a masonry wall. It favours keeping the structure dry mainly in two ways, i.e., by not letting the atmospheric moisture penetrate through the wall and allowing the already present humidity inside the wall to dissipate into the dry weather. There is the possibility that rainwater may penetrate the wall through the tiny cracks between the mortar joints and the bricks. The water must escape back into the environment after the rain stops to avoid moisture entering the wall. The best way to achieve this is through permeable mortar bed joints. If hardened cement mixes with the mortar, it may not release the moisture, and it may stagnate in the bricks, which hikes the chances of damage caused due to crystallisation of soluble salts, Chuang and Zhuge (2005).

The process of filling the exterior part of the bed joints where the old mortar should have got weathered out or become unsuitable is a repointing process. Repointing can improve the aesthetic appearance as well as the durability of the brick masonry. It may affect the brickwork if it is not done correctly, sometimes leading to unrecoverable damage. It is needed most on the exposed face of the brick wall of the structure. The principle of the repointing technique is that the bed joint mortar should be a little weaker than the bricks. Suppose the mortar is more complicated than the brick masonry as such in cement mortars. In that case, the wall is in the danger zone where the permeability is allowed correctly, preventing the moisture content from drying out through the bed joints. Due to this, cement-based mortars started declining; instead, lime-based mortars can be beneficial, strictly following the principle. The types of mortars that can be advantageous for the repointing techniques are lime-based mortars and cement-rich mortars. Two types of lime are easy to use in mortars, i.e., non-hydraulic lime and natural hydraulic lime. After completing the repointing process (Fig. 7), the wall is safeguarded from temperature variations such as rain, sunlight, and heavy winds to prevent any damage. It should be maintained under damp conditions using jute bags or thick mats for allowing the mortar to set. Finally, the cannon is ready for the final step, finishing while still in damp condition. Proper maintenance is necessary until the curing of mortar is complete enough to resist any damage by the variation in temperature.

Centre core technique

This technique follows a method in which holes (cores) are drilled vertically along the height through the already built masonry brick wall through which reinforcement bars are embedded through the brick wall into the basement of the wall as shown in the Fig. 8. The diameter of this core varies between 100 to 150 mm depending on the type and size of the wall. The centre is made using the oil-well drilling technique. This dry process may release large debris that can be removed manually or using any mechanical instrument such as a vacuum cleaner. The most common reinforcement used is solid steel bars placed at the centre of the drilled hole and usually filled with a pump using sand-grout throughout the cavity under pressure. This technique will help in filling out the voids along with the height of the drilled core. The bonding between the inner surface of the grout with the rebar and the outer surface of the grout to the masonry makes it a homogeneous compound better than the core itself. This method helps the masonry infill wall to resist both the in-plane loading and the out-of-plane loading. This method has many advantages rather than disadvantages; for example, this process creates a minimum amount of disturbance during the process. The geometry of the wall is not changed overall since it is one of the non-destructive testing methods (Breiholz, 2000).

Centre core technique (Breiholz, 2000)

Fibre reinforced polymer (FRP)

Many existing structures built with masonry are vulnerable to seismic forces in the in-plane and out-of-plane directions. Hence, these structures need retrofitting to resist these loads to avoid damage or collapse, resulting in property loss or life loss. Available techniques for strengthening masonry infills are more often uneconomic as well as time-consuming. All these limitations led to developing other methods such as fibre reinforced polymer (FRP) strengthening material. Due to its light-weight nature and minor time-consuming procedure, it has gained significant popularity. FRP is available in many types and many forms as well. The different fibres available are carbon fibre, glass fibre, basalt fibre in various forms, such as chopped fibres and woven fibres, (“SHODHGANGA—Chapter 1—Adhesive” xxxx).

Fibre Reinforced Polymers (FRP) has broad applications, including aerospace, automotive, marine, and construction industries. FRP is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass, carbon, or aramid, although other fibres such as paper, wood, or asbestos were sometimes functional. The polymer is usually an epoxy, vinyl ester or polyester thermosetting plastic, and phenol–formaldehyde resins are still available. As shown in Fig. 9 the applicability of FRP to concrete or masonry structures as a substitute for steel bars or pre-stressing tendons has been actively studied in numerous research laboratories and professional organisations worldwide. FRP strengthening offers several advantages as follows: corrosion resistance, nonmagnetic properties, high tensile strength, lightweight and ease of handling. However, they generally have a linear elastic response in tension up to failure (described as a brittle failure) and a relatively inferior transverse or shear resistance, “Bricks and blocks,” (2019). They also have poor resistance to fire and when exposed to high temperatures. They lose significant strength upon bending, and they are sensitive to stress-rupture effects. Moreover, their cost, whether considered per unit weight or based on force carrying capacity, is high compared to conventional steel reinforcing bars or pre-stressing tendons. One of the disadvantages of using FRP solutions is the high costs associated, which turns this solution impracticable for the large majority of the building’s owners, Shrivastava and Gupta (2009).

FRP wrapping around MIW (Elsanadedy et al., Dec. 2016)

Textile reinforced mortar (TRM)

It is known as Textile Reinforced Mortar (TRM) or [Fiber Reinforced Cementitious Matrix (FRCM) or Textile Reinforced Concrete (TRC), in International Literature (Fig. 10)]. It is a newly developed material in which multi-axial fabrics are helpful in combination with fine-grained concrete. The new FRCM externally bonded Composite Strengthening System combines high-performance sprayable mortar with any fibre grid that creates a thin structural layer without significantly increasing the structure's weight or volume (Naaman, 2010).

TRM wrapped around MIW Koutas and Bournas (2019)

TRC is being built as a revolutionary alternative to the steel skeleton, giving Reinforced Concrete (RC) stability. Carbon fibres are too soft to add directly to concrete, so they apply a coating to stiffen after being woven together. The fibres in the weave are adjusted for maximum tenacity to perform optimally in the concrete. These individual fibres form the basis of the concrete: up to 50,000, are combined to create a yarn. It is then processed on an automated loom to produce woven mesh. The new concrete's textile interior emerges from a myriad of fine threads. Another coating is put into the mesh that increases stability. After few minutes, the piece is cut to the required length (Naaman, 2010).

Earthquake-resistant structures are structures designed to protect buildings from earthquakes. While no structure can be entirely immune to damage from earthquakes, the goal of earthquake-resistant construction is to erect structures that fare better during seismic activity than their conventional counterparts. According to Code and Commentary IS: 1893 (Part 1) (1893), masonry infills hold considerable in-plane stiffness and strength and contribute to the overall stiffness and stability. The infills show a lesser effect on the structure if openings are present. However, these infills pose the hazard of out-of-plane collapse, which means the loss of life should be minimal by preventing the destruction of the buildings for rare earthquakes, while the loss of functionality should limit to more frequent ones. Strengthening RC frame structures generally increases the resistance and deformation capacity of the frame itself for the system to satisfy the levels of performance according to the codal provisions. Another possible way to improve the resistance of existing structures under lateral loads is to convert the infill walls into a more stable source of resistance over the whole spectrum of structural response through a significant and indemnified contribution to the structure's strength/stiffness (Curbach & Jesse, 2018).

Research and development on masonry structures

Research on masonry infill walls is not a contemporary topic as it was started a few decades back and is still continuing (Table 2).

Dividing the broad area of masonry

The construction of masonry walls is in two different ways. One method includes filling up the space between columns with walls in which openings such as doors, windows or ventilators are optional. This method is known as masonry infill walls (Fig. 11). In the second method, the brick wall is constructed first by leaving some gap to construct vertical compression members, called tie columns joined with tie beams. The second method of construction is known as confined masonry walls (Fig. 12). In this article, the research and development of masonry infill walls are discussed in the following sections (Table 3).

Experimental work

Researchers performed and are still performing several experiments to investigate the effect of numerous parameters on the performance of reinforced concrete masonry infill frames. Fifty references are considered and segregated year-wise, from recent publication to the oldest (1979 to 2021) and summarised in tabular form as given in Table 4.

Sinha et al. (1979) (Lateral strength o f model brickwork panels) conducted tests on brickwork panels with various aspect ratios (L/H = 0.5–2), boundary conditions supported on top and bottom and continuous on one or both ends. They also investigated the elastic properties that confirmed the nature of brickwork is orthotropic. In addition, results suggested that the flexural capacity of brickwork increases up to 44% by vertical joint filling. The two loading directions are shown in Fig. 13.

Test arrangements for the determination of flexural strengths in two directions (“Lateral strength o f model brickwork panels”. 1979)

Drysdale’ and. Essawy, (1988) tested 21 full-scale MIW with concrete blocks by applying UDL perpendicular to the wall plane with simple support conditions on four sides of the border, i.e., on bottom and top on base and two sides, only on two sides. The bending strength used was extracted from the results of the tests in which bending strength used was removed from the test performed on masonry assemblages. Load for initial cracking and failure load were examined. Both the elastic finite-element plate analysis and the yield-line analyses provide quite good predictions of failure pressure. Figure 14a shows the stack-bonded prism for flexural tests normal to the bed joint using Bond wrench test setup as shown in Fig. 14b.

Flexure normal to bed joint (Drysdale’ & Essawy, 1988)

Ehsani et al. (1999) investigated 3 URM infill walls retrofitted with composite strips with five reinforcement ratios & 2 different glass fabric composite densities by applying OOP cyclic loading. When widens and lighter blended fabrics are helpful, tensile failure controls the mode of failure, whereas stronger ones are fruitful, governed by delamination. Results concluded that URM walls retrofitted with composite strips are effective alternate strengthening techniques. Papanicolaou et al. (2008) compared the performance of TRM overlays and FRP overlays as a strengthening material or NSM reinforcements. Many studies in the past considered parameters such as motor-based vs resin-based matrix materials, the number of layers of TRC, the orientation of moment vector concerning bed joints and concluded that TRM is advantageous over FRP in terms of strength & deformability. In other words, TRM is a promising solution for strengthening MIW under OOP. The testing frame consisted of two similar loading frames, one in the north face and the other in the south face. The tensile failure observed during the experiment can be seen in Fig. 15a and the delamination in Fig. 15b.

a Cracking and delamination pattern at failure on north face. b Tensile failure of GFRP strips on south face (Papanicolaou et al., 2008)

Hak et al., (2014) constructed an external MIW with tongue and groove clay block to understand the seismic performance in the OOP orientation, mainly in terms of failure, mechanical and damage propagation and OOP strength. The masonry unit used in the experimental tests is shown in Fig. 16, along with the dimensions. It has been determined that resistance mechanism formed with respect to two-directional arching action.

Tongue and groove clay masonry blocks (Hak et al., 2014)

Babaeidarabad et al., (2013) conducted OOP experimental tests on nine clay brick MIW in which three specimens were without strengthening and six were with strengthening, with FRCM having one and four reinforcement fabrics (Fig. 22a–c), which proved that it strengthened walls. The behaviour of the infill wall both in terms of stiffness and flexural capacity was in significant improvement. Also neglecting the arching effect, an analysis was carried out, and the output was compared with experimental data. Elsanadedy et al., (2016) conducted experimental and analytical study on the OOP flexural performance of URM infill walls externally bonded with GFRP composites. For this study, six hollow concrete block-cyclic walls were loaded to failure using an airbag and a loading frame to obtain uniform loading by considering FRP reinforcement ratio and stiffness as main parameters. The conclusion derived was that FRP effectively enhances the load-carrying capacity, the load-carrying capacity,and the OOP deformation capacity of URM walls (Fig. 17).

Application of FRCM onto the masonry infill wall S. Babaeidarabad et al. (2013)

Gattesco and Boem (2017) examined the OOP bending effectiveness of GFRP meshes applied on both faces of the existing MIW by carrying out both experimental and numerical studies. For this, 4-point bending load was used on the full-scale MIW as shown in Fig. 18a and b. Constructing three masonry types is solid brick, rubber stone, cobblestones. The conclusion stated that the strengthening technique enhanced the OOP bending moments by 4–5 times the specimen without strengthening. Moreover, numerical results were in good agreement with the experimental results that determined the accuracy of the simulations.

Experimental apparatus for bending tests (Elsanadedy et al., 2016)

In Fig. 19, the numerical results of RM specimens are plotted in addition to the experimental curves referred to as both RM and URM specimens. Both the first cracking and the GFRP wire’s rupture occurred at the height of the upper horizontal force. In solid brick (Fig. 19b) and rubble stone (Fig. 19c) RM cases, the cracking and the ultimate resistance points were estimated accurately. Also, the cobblestones RM specimen (Fig. 19d) evidenced a trend like the experimental one up to the occurrence of the first crack, but then the numerical curve prosecuted with a lower slope and a lower value of maximum load was reached. This aspect is probably due to the marked irregularity of the coating thickness. The cobblestone masonry surface was significantly uneven due to the round and irregular shape of the stone units. This aspect may alternate the tension stiffening effect of the mortar between cracks. Shermi and Dubey (2017) tested 6 URM walls & 18 reinforcements masonry panels applying 3-point loading as per ASTM E518-10 to investigate OOP performance of both URM and WWM URM were strengthened using high strength mortar (1: 4), low strength (1: 6) and WWM of different spacing (25, 38, 50 mm) WWM increased the flexural strength & ductility of masonry. Kariou et al., (2018) suggested TRM has a significant effect on the load-carrying capacity of MIW by testing 18 specimens divided in equal numbers into single-wythe and double-wythe walls, investigating key parameters such as textile reinforcement ratio, textile material, and textile material coating of textile reinforcements with epoxy resin and the wall thickness. The different textiles used for this study is shown in Fig. 20.

Out of plane bending tests: horizontal load, P against deflection d curves of (Gattesco & Boem, 2017)

Textiles used in this study (Kariou et al., 2018)

Furtado et al., (2018) presented a systematic review of the experimental OOP tests grouped into the following three categories: built specimens, specimens within plane damage and retrofitted specimens. According to the masonry and in-plane drifts, to predict the OOP capacity of the infill panel, empirical equations were proposed. The parallel flexural strength parallel to the horizontal bed joints increases the OOP capacity by five times. D’Ambra et al., (2018) performed experiments on full-scale clay infill wall strengthened with basalt grid with inorganic matrix (FRCM) used to strengthen pre-damaged walls and constructed walls to study the effectiveness of FRCM to regain the capacity of pre-damaged wall and to enhance the overall performance of a non-damaged wall. Fagone and Ranocchiai (2018) described the mechanical performance of MIW strengthened with CFRP sheets, subjected to OOP loads, particularly the effect of spike anchors on the reinforcement’s load-bearing capacity and energy dissipation capacity which significantly increased. Padalu et al., (2018) tested 8 URM and 28 strengthened wallets using WWM in perpendicular orientation under 2-point OOP loading. The parameters considered are loading direction, i.e., perpendicular and parallel to the bed joints (Fig. 21), reinforcement ratio and effect of shear span. The results displayed that the WWM increases Wallette's flexural capacity by 9.4 times, over by 61 times and energy absorption capacity by 1024 times compared to URM wallets without strengthening. Di Domenico et al. (2020) presented the OOP response of URM walls by conducting pseudo-static tests to observe the effects of BC in terms of stiffness, strength & displacement capacity with one specimen being mortared on four edges to the bounding RC flame, another model with a gap of 2 mm between the upper edge & beam & the other final one being restrained to the bounding frame only on the upper & lower edges. OOP response during the test experienced also vertical arching.

Details of specimen geometry and strengthening components: strengthened Wallette—bending tension perpendicular to bed joints and parallel to bed joints (Padalu et al., 2018)

Pourfalah and Cotsovos (2020) ECC to enhance the out of plane strength of URM walls subjected to impact loading, ECC layers were fully bonded to the surface. The results revealed that the application of ECC increased the out of a plane performance of MIW subjected to blasts or impact loads and enhanced the strength, ductility and deformability of the MIW by acting as a mesh to prevent debris due to impact load. Al-Jaberi et al., (2019) tested 12 reinforcements MIW constructed with fully grouted concrete masonry units with different amounts of steel reinforcement strengthened with wet layup GFRP and prefabricated carbon FRP and showed the efficacy of FRP as an externally bonded strengthening material in increasing the capacity of MIW in flexure. Verderame et al., (2019) performed experiments on URM and RM infill frames by using OOP lateral loading. These specimens are compared with the other two models, which were strengthened using FRCM and FRP. The results showed that the FRCM boosted with FRCM gave three times the strength, whereas FRP gave two times the strength of the specimen without supporting. da Porto et al. (2020) examined eight whole scales, one bay, one storey MIW RC framed under combined IP/OOP tests conducted on robust clay infill frames and presented the overview of the results obtained from the same. Among eight frames, in four cases, two were constructed of URM and the other two were of RM, i.e. both horizontal and vertical reinforcements. In addition, other four instances of the same configuration, but with openings at the centre and one with lintel, were considered. Further, analytical models were also carried out based on the arcing mechanism. Anić et al. (2021) used non-contact optical techniques for measuring the contour strains and deformation of RC Frames with MIW with and without openings subjecting it to cyclic OOP lateral load for the investigation. The results showed that neither the infills nor the spaces affected the specimen’s overall behaviour. However, it was also found that infills were damaged with storey drift of 1.25–2.5%, which imparts the risk to the occupants' life. Also, infills with eccentric openings suffered further damage than full infill frames without frames’ opening. Finally, the presence of infill could influence the overall combined in-plane performance of the structure.

When subjected to seismic loads, RC frames with brick infill display undesirable failures such as short-column, soft-storey, torsion and out-of-plane collapse. To overcome these effects, C. Murty and Jain (2000) have carried out experimental tests on RC frames subjected to cyclic tests and concluded that infills increase the lateral stiffness, strength, ductility, and energy dissipation capacity. The test setup adopted by the authors is shown in the Fig. 22.

The geometry of frames tested, Murty and Jain (2000)

Chiou et al., (2000) tested three full-scale specimens—a bare RC frame, an RC frame constructed with partial infill and an RC frame filled with brick wall subjecting them to in-plane monotonic loading and carried out the numerical study using DDA considering the concrete and mortar failure to investigate both tensile and shear failure where the latter is assumed to follow Mohr–Coulomb criterion. Observations put forth that the partial infill wall induced a short column effect and was the reason for severe column failure. However, the filled wall helped in increasing the stiffness of the structure. Elgawady (2004) FRP is a technique to strengthen the MIW instead of approaching conventional methods due to its apparent advantages such as economic, less specific weight, no corrosion and high tensile strength. They focussed on the in-plane performance of URM walls retrofitted with FRP. Different parameters considered were another effective moment or shear ratios of 0.5, 0.7 and 1.4, fibre type considered are aramid, glass, carbon hardwires, reinforcement ratio from 0.07% to 0.28% fibre. Results displayed that the lateral resistance depends on reinforcement ratio, specific aspect ratio and fibre characteristics. In contrast, the ultimate drifts were independent of reinforcement ratio and reinforcement type but dependent on aspect ratio and retrofitting configuration. Since past earthquake events in Turkey have damaged many reinforced concrete structures, investigations on strengthening methods for MIW have increased. Two strengthening methods were adopted by the Erdem et al., (2006) in this study: one of the frames was strengthened with reinforced concrete infill, and the other was an RC frame using hollow clay blocks (Fig. 23) strengthened with CFRP considering Strength, stiffness, and storey drifts of the test specimens as variables. Observations concluded that both the strengthening techniques were performed when subjected to reversed cyclic lateral loading.

Dimensions of the hollow clay block (Erdem et al., 2006)

The bare frames were strengthened with partial infills and tested under lateral cyclic loading considering the parameters such as the aspect ratio of the infill wall and the configuration placement. The test output concluded that the frame with partial infills exhibited higher ultimate strength and initial stiffness than the bare frame. Also, both the lateral capacity and the rigidity were increased with the increase in the aspect ratio of the infill wall. In addition to that, the connection between column and beam to the partial infill wall exhibited the best behaviour Anil and Altin (2007). One-storey, one bay 1/3rd scale masonry infill RC frames constructed with perforated clay brick infills have been strengthened using CFRP strips and subjected to lateral cyclic loading to investigate the same performance. The adopted aspect ratio for the frame is 1.73. The CFRP is placed in three different arrangements. They are on both sides of the wall, on the walls' interior side and exterior side. The parameters studied are the additional width of CFRP (Fig. 24) and the arrangement on the MIRCF. CFRP considerably increased the strength and stiffness of the perforated clay brick infill wall. Those symmetrically strengthened specimens showed better performance in terms of lateral stability and stiffness; Altin et al., (2008).

CFRP strip configuration used in specimens (Altin et al., 2008)

Agarwal and Thakkar (2004) used a different strengthening approach and retrofitting method to study the performance of MIW under quasi-static cyclic loading test. The strengthening technique used is the horizontal bond beam placed at the sill and lintel levels combined with vertical reinforcement at corners and openings. The retrofitting methods used are epoxy-sand-mortar and cement-grout injection with WWM in the cracked region. The retrofitting technique for cracked areas was effective to regain initial strength, stiffness and deformation capacity. The use of WWM helped in recovering the ultimate strength; however, we can observe brittle failure. Altin et al., (2010) added a plaster layer with mesh reinforcement to strengthen the masonry infill to one face of the wall and studied the same performance. Studies showed a satisfying increment in terms of lateral strength and stiffness. However, premature failure occurred in one of the specimens due to the dowel bars' inadequate bonding to transfer shear loads from the frame to the plaster. The best lateral performance was attained from the test specimen in which a mesh-reinforced high-strength plaster layer was applied. Sigmund et al., (2010) put forward the results depicting the relation between the drift capacity and the wall-frame system properties controlling the drift capacity by modelling frames according to EC-8, in a scale of 1:2.5, constructed with three masonry types with standard materials and procedures followed in Croatia subjected to constant vertical and cyclic horizontal loading which concluded that the load-carrying capacity of the structure depends on the type of infill that brings on the increment of 5 to 25%. Zovkić et al., (2013) constructed in full 10 RC infill frames with different types of masonry blocks, among which three frames erected with high strength hollow clay blocks, three shelves with medium strength HCB, three shelves with low strength lightweight AAC blocks and one additional being bare RC frame, all of which were subjected to constant vertical and constant lateral loading. The final results displayed a significant increase in the energy dissipation capacity and maximum lateral load-carrying capacity. However, the deformation capacity remained the same. Grubišić and Sigmund (2014) studied the contribution of strengthening methods of the MIW weak and strong frames on which researchers concentrated less. These MIW were constructed using two kinds of infills, i.e., solid and hollow block units with other properties similar to Croatia. Observations have shown that, under cyclic excitation, the displacement and stiffness response is directly affected by the presence of infill walls. The strengthening technique moderately increases the maximum load-carrying capacity and has a rare loss in the lateral stiffness in the high deformation vicinity. Finally, the infills with solid bricks have much higher energy dissipation than the infills with hollow bricks. Kauffman and Memari (2014) studied the performance of structural fuse with various masonry materials subjected to cyclic loads applied by displacement-controlled loads at the first three storeys of 2 bay, three-storey steel frame with infill brick walls, and 1st mode response in the system quasi-static load was used. The parameters considered were bricks used for infills for concrete masonry units, and autoclaved aerated concrete blocks. Sadeghi Marzaleh (2015) studied the use of a post-tensioning system for residential masonry as a seismic rehabilitation method against seismic events. Also identified the lack of shear resistance in URM walls and implemented post-tensioning to overcome it following the Merkblatt SIA 2008 “Assessment of existing”. Abdel-Hafez et al., (2015) used GFRP sheets steel rebar impeded in frame, plastering and ferrocement as strengthening material to improve the behaviour of URM tested under in-plane lateral load. This MIW improved characteristics such as drift toughness ductility and failure load. They recommended the ferrocement method for the improvement of ductility and ultimate failure load of existing frames.

Jiang et al., (2015) performed full-scale reversed cyclic in-plane and oop test on URM walls strengthened with polymer TRM, which were constructed using vintage solid clay bricks and low-strength hydraulic cement mortar to repeat the similar properties of ancient masonry material. The observations concluded that the strength increased up to 128% to 136% when URM was tested in-plane loads and 575% to 789% under OOP loading. Ismail and Ingham (2016) examined the in-plane responses of masonry prisms constructed using cement lime mortars (bastards) by conducting compression, shear and tension test. In addition, experiments and numerical investigation were carried out to study the in-plane characteristics of BM prepared with ancient motors, which includes mud, lime- mud and land- sand; Abaqus FEM was used to model the old masonry structure were the results displaced in unity with the test. Rahgozar and Hosseini (2017) conducted experiments on MIRCF with 1:2 scale considering variables such as wall/frame stiffness ratio, use of configuration elements and horizontal reinforcement and found out that the cracking strength of the wall and the maximum shear strength of the structure is affected by the wall/ frame Stiffness ratio. The effect of horizontal reinforcement is dependent on the stiffness ratio. The final parameter confining elements does not contribute much to the lateral strength or displacement. However, the structure's capacity increases the oop stability of the wall and the bond between wall and frame. Leal et al., (2017) presented a literature survey on the performance of MIW during seismic actions. If the gaps are not provided between the frame and the wall, the stiffness will be high. If the holes are present, damage probability considerably reduces; however, the benefit of increment in strength and stiffness of the infill wall will be lost. Ismail et al., (2018a) tested the performance of 9 2/3 rd scale non—ductile reinforced infill frames with hollow concrete masonry infill strengthened with FRCM subjecting it to cyclic in-plane loading one specimen built without infill and second specimen made with infill but without reinforcing. All models were retrofitted with three different fibre grids, namely basalt, glass and carbon, and three different configurations for retrofitting. A full-scale diagonal band with varying widths finally indicated that frames strengthened with diagonal bars were most effective. In contrast, carbon fibre possessed greater strength than other fabrics, but carbon exhibited the lowest strength for RCFMI. Carried out surveys in China on Wenchuan Eq. (2008) and Dushan Eq. (2013) and provided details on the failure modes of MIW exposed to the equation and sudden damage of MIW due to unplanned arrangement in a building. They also concluded elastoplastic—time—history analyses for ten models based on damaged structures in the Wenchuan equation, concluding that the analytical results match the original failure of the building; however, the work was varying when the vibration period was reduced due to the increase in the stiffness of the structure contributed by MIW. F. Akhoundi, G et al. (2018) ( 2018) conducted experiments on 7 MIWs subjecting them to in-plane static tests to observe the cyclic -in-plane behaviour of convectional brick infills constructed in Portugal, ultimately arriving at the conclusion stating the infills present inside the bare frame increased both the in-plane systems and resistance and TRM improved the lateral strength and reduced the damage of MIW. Ismail et al. (Ismail et al., 2018b) presented an overview expertly conducted on the efficiency of three kinds of FRCM, namely basalt, carbon and glass, to resist the critical shear damage in unreinforced Hollow Concrete Block (HCB) masonry of two types (200 mm and150 mm thickness) which altered the failure mode from sliding bed joint brittle mode to gradual diagonal cracking on toe crushing. Observations indicated that FRCM rupture and debonding did not occur. In addition, other parameters such as shear strength, toughness modulus and energy deformation capacity considerably increased with FRCM. Nasiri (2019) investigated experimentally and numerically the in-plane and out of plane performance and strength of MIW and advanced simulation using finite element technique and provided a rational design method for out of plane behaviour of MIW; however, significant residue can be observed damaged infill that touched the peak in-plane capacity. C. Liu et al. (2019) recycled concrete hollow block (RCHB) to be used for the masonry structure with seismic requirements considering the primary parameters such as the effect of the axial compression stress, aspect ratio, and the materials of structural columns on the seismic performance. Results concluded that with the increase of aspect ratios, the ductility of RCHB masonry walls increased, but the horizontal bearing capacity and energy dissipation of RCHB masonry walls decreased. Dautaj et al. (2019) carried out an experimental study on five MIRC frames with different upper and lower storey heights of MIW to determine the shear resistance capacity using a newly proposed method which offers a promising approach to design RC infill frames. Maheri et al. (2019) used results of in-plane tests conducted on URM constructed by replacing conventional bricks with hollow concrete block masonry with RC layers to carry out pushover analysis which revealed that the response has the effect of Boundary Conditions. Niasar et al. (2020) tested the efficacy of ECC on URM under in-plane loading by constructing three specimens among which the first one is reference wall, second one is strengthened with ECC, and the third was damaged and then retrofitted with ECC as in the case of the previous specimen and observed a hike in terms of energy dissipation capacity and shear strength in the second specimen and 115% and 330% in the third specimen. Lu and Zha (2021) constructed Resilient Infill Wall (RIW) as shown in Fig. 25 whose performance was enhanced by using metal connectors and conducted cyclic in-plane tests to compare the damage evolution and hysteric performance of the same and successfully concluded that the understanding of RIW is much better in terms of initial stiffness, storey drift ratios and has been shown deterioration of strength.

Sketch of the proposed RIW Lu and Zha (2021) (2021)

Numerical work

Several numerical investigations were performed to investigate the effect of numerous parameters on the performance of reinforced concrete masonry infill frames. The references are segregated year-wise, from recent publication to the oldest (1987 to 2021) and summarized in tabular form in Table 5.

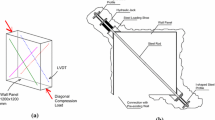

Madan et al., (1997) the development of the hysteretic model and the definitions of the control parameters, which can be determined using any suitable theoretical model for masonry infills, has been done. The proposed macro-model is better suited for representing the behaviour of infills in nonlinear time history analysis of large or complex structures with multiple components, particularly in cases where the focus is on evaluating the inelastic structural response. The stress–strain relationship for masonry in compression, as shown in Fig. 26, used to determine the strength envelope of the equivalent strut, can be idealized by a polynomial function.

Adopted constitutive model for masonry Madan et al. (1997)

Mehrabi and Benson Shing (2003) the experimental results are concisely summarized, and a constitutive model is presented for general modelling of masonry mortar joints and cementitious interfaces. The models eventually can be used for numerical parametric studies to extrapolate existing experimental results to develop comprehensive design guidelines. Kaushik et al. (2017) adopted a linear regression analysis; an elementary analytical model has been suggested for accessing the stress–strain curves for masonry that can be adopted in the research and design procedures. The governing points attained from the analysis can be utilized to limit states for masonry material and members. Al-Chaar (2008) proposed the mode of infilled frames is summarized to actuate essential conditions that must be deliberated and considered. In any case, it is implied that for the successful operation of any F.E. program to infilled frames, the model properties must be evaluated using appropriate material level and structural-level experimental results. Author et al. (2009) proposed a proper model be invented using explicit FEM to study the behaviour of EBFs (Eccentrically Braced Frames) with an infilled masonry wall. The single brick wall and EBF with infilled wall were made, and these models (Fig. 27) were analysed by the explicit finite element method. The software used in this study was Diana. Three different models were examined, by maximizing kinetic energy. The stifness of the braced frames with infill walls showed better yield strength but on the other hand the frame deteriorated due to plastic behaviour (Table 6).

Deformed shape and stress contour for frame with weak infill, analysis using Al-Chaar (2008) (2008)

Haach et al. (2010) proposed an innovative system for reinforced concrete masonry walls based on the combination of vertical and horizontal trussed reinforcement is proposed. The mechanical characterization of the seismic behaviour of such reinforced masonry walls is based on static cyclic tests carried out on panels with appropriate geometry. The results stressed that the increase in the pre-compression level leads to a stiffer and more brittle lateral behaviour of the masonry walls (Fig. 28).

Finite element model of the eccentrically braced frame (Author et al., 2009)

Stavridis and Shing (2010) proposed the initiation of nonlinear FEM models for determining the seismic performance of these structures has been dealt with in this. The suggested modelling technique can apprehend the different failure mechanisms and also the load–displacement responses displayed by infilled R.C. frames. Koutromanos et al. (2011) in this study, nonlinear finite element models have been used to simulate the behaviour of masonry infilled reinforced concrete frames under cyclic lateral loading. The finite element models presented here can accurately reproduce the infilled frames’ load–displacement response, crack patterns, and failure mechanisms. Smeared-crack elements have a stress locking issue that does not permit appropriate shear cracks displaying and can prompt un-conservative outcomes. This issue can be evaded using zero-thickness cohesive interface elements to display shear cracks in a discrete design. To accomplish the mentioned issue without prior information of the areas and directions of the breaks, every quadrilateral component can be supplanted with a module of four triangular smeared-crack elements associated with four, diagonal set, twofold noded, interface components, as outlined in Fig. 29. Each module is associated with the adjoining modules with level and vertical interface components. With this lattice, discrete breaks can create at points of 0°, 90°, and ± θ, where θ can be near 45° to address askew shear breaks. The presentation of discrete breaks does not just eliminate the undesired stress locking under shear yet in addition mitigates the mesh-size sensitivity problem, which is notable for smeared-crack models. A discretization model based on the above discussion is shown in Fig. 30 in which each masonry unit is modelled with two rectangular continuum elements that are interconnected with a vertical interface element. The latter allows for the tensile splitting of the brick units and the relative sliding motion in a fractured unit (Figs. 31, 32, 33).

Finite-element discretization of RC members, Koutromanos et al. (2011)

Finite-element discretization of masonry infill, Koutromanos et al. (2011)

Discretization scheme employed in finite element models, Koutromanos et al. (2011)

Dynamic magnification factors for single and multiple TSWDs Rai et al. (2011)

A beam element subjected to shear and axial deformation (Mallick and Garg 1971))

Rai et al. (2011) proposed an existing masonry infilled R.C. framed structure that can be retrofitted for better rendering under seismic loading by the structural response control methodology using tuned sloshing water dampers (TSWDs) (Fig. 34, 35). The advised retrofitting system will ensure a more regular masonry infilled R.C. structure during ground motion. The mass, stiffness and damping ratio of the structure vary depending on various factors such as constructional and utility, cross-sectional and elastic properties of the construction material and the nature of loading and deformation. These approximations are carried over to the structure’s estimated response, leading to an inaccurate design of TSWD (Figs. 36, 37). This complication may be lectured by amplifying the concept of multiple mass dampers (MMDs) to TSWD (Fig. 38).

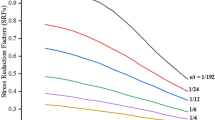

Crisafulli et al., (2000) represented a masonry panel using six strut members located in the panel’s diagonal direction, whereas the R.C. members are embraced with a column macro-element. The main advantages of the model are the capacity to predict not only the stiffness and strength of the structure but also to represent the influence of the masonry panel on the surrounding frame. Zhai et al. (Zhai et al., 2012) (Torrisi & Crisafulli, 2011) proposed an isolated F.E. model for the investigation of out of plane code of the infill wall is established using 3-D elements with deterioration plasticity material model and the surface-dependent contact cohesive cooperation model simulating the assemblage between blocks. Meillyta (2012) aimed to investigate the behaviour of URM wall with openings when horizontal load acted on it and developed load–drift relationship of the wall. The finite element (F.E.) method was chosen to simulate the behaviour of URM with openings numerically. Results showed that the finite model could well capture the behaviour of the URM wall with doors. (Fiore et al., 2012) (Meillyta, 2012). This finite element analysis is performed comparing the results to the experimental data to evaluate the local effects on the frame and underline the influence of the Coefficient of friction at the infill frame interface. In high seismicity, the method is reliable since the increasing horizontal load does not significantly influence the position of the resultant contact forces at each interface (Kai et al., 2013) (Fiore et al., 2012). Robust seismic analysis and optimum spectral displacement assessment of low-rise masonry infilled reinforced concrete buildings presented a coefficient-based method. The coefficient-based process does not require a FEM analysis. It is a favourably simplified, quick non-automatic procedure for evaluating buildings’ spectral accelerations and displacements for a given inter-story drift ratio. Mohyeddin et al. (2013) (Kai et al., 2013) proposed a detailed presentation of a generic three-dimensional discrete finite element model that has been constructed for reinforced concrete frames with masonry infill using ANSYS has been done. The proposed strut model would apply to the analysis of infill-frames well beyond the very early stages of lateral loading. Nazief (Mohyeddin et al., 2013) proposed a finite element (F.E.) technique to model masonry infilled frames using the simplified micro modelling approach. From this, it is observed that the best location for an opening in an infill wall is where the interference with the developed compression strut is minimum. Chen and Liu (2015) (Nazief, 2014) executed to investigate the in-plane behaviour of masonry infills constrained by steel frames, focusing on the infills with openings. It came out that the model used as a single-frame configuration, its applicability to multi-storey multi-bay infilled frames needs further investigation. Karimi et al. (2016) (Chen & Liu Jan., 2015) in this learning, an infilled masonry wall and an arched masonry wall with clay bricks and clay and gypsum mortar are correlated. Their seismic behaviours are verified under cyclic loading. The results from the analysis illustrated that the concrete damaged plasticity model could simulate the cyclic behaviour of masonry walls. Chungman et al. (2016) (Karimi et al., 2016) in this research, F.E. analyses of masonry infilled frames using a general-purpose F.E. program, ABAQUS, were performed. Analysis models comprised of the bare frame infilled structures with masonry wall thickness. Deng and Sun (2016) (Chungman et al., 2016) proposed a finite element simulation method by ABAQUS is used to ascertain an empirical formula to examine the behaviour of equivalent bracing walls and the frame columns. It was denoted through the outcomes that the reliable finite element method was consistent with the actual empirical data (Maidiawati and Sanada 2017) (Deng & Sun, 2016). The intended analytical model put back masonry infill with a diagonal compression strut, delineating distributed compression assigned between frame and infill interfaces. The brick infill notably amplified the strength of the surviving building and may have averted its total disintegration during the earthquakes. Wang et al. (2016) (Maidiawati & Y. Sanada, 2017) proposed an investigation to experimentally demonstrate the performance of masonry walls with conventional concrete columns & FEM models prepared to know the seismic response. It was instituted that FEM simulations cannot replace laboratory testing.

Nasiri and Liu (2017) (Wang et al., 2017) proposed an attributed study concerned with developing a numerical model for simulating the nonlinear behaviour of the concrete masonry infilled R.C. frames subjected to in-plane lateral loading. The ABAQUS FEM software was incorporated in the modelling. FEM results of this study conveyed that the dilatancy of mortar should be considered in the numerical models. Shawkat and Rahman (2017) (Nasiri & Liu Jul., 2017) focused on the evaluation of infill walls’ contribution to the seismic performance of R.C. frames. A numerical model of the infill wall is developed to evaluate its contribution to the seismic performance of the R.C. frame under earthquakes. The finite element model proposed in this work using the elements of ABAQUS with the micro-modelling of the infill wall accurately predicted the behaviour and damage sequence of the R.C. frame and the infill walls under earthquake. Khatiwada and Jiang (Shawkat & Rahman, 2017) utilized the commercialized software ABAQUS to simulate the in-plane seismic behaviour of infilled R.C. frame and validated using the available experimental results. Simulated force–displacement curve and crack patterns displayed satisfactory consensus with the practical work. Abbas and Saeed (Abbas & Saeed, 2017) (Khatiwada & Jiang, 2017) the main objective of this research assesses masonry wall modelling using the representation techniques acquired and use the suitable approach to exhibit masonry room using the ABAQUS software under the seismic load. The use of macro modelling is used in large scale models to save time and effort. Its result is definitive for its excellent approximation with micro modelling and uncomplicated micro modelling. Rahgozar and Hosseini (2017) proposed the in-plane responses of these masonry prisms are regulated through various tests. The compressive results marked that the interface element performance is designated up to the mark, and the model appropriately predicts the complex failure behaviour of brick masonry structures. Šipoš et al. (2018) (Abbas & Saeed, 2017) Analytical and experimental data were used to inspect the association between drift and damage of masonry infilled frames. The implementation of standards and design process for RCC structures in the current practice disregards the impact of masonry infill framed structures. Baghi et al. (2018) (Šipoš et al., 2018) studied the existing model to create a numerical tool to study the behaviour of frame infill separation, and non-linear analysis of was performed with Eigen value consideration subjected to cyclic loading. It is further concluded that both experimental and analytical results is matching to each other with respect to initial stiffness, cracking patterns and maximum shear capacity. In Liberatore et al. (2018) (Baghi et al., 2018), the effectiveness of masonry infill wall on the behaviour of a Reinforced Concrete (R.C.) frame subjected to a column failure is studied experimentally. This model can predict the load–deflection with reasonable accuracy. De Angelis and Pecce (2018) (Liberatore et al., 2018) the proposed strut model incorporates the error terms and the interaction matrix among errors that can be successfully occupied in risk measurement to consider the model uncertainty on the structural response. Khalilzadeh Vahidi and Moradi (2019) (Angelis & Pecce Oct., 2018) the primary purpose of this document is to show an organized survey of experimental studies related to infill masonry walls out of plane action. The use of joints reinforcement is marked as an explanation for wellbeing since it furnishes deformation capacity to the panel. Maheri et al. (2019) explored seismic criterion, ultimate tensile damage, and force transfer mechanisms in an RCC structure under plan load. The infilled walls in the concrete frame wield much compression on the base beam that they are preeminent to split the beam–column joint. The further the enhancement in opening size, the less the compression on the base beam. Nasiri and Liu (2019) (Khalilzadeh Vahidi & Moradi, 2019) This numerical study on the in-plane shear capacity of full-scale unreinforced concrete block masonry walls, externally retrofitted by reinforced concrete layers, is presented. The simplified micro modelling adopted for numerical analyses proved to predict reasonably well the actual in-plane nonlinear static (pushover) response of both the URCBM and RCBM walls. Pantò et al. (2019) (Nasiri & Liu, 2019) handled the analytical simulation of brick infill walls subjected to OOP conditions. The numerical simulation results proved to appraise the satisfactory conduct of the macro modelling advent in simulating failure mechanisms.

Nyunn et al., (2020) (Pantò et al., 2019) in this analysis, bare and infill-wall R.C. frames are reviewed by considering column failure at the corner and outer region. The results demonstrated that as the number of corrosion cycles boosts up, the bearing capacity of wall specimens decreased. Niu et al. (2020) (Nyunn et al., 2020) inspected deals with the response of infill walls on the action of R.C. special moment frames subjected to numerous seismic activities. As the sum of stories upsurges, displacement and rotational ductility are reduced. Kostinakis and Athanatopoulou (2020) (Niu et al., 2020) aimed to propose a multi-strut large-scale model suited for simulating the long-term force–displacement behaviour of infilled frames with various opening configurations. The outcomes show that the extent and spot of the opening have a considerable repercussion on both the inclination and the effective width of the struts. Jalaeefar and Zargar (2020) (Kostinakis & Athanatopoulou, 2020) in this investigation number of experimental tests, data is collected with the focus of examining and determining the vital components of the infill and judging the convenience system proposed. Yekrangnia and Asteris (2020) (Jalaeefar & Zargar, 2020) in this analysis, various tests are operated to weigh the I.P. damage effects on the OOP response of square URM infills with a relatively low slenderness ratio in RCC frames. Tests results enrich the stiffness reduction as a function of geometric properties of the infill (namely, the slenderness ratio and the aspect ratio) and the I.P. displacement demand. Liberatore et al. (2020) (Yekrangnia & Asteris, 2020) Results showed a study on the out of plane behaviour and strength of concrete masonry infills vaulted by R.C. frames before plane damage. The equations were submitted and verified with limited test results. Di Domenico et al. (2021) (Liberatore et al., 2020) aims at enhancing the seismic performance of the infill wall by an alternative method. The results manifested that the seismic performance of the RIW has been adequately progressed. The initial stiffness is lowered by 31%, and the strength depreciation is much retarded than that of the OIW specimen. Nasiri and Liu (2020) (Domenico et al., 2021) deal with the progress of an experimental campaign to probe the cyclic out of plane behaviour of RCC frames enclosing masonry infill walls adopting non-contact optical means to part contour strains and deformations. It was established that neither the infill walls nor the openings compellingly alter the entire behaviour of the specimens. Liberatore and AlShawa (2021) (Nasiri & Liu, 2020) adopted the yield line theory for evaluating the out of plane infill strength is inspected. The equations furnish their OOP strength to be serviced in the local appraisal of infills in both recent and extant buildings.

Analytical work

Mallick and Garg (Liberatore & AlShawa, 2021) has considered the effect of most probable positions of openings on the lateral stiffness of infilled frames. It is recommended that the best position of door opening can be best located in the centre of the lower half of the panel and to the centre from the window. Using FEM stiffness has been calculated for MIW with openings. To derive the stiffness matrices, using Airy’s stress function that fulfils biharmonic equation with B.C. was introduced. By minimizing the energy for linear edge displacement, the stress pattern obtained is

Stress components having seven coefficients for accuracy of the solution is of the form

The stiffness matrix of a beam element subjected to shear and axial deformation

Smith’s formula was used to determine the length of contact for frame without shear connectors

The stiffness of masonry infill wall with shear connectors can be derived using

where h is the height of the wall, W is the weight, t is the thickness, Es is the modulus of elasticity.

Saneinejad and Hobbs (Mallick & Garg, 1971) has considered a new analysis method of steel frames with concrete masonry infill walls subjected to in-plane forces. Further model is analysed for multi-storey infilled frames as braced frames. “A3—Displacement based seismic design criteria” (Saneinejad & Hobbs, 1995) seismic performance is considered to produce structures that satisfy the specific performance of the objectives. The probabilistic approach should be used to deal with the uncertainties in estimating the capacity and demands. Madan et al. (1997) an equivalent strut approach is considered, and hysterical modelling is proposed for masonry infill panels in the non-linear analysis of frame structures. Dynamic analysis is done for a light reinforced concrete structure to find the influence of masonry infill frames.

Where Vm is the maximum lateral force, Um is the displacement, Ld is the lateral length.

The initial stiffness of the wall can be determined by.

where Ko is the stiffness of the wall, Vm and Um is Maximum lateral force and displacement.

The stiffness loss due to deformation is an important property of the hysteric model, including the control parameter η for Z, hysteric parameter

The strength degradation is modelled reducing the yield force Vy from

Crack slip model μ = μ1 + μ2 where μ2 is displacement ductility component given by

Priestley and Kowalsky (2020) a full-scale test verifies in-plane monotonic loading. Finally, after the analysis is completed, full-filled masonry walls show high stiffness, whereas the adjacent column fails with nearly uniform cracks. A complete first-order polynomial is chosen as displacement function for 2D block

where u and v are the lateral force and displacement, respectively.