Abstract

Concrete is more durable against fire than other structural materials. However, high temperature has deteriorating effects on mechanical properties of concrete. Decreases of strength at higher temperatures can be associated with various reasons, such as micro- and macro-cracks on the concrete, the volume expansion in the aggregate, and the deterioration of the calcium silicate hydrate (C–S–H) gels in the cement paste. The main objective of this research work is to study the effect of four different cooling schemes on the ultimate strength of 54 reinforced concrete columns subjected to uncontrolled fire. The tested columns are of different surface area to volume ratios (with three different cross sections; circular, square and rectangular). Four cooling schemes were used; three of them are uniform cooling schemes with different rates (rapid, slow and intermediate) while the fourth cooling scheme was non-uniform. Two different fire temperatures and durations were considered (300 °C for 3 h & 600 °C for 6 h). Non-destructive test (Core test) was used to estimate the deterioration extent of fire on concrete properties. A mathematical model was developed to estimate the ultimate strength of RC columns subjected to fire to decide if the RC columns need repair and strengthening after fire or not. Results of the model and the obtained experimental results were compared together to evaluate the accuracy of the proposed model.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Most popular material is reinforced concrete (RC) used locally in structural system and international too. Thus, the failure shape and behavior of these systems are under consideration. Strength regression of RC because of fire short-term has been considered in the last years. Concrete behavior due to fire submits depend on mix properties and figured by interactions over fire situation. Failure shapes of concrete because of fire changes according to fire kind, applied loads and type of the structure. While failure could be happened according to various parameters such bending loss or loss of tensile strength, shear decrease or decrease of torsional strength, compressive strength shortage. For many years ago, different studies have been considered on the strength loss of RC columns subjected to fire in case of short term (Bikhiet et al., 2014). Fire has detrimental effect on the behavior of different RC elements. This effect depends on several factors such as: fire temperature, fire duration, properties and mix properties of concrete, coarse aggregate type, reinforcement steel ratio, dimensions of concrete elements, extinguishing method which controls the rate of cooling. When estimated the concrete properties in a structural element exposed to high temperature, many factors taken into consideration. These were: fire duration, temperature level, peak temperature, dimensions of element, concrete humidity, concrete age, aggregate type, chemical composition of cement, water to cement ratio (w/c), and the loading conditions of the structural element (Arel & Yazici, 2014). Spalling was siliceous aggregate; with limestone make less spalling and lightweight aggregate the least. This was likely to be connected to the basic porosity of the aggregate, in that siliceous aggregate was secured compared to the others and that moisture transfer has to occur through the mortar matrix. However, there was some index that limestone and lightweight aggregates gave issues, especially in fresher Concretes as the pore structure of the aggregate supplied proper reservoir storage for free water (Purkiss, 2007). The estate of a material or assembly to resist fire or make protection from it. As applied to elements of structure, it was described by the ability to limit a fire or, when submitted to fire, to continue to execute a given structural function, or both (Arel & Yazici, 2014). RC was exactly fire resistant. Cast-in-place RC structures have a great performance record from a fire resistance standpoint (CRSI, 2015). The moment that the border layer of the column was heated by convection and radiation, conduction transmit the thermal energy during the cross section from zones of higher to lower temperatures. The proceeding sections outline the general heat transfer operations used to measure the temperature gradients during the cross section of the column for specified time-steps (Emberley & Leonard, 2013). The effects of high temperatures was determined as the effects on cement paste, aggregate and interfacial transition region, the hydration of cement particles, C–S–H, and Ca(OH)2 created in the concrete. At a temperature of 300 °C (572 °F), the chemically bonded water and gel water of C–S–H begin to evaporate. Ca(OH)2 can change into un-hydrated lime (CaO) at approximately 530 °C (986 °F). Through this conversion, shrinkage up to 33% happened (Arel & Yazici, 2014). The cooling method had a significant effect, when cooled by water jet it has been found that the column strength losses about 38% compared to cooling by room temperature, and it has been found that when cooled by water jet it causes a smaller failure load almost about 17% than when cooled by room temperature. A small concrete strain was found when cooled by water jet compared to cooling by room temperature (higher stiffness), but when the fire cooled by room temperature it indicates more ductile failure compared to cooling by water jet. While the column could have a rapid loss in strength with cracks and a concrete cover sudden shock when cooled by water compared to room temperature (Bikhiet et al., 2014). In the past decade, several experimental and theoretical studies have been carried out on the degradation of column concrete strength due to the short term exposure to fire. These studies of columns exposed to fire have indicated the following observations: surface cracking in concrete occurs at nearly 300 °C with a deeper cracking at 540 °C. Spalling occurs followed by breaking off thin concrete cover at corner and edges. Concrete begins to lose about 30% of its compressive strength when heated up to 300 °C and loses about 70% of its compressive strength when heated up to 600 °C. Concrete modulus of elasticity reaches 60% of its original value at 300 °C and reaches 15% of its original value at 600 °C. Concrete stiffness decreases with the increase in temperature and the reduction in stiffness is accompanied with a reduction in the concrete strength with the increase in the concrete strains. Vertical cracks clearly appear and then crushing of concrete accompanied by crackle sound with a local buckling of the longitudinal reinforcement occurs. Columns with large longitudinal bars diameters lead to fire resistance appreciably smaller than columns with smaller bar diameters and the increase in concrete cover has a positive effect on the columns fire resistance (Bikhiet et al., 2014). While the concrete with siliceous aggregate, the minimum in strength when cooled by air happened after high temperature at 28 days, but the strength minimum when cooled by water happened after heated in the first day. This was means that with water cooling, the minimum strength happened firstly than extinguishing by air. A phase of small increase in standing time happened when submitted to high temperature. After fire when a gap of time happened, the results of concrete strength of calcareous and siliceous aggregate became constant (Zhang et al., 2011). Failure of one or more columns in high-rise buildings may lead to the collapse of the structure (Abdulraheem & Kadhum, 2018). The absence of consideration for the structural behavior under cooling was a significant shortcoming. Any actual fire has a cooling phase where the gas temperatures gradually decrease and return to normal (Gernay, 2019). Structures might not experience a complete failure during fire. Following, it could be plausible to repair the structure safely to make it serviceable again. The possibility of repairing would be significantly cost and time effective compared to rebuilding process (Ekmekyapar & Alhatmey, 2019). There were three main combined aspects that under normal circumstances allow a response to fires in buildings, both active and passive fire protection systems and manual firefighting by a fire brigade. It is necessary to have the availability of water supplies due to the difficulty of extinguishing the fire without water (Hugo Vitorino, 2020). This research is aimed at investigating the effect of fire on the behavior of axially loaded reinforced concrete columns subjected to uncontrolled fire and to estimate the percentage loss of column compressive strength under the effect of the following parameters: fire temperature, fire duration, dimension of concrete element, extinguishing method which control rate of cooling and Properties & mix properties of concrete. To achieve these objectives, mathematical model and laboratory experiments are used to simulate the behavior of columns exposed to uncontrolled fire. Analysis was performed to examine the influence of Cooling Methods, Surface area to volume ratio and fire temperature/duration on the column strength. The results of these analyses are presented and discussed hereinafter.

Problem statement

Estimate how the extinguishing methods can affect the behavior of RC columns subjected to uncontrolled fire. The experimental work consists of two types of test: compression test and core test. These tests accomplished to determine the amount of distortion in concrete. The columns that subjected to fire compared to the columns that not subjected to fire.

Objective

The main objective of this research work is to study the effect of four different cooling schemes on the ultimate strength of 54 reinforced concrete columns subjected to uncontrolled fire. The tested columns are of different surface area to volume ratios (with three different cross sections; circular, square and rectangular). Four cooling schemes were used; three of them are uniform cooling schemes with different rates (rapid, slow and intermediate) while the fourth cooling scheme was non-uniform. Two different fire temperatures and durations were considered (300 °C for 3 h & 600 °C for 6 h). Non Destructive test (Core test) was used to estimate the deterioration extent of fire on concrete properties.

Program of experimental study

The experimental program in this research includes preparing and testing of 54 RC columns in compression to determine the ultimate strength. Ultimate strength of these columns was expressed in terms of the failure loads. The descriptions of the 54 columns are as follows:

Six Columns were used as control specimens for comparison purpose. These 6 columns were not subjected to any fire. Two columns of circular cross section, two columns of square cross section and the last two columns were of rectangular cross section 24 Columns were subjected to a fire of Temperature 300 °C for 3 h duration (Fire A).

These columns are as follows:

-

Eight columns from them were of circular cross section (2 of them were cooled in air, 2 of them were cooled by water, 2 of them were cooled by CO2, and the last two columns were cooled by both water and air).

-

Eight columns were of square cross section and cooled by the same 4 cooling method exactly like the 8 circular columns.

-

Eight columns were of rectangular cross section and cooled by the same 4 cooling method exactly like the 8 circular columns.

-

Twenty-four columns were subjected to a fire of Temperature 600 °C for 6 h duration (Fire B). These columns are as follows:

-

-

Eight columns from them were of circular cross section (2 of them were cooled in air, 2 of them were cooled by water, 2 of them were cooled by CO2, and the last two columns were cooled by both water and air).

-

Eight columns were of square cross section and cooled by the same 4 cooling method exactly like the 8 circular columns.

-

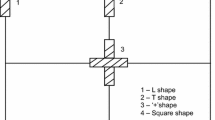

Eight columns were of rectangular cross section and cooled by the same 4 cooling method exactly like the 8 circular columns as shown in Figs. 1, 2, and 3.

Concrete and concrete materials

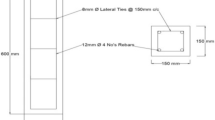

The cement used was ordinary Portland cement that complies with the requirement of the Egyptian standard specifications ESS 4756/2007 of grade N42.5. The coarse aggregate was crushed stone. The used sand was natural sand with fineness modulus of 2.73. Table 1 gives the sieve analysis test results for the used sand and crushed stone. Table 2 gives physical properties of the used sand, crushed stone. The concrete mix was designed to achieve cube compressive strength after 28 days of 250 kg/cm2 as given in Table 3. The steel reinforcement used was high tensile steel with oblique ribs of grade 400/600 and of nominal diameter 12 mm. The used stirrups were plain bars of diameter 10 mm and made from mild steel of grade 240/350. The average measured 7- and 28-days cube compressive strength were 180 and 220 kg/cm2 respectively. All the test specimens were cast and cured by wet burlap until the test date.

Test specimens (RC columns)

The experimental program consisted of 54 RC column specimens (1–54). Divided into three cross sectional shape (circular, square, and rectangular). All specimens have constant 1% percentage of RFT (4Ø12), height (h = 1.5 m) and cross section area = 45,000 mm2 as shown in Table 4 and Fig. 4. All specimens except the reference’s column (1–6) subjected to two fires with different temperatures and durations and different cooling schemes. The theoretical load of the columns was estimated from ECP 203-2018.

Test procedure

All columns, except the control specimens, were subjected to uncontrolled fire and cooled by different methods, then all the columns were tested under compression until failure. By using a crane, the columns were placed in a compression test machine manually. Columns were exposed to a 300 °C & 600 °C constant fires temperature at a desert clear site in new Cairo city using fire material (wheels) and confirmed by thermocouple. After exposure, columns cooled by 4 different schemes (air + water + CO2 + Air/water mix). A hydraulic loading machine was used to test the columns with 200-ton capacity and the accuracy of this machine was 0.5 ton at the Materials Laboratory—Ain-shams University. The load in the testing machine was controlled manually and the lateral and axial strains were estimated by mechanical strain gages in mid-height every 5.0-ton interval. A dial gages were used to record the specimen's lateral deformation. The upper and lower ends of columns were confined by bolted steel boxes of steel plates with thickness = 10 mm and height = 25 mm to avoid ends failure and the ends surface covered by gypsum to ensure fixation as shown in Figs. 3 and 5.

Discussion of test results

Effect of surface area to volume ratio

For columns subjected to fire (A) (300 °C—3 h duration), Tables 5 and 6 shows that by increasing the surface area to volume ratio from 16 to 18 (× 10–3)mm−1, the failure loads of columns decreased by about 6%. By increasing the surface area to volume ratio from 16 to 20 (× 10–3) mm−1, the failure loads of columns decreased by about 13%. Note that the circular columns here are the references since they have the lowest SA/Vol ratio as shown in Fig. 8. Generally, degree of deterioration caused by fire increases by increasing the SA/Volume ratio for all columns. Reduction of columns ultimate strength can be attributed to the reduction of concrete compressive strength due to increasing the surface area exposed to fire (i.e. more cracks, more volume expansion of coarse aggregates, more deterioration of calcium silicate hydrate (C–S–H) gels, more spalling of concrete cover and more losses of bond strength between reinforcing bars and concrete). For columns subjected to fire (B) (600 °C—6 h duration), Tables 5 and 6 shows that by increasing the surface area to volume ratio from 16 to 18 (× 10–3) mm−1, the failure loads of columns decreased by about 3%. By increasing the surface area to volume ratio from 16 to 20 (× 10–3) mm−1, the failure loads of columns decreased by about 5%. Note that the circular columns here are the references as mentioned before as shown in Fig. 8. But here, we have to notice that the effect of SA/Vol ratio is very small compared with fire “A” and can be neglected. The major effect in this case is the fire temperature and duration not the S/Vol ratio. This means that for heavy fires (fires of higher temperatures and durations like fire “B”), the drop in ultimate strength is due to fire temperature and duration regardless the column cross sectional shape (i.e. regardless the S/Vol ratio).

Effect of fire temperature/duration

As shown from Tables 5 and 6: as a general attitude, by increasing the fire temperature and duration, ultimate strength of columns (expressed in terms of failure loads) will decrease.

For fire “A” of 300 °C for 3 h duration, the ultimate strength of circular columns decreased 17%, ultimate strength of square columns decreased 20% and ultimate strength of rectangular columns decreased 23%. An average drop of 20% is happened for all columns with different cross sections compared to reference columns (not exposed to fire). Figure 9 shows the Percentage of failure loads from control columns. Losses in compressive strength (from core test results) are 12%, 14% and 15% for circular, square and rectangular columns, respectively. An average decrease of 13.6% is happened for all core specimens compared to reference core specimens (not exposed to fire). For fire “B” of 600 °C for 6 h duration, the ultimate strength of circular columns decreased 39%, ultimate strength of square columns decreased 40% and ultimate strength of rectangular columns decreased 38%. An average drop of 39% is happened for all columns with different cross sections compared to the reference columns. Figure 9 shows the percentage of failure loads from control columns. Losses in compressive strength (from core test results) are 27%, 32% and 35% for circular, square and rectangular columns, respectively. An average drop of 31% is happened for all core specimens compared to reference core specimens.

Reduction in concrete compressive strength by increasing fire temperature and duration is attributed to micro-and macro-cracks in concrete, volume expansion of coarse aggregates and the deterioration of calcium silicate hydrate (C–S–H) gels in the cement paste. In addition of that spalling of concrete cover and losses of bond strength between reinforcing steel and concrete will increase the reduction percentage of failure loads. That is why the reduction of failure loads are higher than that of concrete compressive strength for both fires “A&B”.

Effect of cooling scheme

Effect of cooling scheme on columns failure loads is shown in Fig. 10 and Tables 5 and 6. For the case of circular columns, it can be noticed that by using the cooling schemes (CO2, air, water, air/water), the ultimate strength of columns (expressed in terms of failure loads) decreased by about (34%, 40%, 43%, 48%) respectively compared to the control columns. For the case of square columns, it can be noticed that by using the cooling schemes (CO2, air, water, air/water), the ultimate strength of columns (expressed in terms of ultimate load) decreased by about (33%, 40%, 42%, 48%) respectively when compared to control columns. For the case of rectangular columns, it can be noticed that by using the cooling schemes (CO2, air, water, mix), the ultimate strength of columns (expressed in terms of ultimate load) decreased by about (31%, 39%, 45%, 52%) respectively when compared to control columns.

Generally, it can be noticed that the failure loads of columns decreased by increasing the rate of cooling. For the three cases of uniform cooling methods with different rates, it can be noticed from the test results that the slow rate (case of CO2 extinguishing) is better than case of intermediate rate (air extinguishing in atmospheric conditions), which is better than rapid cooling rate (case of water extinguishing). An average decrease of 34%, 40% and 43% in ultimate loads occurred for cases of CO2, air, water respectively for all columns cross sections. Core test results (Table 6) show an average drop in concrete compressive strength for the same cross section for uniform cooling schemes of about 27%, 32%, and 34% for CO2, air, water extinguishing schemes, respectively. Increasing the rate of cooling will increase the cracks due to increasing the temperature difference between the concrete surface layer and the internal concrete zone. Sudden cooling of columns (columns cooled by water) will cause a thermal shock in concrete. Water cooling is considered the method of the most rapid rate. Intermediate and slow cooling rates (Air and CO2 respectively) will cause a temperature gradient across the column cross-section without a thermal shock. That is why the maximum drop in column strength is due to water cooling (for uniform schemes). Non-uniform cooling scheme (Air/Water method) is considered the worst extinguishing method; the max. reduction in failure loads occurred by using this method. Reduction in failure loads of about 48% occurred in cases of circular and square columns where a reduction of 53% occurred in cases of rectangular columns. Core test results show a drop of about 40% in the case of non-uniform cooling scheme (Air/Water). Here, the thermal shock occurs not only across the column cross-section but also along the column height. rectangular columns is more severe than that on circular and square columns. This is due to the minimum dimension of rectangular column is affected more strongly by fire than bigger dimensions of circular and square cross-sections. That is why most of the building codes require minimum dimensions for rectangular columns based on the expected fire temperature and duration.

Proposed mathematical model

Practically, the most important decision should be taken after the fire exposure is if the structural members need repair and strengthening or not. The answer to this question depends mainly on: to how extent the fire affected the ultimate strength of the structural members?

Of course, after fire exposure, buildings need a visual inspection and non-destructive tests (like Core, Schmidt hammer, Ultrasonic, …etc.) to estimate the degradation level.

The proposed mathematical model will be used to calculate the ultimate (failure) loads of columns after fire exposure. The model is based on the measured core compressive strength and measured depth of the fire-affected layer. Both measurements are taken from core specimens (core test). Calculations will depend on the following three assumptions:

-

a.

Neglecting the effect of the fire affected layer (outer layer with different color) in resisting the applied compression loads. This layer does not exist in many locations due to the spalling of the concrete cover.

-

b.

The inner part of concrete (after subtracting the fire-affected zone) will resist the full-applied loads. Its compressive strength is determined from the core specimens taken from the column after fire exposure. After extracting the core specimens, the fire-affected layer (if still existing on the concrete surface) was cut and removed from the core specimen before capping the specimens followed by the compression test.

-

c.

Neglecting the effect of steel reinforcement in calculating the column capacity without a significant error since the steel area does not exceed 1% from the total cross-sectional area of the columns. Losses of bond between steel bars and concrete due to high temperature will strongly support this assumption.

The proposed model depends mainly on compressive strength obtained from core tests as well as the measured depth of the fire-affected zone as given in Table 7. Depth of the heat-affected zone was measured from the sides of the core specimens; several values were taken and the average depth was calculated. Fire affected zone (outer layer) has a different color (more dark) than the inner concrete as shown in Fig. 11.

Ultimate load for each column equals the measured core compressive strength (of the inner part) multiplied by the cross-sectional area of the columns after subtracting the fire affected area from the total cross-sectional area of the column as follows:

Pu: ultimate (failure) load of the column.

fc: core compressive strength after removing (cutting) the fire affected layer from the core specimen.

A: total cross-sectional area of the column.

a: cross sectional area of the fire affected zone which calculated from the measured average depth of the fire affected zone as shown in Fig. 9.

For example for square columns exposed to fire “A” (300 °C for 3 h):

-

o

Total area of column cross section (A) = [212]2 = 44,944 mm2

-

o

Area without the heat affected zone (A − a) = [(212 − (2 × 13)]2 = 34,596 mm2

-

o

Core equivalent standard cube strength (fc) = 207 kg/cm2

-

o

Calculated ultimate load (Pu) = 345.96 cm2 × 207 kg/cm2 = 71,613 kg

-

o

Measured ultimate load = 74,000 kg

-

o

Ratio bet. Calculated/measured ultimate load = 0.97 (i.e. − 3.2% error)

It can be noticed from Table 7 that the calculated ultimate load from the proposed mathematical model represents about 86% to 116% from the measured failure loads as shown in Fig. 12. The percentage of error ranging from − 14% to + 16% can be considered acceptable if we consider the variability of RC properties and the fire parameters.

Based on this proposed model, we can estimate the ultimate load for a RC column subjected to fire by extracting core specimens from concrete after fire exposure, measure both compressive strength, and fire affected depth. Estimation of column ultimate load is of great importance to decide repair and strengthening steps based on the level of danger (degradation level) after fire exposure.

Conclusions

These studies of columns subjected to fire have specified the following comments:

-

o

RC columns subjected to Fire B losses from its original ultimate strength (Ultimate strength based on failure load) more than RC columns subjected to Fire A.

-

o

Rapid rate of cooling (by water) causes a drop of ultimate strength of RC columns more than slow rate of cooling (by air and Co2).

-

o

Non-uniform rate of cooling (air/water) is much more severe on ultimate strength of RC columns.

-

o

Increasing surface area to volume ratio will decrease the ultimate strength of RC columns subjected to fire. The Circular column has the minimum strength loss then Square column followed by Rectangular column.

-

o

Effect of fire is much more severe on rectangular columns than columns of other cross sections because of the minimum dimension of the rectangular column.

-

o

Calculated failure loads from the proposed mathematical model represent good agreement from the experimentally measured loads. The percentage of error can be considered acceptable if we consider the variability of RC properties.

Recommendations

It is strongly recommended that further study be done to consider the effect of uncontrolled fire and cooling schemes on the behavior and ultimate strength of different RC elements subjected to different levels of loading and different heights.

References

Abdulraheem, M. S., & Kadhum, M. M. (2018). Experimental investigation of fire effects on ductility and stiffness of reinforced reactive powder concrete columns under axial compression. Journal of Building Engineering, 20, 750–761.

Arel, H. S., & Yazici, S. (2014). Effect of different parameters on concrete-bar bond under high temperature. ACI Materials Journal, 111(6), 633–640.

Bikhiet, M. M., El-Shafey, N. F., & El-Hashimy, H. M. (2014). Behavior of reinforced concrete short columns exposed to fire. Alexandria Engineering Journal, 53(3), 643–653.

CRSI. (2015). Fire resistance of reinforced concrete buildings. Schaumburg: Concrete Reinforcing Steel Institute.

Du, Y., Qi, H. H., Huang, S. S., & Liew, J. R. (2020). Experimental study on the spalling behaviour of ultra-high strength concrete in fire. Construction and Building Materials, 258, 120334.

Ekmekyapar, T., & Alhatmey, I. A. (2019). Post-fire resistance of internally ring stiffened high performance concrete. Engineering Structures, 183, 375–388.

Emberley, R. L., & Leonard, D. A. (2013). A study into the behavior of reinforced-concrete columns under fire exposures using a spreadsheet-based numerical model (Doctoral dissertation, Worcester Polytechnic Institute)

Gernay, T. (2019). Fire resistance and burnout resistance of reinforced concrete columns. Fire Safety Journal, 104, 67–78.

Lang, Z., Liu, H., Meng, N., Wang, H., Wang, H., & Kong, F. (2020). Mapping the knowledge domains of research on fire safety—an informetrics analysis. Tunnelling and Underground Space Technology Incorporating Trenchless Technology Research, 108, 103676.

Lu He, Z. X. (2018). Analysis of entrainment phenomenon near mechanical exhaust vent and a prediction model for smoke temperature in tunnel fire. Tunnelling and Underground Space Technology, 80, 143–150.

Purkiss, J. A. (2007). Fire Safety Engineering Design of Structures (2nd ed.). Routledge: Taylor and Francis.

Vitorino, H., Rodrigues, H., & Couto, C. (2020). Evaluation of post-earthquake fire capacity of reinforced concrete elements. Soil Dynamics and Earthquake Engineering, 128, 105900.

Wróblewska, J., & Kowalski, R. (2020). Assessing concrete strength in fire-damaged structures. Construction and Building Materials, 254, 119122.

Xu, H., Yu, M., Xue, C., Xu, L., & Ye, J. (2020). Experimental study on fire resistance of precast concrete columns with efficient reinforcement. Engineering Structures, 204, 109947.

Zhang, Q. Q., Yuan, G. L., & Dong, Y. N. (2011). Influence of cooling methods and standing time on different aggregate concrete strengths after elevated temperature. Advanced Materials Research, 250–253, 155–159.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Awad, Y., Kohail, M., Khalaf, M.A. et al. Effect of fire extinguishing techniques on the strength of RC columns. Asian J Civ Eng 23, 113–123 (2022). https://doi.org/10.1007/s42107-021-00414-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42107-021-00414-8