Abstract

In steel I beams the corrugated webs are sometimes used as an alternative to plain web in many steel construction. The idea behind this concept is an increase in the shear capacity of steel beams without providing the transverse stiffeners. The recent development in steel construction is the used of web openings for the utilization of various technical utilities in web. This paper presents an extensive parametric study on the steel beam with corrugated web having openings in the web. The objective of the present study is to observe the structural performance of this special type of beam towards the strength capacities. In the parametric study 60 models of steel beams with trapezoidally corrugated web with opening has been analyzed by finite element analysis using ANSYS v12. The variables in the present study are angle of corrugation, thickness of web and diameter of opening. The angle of corrugation, web thickness and diameter of web openings considered in the study are 0°, 30°, 45° and 3 mm, 4 mm, 5 mm and 0.5, 0.6, 0.75 times the overall depth of beam, respectively. The parametric study shows that lesser the angle of web corrugation, the more increase in the load carrying capacity is obtained. Ultimate strength capacity of 30° corrugated web beam with different diameter of opening such as 0.5 D, 0.6 D, and 0.75 D is found to be 15.27%, 14.83%, 9.72%, which is more than the beam with plain web. The height to thickness (h/tw) ratio considered in the study are 30, 37.5, 40, 50, and 66.67, respectively. The height to thickness (h/tw) ratio is found to be the main parameter influencing the buckling behaviour of steel beam with corrugated web.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction and literature review

Steel structures are becoming more and more popular since ancient times because of their many advantages such as its high strength-to-weight ratio, durability, and architectural appearance. In steel building amongst various sections, I sections are normally being used as a beam and column. The common shape of this beam is constructed from two parallel flanges and plain web. One of the recent development in the construction technology is used of corrugated web instead of plain web. Figure 1 shows the step-by-step fabrication procedure of steel corrugated beam with web openings. The purpose of providing the corrugation in the web that weight can be reduced up to 30%, increase in the lateral stiffness and resistance against lateral torsional buckling without adding the transverse stiffeners (Elgaaly et al. 1997; Abbas et al. 2006; Lindner 1990). The effect of web corrugation on the beams strength, such as plain web, vertically and horizontally corrugated web was investigated. It is concluded that the vertically corrugated web provides a strong support against the flange buckling (Chan et al. 2002).

The first attempt to study the corrugated web girders with cut outs (Romeijn et al. 2009) using theoretical and finite element analysis has been carried out to investigate the effect of cut out in corrugated webs. It concludes that increase in the height of the corrugated web with cut out and length of parallel parts, increase in the shear resistance of the beam and local buckling is minimized. The diameter of the cut out in this was limited to 0.4 a1. Sause and Braxtan (2011) developed the correct formula for shear strength of trapezoidal corrugations web girders. Nie et al. (2013) performed experimental as well as extensive parametric study and suggest the simplified equation for calculating the elastic shear bucking strength of trapezoidally corrugated web. Divahar and Joanna (2014, 2018) studied experimentally the effect of web corrugation in cold-formed steel beam with trapezoidal corrugated web. The specimen tested under two point loading for its pure flexural behaviour. From this study, it is found that the cold-formed steel beam with trapezoidally corrugated web having 30° corrugation has higher load carrying capacity compared to the beam having plain web and 45° corrugated web. Kovesdi and Dunai (2014) studied experimentally the fatigue life of girders with trapezoidally corrugated web. It concludes that combination-loading situation improve the fatigue life of corrugated web girders and smaller weld size resulted in the fatigue life of analyzed girder being longer. Wang and Wang (2014) studied fatigue assessment of welds joining corrugated steel web to flange plates. The results show that, the stress concentration at the fatigue point of transition curvature, the influence corrugation angle more significance when ratio of curvature radius to the corrugation depth is smaller. Zirakian et al. (2016) studied the structural performance of corrugated web steel coupling beams. From the analysis result, it concludes that increasing the number of corrugations web and thickness is improving the rotation and energy absorption capacities of the structural elements.

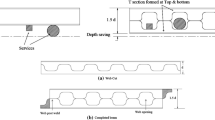

The castellated beams are created by special fabrication process. Since it is a special type of beam, a preventive measure should be taken to achieve the economy in the fabrication process. For obtaining the solution of the design problem, the charged system algorithm is used and cost optimization has been carried out and concluded that hexagonal openings have less cost in comparison to the cellular beams. The application of grey wolf optimizer in the design of castellated beam and optimum design of laterally supported castellated beams using CBO algorithm has been studied in details and the results reveals the high capability of the CBO algorithm in finding the optimum solution (Kaveh and Shokohi 2014, 2015, 2016a, b). Castellated beam is commonly used where large web openings are and provides along the beams. In modem buildings, provision of large ducts and pipes beneath beams and girders of structure steel framing in building structure may lead to unacceptably large construction depths between storeys. Figure 2 shows the reduction in storey height by taking the advantage of web opening concept. There is a tendency to use water pipes and air ducts of increasing sizes, and opening of dimensions up to 75% of the depth of floor beams are often required (Morkhade and Gupta 2015, 2017, 2019; Morkhade et al. 2018, 2019).

Till date, trapezoidally corrugated web beam with openings has not been studied so far. There is still no design specification with respect to uses of opening in trapezoidally corrugated web. In the European standard code Euro code 3: Design of steel structures-EN 1993-1-5 (2006) notice that openings are not included in the design rules for corrugated webs. In modern building where water pipes, air ducts produce large depth between storeys as shown in Fig. 2. Therefore, this study has been carried out based on the demand for additional design specification to make openings in corrugated web and to study the flexural response of trapezoidally corrugated web beam with openings. An extensive parametric study has been carried out using a finite element analysis of trapezoidally corrugated web beam with web openings.

Numerical study

Validation of FE model

The finite element model was validated against the experimental test results of two cold-formed steel beams with trapezoidally corrugated web designated as CWB-150/30° and CWB-150/45°, respectively (Divahar and Joanna 2018). For both the tested beam specimens, the load–deflection curves obtained from the finite element modelling are plotted in Figs. 3 and 4 along with the measured test data for direct evaluation. From the load deflection curves, it is concluded that the beams are modelled suitably.

Finite element modelling

The finite element method has been used to modelled the corrugated web beam with web openings. The ANSYS v 12 is used which is having very good element library to model the moderately thin to thick structure, and present strength capacity behaviour of trapezoidal corrugated web beam with openings in the web. Total 60 models of steel beam with trapezoidally corrugated web with opening has been analyzed. The variables considered in the analysis are angle of corrugation, thickness of web and diameter of openings. The length of horizontal panel is taken as 1.5 times of overall depth of the beam. The angle of corrugation considered in the study is 0°, 30°, and 45°. The thickness of web is considered as 3 mm, 4 mm, 5 mm and the diameter of opening such as 0.5, 0.6, 0.75 times overall depth of beam. The depth of beams is taken as 150 and 200 mm. The material properties are as per Table 1. The geometric property, dimension of corrugated web, its angle of inclination mentioned in Tables 2 and 3, respectively. Figure 5 shows the geometrical details of the corrugated beam. The three dimensional finite element model with loading and boundary condition is as shown in Fig. 6. The summary of the FE models are as follows:

-

Shell 181 element is used to model steel beams with corrugated web, which is having six degrees of freedom at each nodes (three translation and three rotation).

-

Bilinear stress strain curve is used in the analysis.

-

Geometric as well as material non-linearity are considered in the beams model.

-

The initial imperfection of L/1000 was used in the analysis.

-

The load was applied stepwise as pressure.

Results and discussion

Total 60 finite element models were created and analyzed using finite element analysis software ANSYS. All models are assigned with different geometry and material property to study the load carrying capacity of specimen. Tables 4 and 5 show the designation of the models, span length, maximum deflection, and ultimate load for trapezoidal corrugated web beam with openings of various diameters for depth of 150 and 200 mm, respectively. In the present study only circular openings has been considered. Whereas Tables 6 and 7 show the flexural stiffness of the specimens. The deformed shape and the behaviour of stresses under the loading due to effect of corrugated web with different openings are as shown in Fig. 7. The ultimate load vs mid span deflection graphs were plotted for each specimen such as plain web, corrugated web beam with different angles and different size of openings are as shown in Figs. 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 and 19 for various sets.

From the finite element analysis, it has been seen that the ultimate load carrying capacity of the corrugated beam with 150 mm depth having 30° angle with 3 mm, 4 mm and 5 mm thick web is 19.25%, 16.49% and 21.76%, respectively, which is more than plain web beam. In addition, 45° angles with 3 mm, 4 mm and 5 mm thick web is 18.50%, 14.88% and 19.30%, respectively, which is also more than plain web beam. The beam with 200 mm depth having 30° angle with 3 mm, 4 mm and 5 mm thick web is 19.90%, 23.00% and 23.53%, respectively, which is more than plain web beam. For corrugation with 45° angles is 17.11%, 14.82% and 21.50%, respectively, which is more than plain web beam. In case of CWB 150, the flexural stiffness of corrugated beam is more up to 0.5 D opening than plain beam. Whereas, the flexural stiffness slightly decreases due to 0.6 D and 0.75 D opening. In case of CWB 200, the flexural stiffness of corrugated beam is more up to 0.5 D than plain beam, but increase in the diameter of opening such as 0.6 D and 0.75 D then the flexural stiffness will decrease and come near about to the flexural stiffness of plain web beam. From above observation it is concluded that flexural stiffness of CWB 200 mm depth with opening having 30° and 45° corrugated web are more than the specimens having CWB 150 with opening and plain web beam. This may be due to the deflection of the specimen under ultimate load. The prime failure modes found to be Vierendeel mechanism, which is similar to the castellated beam with plain web.

Conclusion

The following are the conclusions drawn based on the investigation done in the present paper.

-

Averagely 18% increase in the ultimate load carrying capacity of the beam with corrugated web.

-

Load carrying capacity trapezoidally corrugated beam with 30° angle is more than 45° and plain web beam; hence, it concludes that lesser the angle of corrugation more the load carrying capacity of beam.

-

Increasing in the diameter of opening in the web, the Von Mises stresses concentration found to be more around opening and stress intensity flow through the flange. This leads to flange buckling and can be avoided by providing greater web thickness and stiffeners.

-

Flexural stiffness of corrugated beam having 30°, 45° with different sizes of opening such as 0.5 D, 0.6 D, and 0.75 D is more than the plain web beam. Hence it is concluded that corrugated web beam with opening is stiffer than plain web beam.

-

Length of horizontal panel is also responsible for the increase in load carrying capacity of the beam. Greater depth also gives higher load carrying capacity of corrugated web beam with opening than plain beam.

-

In case of CWB 150, flexural stiffness of corrugated beam is more for opening up to 0.5 D over a plain web beam and slightly decreases with an increase in diameter to 0.6 D and 0.75 D.

-

In case of CWB 200, the flexural stiffness of corrugated beam is also more for opening up to 0.5 D over a plain web beam, but increasing the diameter of opening such as 0.6 D, 0.75 D then flexural stiffness will decrease and come near about the flexural stiffness of plain web beam.

-

From above observation, it is conclude that the flexural stiffness of CWB 200 mm depth with opening having 30° and 45° corrugated web are more than the specimens having CWB 150 with opening and plain web beam. This may due to the deflection of the specimen under ultimate load. Hence, according to the load carrying capacity point of view, it is concluded that corrugated web beam with opening can be used instead of plain web beam. It is helpful to reduce the floor-to-floor height of the building.

-

The prime failure modes found to be Vierendeel mechanism, which is similar to the castellated beam with plain web.

References

Abbas, H. H., Sause, R., & Driver, R. G. (2006). Behavior of corrugated web I-girders under in plane loading. Journal of Engineering Mechanics, 132(8), 806–814.

Chan, C. L., Khalid, Y. A., Sahari, B. B., & Hamouda, A. M. S. (2002). Finite element analysis of corrugated web beams under bending. Journal of Construction Steel Research, 58, 1391–1406.

Divahar, R., & Joanna, P. S. (2014). The effect of web corrugation in cold-formed steel beam with trapezoidally corrugated beam. American Journal of Engineering Research (AJER), 3(06), 137–142.

Divahar, R., & Joanna, P. S. (2018). Numerical simulation and experimental investigation on static behavior of cold formed steel beam with trapezoidally corrugated web by varying depth-thickness ratio. Asian Journal of Civil Engineering, 19, 121–137.

Elgaaly, M., Seshadri, A., & Hamilton, R. W. (1997). Bending strength of steel beams with corrugated webs. Journal of Structural Engineering, 123(6), 772–782.

Eurocode 3: Design of steel structures-EN 1993-1-5. (2006). Guideline for corrugated web beam. Brussels: CEN.

Kaveh, A., & Shokohi, F. (2014). Cost optimization of castellated beams using charged system search algorithm. Iranian Journal of Science and Technology, Transactions of Civil Engineering, 38(C1+), 235–249.

Kaveh, A., & Shokohi, F. (2015). Optimum design of castellated beams using colliding bodies optimization algorithm. Steel and Composite Structures, 2(18), 305–324.

Kaveh, A., & Shokohi, F. (2016a). Application of grey wolf optimizer in design of castellated beams. Asian Journal of Civil Engineering (BHRC), 17(5), 683–700.

Kaveh, A., & Shokohi, F. (2016b). Optimum design of laterally supported castellated beams using tug of war optimization algorithm. Structural Engineering and Mechanics, 3(58), 533–553.

Kovesdi, B., & Dunai, L. (2014). Fatigue life of girders with trapezoidally corrugated webs: An experimental study. International Journal of Fatigue, 64, 22–32.

Lindner, J. (1990). Lateral torsional buckling of beams with trapezoidally corrugated webs (pp. 305–310). Budapest: Colloquium on Stability of Steel Structures.

Morkhade, S. G., & Gupta, L. M. (2015). An experimental and parametric study of steel beams with web openings. International Journal of Advanced Structural Engineering, 7, 249–260.

Morkhade, S. G., & Gupta, L. M. (2017). Experimental investigation for failure analysis of steel beams with web openings. Steel and Composite Structures, 23(6), 647–656.

Morkhade, S. G., & Gupta, L. M. (2019). Ultimate load behaviour of steel beams with web openings. Australian Journal of Structural Engineering, 20(2), 124–133.

Morkhade, S. G., Kshirsagar, M., Dange, R., & Patil, A. (2019). Analytical study of effect of web opening on flexural behaviour of hybrid beams. Asian Journal Civil Engineering, 20, 537–547.

Morkhade, S. G., Shaikh, S., Kumbhar, A., Shaikh, A., & Tiwari, R. (2018). Comparative study of ultimate load for castellated and plain webbed beam. International Journal of Civil Engineering and Technology, 9(8), 1466–1476.

Nie, J. G., Zhu, L., Tao, M.-X., & Tang, L. (2013). Shear strength of trapezoidal corrugated steel webs. Journal of Construction Steel Research, 85, 105–115.

Romeijn, A., et al. (2009). Basic parametric study on corrugated web girders with cut outs. Journal of Construction Steel Research, 65, 395–407.

Sause, R., & Braxtan, T. N. (2011). Shear strength of trapezoidal corrugated steel webs. Journal of Construction Steel Research, 67, 223–236.

Wang, Z., & Wang, Q. (2014). Fatigue assessment of welds joining corrugated steel web to flange plates. Engineering Structures, 73, 1–12.

Zirakian, T., Hajsadeghi, M., Lim, J. B. P., & Bahrebar, M. (2016). Structural performance of corrugated web steel coupling beams. ICE Proceedings Structures and Buildings, 169(10), 756–764.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Morkhade, S.G., Baswaraj, S.M. & Nayak, C.B. Comparative study of effect of web openings on the strength capacities of steel beam with trapezoidally corrugated web. Asian J Civ Eng 20, 1089–1099 (2019). https://doi.org/10.1007/s42107-019-00166-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42107-019-00166-6