Abstract

Lithium-metal batteries with high energy/power densities have significant applications in electronics, electric vehicles, and stationary power plants. However, the unstable lithium-metal-anode/electrolyte interface has induced insufficient cycle life and safety issues. To improve the cycle life and safety, understanding the formation of the solid electrolyte interphase (SEI) and growth of lithium dendrites near the anode/electrolyte interface, regulating the electrodeposition/electrostripping processes of Li+, and developing multiple approaches for protecting the lithium-metal surface and SEI layer are crucial and necessary. This paper comprehensively reviews the research progress in SEI and lithium dendrite growth in terms of their classical electrochemical lithium plating/stripping processes, interface interaction/nucleation processes, anode geometric evolution, fundamental electrolyte reduction mechanisms, and effects on battery performance. Some important aspects, such as charge transfer, the local current distribution, solvation, desolvation, ion diffusion through the interface, inhibition of dendrites by the SEI, additives, models for dendrite formation, heterogeneous nucleation, asymmetric processes during stripping/plating, the host matrix, and in situ nucleation characterization, are also analyzed based on experimental observations and theoretical calculations. Several technical challenges in improving SEI properties and reducing lithium dendrite growth are analyzed. Furthermore, possible future research directions for overcoming the challenges are also proposed to facilitate further research and development toward practical applications.

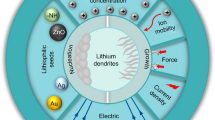

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With the growing applications of portable electronics, electric vehicles, and smart grids, lithium (Li)-based metal batteries, including Li-ion batteries [1], Li-S batteries [2], and Li-air batteries [3], have been rapidly developed in recent years. To increase the mileage of applications, such as electric vehicles, power Li batteries must possess high energy densities. Li-ion batteries appear to have reached their energy density limit, and further increasing the energy density has become difficult. In this regard, Li-sulfur and Li-air batteries with both liquid- and solid-state electrolytes are expected to be the next-generation energy storage devices based on their extremely high theoretical energy densities. In such devices, lithium-metal anodes with a high theoretical specific capacity (3 860 mAh g−1) and a low reduction potential (− 3.04 V vs. SHE) are typically used [4,5,6,7,8]. Experimental results have shown that the energy density of lithium-metal-anode-based batteries is approximately 40%–50% higher than that of classical Li-ion batteries with graphite anodes [9].

Although lithium-metal-anode-based batteries have the advantage of high voltage, two key issues must be resolved before their practical applications. One is that lithium-metal batteries (LMBs) can exhibit rapid dendrite growth in the repeated charging/discharging process. This dendrite growth process punctures the separator, triggers short circuiting of the interior, and causes heat escape and even explosions, hindering the practical application of LMBs [10, 11]. The other issue is that Li dendrites can break away from the current collector to form dead Li, resulting in low Coulombic efficiency (CE) [12]. To resolve these issues, strategies for lithium-metal-anode protection have been developed, focusing on surface control of Li metal, including controlling the surface morphology, decorating the solid electrolyte interphase (SEI) layer, coating artificial protective films, and building three-dimensional lithiophilic frameworks to lower the sedimentary current density. In addition, using a high electrolyte concentration [13,14,15,16,17,18,19,20,21,22,23,24,25,26] and adding electrolyte additives [27,28,29] are reasonable means to prevent dendrite formation.

Regarding regulation and modulation, the electrochemical kinetics play a decisive role in the Li+ stripping/plating process. In this regard, many efforts have been made to investigate the electrochemical kinetics. For example, the Poisson–Nernst–Planck equation can describe the electrochemical mass transport and electrostatic potential across the cell [30], the deposition kinetics of lithium metal can also be analyzed by the Butler–Volmer equation [31], and the heterogeneous nucleation equation gives a growth model for Li embryos [32]. Understanding these kinetic processes can shed light on dendrite growth and the delamination from the current collector mentioned above.

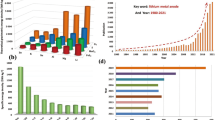

In this Review, we comprehensively summarize the fundamental understanding of the electrochemical kinetics and dendrite growth of lithium-metal anodes in lithium-based batteries using both theoretical approaches, such as density functional theory (DFT) calculations, ab initio molecular dynamics (AIMD), molecular dynamics (MD), and finite element numerical simulations, and experimental validation. We also present a critical survey of the unique phenomena and kinetic mechanisms of Li+ stripping/plating in the electrochemical process. Details of the fundamental mechanisms are also analyzed in terms of electrolyte reduction, charge transfer, the local current distribution, solvation, desolvation, ion diffusion through the interface, inhibition of dendrites by the SEI, additives, asymmetric processes during stripping/plating, the host matrix, and in situ observation of nucleation, as outlined in Fig. 1. Note that extension of the concept of electrochemical kinetics can also play a key role in battery design and improvement of the electrochemical performance, such as the stability of lithium-metal-anode-based batteries.

Copyright © 2016, American Chemical Society. Reprinted with permission from Ref. [34]. Copyright © 2010, American Chemical Society. Reprinted with permission from Ref. [35]. Copyright © 2020, Elsevier. Reprinted with permission from Ref. [36]. Copyright © 2013, American Chemical Society. Reprinted with permission from Ref. [37]. Copyright © 2020, John Wiley and Sons. Reprinted with permission from Ref. [38]. Copyright © 2015, Springer Nature. Reprinted with permission from Ref. [39]. Copyright © 2020, Springer Nature. Reprinted with permission from Ref. [40]. Copyright © 2016, John Wiley and Sons. Reprinted with permission from Ref. [41]. Copyright © 2015, American Chemical Society

Schematic diagram of the Li+ diffusion process from the bulk electrolyte to the anode surface, which is divided into different parts to describe the multi-interface and multidimension issues. Reprinted with permission from Ref. [33].

2 Fundamentals of Electrode Nucleation/Growth Processes

2.1 Electrochemical Processes and Dendrite Growth

In general, understanding the mechanisms of electrode geometric evolution and interface reactions at the electrode/electrolyte interface remains a challenge. The cationic deposition process on the surface of the lithium-metal anode is inevitably involved in the design of a lithium-metal-anode battery. The electrode geometric evolution is a coupled dynamic process of mass transfer and local current density governed by Faraday’s law of electrolysis. The analysis of liquid phase mass transfer can provide insight into lithium dendrite formation and protection. The liquid phase mass transfer is simply divided into two stages: the transient state and the steady state. The transient state is dominated by fast electromigration. Due to the rapid formation of electric fields induced by the nonfaradaic current, the rate of mass transfer via electromigration is much higher than that via diffusion. Meanwhile, the variation range and area of the electrode surface concentration are constantly expanding. As identified in the steady state, the landmark phenomenon is concentration polarization. A dynamic balance can be formed, and the polarization region is no longer extended. In the steady state, mass transfer is the decisive step.

For further analysis, Fig. 2 shows a thin rectangular cell, where the two electrodes are made of Li metal, and the cell is filled with a dilute solution of Li+ salt. The motion of the Li+ salt can be described by the charge, the potential gradient, and diffusion constants (Di), which is a reasonable approximation for dilute solutions if the convection of the electrolyte is neglected. To accurately describe the ion and electron transport behavior, a numerical model can be used to solve the time-based evolution of the Poisson–Nernst–Planck system of equations (PNP equations) that describe the electrochemical mass transport and the electrostatic potential across the cell. The PNP equations take the following forms [42]:

where \(J_{i}\) is the mass flux of the ith species, \(D_{i}\) is the diffusivity of the species, \(Z_{i}\) and \(C_{i}\) are the charge and concentration of the ith species, \(x\) is the position, \(F\) is Faraday’s constant, \(R\) is the ideal gas constant, \(T\) is the thermodynamic temperature, and \(\varphi\) is the electrostatic potential.

Copyright © 1990, American Physical Society. b Profile of the distributions of V (electrostatic potential), Cc, and Ca (ion concentrations of cations and anions), which were obtained from numerical studies with a space-charge model. Reprinted with permission from Ref. [42]. Copyright © 1990, American Physical Society. c The different areas in the diagram can be used to determine whether the size of the embryo is suitable for different nucleation and growth stages. Reprinted with permission from Ref. [32]. Copyright © 2013, The Electrochemical Society. d Profile of a spherical cap-shaped nucleus (N) deposited on a smooth substrate (S) in a liquid electrolyte. a (= rsin θ) is the radius of the circular contact region between the cap-shaped nucleus and substrate. The height of the electrodeposit is h (= r(1 – cos θ)). \(\theta\) is the contact angle, h is the height of the embryo, and r is the radius of curvature. The volume of the cap is \(S_{{\text{V}}} r^{3}\), where \(S_{{\text{V}}} = \frac{\uppi }{3}\left( {2 + \cos \theta } \right)\left( {1 - \cos \theta } \right)^{2}\). The surface area of the cap is \(S_{{\text{A}}} r^{2}\), where \(S_{{\text{A}}} = 2{\uppi }\left( {1 - {\text{cos }}\theta } \right)\). Reprinted with permission from Ref. [32]. Copyright © 2013, The Electrochemical Society

a Scheme of the thin rectangular cell. Reprinted with permission from Ref. [42].

The reaction kinetics at the electrolyte/electrode interface can be described by the Butler–Volmer equation:

where \(\alpha_{{\text{A}}}\) and \(\alpha_{{\text{C}}}\) are the charge transfer coefficients of the anodic and cathodic reactions due to the overpotential \(\eta\). The exchange current density \(i_{0}\) depends on the composition of the reactants and products.

Several factors can affect the electrode kinetics at the electrode/electrolyte interface due to mass transfer and electron transfer. The affecting factors range from the interatomic interaction of crystal nucleation and side reactions to macroscopic electrode geometric evolution. During surface reactions, interface mass transfer and charge transport occur instantaneously, and dendrite growth and accumulation of dead Li can occur, leading to battery failure over time [43].

To date, several models, such as the space-charge model [42], SEI-induced model [4], and heterogeneous nucleation model [32], have been verified to describe Li dendrite formation (including nucleation and growth processes) from different aspects. However, these models cannot accurately describe the nucleation and growth behavior of lithium anodes [44]. Exploring the electrochemical behavior in LMBs via these nucleation models is still worthwhile.

The space-charge model was proposed in the 1990s. It is one of the widely accepted models providing guidance on the initial nucleation process of lithium dendrites [42]. In a dilute solution, the model describes that the deposition rate of Li+ is higher than that of the anions. Li+ depletion on the electrode surface results in a charge space, which ignores the convection of the electrolyte near the electrode, and only electromigration and diffusion are considered. Hence, the space-charge layer near the electrode/electrolyte interface can directly induce dendrite formation. As shown in Fig. 2a and b, the space-charge model simulates a thin rectangular cell filled with dilute solution. When Li+ is deposited on an electrode surface, Region 1 (the quasi-neutral region, \(z_{{\text{c}}} C_{{\text{c}}} \approx z_{{\text{a}}} C_{{\text{a}}}\)) and Region 2 (the space-charge region, \(C_{{\text{c}}} \ll C_{{\text{a}}}\)) are defined (\(z_{{\text{c}}} C_{{\text{c}}}\) and \(z_{{\text{a}}} C_{{\text{a}}}\) are the electrostatic charge densities of anions and cations). Region 1 occurs in the bulk electrolyte, and Region 2 occurs in a tiny area near the electrode/electrolyte interface. In addition, the two regions are dominated by different factors. In Region 1, the ion concentrations of Li+ and anions are mainly regulated and controlled by electromigration. In Region 2, the ion concentration of Li+ is mainly limited by surface diffusion. More specifically, some factors, such as increasing the electrolyte concentration, enhancing the mobility of anions, and reducing the applied electric field (plating at a low current density), could effectively reduce the thickness of the space-charge layer. Because the space-charge layer induces the formation of dendrites, there is a strong correlation between the two. Reducing the thickness of the space-charge layer can directly suppress the formation of dendrites.

However, the space-charge model does not take the reaction between Li metal and the electrolyte into account, and the SEI-induced model was proposed to mitigate the limitations. The presence of the SEI makes the deposition behavior of lithium metal more complex than that of other metals. To understand the role of the SEI in the nucleation process, we first need to describe the structure of the SEI. The SEI is generally considered to be an organic/inorganic composite mosaic structure produced by the reduction of lithium salt and the electrolyte by lithium metal. In the process of Li+ diffusion from the bulk electrolyte to the anode surface, Li+ ion diffusion through the SEI is the largest barrier. The activation energy barrier of Li+ diffusion through the SEI is higher than that through the bulk electrolyte. The Li+ concentration tends to be enriched near the holes of the SEI, which directly leads to a local nonuniform Li+ flux on the surface of the lithium-metal anode. In short, the porous SEI structure can lead to nonuniform Li deposition, resulting in rapid Li plating and dendrite growth. Additionally, during the subsequent stripping/plating processes, due to the fragile SEI, the sizeable volumetric expansion of the lithium-metal anode is not effectively buffered, and tremendous amounts of cracks on the SEI surface can be resulted. When these cracks react with the electrolyte and form a new thin SEI, the resulting electric field and Li+ ion flux are higher. Then, Li+ ions prefer to deposit on these cracks, leading to rapid growth of Li dendrites and stress concentration. Therefore, development of effective strategies for suppressing dendrite growth by stabilizing and strengthening the SEI layer is necessary.

Ely and García [32] employed the heterogeneous nucleation model, beginning from fundamental thermodynamic principles, unifying the concepts of electrochemistry and nucleation and growth theory, and explaining the effect of initial nucleation on Li+ deposition. Five regimes of behavior were identified: the nucleation suppression regime, long incubation time regime, short incubation time regime, early growth regime, and late growth regime. The size of the embryo directly determines whether the nucleation process can form a lithium nucleus. An embryo larger than or equal to the thermodynamic and kinetic critical radius is involved in an electrodeposited stable nucleus. Otherwise, the embryo tends to redissolve into the electrolyte again. In the long incubation time regime, the size of the embryo exceeds the critical radius after overcoming the critical energy barrier. Such embryos will remain and sequentially grow under fluctuations in the electric field and ionic field. Then, in the early growth and late growth regimes, the nuclei gradually grow to reach the same terminal size. Eventually, these embryos become the Li nuclei. Hence, the critical radius limits the initial Li nucleation process.

The growth of Li during electroplating in a flat way is virtually inaccessible. Electrolyte decomposition and SEI formation can occur during electroplating. Then, the Li+ ion diffuses through the SEI layer during the subsequent plating, which is different from the conventional electrodeposition process. Therefore, many embryos will appear at the electrode interface after a delay or incubation period because lithium electrodeposits can easily achieve heterogeneous nucleation conditions [32]. In addition, in situ characterization shows that the growth rate is constant after nucleation, which suggests a variety of competitive driving factors before the growth of the lithium nucleus.

Regarding the heterogeneous nucleation model, the volume change during stripping/plating processes is considered. For the surface of a lithium-metal anode without a host structure, the largest issue is the sharp volume change during stripping/plating processes. The change in volume is favorable for dendrite nucleation from the point of view of the heterogeneous nucleation model. However, it can also destroy the stability of the SEI and continuously consume active substances and the electrolyte, ultimately leading to failure of lithium-metal-anode-based batteries. Chazalviel [42] believed that cations could be rapidly consumed for lithium-metal anodes charged at a high rate in a binary electrolyte, and the cation concentration near the anode was expected to drop to zero [42]. After that, a strong electric field could induce absorption and deposition of a large amount of Li+ ions in a short time, causing dendrite growth. The Sand’s time (τ) can be used to describe the initial nucleation time of lithium dendrites:

where D is the diffusion constant, \(C_{0}\) is the initial concentration, \(J\) is the effective current density, and \(\mu_{{\text{a}}}\) and \(\mu_{{{\text{Li}}^{ + } }}\) are the anionic and Li+ mobilities, respectively.

Equation (4) indicates that the initial nucleation time of lithium dendrites (τ) is proportional to \(J^{ - 2}\). Furthermore, the velocity for the formation of dendrites can be determined by:

where \(\nu\) is the velocity for the formation of dendrites and E is the applied electric field.

Theoretical and numerical studies by Chazalviel [42] found that the dendrite growth rate was constant under a high current density and proportional to the applied electric field and the mobility of anions (\(\mu_{{\text{a}}}\)) for diffusion-limited systems. The critical values of high and low current densities can be expressed by Eq. (6):

where L is the interelectrode distance. Obviously, \(J^{*}\) is inversely proportional to the interelectrode distance (L) according to Eq. (6), indicating that the long electrode spacing of a pouch battery cell makes dendrite growth easier than the short electrode spacing of a coin battery cell.

Furthermore, in addition to at a high current density, dendrites can also grow at a low current density, induced by the nonuniform morphology of the electrode surface. In other words, under the condition of a low current density, uniformity of the electrode surface has an inhibitory effect on dendrite nucleation, and the anode surface also affects the initial nucleation time of lithium dendrites.

In the interpretation of dendrite nucleation evolution, heterogeneous nucleation can be expressed as Eq. (7):

The most basic and widely accepted model is the basis of studying the nucleation dynamics, as shown in Fig. 2c and d [32]. Mathematically, spherical cap-shaped deposition from a liquid electrolyte can be expressed by the total Gibbs free energy (Eq. 7) of transformation. In Eq. (7), \(\Delta G_{{\text{f}}}\) is the volume free energy of transformation, \(\gamma_{{{\text{NE}}}}\) is the interfacial free energy between the nucleus and electrolyte, \(\gamma_{{{\text{SN}}}}\) is the interfacial free energy between the substrate and the nucleus, \(\gamma_{{{\text{SE}}}}\) is the interfacial free energy between the substrate and electrolyte, z is the valence of the electrodepositing ion, F is Faraday’s constant, Ω is the molar volume, \(\eta\) is the overpotential, and \(r\) is the radius of curvature of the nucleus (Fig. 2d). \(S_{{\text{V}}} = \frac{\uppi }{3}\left( {2 + \cos \theta } \right)\left( {1 - \cos \theta } \right)^{2}\), and \(S_{{\text{A}}} = 2{\uppi }\left( {1 - {\text{cos }}\theta } \right)\), which account for the volumetric and area shape factors, where θ is the contact angle.

The critical radius to form a thermodynamically stable precipitate, i.e., \(\frac{{{\text{d}}G_{{\text{T}}} }}{{{\text{d}}r}} = 0\), can be expressed as Eq. (8):

The thermodynamically unstable embryos tend to redissolve in the electrolyte during the nucleation suppression regime, as shown in Fig. 2c. A statistically representative embryo larger than the thermodynamic and kinetic critical radius is required to successfully grow a thermodynamically stable electrodeposited nucleus. In regimes where only \(r > r_{{{\text{eq}}}}^{*}\) is satisfied, embryos can form, redissolve in the electrolyte and interact with each other. Different types of surfaces favored in the nucleation and growth of electrodeposits are demonstrated in Fig. 2c. Heterogeneous nucleation of electrodeposits at a large overpotential is favored on a substrate with a high degree of roughness. In addition, if its radii are larger than the critical kinetic nucleus, then the smooth anode surface in distributed particle form can serve as nucleation sites. However, if the substrate is very smooth or the radius of curvature of the substrate is very large, then no heterogeneous deposition can occur.

The initial nucleation phase can be considered heterogeneous nucleation behavior, which was demonstrated based on both thermodynamics and kinetics by Ely and García [32]. They treated the nucleation as having five regimes: the nucleation suppression regime, long incubation time regime, short incubation time regime, early growth regime, and late growth regime [32]. In the subsequent incubation regimes, the incubation of Li nuclei was entirely driven by thermal noise, local electrochemical reactions, and the Gibbs–Thomson interaction. If the applied overpotential was lower than the critical overpotential, then the long incubation regime would appear. Li nuclei with a broader size could be beneficial in this situation and grow for a long time. In the short incubation time regime, if the applied overpotential was higher than the critical overpotential, then only Li nuclei with a relatively narrow size could grow in a short time. Constant terminal velocities in the early growth regime and the late growth regime were found due to the thermodynamically and kinetically stable Li nucleus. According to the above analysis and calculation, dendrite formation can be inhibited by (1) reducing the roughness of the anode surface; (2) reducing the anode particle size to below the critical thermodynamic radius; (3) lowering the deposition potential to below the critical overpotential and cycle frequency to below the characteristic incubation frequency \(\left( {\frac{1}{\tau }} \right)\); and (4) adjusting the wettability of the Li deposition surface.

2.2 Interfacial Properties of the Anode/Electrolyte Interface

For Li stripping/plating processes, the kinetics of atom/electron diffusion to another phase seem important in understanding dendrite growth. At present, researchers have carried out multidimensional and multiexperimental studies on the mass transfer, electrode morphology evolution, and charge transfer occurring at the electrode interface. Thus, a novel understanding of real-world Li stripping/plating processes involving electrochemistry is required to correctly predict interatomic interactions in SEI and dendrite formation. Researchers have proposed several models for the SEI, as shown in Fig. 3, to fit the complex behavior of this interface. Concerning this, various characterizations and multiscale simulations have been carried out. Atomic- and molecular-level and macroscopic-level interfacial challenges are involved in the search for high-performance LMBs [52, 53].

Copyright © 1979, The Electrochemical Society. b XPS spectra of a Li metal surface. Reprinted with permission from Ref. [46]. Copyright © 1985, The Electrochemical Society. c Schematic diagram of the polyhetero-microphase SEI model. Reprinted with permission from Ref. [47]. Copyright © 1997, The Electrochemical Society. d Schematic presentation of the SEI formation process. Reprinted with permission from Ref. [48]. Copyright © 2000, Elsevier. e Schematic energy diagram of an electrolyte. Reprinted with permission from Ref. [34]. Copyright © 2011, Elsevier. f Schematic illustration of Li+ diffusion through a porous organic layer and a dense inorganic layer. Reprinted with permission from Ref. [49]. Copyright © 2012, American Chemical Society. g Schematic illustration of mosaic and multilayered structures formed on a Li surface. Reprinted with permission from Ref. [50]. Copyright © 2017, The American Association for the Advancement of Science. h Accelerator fluctuations with geometric deformation, and COMSOL simulation with THU. Reprinted with permission from Ref. [51]. Copyright © 2019, John Wiley and Sons

Presentation and recognition of key achievements in SEI and dendrite growth research history. a The effect of a partial short on the deposition process of the SEI. Reprinted with permission from Ref. [45].

At the atomic and molecular level, high chemical reactivity is induced by surface atoms with active atomic and electronic structures, enabling interactions with the electrolyte and solvents [54]. DFT calculations and in situ characterization techniques can enable the investigation and understanding of the adsorbed intermediates as well as the reaction mechanism. In recent years, some specific measurements have been carried out on new types of additives and concentrated electrolyte systems, revealing some novel mechanisms. Atomic and molecular interactions can modify the height and shape of the reaction and migration barriers, eventually affecting the nucleation kinetics, electrochemical polarization, and mass transport of Li+ ions in porous SEIs.

At the macroscopic level, several unique phenomena and the electrode geometric evolution can be captured with the development of in situ characterization technologies. Some reaction kinetics can be described with prominent nonlinear characteristics. The morphologies of the anode and SEI are prone to affect the stability and evolution. The initial conditions greatly affect the system and its changes with time based on the kinetic equation. In the following sections, interface phenomena at both the micro- and macrolevels will be introduced from several perspectives.

3 Interface Interactions

3.1 Electrolyte Reduction Mechanisms

Interface interactions have different features in their respective electrochemical processes, mainly in the SEI at the anode/electrolyte interface of lithium-metal-anode-based batteries. The SEI is the key factor of many processes, limiting the lifetime, performance, and safety. It can affect the inhomogeneous growth of the lithium-metal anode and diffusion of Li+ ions. Thermal runaway in battery failure can be caused primarily by SEI decomposition. The primary capacity fade can also be attributed to the consumption of lithium by the continuous growth of the SEI. Generally, an improvement in interfacial stability is required for high voltage. Thus, innovative design of stable electrolytes and the associated batteries requires a fundamental understanding of the SEI formation mechanism through both modeling and experimental measurements [48, 55, 56].

The initial formation of an SEI film is generally regarded as the process of electrolyte reduction on the lithium-metal-anode surface, which plays a significant role in the SEI composition [57]. At the same time, the formation of the SEI is directly related to the battery cycling process. In the practical battery charging process, the Li+ in the cathode diffuses toward the anode through separators and electrolytes, driven by the increase in the cathode potential and decrease in the anode potential (the cell voltage potential of the battery is increased). During the discharging process, the Li+ ions return to the cathode, where they insert into the cathode material (the cell voltage of the battery decreases) [58]. Considering that an electrode (an anode or cathode) itself has large numbers of ion and electron channels, it can be treated as an equipotential body in which the potential inside the electrode is equal everywhere. Therefore, the change in potential is mainly due to the electrolyte/electrode interface, which can be regarded as a parallel electric double layer (EDL) with resistance. There will be a potential gap between the electrode and electrolyte. Apparently, this potential gap is a trigger that activates the electrochemical reaction between the electrode and electrolyte, resulting in a “new interface” at the middle of the electrode and electrolyte. Hence, the “new interface” plays a key role in balancing the potential of the battery. The interface generated at the surface of the anode is named the SEI [45, 59], and that at the cathode is named the cathode electrolyte interphase (CEI), collectively known as the electrode electrolyte interphase (EEI) [60]. In practice, the SEI is a dominant factor that influences the Li+ diffusion on the anode surface. The reduction process can significantly affect the SEI components. Therefore, many mechanisms have been proposed to explain the process of electrolyte reduction, such as the one- and double-electron reduction mechanisms of electrolytes [61,62,63]. Furthermore, although the SEI chemical composition is diverse and disturbed by local variables, it has been studied by a multitude of experimental techniques, including photoelectron spectroscopy [64], Fourier transform infrared spectroscopy [65], redox shuttle analysis [66, 67], nuclear magnetic resonance (NMR) [68], atomic force microscopy [69], neutron reflectometry [70], capacity analysis during cycling [71], and state-of-charge (SoC) analysis [72, 73]. Some reactions may occur on the picosecond (ps) timescale, and directly capturing reactions at the electrode/electrolyte interface is challenging. Therefore, not only in situ characterization tests but also quantum chemistry (QC), DFT, and MD simulations have been widely used to reveal the initial electrolyte reduction and decomposition mechanisms [74]. Due to the complex structure and physical scale of the SEI, there are many deficiencies in our understanding of the SEI. As a result, researchers have varied in their research emphasis to meet different functional requirements and in their opinions on the SEI. For example, some researchers focused on the failure mechanisms and corresponding SEI regulation strategies [43], a new understanding of the LiF component in the SEI [75], and the formation and transport mechanisms of the SEI. These works have different perspectives and understandings. Therefore, understanding the SEI is a dynamic and tortuous process.

Goodenough et al. [34] used frontier orbital theory (FOT), as shown in Fig. 4a, to describe the nature of the anode and cathode (involving the electrolyte) of the battery. \({\mu }_{\mathrm{A}}\) and \({\mu }_{\mathrm{C}}\) are the chemical potentials of the anode and cathode, respectively. \({E}_{\mathrm{LUMO}}\) and \({E}_{\mathrm{HOMO}}\) represent the voltages corresponding to the lowest unoccupied molecular orbital (LUMO) and highest occupied molecular orbital (HOMO). The electrolyte is affected by the LUMO and the HOMO. If \({\mu }_{\mathrm{A}}>{E}_{\mathrm{LUMO}}\), then the anode electrons tend to diffuse to the electrolyte LUMO, whereas the stability window is extended by the SEI on the negative electrode. In contrast, if \({\mu }_{\mathrm{C}}<{E}_{\mathrm{HOMO}}\), then the electrons of the electrolyte tend to transfer to the cathode surface to form a CEI film [41, 77]. The stability window is extended by surface films, denoted as the CEI and SEI on the electrodes.

Copyright © 2016, Elsevier. c Methods to compute the reduction voltage. Molecules/ions in the solution phase, solid phase, and gas phase are denoted by sol., s, and g, respectively. The subscripts sol and vap represent the vaporization and solvation processes, respectively. ∆G is the free energy, ΦM is the work function of the anode, and the subscript e indicates the ionization process. Reprinted with permission from Ref. [62]. Copyright © 2001, American Chemical Society

a Schematic open-circuit energy diagram of an electrolyte. Eg is the electrolyte electrochemical stability window. μA and μC are the redox potentials of the anode and cathode, respectively. b Several common solvents, additives, and desolvated ion reduction potentials versus Li/Li+, calculated from QC with the developed solvation model. Reprinted with permission from Ref. [76].

The dominant factors of SEI formation are usually attributed to the initial adsorption and formation of the inner Helmholtz plane (IHP) and the solvated coordination behavior [78]. The specific adsorption behavior is the formation of the initial interface on the anode surface, which is the foundation of the SEI and controls the initial state of the interface structure and the chemical composition. Solvated coordination behavior can impact the maintenance of the SEI film in cycling [59]. According to traditional electrochemical theory, the negative electrode tends to lose electrons due to the balance of the high free-electron concentrations when the electrode contacts with the electrolyte.

As shown in Fig. 4c, a thermodynamic chemical cycle for the lithium reaction can be expressed as Eq. (9):

where ∆Gsol is the solvation free energy of Li+, ΦM is the work function of the anode, ∆Ge is the ionization free energy, and ∆Gvap is the vaporization free energy. Using Eq. (9), the difference in the lithium electrode potential can be measured in multitudinous electrolyte systems, which depends only on the variation in G(Li+, sol), the free energy of Li+ in solution. Wang et al. [62] used this equation and found that the reduction potential of Li+(EC)4 (Li+ coordination with four ethylene carbonate (EC) molecules) was approximately − 2.2 V on the physical scale, which agrees with the experimental findings of Naji et al. [79] and Novak et al. [80] of a reduction potential for EC of 0.8 V versus Li/Li+ (corresponding to − 2.36 V on the physical scale). In addition, Arora et al. [81], in dealing with the capacity fade in lithium-ion batteries, obtained a reduction potential of − 3.045 V versus Li+/Li. Many cases have different reduction potentials, as demonstrated in Fig. 4b [76]. H-transfer reactions (intra- and intermolecular H atom transfer during electrolyte oxidation) are usually accompanied by electrolyte oxidation, which directly results in the oxidation potential being lower than the calculated HOMO value [76]. In addition, the LUMO of most electrolyte components is higher than the lithiated graphite (~ 0.1 eV) and lithium metal (0 eV) potentials. Therefore, if the chemical stability window of the electrolyte is not widened, then the reduction reaction of the electrolyte on the anode is inevitable. The SEI on the lithium-metal anode is more fragile than the CEI on the cathode due to the large volume expansion caused by Li+ deposition at the lithium anode surface. Considering their importance in battery performance and durability, extensive research from different perspectives has been performed on anode SEI films. Different anodes and/or electrolytes have diverse lithiation/delithiation characteristics, which lead to variations in the failure mechanisms of the SEI.

With the rapid development of supercomputers and highly sensitive spectroscopy, identification of the products and types of reactions on Li surfaces has become feasible for complex systems. For example, Leung et al. [82] utilized AIMD to track the initial decomposition process of liquid EC with different edge terminations. Two EC decomposition pathways were confirmed. Depending on which C–O bond was cleaved, CO or C2H4 gas could be generated. The multireaction pathways were further elucidated in later studies and confirmed by electron paramagnetic resonance spectroscopy measurements [83, 84]. The major solvent reduction products precipitating on lithium electrodes in ether, ester, and alkyl carbonate solutions were ROLi, RCOOLi, and ROCO2Li species, respectively. As claimed, the specific surface components formed on lithium-metal anodes could be identified, such as (CH2OCO2Li)2 and CH3CH(OCO2Li)CH2OCO2Li formed by reduction of EC and propylene carbonate (PC), CH3OLi and CH3OCO2Li formed by reduction of dimethyl carbonate (DMC), and HCOOLi formed by reduction of methyl formate (MF). Combining experimental and computational approaches, Liu et al. [85] found unambiguous answers in understanding how 1,2-dimethoxyethane (DME) and 1,3-dioxolane (DOL) reductively decompose on lithium through the interfacial chemistry and morphology. A series of possible SEI components, such as LiOCH2CH2OLi, LiOCH2O(CH2)3O(CH2)2OLi, (CH2CH2OCH2OLi)2, LiO(CH2)2O(CH2)3OLi, LiOCH2CH2OCH2CH2OLi, and (CH2OCH2CH2OLi)2, were proposed, all of which arise from reductive decomposition of the cyclic solvent DOL.

Using X-ray photoelectron spectroscopy (XPS), some perfluorinated anions in Li salt of the MFy− type (M = As, P, B) were identified to be reduced on Li to surface LiF and species of the LixMFy type by XPS [86]. The following reaction scheme for surface film formation on Li in this system can be outlined based on the above studies.

EC reduction

One-electron reduction [62, 63]

Two-electron reduction of 2 EC molecules [62]

Two-electron reduction of 1 EC molecule [62]

Two-electron reduction [82]

DMC reduction

One-electron reduction [48, 87]

Two-electron reduction of 1 DMC molecule [88, 89]

Two-electron reduction of 2 DMC molecules [88, 89]

DOL reduction [85]

PC reduction

One-electron reduction of PC [90]

Two-electron reduction of 2 PC molecules [90]

LiPF6 reduction [48, 87, 89, 91,92,93,94,95,96,97]

3.2 Charge Transfer in the Lithium-Metal-Anode Reaction

The homogenization of dendrites at the lithium-metal-anode/electrolyte interface is determined by the relationship between the morphology of the SEI and the deposition behavior of lithium atoms. Electron and Li+ transport during the process of Li deposition on the SEI can systematically achieve orientation of Li atoms during the deposition, which is affected by the subsurface atoms [98]. In addition, the origins of dendrite formation could be associated with the Li+ plating mechanism and the charge transfer mode during Li reduction or lithium-metal oxidation at the anode-electrolyte interface [99]. Charge transfer is usually manifested as the electron tunneling mode [100, 101].

The kinetics of electron and Li+ transport at the interface have been intensively investigated by analyzing the overpotential equation known as the Butler–Volmer Eq. (3), as previously described. In the Butler–Volmer equation, the exchange current density i0 can be expressed by the charge transfer resistance RCT via i0 = RT(FRCT)−1, measured in the linear regime of the electrode kinetics. If RCT is set equal to the interfacial impedance, then the charge transfer can be illustrated by the impedance method [102]. In addition to impedance, the reaction kinetics can also be expressed by the landscape of the excess chemical potential, \(\mu^{{{\text{ex}}}} \left( x \right)\), between local minima \(\mu_{1}^{{{\text{ex}}}}\) and \(\mu_{2}^{{{\text{ex}}}}\) with transitions over an activation barrier \(\mu_{\ddag }^{{{\text{ex}}}}\) (Fig. 5a). In this case, Eq. (25) can be used to express the reaction, where R is the reaction rate, \(k_{0}\) is the reaction rate constant, and \(k_{{\text{B}}}\) is the Boltzmann constant. In a balanced state, R will be equal to zero in equilibrium with \(\mu_{1}\) = \(\mu_{2}\) in Eq. (25), and the reaction rate (R) is consistent with nonequilibrium thermodynamics:

a Schematic diagram of the excess chemical potential reflected by the reaction S1 → S2. b Process of cation adsorption from a liquid onto an electrode, where the transition state (TS) excludes multiple surface sites (s > 1) while shedding the primary solvation shell. c Solid diffusion on a lattice, where the TS excludes two sites. Reprinted with permission from Ref. [36].

In addition to classical kinetics methods, DFT and Monte Carlo (MC)/MD calculations have also been conducted to analyze electron transfer because the interfacial reactions and charge transfer at the lithium-metal-anode/electrolyte interface are difficult to track in experiments. Typically, the extreme reactivity of the Li metal surface can induce a strongly inhomogeneous electron distribution upon deposition of a cation on the surface. Once Li+ receives electrons and plates on the lithium-metal surface, different conditions can result in different Li plating layers. This charge inhomogeneity may promote uneven Li nucleation and growth, eventually resulting in dendritic behavior. Qin et al. [99] reported a simulation model describing both Li (100) and Li cations located in proximity to the surface. In this model, the solvent used was EC and DME, and the electrolyte was a LiPF6 salt; the Li cations were distributed over perfect, defect-containing, and Li2CO3-passivated Li (100) surfaces. The authors demonstrated that Li cations were easily reduced when bonded to DME rather than EC, and their preferred deposition site was the hollow site on both perfect and defective Li (100). Additionally, a compact Li2CO3 layer could inhibit the charge transfer from Li metal to Li cations, thus modifying Li plating. Bertolini et al. [103] utilized MD and observed the evolution of the Li (100) surface, including the formation of regions with varying Li density and oxidation states and the penetration of electrolyte molecules. Furthermore, electron transfer-driven decomposition could lead to the initial formation of SEI products, as shown in Fig. 6a. The formation of the structure and oxidation state of Li and some fragments were followed through the metal dissolution process. A porous SEI can be identified, and a change in the lithium concentration and oxidation state throughout this phase can be found by using simulation approaches. An increase in Li concentration closer to the dense phase is suggested (Fig. 6a). The entire porous phase is pervaded by Li ions and reacted species coexisting with intact electrolyte molecules. The Li distribution is more uneven in the nest phase than in the disperse phase. In the nest phase, Li atoms are organized as nanochannels and nanovoids. With time, clusters are formed in this region (Fig. 6a), and their size can grow over time. The clusters formed in the disperse phase have a high concentration of interconnected Li atoms. The clusters also have a high concentration of other species, such as O- and F-based compounds with Li ions and poly(carbon monosulfide). In the electrolyte containing Li triflate (LiTf), clusters are formed after a time scale of 1.2 ns. Both in the nest and disperse phases, Li has a very different structure from that in the bulk body-centered cubic (bcc) phase. In the Li–Li radial pair distribution function (RPDF) (Fig. 6b and c), the nest and disperse phases present a first peak at approximately 3.2 and 3.5 Å (1 Å = 1 × 10−10 m), respectively, for each simulated electrolyte. In the disperse phase, Li is mainly organized in pairs with a liquid-like structure, which can be formed and dissolved over time, while in the nest phase, Li has an amorphous structure, organized as a solid. As shown in the RPDF, a lower density of dissolved Li atoms can be obtained in pure DME than in other electrolytes for both the nest (Fig. 6b) and disperse (Fig. 6c) phases. Norio et al. [104] developed a hybrid MC/MD reaction method to study the atomistic picture of the SEI film structure (Fig. 6d). The mass density of dimers in the EC-based SEI film (Fig. 6e) was larger than that in the PC-based film (Fig. 6f), indicating a denser network among the organic salts in the EC-based SEI film. From another point of view, the PC-based SEI film does not have a dominant peak but rather a broad distribution of dimers, indicating that flaws exist in the network formation of the PC-based SEI film. As observed, electron tunneling can only work in the initial part of SEI growth. In this mode, electron and Li+ transport processes in the SEI were addressed by an atomistic simulation method [103, 104]. As claimed, electron tunneling allows the migration of electrons over SEI layers as thin as 2–3 nm [105], while the thickness of the SEI usually exceeds 10 nm [106]. This suggested that electron tunneling plays a role only in the initial part of the first-cycle SEI growth.

a Model simulation of the 1.0 M (1 M = 1 mol L−1) LiTf/1,4-dioxane (DX) cell at 2 ns. (I) Front-side view of the cell showing all the atoms. (II) Front-side view of the cell showing only lithium atoms, while the other atoms are hidden. (III) Side view of the cell showing only lithium atoms. The molecules (shown on the right side) are (A) DOL, (B) dimethyltrifluoroacetamide (DMTFA), (C) EC, (D) fluoroethylene carbonate (FEC), (E) DME, (F) DX, and (G) LiTf. Color code: Li (purple), O (red), C (gray), H (white), F (cyan), and S (yellow). Li–Li RPDF in the b nest phase and c disperse phase tested in several electrolytes after 500 ps of simulation. Reprinted with permission from Ref. [103]. Copyright © 2018, American Chemical Society. d Configuration of the cell in the 1.1 M LiPF6/EC or PC simulation, where the origin of the Z-axis is taken as the position of the contact point between the graphite and electrolyte. Color code: Li (blue), C (cyan), O (red), H (white), P (orange), and F (green). Surface number densities \(\rho_{{\text{n}}}^{{\text{S}}}\) of several solvent molecules and reaction products during the MC/MD cycles, that is, SEI film formation simulations, in e EC-based and f PC-based electrolytes. Reprinted with permission from Ref. [104]. Copyright © 2014, American Chemical Society

3.3 Local Current Distribution over the Lithium-Metal Anode

In general, the electrode reaction and growth of the dendrites are determined by the local current density. Hence, understanding and controlling the electrode current distribution to limit dendrite formation is imperative for safe use of a lithium-metal anode. The local current density is expressed in a similar way to electron transport at the interface, which is described by the Butler–Volmer equation. The direction of these studies can be guided by theoretical studies on the relationship among the current distribution, concentration gradient, and dendrite nucleation. To model dendrite formation and growth, the concentration and potential fields in the electrolyte domain need to be considered, and the normal velocity of the lithium interface needs to be calculated. Mass conservation is typically governed by the PNP equations and electroneutrality. Electroneutrality is expressed as the total charge number of cations in the solution being equal to the total charge number of anions:

where the subscript i represents the species, which can be the PF6− anion or other lithium ion salt anions. For each species, ci is the concentration, and \({z}_{i}\) is the charge number. The electroneutrality gives c− = cLi.

The current density, i = \(F\sum\nolimits_{i} {Z_{i} {\varvec{N}}_{i} }\), where \({\varvec{N}}_{i}\) is the flux of species, is governed by Eq. (27):

The total lithium current density is given by it = iLi + iSEI, where the reaction current density, iLi, is described by the Butler–Volmer equation and the SEI formation current density iSEI is determined by the Tafel-type kinetics [107].

Liu and Lu [107] quantitatively analyzed the change in SEI thickness. Consider a small SEI line element and denote its length at time t by l. After a time interval (dt), the length of the element becomes l + dl, while its thickness becomes h + dh. Denote the SEI growth rate from the electrochemical reaction by qSEI, which is the increase in SEI thickness per unit time due to the reaction. Mass conservation gives the following expression:

Numerous experimental studies have been carried out to address the issue of electrode current distribution and dendrite growth in lithium batteries. The increase in the current density in adjacent dendrites or globules is the most prominent driving force for the nucleation process, thus far escaping experimental scrutiny. Therefore, the average current density is mostly reported in relevant reports on lithium-metal-anode-based batteries [108]. For example, Liu et al. [107] found that dendrite growth could show two distinct stages: fast acceleration during SEI penetration and stable growth after reaching an equilibrium SEI thickness at the dendrite tip. Under low current density conditions, the growth rate of dendrites could be scaled up by increasing the current density without much geometrical shape change. The dendrite morphology can be significantly changed by a high current density, forming a needle shape, as shown in Fig. 7a. The larger SEI thickness at the bottom corners of the dendrite can cause lithium to grow slower here than in the flat area, so slight piercing of the substrate surface with a V-shape can be observed at the bottom of the dendrite, as shown in Fig. 7b. This makes dendrite break away from the substrate easier. A simulation with the same parameters but without the SEI is shown in Fig. 7c. Compared to Fig. 7a, clear differences can be seen in the morphology and height, which are rounder and shorter without any V-shape in the bottom corner.

Copyright © 2017, The Electrochemical Society. The growth of the lithium globule was divided into four stages according to the local current density. The local current density is plotted according to the four stages of the growth of the lithium embryo. d In the initial stage, a perturbation at the anode/electrolyte interface results in a higher current density at the tip of the globule than that of the entire region. This current density is measured between time points 0 and 8.27 C cm−2. e With the growth of the embryo, the current is delocalized away from the tip of the globule. Measurement points: 8.27–16.53 C cm−2. f The delocalization behavior spreads. Measurement points: 16.53–35.82 C cm−2. g The globule has grown large enough that the current density concentration is significantly reduced. Measurement points: 35.82–54.72 C cm−2. Reprinted with permission from Ref. [108]. Copyright © 2016, The Electrochemical Society

a Profile of the lithium surface morphology (blue line) and SEI layer thickness (red layer) evolution process with time. b The profile of a V-shaped dendrite was formed at the left corner at t = 50 s. The substrate appears to be slightly pierced by V-shaped dendrites due to the thick SEI, resulting in slow growth at the corner. c Profile of the lithium surface morphology at t = 50 s without inducing an SEI in the simulation. The whole curve is smooth without a V-shape at the bottom corner. Reprinted with permission from Ref. [107].

The local current distribution of the lithium-metal anode with local mechanical stresses is a crucial parameter to reveal the details of the evolution of electrochemical deposition. Time-resolved hard X-ray microtomography was employed by Harry et al. [108] to monitor the internal structure of a symmetric lithium-polymer cell during galvanostatic polarization. The study demonstrated local current density evolution due to local mechanical stress from lithium metal nucleation and growth (Fig. 7d–g). In Fig. 7d, the tip of the protruding lithium globule directly leads to a high local current density. As the lithium globule grows, the local concentrated current density spreads from the protrusion tip to the perimeter, which is the current density delocalization effect. Eventually, when the radius of the globule is sufficiently large, the current density of the protruding globule is only slightly higher than that of the surrounding lithium metal. The current delocalization effect shown in Fig. 7e and f is hypothesized to be caused by the mechanical stiffness of the polymer electrolyte.

Anion depletion under an applied current density results in a local space charge near the electrode, which eventually causes highly branched growth of the metal. As identified, the dendrite growth rate is directly related to the applied current density [109]. The local geometric fluctuations of the substrate or the SEI layer could greatly influence the current and ion distributions, causing dendrite initiation and growth at even small current densities [110]. Based on this understanding, several dendrite prevention avenues have been investigated through studies of the local current density: (1) increasing the surface area of the anode to reduce the effective current density, i.e., using a lithium powder anode [111,112,113,114,115] and a high surface area current collector [114, 116,117,118,119]; and (2) exploiting a self-healing electrostatic mechanism based on repelling the incoming Li+ from the tip to the valley of the potential dendritic surfaces [112, 120,121,122,123].

3.4 Solvation Structure of the Lithium-Metal Anode

In general, the electrolyte provides an electric current between the positive pole (cathode) and the negative pole (anode), and the current is carried only by the moving ions for charge transfer. Dissociated salts in polar solvents can produce most of the mobile ions in the cell, except in the molten state (ionic liquid) or in the decoupled ceramic or glass state [124]. For conventional lithium-ion batteries, lithium ions are mainly provided by lithium salts, such as LiPF6, lithium bis(fluorosulfonyl)imide (LiFSI) and lithium bis(trifluoromethanesulfonyl)imide (LiTFSI). The solvation sheath is closely related to the formation of the SEI. Therefore, some reports describe the formation of the SEI from the competitive reactions of the solvation sheath structure [125], and some describe the solvation structure arising from control of the interface to achieve a high-performance SEI structure [126]. At present, there are still some controversies about the influence of anions on the interface. However, in an organic electrolyte environment, the solvation of anions is highly system-specific because the Coulomb interaction between anions and solvents is weak. In most commonly used nonaqueous solvents, anions are much less solvated than cations [127]. Hence, the solvation structure with Li ions and solvent molecules constitutes the actual ionic species that are mobile in the electrolyte.

Recognition of the solvation structure of lithium ions is necessary to understand the interface interaction process of the solvation structure. Bernal and Fowler [124] proposed that the solvent molecules in the solvent were induced to surround and redirect the ion dipoles, thereby changing the coordination state of the solvent in dilute aqueous solution. From a solvation structure point of view, the most important finding thus far is the change in coordination of both solvent and salt from a dilute solution to a concentrated solution. On the basis of the strength of the association between the solvent molecules and the ions, the solvation sheath structure can be divided into three parts according to Borodin et al. [35] (Fig. 8): “salt-in-solvent”, “salt-solvate”, and “solvent-in-salt”. In the primary solvation sheath region, the center ion forms the strongest association with solvent molecules and maintains the sheath structure during motion, as shown in Fig. 8a. In the “second” solvation sheath region, solvent molecules break the balance and weakly associate with the center ion. Apart from these two regions, the solvent molecules can remain undisturbed and away from the center ion. As the concentration of the solution increases, a heterogeneous structure may occur in the electrolyte. Yu et al. [128] investigated the lithium bis(trifluoromethane)sulfonamide concentrated aqueous electrolyte, where heterogeneous structural features and different dynamic behaviors were observed between negative and positive ion domains with different Li+ mobilities, using experimentally corroborated MD simulations. With increasing salt concentration, the original solvation sheath structure (including the “primary” and “second” solvation sheaths) gradually disappears, and anions are then added into the “primary” solvation sheath, as shown in Fig. 8b. At extremely high salt concentrations, the anions and cations are close to each other in the same solvation sheath, as shown in Fig. 8c.

Copyright © 2020, Elsevier. d Schematic diagram of the solution structures in a concentrated electrolyte. Reprinted with permission from Ref. [129]. Copyright © 2019, Springer Nature

Schematic representation of three salt concentration systems in an electrolyte. a Li+ ions in a dilute electrolyte with three parts: the primary solvation sheath, secondary sheath and free solvent. b With increasing Li salt concentration, the structure of the secondary solvation sheath is disrupted in the absence of free solvent, and part of the primary sheath structure is squeezed in by anions. c The solvation sheath shares its limited solvent molecules, which may result in the presence of domains in the electrolyte. Reprinted with permission from Ref. [35].

For the quantitative ratio of solvent to lithium salt in a dilute electrolyte solution [approximately 1 M (1 M = 1 mol L−1) and a solvent/salt molar ratio > 10], the most common coordination state of lithium ions is being surrounded by three or four solvent molecules, which are named solvent-separated ion pairs (SSIPs) [130]. The solvent molecules mainly remain free, and decomposition of solvent molecules is induced, forming an SEI film. However, for the case of a concentrated electrolyte (> 3 M), the Li+ coordination number was indicated to be less than 1–2 as the solvent molecules were reduced. At the same time, more salt anions entered the electrolyte to coordinate with Li+, taking the place of the solvent molecule, thus forming contact ion pairs (CIPs) and cation–anion aggregates (AGGs), as shown in Fig. 8d. In addition, a higher Li+ salt concentration could degrade the coordination ability of solvents. Highly concentrated electrolytes have been confirmed to enable stable cycling of lithium-metal anodes due to their unique solvation structure and the lack of free solvent molecules [131]. The decomposition/reaction of salt anions instead of solvent molecules could gradually dominate SEI film formation with increasing Li salt concentration. In brief, when the Li+ concentration is increased from 1 M to more than 3 M, the number of free solvent molecules is reduced, and the coordination form is transformed from SSIPs to CIPs and AGGs, especially AGGs, which can be dominant in the case of higher concentrations to yield unusual functions.

The solvation structure is closely correlated with the electrochemical behavior of Li+ ions. The Debye–Hückel model assumes that salts are completely dissociated but not fully independent of the solution system when ignoring direct solvent-salt interactions [132]. Modern ionics science recognizes that the solvation structure is a vital factor for the electrochemical behavior of Li+. The solvation structure is becoming more flexible as a result of different Li+ salt concentrations, types of organic solvents, and additives. Generally, all kinds of organic solvents render coordination by the electrostatic force between high electronegativity atoms (N, O, and so on) and Li+, known as a “complexant”. The study of the solvation structure has attracted attention because of the exfoliation and solvent cointercalation phenomena of the graphite electrodes commonly used in most conventional lithium-ion batteries. Besenhard et al. [133]. proposed a 3D process describing the solvation sheath cointercalation path. The key to this model is to review the previously neglected specific solvation structure movement at the interface and decomposition process of the cation solvation sheath at the microscopic level. Subsequent work demonstrated this model. Wagner et al. [134] utilized in situ X-ray diffraction (XRD) to demonstrate that during the initial lithiation process, due to the solvation sheath cointercalation, the spacing between the graphene sheets expanded, and the potential was 200–300 mV higher than the reduction potential of the known solvent. They believed that the primary solvation sheath was more likely to cointercalate solvent molecules into graphitic electrodes. Xu et al. [135, 136] further suggested that the eventual interface chemistry on graphitic anodes was actually determined by the solvation sheath composition of Li+ in typical nonaqueous electrolytes. Obviously, the constitution of the solvation sheath could directly cause a change in the reduction potential at the interface. Therefore, further exploration of lithium ion complex solvents can directly affect the understanding of the interface interaction. High concentrations of lithium salt are also a double-edged sword, which can cause the electrolyte viscosity to be too high. This leads to poor ionic conductivity and poor wetting capability, which hinder practical applications. To alleviate these defects and reduce the cost, diluting a high concentration electrode liquid with nonpolar solvents to make it a localized high concentration electrolyte has become a hot research field [137, 138]. In addition, weakly solvating electrolytes could achieve an anion-derived, inorganic-rich SEI [139]. Many achievements have been realized by adjusting the solvation sheath of Li ions from the solvation structure, for example, improvement of the uniformity of the SEI, extension of the potential window [140, 141], prevention of electrode corrosion and dissolution [142,143,144], acceleration of electrode reactions [140, 145], increase of the Li+ transference number [146], and decrease of the volatility and flammability [141, 147, 148].

3.5 Desolvation of the Li+ Sheath

In consideration of the cation transport process at the electrolyte interface, researchers have distinguished the contributions of the so-called ion transfer barrier from two parts: (1) desolvation of Li+ before it deposits on the anode surface and (2) subsequent diffusion of bare Li+ through the SEI. Understanding the barrier between these two parts should clarify how lithium ions diffuse from the electrolyte environment to the negative electrode. In general, the diffusion process of the sheath structure is divided into three stages: (1) the sheath structure must diffuse from the electrolyte to being near the SEI interface; (2) the Li+ sheath structure must be desolvated near the SEI surface; and (3) the Li+ ion changes its solvation structure in the electrolyte to adjust the coordination state. Since the final state of the sheath structure is not bare, ions passing through the SEI may be amorphous [149]. The structure of the Li+ solvation sheath is very often accompanied by a change in solvent species [150, 151]. Since the SEI components are often derived from electrolyte reduction, the two phases of the SEI and electrolyte have different chemical environments. Hence, this process is often known as desolvation or, a more accurate description, resolvation. Actually, Li+ diffusing from the electrolyte into the SEI can pass through the defects (interstitials or vacancies) in the SEI film structure, as shown in Fig. 9a and b [152,153,154]. Shi et al. [49] further proposed a knock-off mechanism, showing that Li+ interstitials diffused through Li2CO3 by replacing another Li+ in the lattice position. The final step was Li+ passing through the SEI film to the anode surface in different ways, including diffusion along the grain boundaries, knock-off transport and defect migration, as shown in Fig. 9c–f [49, 155, 156]. Many researchers judged that the second and third stages could control the kinetics of battery chemistry (corresponding to the two ion transport barriers), and efforts have been made to judge the rate-determining step in the kinetics of the lithium-ion battery chemistry.

Copyright © 2018, American Chemistry Society. The transition state structure lies in the upper left inset, the lower figure shows the energy profile, and the upper right inset shows a schematic diagram of the Lii+ diffusion pathway from site Ai along the [010] direction following the c knock-off and d direct-hopping mechanisms with threefold coordination in the transition structure. Reprinted with permission from Ref. [49]. Copyright © 2012, American Chemistry Society. The migration barrier and diffusion direction of Li diffusion through the LiF/Li2O grain boundary are divided into e Path 1, f Path 2, and g Path 3. Reprinted with permission from Ref. [155]. Copyright © 2019, American Chemistry Society

Schematic diagrams of knock-off mechanisms obtained by AIMD. Schematic depiction as a function of the distance from a Li+ atom and b a phosphorus atom from the PF6− anion to an amorphous Li2EDC SEI film. The values of all coordinates in the bulk electrolyte or SEI film are normalized. Reprinted with permission from Ref. [149].

Desolvation of the Li+ solvation sheath is proposed when Li+ diffuses through the electrolyte/SEI interface, as shown in Fig. 10c, which can be fitted by DFT or MD simulations. The activation energy is used to quantitatively describe the barrier of desolvation of the Li+ solvation sheath because it can reflect the basic kinetics of the interfacial process. In fact, the apparent activation barriers could also be estimated through electrochemical impedance spectroscopy (EIS) data [157, 158]. As observed, the activation energy was not affected by the Li+ activity or the effective surface area [159]. Abe et al. [160,161,162] and Yamada et al. [163] reported that the slowest process occurred when the Li+ solvation sheath was trying to enter graphene before Li obtained electrons from the anode, where the primary solvation sheath had to be stripped. Xu et al. [164] proved that the Li+ solvation sheath stripping process gradually occurred in the outer pore diffusion stage, as shown in Fig. 10a.

Copyright © 2010, American Chemical Society. b Integrated ion densities at the SEI/electrolyte interface as a function of SEI thickness and composition. Solid red lines: total density up to 6 Å into the electrolyte region; black dotted lines: division of the density into an ion-adsorbed region; blue dashed lines: 6 Å from this region into the bulk electrolyte region near the interface. Reprinted with permission from Ref. [169]. Copyright © 2013, American Chemical Society. c Li+ activation energy barriers in different electrolyte composition systems. The reference lines for the activation energy at the bottom are obtained from 1.0 M LiPF6/tetrahydrofuran (THF) (red dotted line) and 1.0 M LiPF6/PEG222 (green dotted line) with LTO. Reprinted with permission from Ref. [164]. Copyright © 2010, American Chemical Society. d Schematic depiction of the Li+ desolvation process near the negative interface. Reprinted with permission from Ref. [171]. Copyright © 2019, American Chemistry Society

a Schematic diagram showing the process and activation energy barrier of Li+ diffusion from the bulk electrolyte to the graphite/electrolyte interface. Reprinted with permission from Ref. [164].

Many substantial computational efforts have been dedicated to studies of Li desolvation energetics at the SEI/electrolyte interface [149, 165,166,167]. The SEI-free Li4Ti5O12 (LTO) anode was successfully utilized in measuring the Li+ desolvation energy barrier [approximately (52 ± 3) kJ mol−1 at different EC concentrations], while the overall value of the activation energy of the SEI-covered graphite anode was approximately 60–70 kJ mol−1, as shown in Fig. 10c. Therefore, Li+ required approximately 20 kJ mol−1 energy to pass through the SEI. A similar conclusion was also proven by Pacific Northwest National Lab (PNNL) [168]. The Li+ desolvation process was the major kinetic barrier because of the high activation energies for charge transfer (0.5–0.7 eV). The high activation energies were experimentally determined at the low-temperature operation limit. In addition, the activation energy of the desolvation step was indicated to be constant over a wide range of EC:DMC concentrations [164]. Xu et al. [136] concluded that a similar activation energy to that of Yamada et al. [159, 163] was found in the LiClO4/EC:DMC system of different EC concentrations, where EC had little effect on the activation energy. A later MD simulation by Borodin and Bedrov [166] suggested that the activation energies of Li+ desolvation were approximately 40–44 and 39–41 kJ mol−1 for dilithium butylene decarbonate (Li2BDC)/EC:DMC(3:7)-LiPF6 and dilithium ethylene decarbonate (Li2EDC)/EC:DMC(3:7)-LiPF6, respectively. Jorn et al. [169] utilized AIMD simulations and found that with increasing SEI thickness and LiF, more Li+ was adsorbed on the SEI surface, suggesting that a large amount of Li+ could be easily desolvated, as shown in Fig. 10b. In terms of the composition of the SEI, the diffusion energy barriers of the inorganic and organic SEI components are also different. The energy barrier of the inorganic component is significantly lower than that of the organic component, which can also prove that desolvation is the key step [170]. Meanwhile, Jorn et al. [169] showed that the path for Li+ desolvation is a two-step mechanism, consisting of crossing two energy barriers and then adsorption. Ming et al. [171] presented a new interfacial model for desolvation. Desolvation was identified as a key factor that could affect anode stability. The solvent interaction with Li+ (e.g., strength and conformation) was the key factor for stability in different electrolytes, which was different from the prevailing SEI formation effect.

Recently, Nasara et al. [172] studied different electrolyte systems for a Li4Ti5O12 (LTO) anode at a lowered cutoff potential and found that increasing Li+ concentration and activity (\(\alpha_{{{\text{Li}}^{ + } }}\)) contributed less to the Li+ desolvation activation energy barrier. The activation energies from multiple scenarios suggested that the Li+ desolvation process was dependent on the element composition of the SEI film and the solvent molecule rather than the physical thickness of the SEI film [167]. There is much evidence to support the hypothesis that desolvation is the rate-determining step. Many simulation methods have been used to make further advances in the exploration of such complex reactions and diffusion processes at the interface. In addition, the Li+ transport through the SEI should be given more attention. Currently, there still appears to be no method for resolving the Li+ desolvation and Li migration through the SEI [173,174,175,176,177,178].

3.6 Li+ Diffusion Through the SEI/Electrolyte Interface

To understand Li+ diffusion at the electrode/electrolyte interface, the properties and their effect on battery performance should be deeply studied [179]. 6Li isotope labeling experiments were reported by using a combination of time-of-flight secondary-ion-mass spectrometry (TOF–SIMS) and NMR spectroscopy to directly observe and prove the exchange process between the electrolyte and SEI [180, 181]. The authors demonstrated the existence of an SEI and observed three stages for Li+ to travel from the electrolyte to the anode [168]. In addition, the time scale for Li+ diffusion through the SEI was indicated to be seconds or minutes.

Many studies have been reported on inorganic and organic components as diffusion barriers of the SEI [75]. Diffusion barriers can be limiting factors due to their topological and defect distribution in the mosaic structure of SEI films. Hence, DFT, MD, and multiscale modeling need to complement each other to accurately measure the diffusion process. Shi et al. [49] proposed Li+ diffusion in an SEI film with a two-layer/two-mechanism model. The model demonstrated that the outer porous layer (organic) allowed Li+, salt anions, and even solvent molecules to diffuse, but the dense inner layer (inorganic) could only facilitate Li+ interstitials to diffuse through Li2CO3 via replacement of another Li+ in the lattice position. The structure of the SEI was divided into organic components and inorganic components. The inorganic component had a larger resistance for Li+ diffusion through the SEI.

To quantitatively analyze the main diffusion barrier in the SEI, some researchers have focused on key components (including Li2CO3, Li2O, LiF or Li alkyl carbonate) [91, 182, 183] of the SEI to demonstrate a single crystal affecting Li+. Lu and Harris [180] demonstrated that Li2CO3 was the main component of the SEI in their experiments. Iddir and Curtiss [152] explored the Li+ migration energy in a bulk monoclinic Li2CO3 crystal and found that Li+ migration along the [010] channel could obtain a lower energy barrier and that hopping via this channel was less likely to occur. Chen et al. [184] further demonstrated that vacancies could contribute less to Li+ diffusion along the [010] plane and that vacancies substantially contributed more to Li+ diffusion across the [010] plane. Therefore, the effect of Li+ diffusion for a variety of concentrations of vacancies and interstitials in different crystal orientations was not consistent. The predominant diffusion mechanism for Li2CO3 was vacancy-interstitial diffusion. Chen et al. [184] systematically calculated Li+ diffusion in three structures (Li2CO3, Li2O, and LiF) using the nudged elastic band (NEB) method. LiF was demonstrated to have the slowest Li+ diffusion compared to Li2CO3 and Li2O because Li2CO3 (0.227 eV) and Li2O (0.152 eV) had lower energy barriers than LiF (0.729 eV). TOF–SIMS measurements showed that the anions and electrolyte could only infiltrate the outer porous layer to approximately 5 nm in the SEI, whereas Li+ infiltrated more into the dense inner layer to approximately 20 nm [180]. Pan et al. [185] and Yildirim et al. [153] studied the LiF diffusion mechanism via the nearest-neighbor Schottky pair and expounded that the ionic conductivity of LiF was highly dependent on the electrode it contacted. When it contacted a negative (graphite, silicon) electrode, the ionic conductivity of LiF was dramatically lower by 18 to 20 orders of magnitude compared to LiC2O3 [49, 154]. Moreover, Benitez et al.[186]. systematically observed the diffusion mechanisms under an applied electric field in LiF (knock-off), Li2O (vacancy-assisted) and Li2CO3 (combined vacancy-interstitial diffusion mechanism), as shown in Fig. 11. Benitez et al. [186] utilized the large-scale atomic/molecular massively parallel simulator (LAMMPS) to calculate the Li+ diffusion mechanism with two divided parts of chain movement (knock-off mechanism), as shown in Fig. 11a. The first chain movement (including purple, orange, and yellow balls) was initiated by Li+ (green ball). For the second chain movement, Li+ (red ball) displaces the blue ball (initial position) to start the chain movement. As shown in Fig. 11b, Li+ diffusion in Li2O relies on the vacancies, and Li+ ions move from their own site to the next empty lattice site in the direction of the applied field in sequence. The most special case is Li+ ion diffusion in Li2CO3 in Fig. 11c, which is mainly manifested as combined vacancy-interstitial diffusion. Recently, Lu and Liao [187] reported that the Li+ diffusion energy barrier in Li2O was considerable consistent, directly leading to Li2O cluster exfoliation.

Schematic diagrams of the initial (left) and final (right) positions of Li+ ions. An electric field was applied to show the diffusion processes in a LiF, b Li2O and c Li2CO3. The diffusion mechanism of LiF was knock-off, which involves diffusion by two chain movements (the green line and orange line) of Li+ ions. The diffusion mechanism of Li2O relies on vacancies. Li+ diffusion in Li2CO3 is achieved through combined vacancies and interstitials. Li+ ions (multiple color balls), F (cyan), O (red), and C (brown). Reprinted with permission from Ref. [186].

In addition to the pristine SEI film, introducing other phases or taking advantage of the space-charge layer effect can also enhance the diffusion carrier concentration. Doping a second phase can increase the charge carrier concentration of the SEI film because the main inorganic components of the SEI (LiF, Li2CO3, and Li2O) can form a defect formation energy higher than the diffusion energy barrier. Shi et al. [154] utilized BO33− to replace CO32− in Li2CO3 crystals and created more Li+ interstitials that could increase the ionic conductivity. Doping common metallic cations such as Ca2+, Mg2+, Al3+ and even La3+ into LiF or Li2CO3 could also increase the Li+ vacancy concentration [185, 188]. Liang [189] introduced insulating Al2O3 nanoparticles into LiF to increase the Li+ carrier concentration, which could increase the space-charge layer effect to increase the ionic conductivity. Furthermore, heterogeneous structures and grain boundaries could also contribute to the ionic conductivity [156, 190]. Pan et al. [190] made a prediction based on the different values of Li diffusion carriers in Li2CO3 and LiF and the combined interfacial defect reaction energy. Zhang et al. [156] demonstrated the formation of a space-charge layer across the Li2CO3 and LiF interfaces and observed a dramatically increased defect concentration in Li2CO3 and LiF. In contrast, Li and Maier [191] found that introducing Al2O3 nanoparticles into the SEI could lead to fewer ionic carriers (decreased ionic conductivity) near the interface.

3.7 SEI Modification and Dendrite Inhibition