Abstract

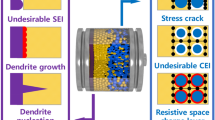

Solid electrolyte interphases (SEIs) in lithium-ion batteries (LIBs) are ionically conducting but electronically insulating layers on electrode/electrolyte interfaces that form through the decomposition of electrolytes. And although SEIs can protect electrodes from the co-intercalation of solvent molecules and prevent the continued decomposition of electrolytes, their formation can consume active lithium and electrolytes and build up impedance for ion conduction. Therefore, the control of SEI structures and properties to allow for stability and ionic conductivity has become a critical but highly challenging task in battery designs. However, several factors contribute to the difficulty in SEI research. First, the chemical and electrochemical reactions leading to SEI formation are immensely complex and heavily influenced by numerous factors including electrolyte solvents, lithium salts, additives, electrode materials and charge/discharge conditions. Second, the chemical nature of film-formation products such as SEI constituents and their distribution and arrangement in the SEI are complex. Finally, SEIs are in situ formed at the electrode/electrolyte interface in assembled batteries, making the direct observation of SEIs difficult. To address these challenges, the development of advanced characterization techniques is key in the fundamental understanding of SEIs in LIBs. Based on this, this review will provide an overview of the progress in SEI characterization, including methods to investigate electrochemical performance, surface morphology, chemical composition, and structure and mechanical properties, with state-of-the-art characterization techniques developed in recent years being emphasized. And overall, the scientific insights obtained by using these advanced methods will help researchers to better understand electrode/electrolyte interfaces toward the development of high-performance secondary batteries.

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Since being introduced by Sony in 1991, lithium-ion batteries (LIBs) employing carbon-based anodes and transition metal oxide cathodes have become widely adopted due to high energy densities and good cyclability [1]. Currently, LIBs are the most widely used electrochemical energy storage devices for portable electronics and power tools. However, ever-growing energy storage demands driven by rapid developments in electric vehicles and renewable electricity sources in recent years have generated increasing interest in the exploration of energy storage systems with higher capacities, better safety and lower costs [2,3,4,5].

During the development of the original LIB, the resolution of problems associated with the electrode/electrolyte interface on anodes was a vital step. Back in the 1970s when lithium metal was the most popular anode material for lithium batteries, Dey et al. [6] reported the existence of a passivation layer on lithium metals soaked in nonaqueous electrolytes. Subsequently, Peled et al. [7] discovered in 1979 that this passivation layer was ionically conducting but electronically insulating and named this layer as the solid electrolyte interphase (SEI). And aside from dendritic problems caused by uneven lithium deposition, lithium metal was found to suffer from unstable SEIs due to the large volume change of lithium metal during cycling, in which the repair of the SEI consumed active lithium and electrolytes, leading to rapid capacity fading, which remains a major obstacle for the application of lithium metal anodes even today. In the 1990s however, Sony found that graphite, a cheap and stable material in nonaqueous electrolytes, could be used as an intercalation host for Li+ similar to LiCoO2 cathodes and possessed a low intercalation potential for Li+ that was close to the lithium reduction potential. This led to the immediate use of graphite as an anode material to replace lithium metal and thus emerged the so-called rocking chair LIB, in which Li ions are shuttled back and forth between a LiCoO2 cathode and a graphite anode in a carbonate-based electrolyte (i.e., LiPF6/propylene carbonate (PC)). Despite this, researchers soon found that without a passivation layer on the graphite anode, carbonate molecules were transported with Li+ as a solvation shell and co-intercalated into graphite, which damaged anode structures and resulted in short-cycle life spans. This problem was subsequently solved by replacing PC-based solvents with ethylene carbonate (EC)-based solvents that can be reduced at a certain potential to form a passivating SEI layer that can de-solvate Li+ and prevent the exfoliation of graphite, ultimately leading to the commercialization of LIBs [8, 9]. And based on this, it can be seen that the SEI is a critical component of current LIBs.

Because the formation of the SEI layer consumes active Li+ and electrolytes and can also increase the resistance of Li ion diffusion into graphite, the formation of the SEI with a stable structure and good ionic conductivity is essential in optimal battery designs. Because of this, researchers are constantly seeking new methods to regulate the SEI structure to achieve less irreversible capacity loss and reduce interfacial resistances to enhance battery performance. And with tremendous efforts in the investigation of SEIs since the 1970s, it is now well recognized in both academic and industrial communities that the properties of SEIs can affect cycle life, power capability and even safety in LIBs [10,11,12,13,14,15,16]. Despite this, the in-depth understanding of SEIs with enough detail information remains lacking (i.e., chemical compositional structure from the molecular level to the nanoscale building block level). This is because the characterization of SEIs is extremely challenging due to several factors. One factor is that SEI formation reactions, which occur along with Li intercalation and are affected by numerous factors including electrolyte composition and charge/discharge conditions, meaning that SEI chemical compositions and structures are complex. In addition, thin SEI layers are buried between two electrodes inside a battery and become unstable and “dead” after being taken out from the volatile electrolyte in the LIB. Furthermore, there are insufficient direct measurements of SEI physical properties. Therefore, the characterization and understanding of SEIs and the correlation between SEI physical properties and battery performances are critically important but remain immensely challenging. And without fundamental understanding, most efforts on the regulation of SEIs can only be conducted through trial-and-error processes. However, LIB manufacturers have already accumulated substantial knowledge on SEI formation, leading to standard production protocols to form stable SEIs, including charging the battery at low current densities after battery assembly, which can be referred to as “formation” [17,18,19], and adding electrolyte additives that are more easily reduced or oxidized than electrolyte solvents to form a SEI/CEI with designed components [20,21,22,23,24,25,26,27]. And with the help of these approaches, the formation of SEIs in current commercial LIBs is relatively “controllable”. However, irreversible capacity loss due to SEI formation and repair remains one of the main causes for capacity decay in current LIBs. And in particular for high-energy density LIBs using nickel-rich layered oxides as the cathode and Si as the anode, the electrolyte can become severely oxidized on cathode surfaces to form a cathode electrolyte interphase (CEI) and the SEI layer on the anode is also not stable during cycling due to the large volume expansion of Si. Furthermore, the development of next-generation battery systems using lithium metal anodes (e.g., Li–S, Li–O2 batteries) also requires the fundamental understanding of SEIs on lithium anodes. Therefore, techniques to obtain fundamental understandings of SEIs are urgently needed to optimize the design of SEIs and enhance the performance of LIBs, especially for the development of next-generation lithium batteries.

To optimize cycle life and power density in batteries, the perfect SEI should be thin (to minimize the consumption of active lithium and the resistance for Li ion conduction), dense (for the insulation of electrons), possess uniform morphology and structure (for uniform Li ion conduction), be (electro)chemically stable (to prevent the need for repairs) and mechanically flexible (to buffer volume expansion of active materials) [28]. And to design these optimal SEIs, characterizations based on morphology, mechanical elasticity, chemical composition and structure, especially with molecular- to nanometer-scale spatial resolution, as well as the in operando investigation of the evolution of these physical properties during growth and cycling are vital in which SEI research in the past few decades has accumulated considerable mastery on the ex situ and in situ characterization of morphology, chemical composition, structure and formation.

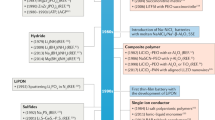

In the characterization of SEIs, traditional characterization techniques such as electrochemical impedance spectroscopy (EIS), differential capacity (dQ/dV), linear sweep voltammetry (LSV) and cyclic voltammetry (CV) have been commonly used to investigate the formation and impedance [29,30,31,32,33], whereas scanning electron microscopy (SEM), transmission electron microscopy (TEM) and atomic force microscopy (AFM) have been intensively used to observe surface features and morphology in the meso- to nanoscale [34,35,36,37,38,39,40]. In addition, X-ray photoelectron spectroscopy (XPS), Fourier transform infrared spectroscopy (FTIR) and secondary ion mass spectrometry (SIMS) are often used to study chemical composition and structure [41,42,43,44,45]. In recent years however, novel characterization techniques have also been adopted to investigate SEIs at high spatial resolution close to the chemical building block and in states that are close to “alive” SEIs. For example, AFM force curves have been used to measure the mechanical elasticity and structure of SEIs with nanometer resolution [46,47,48,49], and apertureless near-field scanning optical microscopy (aNSOM), which employs an AFM tip that is in contact with the measured material surface as an optical probe for high-resolution spectroscopy and imaging measurements, has also been applied to map the chemical composition of SEIs [50, 51]. In addition, time-of-flight secondary ion mass spectrometry (ToF–SIMS) was found to be useful in the construction of depth profiles for chemical components [52,53,54]. And since 2017, cryo-scanning transmission electron microscopy (cryo-STEM), originally designed to preserve hydrated biological specimens, has been introduced to investigate the chemical composition and structure of SEIs and has produced exciting results [55,56,57,58,59].

And based on all these developments, this review will summarize the common knowledge distilled from SEI research in the last few decades and discuss examples reported in the literature concerning the use of traditional characterization techniques to investigate SEIs, including electrochemical performance, morphology and chemistry. This review will also present state-of-the-art SEI characterizations by using advanced techniques such as in situ ToF–SIMS, IR-aNSOM, cryo-TEM and AFM force curves. Overall, the goal of this review is to promote the future characterization of interfaces in batteries and to advance the electrochemistry of high-density, high-performance energy storage systems.

2 Overview of SEIs in LIBs

2.1 Formation

Electrolyte components will reduce on anode surfaces if their lowest unoccupied molecular orbital (LUMO) is lower than the Fermi level of the anode, leading to the deposition of insoluble reduction products on the anode surface to form an SEI layer (Fig. 1a) [60]. Similarly, electrolyte components will oxidize if their highest occupied molecular orbital (HOMO) is higher than the cathode Fermi energy level to form a CEI layer. This reduction and oxidation will continue until electron leakage is stopped by a passivating SEI/CEI layer. And due to the complex environments of the electrolyte, which contains salts, solvents and various additives, the reduction and oxidation potentials of electrolyte components shift significantly from calculation values or electrochemical standard values. (Computed reduction potentials for several common solvents, additives and solvated ions have been summarized by Delp et al. [61].) And in practice, reduction and oxidation potentials are also considerably affected by charge/discharge conditions and surface properties of electrode materials.

a Schematic of the SEI and CEI formation mechanism. Reproduced with permission from Ref. [60]. Copyright 2009, American Chemical Society. b Models of SEI structures: the 2D model is reproduced with permission from Ref. [7]. Copyright 1979, The Electrochemical Society; the mosaic model is reproduced with permission from Ref. [62]. Copyright 1997, The Electrochemical Society; the 3D model is reproduced with permission from Ref. [8]. Copyright 1995, Elsevier; the double-capacitor model is reproduced with permission from Ref. [63]. Copyright 1999, The Electrochemical Society; the multilayered model is reproduced with permission from Ref. [64]. Copyright 1995, Elsevier

2.2 Structure

SEI layers possess complex and heterogeneous substructures, and in the last few decades, researchers have proposed several structural models for SEIs (Fig. 1b) in which a “2D model’” was the earliest proposed for an SEI on the surface of a lithium metal anode [7] followed by a “3D SEI” model proposed for an SEI on the surface of a graphite anode [8]. Subsequently, Peled et al. [62] conducted chemical analysis of SEIs and modified the previous “2D model” to propose a “mosaic model” in which salts were found to be deposited in separate lumps. Ein-Eli et al. [63] also proposed a “double-layer capacitor model” for SEI structures in which solvents and additives produced an efficient passivation film and fixed positive charges in SEIs to counter negatively charged graphite. And with the help of EIS and FTIR spectroscopy, Zaban et al. [64] proposed a “multilayered model” for SEI structures in which the SEI morphology possessed a thickness of 15–100 Å, a compact inorganic inner layer (i.e., LiF, Li2O, Li2CO3) and a porous organic outer layer (i.e., ROLi, ROCO2Li). Here, the researchers suggested that the conductivity of the porous organic outer layer was lower than that of the compact inorganic inner layer, and as a result, as the organic outer layer grows thicker, the electrolyte molecules stop receiving electrons from the electrode for further reduction, resulting in the self-termination of SEI growth. Currently, this model has gained wide acceptance among the scientific community and has been verified by several experimental and theoretical investigations [52, 65,66,67,68]. As for lithium diffusion in this “multilayered model” for SEIs, two different mechanisms have also been proposed for the outer and inner layers [52, 69,70,71] in which Li+ can rapidly pass through the porous organic region together with anions that have been dissolved in the electrolyte in order to maintain local electric neutrality and follow Fick’s law. Alternatively, only Li+ can move across the compact inorganic layer through vacancies or interstitial sites through direct hopping and repetitive “knockoff” of Li+ on lattice sites. Researchers have also reported that below 0.98 V, the main diffusion carriers in the dense layer were Li+ interstitials, whereas above 3.98 V, Li+ vacancies made greater contributions. And in the range of 0.98–3.98 V, Li+ vacancies and Li+ interstitials both played important roles. Researchers have also reported that the main diffusion carriers in the compact layer of SEIs were Li+ interstitials, whereas those in CEIs were Li+ vacancies [71]. Moreover, researcher have also demonstrated that battery performances can be enhanced with multilayered SEIs, which can be achieved through the polishing of lithium electrodes [72] and the addition of electrolyte additives [59]. Furthermore, researchers have reported that the thicknesses of freshly formed SEIs are usually in the ranges of 30–100 Å and 5–10 Å for CEIs [42]. This difference in thickness is possibly due to the extent of secondary reactions and the electrochemical stability window of electrolyte solvents and salts in which currently used electrolytes are more prone to solvent reduction on anodes rather than oxidation on cathodes [73].

2.3 Chemical Composition

The chemical composition of SEIs/CEIs is largely dependent on factors such as the surface property of electrode materials, the electrolyte composition and the impurities in the battery, especially H2O, which can be introduced from the environment during cell assembly. And among these factors, electrolyte composition is the most direct factor deciding SEI/CEI chemistries. Here, LIB electrolytes usually consist of one or more conducting lithium salts (e.g., LiClO4, LiPF6, LiBF4, LiAsF6) dissolved in single or mixed nonaqueous solvents including cyclic and acyclic carbonates such as EC, PC, diethyl carbonate (DEC) and ethyl methyl carbonate (EMC). In addition, numerous additives are also present in electrolytes such as vinylethylene carbonate (VEC), vinylene carbonate (VC) and fluoroethylene carbonate (FEC). And overall, it is generally accepted that the chemical composition of SEIs contains both inorganic and organic compounds. In electrolytes composed of lithium salts dissolved in carbonate solvents, the inorganic constituents of SEIs usually include Li2O, LiF and Li2CO3, whereas the organic constituents include ROCO2Li and ROLi (R = CH3–, CH3–CH2–, CH3–CH2–CH2–, etc.) [74,75,76,77]. Here, the inorganic constituents of SEIs vary greatly based on the different types of salts used in the electrolyte [78,79,80]. For example, in electrolytes containing LiTFSI salt, –SO2-containing species or possibly LiSO4 usually appears in the SEI film. And if LiPF6 salt is used, LixPFy and LixPOyFz are found in the inorganic layer of the SEI. Moreover, inorganic constituents generally exist in the inner layer of SEIs, whereas organic constituents are mostly found in the outer layer [52, 81, 82]. And on the anode side, the chemical composition of SEIs remains similar regardless of the reaction mechanisms involved in the charge storage process in which only in the case of Si-based alloying anodes can the presence of siloxanes and SiOxFy in the SEI be detected, whereas other organic and inorganic components remained the same as in other anodes [83]. Similarly, the chemical compositions of cathode CEIs and anode SEIs are almost the same except that lithium oxides and lithium alkoxides are only found in anode SEIs and transition metal oxides and organometallic components are mostly found in CEIs due to the removal of oxygen from cathode material lattices and reactions on the interfaces [42, 84, 85].

2.4 Factors Affecting SEI Properties

The composition of SEIs is directly related to electrolyte composition in which in carbonate electrolytes, the most observed SEI component is a mixture of Li2CO3 and semi-carbonates (also called alkylcarbonate), whereas in ether electrolytes, the most observed SEI component is lithium alkoxides [86,87,88,89]. Here, semi-carbonates are a result of the single-electron reduction of carbonate solvents and can be further reduced into oxalates by lithiated graphite, which can be significantly promoted at elevated temperatures [90, 91]. In addition, the decomposition products of various solvents depend on the properties of the solvent itself, such as reactivity, viscosity, the dielectric constant, polarity and so on. The reactivity of common carbonate-based electrolytes is in the order of EC > PC > DMC > DEC [92]. Furthermore, the concentration and preferential reduction of mixture carbonates can also affect the constituents of SEIs [93, 94]. Film-forming additives can also significantly alter reaction pathways and SEI properties [95] in which aside from commonly used film-forming additives such as VC, VEC and FEC, other inorganic and organic substances such as polysulfides S2−x [96], LiI [97], Li2CO3 [98], acrylic acid nitrile (AAN) [99] and 1,3-propane sultone (PS) [100] can also be used. For example, Aurbach et al. [92, 101, 102] reported that the enhanced Li2CO3 content in SEIs and improved battery performances can be obtained through the use of CO2 as an additive. Impurities can also affect SEI formation in which trace amounts of water present in electrolytes can affect SEI composition if water-sensitive salts are used. Here, for electrolytes containing LiTFSI salts, which possess much better thermal and chemical stability than LiPF6, the presence of water does not affect SEI components [103, 104]. However, for LiPF6-based electrolytes, trace amounts of water can react with LiPF6 and generate HF, which can decompose major components in SEIs and consume Li+, leading to capacity decay. In addition, generated HF can corrode electrode materials and current collectors [105,106,107,108].

Different electrode materials have different effects on the chemistry and structure of SEIs. For example, although SEIs formed on graphite anodes may be stable, similar electrolytes and formation conditions may generate SEIs that are unstable on Si anodes due to large volume changes in cycling [109, 110]. And aside from chemical nature, other factors in anode materials such as specific surface area, crystallographic structure, particle morphology, defect concentration and nature and exposed crystalline planes can also affect SEIs [111,112,113,114,115] in which SEIs on the edge plane of graphite particles generally contain more inorganic components such as LiF, whereas SEIs on the basal plane contain more soft organic compounds [79, 116,117,118]. Therefore, the edge-to-basal-plane ratio of anode materials is also a factor affecting SEI properties.

The electrochemical conditions in the initial cycle of LIBs also play a critical role in SEI formation. These conditions include factors such as charge/discharge current density, polarization, temperature and shelving time [93, 119,120,121]. In addition, two types of reactions can occur at elevated temperatures in which one is the transformation of the SEI, which involves components such as lithium alkyl carbonates and semi-carbonates being turned into stabler components such as Li2CO3. As for the other reaction, this involves multiple reactions between active materials and SEIs, SEIs and electrolytes or electrolytes and active materials [122, 123], most of which are exothermic and detrimental to the performance of LIBs, especially in terms of safety. Furthermore, influences from contamination, air and humidity on SEI chemistry are also significant, for example, ROCO2Li and ROLi can convert to Li2CO3 through reactions with CO2, and ROCO2Li can react with water to form Li2CO3, CO2 and ROH. In addition, other alkyl lithium carbonates can also react with water to form LiOH or Li2CO3 [124, 125].

3 Advanced Characterizations of SEIs

3.1 Electrochemical Characterization

Electrochemical characterization techniques such as EIS, dQ/dV, LSV, CV and electrochemical quartz crystal microbalance (EQCM) are essential for the direct investigation of electrochemical performances for SEIs during formation and evolution. In the case of EIS, it can provide important insights into electrolyte resistance, ionic diffusion impedance, electrode kinetic and double-layer capacitance in complex electrochemical systems such as LIBs in which a reasonable equivalent circuit model is usually needed to diagnose EIS spectra properly. Here, typical equivalent circuit models proposed for secondary batteries include an Re (the bulk resistance of the cell that reflects the combined resistances of the electrodes, the electrolyte and the separator), an Rsei and a Csei (the resistance and capacitance of the SEI/CEI corresponding to the semicircle in the high frequency range), an Rct and a Cdl (the charge transfer resistance and its relative double-layer capacitance corresponding to the semicircle in the medium frequency range) and a W (the Warburg impedance that is related to the diffusion of Li+ in the material bulk) and are also dependent on the battery system [32, 126]. For example, based on the knowledge that the formation and growth of SEIs are accompanied by changes in Rsei, Zhang et al. [32] used EIS as an in situ tool to investigate SEI formation in Li||graphite cells in which they investigated the correlation between Rsei and cell voltage and found that Rsei varied significantly with cell voltage. Here, the researchers reported that the Rsei of the SEI increased significantly with lithiation and decreased reversibly in subsequent de-lithiation between 0.15 and 0.04 V and proposed that the formation of the SEI can be divided into two voltage regions based on the evolution of Rsei during the initial lithiation in which the SEI formed above 0.15 V was less conductive and the SEI formed below 0.15 V was highly conductive. In addition, these researchers also observed the effects of electrolyte chemistry on the Rsei of the Li||graphite cell and reported that the ionic conductivity of the preliminarily formed SEI was largely dependent on the types of solvents and salts of the electrolyte in which the Rsei decreased in the order of LiBF4 > LiSO3CF3 > lithium bis(oxalato)borate (LiBOB) > LiPF6 for salts and NMP > EMC > MB for solvents. Moreover, these researchers also reported that the addition of VC into the electrolyte resulted in a considerable increase in the Rsei.

To obtain more precise results, Friedrich et al. [127] used the distribution of relaxation time (DRT) from measured spectra as an auxiliary means of EIS analysis to study SEI formation at different SOCs and temperatures and reported that the comparison of Rsei during the first and the second lithiation cycles showed maximum SEI resistance in the voltage region between 0.8 and 0.3 V versus Li/Li+ during the first lithiation process that was not present during the second lithiation, indicating that the formation of an SEI with high Li+ conductivity is completed after the first cycle. In addition, temperature-dependent measurements in this study showed that the overall resistance decreased with increasing temperatures between 20 °C and 45 °C, which the researchers attributed to the temperature-dependent charge transfer and ion transport in the electrolyte and SEI. However, these researchers also reported that at 55 °C, the overall resistance increased as compared with that at 45 °C, indicating undesirable thermally induced resistances. In another study, Heins et al. [29] calculated the activation energy of electrochemical processes based on temperature-dependent impedance spectra and found that during the first charging cycle, the structural and chemical compositions of SEI films on graphite surfaces can change with the increasing SOC in which SEI films with low SOC possessed higher impedance and lower activation energy, whereas SEI films with high SOC possessed higher ionic conductivity and higher activation energy. These researchers also reported that after obtaining a stable SEI film, the activation energy change of the SEI film was small under different charged states.

Aurbach et al. [33] also used EIS to investigate the SEI on graphite electrodes cycled in a 1.0 M LiAsF6/EC + DMC (1:1) electrolyte with VC additives and reported that the addition of VC can reduce Rsei and overall resistances at 25 °C. However, these researchers also reported that at 60 °C, the Rsei and overall resistance of the SEI formed in the presence of VC were higher than those formed in VC-free electrolytes. Here, the researchers attributed the higher resistances to the formation of poly-alkyl Li-carbonate species that can suppress the reduction of both solvents and anions. Furthermore, Xu et al. [21] found that FEC additives can reduce the room-temperature overall impedance of SEIs on silicon anodes cycled in 1.0 M LiPF6/EC + DEC (1:1) electrolytes.

EIS can also be applied to investigate CEIs on cathodes. For example, Zhang et al. [128] studied the property and evolution of CEIs formed in LiCoO2||Li cells and reported that the semicircle at the high-frequency region of the obtained EIS spectra showed little change, whereas the semicircle at the intermediate-frequency region enlarged sharply as the cell cycled, indicating that the CEI layer was stabilized after several cycles but that the aging of the electrode resulted in further increases in cell resistance. In addition, Sun et al. [129] applied EIS to investigate the synergistic effects of FEC and hexamethylene diisocyanate (HDI) on CEI formation on a LiNi0.5Mn1.5O cathode and found that CEI impedances decreased significantly with the addition of 25 mM HDI as compared with that of the baseline electrolyte, but increased with the addition of 500 mM HDI. Zhao et al. [130] also studied the effects of additives on a LiNi0.76Mn0.14Co0.10O2 (NMC76) cathode using EIS in which by comparing the EIS spectra of cells with the baseline electrolyte (1 M LiPF6/EC–EMC) and an optimized electrolyte [0.6 M LiTFSI + 0.4 M LiBOB + 0.05 M LiPF6 dissolved in EC:EMC (4:6, in weight ratios)] during 200 cycles, it was found that surface film resistances remained small throughout cycling but charge transfer impedances increased with cycles in the baseline electrolyte, whereas surface film resistances were initially large but subsequently decreased in the optimized electrolyte, with charge transfer impedances only slightly increasing during cycling. Here, the researchers attributed the difference in the two electrolytes to the fact that the CEI film formed in the optimized electrolyte was more conductive, more compact and stabler as compared with the base electrolyte.

LSV and CV are complementary electrochemical methods and together, can provide more details concerning the reactions of electrolytes with electrode surfaces. As a result, LSV and CV have been used to understand SEIs. For example, Yoon, et al. [30] used LSV in a three-electrode cell (the Pt disk, Li foil and Pt wire were used as the working, the reference and the counter electrodes, respectively) to examine N-substituted caprolactam (CL) derivatives as SEI-forming additives and found that the reduction potentials derived from dQ/dV curves for acetyl-CL, ξ-CL, methyl-CL, vinyl-CL and VC were 1.02, 0.78, 0.82, 1.10 and 1.05 V, respectively. In another study, He et al. [131] used CV to study the activation characteristics and current density effects on SEI formation in Li||graphite, Li||LiCoO2 and graphite||LiCoO2 cells and Zheng et al. [132] used CV to investigate the effects of typical impurities (different volumetric concentrations of water and CH3OH) in an electrolyte system of 1.0 M LiPF6/(EC + DMC + EMC) on the formation of SEI films on the surface of MCF (mesophase-pitch-based carbon fiber) negative electrodes. Furthermore, Zhang et al. [133] used CV to determine the reduction potentials of EC, PC, DEC, DMC and VC using inert electrodes in a LiClO4/tetrahydrofuran (THF) electrolyte and reported that each solvent possessed its own reductive peak related to its reaction pathway and that the experimental potentials of EC, DEC, PC, DMC and VC were 1.36, 1.32, 1.0–1.6, 1.32 and 1.4 V, respectively. Moreover, Ota et al. [24] compared the CV curves of graphite electrodes recorded in 1.0 M LiPF6/EC + DMC (1:1), 1.0 M LiPF6/EC + DMC (1:1) +2 wt% VC and 1.0 M LiPF6/VC and found that the cathodic peaks of EC and VC appeared at 0.7 and 1.1 V versus Li/Li+ and that (CHOCO2Li)2, (CH = CHOCO2Li)2, (CH = CHOLi)2 and RCOOLi were formed on graphite as VC reduction products. These researchers also found that the presence of VC in the EC-based electrolyte can decrease the evolution of reductive gases such as C2H4, CH4 and CO. Aurbach et al. [33] also found that VC can suppress irreversible charge in the first cathodic process at both 25 and 60 °C, which can enhance cycle life. Moreover, Kjell et al. [134] used LSV and CV to study SEI growth on silicon anodes in a 1.0 M LiPF6/EC + DEC(1:1) electrolyte and found that SEI formation started at 1.4 V and continued to form on the electrode in the following second–fourth cycles, which was different from SEI formation on graphite electrodes. In addition, Lindgren et al. [135] found that the reductive decomposition of FEC on silicon electrodes occurred at ~ 1.3 V (vs. Li/Li+) and that FEC can form a stable SEI before EC and DEC to avoid large cracks on the electrode and suppress continuous SEI formation.

Overall, the techniques mentioned above are widely used in the research of batteries; however, it is difficult to quantify chemical components during SEI formation. To address this, electrochemical quartz crystal microbalance (EQCM), which can detect sensitive changes in electrode masses as small as a few nanograms, has been adopted to study SEI formation. For example, Aurbach et al. [33] used EQCM and CV to study SEI formation on graphite electrodes in a 1.0 M LiAsF6/EC + DMC (1:1) electrolyte. Here, the researchers reported that both voltammograms showed that the onset potential of the reduction process was below 2.5 V (vs. Li/Li+) and that as compared with VC-free electrolytes, mass accumulation on the electrode in an electrolyte with VC additives was 50% higher. Liu et al. [31] also studied SEI formation on graphite electrodes in a carbonate electrolyte using EQCM and proposed that the cathodic polarization of graphite can be divided into four regions based on the mass change results recorded by EQCM during SEI formation. These four regions include region I (above 2.4 V) in which both current and mass changes remained essentially at the background baseline; region II (2.4–1.1 V) in which the current started to depart from the background and reached a local maximum at ~ 1.6 V accompanied by mass change, which could be the onset of certain reactions; region III (1.1–0.74 V) in which a broad current response occurred, which could correspond to the initial decomposition of electrolyte components; and region IV (0.74–0.0 V) in which the major electrochemical reduction of intercalated species, the exclusive decomposition of the liquid electrolyte and the formation of the eventual SEI occur.

3.2 Morphological Characterizations

Ideally, SEI/CEI layers should be thin and dense and can uniformly cover electrode surfaces and remain stable during cycling, so as to effectively and evenly conduct Li+ but insulate electrons to prevent the electrolyte from further decomposition. Here, SEM, TEM and AFM are common techniques used for the imaging of the morphology of interphases in which both SEM and TEM require high vacuums to operate and therefore are not usually suitable for the in situ study of SEIs/CEIs in electrolytes. Alternatively, AFM is a scanning probe microscopy technique that is capable of studying liquid–solid interfacial morphology with nanometer-scale spatial resolution.

3.2.1 Morphological Characterization by SEM

SEM is a common microscopic characterization technique in materials science, and in addition to morphological imaging, SEM-based energy spectroscopy techniques such as energy-dispersive X-ray analysis (EDX) can provide quantitative information about local elemental compositions. Based on this, numerous studies have been conducted on the dependence of SEI morphology on electrolytes, electrode materials and electrochemical cycling conditions by using in situ and ex situ SEM [34, 35, 41, 135,136,137,138,139,140,141,142] in which as early as 1996, Kominato et al. [140] found by using SEM the morphology of surface films formed on lithium metal deposited on a nickel substrate in an EC/DMC-based electrolyte is dependent on electrolyte salts (LiPF6, LiClO4 and LiTFSI). In addition, Lee et al. [34] applied extremely high-resolution SEM using low acceleration voltage to avoid electron beam-induced damage to visualize SEI layers on a graphite anode and obtained the outermost surface and cross-sectional SEM images of the graphite anode before and after low-energy ion etching. As a result, these researchers found that the fine particles were present in a dense surface film and that after 5 min of etching, the SEI layer was almost completely removed except for the particles, which was attributed to the difference between the film thickness and the particles (Fig. 2a).

In situ and ex situ SEM for SEI morphology observations. a XHR-SEM images of SEI layers on graphite electrodes before and after etching for 2 or 5 min. Reproduced with permission from Ref [34]. Copyright 2013, Elsevier. b The figures on the top row are the experimental setup, an SEM micrograph of a V2O5 whisker embedded in an electrolyte and cyclic voltammograms of two single-whisker battery devices; the figures on the bottom row from left to right are the in situ morphological changes during SEI formation. Reproduced with permission from Ref [35]. Copyright 2015, The Royal Society of Chemistry. c Cross-sectional FIB-SEM images of graphite electrodes after cycling in full cells with a standard electrolyte (top) and with transition metal salts added into the electrolyte (bottom). Reproduced with permission from Ref. [144]. Copyright 2014, The Electrochemical Society. d EDX maps of Si, C, O and F elements on FIB ablated cross sections of pristine, the first-cycle and the 100th-cycle electrodes. Reproduced with permission from Ref. [145]. Copyright 2016, The Electrochemical Society. e The images in the left column show FIB-SEM cross-sectional images of Si/graphene anodes in an EC/DEC (1:1, in weight ratios) electrolyte before and after 50 cycles from the discharged pouch full cells with 0% and 5 wt% FEC additives. The images in the right column show corresponding ion beam surface images of the Si/graphene anodes. Reproduced with permission from Ref. [36]. Copyright 2014, Elsevier

Although SEM measurements require high-vacuum environments and are therefore usually unsuitable for in situ observations of SEIs, in situ SEM can be achieved by using special sample transfer chambers and ionic-liquid (IL) electrolytes. For example, Strelcov et al. [35] investigated the formation of the SEI on the surface of a V2O5 nanowire anode during the in situ SEM study of lithium intercalation in a V2O5-based single-nanobelt battery with a LiCoO2 cathode and an ionic liquid electrolyte using a custom-made experimental setup (upper left in Fig. 2b) and were able to observe that the SEI layer exerted significant influences on lithium-ion diffusion and overall capacity of the single-nanobelt (NB) battery. Tsuda et al. [136] also observed SEI formation on silicon electrodes in [C2mim][FSA] with Li[TFSA] and [C2mim][TFSA] with Li[TFSA] electrolytes and reported that the in situ SEM observations revealed nonuniform darker deposits in comparison with those of other ionic liquid electrolytes, which suggested lower atomic numbers of the SEI constituents. And based on these observations of the contrast change during the electrochemical reaction, these researchers concluded that SEI formation can be suppressed in selected ionic liquid electrolytes.

To obtain more detailed information on SEI morphology, the focused ion beam (FIB) technique can also be used to prepare cross-sectional SEM samples. For example, Zhang et al. [143] were the first to apply FIB-SEM to the SEI research of a natural graphite sphere in an electrolyte composed of 1.0 M LiPF6 dissolved in EC/DMC (1:1, in volume ratios). Here, these researchers reported that the SEI film also formed around cracks inside the natural graphite spheres and was relatively stable once formed with its thickness not increasing significantly during cycling. Following this study, numerous studies followed up on use of the FIB-SEM method [36, 144,145,146,147,148,149]. For example, Joshi et al. [144] investigated the effects of transition metal dissolution on the properties of the SEI layer in a graphite||Li1.05Ni1/3Co1/3Mn1/3O2 full cell with an electrolyte composed of 1.0 M LiPF6 dissolved in EC/DEC (1:1, in weight ratios) with or without Ni(TFSI)2, Co(TFSI)2 and Mn(TFSI)2 as additives and observed that the addition of transition metal ions into the electrolyte accelerated the growth of the SEI layer on the graphite anode into an irregular and much thicker film (Fig. 2c), thus explaining the cause of capacity and power attenuation in LIBs by using transition metal oxides as positive electrodes. In another study, Etiemble et al. [145] employed FIB-SEM to study SEI evolution on a silicon anode before and after 1, 10 and 100 cycles and reported that the silicon anode was progressively filled with SEI layers during cycling (Fig. 2d) and attributed this to the continuous accumulation of insoluble electrolyte degradation products, confirming the essential need to develop more effective electrolyte formulas to prevent excessive SEI formation to obtain viable Si-based electrodes. Bordes et al. [36] also investigated the effects of FEC additives on the capacity fading of full cells employing a Si/graphene anode and a NCA cathode and reported that optimized cell performances can be obtained at the FEC content of 5 wt%, which may be a result of the much thinner and more uniform SEI layer formed on the electrode as compared with other contents (Fig. 2e).

3.2.2 Morphological Characterization by TEM

TEM can provide much higher spatial resolution than SEM, and TEM-based electron energy loss spectroscopy (EELS) can examine chemical elements and valence states on imaged areas. However, the electron beams used in TEM can degrade electrolytes and SEIs, which is a problem that needs to be avoided. And similar to SEM, in situ TEM studies can also be carried out by using special liquid cells or IL electrolytes. Here, in situ TEM electrochemical cells can be divided into closed cells [150,151,152] and open cells [153, 154] in which in an open-cell configuration, the two electrodes are usually connected to a potentiostat and remain open in the TEM vacuum chamber, thus requiring the electrolyte used in these cells to be either solid electrolytes or ILs. As for closed-cell configurations, the entire electrochemical device is encapsulated in a thin flow-through liquid device with electronically transparent windows composed of materials such as silicon nitride (SiNx). In addition, closed-cell configurations are typically designed on microfabricated silicon wafers with nanoscaled channels for the continuous flow of ordinary battery electrolytes. Furthermore, because the high vacuum of the TEM chamber is isolated from the liquid cell and has no effect on batteries, most common liquid electrolytes of LIBs can be used in these cells for in situ and in operando TEM investigations. As a result, the design of in situ TEM liquid cells opens up a wide field of application not only in battery materials, but also in other basic research of nanotechnologies.

In situ TEM has been used to investigate the SEI morphology of various electrode materials in LIBs, including carbon, silicon and alloying anodes as well as LixMOy cathodes (M: Co, Mn, Ni and binary or ternary mixtures of transition metals) [37,38,39, 150, 155,156,157,158,159,160,161,162,163]. For example, Unocic et al. [150] studied SEI formation on glassy carbon electrodes in a LiPF6/(EC + DMC) electrolyte using in situ electrochemical TEM (in situ EC-TEM) and were able to identity SEI constituents (such as LiF and Li2CO3) and lithium deposited on the glassy carbon through contrast changes in dark and bright-field imaging due to mass density differences. Furthermore, researchers have also used EELS analysis to reveal that SEI composition can include Li2O, LiOH and LiF [164] in which the confirmation of LiF was consistent with the results observed in the graphite SEI by Wang et al. [165] using ex situ TEM–EELS.

Liao et al. [37] also investigated the cycling stability of a graphite||LiNi0.5Co0.2Mn0.3O2 cell with electrolytes of 1.0 M LiPF6 in EC + EMC (1:2, in weight ratios) with or without LiDFBOP additives at low temperature and found that cell performances in the LiDFBOP-containing electrolyte were significantly better. Here, the researchers attributed this performance difference to the serious electrolyte decomposition of the LiDFBOP-free electrolyte, which can result in a thick SEI layer covering the electrodes (especially the graphite anode) (Fig. 3a, b). Alternatively, LiDFBOP can be preferentially oxidized or reduced into bulk electrolyte components in the LiDFBOP-containing electrolyte to construct protective interface films on both the graphite anode and the LiNi0.5Co0.2Mn0.3O2 cathode, resulting in a homogeneous film that can not only inhibit electrolyte decomposition, but also exhibit high ionic conductivity due to the introduction of Li+ from LiDFBOP into the films.

Silicon as an anode material can exhibit a specific capacity (4200 mAh g−1) that is even higher than that of metallic lithium; however, Si experiences significant volume change of over ~ 300% upon alloying with lithium, resulting in significant issues including unstable SEIs. Therefore, the understanding of the formation and evolution of SEIs on Si anodes is important. And although initial SEI formation has rarely been observed on Si surfaces, Liu et al. [38] were able to observe nanometer-thick lithiation interfaces using TEM in which a 1-nm-thick interface between c-Si and a-LixSi [named as the amorphous crystalline interface (ACI)] was identified (Fig. 3c). Here, the researchers found that as the ACI moved toward the core of the c-Si wire, the a-LixSi increasingly thickened. In addition, the migration of the ACI was found to control lithiation kinetics in the Si nanowire without changing its thickness. In another study, Yuk et al. [162] studied the SEI on Si nanoparticles in a LiPF6/(EC + DMC + DEC) electrolyte of a graphene liquid cell using TEM and reported that although the electron beam induced lithium accumulation around Si nanoparticles, lithiation preferentially started in the [110] direction of the Si particle. In addition, isotropic Li diffusion and anisotropic volume expansion were visualized in this study in which obtained EDS patterns showed the presence of high concentrations of C, O, P and F over the Si nanoparticles due to the SEI layer formation. Furthermore, these researchers also used selected-area electron diffraction to confirm the presence of LiF in this SEI layer.

Morphology observations of SEIs on various electrodes by using TEM. a TEM images of LiNi0.5Co0.2Mn0.3O2 cathodes from left to right: fresh, cycled at 0 °C and LiDFBOP-containing electrolytes. Reproduced with permission from Ref. [37]. Copyright 2018, John Wiley and Sons. b TEM images of graphite electrodes from top: fresh, cycled at 0 °C and cycled in LiDFBOP-containing electrolytes. Reproduced with permission from Ref. [37]. Copyright 2018, John Wiley and Sons. c Delayed images of {112} ACI migration in the lithiation process on a silicon electrode. Reproduced with permission from Ref. [38]. Copyright 2012, Springer Nature. d In situ TEM observations of the electrochemical reaction by using an electrochemical liquid cell (left) and SEI formation on Au electrode/liquid electrolyte interfaces (right). Reproduced with permission from Ref. [159]. Copyright 2014, American Chemical Society. e Beam-induced SEI growth on the surface of Li deposits and at the expense of Li stripping. Reproduced with permission from Ref. [160]. Copyright 2015, American Chemical Society

Moreover, Zeng et al. [159] used in situ TEM to investigate SEI formation on Au surfaces as an example of alloying materials and found that SEI thicknesses increased with increasing Au electrode volumes due to Li alloying with Au in which after a certain thickness, gas bubble formations on Au surfaces were observed, which subsequently can be peeled off from the SEI (Fig. 3d), demonstrating that Au is unsuitable as current collectors for LIBs due to its alloying nature and its catalytic reactions with lithium and battery electrolytes. Sacci et al. [157] also observed SEI growth during lithium electrodeposition on Au electrodes in a LiPF6/(EC + DMC) electrolyte using in situ TEM and found that dendrite-shaped SEIs can form on Au electrode surfaces prior to Li electrodeposition and remain stable even after lithium dissolution. In addition, these researchers also found that the electrodeposition of Li also occurred through the SEI, which forms small nanoparticles within the SEI, suggesting that the entangled lithium particles in the SEI matrix can lead to dendrite formation.

Furthermore, the effects of electron beams in in situ TEM on electrolytes during cycling were also studied by Leenheer et al. [160] in a 1.0 M LiPF6/EC + DMC (1:1) electrolyte on electrodeposited metallic lithium. Here, the researchers reported beam-induced SEI growth if beam scanning occurred near a growing Li deposit (Fig. 3e) in which a dark deposit formed and grew on the side of the Li grain closer to the beam exposure. In addition, these researchers also found that with increased beam exposure for 5 min, Li was electrochemically stripped, but the dark deposit remained and continued to grow. Moreover, the bright-field scanning transmission electron microscopy (BF STEM) contrast in the SEI became lighter than the electrolyte as beam scanning time increased, indicating that beam-induced SEIs may consist of chemical components such as LiF that can be reduced back to metallic Li.

3.2.3 Morphological Characterization by AFM

AFM can provide nanometer-scaled spatial resolution and versatile imaging environments for morphological characterizations. In addition, AFM can be used on a variety of samples including insulating materials, and because this technique does not use beams (electron or optical) or lenses, it can operate in liquid environments. Furthermore, its high-magnification imaging allows for the monitoring of nanoparticles in electrochemical reactions in which the constant repulsion contact force between the tip and the specimen is used to scan the surface morphology of specimens. However, AFM requires relatively flat sample surfaces to achieve stable and good-quality images.

Highly oriented pyrolytic graphite (HOPG) is a commonly used graphite anode model in AFM-based LIB studies. For example, Deng et al. [166] reported that for HOPG cycled in a LiTFSI/DEC electrolyte, SEI formation started at 1.45 V versus Li/Li+ on electrode surface defects but that the surface of HOPG carbon was not completely covered by ring-like SEIs and that the SEI thickness remained at 10.4 ± 0.2 nm in the first cycle. However, these researchers also reported that in the following cycle, the surface of HOPG carbon became completely covered (Fig. 4a). Jeong et al. [167] further studied SEI films on the basal plane of HOPG in a LiClO4/(EC + DEC) electrolyte using in situ AFM and proposed two types of SEI morphology, including a hill-like 1–2-nm-tall structure and a blister-like structure with a large swelling of heights to 5–20 nm in which the appearance of the latter morphology in the potential range of 1.0–0.8 V confirmed the intercalation of solvated Li+. And at potentials below 0.65 V, particle-like precipitates appeared on the basal plane, which were also observed by Alliata et al. [168] in their study, indicating that electrolyte breakdown was easier in this potential range and resulted in these granular structures. Furthermore, Jeong et al. [167] also reported that the thickness of the SEI in the first cycle was ~ 40 nm and increased to 70 nm in the second cycle, confirming that SEI formation is a dynamic process. Moreover, Novak et al. [169] also investigated the dynamic process of SEI growth on a carbon electrode in a LiPF6/(EC + DMC) electrolyte and found that the changes in the surface profiles started at ~ 0.7 V and that an SEI with a thickness of 15 nm formed after reaching 0.25 V versus Li/Li+ (Fig. 4b). And at the end of the second charge/discharge cycle, a uniform SEI with a thickness of 20 nm formed, indicating the completion of SEI growth.

Morphology observations of SEIs on various electrodes and electrolytes by using in situ and ex situ AFM. a In situ AFM images of an HOPG electrode at open-circuit potential and continuous potential scanning. The arrow indicates the direction of voltage and the scan. Reproduced with permission from Ref. [166]. Copyright 2013, Science China Press and Springer-Verlag Berlin Heidelberg. b Vertical surface profiles of an SEI protective film formed on an HOPG electrode obtained by in situ AFM. Reproduced with permission from Ref. [169]. Copyright 2001, Elsevier. c AFM images of SEI layers formed on HOPG electrodes in various electrolytes after the first CV cycle. Reproduced with permission from Ref. [175]. Copyright 2018, Elsevier. d AFM images of the in situ monitoring of freshly cleaved HOPG electrodes in 1.0 M LiPF6/(EC + DMC) electrolytes with no additives, 1 wt% ES and 1 wt% PES, and their corresponding voltammetry. Reproduced with permission from Ref. [189]. Copyright 2013, The Royal Society of Chemistry. e In situ AFM images of Sn-foil anodes in 1.0 M LiPF6/(EC + DEC) (1:2, in weight ratios) electrolytes recorded at various potentials. Reproduced with permission from Ref. [40]. Copyright 2009, Elsevier. f SEI growth model proposed by in situ AFM on a Si anode in a LiPF6/(EC + DMC) electrolyte. Reproduced with permission from Ref. [180]. Copyright 2014, American Chemical Society. g In situ formation and imaging of CEI film formation and decomposition on different planes of LiCoO2 with or without ALD coating crystals at different states. Reproduced with permission from Ref. [184]. Copyright 2017, American Chemical Society

Effects of temperature, lithium salts and film-forming additives on SEI formation can also be investigated on carbon-based anodes by using in situ AFM [170,171,172,173,174,175,176,177,178,179]. For example, Edstrom et al. [170] observed the formation of a ~ 5-nm-thick SEI at 0.8 V using in situ AFM in a LiBF4/(EC + γ-BL) electrolyte but reported that as temperatures reached 50 °C or above, the formed SEI cracked, leading to the exposure of fresh HOPG carbon surfaces to the electrolyte. Koltypin et al. [171] also investigated the effects of anions in lithium salts on SEI morphology through the in situ AFM observation of SEI growth on HOPG in LiPF6 and LiAsF6 (in EC + DMC) electrolytes and found that in the case of LiPF6 salt, the SEI surface morphology was compact with fine grains, whereas in the case of LiAsF6 salt, it was smooth and smeared. In addition, Morigaki et al. [174] used in situ AFM to find that SEI morphology was dependent on lithium salts of electrolytes and proposed that differences in SEI chemistry can result in different SEI structures. Furthermore, researchers have also reported that electrolyte salt concentrations can significantly influence interfacial structures in which Liu et al. [172] reported that concentrated electrolytes with molar ratios (Li:DMSO) of 1:2 or 1:3 enabled SEI formation on HOPG edges to effectively stop the co-intercalation of solvated Li+ in graphite lattices, whereas diluted electrolytes with a molar ratio of 1:4 enabled SEI formation at the basal plane, which cannot stop the co-intercalation of solvated Li+. Furthermore, Huang et al. [175] studied the SEI on HOPG cycled in electrolytes with lithium difluoro(oxalate)borate (LiDFOB) and LiBOB additives and reported that after the first CV cycle, the particle sizes on the SEI film in the LiBOB-containing electrolyte were much bigger than those formed in the LiDFOB-containing electrolyte (Fig. 4c). And based on the thickness of the SEI layers formed in four different electrolytes (0.2 M LiDFOB + 0.8 M LiFP6, 0.1 M LiDFOB + 0.9 M LiFP6, 0.2 M LiBOB + 0.8 M LiFP6 and 0.2 M LiBOB + 0.8 M LiFP6), these researchers concluded that increasing amounts of LiDFOB additives in the electrolyte can lead to thinner SEI films, whereas increasing amounts of LiBOB can lead to thicker SEI films, suggesting that the decomposition of LiBOB additives was more intense than LiDFOB additives.

The effects of solvent additives such as ethylene sulfite (ES) and prop-1-ene-1,3-sultone (PES) on SEI formation were also investigated by Lin et al. [176] by using in situ AFM. Here, the researchers observed SEI film formation on HOPG in different electrolytes (1.0 M LiPF6/EC + DMC, 1.0 M LiPF6/EC + DMC and 1.0 M LiPF6/EC + DMC + 1%PES) and reported that the reduction potentials of ES and PES to form SEI layers were higher than those in the baseline electrolyte (Fig. 4d) and that the initial particle sizes in the SEI layer formed with the ES additive were in the range of 40–60 nm with the lateral dimension of the particles being ~ 500 nm, which were much larger than those formed with the PES additive. These researchers subsequently combined TEM results with these in situ AFM results and concluded that the SEI layer formed in the ES-containing electrolyte was thicker and denser than that formed in the PES-containing electrolyte, possibly explaining the enhanced battery performance as promoted by ES additives.

Sn and Si can both be used as high-capacity anode materials for LIBs; however, they both experience significant volumetric change along with instability of the passivation film during battery cycling, resulting in large irreversible capacity losses and low CEs and inhibiting application in LIBs. To address these issues, the understanding and modification of surface film stability on these electrodes are required. Based on this, Lucas et al. [40] investigated SEI formation on Sn electrodes in 1.0 M LiPF6/EC + DEC (1:2, in weight ratios) electrolytes using in situ AFM and found that at the first CV scan starting from OCP to ~ 0.7 V, SEI formation started at ~ 2.5 V and that between the range of 2.5 V to ~ 2 V, the SEI layer grew rapidly to form a 100–150 nm rough film consisting of micron-sized platelets (Fig. 4e). In addition, these researchers also found that if the voltage decreased below 2 V, the SEI layer changed to a porous membrane surface composed of larger particles. And by comparing the morphology of the SEIs formed at different potentials and the CV results, these researchers suggested the existence of an overlayer on the SEI film that may dissolve in the electrolyte. In addition, these researchers also observed rougher SEI reformation in the subsequent two cycles, indicating that the SEI layer was unstable and that optimizations to form stable surface films were needed.

In another study, Tokranov et al. [180] investigated the initial process of SEI formation on Si anodes under various conditions in a 1.0 M LiPF6/EC + DMC (1:2, in volume ratios) electrolyte using in situ AFM and found that the rapidly formed initial SEI can be stabilized before significant Li alloying with Si and that the rate at which this occurred varied significantly with the nature of the electrode (bare Cu, bare Si, Al2O3-coated Si). In addition, these researchers reported that the initial cycling conditions also had a substantial impact on SEI morphology, with faster current rates leading to smoother, thinner SEI films. And based on these results, these researchers proposed the so-called multilayered SEI model (Fig. 4f).

Compared with anode materials, cathode materials usually exhibit less volume expansion during cycling. In addition, typical electrolytes are stable at cathodes up to ~ 4.20 V. Nevertheless, CEIs can still form on cathodes and are as important as SEI formation, especially in high-voltage LIBs. Therefore, increasing investigations on CEIs through AFM have been conducted [128, 181,181,182,183,184,185,186,187,188]. For example, Li et al. [181] investigated the morphology evolution of the CEI formed on a LiNi0.5Mn1.5O4 (LNMO) cathode in a LiPF6/(EC + DMC + EMC) electrolyte in the first charge/discharge cycle and found that on the LNMO surface, precipitates started to appear if the battery was charged to 4.65 V due to the oxidative decomposition of the electrolyte components. These researchers also reported that if the battery further charged to 4.75 and 4.95 V, the precipitates increased significantly, whereas during discharge back to 4.65, 4.20 and 3.20 V, the precipitates partially decomposed, indicating the instability of the CEI at high-voltage cycles. Lu et al. [184] also investigated CEI formation on layered LiCoO2 microcrystals (another commonly used cathode material) in a LiPF6/(EC + DMC + EMC) electrolyte in high-voltage cycling and reported that the in situ AFM results showed different CEI morphology evolution behaviors on the basal plane versus the edge plane, with or without thin ALD coatings (Fig. 4g). Here, these researchers found that CEI films with loose fibrillar structures formed on the edge planes of LiCoO2 microcrystals if charged to 4.5 V and were unstable and decomposed at lower voltages, whereas CEIs were not observed on the basal planes or edge planes with a thin ALD coating of Al2O3, suggesting that cobalt ions exposed on edge planes can catalyze the oxidative decomposition of electrolytes. And overall, these results indicated that the high-voltage cycling stability of LiCoO2 and related layered cathode materials can be improved through the regulation of surface compositions.

3.3 Compositional Characterization Techniques

3.3.1 Fourier Transform Infrared Spectroscopy (FTIR)

FTIR is a vibrational spectroscopy technique that is widely used in chemistry to identify functional groups and chemical structures [190]. And in SEI research, FTIR has become a powerful tool to track chemical changes in electrolyte/electrode interfaces. For example, Aurbach et al. [191] first used ex situ FTIR to monitor SEI formation and degradation on metal electrodes (Au, Pt, Ag) in lithium salt solutions in γ-butyrolactone (BL). Here, these researchers found that BL can reduce to carboxylates on metal electrode surfaces, whereas the oxygen-containing solution showed typical carboxylate moiety (Fig. 5a) and that as these compounds reacted further, SEIs can form with the solvent nucleophilically. Aurbach et al. [192] also summarized the chemical composition characterizations of SEIs/CEIs on various carbon electrodes (graphite, hard and soft disordered carbons, carbon nanotube electrodes) and several commonly used cathode materials (LiNiO2, LiCoO2 and LiMn2O4) using ex situ FTIR in which for carbon particles, the initial species found during the first cathodic polarization were oxygen-containing groups on the surface (i.e., OH, COOH, C = O, which can be reduced to –OLi, –COOLi, etc.). However, these researchers also found that the dominant components in the SEI were dependent on the electrolyte. Here, these researchers reported that if electrolytes did not generate HF [solutions of LiClO4, LiAsF6, LiN(SO2CF3)2, LiN(SO2CF2CF3)2], SEI chemistries were controlled by solvent reduction processes. Therefore, in alkyl carbonate solvents, major SEI components were R(OCO2Li)2 (reduction products of EC, PC), ROCO2Li and ROLi (reduction products of DMC, EMC, etc.) and Li2CO3 (a reaction product of trace H2O with ROCO2Li). And in cases in which electrolytes can generate the high HF content (e.g., in LiPF6 solutions at high electrolyte/electrode ratios and conditions for hydrolysis), the SEI was dominated by LiF and ROLi due to the removal of ROCO2Li from the surface due to their reaction with HF. And for the above-mentioned cathode materials in electrolytes of LiPF6 dissolved in EC + DMC mixtures, these researchers concluded that the surfaces of LiNiO2 and LiCoO2 particles are more nucleophilic and basic than LiMn2O4 and therefore can react more readily with solution species (nucleophilically with alkyl carbonates and as bases with HF, Fig. 5b).

In situ and ex situ FTIR for the chemical composition analyses of SEIs. a FTIR spectra obtained from uncontaminated and O2-contaminated solutions. Reproduced with permission from Ref. [191]. Copyright 1989, The Electrochemical Society. b FTIR spectra obtained from pristine and cycled composite LiMn2O4, LiCoO2 and LiNiO2 electrodes. Reproduced with permission from Ref. [192]. Copyright 2003, Elsevier. c Au (top) and Sn (middle) electrodes obtained at various potentials and ATR-FTIR spectra of sodium propionate, DEDOHC and LiEDC (bottom). Reproduced with permission from Ref. [45]. Copyright 2015, American Chemical Society. d From left to right: difference FTIR spectra at 0.8 V in the lithium removal process, in situ infrared spectra of silicon-powder electrodes at different potentials and in situ FTIR spectra in the wave number region of 1900–3500 cm−1. Reproduced with permission from Ref. [203]. Copyright 2016, John Wiley and Sons. e In situ PM-FTIR spectra of LiCoO2 films in the CV scanning of PC-containing electrolytes. Reproduced with permission from Ref. [204]. Copyright 2007, Elsevier

To overcome intense masking effects of solvent IR bands, special electrochemical cells with IR transparent windows have been designed to enable in situ FTIR measurements [99, 193,194,195,196]. In addition, the existence of similar functionalities between electrolytes and SEI components can result in overlapping peaks, making the identification of chemical species difficult. To address this, various IR modes such as attenuated total reflectance (ATR), photoacoustic IR, diffused reflectance IR, subtractive normalized interfacial FTIR (SNIFTIR), transmission IR, near-normal incidence reflectance, grazing incidence reflectance and double-modulation IR have been used to monitor the in situ chemical composition evolution of SEIs/CEIs [197,198,199,200]. For example, Pyun et al. [198] used in situ ATR-FTIR to accurately monitor SEI components in two different electrolytes of LiPF6 and LiAsF6 dissolved in EC/DEC and found that LiPF6 was less reductive than LiAsF6 in electrochemical cycling and that the ROCO2, Li2CO3, LixPFy and LixAsFy in the SEI originated from the reduction of solvents and lithium salt. Winter et al. [199] also monitored SEI formation in chloro-ethylene carbonate (ClEC) and LiN(SO2CF3)2 in EC using in situ SNI-FTIR and found that CO2 formation assisting in SEI formation only existed in ClEC. In addition, Lanz et al. [200] found that the SEI formed on graphite in LiClO4/(EC + DMC) electrolytes was composed of various organic/inorganic species such as (CH2OCO2Li)2, alkyl(di)lithium carbonate and Li2CO3 using FTIR and Hongyou et al. [201] studied the role of VC additives in LiClO4/(EC + DMC) electrolytes on graphite surfaces using in situ FTIR. Here, the obtained results showed that the formation of lithium alkyl carbonate was reduced by VC, indicating the suppression of EC decomposition and demonstrating that VC can play a crucial role in the protection of electrolytes from decomposition. Furthermore, other additives such as ES, benzyl isocyanate (BIC) and 4-bromobenzyl isocyanate (Br-BIC) in PC-based electrolytes have also been found to be capable of preventing PC solvent decomposition by using FTIR [202].

Compared with graphite anodes, lithium metal and alloy anodes possess higher energy densities and are regarded as promising anode materials for next-generation lithium batteries. However, lithium metal is highly reactive toward electrolytes. As a result, researchers have applied FTIR techniques to investigate the SEI characteristics of these highly reactive lithium-based electrodes. For example, Morigaki et al. [174] used in situ FTIR to show that in LiPF6/(EC + DMC) electrolytes, EC and DMC can be reduced to lithium alkyl carbonate after the immersion of a lithium metal electrode into the LiPF6/(EC + DMC) electrolyte for 15 h. In addition, these researchers also found that if the lithium metal electrode was soaked in the electrolyte for longer time, CO2 peak intensities increased and solvent peak intensities decreased in the FTIR spectra, confirming the reduction of EC into ROCO2Li and CO2. In another study, Shi et al. [45] used in situ ATR-FTIR analysis to study SEI formation on Sn and Au electrodes in a LiPF6/(EC + DEC) electrolyte and reported that both electrodes possessed lithium propionate as a common SEI constituent, but that the SEI on the Sn electrode contained diethyl 2, 5-dioxahexane dicarboxylate (DEDOHC), whereas the SEI on the Au electrode contained lithium ethylene dicarbonate (LiDEC). Here, the researchers proposed that the mechanism of SEI formation involved the strong interaction between the Sn surface and the solvent (mainly DEC) due to surface oxygens, which led to the formation of ethyl oxide. This ethyl oxide radical can subsequently serve as an intermediate to further decompose EC to form DEDOHC (Fig. 5c).

Yang et al. [203] also used in situ FTIR to investigate SEI formation on Si electrodes in a LiPF6/(EC + DMC) electrolyte and found that SEI formation over Si electrodes started at 0.87 V (Fig. 5d). In addition, these results revealed that SEI thicknesses increased and lithium alkyl carbonates started to appear as Si electrodes polarized toward lower potentials. This large volume expansion during the alloying of Si subsequently led to the breakage of the SEI layer and the exposure of fresh Si surfaces. And as a result, substantial electrolyte decomposition occurred during de-lithiation. In addition, degradation of the electrolyte salt LiPF6, starts during de-lithiation leading to the decomposition of lithium alkyl carbonate through reactions with HF and free radicals or Li, resulting in the formation of alkyl phosphate and Li2CO3. Furthermore, these researchers reported that de-lithiation can also lead to the formation of organic components such as lithium oxalate and lithium alkyl carbonates, thus suggesting that more SEI components are formed during de-lithiation than lithiation.

The CEI on cathode materials has also been frequently studied by using in situ FTIR. For example, Matsui et al. [204] investigated the electrochemical oxidation behaviors of LiClO4/(EC + DEC) and LiClO4/PC electrolytes with a LiCoO2 cathode using in situ FTIR and found that the solvents and salts both degraded during the discharge process and that this degradation resulted in the deposition of Li2CO3 and poly-oxyethylene to form a surface film that was unstable and stripped out during cathodic polarization (Fig. 5e). In addition, these researchers found that because the oxidized species were only weakly adhered to the LiCoO2 surface, the deposition and stripping process continued for a few cycles until the interfacial film reached a certain thickness so that no electrons could penetrate through. Subsequently, these researchers extended this experiment to LiMn2O4 and LiNi1/2Mn3/2O4 cathodes and observed similar phenomena. And by combining the results of these three materials, these researchers suggested that electrolyte salts can decompose and form a layer of carboxylic derivatives, which can further decompose to form a complex CEI [205]. Matsui et al. [206] also investigated LiCoO2 cathode interfaces in electrolytes of LiBOB/(EC + DEC), LiPF6/(EC + DEC) and (LiBOB + LiPF6)/(EC + DEC) using in situ FTIR and found that LiBOB preferred to adhere to cathode surfaces and that BOB− anions could protect PF6− ions in LiPF6 salts from decomposing into PF5 and LiF, which prevented interface formation and therefore minimized electrolyte breakdown. Matsushita et al. [207] also studied CEIs on LiCoO2 cathodes in PC-based electrolytes with various salts (i.e., LiPF6, LiBF4 and LiClO4) using in situ FTIR and found that PC can oxidize into carboxylic-group-containing compounds and further convert into an anhydride form and remain on the electrode surface. These researchers also found that the above reactions of PC were influenced by the various salts and were more active in LiPF6 salts as compared with the others.

3.3.2 X-ray Photoelectron Spectroscopy (XPS)

In XPS analysis, incident X-rays photons (typically Al Kα = 1486.6 eV, Mg Kα = 1253.6 eV) are absorbed by material surfaces and photoelectrons are ejected from the surface in which the energy spectra of these photoelectrons are analyzed with a detector. As a result, XPS is capable of analyzing almost all elements of the periodic table (except H and He) if their concentrations are > 0.1 at % of the material surface with energy resolution of 0.1 eV [208]. And although XPS is a surface analysis technique, it can also provide depth analysis in which a nondestructive method involves the adjustment of incident angles to tune the penetration depth of the X-rays (< ~10 nm), whereas a destructive method involves the etching of sample surfaces by several hundred nanometers with a sputtering ion gun. Here, both methods can be useful for SEI/CEI studies; however, due to the electronically insulating nature of SEIs/CEIs, the charging up of samples due to the ejection of photoelectrons needs to be carefully avoided in XPS measurements. In addition, special liquid electrolyte cells or special instrument designs are required for in situ XPS studies on SEIs/CEIs because an ultrahigh-vacuum (< 10−8 Pa) environment is necessary for the energy analyzer.

For example, Malmgren et al. [42] investigated chemical composition differences between SEIs on lithiated graphite anodes and CEIs on delithiated lithium iron phosphate cathodes using XPS and found that the inner layer of the SEI contained compounds such as lithium oxide and alkoxides that were not observed in the cathode CEI (Fig. 6a). Here, these researchers largely attributed these differences to the different electrochemical reactions at the operating potentials of the anode and the cathode. In addition, these researchers also found from their XPS results that the main components in the outer layer of the SEI were C–H- and C = O-containing compounds, which were also found to be the main components of the cathode CEI, and proposed that the similarities between the SEI outer layer and the CEI were associated with the dissolved portion of the electrolyte reduction products originating from the formation of the inner layer SEI on the anode. Furthermore, these researchers also conducted depth profile analysis by XPS and found that after a few cycles, the SEI thickness on the lithiated graphite anode was ~ 17 nm, whereas the CEI on the delithiated lithium iron phosphate cathode was estimated to be a few nanometers.

In situ and ex situ XPS for the composition analysis of SEIs/CEIs on various electrodes. a Schematic of the SEI on a lithiated graphite anode and the CEI on a carbon-coated delithiated LiFeO4 cathode. Reproduced with permission from Ref. [42]. Copyright 2013, Elsevier. b Molecular species found at different surface potentials of SiNW samples by using XPS high-resolution scanning. Reproduced with permission from Ref. [41] Copyright 2009, Elsevier. c Synchronized (left) and unsynchronized (right) 2D C1 s XPS spectra of LiCoO2 particles during overcharging. Reproduced with permission from Ref. [44] Copyright 2014, Elsevier. d Diagram of a sample holder (top) for in situ XPS characterization and XPS chemical imaging of the lithium electrode–electrolyte interface after the first charge/discharge cycle (bottom right) and a picture representation of the SEI layer growth mechanism of Li–S batteries based on XPS and computational results (bottom left). Reproduced with permission from Ref. [43] Copyright 2017, American Chemical Society

In another study, Chan et al. [41] studied SEI formation on a silicon nanowire anode in a LiPF6/(EC + DEC) electrolyte using ex situ XPS and found that the chemical composition of the SEI was voltage dependent in which after the initial charge to 0.5 V, the SEI film was found to be composed of similar amounts of hydrocarbons, LiF, LixPFy, LixPFyOz and PEO-type oligomers, along with less amounts of ethers and lithium alkyl carbonates (Fig. 6b). And if the anode was further charged to 0.1 V, the SEI was found to be composed of mainly hydrocarbons and PEO-type oligomers, indicating the reduction of more electrolytes. Moreover, Li2CO3 was detected in the SEI at 0.1 V but ethers or lithium alkyl carbonates were not, indicating that these meta-stable components may have transformed into Li2CO3. Furthermore, the amounts of LiF and LiPF6 in the SEI at 0.1 V were found to be lower than those at 0.5 V and that if fully charged to 10 mV, the SEI consisted mainly of stable Li2CO3 and LiF. In another study, Chen et al. [139] characterized the chemical components of the SEI formed on a Si film anode in LiPF6/EC: DEC electrolytes with and without VC using ex situ XPS, and found that the existence of VC in the electrolyte decreased the LiF content in the SEI layer and improved the electrochemical performance of the Si film anode. In addition, Song et al. [209] investigated the effects of VC on the cycling performances of a graphite||LiFePO4 cell at elevated temperatures using ex situ XPS and based on their obtained results, suggested that the addition of VC can help to form a CEI layer on the cathode to suppress the dissolution of Fe from the LiFePO4 cathode and improve the SEI stability on the anode.

Maibach et al. [210] proposed in situ XPS for SEI analysis in LIBs, and as a result, numerous in situ XPS studies have emerged [43, 44, 84, 211, 212]. For example, Park et al. [44] investigated the electrochemical performance of a Li||LiCoO2 cell in a 1.0 M LiPF6/EC + DEC (1:1, in volume ratios) electrolyte with or without FEC additives using 2D correlation XPS for cathode materials and found that the 2D correlation spectra of the C1 s region obtained from the charged LiCoO2 electrode in the FEC-free and FEC-containing electrolytes were different (Fig. 6c) and concluded that the PVDF binder and electrolyte components had decomposed to form a CEI on LiCoO2 and that the addition of FEC increased the amount of polycarbonate, which became the dominant species in the CEI film. Nandasiri et al. [43] also investigated the evolution of SEI layers on lithium anodes within Li–S batteries using in situ XPS and found that the SEI layer evolution consisted of three major processes, including the formation of a primary composite containing stable lithium compounds (e.g., Li2S, LiF, Li2O), the formation of a secondary matrix as a result of cross-interactions between reaction products and electrolytes and a highly dynamic monoanionic polysulfide (i.e., LiS5) fouling process (Fig. 6d). Recently, Tang et al. [211] also used in situ XPS and Auger electron spectroscopy to study the use of carbon-supported titanium grid current collectors and ionic-liquid-based electrolytes in which partially reversible conversions between Cu and CuO, and Li2O formation were observed in a LiTFSI/P13TFSI electrolyte against a Li counter electrode.

3.3.3 Secondary Ion Mass Spectrometry (SIMS)