Abstract

In the present study, an attempt has been made to predict flank wear during milling operation with the help of signal processing and machine learning techniques. The vibration and acoustic emission signals obtained from the spindle of milling machine with variations in feed and depth of cut are decomposed into various levels using symlet wavelet. To select the best level permutation entropy criteria were applied. Level giving minimum permutation entropy was selected for the calculation of statistical features. Eleven statistical features such as skewness, kurtosis, mean, etc. were extracted from symlet wavelet and feature vector is formed. To select the relevant features, correlation-based feature selection criterion was used for reducing the size of feature vector. Feature vector with vibration signals and acoustic emission signals is fed into machine learning techniques such as linear regression and K-Star to predict the flank wear measured during milling operation. It is observed that K-Star gives higher prediction rate of tool wear with both training and testing of the classifier and feature vector with the reduced feature set with acoustic emission signals gives better prediction accuracy compared to vibration signals.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In milling process, a cutter is used to remove material from the surface of a workpiece. Speed, feed, and depth of cut are the important parameters which control the operation during the milling process. When it comes to the manufacturing industry, it is required to control the machining process of a workpiece to increase the quality as well as productivity. One of the major factors that affect the quality of components is tool wear which is a phenomenon observed due to the interaction between the tool and workpiece during manufacturing operations. Specifically, the wear on the tool flank is of more importance compared to the other face wears such as rake face wear. Flank face wear occurs due to the friction between the newly generated workpiece surface and the tool flank. When the tool wears significantly and is not replaced, it would cause poor surface finish/quality of the workpiece and leads to dimensional inaccuracy (Niu et al. 1998). Recent studies have shown interest in the prediction of tool wear as that would provide a great advantage to the industry in terms of production cost, waste reduction, and accuracy. The average machine downtime because of tool wear is 7–20%. There have been many techniques to measure the tool condition including using sensor signals from sensors such as acoustic emission sensors, current sensors, and vibration sensors (García Plaza and Núñez López 2018). From the data provided by these sensors, it is possible to predict the wear of tools during the manufacturing processes so that it may be possible to machine a product with desired quality and accuracy. The procedure requires predicting tool wear are data acquisition, signal processing, feature extraction, feature selection, and finally classification or prediction (Vakharia et al. 2015).

In a study conducted by the authors (Khamel et al. 2012), ANOVA was used to investigate the influence of process parameters cutting speed, feed rate, and depth of cut in finish hard turning of AISI 52,100 bearing steel with CBN tool. Response surface methodology was used by Jeyakumar et al. (2013) for the prediction of cutting force, tool wear, and surface roughness of Al6061/SiC composite for end milling operations. A good agreement between the developed model and experimental results was observed. When machining is done then vibration occurs and it is an important signature which can describe the status of tool, chatter, wear, and even any abnormality in component or machinery. For investigation of tool wear and surface finish in turning operation, Sivasakthivel et al. (2017) captured vibration signals with and without cutting conditions with the help of triaxial accelerometer mounted on a tool holder. In recent researches, artificial neural network (ANN) as well as the wavelet packet transform were used for the prediction of tool wear. Wavelet packet theorem is used to reduce noise and extract the energy feature of the signal (Vakharia et al. 2017), whereas ANN was used for classification. ANN and Fuzzy logic were used for online monitoring of tool wear by Kuo (2000). The authors after conducting experiment reveal that the methodology developed significantly improves the accuracy compared to the conventional approaches. Drouille et al. (2016) used the ANN and RMS powers in end milling tests to predict the tool wear which takes into account the uncertainty of tool wear and was shown to be a very quick process and inexpensive. In another study, Wang and Wang (2012) diagnosed the tool wear in milling by combining wavelet packet theory and Hidden Markov Model; the tool wear predicted using Gaussian regression model. Fang et al. (2011) and Mishra et al. (2016) predicted the wear of tools using the fast Fourier transform (FFT) technique and discrete wavelet transform technique. It is concluded that discrete wavelet transform technique is a more effective signal processing technique compared to FFT at higher cutting speeds. There have been a few authors who have focused on the acoustic emission (AE) sensors to extract the signals for predicting the tool wear. Acoustic emission is an effective sensor which accurately senses the friction of rubbing, during wear and the action of dislocation in the shearing zone in tool condition monitoring. Li (2002) discussed the utility of AE for tool wear monitoring during turning process. AE signal classification was discussed and the utility of AE sensors in tool wear monitoring highlighted. Liang and Dornfeld (1989) developed an autoregressive time-series model to detect cutting tool wear with acoustic emission signals. The advantage of AE signals is that the frequency ranges of the AE signals are much higher than that of the mechanical vibrations. Further using filter, uncontaminated signals were collected by simply mounting a piezoelectric transducer on the tool holder. For classification/prediction of tool wear condition, various methods such as ANN, support vector machine, naïve bayes exist in the current research area of condition monitoring, each having their own merits and demerits. Effective condition monitoring methodology will reduce errors of identifying tool wear. It is believed that machine learning algorithm provides a quick and right decision about the condition of the cutting tool. A multiple linear regression model was used by Bhattacharyya et al. (2007) to estimate tool wear in face milling operation. The feature vector was constructed using current and power signals. Ramalingam and Mohan (2016) utilized K-Star algorithm to detect and predict the changes in the EEG signals with finger open, finger close, wrist clockwise, and wrist counter-clockwise movements of prosthetic arm. Madhusudana et al. (2016) conducted an experimental study for the fault diagnosis of face milling tool using histogram features and K-Star algorithm. The authors after detail study claim that K-Star algorithm provided better classification accuracy compared to other classifiers.

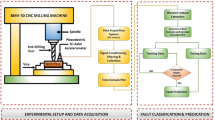

In the present study, the acoustic emission and vibration signals are utilized to predict the flank wear in milling operations. Discrete wavelet transform with symlet as a base wavelet is used for extraction of coefficients from the measured signals. To decide suitable levels, the entropy of the wavelet coefficients is calculated and the level giving least entropy is used for formation of a feature vector. Correlation-based feature selection criterion is used to select the best features among all extracted features. Machine learning techniques such as linear regression and K-Star are utilized for predicting the flank wear of milling tools. The methodology also compares the utility of vibration signals and acoustic signals which are reported less in the literature. Figure 1 shows the methodology adopted to predict tool wear using vibration signals.

2 Machine learning techniques

When algorithm shows certain intelligence based on historical data and training which is different than the intelligence in humans and animals, it is known as artificial intelligence (AI) or machine learning. Artificial intelligence is an emerging technique that can perceive the environment around it and hence can take necessary action to maximize to succeed at a certain goal. Algorithms such as neural networks, different types of mathematical and search optimization and methods based on probability, statistics, and economics are commonly used machine learning techniques for solving a variety of problems. For prediction, i.e., regression, a model is built from the training set as an input to the classifier and it establishes the relationship between inputs and outputs to predict how the output changes as the input vary. Commonly used regression methods are ANN, Support vector machine, tree-based algorithms, and ensemble methods.

2.1 Linear regression

Linear regression uses the linear function for modeling the relationship between a scalar dependent variable B and one or more independent variables A. The practical uses of linear regression can be categorized as shown below:

-

1.

If our goal is prediction, error reduction or forecasting, linear regression can be used as a predictive model for an observed dataset of A and B values. After the model is developed, it is possible to predict the value of B for an additional given value of A. This means that the model can be used to predict the value of B.

-

2.

If we are given a variable B and many variables A1, A2…Ap that might be related to B, then the linear regression analysis is used to quantify the relationship strength between B and Ai so as to find out which Ai has no relation with B and to identify the subsets of Ai contain redundant information about B.

When given a dataset of \(\left\{ {b_{i} , \, a_{i1} , \, \ldots , \, a_{ip} } \right\}^{{n_{i} }}\) of n statistical units, the relationship between the dependent variable bi and the p vector of regressor ai is assumed to be linear by the linear regression model. The model of this relationship is through an error variable ei which is an unobserved random variable which is adding noise to the linear relationship between the regressors and dependent variables. Hence the model is of the form given below:

where T stands for the transpose and hence this equation can be written as below when the n equations are stacked together

2.2 K-Star

K-Star clustering is a vector quantization method and is used in data mining for cluster analysis. The K-Star method is meant to part n observations into k number of clusters in which each observation belongs to the cluster with the nearest mean which serves as a prototype of the cluster. For a set of observations (a1, a2, …an) in which each observation is a d dimensional real vector, K-Star clustering aims to partition the n observations into k ≤ n sets S ={S1, S2, …, Sk} so that we can minimize the variance

Here μi is the mean of points in Si.

3 Experimentation and feature extraction

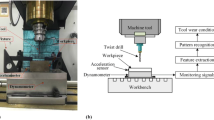

For predicting the tool wear, the experiments were conducted on a milling machine under the various operating conditions. The cutting speed was set to 200 m/min, the feed was varied at 0.5 and 0.25 mm/rev, and the depth of cut was varied at 1.5 and 0.75 mm. The material used for the workpiece was cast iron. A face mill of 70 mm face with six inserts of insert-type KC710 was chosen as the tool for the experiment which is coated with TiC, TiC-N, and TiN for toughness. The tool wear was taken into consideration and investigated under the following different cuts: entry cut, regular cut, and exit cut. The data collected from this experiment belong to the vibration sensor mounted at the spindle of the Matsuura milling center MC-510V. The vibration sensor was an accelerometer (model 7201-50, ENDEVCO). The signal was fed into a Phoenix contact cable connector and was amplified by a charge amplifier and filtered by an LP/HP filters before its root mean square was calculated and entered into the computer for data acquisition (Agogino and Goebel 2007). The next part of the data collected from this experiment was taken by an acoustic emission sensor (model WD 925, Physical Acoustic Group) which had a range of frequency of up to 2 MHz. This sensor was attached to a clamping support. The signal went into the terminal of a preamplifier (model 1801, Dunegan/Endevaco) which had a 50 kHz high-pass filter and then was amplified by a dual amplifier (model DE 302A). The signal goes through a custom-made RMS meter and then into a cable that feeds the signal into a high data acquisition board (MIO-16). Figure 2 shows the schematic diagram of the milling machine.

For the analysis of the vibration signals and acoustic emission signals obtained from the spindle of milling machine, the authors have used time–frequency signal processing techniques, i.e., discrete wavelet transform (DWT) and lifting wavelet transform (LWT). After conducting experiments, it is revealed that the energies of both the methods were different which is shown in Table 1. The statistical features were calculated using DWT as it is giving higher energy compared to LWT. Symlet was chosen as mother wavelet for DWT (Jemielniak and Kossakowska 2010), and for choosing the best level, entropy was compare for the cases considered (Wang et al. 2017). It is observed that approximation coefficients A1 is the appropriate level for the formation of feature vector as it showed the least entropy, which is shown in Table 2. When signals contain disorder/randomness then chances of predicting the correct condition of tool or component is difficult. Therefore, the authors in the present study have chosen minimum entropy for selecting approximate coefficients. Table 3 lists the statistical features considered for tool wear prediction in the present study (Vakharia et al. 2016a, b). The variation of statistical features with respect to time for both the signals, i.e., vibration and acoustic emission is shown in Fig. 3. Further to select the relevant features correlation-based feature selection methodology was used. Four features such as skewness, mean, RMS, and RSSQ were selected as the best features with vibration signals and kurtosis, maximum-to-minimum difference, peak-magnitude-to-RMS ratio, and energy were selected as beast features with acoustic emission signals.

4 Results and discussion

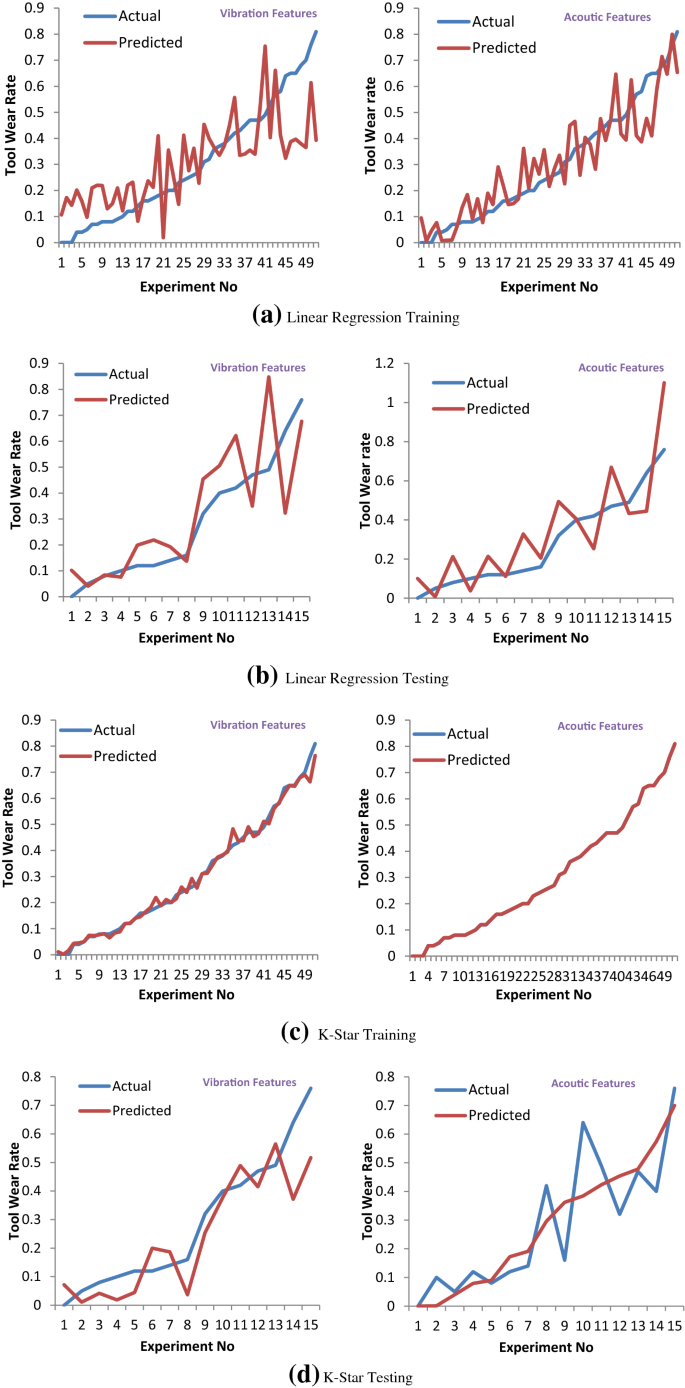

In the present study, the vibration signals and acoustic emission signals measured from spindle of milling machine with various operating conditions are utilized for tool wear prediction. Signals are acquired from the sensors with variations in the feed and depth of cut. The vibration and acoustic emission signals are decomposed into various levels considering symlet as base wavelet for extracting useful information and calculation of statistical features. In total 11 statistical features are used for the formation of feature vector. For prediction of flank wear, two artificial intelligence techniques linear regression and K-Star are utilized. Figures 4(a–d) and 5(a–d) show the actual and predicted value of tool wear rate using training and testing of classifier without feature selection and with feature selection. It is observed that there is a significant deviation between actual value and predicted value of flank wear when training and testing of classifier is conducted with and without feature selection. Correlation coefficient and mean absolute error are shown in Tables 4 and 5 which are widely used parameter to test the accuracy of regression analysis. The correlation coefficient for linear regression training with vibration and acoustic emission features obtained as 0.717 and 0.908, respectively, is shown in Table 4. The mean absolute error with vibration and acoustic emission features obtained as 0.12 and 0.07. When testing of classifier is done considering 30% of features for testing and 70% of features for training then prediction accuracy is enhanced which is seen in Fig. 4(a–b). The trend shows that there is comparatively less significant difference between the actual value of flank wear and predicted value of flank wear with feature sets obtained from both vibration and acoustic emission data when linear regression is used as a classifier for testing of features. The mean absolute error with vibration and acoustic features obtained as 0.73 and 0.756 while mean absolute error with vibration and acoustic features obtained as 0.1 and 0.12. Since correlation coefficient in case of acoustic emission features are high compared to vibration signals and mean absolute error is low with acoustic emission features, therefore it can be judged that the signals obtained from acoustic emission sensors are better than the vibration signals for predicting the flank wear with linear regression technique. Figure 4(c–d) illustrates the training and testing accuracy of predicting flank wear with K-Star algorithm with vibration and acoustic emission feature sets. The prediction accuracy after using K-Star for training is found to be better compared to linear regression. Furthermore, the flank wear predicted with the feature set obtained from acoustic emission signals gives 100% prediction since predicted values superimposed with actual values which is shown in Fig. 4(c–d). Correlation coefficient for the feature extracted from vibration and acoustic emission are one for both the signals and mean absolute error is zero suggesting that K-Star correctly identified all the cases of flank wear when training of classifier was done. When K-Star is used as a classifier for testing of feature vector, from Table 4 it is clear that the correlation coefficient is 0.76 and 0.866 and mean absolute error is 0.12 and 0.08, respectively, with features calculated from vibration and acoustic emission signals, respectively. After detailed study it is worthy to mention that the correlation between actual and predicted tool wear rate is high both in training and testing of K-Star and mean absolute error is lowest with both training and testing of K-Star with all 11 statistical features. When correlation-based feature selection criterion is applied then only four features out of eleven were selected for training and testing of classifiers. Figure 5(a–d) shows the actual and predicted value of tool wear rate using training and testing of classifier with feature selection criterion. Table 5 shows the performance evaluation of classifier with correlation coefficient and mean absolute error. When training is done with K-Star classifier and with reduced feature set then small deviation is observed compared to K-Star classifier and considering all features which is seen in Figs. 4(c) and 5(c). After comparing the evaluation parameters for analyzing the performance of classifier, it is observed that with reduced feature set, the tool wear prediction is better compared to all feature set which is shown in Table 5.

Figures 6 and 7 show the variations in absolute error from linear regression and K-Star testing for both the conditions. The maximum absolute error in prediction of flank wear is 0.29 with linear regression and 0.18 with K-Star whereas minimum absolute error is 0.03 and 0.01 with linear regression and K-Star, respectively, with vibration feature set as shown in Fig. 6. When acoustic feature set is used then maximum absolute error observed is 0.34 with linear regression and 0.25 with K-Star, whereas minimum absolute error observed is 0.01 and 0, respectively, with linear regression and K-Star, respectively, as shown in Fig. 7. Figures 6 and 7 represent the conditions when all 11 features were used. Figures 8 and 9 represent the plot of absolute errors with only four features. When feature selection is used then the absolute error is comparatively less as observed with all features. Since variations in absolute error are less with acoustic emission feature set compared to vibration feature set without feature selection and with feature selection, therefore, it is revealed that the acoustic feature set gives the better result for predicting the flank wear in the present study.

5 Conclusion

Tool wear prediction from the vibration signals and acoustic emission signals acquired from milling machine has been utilized in the present study. Discrete wavelet transforms considering symlet as base wavelet are used for the calculation of statistical features. Eleven statistical features have been extracted from the symlet wavelet coefficients and feature vector is formed using vibration feature set and acoustic emission feature sets. Prediction accuracy is compared with linear regression and K-Star algorithm. The result reveals that the reduced feature set formed with acoustic emission feature set gives better prediction accuracy and K-Star is the better machine learning algorithm to predict flank wear in milling. Present methodology is efficient for predicting flank wear when K-Star is used for both training and testing, since prediction error is very low while testing of the classifier.

References

Agogino A, Goebel K (2007) BEST lab, UC Berkeley milling data set, NASA Ames prognostics data repository (http://ti.arc.nasa.gov/project/prognostic-data-repository). Accessed Nov 2017

Bhattacharyya P, Sengupta D, Mukhopadhyay S, Chattopadhyay AB (2007) Online tool condition monitoring in face milling using current and power signals. Int J Prod Res 46(4):1187–1201

Drouille C, Karandikar J, Natha C, Journeauxa AC et al (2016) Tool life predictions in milling using spindle power with the neural network technique. J Manuf Process 22:161–168

Fang N, Pai PS, Mosquea S (2011) Effect of tool edge wear on the cutting forces and vibrations in high-speed finish machining of Inconel 718: an experimental study and wavelet transform analysis. Int J Adv Manuf Technol 52:65–77

García Plaza E, Núñez López PJ (2018) Application of the wavelet packet transform to vibration signals for surface roughness monitoring in CNC turning operations. Mech Syst Signal Process 98:902–919

Jemielniak K, Kossakowska J (2010) Tool wear monitoring based on wavelet transform of raw acoustic emission signal. Adv Manuf Sci Technol 34(3):5–17

Jeyakumar S, Marimuthu K, Ramachandran T (2013) Prediction of cutting force, tool wear and surface roughness of Al6061/SiC composite for end milling operations using RSM. J Mech Sci Technol 27(9):2813–2822

Khamel S, Ouelaa N, Bouacha K (2012) Analysis and prediction of tool wear, surface roughness and cutting forces in hard turning with CBN tool. J Mech Sci Technol 26(11):3605–3616

Kuo RJ (2000) Multi-sensor integration for on-line monitoring tool wear estimation through artificial neural networks and fuzzy neural network. Eng Appl Artif Intell 13:249–261

Li X (2002) A brief review: acoustic emission method for tool wear monitoring during turning. Int J Mach Tools Manuf 42(2):157–165

Liang SY, Dornfeld DA (1989) Tool wear detection using time series analysis of acoustic emission. J Eng Ind 111:199–205

Madhusudana CK, Kumar H, Narendranath S (2016) Condition monitoring of face milling tool using K-star algorithm and histogram features of vibration signal. Eng Sci Technol Int J 19(3):1543–1551

Mishra SK, Rao US, Kumar S (2016) Tool wear prediction by using wavelet transform. Int J Precis Technol 6(3/4):216–230. https://doi.org/10.1504/ijptech.2016.080000

Niu YM, Wong YS, Hong GS (1998) An intelligent sensor system approach for reliable tool flank wear recognition. Int J Adv Manuf Technol 14(2):77–84

Ramalingam VV, Mohan S (2016) Prosthetic arm control with statistical features of EEG signals using K-star algorithm. J Appl Sci 16:138–145

Sivasakthivel PS, Sudhakaran R, Rajeswari S (2017) Optimization and sensitivity analysis of geometrical and process parameters to reduce vibration during end milling process. Mach Sci Technol 21(3):452–473

Vakharia V, Gupta VK, Kankar PK (2015) Ball bearing fault diagnosis using supervised and unsupervised machine learning methods. Int J Acoust Vib 20:244–250

Vakharia V, Gupta VK, Kankar PK (2016a) A comparison of feature ranking techniques for fault diagnosis of ball bearing. Soft Comput 20(4):1601–1619

Vakharia V, Gupta VK, Kankar PK (2016b) Bearing fault diagnosis using feature ranking methods and fault identification algorithms. Procedia Eng 144:343–350

Vakharia V, Gupta VK, Kankar PK (2017) Efficient fault diagnosis of ball bearing using ReliefF and Random Forest classifier. J Braz Soc Mech Sci Eng 39(8):2969–2982

Wang M, Wang J (2012) HMM for tool condition monitoring and remaining useful life prediction. Int J Adv Manuf Technol 59:463–471

Wang F, Liu J, Shu Q (2017) Milling wear of carbide tool for processing nickel-based alloy in cryogenic based on the entropy change. Int J Adv Manuf Technol 90(5–8):1703–1713

Acknowledgement

The authors are thankful for Kai Goebel (NASA Ames) and Alice Agogino (UC Berkeley) for providing permission to use milling dataset for research purpose.

The authors are thankful to the Editor and anonymous reviewers of Journal of Life Cycle Reliability and Safety Engineering for providing opportunity to publish journal paper. The authors would like to acknowledge the support of PDPU, Gandhinagar for providing the infrastructure required for carrying out the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vakharia, V., Pandya, S. & Patel, P. Tool wear rate prediction using discrete wavelet transform and K-Star algorithm. Life Cycle Reliab Saf Eng 7, 115–125 (2018). https://doi.org/10.1007/s41872-018-0057-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41872-018-0057-5