Abstract

Controlled release of probiotic bacteria via edible films as a vehicle is a novel approach. Therefore, in this study, the stability of two probiotic microorganisms, Bacillus coagulans IBRC-M 10807 and Lactobacillus plantarum PTCC 1058, were investigated in milk protein concentrate (MPC)-based edible films under different temperatures. For this purpose, effect of four factors, the probiotics (B. coagulans IBRC-M 10807 and L. plantarum PTCC 1058), glycerol concentration (6, 7.5, and 9%w/w), storage temperature (− 16, 4.5, and 25 °C) and storage time (3, 5, and 7 days) was investigated in edible films prepared using 10% w/w of milk protein concentrate containing 7 Log10 CFU/g of probiotics. Then the viability of each probiotic bacterium as well as important characteristics of probiotic edible films: pH, moisture content, solubility, water vapor permeability, and whiteness index were evaluated for optimization. Probiotic type and glycerol concentration had a significant effect on live-cell count (p < 0.05). The survival of B. coagulans spores was higher than that of L. plantarum. The optimum conditions included 9% glycerol concentration, − 16 °C and 7 day storage, in which survivability of B. coagulans and L. plantarum was 6.67 and 6.53 Log10 CFU/g, respectively. The overall results showed that MPC-based edible film could be a suitable carrier for probiotic bacteria to pack food stored at freezing temperatures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Edible films and coatings are manufactured from biopolymers and food-grade additives. Biopolymers are defined as a continuous matrix of proteins, polysaccharides, or fats that are capable of altering food surface properties [10]. Food coatings have been used for many years to better preserve food products and increase their appeal. In addition to preventing drying and creating an attractive appearance, these coatings reduce the exchange of respiratory gases and the growth of molds and insects on foods or reduce chemical and biochemical activity in them. In recent decades there has been a growing interest in the development of new technologies in the production and application of biodegradable films. They are being used as carriers of antioxidant, antimicrobial, enhancers, flavors, and colorings, as well as for enhancing nutritional value, enriching foods with vitamins and minerals [23].

Over the last decade, consumer demand for food products with health effects has increased [7]. Therefore, the role of food in the prevention of chronic diseases has received much attention. As a result, both producers and consumers show great interest in "functional foods". Foods containing probiotic bacteria have gained a significant attend of customers which led to an increase in their annual market [3, 4]. Probiotics are beneficial living bacteria that, if taken in sufficient counts, have health effects for the consumer [5, 6]. Lactobacillus strains are Gram-positive, micro-aerophilic, acid-resistant, non-spore-forming and low G + C group bacteria. These bacteria have a wide range of applications in the food industry as a starter and protective culture [8, 29]. Lactobacillus produces organic acids such as acetic acid, benzoic acid, and lactic acid as the main metabolites [28]. The antibacterial, antifungal and probiotic properties of LAB have been extensively studied [27]. Lactobacillus plantarum grows under low buffering capacity in the stomach and other bile salt secretions in humans and other mammals. In addition to applications in the food industry, and it is widely used in the pharmaceutical industry and significantly assists human medicine without any adverse effects. Recently, L. plantarum has been used in medical fields for the treatment of various chronic and cardiovascular diseases such as Alzheimer, Parkinson, diabetes, obesity, cancer, hypertension, urinary complications, liver disorders, etc. [15]. In the last 2 decades, attention has been given to Bacillus species as a probiotic due to adaptation to adverse conditions. Lactobacillus sporogenesis was isolated and described in 1932 by Wlassow Horowitz and Nowotelnow and subsequently classified as Bacillus sporogenesis but was never accepted as Lactobacillus because of its sporadic origin. Recently, evidence suggests that the bacterium has the same traits as Bacillus coagulans and was, therefore, transferred to that group. In general, B. coagulans is a bacterial species that forms lactic acid but of Bacillus genus [13].

One of the most important challenges in the production and processing of probiotic products is the low viability of probiotic bacteria due to susceptibility to harsh conditions within the food product as well as adverse gastrointestinal conditions. Microencapsulation is the technology of packing solids or liquids in small packages that release their contents at controlled speeds under specific conditions. The microcapsule is a thin, semipermeable sphere with a tight membrane of a size of a few microns to a millimeter that protects its internal materials. Microencapsulation of probiotics in hydrocolloid substrates can be adopted as a novel method to improve their survival in food during the process, storage, and conversion into powder form for ease of use. This technique is targeted to different types of dairy products such as yogurt, ice cream, milk powder. The microcapsule may be designed for the controlled release of its contents. The factors that cause to break the microcapsule are heat, solubility, diffusion, and pressure and the coating may be designed to release in a specific part of the body. The microcapsule should pass the acidic conditions of the stomach without destruction and open in the intestine [2, 11, 18, 20, 37]. There are several techniques to entrap probiotic bacteria and convert them into powder including spray-drying, freeze-drying, electrospray but these techniques have some disadvantages and limitations which includes expensive equipment, reducing the number of live bacteria after the process, and high production costs [21].

Different materials were used in the encapsulation and entrapment of probiotics including carbohydrates, proteins, and lipids [21]. Milk proteins concentrate (MPC) is produced directly from milk with a combination of ultrafiltration/diafiltration. MPC can have a protein content range of 55–85% including casein and whey proteins. MPC is additive in many food processes due to high absorbable calcium content, a favorable taste, high water absorption, and ability to increase the viscosity of products. Increasing the efficiency of cheese and yogurt production, formulation of beverages that have high nutritional value are some examples of the use of MPC in the food industry [22, 38].

It seems that a novel strategy is necessary to use probiotics in cereal products due to the disadvantages of common methods of probiotics microencapsulation and the limitations of adding encapsulated probiotics to these foods. There are very few studies on this topic, especially with the use of milk protein concentrate-based films. Therefore, this study aimed to produce edible films containing probiotic bacteria. Hence, MPC-based edible films containing B. coagulans IBRC-M 10807 and L. plantarum PTCC 1058 were developed. Then the viability of probiotics at different temperatures and storage times was compared and the properties of films were investigated.

Materials and Methods

Materials

MPC powder (protein, lactose, moisture, ash, and fat content of MPC were 84 ± 1% (w/w), 3.5 ± 0.3% (w/w), 4.0 ± 0.2% (w/w), 2.8 ± 0.1% (w/w), and 1.1 ± 0.1% (w/w), respectively) was purchased from Westland New Zealand company. Lyophilized form of L. plantarum PTCC 1058 and B. coagulans IBRC-M 10807 were obtained from Persian type culture collection (PTCC) and Iranian Biological Research Center (IBRC), respectively. Microbial culture media including De Man, Rogosa and Sharpe (MRS) and Tryptic Soy (TS) broth/agar (TSB/TSA) were purchased from Merck Germany. Glycerol and other chemicals used were laboratory grade and obtained from the Merck Company, Germany.

Activation of L. plantarum

Lactobacillus plantarum was inoculated to 10 ml of sterilized MRS broth and incubated at 37 ℃ for 48 h for reactivation. Then the cultivation was repeated in the 250 ml of MRS broth at same condition. Finally, L. plantarum cells were collected by centrifugation at 5000 × g for 15 min at 4 ℃ and washed twice by sterile normal saline [24].

Preparation of B. coagulans Spores

Bacillus coagulans was added to 10 ml of sterile TSB medium and incubated at 35 ℃ for 48 h to reactivate the spore of this probiotic. Then it was inoculated to the 250 ml of TSB medium and incubated at the same temperature and time. Bacterial spores were harvested by centrifugation at 7500 × g for 20 min at 4 ℃ and washed twice in sterile normal saline. Then purified spores were heated at 65 °C for 45 min to kill any residual vegetative cells. The concentration of spores per ml of spore suspension was verified using the Neubauer chamber and plate count [16].

Preparation of Probiotic Edible Film

The edible films were made according to the method proposed by Schou et al. [33] with little modification. Briefly, a 10% w/v MPC powder solution was prepared, then different amounts of glycerol (6, 7.5, and 9%w/w) were added according to the experimental design. Then, the bacterial suspension was added (previously set to the half-McFarland standard) to the edible film solution and was stirred for 10 min with a magnetic stirrer. Then the prepared solution was slowly poured into Petri dishes with 12 cm diameter under sterile conditions and dried at 35 ℃ and 50% relative humidity for 48 h. Finally, the homogeneous films formed were separated from the Petri dishes.

Enumeration of Probiotic Bacteria

According to the statistical design, viability of the bacteria at different temperatures was monitored during storage. Three circular discs of 1 cm in diameter were cut from each film and stored in sterile plastic bags at − 16, 4.5, and 25 °C for 3, 5, and 7 days. On the test day, the disc was placed in a sterile tube and 1 ml of sterile peptone water (0.1% w/v) was added and homogenized with vortex for 1 min until the film was completely dissolved to extract the probiotic bacteria. Subsequent serial dilution was performed in sterile peptone water. Lactobacillus plantarum was counted with MRS agar at 37 °C during 72 h of incubation [26]. Bacillus coagulans was counted with TSA agar (pH 6.7) at 37 °C for 72 h under aerobic condition [16].

Characteristics of the Probiotic Edible Films

Thickness Measurement

The film thickness measurements were necessary to determine the physical and mechanical properties. A digital micrometer (Mitutoyo-No.293-821, Tokyo, Japan) 0–25 mm was used to measure the thickness with a precision of 0.0001 mm at 5 points (4 points around and one point at center) and the mean was reported for each film [17].

Measurement of pH

pH of the prepared films was measured by a digital pH meter (781, Mertohm, Netherlands).

Measurement of Water Solubility

The film samples were cut into 3 × 3 cm squares and dried in an oven at 90 °C until constant weight. Then its weight was measured with an accuracy of 0.001 g and was considered as the initial dry weight of the film. The samples were added in 50 ml distilled water at 25 °C for 6 h under constant stirring (100 rpm) on a shaker. The solution containing the suspended particles of the film was poured onto the paper filter (Whatman No. 5) and dried in an oven at 90 °C until constant weight [17]. The percentage of soluble dry matter was calculated by the following formula:

where, W1 and W2 are first constant weight of dried sample (g) and final stable weight of sample (g), respectively.

Measurement of Moisture Content (MC)

Moisture content of the films was calculated by drying the sample in an oven at 103 °C for 24 h using the following equation:

where, Mi and Mf are the primary and secondary weight of the film sample, respectively [9, 32].

Measurement of Water Vapor Permeability (WVP)

ASTM E96-00 method at 25 °C was used to determine the water vapor permeability of the films. Prior to measurement, the film samples were conditioned in a desiccator containing saturated magnesium nitrate to reach 52% humidity at 25 °C. The conditioned films were cut into circles with a diameter of 6.5 cm and sealed in vials. Inside the vials was deionized water and there was a gap of about 2 cm between the film and the deionized water. Then, the vials were placed in a desiccator containing silica gel to maintain 0% relative humidity. The weight of the vials was measured at specified intervals and over a specified period of time. The weight loss of the vials will be equivalent to the amount of water passing through the film surface. The weight loss of the vials is recorded over a certain period of time and a chart was drawn. To calculate the water vapor transmission rate (WVTR), the graph slope is calculated in the linear section and divided by the area of the cup span:

In these equations, the ratio of increasing moisture to time (g/s), A is the film surface area (m2) in the test vials, X is the film thickness (m), and P is the difference between pure water vapor pressure across the film surface (ΔP) [17].

Measurement of Color Indexes

Color parameters of the films on the standard screen were measured by the MINOLTA colorimeter. The color value is expressed using Hunter parameters in lightness (L), red-green (a), and yellow-blue (b), and whiteness index (WI) are calculated as follows [14].

Experimental Design, Statistical Analysis and Numerical Optimization

In this study, four factors including probiotic type (B. coagulans and L. plantarum), glycerol (6%, 7.5%, and 9%), temperature (− 16, 4.5, and 25 ℃), and storage time (3, 5, and 7 days) were investigated by Fractional Factorial design with 22 samples (Table 1). The ANOVA test was used to analyze the obtained results at α = 0.05. The numerical optimization was performed based on desirability function. The Design-Expert Software Version 10 (Stat-Ease, Minneapolis, MN, USA) was used for statistical design and data analysis.

Results and Discussion

Survivability of Probiotic Bacteria

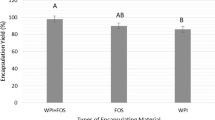

The results showed that probiotic type and glycerol concentration had a significant effect on survivability of probiotics (p < 0.05). Also, the interaction between probiotic type and glycerol concentration as well as the interaction of glycerol concentration and storage temperature on viability of probiotic bacteria were statistically significant (p < 0.05). As can be seen in Fig. 1a, the survivability of B. coagulans spores was higher than that of L. plantarum. Survivability of L. plantarum increased by about 0.30 Log10 CFU/g, upon increasing glycerol concentration from 6 to 9% (Fig. 1a). Figure 1b shows that the viability of B. coagulans was almost constant at different studied temperatures. However, survivability of L. plantarum with 6% glycerol at 25 °C was about 0.5 Log10 CFU/g higher than that at − 16 °C and upon increasing glycerol concentration up to 9%, survivability of this probiotic bacterium at − 16 °C was about 0.2 Log10 CFU/g higher than that at 25 °C (Fig. 1c). The decrease in the initial count of probiotic bacteria can be due to the drying of the films at room temperature. Soukoulis et al. [35] reported that WPC significantly improved the viability of Lactobacillus rhamnosus GG during drying and storage at room temperature. They also observed a significant decrease in the viability of L. rhamnosus GG during the first 24 h of storage. The decrease in viable cell number during the second and third days of storage was low and growth was observed at the last days of storage (days 5–7). The use of protein-based film solutions improved the viability of L. rhamnosus GG under simulated gastric and intestinal conditions, and the food matrix had no effect on the inactivation rate [35]. In another study, Soukoulis et al. [36] showed that oligosaccharides and polydextrose significantly increased the survival of L. rhamnosus GG during air drying (300% and 75%, respectively), while a decrease by 33% and 80% was observed in the bacterial count for wheat inulin and dextrin. However, inulin had the greatest effect in controlling the lethal effects on L. rhamnosus GG during storage. In general, addition of probiotics to edible films improved the stability of L. rhamnosus GG during storage [36]. Pereira et al. [26] reported that the viability of Bifidobacterium animalis BB-12 and Lactobacillus casei-01 in whey protein isolate-based edible films was decreased about 3 Log10 CFU/g after storage at 23 and 4 °C for 60 days. Their results showed that B. animalis BB-12 survived a long time with a lower decrease in its cell number in comparison with L. casei-01 [26]. Kanmani and Lim [19], reported that pullulan and pullulan/starch films were the most suitable carrier matrix, with maximum viability, 70–80% bacterial cells, after storage at 4 °C for 60 days.

pH of Films

The results showed that the effect of glycerol concentration and temperature on the pH of probiotic films based on MPC was significant (p < 0.05). Figure 2a shows that increase in glycerol concentration resulted in an increase in the pH of probiotic edible films, which could have a positive effect on probiotic viability. The pH of probiotic edible films increased upon increasing temperature from − 16 to 25 °C (Fig. 2b). Sadeghnezhad et al. [30] demonstrated that the pH of film was influenced by the components. According to their results, in protein-based films the amphoteric property of casein protein prevented the increase or decrease of acidity which is not in agreement with findings of this study. This might be due to the presence of lactose in MPC, which causes a slight activity of probiotics in the biopolymer matrix by an increase in glycerol and temperature. Also, with increasing temperature, the side groups of amino acid in MPC might be changed which led to an increase in pH due to increasing hydrogen receptors.

Solubility of Films

Water solubility is one of the most important properties of edible films. In other words, the solubility of films in water determines the release of antioxidant and antimicrobial compounds from active films when used for food coatings [1]. Resistance to water is an important property of biodegradable and edible films which demonstrates their efficiency in protecting foods with high water activity or fresh and frozen foodstuffs [12]. Shakeri et al. [34] demonstrated that, protein-based films show high water absorption and solubility, which limits their application as coating. Usually gum and glycerol due to being soluble in water, increase solubility and lipids due to insolubility, decrease solubility. However, due to interactions between components, gum and glycerol may decrease the solubility of prepared films [39]. The results showed that temperature had a significant effect on the solubility of MPC-based films (p < 0.05), as well as the interaction between temperature and time was statistically significant on the solubility of probiotic edible films (p < 0.05). The results showed that, the solubility of the films increased by increasing the storage temperature from − 16 to 25 °C (Fig. 3a, b). According to this Fig. 3c, the interaction of storage temperature and storage time on solubility, it was increased at − 16 °C by increasing time from 3 to 7 days. Solubility was increased by increasing temperature from − 16 to 25 °C. Chick and Ustunol [12], demonstrated that plasticizers can reduce interactions between (polymer molecules) and increase solubility due to the hydrophilic property of the polymer molecules. Due to the above fact, the effect of the crystallinity and crosslinking between the polymer chains in the molecular structure of the film is very effective on the water solubility of the films [31]. It has been found that by reducing crosslinking between polymer chains, glycerol modifies its molecular structure and significantly increases the solubility of the films in water [12].

Moisture Content of Films

The results showed that the effect of glycerol and storage time and the interaction between glycerol concentration and temperature on the moisture content (MC) of the films were significant (p < 0.05). As can be seen in Fig. 4a, an increase in glycerol concentration increased the moisture content of the films. Increasing storage temperature and time led to decrease the moisture content of the films. The interactions of glycerol (%) and time (day) had significant effect on MC of probiotic edible films and MC was increased by increasing glycerol (%) and time (day) (Fig. 4b). The observed increase in MC value of films may be attributed to the hygroscopic nature of glycerol, which attracts and holds water molecules during storage time. Therefore, an appropriate selection of the plasticizer type and concentration will be helpful in controlling the MC and, as a consequence, the moisture adsorption rate of a film, thereby improving the film stability under varying RH conditions during storage [30].

Water vapor permeability of films

Water vapor permeability is a simple way to measure the amount of moisture penetrating and passing through a material. Water vapor transfer from films depends on two factors including solubility and water molecule permeability in the film matrix. This characteristic is one of the important parameters of biodegradable films which is influenced by several factors such as mobility of polymer chains, interaction between functional polymer groups, film structure integrity, hydrophilic to hydrophobic groups ratio and crystalline-to-amorphous region ratio. Based on the results of storage time and the interaction between glycerol concentration and temperature had significant effect on vapor permeability of probiotic films (p < 0.05). As shown in Fig. 5a, at 6% glycerol concentration the permeability increased on increasing the storage temperature from − 16 to 25 °C, but no difference was observed at 9% glycerol concentration. However, at 6% glycerol concentration, water vapor permeability decreased with increasing storage time from 3 to 7 days, but did not differ at 9% glycerol (Fig. 5b). Water vapor permeability of edible films is a main characteristic for the ability of food products to stay healthy against water vapor, especially in dry foods. In fact, one of the main causes of corruption is relative humidity. This is why water vapor deterrence is one of the most important properties of food packaging materials [12]. Food packaging films often need to prevent or at least reduce the transfer of moisture between food and the surrounding atmosphere. The water vapor permeability should be reduced as far as possible in edible films. In this study the MPC-based probiotic films has very low permeability. The vapor permeability of the films depends on the number of polar groups of the polymer that attracts water molecules to their surface and thus facilitates the water transfer. The higher ratio of hydrophobic compounds causes more inhibition. Edible films based on polysaccharides and proteins have little inhibition against water vapor [12].

Surface color of films

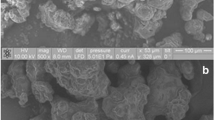

The results showed that the interaction between probiotic bacteria and temperature had a significant effect on the whiteness index of the films (p < 0.05). As shown in Fig. 6, by increasing the temperature, the whiteness index of the L. plantarum containing films increased whereas no change was observed in B. coagulans containing edible films. This result may be due to differences in size L. plantarum cells and B. coagulans spores. The spores of B. coagulans had non-significant effect on whiteness of edible films due to their much smaller size than L. plantarum cells. The color parameters of the films used in food packaging are of great importance because of their effects on consumer acceptability. Higher whiteness index, shows the white color of film [25].

Numerical optimization of films

Numerical optimization was performed based on desirability function considering maximum probiotic viability, solubility, moisture and whiteness as well as minimum water vapor permeability. The results showed that optimum conditions were 9% glycerol concentration, − 16 °C and 7 day storage time in which B. coagulans viable count was 6.67 Log10 CFU/g. The characteristics of optimized probiotic film containing this bacterium were pH 6.25, solubility 89.73%, moisture content 13.58%, WI 44.08 and water vapor permeability 1.39 × 10−6 kg m−1 s−1 Pa−1. Under the optimum conditions, viable count of L. plantarum was 6.53 Log10 CFU/g and characteristics of this probiotic containing edible film included pH 6.25, solubility of 89.98%, moisture content of 14.34%, WI of 44.04 and water vapor permeability of 4.93 × 10−6 kg m−1 s−1 Pa−1. Five samples of each probiotic film were prepared under the optimized conditions for confirmation of optimization.

Conclusion

In recent decades, the use of edible films has become one of the most important methods of food packaging. Recent applications of this technique as carriers of bioactive compounds with increased nutritional value have led to their use as carriers of probiotic bacteria. Among the main materials used in the preparation of edible films, proteins due to their special matrix are the major ones. Therefore, this study utilized the incorporation of milk protein concentrate to produce probiotic edible films. Glycerol, on the other hand, is used as a plasticizer in the structure of edible films, which can have a protective effect on probiotics trapped in the film matrix. In this study, in addition to introducing edible film with new formulations, it was used as a carrier for releasing beneficial bacteria with health effects. The results of present study indicated the suitability of the edible film matrix based on milk proteins as a carrier for probiotics. The results of this study showed that both probiotics used had high viability in edible film. Both bacteria had high viability at low temperatures (− 16 °C) due to the presence of glycerol in the edible film structure.

References

Abdollahi M, Rezaei M, Farzi G (2012) Improvement of active chitosan film properties with rosemary essential oil for food packaging. Int J Food Sci Technol 47:847–853. https://doi.org/10.1111/j.1365-2621.2011.02917.x

Anal AK, Singh H (2007) Recent advances in microencapsulation of probiotics for industrial applications and targeted delivery. Trends Food Sci Technol 18:240–251. https://doi.org/10.1016/j.tifs.2007.01.004

Amiri S, Aghamirzaei M, Mostashari P, Sarbazi M, Tizchang S, Madahi H (2020) The impact of biotechnology on dairy industry. In Microbial biotechnology in food and health. Academic Press, New York, pp 53–79

Amiri S, Mokarram RR, Khiabani MS, Bari MR, Khaledabad MA (2020) In situ production of conjugated linoleic acid by Bifidobacterium lactis BB12 and Lactobacillus acidophilus LA5 in milk model medium. LWT 132:109933. https://doi.org/10.1016/j.lwt.2020.109933

Amiri S, Mokarram RR, Khiabani MS, Bari MR, Alizadeh M (2020) Optimization of food-grade medium for co-production of bioactive substances by Lactobacillus acidophilus LA-5 for explaining pharmabiotic mechanisms of probiotic. J Food Sci Technol. https://doi.org/10.1007/s13197-020-04894-5

Amiri S, Mokarram RR, Khiabani MS, Bari MR, Khaledabad MA (2019) Exopolysaccharides production by Lactobacillus acidophilus LA5 and Bifidobacterium animalis subsp. lactis BB12: optimization of fermentation variables and characterization of structure and bioactivities. Int J Biol Macromol 123:752–765. https://doi.org/10.1016/j.ijbiomac.2018.11.084

Amiry S, Esmaiili M, Alizadeh M (2017) Classification of adulterated honeys by multivariate analysis. Food Chem 224:390–397. https://doi.org/10.1016/j.foodchem.2016.12.025

Arasu MV, Kim DH, Kim PI, Jung MW, Ilavenil S, Jane M, Lee KD, Al-Dhabi NA, Choi KC (2014) In vitro antifungal, probiotic and antioxidant properties of novel Lactobacillus plantarum K46 isolated from fermented sesame leaf. Ann Microbiol 64:1333–1346. https://doi.org/10.1007/s13213-013-0777-8

Asdagh A, Sani IK, Pirsa S, Amiri S, Shariatifar N, Eghbaljoo-Gharehgheshlaghi H, Shabahang Z, Taniyan A (2020) Production and characterization of nanocomposite film based on whey protein isolated/copper oxide nanoparticles containing coconut essential oil and paprika extract. J Polym Environ. https://doi.org/10.1007/s10924-020-01882-w

Campos CA, Gerschenson LN, Flores SK (2011) Development of edible films and coatings with antimicrobial activity. Food Bioprocess Technol 4:849–875. https://doi.org/10.1007/s11947-010-0434-1

Capela P, Hay TKC, Shah NP (2006) Effect of cryoprotectants, prebiotics and microencapsulation on survival of probiotic organisms in yoghurt and freeze-dried yoghurt. Food Res Int 39:203–211. https://doi.org/10.1016/j.foodres.2005.07.007

Chick J, Ustunol Z (1998) Mechanical and barrier properties of lactic acid and rennet precipitated casein-based edible films. J Food Sci 63:1024–1027. https://doi.org/10.1111/j.1365-2621.1998.tb15846.x

Drago L, De Vecchi E (2009) Should Lactobacillus sporogenes and Bacillus coagulans have a future. Chemotherapy 21:371–377. https://doi.org/10.1179/joc.2009.21.4.371

Ghasemi S, Bari MR, Pirsa S, Amiri S (2020) Use of bacterial cellulose film modified by polypyrrole/TiO2–Ag nanocomposite for detecting and measuring the growth of pathogenic bacteria. Carbohydr Polym 232:115801. https://doi.org/10.1016/j.carbpol.2019.115801

Grangette C, Nutten S, Palumbo E, Morath S, Hermann C, Dewulf J, Pot B, Hartung T, Hols P, Mercenier A (2005) Enhanced anti-inflammatory capacity of a Lactobacillus plantarum mutant synthesizing modified teichoic acids. Proc Natl Acad Sci 102:10321–10326. https://doi.org/10.1073/pnas.0504084102

Jafari M, Mortazavian AM, Hosseini H, Safaei F, Khaneghah AM, Sant’Ana AS (2017) Probiotic Bacillus: fate during sausage processing and storage and influence of different culturing conditions on recovery of their spores. Food Res Int 95:46–51. https://doi.org/10.1016/j.foodres.2017.03.001

Jouki M, Yazdi FT, Mortazavi SA, Koocheki A, Khazaei N (2014) Effect of quince seed mucilage edible films incorporated with oregano or thyme essential oil on shelf life extension of refrigerated rainbow trout fillets. Int J Food Microbiol 174:88–97. https://doi.org/10.1016/j.ijfoodmicro.2014.01.001

Kailasapathy K (2002) Microencapsulation of probiotic bacteria: technology and potential applications. Curr Issues Intest Microbiol 3:39–48

Kanmani P, Lim ST (2013) Development and characterization of novel probiotic-residing pullulan/starch edible films. Food Chem 141:1041–1049. https://doi.org/10.1016/j.foodchem.2013.03.103

Krasaekoopt W, Bhandari B, Deeth H (2003) Evaluation of encapsulation techniques of probiotics for yoghurt. Int Dairy J 13:3–13. https://doi.org/10.1016/S0958-6946(02)00155-3

Maleki O, Khaledabad MA, Amiri S, Asl AK, Makouie S (2020) Microencapsulation of Lactobacillus rhamnosus ATCC 7469 in whey protein isolate-crystalline nanocellulose-inulin composite enhanced gastrointestinal survivability. LWT 126:109224. https://doi.org/10.1016/j.lwt.2020.109224

McCarthy NA, Kelly PM, Maher PG, Fenelon MA (2014) Dissolution of milk protein concentrate (MPC) powders by ultrasonication. J Food Eng 126:142–148. https://doi.org/10.1016/j.jfoodeng.2013.11.002

Mellinas C, Valdés A, Ramos M, Burgos N, Garrigos MDC, Jiménez A (2016) Active edible films: current state and future trends. J Appl Polym Sci 133:42631. https://doi.org/10.1002/app.42631

Moghanjougi ZM, Bari MR, Khaledabad MA, Almasi H, Amiri S (2019) Bio-preservation of white brined cheese (Feta) using probiotic bacteria immobilized in bacterial cellulose: optimization by response surface method and characterization. LWT 117:108603. https://doi.org/10.1016/j.lwt.2019.108603

Moradi M, Tajik H, Rohani SMR, Mahmoudian A (2016) Antioxidant and antimicrobial effects of zein edible film impregnated with Zataria multiflora Boiss. essential oil and monolaurin. LWT 72:37–43. https://doi.org/10.1016/j.lwt.2016.04.026

Pereira JO, Soares J, Sousa S, Madureira AR, Gomes A, Pintado M (2016) Edible films as carrier for lactic acid bacteria. LWT 73:543–550. https://doi.org/10.1016/j.lwt.2016.06.060

Rejiniemon TS, Hussain RR, Rajamani B (2015) In-vitro functional properties of Lactobacillus plantarum isolated from fermented ragi malt. South Indian J Biol Sci 1:15–23

Reis JA, Paula AT, Casarotti SN, Penna ALB (2012) Lactic acid bacteria antimicrobial compounds: characteristics and applications. Food Eng Rev 4:124–140. https://doi.org/10.1007/s12393-012-9051-2

Rezazadeh-Bari M, Najafi-Darmian Y, Alizadeh M, Amiri S (2019) Numerical optimization of probiotic Ayran production based on whey containing transglutaminase and Aloe vera gel. J Food Sci Technol 56:3502–3512. https://doi.org/10.1007/s13197-019-03841-3

Sadeghnezhad Z, Amiri S, Rezazadeh-Bari M, Almasi H (2020) Physical and morphological characteristics of edible composite film of sodium caseinate/pectin/zedo gum containing poulk (Stachys schtschegleevii) extract: optimizing bioactivity and physicochemical properties. J Package Technol Res 4:187–203. https://doi.org/10.1007/s41783-020-00094-w

Sánchez-González L, González-Martínez C, Chiralt A, Cháfer M (2010) Physical and antimicrobial properties of chitosan–tea tree essential oil composite films. J Food Eng 98:443–452. https://doi.org/10.1016/j.jfoodeng.2010.01.026

Sani IK, Marand SA, Alizadeh M, Amiri S, Asdagh A (2020) Thermal, mechanical, microstructural and inhibitory characteristics of sodium caseinate based bioactive films reinforced by ZnONPs/encapsulated Melissa officinalis essential oil. J Inorg Organomet Polym Mater. https://doi.org/10.1007/s10904-020-01777-2

Schou M, Longares A, Montesinos-Herrero C, Monahan FJ, O’Riordan D, O’sullivan M (2005) Properties of edible sodium caseinate films and their application as food wrapping. LWT 38:605–610. https://doi.org/10.1016/j.lwt.2004.08.009

Shakeri MS, Shahidi F, Beiraghi-Toosi S, Bahrami A (2011) Antimicrobial activity of Zataria multiflora Boiss. essential oil incorporated with whey protein based films on pathogenic and probiotic bacteria. Int J Food Sci Technol 46:549–554. https://doi.org/10.1111/j.1365-2621.2010.02519.x

Soukoulis C, Behboudi-Jobbehdar S, Yonekura L, Parmenter C, Fisk ID (2014) Stability of Lactobacillus rhamnosus GG in prebiotic edible films. Food Chem 159:302–308. https://doi.org/10.1016/j.foodchem.2014.03.008

Soukoulis C, Yonekura L, Gan HH, Behboudi-Jobbehdar S, Parmenter C, Fisk I (2014) Probiotic edible films as a new strategy for developing functional bakery products: the case of pan bread. Food Hydrocoll 39:231–242. https://doi.org/10.1016/j.foodhyd.2014.01.023

Sultana K, Godward G, Reynolds N, Arumugaswamy R, Peiris P, Kailasapathy K (2000) Encapsulation of probiotic bacteria with alginate–starch and evaluation of survival in simulated gastrointestinal conditions and in yoghurt. Int J Food Microbiol 62:47–55. https://doi.org/10.1016/S0168-1605(00)00380-9

Ye A (2011) Functional properties of milk protein concentrates: emulsifying properties, adsorption and stability of emulsions. Int Dairy J 21:14–20. https://doi.org/10.1016/j.idairyj.2010.07.005

Zahedi Y, Ghanbarzadeh B, Sedaghat N (2010) Physical properties of edible emulsified films based on pistachio globulin protein and fatty acids. J Food Eng 100:102–108. https://doi.org/10.1016/j.jfoodeng.2010.03.033

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gholam-Zhiyan, A., Amiri, S., Rezazadeh-Bari, M. et al. Stability of Bacillus coagulans IBRC-M 10807 and Lactobacillus plantarum PTCC 1058 in Milk Proteins Concentrate (MPC)-Based Edible Film. J Package Technol Res 5, 11–22 (2021). https://doi.org/10.1007/s41783-021-00106-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41783-021-00106-3