Abstract

Lactobacillus rhamnosus GG (L. rhamnosus GG) cells were encapsulated in buttermilk proteins by spray drying, alone (E), or with Agave tequilana fructans (CEF). Buttermilk proteins acted as a thermo-protector for the probiotic cells undergoing the spray-dried process. The addition of Agave fructans in CEF microcapsules significantly enhanced storage stability and survival to in vitro simulated gastrointestinal conditions, compared to E capsules. After 14 days storage at − 20 °C, the number of living cells in CEF microcapsules was in the order of 7.7 log CFU • mL−1 and the survivability in simulated gastrointestinal environment was 73.23%. Spray-dried microparticles were cultured in goat milk to study biomass production. Agave fructans offered a favorable microenvironment and better growth substrate. The population of CEF viable cells reached 1.08 ± 0.02 × 1010 CFU • mL−1 after 18 h of fermentation. In contrast, the population of E viable cells were 3.0 ± 0.01 × 109 CFU • mL−1. The generation time of CEF, L. rhamnosus GG was 15% faster than E, L. rhamnosus GG. Encapsulation with buttermilk proteins in the presence of Agave fructans by spray drying could be suitable for preservation of probiotic powders and may be for a more effective application of probiotics in goat dairy products.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Several studies have shown that goat milk is an excellent culture medium for probiotics such as Bifidobacterium lactis and Lactobacillus acidophilus [1]. Furthermore, owing to its high digestibility, tolerance by allergic individuals and other properties, goat milk can provide a commercial alternative to cow milk products supplemented with probiotics [2]. Therefore, the use of goat milk in combination with probiotic strains may represent an option for the manufacture of new functional dairy foods [3].

The growth of probiotics can be enhanced by the inclusion of prebiotics such as inulin or fructooligosaccharides (FOS) in the media [4]. In this context, branched-type fructans of Agave tequilana could be a good alternative instead linear-type fructans like inulin [5]. In addition, many probiotics require protection to retain their properties. Encapsulation can protect bacterial cells against adverse conditions including low pH, oxygen toxicity and high temperatures [4] and allow dairy food products to become effective carriers of beneficial microorganisms [6].

Spray drying has been extensively investigated as an alternative encapsulation method to produce probiotic cultures [7]. However, one disadvantage of this method is the use of high temperatures, which causes sub-lethal cell damage that diminishes the survival of bacteria. In addition, significant inactivation of probiotic cells can occur during subsequent storage [6].To improve probiotic survival, protein matrices used for encapsulation of probiotics can be stabilised by chemical cross-linking either with enzymes, such as transglutaminase or genipin [8], or chemically via a Maillard reaction [9]. Bifidobacterium infantis encapsulated by spray drying in an oil in water (o/w) emulsion followed by a Maillard reaction showed a significant improvement in survival and viability during storage and low-pH challenge [9].

Milk proteins have shown good encapsulation performance due to their structural and physicochemical properties that provide resistance for the bacteria from external stresses. In addition, these proteins allow the diffusion of bacterial metabolites out of and flow of nutrients into encapsulated structures [7, 10]. Buttermilk is a co-product from butter manufacture, particularly rich in casein and whey milk proteins, that could find application as encapsulation matrix.

In the present study, the survival and the growth kinetics of L. rhamnosus GG encapsulated and co-encapsulated with Agave tequilana fructans in a buttermilk protein matrix were evaluated in a milk goat medium.

Materials and Methods

Materials

Agave tequilana fructans, fructose-based polymers, were obtained from Extrusiones Home S. de R.L de C.V. (Guadalajara, Jalisco, México). Canola vegetable oil was from Alimentos Capullo, S. de R. L. de C.V. (Santa Fe, D.F, México). Glucose syrup was purchased from ACH Food Companies Inc. (México). Buttermilk protein powder was donated from the Dairy Products Technology Center of California Polytechnic State University (St. Louis Obispo, CA). All other reagents were from Sigma (St. Louis, MO) unless stated otherwise.

Bacterial Strain and Growth Conditions

L. rhamnosus GG American Type Culture Collection (ATCC) 53103 was obtained in a freeze-dried form (ATCC, Manassas, VA, USA). Bacteria were transferred twice in de Man Rogosa and Sharp broth (Difco, NJ, USA) supplemented with 0.5% cysteine hydrochloride (MRS-cys) at 37 °C. Culture cells were harvested in the stationary growth phase by centrifugation at 2600×g for 15 min at 4 °C, washed twice with physiological saline solution and suspended in 0.1% peptone water. The inoculum obtained was used for free-suspended cells and for encapsulation.

Goat Milk Samples

Six samples of raw goat milk were obtained from four local dairy farms at Comarca Lagunera, Coahuila, Mexico, that have established a program of good handling practices in milk collection, as determined by the Ministry of Agriculture, Livestock, Rural Development, Fisheries and Food of Mexico [11].The milk was from healthy animals (< 450,000 somatic cells mL−1) that had not received antibiotics or other drug treatments at least 45 days before the study.

Samples were transported in closed containers at 4 °C. Once at the laboratory, the samples were analysed for chemical composition and used for growth experiments with L. rhamnosus GG.

L. rhamnosus GG Encapsulation and Co-encapsulation with A. tequilana fructans

Bacteria were microencapsulated according to Crittenden et al. [9], with minor modifications. Briefly, oil-in-water emulsions were prepared, containing canola vegetable oil, whey cream buttermilk proteins and glucose syrup. Similar conditions were used when including A. tequilana fructans. The emulsions were heated to 80 °C for 30 min to promote Maillard reaction products and improve milk protein matrix stabilisation by crosslinking it with the added glucose. Mixtures were cooled to 20 °C before addition of probiotic bacteria (suspended in phosphate buffer (0.1 M, pH 7.2, PBS). For encapsulation, the emulsions were spray dried using an SD-Basic (SDB 12090082, Keison Products, Oregon, USA) laboratory scale spray dryer with an inlet temperature of 160 °C and an outlet of 75 °C. The final encapsulating formulation (wt/wt) was as follows: 32% oil, 20% whey buttermilk proteins, 20% A. tequilana fructans, 20% glucose syrup and 2.8 × 108 CFU g−1 of bacteria. Three independent batches of CEF or E microcapsules (with or without Agave fructans) were prepared.

Examination of Microcapsules

Microcapsules were subjected to particulate analysis using an Olympus BH2-RFCA microscope (Tokyo, Japan) attached to a Leica DFC100 camera image capture system (Heerbrugg, Switzerland). Before imaging, the microcapsules were placed in PBS and hydrated for 15 min. The diameters of 1000 arbitrarily chosen microcapsules were measured using Leica IM500 imaging software (Wetzlar, Germany). The mean diameters of microcapsules were calculated and are presented with standard deviations. The measurements for each treatment (microcapsules with and without fructans) were performed in duplicate.

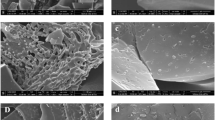

Scanning electron microscopy (SEM) was used to examine the shape and surface morphology of microcapsules. Samples were sent to the Electron Microscopy Lab at Centro de Investigación en Química Aplicada in Coahuila, Mexico. The microcapsules were placed on a conductive carbon film, coated by sputtering with an Au-Pd alloy and observed using an FEI Quanta 200 3D scanning electron microscope in low vacuum mode (5 Pa) at an accelerating voltage range of 5 kV.

Survival Assays and Cell Growth in Batch Fermentation

Spray-dried CEF or E microcapsules were stored for 14 days at − 20 °C before survival and fermentation assays.

Inoculum Preparation

Initial experiments were performed to determine the inoculum necessary to begin survival and fermentation assays with comparable numbers of cultivable cells. Twenty-five millilitres of sterile MRS-cys broth was inoculated individually with different quantities (0.5, 1, 1.5 g) of CEF or E microcapsules and incubated at 37 °C for 24 h. The cultures were then serially diluted to obtain 1 × 109 CFU • g−1 cells as determined by plate counts.

Survival of L. rhamnosus GG After Spray-Dried and Storage Conditions

The log cell number of viable cells released from the CEF and E microcapsules at 0 (after spray dried), 7 and 14 days of storage was evaluated agreeing to the standard plate method. The entrapped bacteria were released from microcapsules according to the method described by Fritzen-Freire et al. [12]. The results were expressed as the means of log colony forming units per millilitre (log CFU • mL−1) from three independent experiments with two replicates.

Survival in Simulated Gastrointestinal Conditions (SGIC)

The in vitro resistant to gastrointestinal conditions was conducted according to Doleyres et al. [13] with modifications. Briefly, a solution of 0.5% NaCl-0.3% pepsin, adjusted to pH 1.8, was used to simulate gastric conditions (GC). The encapsulated (CEF or E) bacteria (1 g of spray-dried powder) were added independently in prepared solution and incubated 90 min at 37 °C. After incubation, the cells were removed for survival assay and placed in sterile simulated intestinal juice (0.4% bile salts-0.2% pancreatin-0.2% bovine pancreas trypsin suspended in 0.05 M KH2PO4, pH 6. 5). The microorganisms were counted after 30 for GC and 180 min for intestinal conditions (IC). The survival of probiotics was assayed by plate count, and the results expressed as the means of log CFU • g−1 from three independent experiments with two replicates.

Fermentation Assays

Fermentation assays were performed in a 3-L bioreactor (ADI 1025; Applikon Biotechnology B.V., Schiedam, NL) with 900 mL of pasteurised goat milk. Prior to use, the bioreactor was sterilised at 121 °C for 15 min. The system was monitored using the BioXpert R software (Applikon Biotechnology B.V., Schiedam, UK). CEF L. rhamnosus GG was inoculated at a bacterial concentration of 2.8 × 108 CFU • g−1. Samples (30 mL) were taken every 2 h for cell enumeration and pH and lactic acid determination. The fermentation was performed three times with the same volume of capsules containing a similar number of cells. Experiments were conducted for three independently prepared batches of microcapsules. Similar experiments were conducted with E L. rhamnosus GG encapsulated without Agave fructans.

The maximum specific growth rate (μmax) was calculated for each treatment during the exponential growth phase according to Oliveira et al. [14], using the equation:

where X2 and X1 are counts (CFU mL−1) at time t2 and t1 (h). The generation time (tg) was calculated for each culture from the corresponding value of μmax by the equation:

The maximum acidification rate (Vm) was calculated from the pH curves as the time variation of pH (dpH/dt) and expressed in absolute values as 10–3 pH units min −1 [15]. The following kinetic parameters were also calculated: tmax (h), the time at which Vm was reached; tpH5.0 (h), the time to reach pH 5.0; and tpH4.5 (h), the time to complete the fermentation [14].

Cell Counts and Lactic Acid Determination

One millilitre of each fermented goat milk sample was individually diluted with 9 mL of sterile 0.1% (w/v) peptone water (Difco, NY, USA) and mixed uniformly with a vortex mixer. Serial dilutions were prepared, and the number of viable cells enumerated by plate counting as described above. Cell concentration was expressed as CFU mL−1 of fermentation medium. The results are expressed as the means from three independent experiments with two replicates. Lactic acid was determined according to Horwitz and Latimer [16].

Experiments were conducted in triplicate.

Statistical Analysis

The bacterial counts were converted into logarithms of the number of colony forming units per mL (log CFU • mL−1) for statistical analysis. The means were compared using analysis of variance (ANOVA) followed by the Tukey test to determine a difference among means at the 95% confidence level (significance level at P < 0.05).

Results and Discussion

Size and Shape of Microcapsules

Probiotic encapsulation technology has the potential to protect cells against adverse conditions including low pH, oxygen toxicity and high temperatures [4, 6]. Various elements should be considered when designing microcapsules to obtain successful products. The size of microcapsules has a significant effect on probiotic viability and organoleptic properties of the carrier food [4]. Particle sizes smaller than 100 μm in diameter allow the direct addition of encapsulated probiotic to dairy foods [17]. On the other hand, diameters larger than 40 μm increase the likeliness of a protective effect [6].

The size of the spray-dried CEF microcapsules was 52.4 ± 10.8 μm, which is acceptable to effectively protect bacteria against environment stresses and gastrointestinal conditions [18]. In addition, to avoid negative mouth sensory effects and product texture, it is desirable to obtain microparticles with diameters less than 80 μm [19]. There was no significant reduction (P > 0.05) in diameter size (51.5 ± 9.8) when L. rhamnosus GG was encapsulated without Agave fructans in E microcapsules.

SEM data showed an absence of free bacteria on the exterior of the capsules. Particles were amorphous and rough-surfaced, with indentations in microcapsules both with and without Agave fructans (Fig. 1a, b). Indentations can be attributed to the shrinkage of the atomised particles during the drying process and to the rapid evaporation of the liquid drops [20]. Amorphous microparticles with indentations produce negative sensory perception at smaller sizes than smooth microparticles do [21]. However, perception of grittiness decreases with increasing hydration of particles [22]. In addition, milk proteins have demonstrated effective aqueous lubrication when used as matrix of encapsulation [23].

Viability of Encapsulated L. rhamnosus GG

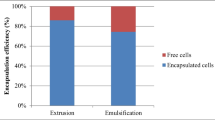

The microbial reduction of L. rhamnosus GG encapsulated in CEF or E microcapsules after the spray drying process and after 7 and 14 days of storage at − 20 °C is presented in Fig. 2. Co-encapsulation with Agave fructans did not improve the probiotic survival after drying (P > 0.05). Total counts of CEF and E, L. rhamnosus GG ranged from 7.7 to 7.9 log CFU mL−1, which represents a reduction of approximately 13% of the viability with respect to the initial solution. This fact suggests that buttermilk proteins maybe acted as a thermo-protector for the probiotic cells undergoing the spray-dried process.

Survivability of Lactobacillus rhamnosus GG encapsulated with (CEF) or without (E) Agave fructans in a buttermilk matrix, after storage at − 20 °C. The data represent the means of three replicates ± standard deviation. Different letters (a, b) indicate significantly different values according to the Tukey–Kramer test (P < 0.05)

Mixtures of casein and whey proteins have shown the best encapsulation material and most enhanced the survival of probiotics (99%) when encapsulated by rennet-induced gelation [24]. Therefore, milk co-products, such as regular buttermilk, that are rich in caseins (75% of the total proteins) and also contain 8–15% of whey proteins [25], could be used directly for probiotic encapsulation by different techniques.

Agave fructans significantly enhanced storage stability of spray-dried CEF encapsulated L. rhamnosus GG compared to E encapsulated L. rhamnosus GG (Fig. 2). After 14 days storage, the number of living cells in CEF microcapsules was in the order of 7.7 log CFU • mL−1. In contrast, the final number of L. rhamnosus GG in E microcapsules was 7.3 log CFU mL−1. Co-encapsulation of probiotics with fructans from chicory root has previously been studied for improving the survival of lactobacillus and bifidobacteria during the storage at low temperatures [26].

The reduction of cell death in the presence of this carbohydrate was attributed to its cryoprotectant effect. Ying et al. [27] attributed a similar behavior to the combination of glucose and chicory inulin. In the present work, glucose was integrated into the formulation in order to increase milk protein matrix stabilisation through the Maillard reaction. This Maillard reaction method also showed a significant improvement in survival of encapsulated Bifidobacterium infantis during storage [9].

As far as we know, there are no reports that compare the effect of inulin (linear moiety) vs Agave fructans (branched moiety) in probiotic survival during storage. However, other studies report that chicory FOS and Agave fructans show a higher water adsorption capacity than chicory inulin does [28, 29]. Molecular weight, type and proportions of microencapsulating materials as well as residual moisture and water activity of the microcapsules and bacteria strain are factors that affect the survival of probiotics during storage in dry conditions [30, 31]. Thus, each of this factors must be optimised in order to improve the shelf-life of encapsulated probiotics. For example, Rajam and Anandharamakrishnan [32] observed that the highly hygroscopic capacity of FOS limit the use of this prebiotic as encapsulating matrix for spray-dried powders containing L. plantarum. However, combination of FOS with denatured whey proteins (1:1.5 ratio) significantly increased the microcapsules stability and the survival of L. plantarum during storage conditions.

Figure 3(a) shows the viability CEF and E encapsulated L. rhamnosus GG in a simulated gastric juice. Cell counts decreased approximately 2 log units in both treatments. When bacteria were transferred to intestinal conditions (180 min, 37 °C, Fig. 3(b) after GC treatment, the number of living bacteria cells dropped, for E encapsulated L. rhamnosus GG (5.21 ± 0.05 CFU log g−1). On the contrary, viable numbers of CEF encapsulated L. rhamnosus GG with Agave fructans reaching counts of 5.79 ± 0.08 CFU log g−1 which represent a survival of approximately 83%. A probiotic survival rate of 99% was obtained by Burgain et al. [24] when encapsulated probiotics using a mixture of casein and whey proteins by rennet-induced gelation without the addition of Agave fructans. However, the spray-dried technique could be an alternative approach because of scale-up benefits. This study showed that co-encapsulation with Agave fructans significantly improved the L. rhamnosus GG survival in spray-dried beads during in vitro gastrointestinal-simulated conditions. These beads would be likely to keep live bacteria to meet the requirements for potential health benefits.

Survivability of Lactobacillus rhamnosus GG encapsulated with (CEF) or without (E) Agave fructans in a buttermilk matrix, after each step of in vitro gastrointestinal simulated conditions. (a), gastric juice (b), intestinal juice. The data represent the means of three replicates ± standard deviation. Different letters (a, b) indicate significantly different values according to the Tukey–Kramer test (P < 0.05)

Mixtures of other prebiotics like chicory FOS, galactooligosaccharides (GOS) or maltodextrins with whey proteins have shown a positive effect on the probiotic survival after spray drying [32, 33]. This protective effect was attributed to an increase in the microcapsules wall material concentration [32]. In contrast, addition of chicory inulin or polydextrose to sweet whey encapsulating formulation decrease the survival of Bifidobacterium BB-12 after exposure to SGIC [34].

Cell Growth in Batch Fermentation

Growth profiles in goat milk of L. rhamnosus GG encapsulated in CEF and E microcapsules were compared after 14 days of storage at − 20 °C (Fig. 4(a). No significant lag-phase was observed in cell cultures from CEF, while growth curves for E showed lag phases of 4 h. After 18 h, the CEF cell culture in goat milk contained 1.08 ± 0.02 × 1010 CFU • mL−1 of L. rhamnosus GG, while E encapsulated L. rhamnosus GG reached 3 ± 0.01 × 109 CFU • mL−1. Thus, it appears that Agave fructans stimulated the growth of probiotic.

Time courses of encapsulated Lactobacillus rhamnosus GG with (CEF) and without (E) Agave fructans in goat milk. (a) Growth kinetics and (b) pH depletion and lactic acid formation. The data represent the means of three replicates ± standard deviation. Different letters (a, b) indicate significantly different values according to the Tukey–Kramer test (P < 0.05)

Linear moiety chicory inulin was successfully employed by other facultative heterofermentative probiotics like L. paracasei 8700:2 and L. rhamnosus LBA as sole or additional energy source Oliveira et al. [14]. The growth stimulation of L. rhamnosus GG founded in this study suggest that these bacteria expresses some fructofuranosidase enzyme which can partially hydrolyse the branched Agave fructans, using the fructose released as an additional carbon source. However, additional studies are necessary to confirm this hypothesis.

Figure 4(b) shows changes in pH during the fermentation of goat milk samples with different treatments. The results showed a slow acidification profile, perhaps due to the buffering capacity of proteins and minerals present in the goat milk [35]. The pH dropped from the initial 6.5 to 4.5, after 18 h of fermentation. Comparable slow acidification profiles were observed when goat milk was inoculated with pure cultures of L. acidophilus [36].

The kinetic parameters of goat milk acidification by CEF and E encapsulated L. rhamnosus GG are listed in Table 1. Maximum rate of acidification (Vm) was 15% higher (P < 0.05) in cultures inoculated with CEF microcapsules than in those inoculated with E microcapsules. These data support the prebiotic activity of Agave fructans. Additionally, the time to reach the maximum cell concentration (Tg) was shorter for CEF encapsulated cells (0.39 h) than E encapsulated cells (0.46 h). For both cultures, the time to reach the maximum acidification rate (tm) was 10 h.

Interestingly, bacterial populations from both CEF and E microcapsules maintained their viability and continued to produce lactic acid until the end of the experiment (Fig. 4b). This behavior might be explained by a higher local pH value inside the capsule caused by the buffering capacity of the buttermilk protein matrix [37]. In addition, the buttermilk proteins used as the encapsulation matrix might allow the formation of microcapsules with a high-density network. It is important to note that the protein networks were cross-linked by a Maillard reaction and appeared to offer an adequate micro-environment for the encapsulated L. rhamnosus GG either with or without the presence of Agave fructans.

Conclusion

Spray drying is a simple, economic and easy to scale-up process and uses equipment that is readily available for the food industry. Despite these advantages, significant inactivation of probiotic cells can occur during the spray drying and subsequent storage [6]. Stress caused by dehydration mainly affects the fluidity of the cytoplasmic membrane. However, cellular damage to probiotics may be reduced and viability preserved by the incorporation of appropriate carriers into the drying medium [9]. The present study indicates that buttermilk proteins provided cellular protection through drying. Furthermore, co-encapsulation using Agave fructans, improved the probiotic viability during storage, protected the cells from acidic stress and offered a favorable microenvironment and better growth substrate. Under these conditions, encapsulation by spray drying could be suitable for preservation of probiotic powders and may be for a more effective application of probiotics in goat dairy products.

References

Meira QGS, Magnani M, de Medeiros Júnior FC, Queiroga RCRE, Madruga MS, Gullón B, Gomes AMP, Pintado MME, de Souza EL (2015) Effects of added Lactobacillus acidophilus and Bifidobacterium lactis probiotics on the quality characteristics of goat ricotta and their survival under simulated gastrointestinal conditions. Food Res Int 76:828–838. https://doi.org/10.1016/j.foodres.2015.08.002

Raynal-Ljutovac K, Lagriffoul G, Paccard P, Guillet I, Chilliard Y (2008) Composition of goat and sheep milk products: an update. Small Rumin Res 79:57–72. https://doi.org/10.1016/j.smallrumres.2008.07.009

Salva S, Nuñez M, Villena J, Ramón A, Font G, Alvarez S (2011) Development of a fermented goats’ milk containing Lactobacillus rhamnosus: in vivo study of health benefits. J Sci Food Agric 91:2355–2362. https://doi.org/10.1002/jsfa.4467

Burgain J, Gaiani C, Linder M, Scher J (2011) Encapsulation of probiotic living cells: from laboratory scale to industrial applications. J Food Eng 104:467–483. https://doi.org/10.1016/j.jfoodeng.2010.12.031

Gomez E, Tuohy KM, Gibson GR, Klinder A, Costabile A (2010) In vitro evaluation of the fermentation properties and potential prebiotic activity of Agave fructans. J Appl Microbiol 108:2114–2121. https://doi.org/10.1111/j.1365-2672.2009.04617.x

Anal AK, Singh H (2007) Recent advances in microencapsulation of probiotics for industrial applications and targeted delivery. Trends Food Sci Technol 18:240–251. https://doi.org/10.1016/j.tifs.2007.01.004

Ying D, Schwander S, Weerakkody R, Sanguansri L, Gantenbein-Demarchi C, Augustin MA (2013) Microencapsulated Lactobacillus rhamnosus GG in whey protein and resistant starch matrices: probiotic survival in fruit juice. J Funct Foods 5:98–105. https://doi.org/10.1016/j.jff.2012.08.009

Heidebach T, Först P, Kulozik U (2009) Transglutaminase-induced caseinate gelation for the microencapsulation of probiotic cells. Int Dairy J 19:77–84. https://doi.org/10.1016/j.idairyj.2008.08.003

Crittenden R, Weerakkody R, Sanguansri L, Augustin M (2006) Synbiotic microcapsules that enhance microbial viability during nonrefrigerated storage and gastrointestinal transit. Appl Environ Microbiol 72:2280–2282. https://doi.org/10.1128/aem.72.3.2280-2282.2006

Livney YD (2010) Milk proteins as vehicles for bioactives. Curr Opinion Colloid Interface Sci 15:73–83. https://doi.org/10.1016/j.cocis.2009.11.002

Figueroa Valenzuela C, Meda Gutiérrez F, Janacua Vidales H (2004) Manual de Buenas Prácticas en Producción de Leche Caprina. http://senasica.senasica.sagarpa.gob.mx. Accessed 10 Jan 2017

Fritzen-Freire CB, Prudêncio ES, Amboni RDMC, Pinto SS, Negrão-Murakami AN, Murakami FS (2012) Microencapsulation of bifidobacteria by spray drying in the presence of prebiotics. Food Res Int 45:306–312. https://doi.org/10.1016/j.foodres.2011.09.020

Doleyres Y, Fliss I, Lacroix C (2004) Increased stress tolerance of Bifidobacterium longum and Lactococcus lactis produced during continuous mixed-strain immobilized-cell fermentation. J Appl Microbiol 97:527–539. https://doi.org/10.1111/j.1365-2672.2004.02326.x

Oliveira RPDS, Perego P, de Oliveira MN, Converti A (2012) Effect of inulin on the growth and metabolism of a probiotic strain of Lactobacillus rhamnosus in co-culture with Streptococcus thermophilus. LWT Food Sci Technol 47:358–363. https://doi.org/10.1016/j.lwt.2012.01.031

Kristo E, Biliaderis CG, Tzanetakis N (2003) Modelling of rheological, microbiological and acidification properties of a fermented milk product containing a probiotic strain of Lactobacillus paracasei. Int Dairy J 13:517–528. https://doi.org/10.1016/S0958-6946(03)00074-8

Horwitz W, Latimer GW (2005) Official methods of analysis of AOAC international. AOAC International, Gaithersburg

Heidebach T, Forst P, Kulozik U (2012) Microencapsulation of probiotic cells for food applications. Crit Rev Food Sci Nutr 52:291–311. https://doi.org/10.1080/10408398.2010.499801

Mokarram RR, Mortazavi SA, Najafi MBH, Shahidi F (2009) The influence of multi stage alginate coating on survivability of potential probiotic bacteria in simulated gastric and intestinal juice. Food Res Int 42:1040–1045. https://doi.org/10.1016/j.foodres.2009.04.023

Ding WK, Shah NP (2009) Effect of various encapsulating materials on the stability of probiotic bacteria. J Food Sci 74:M100–M107. https://doi.org/10.1111/j.1750-3841.2009.01067.x

Saénz C, Tapia S, Chávez J, Robert P (2009) Microencapsulation by spray drying of bioactive compounds from cactus pear (Opuntia ficus-indica). Food Chem 114:616–622. https://doi.org/10.1016/j.foodchem.2008.09.095

Engelen L, Van der Bilt A, Schipper M, Bosman F (2005) Oral size perception of particles: effect of size, type, viscosity and method. J Texture Stud 36:373–386. https://doi.org/10.1111/j.1745-4603.2005.00022.x

Imai E, Hatae K, Shimada A (1995) Oral perception of grittiness: effect of particle size and concentration of the dispersed particles and the dispersion medium. J Texture Stud 26:561–576. https://doi.org/10.1111/j.1745-4603.1995.tb00804.x

Sarkar A, Kanti F, Gulotta A, Murray BS, Zhang S (2017) Aqueous lubrication, structure and rheological properties of whey protein microgel particles. Langmuir 33:14699–14708. https://doi.org/10.1021/acs.langmuir.7b03627

Burgain J, Gaiani C, Cailliez-Grimal C, Jeandel C, Scher J (2013) Encapsulation of Lactobacillus rhamnosus GG in microparticles: influence of casein to whey protein ratio on bacterial survival during digestion. Innovative Food Sci Emerg Technol 19:233–242. https://doi.org/10.1016/j.ifset.2013.04.012

Morin P, Pouliot Y, Jiménez-Flores R (2006) A comparative study of the fractionation of regular buttermilk and whey buttermilk by microfiltration. J Food Eng 77:521–528. https://doi.org/10.1016/j.jfoodeng.2005.06.065

Capela P, Hay TKC, Shah NP (2006) Effect of cryoprotectants, prebiotics and microencapsulation on survival of probiotic organisms in yoghurt and freeze-dried yoghurt. Food Res Int 39:203–211. https://doi.org/10.1016/j.foodres.2005.07.007

Ying D, Sun J, Sanguansri L, Weerakkody R, Augustin MA (2012) Enhanced survival of spray-dried microencapsulated Lactobacillus rhamnosus GG in the presence of glucose. J Food Eng 109:597–602. https://doi.org/10.1016/j.jfoodeng.2011.10.017

Espinosa-Andrews H, Rodríguez-Rodríguez R (2018) Water state diagram and thermal properties of fructans powders. J Therm Anal Calorim 132:197–204. https://doi.org/10.1007/s10973-017-6868-1

Schaller-Povolny LA, Smith DE, Labuza TP (2000) Effect of water content and molecular weight on the moisture isotherms and glass transition properties of inulin. Int J Food Prop 3:173–192. https://doi.org/10.1080/10942910009524626

Ying DY, Phoon MC, Sanguansri L, Weerakkody R, Burgar I, Augustin MA (2010) Microencapsulated Lactobacillus rhamnosus GG powders: relationship of powder physical properties to probiotic survival during storage. J Food Sci 75:E588–E595. https://doi.org/10.1111/j.1750-3841.2010.01838.x

Dianawati D, Mishra V, Shah NP (2016) Survival of microencapsulated probiotic bacteria after processing and during storage: a review. Crit Rev Food Sci Nutr 56:1685–1716. https://doi.org/10.1080/10408398.2013.798779

Rajam R, Anandharamakrishnan C (2015) Microencapsulation of Lactobacillus plantarum (MTCC 5422) with fructooligosaccharides as wall material by spray drying. LWT Food Sci Technol 60:773–780. https://doi.org/10.1016/j.lwt.2014.09.062

Sosa N, Gerbino E, Golowczyc MA, Schebor C, Gómez-Zavaglia A, Tymczyszyn EE (2016) Effect of galactooligosaccharides: maltodextrin matrices on the recovery of Lactobacillus plantarum after spray-drying. Front Microbiol 7:584. https://doi.org/10.3389/fmicb.2016.0058

Pinto SS, Verruck S, Vieira CRW, Prudêncio ES, Amante ER, Amboni RDMC (2015) Influence of microencapsulation with sweet whey and prebiotics on the survival of Bifidobacterium-BB-12 under simulated gastrointestinal conditions and heat treatments. LWT Food Sci Technol 64:1004–1009. https://doi.org/10.1016/j.lwt.2015.07.020

Park YW, Juárez M, Ramos M, Haenlein GFW (2007) Physico-chemical characteristics of goat and sheep milk. Small Rumin Res 68:88–113. https://doi.org/10.1016/j.smallrumres.2006.09.013

Kongo JM, Gomes AM, Malcata FX (2006) Manufacturing of fermented goat milk with a mixed starter culture of Bifidobacterium animalis and Lactobacillus acidophilus in a controlled bioreactor. Lett Appl Microbiol 42:595–599. https://doi.org/10.1111/j.1472-765X.2006.01882.x

Gbassi GK, Vandamme T (2012) Probiotic encapsulation technology: from microencapsulation to release into the gut. Pharmaceutics 4:149–163. https://doi.org/10.3390/pharmaceutics4010149

Acknowledgements

We are grateful to the National Council of Science and Technology of Mexico, CONACyT, for the financial support for this research, under project CB169358, as well as for the scholarship awarded for MSc. studies. The authors are thankful to Ana María Domínguez Vergara and Hayde Gonzalez Carrillo for their technical assistance in this work.

Funding

This study was supported by the National Council of Science and Technology of Mexico, CONACyT under project CB169358.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflicts of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Alvarado-Reveles, O., Fernández-Michel, S., Jiménez-Flores, R. et al. Survival and Goat Milk Acidifying Activity of Lactobacillus rhamnosus GG Encapsulated with Agave Fructans in a Buttermilk Protein Matrix. Probiotics & Antimicro. Prot. 11, 1340–1347 (2019). https://doi.org/10.1007/s12602-018-9475-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12602-018-9475-y