Abstract

In this study, the impact of thulium oxide on the structural and elastic characteristics of magnesium borotellurite glass systems produced through the melt-quenching technique is examined. The findings reveal a direct relationship between the thulium concentration and several elastic parameters in the glass sample, such as ultrasonic velocity and elastic modulus. The sample’s density increased from 4.12 to 4.30 g/cm3, and its molar volume increased from 29.29 to 29.62 cm3/mol as Tm3+ concentration progressed. The XRD study confirmed that the samples were amorphous. The incorporation of Tm2O3 into the glass acts as a network modifier and leads to an increase in NBO content. Moreover, the shear and longitudinal velocities range within the respective ranges of 1966.02 to 2495.90 m/s and 3474.78 m/s to 4085.13 m/s. Young’s modulus, bulk, shear, and longitudinal elastic moduli fall between 40.28 and 64.45 GPa, 28.51 and 36.07 GPa, 15.92 and 26.81 GPa, and 49.75 and 71.81 GPa, respectively. Moreover, the sample’s Poisson ratio decreases from 0.26 to 0.20 with an increase in Tm3+ concentration. The experimental results are compared to the theoretically calculated results. By comparing to experimental data, the Mackenzie Makishima and Rocherulle models demonstrate a high level of accuracy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Amorphous solid materials, such as glasses, have short-range order atomic arrangements and exhibit time-dependent transformation behaviors. In general, glass is transparent, hard, brittle, and pure based on its elements. Due to its high viscosity at ambient temperatures, glass can be considered a supercooled liquid. The glass transition region refers to the range of temperatures between which glass forms. The network structures of glass formation have been studied for decades, but there are still no specific answers, and confusing. In order to understand the fundamental principles of glass formation, it is necessary to study and consider the changes in volume with respect to the temperature of a melt or liquid [1]. The liquid quenched with different cooling rates or thermal histories will provide the glasses with superior structures and properties. As well as optical fields like data transmission, sensor detection, and sensor technology, glasses are also used in the field of optics [2]. It is also a good candidate for solid-state lasers. Furthermore, glass also can be used in optical magnet devices such as lasers, magnetic amplifiers, and frequency converters which are used in the communications industry [3].

Glasses possess elastic properties, including elasticity, compliance, and rigidity, which influence their mechanical behavior. Elasticity is a measure of a glass’s ability to return to its original shape after being deformed by an external force. Compliance is the opposite of elasticity, indicating a glass’s willingness to deform under an applied force [4]. Rigidity is the level of resistance that a glass exhibits when being deformed or deflected. These properties are influenced by factors such as the glass’s composition, temperature, and the rate of deformation, which make studying the elastic behavior of glasses complex and challenging. A glass’s elastic properties determine its mechanical strength and durability, which are critical for practical applications [5]. Understanding the glass’s elasticity can help predict its fracture behavior under external stresses and improve its design for various uses. Besides, the elastic properties are also critical during the manufacturing and processing of glass. The behavior of glass during shaping, cutting, and bonding is determined by its elasticity, and knowledge of these properties is essential to optimize the processing techniques and improve the quality of the finished product. Furthermore, the elastic properties of glass also provide essential insights into the nature of the glassy state and the mechanisms of glass formation. Research into the elastic properties of glasses can lead to a better understanding of the underlying physics of glassy materials and improve our understanding of their behavior [6]. The correlation between stress and strain in a substance can be explained by its elastic properties. In simple terms, it allows for analyzing a material’s capacity to withstand pressure. The characteristics of a glass are typically indicated by the values of the elastic modulus and Poisson’s ratio. The common perception is that materials having a high modulus are inflexible and do not undergo much deformation when subjected to compression or extension. In contrast, materials that are elastic with a low modulus undergo significant strains when a force is exerted on them. Elastic moduli are closely linked to a material’s structure since they reflect the interatomic pressures within it. Elasticity statistics can be employed to analyze a material’s internal structure. The ultrasonic methodology is a non-destructive method that has recently been discovered to be one of the more flexible ways to analyze elastic features. In practice, compared to other destructive testing methods, non-destructive testing is preferred by researchers since it has the benefit of not damaging the sample.

Tellurium oxide is a prospective conditional glass former that has recently been discovered to be appropriate for use in modern technological applications. The unique characteristics of tellurite glass, such as a low melting point, good dielectric constant, and high refractive index, have made it a fascinating subject of study [7]. Tellurite glasses provide a number of advantages, including simplicity of manufacturing, low temperature of processing, strong chemical stability, decent mechanical strength, and a broad transmission range [8]. In tellurite-based glasses, the tellurium atom has a single pair of highly hyperpolarized electrons in the 5 s orbit. Tellurite-based glasses are highly desirable for their potential use as nonlinear optical glasses, owing to their unique characteristics [9]. These glasses can easily incorporate heavy metal and rare-earth ions due to the weak Te‒O bond. However, adding a significant quantity of rare-earth (RE) dopants may cause the glass to become fragile and easily breakable, impeding its formation. Therefore, the amount and concentration of RE oxides used in the glass are determined by the intended use of the glass material. Thulium oxide (Tm2O3) has been identified as an excellent candidate for rare-earth doping into borotellurite glasses due to its high solubility in the network and unique properties [10]. The selection of RE oxide is dependent on the interplay between radiative or non-radiative RE ions and the host glass’s composition, as demonstrated by prior research. Additionally, Tm2O3 has a significant impact on enhancing the glass properties as it functions as a powerful material for laser applications. There are several previous works that used Tm2O3 as dopant in the glass system. Lakshminarayana et al. (2017) study the effect of Tm2O3 to the physical and structural properties of borotellurite glasses [11]. From the work, Tm2O3 addition had enhanced the glass’s density, thermal stability, glass transition temperature, refractive index, and optical bandgap. In addition, Tm2O3 has been studied as a potential dopant in various glass systems due to its unique optical and physical properties [12]. However, the effect of Tm2O3 on the properties of the resulting glasses is not fully understood. In particular, the concentration-dependent effects of Tm2O3 on glass density, glass transition temperature, thermal stability, refractive index, elastic moduli, and mechanical properties have not been fully investigated. Additionally, the potential impact of Tm2O3 as a glass modifier is not well understood. Therefore, a detailed investigation of the effects of Tm2O3 on the properties of glass is necessary to better understand the potential applications of these materials.

Understanding the connection between the thulium ions doped glass and the following elastic characteristics of the glass is crucial since it offers important insights into the behavior of the newly doped rare-earth material. Due to the inclusion of the rare earth substance, researchers can better comprehend the underlying theories driving the elastic response of the glass. Researchers can modify elastic parameters like stiffness, strength, or damping characteristics by varying the concentration of rare earth materials doped into the base glass. This information can spur development in many technology areas and open the door for novel uses. In this work, Tm2O3 was used to determine the efficiency of RE ions when combined with tellurite-based glasses. Numerous academics have recently expressed interest in the potential of Tm3+-doped glasses to improve the elastic properties of glass. Understanding on their compatibility is also essential to ensure mechanical compatibility and avoid issues such as stress concentration and deformation mismatch. In addition, the incorporation of thulium into tellurite glass has the potential to lead to optical amplification and blue laser light pumping in the infrared region. Therefore, our investigation contributes to the understanding of the properties of thulium-doped magnesium borotellurite glass. In this context, the purpose of this experiment was to find out how thulium oxide addition alters the elastic properties of the glasses. This doping was predicted to improve the material’s structural network while increasing the glass’s stiffness and elastic moduli.

Methodology

A high-purity raw material mixture was used to prepare Tm3+-doped magnesium borotellurite (MBT) glass sample such as TeO2, MgO, B2O3, and Tm2O3 powder by referring to the empirical formula x(Tm2O3)-10MgO-30B2O3-(60-x)TeO2, where x = 0, 0.5, 1.0, 2.0, and 3.0 mol%. The concentration of the thulium oxide was chosen after the previous study, where a series of magnesium borotellurite glass doped with different amounts of rare-earth ion prepared [13]. Tm3+ ions exhibit unique optical properties, especially in the near-infrared range. They can efficiently absorb and emit light at specific wavelengths, making them useful for applications such as fiber lasers, amplifiers, and optical waveguides. Besides, Tm3+ ions also are relatively stable in glass matrices, allowing for long-term optical performance without significant degradation. They can withstand high temperatures and exhibit low photo bleaching, ensuring the durability and reliability of the doped glass. Most important, Tm3+ ions can be easily incorporated into the glass composition during the fabrication process. It forms a solid solution with the glass matrix, ensuring good homogeneity and distribution of the dopant throughout the material. In this work, the percentage of doping from 0 to 3.0 mol% has been chosen because the concentration of dopant ions in the glass directly affects the optical properties of the material. By selecting a small percentage of Tm2O3 doping, it is possible to achieve specific desired optical characteristics while minimizing any potential adverse effects. Moreover, doping glass with a high concentration of certain ions can lead to phase separation, which negatively impacts the homogeneity and stability of the material. The experimental procedure involved weighing and blending each raw material using a mortar and pestle for homogeneity, followed by a 1-h melting process at 900 °C in a crucible made of 99.99% pure alumina. The molten material was then quenched in a heated stainless steel mold to produce a transparent glass bulk, which was annealed at 400 °C for 3 h and slowly cooled to room temperature. The resulting glass sample was ground into powder, shaped, and optically polished for further characterization.

The density of the bulk sample was determined using Archimedes’ principle with distilled water as the immersion liquid. During the process, particle diffusion caused physical and structural changes in the material. The following relations can be used to calculate the density of the sample:

where the density of water is denoted by ρwater, the mass of the prepared sample in air is represented by \({m}_{a}\), while the mass of the prepared sample in water is denoted by \({m}_{w}\).

To obtain the XRD pattern, CuKα radiation was used to scan the samples from 20° to 80°, with the data recorded using PANalytical (Philips, PW3040/60 X’pert PRO Source: X-ray tube 3 kW with copper). The PANalytical X’Pert High Score software was used to analyze the XRD pattern results and identify any amorphous or crystalline phases that were produced. FTIR spectra (Perkin Elmer, Spectrum 100) were used to illustrate the development of chemical bonding in the sample within the wave number range of 400 to 1400 cm−1. Ultrasonic velocity measurements at 5 MHz were conducted using the RITEC RAM-5000 Snap System to analyze the longitudinal and shear wave velocities. The wave velocity data was then used to calculate the elastic moduli and Poisson’s ratio of the sample. The sample’s elastic moduli were determined by utilizing the provided structural formula, as follows:

In this article, two theoretical models are proposed to study the elastic properties of magnesium borotellurite glass doped with thulium. The Makishima and Mackenzie model and Rocherulle model were used to calculate the theoretical elastic properties and compare them with the experimental data. The Makishima and Mackenzie model was originally developed to determine the elastic properties of oxide glasses. The model considers the bond dissociation energies of various oxide components that make up the glass material (\({G}_{i}\)), their chemical makeup (\({x}_{i}\)), and their packing factor (\({V}_{i}\)). Based on average dissociation energy, \({G}_{t}\), and glass packing density, (\({V}_{t}\)), the following equation represents the Young modulus of glass [14]:

The packing factor \({V}_{i}\) and the chemical composition \({x}_{i}\) are utilized to determine \({V}_{t}\) using the following equation:

The packing factor \({V}_{i}\) for each oxide is determined by the formula (AxOy), where \({x}_{i}\) represents the molar percentage of the ith component, is the density of the glass, M is the molecular weight of the glass, and \({R}_{O}\) and \({R}_{A}\) represent the ionic radii of the oxygen atom and cation, respectively. The following formulas are taken into account to calculate the elastic moduli [15]:

Rocherulle model improved the Makishima and Mackenzie model by implementing adjustments. They did this by using the model Makishima and Mackenzie provided as their reference basis. The dissociation energy utilized in this model is similar to that of the Makishima model. However, in Rocherulle approach, the packing factor is calculated using the \({C}_{i}\) rather than the \({V}_{i}\):

The packing density, Ct, for multi-component natured glass systems is written as:

Results and discussion

As shown in Fig. 1, several sturdy and transparent glasses have been prepared. The color of the magnesium borotellurite glass is unaffected by the presence of Tm3+. From the figure, the tellurite-based glasses become more transparent with a higher concentration of thulium ions. Tm3+ ions can contribute to the improved transparency of glass through a phenomenon called energy transfer. Tm3+ ions have absorption bands in the visible and ultraviolet regions of the electromagnetic spectrum. By incorporating Tm3+ ions into the telluride-based glasses, they can absorb and effectively quench (deactivate) undesirable wavelengths of light that may otherwise contribute to the glass’s opacity or coloration [16]. This absorption helps to reduce the presence of light that would otherwise be scattered or absorbed within the glasses. The thickness of each of the five glasses ranges from 0.5 to 0.6 cm for the optimum thickness sample to be attached with transducer during the ultrasonic test.

Figure 2 displays the density and molar volume of magnesium borotellurite glass doped with thulium. As depicted in the graph, an increase in the mol content of Tm2O3 resulted in a corresponding increase in both density and molar volume. The increasing trend could be due to the fact that Tm2O3 has a higher molecular weight (385.8 g/mol) compared to the combined weight of all the other chemical compounds (269.524 g/mol). When a heavier object replaces a lighter one, the overall molecular weight of the sample will increase. Therefore, the density will also increase since mass and density are directly proportional. In addition, the extra ions may occupy the interstitial spaces of the network, leading to a more compact network. In terms of molar volume, the increase can be attributed to Tm2O3 bond length (approximately 2.34 to 2.47 Å) and higher coordination number (thulium ion is surrounded by eight oxygen ions in a cubic close-packed arrangement. This arrangement results in a coordination number of 8 for thulium ions in Tm2O3), which resulted in an increase in free volume within the glass structure [17].

Figure 3 shows XRD pictures of thulium-doped magnesium borotellurite glass. All of the prepared samples exhibited an identical pattern, with no discernible diffraction peaks. The enormous humps created between 20° and 30° indicate that the glass is amorphous, no peak presence implying that no crystallinity structures could be produced. The prepared samples are hence amorphous in character.

In this investigation, FTIR spectra between 400 and 4000 cm−1, as shown in Fig. 4, revealed several bending or stretching vibrational bands that provided information on the varied structures of prepared samples. Based on Fig. 4, tellurite oxide structural units with parameters range from 585 to 930 cm−1. Glass with B2O3 as a network former demonstrates three functional groupings of borate networks, such as BO3, BO4, and B − O − B connections. Each boron atom is bonded to three oxygen atoms, creating a trigonal planar arrangement. The boron-oxygen bonds in B2O3 are covalent and exhibit partial double-bond character, resulting in a stable molecular structure. When B2O3 is combined with other glass-forming components such as TeO2, it participates in the formation of a network structure. B2O3 acts as a cross-linking agent, linking together neighboring network-forming units by sharing oxygen atoms [17]. The boron atoms form bridges between other atoms, helping to create a continuous three-dimensional network throughout the glasses. Tellurite oxide generates two structural units during glass formation which is trigonal bipyramidal TeO4 and trigonal pyramidal TeO3. The first bands can be seen in Fig. 4 which located between 585 and 765 cm−1, corresponding to a TeO4 structural unit with a trigonal bipyramidal form [18]. The trigonal pyramidal TeO3 structural unit is linked to the second band, which can be found within the range of 785 to 930 cm−1. The graph illustrates that the formation of NBO’s is driven by the creation of trigonal pyramidal TeO3 in the glass system. In the glass-forming process, the tellurium atoms form covalent bonds with oxygen atoms, linking them together and contributing to the formation of a three-dimensional network structure. The addition of tellurium oxide can lead to the creation of NBOs. NBOs are oxygen atoms that are bonded to only one network-forming element instead of two. They lack a bridging role between two network-forming units and instead create terminal bonds with the network. The coordination geometry of the TeO3 unit provides a site where an oxygen atom can easily detach from the tellurium atom, resulting in the creation of an NBO [19]. The NBO arises when an oxygen atom in the TeO3 unit forms a bond with a network-forming atom, leaving the other oxygen unbound and acting as NBOs. Three spectral regions are linked to borate oxide structural units. Within the range of 1160 to 1270 cm−1, the second band corresponds to the B–O stretching of tetrahedral BO4 units. The B–O stretching of the trigonal BO3 units is the reason for the third band, which can be found within the range of 1315 to 1500 cm−1. Based on Fig. 4, Table 1 presents the vibration bands for the functional groups.

Figure 5 shows the variation of longitudinal and shear velocity of Tm3+-doped MBT glasses. Based on Fig. 5, there is a positive correlation between the Tm3+ concentration and the longitudinal and shear velocities. Specifically, as the Tm3+ concentration increases from 0 to 3% mol%, both longitudinal and shear velocities increase from 3474.78 to 4085.13 m/s and 1966.02 to 2495.90 m/s, respectively. Furthermore, addition of thulium oxide from 0 to 3% increased the ultrasonic velocity, implying that the glass network was strengthened, and the samples become more rigid. One possible explanation for this phenomenon is that the increase in packing density observed in the prepared glass samples may be attributed to the transitions in structural units from TeO3 to TeO4 and from BO3 to BO4. Another factor that contributed to the increase in density was the relatively small ionic radii of Tm3+ ions, which allowed them to occupy interstitial spaces [19]. The longitudinal velocity could exceed the shear velocity in particular materials or circumstances. In most glass samples, the longitudinal velocity (also known as the compressional or P-wave velocity) is higher than the shear velocity (also known as the S-wave velocity). This behavior can be attributed to the specific structural characteristics of glasses. Glass is an amorphous solid, meaning it lacks a long-range crystalline order. Its atomic or molecular arrangement is disordered, leading to isotropic properties in most cases. When a mechanical wave propagates through a glass sample, it encounters an irregular atomic arrangement. In the glass matrix, longitudinal waves propagate by compression and expansion of the material along the direction of wave propagation, and the strong bonds allow for efficient transmission of these compressional waves, resulting in a higher longitudinal velocity as compared to shear velocity.

Figure 6 illustrates the elastic moduli (L, G, K, and E) of MBT glass system as a function of different Tm3+ concentrations. Table 2 and Fig. 6 both show a rising trend in elastic values. When the Tm3+ mol content rises by up to 3%, the elastic moduli exhibit an increasing trend. The fact that the elastic moduli increased despite the simultaneous discovery of both NBOs and BOs in the glass network can be explained by the consistency of the findings from previous studies [20]. Increases in glass density are connected with increases in elastic moduli, which lead to the condensing of the glass structure. In general, there is a positive correlation between density and elastic properties such as Young’s modulus and Poisson’s ratio. The basic idea behind this relationship is that denser glasses tend to have more tightly packed atomic structures, which results in stronger atomic bonds and greater resistance to deformation. This can be observed, for example, in tellurite glasses, where an increase in density generally leads to an increase in Young’s modulus.

In addition to this, Fig. 7 and Table 2 demonstrate that Poisson’s ratio displayed an opposite relationship to the elastic moduli. The addition of Tm2O3 resulted in a decrease of Poisson’s ratio, which is a measure of the cross-link density in the glass network. The modified bonding and lattice structure causes the abrupt decrease in Poisson’s ratio following the addition of thulium ions to the magnesium borotellurite glass. Due to the altered interatomic distances and angles, materials become more elastic. The Poisson’s ratio, which measures the correlations between axial and lateral strains, abruptly decreases under the influence of thulium doping. The Young’s modulus or overall stiffness of the magnesium borotellurite glass is susceptible to influence by thulium ions. The changes in stiffness affect how a material reacts to external forces and deformations. Thulium doping can alter the stiffness qualities of a material, causing it to resist lateral contraction differently than axial deformation. The Poisson’s ratio also abruptly decreases due to this mismatch in deformation behavior. Poisson’s ratios falling between 0.1 and 0.2 usually indicate high cross-link density, while ranges between 0.3 and 0.5 typically indicate low cross-link density. The deformation within the glass network can also be associated with Poisson’s ratio. If the glass experiences distortion from structural unit expansion or compression, the Poisson’s ratio will be 0.25. However, if bond bending causes distortion of structural units, the Poisson’s ratio will be less than 0.25. Poisson’s ratio values are related to the ratio between lateral strain (perpendicular to the applied stress) to the longitudinal strain (parallel to the applied stress) in a glass. Poisson’s ratio provides insights into the cross-link density, which refers to the degree of bonding or connectivity between the atoms or molecules in the glass structure. When Poisson’s ratio of a glass falls within the range of 0.1 to 0.2, it indicates a relatively high cross-link density. This means that the glass structure has a significant amount of atomic or molecular bonds, resulting in strong interatomic forces and connectivity between the structural units. As a result, the glass is less compliant or deformable, and it exhibits less lateral expansion when subjected to an applied longitudinal stress. The higher cross-link density restricts the movement of atoms or molecules, making the glass more rigid and less prone to large deformations [21]. In addition to network distortion, a ratio greater than 0.25 denotes that the ions are distorted, as seen on the undoped glass sample. Conversely, Poisson’s ratios falling within the range of 0.3 to 0.5 are typically associated with glasses having a lower cross-link density. In such glasses, the atomic or molecular bonding and connectivity are less extensive. The relatively weaker interatomic forces allow for more freedom of movement and deformability within the glass structure. When subjected to an applied longitudinal stress, these glasses exhibit more lateral expansion or strain compared to their longitudinal deformation. The lower cross-link density provides greater flexibility, making the glass more compliant and capable of larger deformations. In this investigation, the Poisson’s ratio decreased from 0.26 to 0.20, demonstrating the glass’s high cross-link density, network change, and deformed structure. The decrease in the value of Poisson’s ratio from 0.26 to 0.20 as the Tm3+ concentration increases in glass can be attributed to changes in the structural characteristics and mechanical behavior of the glasses. The addition of Tm3+ ions to the glass composition can act as network modifiers, meaning they disrupt the regular connectivity and bonding between the glass-forming units [22]. Tm3+ ions can introduce structural irregularities and modify the glass network, altering the atomic arrangements and interatomic forces. Besides, with an increase in Tm3+ ion concentration, the cross-link density within the glass network may decrease. This means that the connectivity and bonding between the atoms or molecules in the glass structure may become weaker or less extensive. As a result, the glass becomes more compliant and deformable, leading to an increase in lateral expansion relative to longitudinal deformation. The previous studies also showed a similar trend of the opposite Poisson’s ratio with the addition of rare-earth ions [23, 24].

Microhardness can be described as a stress that reduces the available volume for deformation in glass systems. The microhardness results for the magnesium borosilicate glass at various Tm3+ concentrations are presented in Fig. 8, with corresponding values listed in Table 3. As the mol content of Tm3+ increases, the microhardness increases from 4.00 to 7.69 GPa. There is a correlation between the increase in microhardness and the improvement in stiffness and rigidity of the prepared sample as the concentration of Tm3+ increases. The increase in glass stiffness and rigidity is indicated by the rise in microhardness [25].

The Makishima and Mackenzie model was used to calculate the theoretical elastic properties of the glass being studied. The Makishima and Mackenzie model calculates the Young’s modulus of oxide glasses based on their atomic packing density and bond strengths, using the densities and bulk molecular weights of the atoms involved. According to the model, the elastic moduli of the atoms or individual oxides comprising the glass are linked to their corresponding dissociation energies and packing densities. As the concentration of Tm2O3 increased from 0.00 to 0.03 molar fraction, the packing density of the glass rose from 0.5315 to 0.5356 cm3/mol. The increase in packing density is caused by the higher packing factor of Tm2O3 and the resulting increase in glass density. The introduction of Tm2O3 to the glass composition increased the packing density by filling the interstitial spaces in the glass network with ions. This demonstrates that the glass was capable of withstanding the applied forces. This is because Tm3+ ions have smaller ionic radii than other ions in the glass, and the network structure has become more rigid, which was also described by the increase in overall packing density [26].

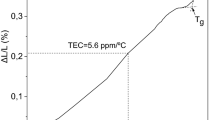

As shown in Fig. 9, it is discovered that adding Tm2O3 to the glass network raises both Gt and Vt. The overall dissociation energy may have increased due to Tm2O3’s higher dissociation energy (70.2 × 109 J/m3) compared to other chemical compounds [27]. Additionally, the increase in network bonds in the glass sample directly contributed to the increment in total dissociation energy. The elastic moduli rise as Gt increased because the glass grew more rigid, as shown in Table 3.

The Poisson’s ratio value exhibits an increasing trend and is narrow in the range of 0.2387 to 0.2407, according to the given statement. According to the explanation, the ever increasing tendency is caused by the glass’s packing density and the plenty of room for atomic movement. While molecules or atoms are more loosely packed in glasses, they have more room to move about or reorganize under stress. The material experiences less lateral strain when deformed lengthwise because of the higher range of motion. As a result, the Poisson’s ratio tends to be lower in loosely packed glasses because the lateral contraction is less severe than the axial deformation. Conversely, in tightly packed glasses, there is less room for movement due to the close packing of the atoms or molecules. When an external force is applied to such a network, the closely packed structure’s limitations cause the lateral strain to increase in severity. The Poisson’s ratio tends to rise because the lateral contraction becomes more substantial compared to the axial deformation in densely packed glasses. In conclusion, the explanation shows that the different levels of packing density in the glass samples are most likely responsible for the observed trend of an increasing Poisson’s ratio within the defined tight range (0.2387 to 0.2407). Glasses packed loosely have less lateral strain and, as a result, a lower Poisson ratio, while glasses packed tightly have more lateral strain and, as a result, a higher Poisson ratio. The increase in the value of Poisson’s ratio from model calculations for glass can occur due to several factors related to the assumptions and limitations of the model used. Models used for calculating material properties, including Poisson’s ratio, often make simplifying assumptions about the material’s behavior. These assumptions may not fully capture the complex nature of glass, leading to discrepancies between the model prediction and experimental values. Besides, model calculations can be sensitive to input parameters such as interatomic potentials, bond lengths, or force constants. Small variations in these parameters can lead to significant deviations in the predicted mechanical behavior, including Poisson’s ratio.

The Rocherulle model was used to compute the theoretically elastic moduli and presented in Tables 4 and 5. The addition of thulium oxide raises all elastic moduli and Poisson’s ratio. Upon the addition of Tm2O3, it can be observed that all the data underwent only minor changes in comparison to the previous models (ranging from 23.25 to 23.49 GPa for KR, 13.83 to 3.95 GPa for GR, 32.80 to 33.10 GPa for ER, and 0.26554 to 0.26593 for \({\sigma }_{R}\)). The glass samples get more rigid and stiff as a compound with a high density replaces one with a lower density as thulium oxide has a higher density (8.6 g/cm3) than the other oxide ingredients (Figs. 10, 11, and 12). The increase might be due to the glass’s increased packing density and network rigidity [28]. The values for elastic moduli are generally greatly affected by any changes to the network structure. Figure 13 illustrates how the experimental and theoretical elastic data differed slightly in Poisson’s ratio. Previous studies of thulium-doped borotellurite glass revealed the same theoretical and experimental contradictions in Poisson’s ratio values.

Conclusion

The addition of Tm2O3 to magnesium borotellurite glass increased the density, molar volume, ultrasonic velocity, and elastic moduli, while decreasing the Poisson’s ratio. The rise in ultrasonic velocity and elastic moduli was due to the formation of bridging oxygen at higher rates with increasing thulium concentration. However, earlier research has suggested that the formation of NBOs at higher Tm3+ concentrations leads to a reduction in ultrasonic velocity. The addition of thulium oxide caused a decrease in the Poisson’s ratio from 0.26 to 0.20, indicating that the sample’s network became more stable. The longitudinal and shear velocities both increased with the increase in Tm2O3 concentration, and all moduli values increased as well. Structural changes were observed in the glass network, and the microhardness values increased with the addition of thulium oxide. The Makishima Mackenzie and Rocherulle models are commonly used for elastic calculations in various materials, including glasses and ceramics. The Makishima Mackenzie model takes into account the composition of the glass or ceramic material, allowing for more accurate predictions of elastic properties. By considering the atomic fractions of different constituents, the model can accommodate variations in composition and provide more reliable elastic calculations. While, the Rocherulle model offers a simplified approach to elastic calculations, making it relatively straightforward to implement. It reduces the complexity of the elastic problem by assuming an isotropic behavior and neglecting certain higher-order effects. Rare-earth doped magnesium borotellurite glass can make mechanical strain or pressure-sensitive optical fiber sensors.

Data availability

As a result of internal rules for data processing at some participating organizations, the data sets generated and analyzed in this study are not publicly accessible, but they can be obtained from the corresponding author upon reasonable request.

References

Désévédavy, F., Strutynski, C., Lemière, A., Mathey, P., Gadret, G., Jules, J.C., Kibler, B., Smektala, F.: Review of tellurite glasses purification issues for mid-IR optical fiber applications. J. Am. Ceram. Soc. 103, 4017–4034 (2020)

Doğan, A., Erdem, M.: Investigation of the optical temperature sensing properties of up-converting TeO2-ZnO-BaO activated with Yb3+/Tm3+ glasses. Sens. Actuator A-Phys. 322, 112645 (2021)

Sailaja, P., Mahamuda, S., Swapna, K., Venkateswarlu, M., Rao, A.S.: Near-infrared photoluminescence studies of neodymium ions doped SrO-Al2O3-BaCl2-B2O3-TeO2 glasses for laser and fiber amplifier applications. Opt. Laser Technol. 156, 108569 (2022)

Tafida, R.A., Halimah, M.K., Muhammad, F.D., Chan, K.T., Onimisi, M.Y., Usman, A., Hamza, A.M., Umar, S.A.: Structural, optical and elastic properties of silver oxide incorporated zinc tellurite glass system doped with Sm3+ ions. Mater. Chem. Phys. 246, 122801 (2020)

Mostafa, A.M.A., Issa, S.A., Zakaly, H.M., Zaid, M.H.M., Tekin, H.O., Matori, K.A., Sidek, H.A.A., Elsaman, R.: The influence of heavy elements on the ionizing radiation shielding efficiency and elastic properties of some tellurite glasses: theoretical investigation. Res. Phys. 19, 103496 (2020)

Awshah, A.A.A., Nazrin, S.N., Halimah, M.K., Effendy, N., Khaliq, M.A.S.M.S., Azlan, M.N., Awad, A.I.: Novel of neodymium nanoparticles zinc tellurite glasses in experimental and theoretical elastic properties using artificial intelligence approach. Chin. J. Phys. 81, 332–353 (2023)

El-Mallawany, R., El Adawy, A., Gamal, A., Rammah, Y.S.: Experimental and theoretical elastic moduli of sodium–zinc–tellurite glasses. Optik 243, 167330 (2021)

El-Mallawany, R., Ribeiro, M.A., Lara, L.S., Lenzi, E.K., Alsadig, I.A.A., Novatski, A.: Refractive index behavior of tellurite glasses. Opt. Mater. 112, 110810 (2021)

Boukhris, I., Kebaili, I., Sayyed, M.I., Askin, A., Rammah, Y.S.: Linear, nonlinear optical and photon attenuation properties of La3+ doped tellurite glasses. Opt. Mater. 108, 110196 (2020)

Elias, A.M., Mwanga, S.F., Mwankemwa, B., Anjaiah, J., Laxmikanth, C.: Influence of Bi+ ions on photoluminescence properties of Tm2O3 doped borotellurite glasses for the near-infrared emission applications. Opt. Mater. 125, 112140 (2022)

Lakshminarayana, G., Baki, S.O., Lira, A., Kityk, I.V., Mahdi, M.A.: Structural, thermal, and optical absorption studies of Er3+, Tm3+, and Pr3+-doped borotellurite glasses. J. Non-Cryst. Solids. 459, 150–159 (2017)

Sharma, R., Prasad, A., Kaur, S., Deopa, N., Rani, R., Venkateswarlu, M., Rao, A.S.: Spectroscopic properties of deep red emitting Tm3+ doped ZnPbWTe glasses for optoelectronic and laser applications. J. Non-Cryst. Solids. 516, 82–88 (2019)

Zalamin, S.N.F., Zaid, M.H.M., Matori, K.A., Karim, M.K.A., Yamin, N.A.M., Ismail, N.A.N.: Comprehensive study on optical and luminescence properties of Sm3+ doped magnesium borotellurite glasses. J. Phys. Chem. Solids. 163, 110563 (2022)

Effendy, N., Aziz, S.H.A., Kamari, H.M., Zaid, M.H.M., Wahab, S.A.A.: Ultrasonic and artificial intelligence approach: elastic behavior on the influences of ZnO in tellurite glass systems. J. Alloys Compd. 835, 155350 (2020)

Effendy, N., Zaid, M.H.M., Matori, K.A., Iskandar, S.M., Hisam, R., Azlan, M.N., Yusof, N.N., Zakaly, H.M., Issa, S.A., Saddeek, Y.B.: Fabrication of novel BaO–Al2O3–Bi2O3–B2O3 glass system: comprehensive study on elastic, mechanical and shielding properties. Prog. Nucl. Energy. 153, 104418 (2022)

Shi, Y., Tandia, A., Deng, B., Elliott, S.R., Bauchy, M.: Revisiting the Makishima-Mackenzie model for predicting the young’s modulus of oxide glasses. Acta Mater. 195, 252–262 (2020)

Dai, S., Lin, C., Chen, F., Zhang, X., Liu, C., Xu, K., ... & Wang, X.: Enhanced mid-IR luminescence of Tm3+ ions in Ga2S3 nanocrystals embedded chalcohalide glass ceramics. J. Non-Cryst. Solids. 357 2302–2305 (2011)

Abou Hussein, E.M., Madbouly, A.M., Eldin, F.E., ElAlaily, N.A.: Evaluation of physical and radiation shielding properties of Bi2O3–B2O3 glass doped transition metals ions. Mat. Chem. Phys. 261, 124212 (2021)

Mhareb, M.H.A., Almessiere, M.A., Sayyed, M.I., Alajerami, Y.S.M.: Physical, structural, optical and photons attenuation attributes of lithium-magnesium-borate glasses: role of Tm2O3 doping. Optik 182, 821–831 (2019)

Hasnimulyati, L., Halimah, M.K., Zakaria, A., Halim, S.A., Ishak, M.: A comparative study of the experimental and the theoretical elastic data of Tm3+ doped zinc borotellurite glass. Mater. Chem. Phys. 192, 228–234 (2017)

Al-Buriahi, M.S., Rashad, M., Alalawi, A., Sayyed, M.I.: Effect of Bi2O3 on mechanical features and radiation shielding properties of boro-tellurite glass system. Ceram. Int. 46, 16452–16458 (2020)

Halimah, M.K., Asyikin, A.S., Nazrin, S.N., Faznny, M.F.: Influence of erbium oxide on structural, physical, elastic and luminescence properties of rice husk biosilicate zinc borotellurite glasses for laser application. J. Non-Cryst. Solids. 553, 120467 (2021)

Cankaya, H., Gorgulu, A.T., Kurt, A., Speghini, A., Bettinelli, M., Sennaroglu, A.: Comparative spectroscopic investigation of Tm3+: tellurite glasses for 2-μm lasing applications. Appl. Sci. 8, 333 (2018)

Alothman, M.A., Kurtulus, R., Olarinoye, I.O., Kavas, T., Mutuwong, C., Al-Buriahi, M.S.: Optical, elastic, and radiation shielding properties of Bi2O3-PbO-B2O3 glass system: a role of SnO2 addition. Optik 248, 168047 (2021)

Adamu, S.B., Halimah, M.K., Chan, K.T., Muhammad, F.D., Nazrin, S.N., Scavino, E., Kamaruddin, S.A., Az’lina, A.H., Ghani, N.A.M.: Structural, prediction and simulation of elastic properties for tellurite based glass systems doped with nano and micro Eu2O3 particles via artificial neural network model. J. Mater. Res. Techno. 17, 586–600 (2022)

Mao, L.Y., Liu, J.L., Li, L.X., Wang, W.C.: TeO2-Ga2O3-ZnO ternary tellurite glass doped with Tm3+ and Ho3+ for 2 µm fiber lasers. J. Non-Cryst. Solids. 531, 119855 (2020)

Bassam, S.A., Naseer, K.A., Prakash, A.J., Mahmoud, K.A., SuchandSangeeth, C.S., Sayyed, M.I., Alqahtani, M.S., El Sheikh, E., Khandaker, M.U.: Effect of Tm2O3 addition on the physical, structural, elastic, and radiation-resisting attributes of tellurite-based glasses. Rad. Phys. Chem. 209, 110988 (2023)

Halimah, M.K., Tafida, R.A., Chan, K.T., Muhammad, F.D.: A comparative study of the experimental and the theoretical elastic data of silver oxide incorporated zinc tellurite glass system doped with Sm3+ Nps ions. Optik 238, 166536 (2021)

Nazrin, S.N., Halimah, M.K., Awshah, A.A.A., Yee, S.P., Hasnimulyati, L., Boukhris, I., Gowda, G.J., Azlan, M.N., Nadzim, S.N.: Experimental and theoretical elastic studies on neodymium-doped zinc tellurite glasses. J. Non-Cryst. Solids. 575, 121208 (2022)

Funding

This research work received support from the Geran Putra Berimpak (GP-GPB/2021/9702600) granted by the Universiti Putra Malaysia.

Author information

Authors and Affiliations

Contributions

Yazri Azdi Rasdi: conceptualization, data curation, formal analysis, investigation, methodology, software, visualization, writing — original draft. Mohd Hafiz Mohd Zaid: conceptualization, data curation, formal analysis, funding acquisition, project administration, resource, software, supervision, visualization, writing — original draft. Khamirul Amin Matori: conceptualization, data curation, formal analysis, supervision, visualization, writing — original draft. Yap Wing Fen: conceptualization, formal analysis, supervision, methodology, software, writing — original draft.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rasdi, Y.A., Zaid, M.H.M., Matori, K.A. et al. Correlation between thulium concentration and elastic properties in magnesium borotellurite glass systems. J Aust Ceram Soc 59, 1325–1336 (2023). https://doi.org/10.1007/s41779-023-00913-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-023-00913-8