Abstract

This study evaluates the recent investigations and economic assessments on using the solar-driven organic Rankine cycle (ORC) as a power source for membrane-based desalination systems, specifically reverse osmosis (RO) systems. Several numerical and experimental studies from the last decade on the design and performance of RO-ORC desalination systems have comprehensively been reviewed. This intensive study aims to critically review RO-ORC systems and update on the recent advancements in systems performance, design, and characteristics. It also focuses on the main challenges, limitations, improvements, and techno-economic factors affecting RO-ORC performance. Four categories were used to group the investigations: the RO desalination process, the Organic Rankine cycle (ORC), the solar ORC-powered RO desalination, and economic assessment criteria. RO-ORC performance is affected by the system design parameters, RO unit characteristics, feed water qualities, climatic conditions, and the ORC process’s working fluid. The assessment focuses on recovery ratios, water quality, system efficiency, system, and plant design and the SEC as performance evaluation measures. The literature review declared that improved membrane materials and module designs have reduced energy usage because of the continual process improvements and cost savings. These advances cut membrane costs per unit of water produced in half. In addition, many modern technology combinations have been studied and used to boost efficiency and reduce energy needs in reverse osmosis plants. Using solar-driven ORC-RO has shown promising results in places with ample solar resources or low-grade thermal energy. Many conclusions and expected remaining challenges are highlighted in the study.

Highlights

• Covers updates on current solar ORC-RO features and recent design and performance evaluations.

• Examines the numerical and experimental studies conducted on solar RO-ORC.

• Discusses the primary technical and economic issues impacting solar RO-ORC performance.

• Briefly describes RO desalination systems, covering forward and reverse osmosis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The importance of seawater desalination processes is evident in the wide and multiple spread of these processes. Now, there are around 20 distinct technologies in use [1]. Reverse osmosis (RO) is a widely used desalination technology that is also one of the most stable and well-developed [2]. The reverse osmosis principle is a simple process. Water will pass through the membrane from the low-chloride side to the high-chloride side [3]. Water will transfer faster if pressure is given to the high-chloride side that exceeds the osmotic pressure [4]. Most RO plants follow the same type of layout. They can be divided into three main sections: pretreatment, RO membrane treatment, and post-treatment. This is vital since the membrane cells are the most significant and most expensive component of the reverse osmosis plant, and it is critical to avoid membrane deterioration to increase their lifetime [5].

According to its low energy consumption, straightforward design of compact size and flexibility of its units, ease of operation at ambient temperature, low investment costs, and low periodic maintenance, the RO process has topped the other desalination technologies [6], such as multi-stage flash (MSF), multiple-effect desalination (MED), electrodialysis, and vapor compression, which share the remaining water produced. RO has been combined with several new technologies to make it more efficient and use less energy. These include photovoltaic-assisted reverse osmosis (PV-RO), microbial desalination cell integrated reverse osmosis (MDC-RO), batch reverse osmosis desalination, closed-circuit reverse osmosis (CCRO), and FO-RO hybrid systems [1, 7,8,9,10].

RO desalination is a mechanical separation process that uses pressure to drive salty water through a semi-permeable membrane. Roughly 60% of all desalinated water is produced using RO, which is cheaper than conventional distillation technologies [11]. The main problem with RO is that it needs much power to reach the high pressure (60–70 bar) that is needed to filter seawater [11]. An organic Rankine cycle (ORC) heat engine can supply the pressure energy necessary for RO desalination [12]. Applications in ORC include seawater desalination systems, fuel cells, microturbines, Brayton cycles, thermoelectric generators, and cascade systems. Combining an ORC with a desalination system has several advantages. The saltwater acts as a heat sink for the condensation process in ORC. It is also heated to improve the permeability of the RO membrane, which uses less power [13]. One active research area uses an ORC and reverse osmosis RO to remove salt from salt water using solar thermal energy [13]. The ORC-RO system is a cost-effective and ecologically sustainable process for producing fresh water using low-grade thermal energy [14]. The solar ORC-RO desalination unit includes a Rankine cycle power plant, a solar field, and an RO unit. Thermal energy can be supplied to the Rankine cycle by flat plate collectors (FPC), evacuated tube collectors (ETC), and parabolic trough collectors (PTC) [15]. Before 1940, the energy efficiency of energy systems was analyzed using the first law of thermodynamics [16]. The second law analysis, an exergy analysis, reveals loss locations, amounts, causes, sources, and quality of energy loss. It helps to uncover sources of thermodynamic inefficiency in systems. In addition, it aids in designing, assessing, optimizing, and improving energy systems [17,18,19,20].

It is noted that the traditional energy analysis approach is incorrect since it focuses on energy quantity while ignoring its quality. However, in some instances, this method is ineffective. The first law of thermodynamics concerns the amount of energy transferred, regardless of the form or conditions. According to the first law of thermodynamics, 1 kJ of electricity, the chemical energy of fuel, thermal energy at 500 °C, and thermal energy at 50 °C are all equivalent. However, their economic values are not equivalent in actuality. As a result, it is critical to develop a technique for evaluating thermal systems that consider both the quantity of energy converted and the actual worth of that energy. Exergy is the term for this strategy [21]. Recent publications have emphasized the need to include both quantitative and qualitative energy analysis [22, 23]

There have been some reviews of solar ORC-RO systems [14, 15, 24]. Torres and Rodríguez [24] provided design recommendations for solar RO desalination systems based on organic Rankine cycles (ORC), focusing on selecting working fluid, solar collector and thermal energy storage technology, and other design parameters. The review was drawn on previous studies and experimental works to guide future research and development of solar RO systems based on ORC. Shalaby [15] then reviewed RO water desalination systems powered by PV and solar RC cycle technologies. The review examined various design options, the software tools used to optimize desalination plant productivity, and the types of solar collectors, membranes, and working fluids used. The review also assessed the specific energy consumption and cost of fresh water production. It was concluded that using batteries with PV to drive RO desalination plants is not recommended due to high capital and replacement costs. Also in 2022, Shalaby et al. [14] attempted to completely integrate the majority of their research to provide a complete picture of the most current advancements in reverse osmosis plants, centered on solar-powered reverse osmosis systems, which were developed to reduce the energy consumption of PV or solar thermal plants, particularly the organic Rankine cycle. Additionally, several preheating methods and relevant papers were provided.

Throughout the literature and up to the authors’ knowledge, no comprehensive study on the RO-ORC desalination systems covered the complete design and economic assessment for comparison. In the recent review article, several numerical and experimental studies on the design and performance of RO-ORC desalination systems have been comprehensively reviewed, which covered the last decade (2012–2022). Comparatively, the present work is comprehensive and critically reviews recent research on solar-driven ORC-RO desalination systems over the past decade. The review covers four main categories: the RO desalination process, the ORC, solar ORC-powered RO desalination, and economic assessment criteria. The review examines the factors affecting RO-ORC performance, including system design parameters, feed water qualities, climatic conditions, and the working fluid of the ORC process. The review evaluates the performance of the systems based on measures such as recovery ratios, water quality, system efficiency, plant design, and specific energy consumption. The review also discusses recent technological advancements that have improved the energy efficiency of RO desalination systems, such as improved membrane materials and module designs. Additionally, the review highlights the potential of solar-driven ORC-RO systems in locations with abundant solar resources or low-grade thermal energy.

The novelty of the review lies in its comprehensive and critical examination of recent research on solar-driven ORC-RO desalination systems. The review covers a wide range of topics, including the design and performance of RO-ORC systems, recent technological advancements, economic assessment criteria, and remaining challenges. The review provides an in-depth analysis and evaluation of the factors affecting the performance of these systems, as well as the potential benefits and limitations of using solar-driven ORC-RO for desalination. The authors have provided a valuable resource for researchers and practitioners working in this field by synthesizing and updating the current state of knowledge on solar-driven ORC-RO desalination systems.

This intensive study aims to give a critical review of RO-ORC systems and an update on the recent advancements in systems performance, design, and characteristics. It also focuses on the main challenges, limitations, improvements, and techno-economic factors affecting RO-ORC performance. This study implements the review methodology as described in [25]. The review deals with the design and performance of RO-ORC desalination systems and identifies challenges limiting technology development. An extensive literature survey was, however, conducted from a list of evidence-based studies in scholarly papers, expert reports, conference proceedings, and peer-reviewed journals for the past 10 years (with reverse osmosis, organic Rankine cycle, solar, RO, ORC, and desalination as keywords). It was then evaluated in terms of findings from numerical and experimental studies on the systems’ features, variables, and performance to analyze and answer the research problems.

This paper comprises eight sections, including the introduction, five main sections, and three appendices. The following sections are outlined: The “RO desalination powered by solar ORC” presents numerical and experimental investigations of the RO-ORC system. Also, performance-evaluation parameters and integration methods for system operation analysis are described. The “Economical assessment” discusses the economic assessment of the RO-ORC based on recent research studies. “Conclusions” and “Future recommendations/challenges” summarize the main conclusions and challenges for RO-ORC. The last three sections were placed in the appendices at the end of the article due to their importance for the basic knowledge of the topic. Appendix Reverse osmosis desalination (RO) briefly introduces reverse osmosis (RO) desalination systems, including the forward osmosis (FO) and reverse osmosis (RO) techniques. On the other side, Appendix The treatment processes accompanying RO outlines the pretreatment, treatment, and posttreatment processes engaged with the RO systems. In the end, Appendix Organic Rankine cycle (ORC) demonstrates the designing, performing, and analyzing of the Organic Rankine cycle (ORC) systems concerning numerical and experimental methods and highlights these technologies’ main challenges, advancements, and limitations.

RO Desalination Powered by Solar ORC

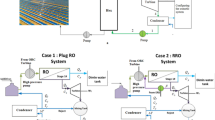

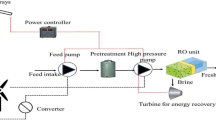

This section discusses the studies conducted on the design and performance analysis of the RO desalination process powered by a solar organic ranking cycle (ORC). As mentioned earlier, the solar ORC-driven RO desalination technology comprises the RO unit, ORC plant, and solar system. The solar field may be employed to give thermal energy to the Rankine cycle (RC) using flat, evacuated tubes and parabolic trough collectors. The solar field’s thermal energy heats the working fluid and maintains it at high pressure and temperature, which drives the RC turbine. The mechanical power produced drives the RO’s HPP directly without converting it to electricity, as shown in Fig. 1. The RC often uses water as the working fluid. In contrast, organic liquids, such as siloxanes, fluorocarbons, and hydrocarbons, were utilized when the RC was performed at temperatures lower than equivalent water-based cycles [15].

A schematic diagram for an ORC powered by solar energy and connected to a RO system [26]

In the last decade, several numerical and experimental research studies were conducted on RO desalination driven by a solar ORC, as discussed hereafter. Peñate et al. [27] designed a solar desalination unit with capacities ranging from 1000 to 5000 m3/day. Figure 2 illustrates an ORC-driven SWRO desalination system powered by a PTC solar system. A 2500 m3/day SWRO plant has been constructed to connect to the power supplied by two solar ORCs: a single ORC with superheating, regeneration, and a cascade of ORCs. The results declared that the overall specific energy consumption (SEC) was 2.99 kWh/m3. To prevent operating pressures below ambient, the cascade Rankine cycle needed a 23% larger solar field than the standard ORC with regeneration and superheating.

Schematic diagram of cascade ORC [27]

Li et al. [13] investigated a supercritical organic Rankine reverse osmosis (SORC-RO) using ROSA software, as shown in Fig. 3. The SORC-RO system was analyzed and compared to a traditional organic Rankine cycle–driven saltwater reverse osmosis system (ORC-RO) utilizing two different types of low-grade heat supply with a peak temperature of 150 °C. The findings demonstrated that the SORC-RO system might utilize various heat sources while maintaining a relatively consistent performance. When the geothermal fluid was the heat source, the system produced 40% extra freshwater with the equivalent quantity of the geothermal stream. Figure 4 clarifies that R152a was suitable for use in both once-through and recirculating heating systems.

Illustration of a low-grade heat ORC/OSORC-RO plant [13]

Potential SORC-RO working fluids for low-temperature heat sources [13]

The performance of a solar desalination ORC system was studied by Ibarra et al. [28]. R245fa for the ORC and water as a working medium for a solar field (Fig. 5). The operation of a solar desalination ORC system was demonstrated during a part-load performance to understand its characteristics better and estimate overall water generation under different operating scenarios. If thermal storage was supplied, the organic Rankine cycle might have utilized the heat produced by the solar collector system. It was also possible to operate it at half-load, and the power output did not change during the day. The results revealed that water generation was roughly 1.2 m3/h, steady through the day and night, and global efficiency was constantly around 7%. ORC can efficiently recover solar electricity and produce drinking water in remote areas with high irradiation.

Desalination process of ORC [28]

Xia et al. [29] presented a simulation model for RO desalination driven by solar ORC and wind energy. Energy storage devices were used to guarantee that production would not stop. The total system was simulated using a mathematical model that included an ORC subsystem, a wind energy system, a solar collector field, and an RO desalination system. A sensitive investigation of the turbine input pressure, ORC condenser temperature, feed water pressure, and water salinity was performed to evaluate the interaction between these factors and freshwater production. As shown in Fig. 6, the daily freshwater production increased with increasing turbine input pressure and decreased with increasing feed water pressure. Also, the condenser temperature influenced freshwater daily output. The authors reported that the feed water pressure arose, and the freshwater production and membrane area fell. The freshwater production was responsive to water salinity, although the membrane area was less too.

Water production at various: a turbine inlet pressures, b condenser temperatures, and c feed pressures [29]

Igobo and Davies [30] investigated the isothermal expansion of the working fluid in the ORC system to enhance system efficiency while powering the “DesaLink” batch-RO unit. The liquid was vaporized directly in the expansion device and heated externally by a heat transfer medium. DesaLink generated 256 l of drinking water from 4000 ppm salty feed every 8 h/day, with a thermo-mechanical SEC of 2.5 and 0.36 kWh/m3. A cycle efficiency of 8.8% was discovered in experimental studies using R245fa (see Fig. 7).

The efficiency of various working mediums as a function of temperature [30]

Almost a year later, TRNSYS was used to model a solar thermal RO Organic Rankine desalination plant by Bocci et al. [31], as shown in Fig. 8. The system consists of 3 m3 of thermal storage and 50 m2 of CPC solar field, a 3 kWe-ORC, an 8 kWth-absorber, and a 200 l/h direct RO unit using R245fa as a working fluid. The system was designed to provide residents electricity, fresh water, and heating and cooling. Economic energy evaluations have been undertaken. The results showed that the low-temperature cooling and heating terminals have boosted thermal energy utilization and ORC and absorber efficiency. The ORC-Absorber design, working medium, and temperatures were crucial. Therefore, with annual radiation of around 90,000 kWh, the yearly thermal energy production of the system was about 32,800 kWh. A 30% cost reduction was required to get a positive net present value. The performance of an ORC-RO desalination using zeotropic mixtures was numerically studied by Geng et al. [32]. The effect of increasing water temperatures on system operation was evaluated in a case study with R600/R601a and R600/R601, as shown in Fig. 9. The maximum output of 29.3 kW was discovered for the mix R600/R601 at a molar ratio of 0.9/0.1 with a 26 K temperature increase, and the maximum output of 30.9 kW was found for the combination R600/R601a at a molar ratio of 0.9/0.1.

The layout of the TRNSYS model [31]

Variations in network production due to seawater temperature increase: a R600/R601 and b R600/R601a [32]

As described in Fig. 10, in north Iran, a direct two-stage RO-ORC design was quantitatively improved by Mokhtari et al. [33]. Water has been given in this city for the last 20 years, and as a conclusion of that time, a population of 12,125 people has been served. The estimate relied on a maximum TDS of 13,000 ppm in Caspian saltwater and a permeate output of 4000 m3/day. Mokhtari et al. [33] found that the best recovery and total price per cubic meter were 76% and 0.37 $/m3, respectively (see Fig. 11). In a power-generating cycle, feedwater should be warmed to 10 °C with a pumping requirement of 362 kW of electricity. Compared to water and R717, R290 has the cheapest desalination cost, at 0.568 $/m3.

A diagram of the simulated system [33]

Optimization of the RO system [33]

Sun et al. [34] described a mathematical model for a novel RO organic Rankine cycle desalination system that was based on solar energy, and ocean thermal energy conversion utilization was presented. Numerous indicators were used to assess the system’s performance from a thermo-economic perspective, including freshwater production, daily exergy efficiency, turbine shaft power, thermoeconomic unit cost, and total water price. The results reveal that the solar collection temperature and turbine inlet pressure were at their optimum levels for reaching the system’s maximal performance; however, rises in terminal temperature gradient and pinch point temperature difference have negatively affected the system. In addition to solar thermal collectors, heat exchangers suffered the most exergy losses. Igobo and Davies [35] investigated experimentally using R245fa as the working medium, a new isothermal ORC-driven batch RO desalination machine (DesaLink) (Fig. 12). According to the findings and at a heat supply temperature of 95 °C, a flow rate of 50 l/min, and a power of 1.5 kW, the energy needs were cut in half, equivalent to SEC of 0.34 kWh/m3. According to a tested case, the system could recover waste heat from a bakery factory and generate roughly 0.4 l of drinking water per kg of baked food.

ORC DesaLink: a schematics representation, b actual prototype [9]

El Mansouri et al. [36] evaluated the RO desalination unit using a solar pond in the semi-arid and Mediterranean regions. As demonstrated in Fig. 13, a salt gradient solar pond feeds the pumps of an RO desalination system using ORC. A genetic algorithm was used to integrate each model to get the best design and operation parameters. The desalination plant, consisting of three pressure exchangers and 31 hybrid pressure vessels, was powered by a 0.28 MW recuperative ORC with a 54% exergy efficiency. The hybrid pressure vessel produced freshwater with a salinity of 376.6 mg/l and 2.1 kWh/m3. According to the data, desalination units in semi-arid climates need less solar pond land than in Mediterranean climates. A desalination system could provide fresh water for 73.3% of the year in a semi-arid environment, compared to 50% in a Mediterranean climate. Alirahmi and Assareh [37] examined a multigeneration energy source for hydrogen, drinking water, power, heating, cooling, and hot water production. The cycle’s primary subsystems were the steam RC, ORC, geothermal well, PTC collectors, absorption chiller, electrolyzer, and RO unit. Figure 14 shows the impact of solar intensity on the proposed system’s output power and exergy efficiency. The exergy destruction was most significant in the PTCs, absorption chiller, and PEM electrolyzer. According to weather data for Dezful City on the 17th of September, the system produced 147.42 m3/day of drinking water and 13.25 kg/day of hydrogen on the 17th of September. Moreover, the exergy efficiency was 60.56% at night, with a peak output of 296.7 kW. In addition, the overall unit cost rate was 21.9 $/GJ.

Description of the solar-driven desalination system [36]

The impact of solar intensity on output power and exergy efficiency [37]

Three kinds of desalination systems were studied based on Iran’s weather conditions. Multi-effect distillation (MED), thermal vapor compression (TVC), and reverse osmosis (RO) were studied by Makkeh et al. [38] (see Fig. 15). The heat produced in the solar collector was fed into the organic Rankine cycle (ORC) to create electricity in this unique device. As a result, the reverse osmosis unit could use the produced power from the organic Rankine cycle and an auxiliary wind turbine, and the excess energy could be supplied to the electrical grid. According to meteorological data in Chabahar City, this configuration lowered water production costs by 23%. The RO system required less energy due to the combined effect of hot water and feed water output from the MED condenser, which resulted in an energy saving of 8.9%. Moreover, combining (MED) and (TVC) systems increases the generated freshwater. Optimization demonstrated 26.2% exergy efficiency and a 3.08 US$/m3 cost of drinking water production. This hybrid model saves 52,164 tCO2/year. Ghaebi and Rostamzadeh [39] investigated two novel cogeneration systems, Kalina cycles (KC) and organic Rankine cycles (ORC), powered by a salinity-gradient solar pond (SGSP), as clarified in Fig. 16. A thermoelectric generator (TEG) integrated with an exchanger was also considered a viable device for improving system performance and generating more power using heat from the higher convective zone. The theoretical investigation for the two systems was carried out under identical conditions to provide freshwater and electricity. The energy and exergy balancing models were applied to the Urmia lake in Iran. As illustrated in Fig. 17, the results showed that when R600a was used in the ORC, the SGSP-ORC/RO system could generate net electricity and freshwater of 29.6 kW and 4 m3/h, respectively, while for the SGSP-KC/RO system, these values were 15.5 kW and 3.3 m3/h. In addition, the exergy efficiency and cogeneration-based gain-output-ratio (CGOR) for the SGSP-ORC/RO system were 47.2% and 8.3%, respectively, whereas for the SGSP-KC/RO system, they were 26.0% and 6.9%.

Illustration of the hybrid desalination process [38]

Description of the proposed system [39]

During spring and summer: a water production, b electricity production [39]

Recently, in 2021, Mir and Bicer [40] investigated the performance of the solar-pond RO-ED system (explained in Fig. 18) through (EES) software for hydroponic fertilizer generation and saltwater desalination. In their study, the waste stream from the reverse osmosis unit, rich in many beneficial ions and minerals, was sent to an electrodialysis unit, which rejected magnesium, calcium, and sulfate ions using monovalent membranes. These ions helped the plants’ growth, and the product could be used as a hydroponic fertilizer solution for farming. Mir and Bicer employed the solar pond to reduce their electricity needs by storing the solar energy in a big pool of concentrated salt water at 90 °C. The extracted thermal energy was used in an organic Rankine cycle with R113 to construct a solar-powered desalination and waste-treatment plant. A thermodynamic was applied to the investigated system, including the energy, entropy, and exergy analyses. The system was designed to be self-sufficient so the solar pond could generate the needed energy to produce 4.75 kg/s of hydroponic fertilizer and 4.52 kg/s of fresh water. The results revealed that the RO desalination system consumed 2.94 kWh/m3, while the ED system consumed only 1.5 kWh/m3. The energy efficiencies of the RO, ED, ORC, and solar pond were 42.06%, 69.97%, 19.77%, and 23.15%, respectively, while the exergy efficiencies were 27.5%, 7.35%, 50.025%, and 2.7%. The system’s overall energy and exergy efficiencies were 20% and 2.5%, respectively.

Solar-pond-aided RO-ED plant diagram [40]

At the same time, Atiz et al. [12] studied an integrated desalination system with ETC, PTC, a flash turbine, organic Rankine cycles, RO, water electrolysis, a greenhouse, and a moderate geothermal reservoir (see Fig. 19). The generation of hydrogen and electricity in an integrated system was examined in addition to the energetic and exergetic analyses. The system was analyzed thermodynamically in August in Turkey under daily solar radiation. The ETSCs and PTSCs raised the fluid temperature of medium-temperature geothermal resources to run the flash turbine and ORCs. The ETSCs and PTSCs increased the temperature of the geothermal fluid from 130 to 323.6 °C. The results declared that the system produced 1.215 kg of hydrogen, 162 kg of pure water, and 2111.04 MJ of total energy. As shown in Fig. 20, the system’s maximum energy and exergy efficiencies were 10.43% and 9.35%, respectively.

Multi-heat-driven ORC schematic diagram [12]

Energy efficiency and overall system energy [12]

Musharavati et al. [41] modeled and optimized a multigeneration plant with an ORC, RO unit, NH3-LiNO3 refrigeration, and hydrogen generation system. A parametric analysis using Matlab software showed the influence of changing major system parameters on outcomes such as total energy, exergetic efficiency, and total exergy yield. The outcomes of the analysis for propane, iso-butane, and n-octane were compared. Figure 21 shows the variation of solar radiation with exergy efficiency, net outpower, water production, and hydrogen production. Results declared that using n-octane as a working fluid increased hydrogen generation by around 150% at 800 W/m2, typical for much of the Middle East. This underscores the necessity of choosing the correct ORC working fluid. Also, optimization indicated a 30% exergy efficiency with a cost of 205.5 $/h for the proposed system.

Variation of a exergy efficiency, b net outpower, c water production, and d hydrogen production with solar radiation [41]

Tariq et al. [42] proposed a thermo-mathematical model for solar-driven steam jet ejector–based multigeneration systems through EES software. Figure 22 includes Rankine cycles, organic Rankine cycles, and RO desalination. A water-exergy nexus study compared the hot utility’s water use to two typical fossil fuels. The system was analyzed in a stand-alone and comparative framework, considering thermodynamic efficiency, exergy efficiency, global warming potential, and annual costs. A water-exergy nexus assessment compared the hot utility’s water usage versus two conventional fossil fuels. The analysis revealed that the solar collectors used 73% of the total exergy. Using R11, the suggested system has an energy cost of 0.0171 $/MWh and an energy efficiency of 57.29%. Compared to a gas-fired utility, the proposed system lowered freshwater extraction and consumption by 16 and 13 times. The system attained an exergy efficiency of 74.37% at an energy cost of 0.013 $/MWh. They concluded that the R365mfc was the optimal fluid in the ORC (see Fig. 23).

Illustration diagram of the proposed system [42]

A comparison of the proposed model with different working fluids [42]

Jaubert et al. [43] analyzed the operation of a CSP-RO-ORC. Testing on a bench-scale RO pilot revealed ideal operating conditions and alternatives to overcome the technology’s principal limitations by hybridizing with low-temperature MED. These figures were used to model a large-scale solar poly-generation facility with a hybrid RO-LTMED desalination system for desalination and parabolic trough collectors for CSP. The study looked at merging concentrated solar power (CSP) with an organic Rankine cycle (ORC) to generate power and water using a hybrid desalination process that combines low-temperature multi-effect distillation (LTMED) with reverse osmosis (RO). Various ORC design suggestions were simulated, and the ideal configuration was determined based on energetic and exergetic thermodynamic parameters and an economic evaluation utilizing two working fluids: an alkane and a green ester. Results revealed that the perfect design includes a two-stage turbine, an intermediate reheater, and a regenerator. Using ethyl butanoate as a working medium for RO units resulted in exergetic destruction by 18% and a 43% increase in thermal efficiency.

Recently, in 2022, Naminezhad and Mehregan [44] examined the performance of the PTC-ORC-RO desalination. EES software was used to investigate the effects of organic medium, solar radiation, the flow rate for solar collector field, and collector size on freshwater production, power production, and exergy destruction. The findings showed that when collector length and solar intensity rise, ORC power production, generated drinking water, and overall exergy destruction rise. The overall power production of the organic Rankine unit was raised by increasing the length of the collector module from 5 to 10 m, as was the amount of freshwater generated by the whole system and each unit. The amount of overall exergy destruction, as well as the amount of exergy destruction of distinct components, increased as the length of the collection grew. The collector component’s slope, or intensity of exergy destruction, was larger than that of other components in this scenario, thus accounting for a higher proportion of exergy destruction. The system and each unit have generated less freshwater by increasing feed water concentration. The fluid temperature for the solar field was reduced as the collector flow rate was raised, while the mass flow rate was increased, resulting in the maximum net output power of 11,000 l/min. According to the exergy study, the solar collector has the largest overall exergy destruction at 65%, as depicted in Fig. 24. On the other hand, for ORC, n-decane, toluene, n-nonane, and n-octane have maximum drinking water production, maximum ORC power, and minimum exergy destruction.

Exergy destruction rate by the system component [44]

Naminezhad and Mehregan [44] examined the energetic and exergetic performance of a unique configuration comprising a multi-effect distillation (MED) desalination system, two reverse osmosis (RO) desalination units, and a solar-driven organic Rankine cycle (ORC) (see Fig. 25). The RO unit’s high-pressure pump and the MED unit’s pumping system were powered by ORC electricity. Additionally, the heat impulse for the MED unit was generated from the waste heat of the ORC condenser. According to the findings, increasing the collector module length and solar radiation intensity causes an increase in ORC power production, supplied freshwater, and overall exergy destruction. The maximum overall output power from the ORC system was achieved at a volume flow rate of 11,000 l/min, despite a decrease in output fluid temperature as the volumetric flow rate of the collector increased. According to the exergy study, the solar collector, which serves as the system’s primary heat supply, has the system’s greatest overall exergy destruction share of 65%. Moreover, toluene, n-decane, n-nonane, and n-octane are the organic fluids with the greatest ORC powers, the most supplied freshwater supplies, and the least amount of exergy destruction for ORC, respectively.

Diagram of a solar desalination plant's hybrid ORC, RO, and MED cycle [44]

Assareh et al. [45] modeled and evaluated an intelligent hybrid energy system that consists of a thermoelectric generator, reverse osmosis unit, organic Rankine cycles, Brayton, steam Rankine, and a concentrated solar power plant, as illustrated in Fig. 26. The thermodynamic findings showed that the most critical system performance characteristics were the steam Rankine cycle pump inlet temperature, compressor pressure ratio, turbine efficiency, intake temperature, number of heliostats, and direct normal irradiance. A multi-objective evolutionary algorithm was then used to optimize the suggested system while considering system cost rate and exergy efficiency. The best cost rate and exergy efficiency were found by multi-objective optimization to be 312.3 $/h and 21.66%, respectively. Finally, a Pareto frontier was plotted, giving a series of optimum sites where costs decreased if exergy efficiency was marginally compromised, identifying an ideal position within the frontier.

Schematic of the suggested energy system [45]

It is noted that the traditional energy analysis approach is incorrect since it focuses on energy quantity while ignoring its quality. However, in some instances, this method is ineffective. Energy analysis concerns the amount of energy transferred, regardless of the form or conditions. According to the first law of thermodynamics, 1 kJ of electricity, thermal energy at 500 °C, the chemical energy of fuel, and thermal energy at 50 °C are all equivalent. However, their economic values are not equivalent in actuality. As a result, it is critical to develop a technique for evaluating thermal systems that have considered both the quantity of energy converted and the actual worth of that energy. Exergy is the term for this strategy [21]. Recent publications have emphasized the need to include quantitative and qualitative energy analysis [22, 23].

We discussed the hybridization of organic Rankine cycle (ORC) and reverse osmosis (RO) technologies, which can potentially improve the overall efficiency of energy conversion systems. However, temperature cascading is a critical consideration in the design of hybrid ORC-RO systems, as it involves using waste heat from a high-temperature process to meet the heating needs of a lower-temperature process. This can increase the system’s overall efficiency and reduce the amount of energy that would otherwise be wasted. Similarly, mass interaction between the working fluids of the two cycles can also improve the system’s overall efficiency. The energy required for separation processes can be reduced by exchanging mass between the two cycles, making the system more economically and environmentally sustainable. According to previous research on the organic ranking cycle (ORC)–driven RO desalination processes, the ORC-RO performance is influenced by various factors such as solar system design parameters, RO unit characteristics, feed water properties, climate conditions, and the working fluid in the ORC process. The ORC working fluid selection must be evaluated since different organic chemicals are accessible, and the solar field design used affects the selection. Previous studies have shown promising results for employing this technique, particularly in a place endowed with abundant solar resources or with easy access to low-grade thermal energy at reasonable prices. The studies on ORC desalination are summarized in Table 1. As seen, most of the connected studies are theoretical, except [30, 31, 35, 43], which are experimental research. It is advised to do more experimental studies to validate the numerical model.

Economical Assessment

The economic assessment of any desalination system is an essential factor in ensuring the success of the system’s methodology and its widespread use. Kosmadakis et al. [46] detected the economic assessment of RO desalination systems using solar irradiation by solar collectors, and they found that 23,500 V costs for the system of photovoltaic reverse osmosis with batteries; 22,200 V costs for the system of photovoltaic reverse osmosis without batteries; 82,000 V costs for the system of reverse osmosis Rankine with low temperature; and 186,000 V costs for the system of reverse osmosis Rankine with two stages (Table 2).

Salcedo et al. [11] studied the economic assessment of ORC of RO desalination using a numerical approach. They used solar radiation through solar collectors and reduced energy consumption by using solar energy (14%) from the entire cost in addition to natural gas (51%). They found that the specific total cost equals 1.078 €/m3, the lowest cost solution has a collector area ratio of 36 m2 per m3/h of treated freshwater, the average annual solar fraction equals 29.1%, and the cost of electricity in the RC is 0.21 €/kWh. Also, Nafey et al. [47] estimated a numerical approach to detect the economic assessment of ORC of RO desalination using solar irradiation by solar collectors. A total of 1887 m2 area from solar collectors was needed to produce energy sufficiently due to the presence of the recovery unit with a pressure exchanger. The specific total cost equals 1.078 €/m3, the lowest cost solution has a collector area ratio of 36 m2 per m3/h of treated freshwater, the average annual solar fraction equals 29.1%, and the cost of electricity in the RC is 0.21 €/kWh. Nafey et al. [48] specified the capital costs of RO desalination using solar irradiation by Flat Plate Solar Collectors, PTC, and CPC in the presence of three working fluids: butane, hexane, water, and toluene. As illustrated in Fig. 27 and in comparison to the working fluids, PTC using toluene or water was capable of saving significantly more money than butane and hexane.

Specific capital costs for various fluids and operating conditions for steam with various solar collectors [48]

Hajabdollahi et al. [49] confirmed the benefits of working fluid types such as isobutane, R123, and R245fa. During the experimental study, they found that isobutane was the best working fluid used, with 258,810 $/year benefits, followed by R245fa with 68,173 $/year benefits and R123 with 64,028 $/year benefits. Bocci et al. [31] studied the ORC of RO desalination and determined its economic assessment by a software study. They utilized a solar thermal collector. They found that it could reduce the cost by using renewable energy, thermal energy, electrical energy, and water via solar energy, avoiding using an inverter to control the flow of the pumps, and using a data logger. The project, control, and installation cost was more than 70,000 €. It could prevent the project’s high cost (about 20.000 €). One-seventh of the control and installation costs can be saved.

Schuster et al. [50] found that utilizing waste heat with low levels from other operations could be coupled via the recovery of heat wastage from micro-CHP systems or methane digestion facilities. And for that, desalinated water has consumed five to six times less energy per m3 than thermal processes. They reported a specific investment cost of 3755 and an investment cost 131 k. Ehyaei et al. [51] studied the economic assessment of RO desalination ORC through a mathematical modeling approach through CPVT and an evacuated solar collector by adding the NaClO plant for salt and hydrogen production. And they found that from 0.6 to 3.1, the NPV improved dramatically, and it is higher than five times. The NaClO plant compensates for this loss by adding to the Goswami reverse osmosis system from 0.12 to 0.39. According to the economic study, the reverse osmosis system should be integrated with the NaClO system to maximize the benefits of the system. The Goswami reverse osmosis NPV was equal to 0.6 million US$. The NPV of PP, SPP, and IRR systems were 3.1 million US dollars, 2.7 years, 2.56 years, and 0.39%, respectively.

Wang et al. [52] used R245fa and R123 as working fluids, low-level evaporation pressure, and low-level mass flow rate. They found that this type of solar collector made the system’s cost and operating pressure low. Patil et al. [53] found that the system would be the most cost-effective when using isobutane as a fluid with high CUF and thermal energy storage. The results showed that the lowest LCOE was 0.19 USD/kWh with a CUF of 0.56. In addition, S-ORC technology could improve power supply reliability through cost-effective TES and a specific capital cost of 0.934 USD/W.

To sum up, it can be concluded that the economic assessment of any desalination system is an essential factor in ensuring the success of the system’s methodology and its widespread use.

Conclusions

This research examined recent studies on solar ORC-RO plant performance augmentation and the relevance of reverse osmosis (RO) desalination facilities. The investigations were organized into four categories: RO desalination process, organic Rankine cycle (ORC), solar ORC-powered RO desalination, and economic evaluation criteria. The assessment focused on the SEC, production water cost, system efficiency, plant design, recovery ratios, and water quality as performance evaluation metrics. The main salient findings of the review are listed as follows:

-

Compared to RO, conventional desalination methods such as multi-stage flash distillation and multi-effect distillation consume too much solar energy.

-

FO has been discovered to have more excellent permeability for membrane fouling than RO, while integrated RO and FO help to improve the performance of RO, increasing efficiency and lowering energy consumption.

-

After complete development, membrane-based desalination technologies will have prospects in the market for relatively small-capacity saltwater desalination systems. Otherwise, a poor recovery rate was observed.

-

The innovations in RO technology, including membrane materials, process design, feed pretreatment, and energy recovery, have lowered the membrane cost per unit volume of water generated by more than 10 times, resulting in industrial interest in RO.

-

Solar systems with linear concentrators, such as linear Fresnel concentrators, or parabolic troughs, were suggested to achieve the maximum efficiency of the solar desalination system.

-

The ORC-RO performance is influenced by various factors such as solar system design parameters, RO unit characteristics, feed water properties, climate conditions, and the working fluid in the ORC process.

-

Evaluating how a specific collector’s peak temperature affects the solar ORC performance is suggested. This temperature influences the efficiency and heat transfer fluid and mass flow rates of the ORC working fluid.

-

Reducing power usage by 21% is possible by raising feedwater temperature by roughly 25 °C.

-

The nature of the organic working fluid influences the selection of low-grade energy sources for ORC-RO systems.

-

Various organic chemicals may be used as the ORC’s working fluid, and the solar collector design can affect this choice.

-

R290 had the cheapest desalinated cost, while n-octane in ORC exhibited the most outstanding performance.

-

The economic assessment of desalination systems is essential in ensuring the system’s methodology’s success and widespread use.

-

RO membrane technology does not produce safe drinking water or guarantee an efficient plant on its own; hence, the desalination plants required pre-treatment and post-treatment to adapt the desalination plants.

Future Recommendations/Challenges

Because of the scarcity and high cost of electricity in rural regions, RO desalination presents an extra obstacle. A further major challenge connected RO process is membrane fouling and deterioration, so additional scientific research for modified RO membranes should be investigated to examine highly stable and consistent membranes. The new adapted desalination technologies such as photovoltaic assisted reverse osmosis (PV-RO), microbial desalination cells integrated reverse osmosis (MDC-RO), batch reverse osmosis desalination, and closed-circuit reverse osmosis (CCRO) can treat seawater with less energy and fouling than RO; however, additional energy consumption and costing investigations are necessary of these technologies to be better comprehended. Finally, most of the research conducted on RO desalination is theoretical. Therefore and to validate the numerical model, it is advised to do more experimental studies.

Due to their importance to the reader for broader knowledge and understanding of the topic, sections summarizing the RO process and the difference with the forward osmosis (FO) process, the treatment processes accompanying the RO process, and the different power sources for the ORC are covered hereafter in the appendices.

Appendices

Reverse Osmosis Desalination (RO)

Desalination technologies can be used anytime as a reliable source of water. There are two types of seawater desalination procedures: membrane processes and thermal processes. The typical desalination process is based on reverse osmosis membrane technology, but it does not produce safe drinking water or guarantee an efficient plant. Hence, the desalination plants require pre-treatment and post-treatment to adapt to the desalination plants.

According to the scarcity of freshwater resources, developing non-conventional resources such as water desalination technology seems to be the most essential goal for the whole world [54]. Desalination technologies are categorized based on their energy source, which might be thermal, electrical, mechanical, or chemical. Further categorization is based on the desalination process, which includes evaporation–condensation, filtering, and crystallization [55], as shown schematically in Fig. 28.

Stages of RO process according to water purification [55]

To improve the performance of reverse osmosis plants, many combinations with some recent technologies have been studied and applied to increase efficiency and reduce the energy used, as shown in Table 3.

The recommendations extracted from previous studies mentioned in the above table emphasize that some enhancements, compound units, and environmentally friendly technologies could be the best choices to maximize the overall efficiency of the desalination process, such as using compound parabolic concentrators, PV panels, trigeneration, and poly-generation systems with ORC sub-systems and batch RO process. The previously indicated development process is a viable approach for future research of solar-ORC technology and for advancing sustainable and renewable energy systems in general.

Forward osmosis (FO) has been demonstrated to be a reliable low-pressure-membrane extraction technique that effectively denies various pollutants, resulting in high-quality diluted seawater appropriate for advanced desalination [59]. In the forward osmosis (FO) process, a saline solution having greater osmotic pressure on one side of a selective membrane sucks water from the influent with a smaller osmotic pressure on the other side of the membrane [54]. While reverse osmosis (RO) is a procedure that uses much energy, the FO process only requires a minimum amount of electrical energy to extract substances via membranes [60].

Therefore, FO can be used as a stand-alone desalination method or as a pretreatment for reverse osmosis (RO) or other desalination procedures [61]. Table 4 shows the advantages and disadvantages of osmosis and reverse osmosis. The FO-RO hybrid could be a suitable development for conventional desalination processes to overcome technical limitations over stand-alone (RO) or (FO) desalination to become economically attractive [62].

The energy consumption of RO is gaining attention, as it must be reduced to be qualified as a sustainable technology employing renewable energy sources such as hydropower, wind, and the sun [64]. Several investigators examined the energy sources of RO technology from both ecological and economic aspects. Examples are the increasing expense of fossil fuels and the adverse impacts of greenhouse gas pollutants [65, 66]. The investigators have provided alternatives and hybrid technologies such as capacitive deionization, battery desalination, thermal vapor compression, deep seawater cooling, and desalination to save energy consumption [67, 68].

Renewable energy systems (clean energy) such as geothermal, hydroelectricity, biomass energy, salinity gradient energy, photovoltaic cells, and wind power are recommended to decrease the energy intensity [69,70,71]. To reduce energy consumption problems, alternative desalination technologies are being developed, such as forward osmosis (FO), capacitive deionization, battery desalination, and thermal vapor compression. FO can treat seawater at lower energy consumption and fouling than RO; also, hybrid systems have shown to be a very effective and more resilient process than stand-alone RO. On the other side, using an ORC is a viable renewable energy solution because of the high compliance between the operating temperatures of solar thermal collector devices and the temperature requirements of the cycle [13].

Popular solar-ORC systems, including flat-plate collectors (FPCs), compound parabolic collectors (CPCs), evacuated-tube solar collectors (ETCs), parabolic trough concentrators (PTCs), and linear Fresnel reflectors (LFRs), parabolic solar dish collectors (SDCs), and other hybrid systems [58], have proven to be more efficient and cost-effective.

The Treatment Processes Accompanying RO

The desalination process, which is based on stand-alone RO membrane technology, does not ensure safe drinking water or plant efficiency [72]. Most RO plants follow the same type of layout, as shown schematically in Fig. 28. They can be divided into three main sections: pretreatment, treatment using RO membrane, and post-treatment. All essential treatment steps before reverse osmosis are included in the pre-treatment. The pre-treatment process affects plant life, plant productivity, and the amount of chemical cleaning and required membrane replacement [5]. Post-treatment processes are necessary to make the water appropriate for usage after the reverse osmosis process [73].

Pre-treatment

It is vital to pre-treat input water in RO to reduce harmful contamination, as untreated water results in limited RO membrane durability, costly maintenance, and short operating time [74]. Seawater chlorination is a costly approach to avoid biological contamination. Because chlorine oxidizes the membrane material, only 1000 parts per million of hydrogen may be allowed. Chlorine may be extracted using granulated activated carbon, whereas particles and colloids can be removed using the traditional coagulation procedure and deep granular filtration for low-turbidity water [75]. Further stages, such as flocculation and sedimentation, are performed in the case of exceptionally turbid shallow seawater [76]. Ultrafiltration is a non-traditional pretreatment for particles and colloids, in addition to an antiscalant solution dosed before reverse osmosis membranes to spread calcium carbonate and sulfate precipitates and minimize their variation [77, 78]. Combining several pre-treatments raises the system’s capital costs but saves operational expenses [75].

Treatment

The reverse osmosis process, illustrated in Fig. 28, comprises a high-pressure pump, an energy recovery device, and reverse osmosis membranes. Spiral wound thin-film composite membranes are the most popular RO membrane used in desalination. They are made out of a flat sheet wrapped in a spiral-wound module [79]. The membranes are connected in a series of pressure vessels, which are then placed in parallel to meet the membrane’s flow and pressure requirements and the plant’s output needs. Permeate flow, applied pressure, salinity, and temperature determine the total number of membranes and pressure vessels required and their arrangement [80].

Post-treatment

Membrane techniques affect saline water’s mineral and organic content because it is ineffective at eliminating dissolved carbon dioxide. Furthermore, RO is a non-selective process, meaning if the input water is lower in calcium and magnesium than sodium, the permeate water will have deficient calcium and magnesium concentrations [81, 82].

Based on the above, Duranceau et al. [83] also confirmed that the RO process must be further conditioned before being sent to users by neutralization/remineralization, defined as the post-treatment stage. Low mineralized water has few negative consequences [84] because of the high corrosion potential and risks of ischemic heart disease and cerebrovascular illness due to dietary deficit. The typical remineralization process can be summarized according to [73, 85] as organic fouling, mineral fouling, blend with clarified feed water plus pH neutralization, the addition of CaCl2 + NaHCO3 and CO2 addition + Na2CO3 + calcite limestone (CaCO3, MgO) percolation.

ORC

Organic Rankine cycle (ORC) technology has the potential to harness lower-temperature sources of heat like waste heat, biomass power plants, geothermal plants, solar thermal, and wind thermal energy. The ORC is a promising method of converting medium- and low-temperature heat into electricity. The ORC process operates similarly to a Clausius–Rankine steam power plant, except it employs an organic working fluid instead of water. Recent years have seen much interest in ORC as a mechanical energy–generating method because of its potential incorporation in upcoming distributed generating systems and its ability to utilize low-temperature heat sources better than traditional steam power cycles. One of its benefits is the ability to adapt the ORC operation to the source of heat and heat sink parameters by choosing from a wide range of working fluids [86].

Waste Heat Recovery ORC

Water as the working fluid cannot achieve great cycle efficiency. Therefore, a new type of working fluid should be utilized for waste heat recovery in the thermodynamic cycle. Low latent heat and high sensible heat are required in the working fluid. Only organic working fluids match both of the above criteria [87]. The ORC is a well-known technique that can be considered helpful in converting low-temperature heat to mechanical energy. The simple ORC could be regarded as a valuable technology for waste heat recovery because of its simplicity, reliability, and versatility. Engine waste heat is one of the most common energy sources for powering ORC systems, and many studies have been conducted in this area [88].

He et al. [87] detailed a steady-state experiment, energy balance, and analysis of exergy in the exhaust gas to maximize waste heat recovery from an ICE. For ICE waste heat recovery, the use of a coupled thermodynamic cycle was proposed. This coupled thermodynamic cycle consisted of the ORC, which recovered waste heat from lubricant and high-temperature exhaust gases, and the Kalina, which recovered waste heat from low-temperature cooling water. The efficiency of this coupled thermodynamic cycle was analyzed, and recommendations were made for optimal working fluids in high-temperature ORC.

Chen et al. [89] proposed a novel cascade ORC system to recover waste heat from diesel engines. They stated that the engine’s maximum thermal efficiency had grown from 45.3 to 49.5% and that the BSFC could be lowered from 185.6 to 169.9 g/kWh. The effect of ORC working fluid on engine waste heat recovery was studied by Wang et al. [90]. The efficient fluids R11, R141b, R113, R245fa, R245ca, R236ea, R141b, R123, and Butane were developed for use in ORC. The data showed that when comparing thermodynamic properties, R11, R141b, R113, and R123 performed marginally better than the rest. However, when it came to recovering waste heat from engines, the most environmentally friendly operating fluids were R245fa and R245ca. Extracting waste heat from a compressed natural gas (CNG) engine using a dual-loop ORC system was analyzed by Yang et al. [91]. Based on their results, the energy efficiency of the dual loop ORC system was anywhere from 8.79 to 10.17%. Maximum net power production from the dual-loop ORC system under engine-rated conditions was 23.62 kW. Yu et al. [92] explored a novel cascaded steam/organic Rankine cycle to recover useful heat from the exhaust of a heavy-duty diesel engine. The results indicated that the novel system has the potential to generate 12.7 kW of output power, which is 5.6% more power than a regular diesel engine. Mansouri et al. [93] recently presented a novel hybrid power and desalination system. To power the ORC, the gas turbine’s byproduct heat was diverted to the RO facility. The model’s primary objectives were maximizing economic benefit (year profit of the system) while minimizing CO2 emissions per unit of desalinated water.

Biomass Power Plant ORC

Biomass has been studied extensively because of its added social, economic, and environmental benefits, especially when combined with using organic by-products [94]. A bottoming ORC plant and an externally fired gas turbine (EFGT) powered by biomass (wood chips) made up a novel solar and biomass hybrid power-generating system that was presented by Pantaleo et al. [94] in 2020. The utilization of thermal energy storage (TES) to recover heat from EFGT exhaust gases and the integration of heat from a parabolic-trough collectors (PTCs) field with molten salts as a heat-transfer fluid (HTF) were the two most significant new developments (see Fig. 29). The heating demand profile determined where the TES’s transported heat would be most helpful to the ORC plant and thermal end-users. The electric output of the ORC plant was 700 or 800 kW, depending on the presence or absence of the solar hybridization arrangement, while the thermal input and electrical output of the EFGT were, respectively, 9 MW and 1.3 MW. The proposed system’s levelized energy cost (LCE) was close to 140 Eur/MWh.

The proposed plant’s power blocks and energy flows [94]

Karellas and Braimakis [95] examined thermodynamics and its economic advantages for an ORC–VCC trigeneration system based on biomass and solar energy, as shown in Fig. 30. They reported that while using R245fa as a working medium and an evaporation temperature of 90 °C, the ORC’s thermal efficiency was maximized (ƞth = 5.5%). The biomass boiler’s exergy efficiency at the entire load operation was around 7%.

The idea of hybrid-powered trigeneration [95]

The DSS software tool for optimizing operating decisions and diagnostics of a biomass-fired cogeneration plant with an ORC unit was presented by Kalina et al. [96]. Simulations revealed that the energy conversion efficiency was highly sensitive to load factor, biomass water content, and DHS network water temperature. Khanmohammadi et al. [97] studied the thermodynamics and economics of combining a gas turbine and an organic Rankine cycle with a biomass gasifier. Regardless of the system’s overall cost rate as a criterion function, the result of multi-objective optimization showed that the system’s exergy efficiency is 15.6%, which could be increased to 17.9% in the optimal state. Khalid et al. [98] investigated a multigeneration system’s energy and energy efficiency powered by solar and biomass energies. The developed system using biomass and solar energy reached overall energy and exergy efficiencies of 66.5% and 39.7%, respectively. When the biomass system was used alone, the energy and exergy efficiencies decreased to 64.5% and 37.6%, and when the solar system was used alone, they reached only 27.3% and 44.3%. On the other side, Mouaky and Rachek [99] explored the thermodynamic and thermo-economic performance of a unique hybrid solar/biomass poly-generation system for the case of a rural village in a semi-arid environment. The annual findings of the exergy analysis are summarized in Fig. 31.

The annual findings of the exergy analysis [99]

Geothermal Plants ORC

With the global trend of using clean energy, researchers are directed to study different types, such as geothermal energy, a clean and sustainable energy source that emits little or no pollutants into the atmosphere. The ORC converts geothermal energy to electrical energy, which powers the electrolyzer and desalination unit, which produces fresh water and hydrogen. Heberle et al. [100] investigated the exergy-based working fluid choice of a geothermal-driven ORC for combined heat and power generation at a temperature level of 450 K. The results suggest that, compared to power generation, a geothermal power plant’s efficiency may be greatly boosted by combining heat and power generation. Also, an RO desalination unit and a geothermal-driven dual fluid ORC with a PEM electrolyzer were examined by Aali et al. [101]. The impacts of geothermal water temperature on the proposed cogeneration system’s exergetic performance were investigated, and the exergy efficiency of 53.32% was calculated.

From an economic point of view, studies have confirmed the advantage of using geothermal energy in reducing costs, similar to the one proposed by Kianfard et al. [102]. They studied the geothermal-driven dual fluid organic Rankine cycle (ORC), reverse osmosis (RO) desalination unit, and proton exchange membrane (PEM) electrolyzer. According to the exergo-economic study, distilled water and produced hydrogen had costs of 32.73 cents/m3 and 4.257 $/kg, respectively, while the unit exergy cost of 1.3 $/GJ for geothermal hot water.

Solar Thermal Power ORC

Kosmadaki et al. [103] used the solar organic Rankine cycle as an alternative thermal desalination system. The system which has been used is illustrated in Fig. 32. The procedure can be summarized as follows: the high-temperature solar organic Rankine cycle converts heat produced by solar collectors into mechanical energy. The refrigerant R-245fa was chosen for this cycle because it has suitable thermodynamic parameters in the specified temperature range (critical point, T = 154.05 °C, P = 36.4 bar) and is environmentally friendly. Based on this system, they found that desalinated water production increased by roughly 260%, while efficiency climbed from 7 to 11.8%.

Simplified diagram of the system [103]

Nafey and Sharaf [48] designed and ran their calculations on the MatLab/Simulink platform. As shown in Fig. 33, the thermal solar collectors (flat plate solar collectors, compound parabolic concentrators, or parabolic trough collectors) provide the heat input, the expansion turbines generate the work, the condenser units reject the heat, the pump units circulate the fluid, and the RO units purify the water. The RO desalination plant in Sharm El-Shiekh, Egypt, served as the basis for the unit specifications used in this research. It examines and contrasts a number of different types of working fluids. Based on the solar collector’s operating temperature and the working fluid’s thermophysical properties, butane, hexane, and toluene are all suitable options. Energy efficiency, thermal efficiency, total exergy destruction, and specific capital cost were used to assess the direct vapor generation (DVG) process; the suggested model showed good validity compared to the existing literature.

A schematic illustration of the solar Rankine cycle components for DVG [48]

The energy, exergy, economic, and environmental effects of an ORC and solar collector-powered reverse osmosis system were studied by Mokhtari et al. [33]. As an organic fluid in ORC, R290 had a 76% optimum unit recovery and a desalination cost of US$0.568 per cubic meter of water. Using the thermal heat of a solar pond as a low-cost solar collector, Namin et al. [104] performed thermodynamic and thermoeconomic studies of three novel cascade systems based on ORC and KC. Maximum net power, power efficiency, and exergy efficiency were found in the ORC/ORC/RO system, along with the lowest SUCP (sum unit cost of product) and total exergy destruction. Figure 34 shows how various parts of the system affect the cost–benefit analysis.

The proposed hybrid power and desalination systems’ various components all contribute to the overall cost balance [104]

Makkeh et al. [105] combined the advantages of a membrane-thermal desalination plant with an integrated system that produces power and freshwater using parabolic trough collectors and wind turbines in conjunction with the electrical grid. The heat generated in the parabolic trough collector was transported into the organic Rankine cycle (ORC) to generate power in this unique device. Freshwater production’s exergy efficiency and cost were 26.2% and 3.08 US$/m3, respectively.

Abbreviations

- BSFC:

-

Brake-specific fuel consumption

- CCRO:

-

Closed-circuit reverse osmosis

- CHP:

-

Combined heat and power

- CNG:

-

Compressed natural gas

- CPC:

-

Compound parabolic collectors

- CSP:

-

Concentrated solar power

- DSS:

-

Dahua security software

- DVG:

-

Direct vapor generation

- ED:

-

Electro dialysis

- EES:

-

Energy equation solver

- EFGT:

-

Externally fired gas turbine

- ETC:

-

Evacuated-tube concentrators

- ETSC:

-

Evacuated-tube solar collectors

- FO:

-

Forward osmosis

- FPC:

-

Flat-plate collector

- HDD:

-

Humidifier dehumidifier desalination

- HTF:

-

Heat-transfer fluid

- ICE:

-

Internal combustion engine

- IRR:

-

Internal rate of return

- KC:

-

Kalina cycles

- LCE:

-

Levelized cost of energy

- LFR:

-

Linear Fresnel reflectors

- LTMED:

-

Low-temperature multi-effect distillation

- MDC-RO:

-

Microbial desalination cells integrated reverse osmosis

- MED:

-

Multi-effect distillation

- MSF:

-

Multi-stage flash

- NPV:

-

Net present value

- ORC:

-

Organic Rankine cycle

- PEM:

-

Proton exchange membrane

- PSDC:

-

Parabolic solar dish collectors

- PTC:

-

Parabolic trough concentrators

- PTSC:

-

Parabolic trough solar collector

- PV-RO:

-

Photovoltaic-assisted reverse osmosis

- RO:

-

Reverse osmosis

- SEC:

-

Specific energy consumption

- SGSP:

-

Salinity-gradient solar pond

- SORC-RO:

-

Solar organic ranking cycle-powered reverse osmosis

- SORC-RO:

-

Supercritical organic Rankine reverse osmosis

- SUCP:

-

Sum unit cost of product

- SWRO:

-

Sea water reverse osmosis

- TDS:

-

Total dissolves solids

- TES:

-

Thermal energy storage

- TVC:

-

Thermal vapor compression

References

Feria‐Díaz JJ, Correa‐Mahecha F, López‐Méndez MC, Rodríguez‐Miranda JP, Barrera‐Rojas J. Recent desalination technologies by hybridization and integration with reverse osmosis: a review. Water 2021, Vol 13, Page 1369 2021;13:1369. https://doi.org/10.3390/W13101369.

Ashraf HM, Al-Sobhi SA, El-Naas MH (2022) Mapping the desalination journal: a systematic bibliometric study over 54 years. Desalination 526:115535. https://doi.org/10.1016/j.desal.2021.115535

Ritt CL, Stassin T, Davenport DM, DuChanois RM, Nulens I, Yang Z et al (2022) The open membrane database: synthesis–structure–performance relationships of reverse osmosis membranes. J Memb Sci 641:119927. https://doi.org/10.1016/J.MEMSCI.2021.119927

Wang Z, Zhang Y, Wang T, Zhang B, Ma H (2021) Design and energy consumption analysis of small reverse osmosis seawater desalination equipment. Energies 14:8. https://doi.org/10.3390/EN14082275

Zapata-Sierra A, Cascajares M, Alcayde A, Manzano-Agugliaro F (2021) Worldwide research trends on desalination. Desalination 519:115305. https://doi.org/10.1016/J.DESAL.2021.115305

Alsarayreh AA, Al-Obaidi MA, Ruiz-García A, Patel R, Mujtaba IM (2021) Thermodynamic limitations and exergy analysis of brackish water reverse osmosis desalination process. Membranes (Basel) 12:1. https://doi.org/10.3390/MEMBRANES12010011

Saleem MW, Abbas A, Asim M, Uddin GM, Chaudhary TN, Ullah A (2021) Design and cost estimation of solar powered reverse osmosis desalination system. Adv Mech Eng 13:1–11. https://doi.org/10.1177/16878140211029090

Kensara M, Dayem AMA, Nasr A (2021) Reverse osmosis desalination plant driven by solar photovoltaic system-case study. Int J Heat Technol 39:1153–63. https://doi.org/10.18280/IJHT.390413

Chougradi A, Zaviska F, Abed A, Harmand J, Jellal JE, Heran M (2021) Batch reverse osmosis desalination modeling under a time-dependent pressure profile. Membranes (Basel) 11:1–20. https://doi.org/10.3390/MEMBRANES11030173

Li S, Duran K, Delagah S, Mouawad J, Jia X, Sharbatmaleki M (2020) Energy efficiency of staged reverse osmosis (RO) and closed-circuit reverse osmosis (CCRO) desalination: a model-based comparison. Water Sci Technol Water Supply 20:3096–3106. https://doi.org/10.2166/WS.2020.208

Salcedo R, Antipova E, Boer D, Jiménez L, Guillén-Gosálbez G (2012) Multi-objective optimization of solar Rankine cycles coupled with reverse osmosis desalination considering economic and life cycle environmental concerns. Desalination 286:358–371. https://doi.org/10.1016/J.DESAL.2011.11.050

Atiz A, Karakilcik H, Erden M, Karakilcik M (2021) The integration of parabolic trough solar collectors and evacuated tube collectors to geothermal resource for electricity and hydrogen production. Int J Hydrogen Energy 46:29027–29037. https://doi.org/10.1016/j.ijhydene.2020.09.266

Li C, Besarati S, Goswami Y, Stefanakos E, Chen H (2013) Reverse osmosis desalination driven by low temperature supercritical organic rankine cycle. Appl Energy 102:1071–1080. https://doi.org/10.1016/j.apenergy.2012.06.028

Shalaby SM, Sharshir SW, Kabeel AE, Kandeal AW, Abosheiasha HF, Abdelgaied M et al (2022) Reverse osmosis desalination systems powered by solar energy: preheating techniques and brine disposal challenges – a detailed review. Energy Convers Manag 251:114971. https://doi.org/10.1016/j.enconman.2021.114971

Shalaby SM (2017) Reverse osmosis desalination powered by photovoltaic and solar Rankine cycle power systems: a review. Renew Sustain Energy Rev 73:789–797. https://doi.org/10.1016/j.rser.2017.01.170

Khaleel OJ, Basim Ismail F, Khalil Ibrahim T, Bin Abu Hassan SH (2022) Energy and exergy analysis of the steam power plants: a comprehensive review on the classification, development, improvements, and configurations. Ain Shams Eng J 13:101640. https://doi.org/10.1016/j.asej.2021.11.009

Dincer I, Rosen MA (2021) Chapter 2 - Exergy and energy analyses. In: Dincer I, Rosen MA (eds) Exergy, 3rd edn. Elsevier, pp 23–35. https://doi.org/10.1016/B978-0-12-824372-5.00002-6

Mitrović DM, Stojanović BV, Janevski JN, Ignjatović MG, Vučković GD (2018) Exergy and exergoeconomic analysis of a steam boiler. Therm Sci 22:S1601–S1612. https://doi.org/10.2298/TSCI18S5601M

Ahmadi GR, Toghraie D (2016) Energy and exergy analysis of Montazeri Steam Power Plant in Iran. Renew Sustain Energy Rev 56:454–463. https://doi.org/10.1016/j.rser.2015.11.074

Singh OK (2016) Assessment of thermodynamic irreversibility in different zones of a heavy fuel oil fired high pressure boiler. J Therm Anal Calorim 123:829–840. https://doi.org/10.1007/s10973-015-4959-4

Zabihian F (2015) Educating undergraduate mechanical engineering students about exergy analysis paper presented at 2015 ASEE Annual Conference & Exposition. Seattle, Washington. https://doi.org/10.18260/p.23908

Ng KC, Burhan M, Chen Q, Ybyraiymkul D, Akhtar FH, Kumja M et al (2021) A thermodynamic platform for evaluating the energy efficiency of combined power generation and desalination plants. Npj Clean Water 4:1–10. https://doi.org/10.1038/s41545-021-00114-5

Ng KC, Shahzad MW, Son HS, Hamed QA (2017) An exergy approach to efficiency evaluation of desalination. Appl Phys Q 110(18)

Delgado-Torres AM, García-Rodríguez L (2012) Design recommendations for solar organic Rankine cycle (ORC)-powered reverse osmosis (RO) desalination. Renew Sustain Energy Rev 16:44–53. https://doi.org/10.1016/j.rser.2011.07.135

Ukueje WE, Abam FI, Obi A (2022) A perspective review on thermal conductivity of hybrid nanofluids and their application in automobile radiator cooling. J Nanotechnol;2022. https://doi.org/10.1155/2022/2187932.

Deniz E (2015) Solar-powered desalination. IntechOpen, London, UK, pp 89–124

Peñate B, García-Rodríguez L (2012) Seawater reverse osmosis desalination driven by a solar organic Rankine cycle: design and technology assessment for medium capacity range. Desalination 284:86–91. https://doi.org/10.1016/j.desal.2011.08.040

Ibarra M, Rovira A, Alarcón-padilla DC, Zaragoza G, Blanco J (2014) Performance of a 5 kW e solar-only organic Rankine unit coupled to a reverse osmosis plant. Energy Procedia 49:2251–2260. https://doi.org/10.1016/j.egypro.2014.03.238

Xia G, Sun Q, Wang J, Cao X, Yu Y, Wang L (2015) Theoretical analysis of a reverse osmosis desalination system driven by solar-powered organic Rankine cycle and wind energy. New Pub Balaban 53:876–886. https://doi.org/10.1080/19443994.2014.927185

Igobo ON, Davies PA (2014) Low-temperature organic Rankine cycle engine with isothermal expansion for use in desalination. New Pub Balaban 55:3694–3703. https://doi.org/10.1080/19443994.2014.940657

Bocci E, Villarini M, Vecchione L, Sbordone D, Di Carlo A, Dell’Era A (2015) Energy and economic analysis of a residential solar organic Rankine plant. Energy Procedia 81:558–568

Geng D, Du Y, Yang R (2016) Performance analysis of an organic Rankine cycle for a reverse osmosis desalination system using zeotropic mixtures. Desalination 381:38–46. https://doi.org/10.1016/j.desal.2015.11.026

Mokhtari H, Ahmadisedigh H, Ebrahimi I (2016) Comparative 4E analysis for solar desalinated water production by utilizing organic fluid and water. Desalination 377:108–122. https://doi.org/10.1016/j.desal.2015.09.014

Sun Q, Wang J, Zhao P, Dai Y (2017) Thermoeconomic analysis and optimization of a reverse osmosis desalination system driven by ocean thermal energy and solar energy. Desalin. Water Treat. 77:194–205

Igobo ON, Davies PA (2018) Isothermal Organic Rankine Cycle (ORC) driving Reverse Osmosis (RO) desalination: experimental investigation and case study using R245fa working fluid. Appl Therm Eng 136:740–746. https://doi.org/10.1016/j.applthermaleng.2018.02.056

El Mansouri A, Hasnaoui M, Amahmid A, Hasnaoui S (2020) Feasibility analysis of reverse osmosis desalination driven by a solar pond in Mediterranean and semi-arid climates. Energy Convers Manag 221:113190. https://doi.org/10.1016/j.enconman.2020.113190

Alirahmi SM, Assareh E (2020) Energy, exergy, and exergoeconomics (3E) analysis and multi-objective optimization of a multi-generation energy system for day and night time power generation - case study: Dezful city. Int J Hydrogen Energy 45:31555–31573. https://doi.org/10.1016/j.ijhydene.2020.08.160

Ali S, Ahmadi A, Esmaeilion F, Ehyaei MA (2020) Energy, exergy and exergoeconomic optimization of a cogeneration system integrated with parabolic trough collector-wind turbine with desalination. J Clean Prod 273:123122. https://doi.org/10.1016/j.jclepro.2020.123122

Ghaebi H, Rostamzadeh H (2020) Performance comparison of two new cogeneration systems for freshwater and power production based on organic Rankine and Kalina cycles driven by salinity-gradient solar pond. Renew Energy 156:748–767. https://doi.org/10.1016/j.renene.2020.04.043

Mir N, Bicer Y (2021) Solar-pond assisted reverse osmosis-electrodialysis system for seawater desalination and hydroponic fertilizer solution production. Energy Sources, Part A Recover Util Environ Eff 00:1–20. https://doi.org/10.1080/15567036.2021.2008060

Musharavati F, Khanmohammadi S, Mansir IB (2021) ScienceDirect Design, exergy analysis, and optimization of a hydrogen generation / storage energy system with solar heliostat fields and absorption-ejector refrigeration system. Int J Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2021.10.087