Abstract

In this study, the age-dependent splitting and flexural tensile strength have been investigated by incorporating the various percentages of fly ash in the plain concrete mixes. The partial replacement of cement by fly ash was varied from 0 to 60% on an equal weight basis. Standard concrete specimens were cast for measuring splitting and flexural tensile strength at different ages, i.e., 7, 28, 56, 90, 150, and 180 days, for all plain and fly ash concrete mixes. Experimental results show that the fly ash produced a significant effect on the tensile strength of concrete mixes. It has been observed that the fly ash concrete mixes gain considerable tensile strength with respect to age beyond 28 days. In the low-calcium fly ash concrete mixes, the rate of development of tensile strength from 28 to 180 was observed higher in comparison with the plain concrete mixes. The assessment of the existing models for the estimation of age-dependent tensile strength recommended by design codes and researchers with experiments has also been done on various mixes of plain and fly ash concrete. New models to predict the age-dependent splitting and flexural tensile strength of concrete having different percentages of fly ash are proposed. The present experimental and analytical study will be helpful for the designers and practicing engineers for fixing preliminary dimensions of reinforced and prestressed concrete members and mix proportioning of low-calcium fly ash concrete mixes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The tensile strength of concrete plays an important role in the performance of the reinforced concrete structures. The deflection and flexural reinforcement in reinforced concrete (RC) structures are controlled by the tensile strength of concrete. It prevents cracking in the concrete structures, thereby increasing the serviceability of flexural elements [1]. In the past few decades, the use of high content of fly ash (FA) in the concrete industry has increased up to a greater extent. The contribution of FA produces some positive results in the construction industry by reducing greenhouse gases emission and creates various environmental and economic benefits. It advances the durability of concrete, reduces the overall cost of the structure and water demand, minimizes the various types of shrinkages in the concrete, and protects against reinforcement corrosion, sulfate attack, and alkali-silica expansion [2]. Sustainable construction can be achieved if the percentage replacement of cement by fly ash is 50% or more in the concrete mix and the water–cement ratio should be kept low in order to achieve the required strength for structural application [3, 4]. The concrete made with high-content fly ash is believed to be more crack resistant than the conventional concrete because of the low content of cement and the low water–cement (w/c) ratio [5]. Several studies have been carried out on high-volume fly ash (HVFA) concrete owing to the pozzolanic behavior of fly ash focusing on long-term strength development.

Literature review

Past studies on fly ash (FA) concrete mixes reported that the tensile strength of concrete was influenced by the types of concrete and its compositions used in making the concrete such as mineral admixture [6, 7]. Partial replacement of cement with fly ash is usually done on a weight basis, and the mass replaced by cement is the same as that of the mass of fly ash. The past researches show that by increasing the percentages of FA in the concrete mixes, various strengths like compressive, tensile, and elastic modulus of concrete are decreased, especially during the initial age (i.e., up to 28 days) [8, 9]. Previous studies also show that the high content of FA in the concrete has significantly lower initial strength in comparison with cement concrete due to the slower rate of pozzolanic response in comparison with hydration of cement [10, 11]. Higher strength in FA concrete can be achieved by reducing the w/c ratio. Many researchers have shown that similar or higher strength in FA concrete can be obtained by decreasing the w/c ratio and the use of superplasticizer [12,13,14]. Dragas et al. [15] conducted experiments to determine the time-dependent properties of FA concrete by partial replacement of cement and fine aggregate with fly ash varying from 50 to 70%. They concluded that the compressive and tensile strength of high-volume fly ash (HVFA) concrete increased with time. In another study, the mechanical properties of fly ash concrete with steel fiber have been investigated by Singh et al. [16]. The optimum dosage of steel fibers and partial replacement of cement with fly ash in concrete to get maximum flexural strength were found as 2% and 10%, respectively. Hashmi et al. [17] conducted an experimental and analytical investigation to find the flexural performance of HVFA concrete. It was observed that the optimum behavior of concrete can be achieved at 40% cement replacement by fly ash. Wee et al. [18] observed that the various strengths such as compressive and tensile strengths are influenced by various types of mineral admixtures. Yoshitake et al. [19] conducted experimental findings on direct and splitting tensile strength of 50% FA concrete and observed that high-volume FA concrete attains equal or greater tensile strength as that of normal concrete. Siddique and Khateeb [20] performed an experimental investigation on the tensile strength of FA concrete and observed that splitting and flexural tensile strength of FA concrete was enhanced by 15–20%. Mimura et al. [21] conducted research to know the characteristics of bond and uniaxial tensile strength on the prismatic concrete specimens and observed that Young’s modulus in tension was more than Young’s modulus in compression. Yoshitake et al. [22] proposed an expression to predict the early-age tensile Young’s modulus of FA-based concrete. A good agreement was obtained between the proposed model and the experimental results. Swaddiwudhipong et al. [23] performed the uniaxial tension test on ground granulated blast furnace slag (GGBFS) and pulverized FA to know the effect of mineral admixture on compressive and tensile properties of concrete. It was found that the tensile strength is an independent property of concrete that does not depend on compressive strength. Zhang et al. [24] reported the increased dynamic splitting tensile strength of concrete when fly ash was added to the concrete. Sahoo et al. [25] observed significant improvement in the flexural and splitting tensile strength of fly ash-based concrete. Rao and Rao [26] carried out experimental investigations on the M30 grade of concrete with different percent replacements of cement by fly ash. It was observed that 30% of FA content concrete showed good tensile strength. Overall, the literature revealed that in some cases, the tensile strength increases by using mineral admixtures such as fly ash but in some investigations, it is also observed that the FA decreases the properties of concrete in tension.

From the past studies carried out by different researchers into the effect of FA on the tensile behavior of concrete, it has been revealed that no definite trend is observed on the effect of FA in the development of tensile strength of concrete due to limited experimental work and lack of analytical solutions. Siddique [27, 28] and Mehta [29] did some experimental investigations on age-dependent splitting and flexural tensile strength of class F fly ash concrete but no proposed models to predict the age-dependent tensile strength for different percentages of fly ash have been developed so far. Shariq et al. [30] also reported that the limited investigations have been performed experimentally and analytically on the age-dependent tensile strength of mineral admixture-based concrete. Therefore, in the present research work, a detailed experimental and analytical investigation has been carried out to study the splitting and flexural tensile strength of concrete prepared with different percentages of FA (0% to 60%) at the ages of 7, 28, 56, 90, 150, and 180 days. Three different percent replacements of cement by fly ash were considered, i.e., 25%, 40%, and 60%, on an equal weight basis. As per IS 1489 [31], the percentage of fly ash as a partial replacement of cement in concrete shall be used up to 35%. In the present study, 25% and 40% replacement can be used for ordinary reinforced and prestressed concrete works, and focus is also given on the use of high volumes of fly ash (60%) in concrete to achieve sustainable concrete construction. Hashmi et al. [17] studied the elastic behavior of reinforced concrete beams and slab by making concrete with the partial replacement of cement with 25%, 40%, and 60% of fly ash. Therefore, based on the available literature and design codes, these percent replacements have been taken to investigate the tensile behavior of HVFA concrete. The novelty aspect includes the determination of the long-term age effect of the high content of low-calcium fly ash in concrete on the tensile strength by proposing different mathematical models for the prediction of flexural and splitting tensile strength of concrete at any age and at any percent of FA in concrete for the given 28-day compressive strength of plain concrete.

Experimental program

Material properties

The basic properties of the concrete mix ingredient have been confirmed to Indian standards and code specifications. The mix ingredient includes cement, low-calcium fly ash, fine and coarse aggregates, and water. The 43-grade ordinary Portland cement with its properties in compliance with IS 4031 [32] and IS 8112 [33] has been used in the present investigation. The low-calcium FA was procured from Harduaganj Power Station, India, and stored and covered with airtight polythene sheets. FA used in the present study confirmed the specifications as per IS 3812 [34]. Energy-dispersive X-ray spectroscopy (EDS) analysis was done to know the composition of FA and chemical characterization. The technique uses the principle of electromagnetic emission spectrum which states that each element has a unique atomic structure, thereby giving a unique set of peaks. Results obtained by EDS analysis are shown in Fig. 1. It is found that fly ash used in the experimental investigation has a very low content of calcium and a high concentration of carbon and oxygen with relatively less concentration of aluminum and silicon. Lesser amounts of the elements of potassium, titanium, and iron were also observed in the fly ash.

The SEM analysis has also been carried out on all the mixes of plain and fly ah concrete to know the microstructure of the concrete. It helps in understanding the morphology of the material and the distribution of fly ash and cement particles in the mix along with its bonding characteristics with the aggregates. The SEM images of different percentages of fly ash concrete are shown in Fig. 2. The plain concrete specimens have a compact internal structure with a minimum number of voids, and the aggregates are tightly bound with the cement paste as presented in Fig. 2a. The shape of the particles of cement and FA is shown in Fig. 2b which would help in anticipating the behavior of composition materials when cement reacts with FA. The HVFA concrete specimens, i.e., in Fig. 2c and d, show more percentages of calcium silicate hydrate (C–S–H) gel in concrete. These C–S–H gels are formed when calcium oxide (obtained by the hydration of cement) reacts with fly ash. It has good cementitious properties and helps in imparting strength to the HVFA concrete at later ages.

The locally available river sand passing through IS 480 sieve and having an aperture of 4.75 mm was used as fine aggregate. The crushed stone ballast having a 16 mm average size was used as coarse aggregate in preparing concrete mixes. The water free from hazardous materials and harmful salts was used in the mix with other ingredients. The detailed physical and chemical properties of the ingredients used for preparing different mixes of concrete are shown in Tables 1 and 2. The properties of fine and coarse aggregates used in the design of the mix are shown in Table 3.

Casting and testing methodology

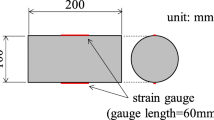

Two mixes of plain concrete designated as M1F0 and M2F0 for 28-day target strength not lesser than 20 MPa and 30 MPa, respectively, were prepared according to the method of trials as per the guidelines given in IS 10262 [36]. FA concrete mixes were equipped after re-proportioning of the mixes of plain concrete and cement was replaced directly based on the equivalent weights of 25, 40, and 60 percents of FA to obtain the corresponding FA concrete mixes. To determine the flexural and splitting tensile strength of plain and FA concrete mixes, three specimens each of prisms of size 100 × 100 × 500 mm (B × D×L) and cylinders of 100 mm diameter and 200 mm height were prepared in the laboratory. The details of plain and FA concrete mixes are given in Table 4, and the shape and size of the specimens are shown in Fig. 3. The entire mix proportioning of concrete has been divided into two mix groups (M1 and M2), and in each mix group, there are four concrete mixes—one plain concrete mix and three fly ash concrete mixes as shown in Table 4. The percent replacement of cement by fly ash has been decided based on the available literature and IS codes [17, 31] to obtain HVFA concrete. Thus, a total of eight concrete mixes have been designed and Mix ID is also shown in the table, where the first two letters represent mix group (M1 and M2) and the next two letters stand for percent replacement of cement by fly ash (F0, F1, F2, and F3 represent 0%, 25%, 40%, and 60%, respectively).

A rotating drum-type mixer was used for mixing the aggregate, cement, and water for about 2 min before pouring the mix into the molds in three layers and subjected to vibrations for about 30 seconds for each layer on an electromechanically driven vibration table. The emphasis in the present experimental study was to obtain early-age and age-dependent flexural and splitting tensile strength of HVFA concrete mix. For estimating early-age concrete tensile strength, the samples were tested at 7 and 28 days of submerged curing (i.e., underwater curing) on surface dry conditions. Remaining samples were stored at ambient temperature conditions, and age-dependent splitting and flexural tensile strength was obtained by performing the tests on all dried specimens at 56, 90, 150, and 180 days. The flexural and splitting tensile strength test (shown in Fig. 4) was carried out as per the guidelines of IS 516 [37] and IS 5816 [38], respectively, and the schematic test setup is represented in Fig. 5. The load was applied gradually at the rate of 180 kg per minute to the specimens in the flexural tensile strength testing, whereas in the splitting tensile strength test, the load was applied at the rate of 1.2 to 2.4 N/mm2 per minute until the failure of the specimens. The average of three specimens were recorded to define the flexural and splitting tensile strength of the concrete mixes.

Results and discussions

The tensile strength is an essential property of concrete as the structural member of concrete highly prone to tensile cracking due to the various types of effects and loading conditions. The tensile strength of plain and FA concrete is quite low in comparison with the compressive strength of concrete. The different types of analysis along with the discussion of test results on splitting and flexural tensile strength of plain and FA concrete mixes have been presented in the following sections.

Experimental development of tensile strength of low-calcium FA concrete with age

Flexural tensile strength

The development of flexural tensile strength of plain and FA concrete obtained experimentally for both the mix groups with age is shown in Fig. 6. The strength of 40 and 60 percent FA concretes has been found lower at initial ages in contrast to conventional concrete but with the passage of time, it gains satisfactory strength due to the pozzolanic behavior of FA. The 25% replacement gains almost similar strength as that of plain concrete at the end of 180 days. Fly ash particles chemically react with calcium hydroxide (liberated on hydration in the cement) to form compounds, i.e., calcium–silicate–hydrate (C–S–H), that possess cementitious properties. As the percentages of FA increased, the flexural tensile strength decreased considerably due to the slower rate of hydration in comparison with cement. For lower percent replacement, FA concrete gains good strength with time but for higher cement replacement by FA, there is more reduction in the flexural strength of concrete as it can be observed in Fig. 6. For mix group M1, at 180 days of age, the flexural strength of fly ash concrete mixes containing 25%, 40% and 60% of fly ash is observed as 91%, 76%, and 60%, respectively, of plain concrete. For mix group M2, the flexural strength of fly ash concrete mixes containing 25%, 40%, and 60% of FA is obtained as 90%, 72%, and 65%, respectively, of plain concrete at the end of 180 days. It is found that in higher volumes of FA concrete mixes, there is much enhancement in the strength development of concrete at the end of 180 days. Further, for mix group M1 concrete mixes, the rate of increase in flexural strength from 28 to 180 days for plain concrete is observed as 23% whereas the rate of increase in flexural tensile strength of 40% and 60% FA concrete from 28 to 180 days is observed as 44% and 33%, respectively. For mix group M2 concrete mixes, the rate of increase in flexural strength from 28 to 180 days is obtained as 27% for plain concrete, 29% and 37% for 40% and 60% fly ash concrete mixes, respectively. It indicates that the rate of development of the flexural strength of HVFA concrete is quite more than that of conventional concrete. The flexural tensile strength of concrete depends on the water binder ratio, age of concrete, type, and characteristic of proportioning of the mix. The pozzolanic reactivity of FA pays to the gain of strength at later ages. The rate of hydration for FA particles is slower than that of the particles of cement in all the concrete mixes.

Splitting tensile strength

The influence of low-calcium FA on splitting tensile strength of concrete with age for all concrete mix groups is shown in Fig. 7. The strength pattern is observed similar to flexural tensile strength for all the concrete mixes having different percentages of fly ash at all ages. The figure indicates that the splitting tensile strength increases with age at a decreasing rate and the pattern of strength development is the same in all the concrete mixes. However, the values of the tensile strength of the concrete in splitting are lower than the flexural tensile strength of concrete. It is observed that FA concrete is weaker in splitting tensile strength than the flexural strength which may be due to testing methodology. At 28 days of age, the FA concrete splitting tensile strength having 25%, 40%, and 60% of FA is observed as 93%, 86%, and 66%, respectively, of plain concrete for mix group M1. But at the age of 180 days, little higher strength is observed, i.e., 96%, 88%, and 74% for 25%, 40%, and 60% of FA, respectively, of that of plain concrete strength. Similarly for mix group M2, at the age of 28 days, the splitting tensile strength of fly ash concrete containing 25%, 40%, and 60% of fly ash is obtained as 86%, 79%, and 72%, respectively, of plain concrete. At the age of 180 days, the splitting tensile strength of FA concrete mixes containing 25%, 40%, and 60% of fly ash is equivalent to 96%, 93%, and 82%, respectively, of plain concrete. Further, the rate of increase in splitting strength from 28 to 180 days for plain concrete is observed as 11–19%, whereas the rate of increase in splitting tensile strength of HVFA concrete, i.e., 40% and 60% FA concrete, from 28 to 180 days is observed as 23–28% and 25–33%, respectively. It indicates that the rate of development of splitting tensile strength of HVFA concrete is more than that of plain concrete. On comparing the flexural and splitting tensile strength development of various mixes of plain and fly ash concrete, it has been observed that there is more improvement in the flexural tensile strength than the splitting tensile strength of concrete with the passage of time.

From the above observations, it is concluded that the tensile strength development (i.e., from 28 to 180 days) of HVFA concrete has been found higher than the plain concrete. This is due to the development of strong bonds between the cement, FA, and aggregate and also because of the increase in the C-S–H gel at later ages in the HVFA concrete.

Assessment of the existing models for the prediction of the tensile strength of concrete

The applicability of available age-dependent analytical models recommended by the design codes and researchers for the estimation of the tensile strength of concrete has also been made with the present experimental flexural and splitting tensile strength of FA concrete for both concrete mix groups. The analytical models used in the prediction of flexural and splitting tensile strength of concrete with age are listed in Table 5. The experimental flexural tensile strength has been compared with the values predicted by using the ACI-209 model [39] as presented in Figs. 8 and 9 for all concrete mix groups and at various ages. Similarly, the age-dependent experimental results of splitting tensile strength of plain and FA concrete mixes are compared with the analytical models proposed by Larrard and Malier model [40], Zain model [41], and Zhao model [42], and the comparison is shown in Figs. 10 and 11.

Further, the empirical power relation recommended by the researchers and different countries design codes [1, 30, 42,43,44,45,46] to calculate the tensile strength of concrete for the given compressive strength of that concrete can be written as:

where \(f_{r}\) and \(f_{\text{spt}}\) are the flexural and splitting tensile strengths of concrete, respectively (in MPa), \(f_{c}^{{\prime }}\) and \(f_{c}\) are the 28-day strengths of cylinder and concrete cube, respectively (in MPa), c1 and c2 are the model constants, and the values are varied from and c1 = 0.3 to 0.94 and c2 = 0.5 to 0.67 for flexural tensile strength of concrete and c1 = 0.185 to 0.59 and c2 = 0.5 to 0.735; for splitting tensile strength of concrete [1, 30, 42,43,44,45,46]. In the present study, only age-dependent models for the prediction of the tensile strength of concrete have been considered to check their applicability with the experiments.

Notably, the percentages of FA have not been mentioned in any of the age-dependent tensile strength prediction models given in Table 5. The limitations of the existing models for the prediction of the tensile strength of concrete are that the Larrard and Zain model can predict only the splitting tensile strength of high-performance concrete and it is not applicable for the prediction of high-strength concrete tensile strength. The Zhao model was developed to predict the splitting tensile of concrete designed with manufactured sand. Thus, these models are not helpful in predicting the splitting tensile strength of concrete containing FA as a mineral admixture. Therefore, it is concluded that these models are not designed for the concrete containing a variable amount of fly ash. The prediction of the age-dependent flexural and splitting tensile strength of plain and FA concrete using the models given in Table 5 is discussed herein.

Flexural tensile strength

The trend of development of predicted flexural tensile strength by using the ACI-209 model is almost similar to the experiments for all concrete mixes and at different ages. The predicted strength using the ACI-209 model with gr = 0.021 is close to the experimental strength at later ages and for the high grade of plain concrete mix. For fly ash concrete mixes, the ACI-209 model overestimates the tensile strength as compared to the experimental strength. The tensile strength predicted by using the ACI-209 model with gr = 0.012 is lower than the experimental flexural tensile strength for 25% FA concrete mixes at all ages. But the predicted tensile strengths of 40% and 60% fly ash concrete are comparable with the models for low-grade concrete mix (M1) and the predicted values are lower when high-grade concrete (M2) is used. The predicted strength (for gr = 0.021) development rate from 28 to 180 days for plain concrete is about 7–13.4% and 9–16%, 13–19%, 14.8–18% for 25%, 40% and 60% FA concrete mixes, respectively. A similar trend of the development of tensile strength is also observed with the predicted values for gr = 0.012 for all concrete mixes. It is also observed that the experimental flexural tensile strength is almost lying in between the model constants, i.e., gr = 0.021 and 0.012, for all concrete mixes and at all ages. Thus, no definite trend is observed in the prediction of the flexural tensile strength of fly ash concrete mixes by using the ACI-209 model. It can be said that the deviation of tensile strength predicted by using ACI-209 model may be due to the constant (gr) used in the model. Hence, the proposed range of constant (gr) used in ACI-209 is not applicable to predict the flexural tensile strength of concrete containing fly ash.

Splitting tensile strength

The comparison of experimental splitting tensile strength development with the predicted strength development calculated by using models (i.e., Larrard and Malier, Zain et al., and Zhao et al. models) at different ages for both the concrete mix groups (M1 and M2) is shown in Figs. 10 and 11. The predicted values at early ages (7 days) by using the Zain model are close to the experiments for all concrete mixes. Beyond 7 days, the splitting tensile strength predicted by the Zain model significantly overestimates the values obtained experimentally and underestimates the strength predicted by other models for lower grade concrete mix, i.e., M1. However, for higher grade concrete mix, i.e., M2, the values of splitting tensile strength obtained experimentally are higher than all the other values predicted by different models. It means that the splitting tensile strength predicted by using Larrard and Malier model and Zhao model is greatly underestimated in comparison with the experimental values for all concrete mixes and at all ages. For concrete mixes containing high content of FA, the experimental values of splitting tensile strength up to 28 days are lower than all the model-predicted values but beyond 28 days, the development in tensile strength is quite more and the experimental values greatly underestimate the values predicted by different models. It is due to the fact that the rate of development of the tensile strength of HVFA concrete mix is higher with the passage of time. The Larrard and Malier model and Zhao model predict the lowest values of splitting tensile strength for all FA percentage replacement at all ages in both the concrete mix groups M1 and M2. The trends of the values obtained by different models are the same but the deviation between Zain model values is higher than all the other values. For the lower age of concrete, the prediction of tensile strength is close but, however, with the passage of time, the variation among all the values increased. The rate of development of splitting tensile strength of plain and FA concrete from 28 to 180 days has been found in the range of 15–25% for the Zain model, 18–24%, 13–18% as predicted by Larrard and Malier and Zhao models, respectively. However, the rate of development of splitting tensile strength of experimental values from 28 to 180 days has been found as 11–19% for plain concrete, whereas for HVFA concrete mixes, the increment in splitting tensile strength is quite high which is in the range of 25–33%. Thus, none of the available models is found suitable for the prediction of splitting tensile strength of concrete containing low-calcium fly ash.

Proposed models for the prediction of age-dependent tensile strength of concrete

It is evident by considering research-based models and models recommended by different countries design codes for the estimation of the tensile strength of concrete that it is inherently related to the compressive strength of that concrete. From the above discussion on the literature and the applicability of the available models with the experiments, it is revealed that experimental data which are available on the flexural and splitting tensile strength of concrete designed with low-calcium FA are very limited and the analytical models for the prediction of age-dependent flexural and splitting tensile strength of low-calcium FA concrete are not available in the literature. The tensile strength of concrete obtained experimentally depends upon various factors such as the ratio of water to binder (linked with compressive strength), age of concrete and percent replacements of cement by fly ash. Therefore, the models are proposed for the prediction of flexural and splitting tensile strength of low-calcium FA concrete as a function of time, 28-day compressive strength of cylinder, and percent of FA in the concrete mix. Based upon the multivariable regression analysis using statistical software and by considering experimental parameters, the following analytical models are proposed which are useful for the prediction of flexural and splitting tensile strength of concrete containing low-calcium fly ash. These models are given as follows:

where \(\left( {f_{r} } \right)_{t}\) is the flexural tensile of FA concrete at any age ‘t’ in days; \(\left( {f_{spt} } \right)_{t}\) is the splitting tensile of FA concrete at any age ‘t’ in days; \(\left( {f_{c}^{'} } \right)_{28}\) is the 28-day cylinder compressive strength of plain concrete; t is the age in days; pfa is the percentage ratio of fly ash; k1, k2, k3,k4,k5, k6, k7 and k8 are the model parameters; and the values are 3.838, 0.831, − 1.460, − 1.063, 0.06, 1.29, 0.12 and 0.99, respectively. Hence, the models can be rewritten as:

Figure 12a and b shows the comparison between the age-dependent flexural and splitting tensile strengths of plain and FA concrete mixes predicted using the proposed models and the experimental results, respectively. It is examined that the data points of 93.75% and 95.83% for flexural and splitting tensile strengths, respectively, lie within ± 10 percent error band. The validation of proposed models for the prediction of age-dependent flexural and splitting tensile strengths (Eqs. 2 and 3) with the experimental results is shown in Figs. 13 and 14 for concrete mix groups M1 and M2, respectively. It can be concluded from these figures that the models which are proposed for the prediction of flexural and splitting tensile strength of concrete containing different percentages of low-calcium fly ash are in good agreement with the experiments at all ages.

Figure 15a and b shows the histogram of error carried by covering all experimental data for all mixes used in the prediction of flexural and splitting tensile strength, respectively. The figure shows that at 90 days, for 87.5% data points, the error is less than 5% for flexural tensile strength and for 87.5% data points at 56 and 90 days, the error is less than 5% for the tensile strength of concrete in splitting by considering all data points of all concrete mixes. The error lies in the range of 10–15% for only 12.5% data points at 7 and 56 days for flexural tensile strength and at 7 days for splitting tensile strength of concrete by considering all concrete mixes. Overall the error of most of the data is less than 10% by considering all the data points for both flexural and splitting tensile strengths of all concrete mixes. This shows that the proposed models used to predict the flexural and splitting tensile strengths of various concrete mixes having low-calcium FA were found to fit well with the experimental results for all concrete mixes and at different ages varying from 7 to 180 days. The mean error calculated in the prediction of flexural and splitting tensile strength of concrete by using proposed models with error bars is shown in Fig. 16 at all ages and for all concrete mixes. It can be observed from the figure that in the prediction of flexural and splitting tensile strength of low calcium FA concrete by using proposed models and for various concrete mixes, the range of mean error lying in 3.6–7.2% and 3.3–9.1% at the ages varies from 7 to 180 days, respectively. Thus, the considerable agreement of predicted flexural and splitting tensile strength with the experimental results for all concrete mixes with a high value of the coefficient of determination R2 = 0.96 and 0.97 for flexural and splitting tensile strengths, respectively, shows the applicability of the proposed empirical models for the prediction of flexural and splitting tensile strength of concrete containing low-calcium FA at any age.

The proposed models for the prediction of splitting and flexural tensile strength of fly ash concrete are further validated with the available experimental data measured by (Siddique [28, 27]; Pal et al. [47]) and the present experimental data with the same model parameters. Figure 17a and b shows the comparison between the measured (Siddique [27]; Pal et al. [47] and present data) and the predicted values with the age varying from 7 to 90 days. It can be seen in Fig. 17a and b that 94.4% and 95% data predicted by using the proposed model for the prediction of splitting and flexural tensile strength of fly ash concrete, respectively, lie within an error band of ± 15% . This close agreement between measured and predicted values shows the applicability of the proposed models for the prediction of age-dependent splitting and flexural tensile strength of concrete containing any percentage of fly ash. The proposed models can be used to predict the tensile strength of fly ash-based concrete when only 28-day plain concrete strength is known.

Conclusions

The age-dependent flexural and splitting tensile strength of FA concrete has been studied keeping in view of the use of high content of low-calcium FA in concrete construction. It was expected that the FA concrete performs better than the plain concrete at different ages beyond 28 days. The following conclusions have been drawn from the present experimental and analytical investigation on plain and FA concrete mixes.

-

The flexural and splitting tensile strength of concrete containing low-calcium fly ash is found lesser at initial ages (up to 28 days) in comparison with plain concrete but at later ages, strength is comparable with the plain concrete strength for both mix groups M1 and M2.

-

The 180-day average flexural tensile strengths of 25%, 40% and 60% low-calcium fly ash concrete are 90%, 74%, and 63% respectively, whereas the average splitting tensile strengths are 96%, 90%, and 78%, respectively, of that of 28-day plain concrete strength.

-

The rate of development of tensile strength from 28 to 180 days is found higher in concrete mixes containing low-calcium FA in comparison with the strength of plain concrete for both concrete mix groups M1 and M2. The optimum rate of the development of tensile strength from 28 to 180 days has been obtained in 40% FA concrete mixes.

-

The splitting tensile strength of concrete predicted by using the Zain model for all ages is found closer with the experimental strength for both the concrete mix groups, i.e., M1 and M2, but, however, the strength predicted by Larrard and Malier and Zhao models is quite different for all the concrete mixes. Thus, none of the existing models is found applicable to predict the age-dependent splitting tensile strength of low-calcium fly ash concrete.

-

The experimental flexural tensile strength is lying in between the ACI-209 model constants, i.e., gr = 0.021 and 0.012, for various concrete mixes and at all ages. Thus, ACI-209 model cannot be considered for the prediction of the age-dependent flexural tensile strength of concrete containing low-calcium fly ash.

-

The proposed models are found suitable for the prediction of age-dependent flexural and splitting tensile strength of low-calcium FA concrete and also validated with the experimental results for different grades of concrete and for variable percentages of fly ash.

References

Legeron F, Paultre P (2000) Prediction of modulus of rupture of concrete. ACI Mater J 97(2):193–200

Wang XY, Park KB (2015) Analysis of compressive strength development of concrete containing high volume fly ash. Constr Build Mater 98:810–819. https://doi.org/10.1016/j.conbuildmat.2015.08.099

Sivasundaram V, Carette GG, Malhotra VM (1990) Selected properties of high-volume fly ash concretes. Concr Int 12(10):47–50

Monteiro P (2006) Concrete: microstructure, properties, and materials. McGraw-Hill Publishing, London

Khan AA, Cook WD, Mitchell D (1996) Tensile strength of low, medium, and high-strength concrete at early ages. ACI Mater J 94(2):487–493

Mehta PK, Monteiro PJ (2017) Concrete microstructure, properties and materials. http://matteopro.com/images/materiali-non-convenzionali/Concrete_microstrutture_-book.pdf

Zhou FP, Balendran RV, Jeary AP (1998) Size effect on flexural, splitting tensile and torsional strengths of high-strength concrete. Cem Concr Res 28:1725–1736. https://doi.org/10.1016/S0008-8846(98)00157-4

Duran-Herrera A, Juarez CA, Valdez P, Bentz DP (2011) Evaluation of sustainable high-volume fly ash concretes. Cem Concr Compos 33:39–45. https://doi.org/10.1016/j.cemconcomp.2010.09.020

Hashmi AF, Shariq M, Baqi A, Haq M (2020) Optimization of fly ash concrete mix–a solution for sustainable development. Mater Today Proc 26(2):3250–3256. https://doi.org/10.1016/j.matpr.2020.02.908

Huang CH, Lin SK, Chang CS, Chen HJ (2013) Mix proportions and mechanical properties of concrete containing very high volume of class F fly ash. Constr Build Mater 46:71–78. https://doi.org/10.1016/j.conbuildmat.2013.04.016

Yoshitake I, Komure H, Nassif AY, Fukumoto S (2013) Tensile properties of high volume fly-ash (HVFA) concrete with limestone aggregate. Constr Build Mater 49:101–109. https://doi.org/10.1016/j.conbuildmat.2013.08.020

Bouzoubaa N, Lachemi M (2001) Self-compacting concrete incorporating high volumes of class F fly ash preliminary results. Cem Concr Res 31(3):413–420. https://doi.org/10.1016/S0008-8846(00)00504-4

Lam L, Wong YL, Poon CS (1998) Effect of fly ash and silica fume on compressive and fracture behaviour of concrete. Cem Concr Res 28:271–283. https://doi.org/10.1016/S0008-8846(97)00269-X

Pilehvar S, Cao VD, Szczotok AM, Carmona M, Valentini L, Lanzón M, Kjøniksen AL (2018) Physical and mechanical properties of fly ash and slag geopolymer concrete containing different types of micro-encapsulated phase change materials. Constr Build Mater 173:28–39. https://doi.org/10.1016/j.conbuildmat.2018.04.016

Dragas J, Nikola T, Ignjatovic I, Marinkovic S (2016) Mechanical and time-dependent properties of high-volume fly ash concrete for structural use. Mag Concr Res 68:632–645. https://doi.org/10.1680/jmacr.15.00384

Singh P, Shukla A, Trivedi AS, Vardhan J (2018) An experimental investigation of mechanical properties of concrete due to the effect of fiber and fly ash. Int J Adv Res Ideas Innov Technol 4:1900–1905

Hashmi AF, Shariq M, Baqi A (2020) Flexural performance of high volume fly ash reinforced concrete beams and slabs. Structures 25:868–880. https://doi.org/10.1016/j.istruc.2020.03.071

Wee TH, Matsunaga Y, Watanabe Y, Sakai E (1995) Microstructure and strength properties of high strength concrete containing various mineral admixtures. Cem Concr Res 25:715–720. https://doi.org/10.1016/0008-8846(95)00061-G

Yoshitake I, Komure H, Nassif AY, Fukumoto S (2013) Tensile properties of high volume fly-ash (HVFA) concrete with limestone aggregate. Construction and Building Materials 49:101–109

Siddique R, Khatib JM (2010) Abrasion resistance and mechanical properties of high-volume fly ash concrete. Mater Struct 43(5):709–718. https://doi.org/10.1617/s11527-009-9523-x

Mimura Y, Yoshitake I, Zhang W (2011) Uniaxial tension test of slender reinforced early age concrete members. Materials 4(8):1345–1359. https://doi.org/10.3390/ma4081345

Yoshitake I, Rajabipour F, Mimura Y, Scanlon A (2012) A prediction method of tensile Young’s modulus of concrete at early age. Adv Civil Eng. https://doi.org/10.1155/2012/391214

Swaddiwudhipong S, Lu HR, Wee TH (2003) Direct tension test and tensile strain capacity of concrete at early age. Cem Concr Res 33(12):2077–2084. https://doi.org/10.1016/S0008-8846(03)00231-X

Zhang H, Bai L, Qi Y, Hong H, Neupane A, Pan Q (2020) Impact of splitting tensile properties and dynamic constitutive model of fly ash concrete. J Mater Civ Eng 32(8):04020225. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003302

Sahoo S, Selvaraju AK (2020) Mechanical characterization of structural lightweight aggregate concrete made with sintered fly ash aggregates and synthetic fibers. Cem Concr Compos 113:103712. https://doi.org/10.1016/j.cemconcomp.2020.103712

Rao AV, Rao KS (2020) Effect of fly ash on strength of concrete. In: Circular economy and fly ash management, Springer, Singapore, pp 125–134. https://doi.org/10.1007/978-981-15-0014-5_9

Siddique R (2004) Performance characteristics of high-volume class F fly ash concrete. Cem Concr Res 34:487–493. https://doi.org/10.1016/j.cemconres.2003.09.002

Siddique R (2003) Effect of fine aggregate replacement with Class F fly ash on the mechanical properties of concrete. Cem Concr Res 33(4):539–547. https://doi.org/10.1016/S0008-8846(02)01000-1

Mehta A, Siddique R (2017) Properties of low-calcium fly ash based geopolymer concrete incorporating OPC as partial replacement of fly ash. Constr Build Mater 150:792–807. https://doi.org/10.1016/j.conbuildmat.2017.06.067

Shariq M, Prasad J (2019) Effect of ground granulated blast furnace slag on time-dependent tensile strength of concrete. Comput Concr 23(2):133–143. https://doi.org/10.12989/cac.2019.23.2.133

IS 1489 (part 1), (1991) Portland Pozzolana cement—specification part 1 (fly ash based). Bureau of Indian Standards, New Delhi

IS 4031 (Part 1–15) (1999) Indian standard methods of physical tests for hydraulic cement. Bureau of Indian Standards, New Delhi

IS 8112 (1997) Indian standard 43 grade ordinary Portland cement—specification. Bureau of Indian Standards, New Delhi

IS 3812-2003 (Part 1) (2003) Pulverized fuel ash—specification part 1 for use as Pozzolana in cement, cement mortar and concrete. Bureau of Indian Standards, New Delhi

IS 383 (2002) Specification for coarse and fine aggregate from natural sources for concrete. Bureau of Indian Standards, New Delhi

IS 10262 (2009) Recommended guidelines for concrete mix design. Bureau of Indian Standards, New Delhi

IS 516:1959 Reaffirmed (2004) Method of tests for strength of concrete. Bureau of Indian Standards, New Delhi

IS 5816:1999 Reaffirmed (2004) Splitting tensile strength of concrete—method of test. Bureau of Indian Standards, New Delhi

ACI 209 (1999) Prediction of creep and shrinkage, and temperature effects in concrete structures, ACI, Farmington Hills, Michigan, USA, ACI Committee, p 209

Larrard FD, Malier Y (1992) Engineering properties of very high performance concrete. In: Malier Y (ed) High performance concrete: from material to structure. E & FN Spon, London

Zain MFM, Mahmud HB, Ilham A, Faizal M (2002) Prediction of splitting tensile strength of high-performance concrete. Cem Concr Res 32:1251–1258. https://doi.org/10.1016/S0008-8846(02)00768-8

Zhao S, Ding X, Zhao M, Li C, Pei S (2017) Experimental study on tensile strength development of concrete with manufactured sand. Constr Build Mater 138:247–253. https://doi.org/10.1016/j.conbuildmat.2017.01.093

Oluokun FA, Burdette EG, Deatherage JH (1991) Splitting tensile strength and compressive strength relationship at early ages. ACI Mater J 88(2):115–121

Oluokun FA (1991) Prediction of concrete tensile strength from its compressive strength: evaluation of existing relations for normal weight concrete. ACI Mater J 88(3):302–309

Atici U (2011) Prediction of the strength of mineral admixture concrete using multivariable regression analysis and an artificial neural network. Expert Syst Appl 38:9609–9618. https://doi.org/10.1016/j.eswa.2011.01.156

Saridemir M (2016) Empirical modeling of flexural and splitting tensile strengths of concrete containing fly ash by GEP. Comput Concr 17(4):489–498. https://doi.org/10.12989/cac.2016.17.4.489

Pal S, Shariq M, Abbas H, Pandit AK, Masood A (2020) Strength characteristics and microstructure of hooked-end steel fiber reinforced concrete containing fly ash, bottom ash and their combination. Constr Build Mater 247:118530. https://doi.org/10.1016/j.conbuildmat.2020.118530

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known conflict of interest or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

Hashmi, A.F., Shariq, M. & Baqi, A. Experimental and analytical investigation on the age-dependent tensile strength of low-calcium fly ash-based concrete. Innov. Infrastruct. Solut. 6, 72 (2021). https://doi.org/10.1007/s41062-020-00437-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-020-00437-1