Abstract

This paper presents the use of bacteria for improving the mechanical properties of concrete and healing of crack in concrete structures. Two different types of bacteria namely Bacillus subtilis and Sporosarcina pasteurii were cultured using different media and three different mixes of concrete which were prepared by replacing 1%, 3% and 5% of water with bacteria solutions. The concrete specimens were then tested to evaluate the ability of the bacteria to heal cracks, which were evaluated by measuring the compression and flexural strength of concrete at different curing period. Two different mechanisms were used to check whether the concrete has healed i.e., by visualization of the cracked specimen and by re-loading the cracked specimen. Re-loading mechanism was performed by applying a flexural load on beam specimens to form micro-cracks in the concrete. The experimental test results indicated that the compressive strength and flexural strength of bacteria concrete increases compared to normal concrete at different ages of curing period. Both species of bacteria showed a positive influence in healing of concrete cracks. Out of the two types of bacteria and different nutrients used in this study, it was concluded that B. subtilis cultured with nutrient broth media has a better healing capability in concrete.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Concrete structures tend to deflect under external loads and consequently micro cracks are developed in their tension zones. This has been a serious concern over the life of the structures. Over last few decades, application of various types of fibres in concrete has helped to address this concern [1]. Even though different forms of repairs like stitching, epoxy injection, drilling and pulgging and gravity filling etc., have helped to arrest the cracks [2], repairs are costly and may not be affordable in economically developing countries like Ethiopia. Moreover, most heritage structures undergo frequent repair and maintenance and needs a long-term solution.

Autogenously healing process could be observed in concrete covering cracks in the range of 0.05–0.1 mm by the mechanism of capillarity in the crack width. Then, non-reacted cement particles hydrated by the water particles which enlarge there by autogenous healing of concrete. However, the autogenous healing may not be of significant help for the cracks beyond 0.1 mm [3].

In recent times, a newly developed smart concrete called bacteria concrete has been developed which seals the cracks in concrete due to the addition of bacteria by the mechanism of dry and wet cycles and has a potential to be a solution to address the above concerns [3,4,5,6,7,8,9]. Bacteria concrete is also called as self-healing concrete due to the fact that it has the capability of repairing its own crack without the involvement of human effort. The bacteria used in this special concrete produces Urease Enzyme as shown in Fig. 1 that helps to precipitate calcium carbonate, one of the major components of concrete, thus also referred as microbial concrete enzyme.

Formation of calcium carbonate from bacterial cell wall [8]

The main reason for the improvement in compressive strength of concrete with the addition of bacteria is the accumulation of CaCO3 on the microorganism cell surface, which fills the pores found in the matrix of cement-sand. Calcium carbonate, which are formed by the reaction of calcium ions produced by Sporosarcina pasteurii bacteria, does not directly react with the particles consisted by cement (C3S, C2S, C3A and C4AF). However, it acts as a catalyst for the cement hydration reaction. The equation below, taken from [10], expresses the process both on calcium carbonate formation (1) and cement producing chemicals reaction with water (2) [4, 6, 7, 9, 11,12,13,14].

In the past, few bacterias have been tried by researchers to be used to improve self-healing properties of concrete [3, 15]. An extensive review on the performance evaluation of autonomous self-healing bacterial concrete is recently made by [16,17,18]. Other researchers tried bio-chemical additive and organic compounds packed in porous expanded clay particles to enhance concrete strength and durability [19]. In this experimental study, two types of bacteria namely Bacillus subtilis and S. pasteurii have been cultured by different nutrients under local environmental conditions and have been tried in concrete to investigate their crack healing abilities, which is monitored by tests on mechanical properties of concrete. An effort has also been made to find the most suitable bacteria and nutrient and their optimum doses to be used for the local environmental condition.

2 Materials and methods

2.1 Materials

Ordinary Portland cement (OPC) of 42.5 grade produced by Muger Cement factory was used for this experimental investigation. The physical and chemical properties of cement are presented in Table 1.

Locally available angular crushed granite having a maximum size of 20 mm, fineness modulus of 7.63, specific gravity of 2.65, bulk density of 1468 kg/m3 at compacted state, and water absorption of 1.2% was used as coarse aggregate. River sand with specific gravity 2.5, fineness modulus 2.8, bulk density of 1700 kg/m3 at compacted state, and the water absorption of 2.04% was used as fine aggregate. Potable water was used for mixing concrete and curing.

Two species of non-pathogenic, spore forming and urease producing bacteria were used in this experimental investigation. These are S. pasteurii and B. subtilis (shown in Figs. 2, 3), which are genus of bacillus isolated and identified from soil samples. In the current investigation two types of nutrient mediums namely Urea-CaCl2 and Nutrient Broth were used to culture both the species of bacteria shown in Fig. 4.

2.2 Mix design of concrete

The mix design was carried out for C30 grade of concrete based on ACI 211 [20], and the quantity of materials were designed. There are two ways by which bacteria concrete can be prepared: by direct application or by encapsulation in lightweight concrete. In this study bacteria spores and calcium lactate were added into concrete directly when mixing of concrete was done. The use of bacteria and calcium lactate does not change the normal proportions of concrete. Twelve (12) different type of mixes of concrete were prepared by using the two different bacteria i.e., S. pasteurii and B. subtilis, which were cultured with two different mediums namely Urea CaCl2 and Broth, as shown in Table 2. The mix proportions are presented in Table 3.

2.3 Testing procedure

For preparation of good concrete, the vital factors are appropriate mixing, compaction and sufficient curing which were adopted during the test sample preparation process. Cube specimen of size 150 mm × 150 mm × 150 mm and prism specimen of size 150 mm × 150 mm × 700 mm were casted as part of this investigation. Pan mixture was used for mixing process and the time for mixing was kept for 3–4 min. To examine the effect of bacteria on workability of fresh concrete slump test was performed as shown in Fig. 5. After 24 h of casting the test samples were demoulded and adequately cured using potable water as shown in Fig. 6.

The specimens were tested for compressive strength at three different ages i.e., 7 days, 14 days and 28 days as shown in the Fig. 7 and the flexural strength was tested at 28 days as shown in Fig. 8.

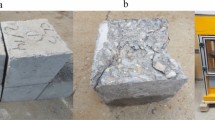

The healing of the cracks was evaluated by two methods: visual inspection and pre loading of beams. As part of visual inspection method, cracks were introduced in the concrete and pictures of cracks with high resolution power camera were taken every 3 days to observe the healing of concrete cracks. As part of pre loading method, 30% of compressive strength was applied as a flexural load on the prism specimens of bacteria concrete to develop micro cracks at 14 days of curing and further cured until 28 days. At 28 days the prism specimens were loaded with flexure load till the ultimate flexural strength and then has been compared with the unloaded beams of the same mix at 14 days.

3 Results and discussion

3.1 Effect of bacteria on workability of concrete

The effect of Bacteria on the workability of concrete has been presented in Fig. 9. It can be clearly seen that workability of concrete increases by inclusion of bacteria from 1 to 5%. It can also be observed that workability of concrete with B. subtilis bacteria grown in Nutrient Broth has the maximum workability. The increase in the workability may be attributed to the fact that bacteria help in reducing the friction between the constituent materials of concrete, as was also summarized in [17].

3.2 Effect of bacteria on self-healing of cracks in concrete

From the visualization it was clearly seen that both species of bacteria fills the crack developed in concrete. The crack healing captured in high resolution camera has been presented in Fig. 10. The crack healing is found to be because of urease enzyme produced when the bacteria is exposed to air there by inducing calcium carbonates and limestone into the cracks in concrete.

As described before, the specimens which were allowed to heal have been reloaded it has been found that the flexural strength of concrete at 28 days of curing period which was loaded with 30% of compressive strength load at 14 days to develop cracks in the prism specimen was similar to that of flexural strength of specimens not loaded at 14 days.

3.3 Effect of bacteria on compressive strength of concrete

The effect of Bacteria on the compressive strength of various concrete mixes at 7 days, 14 days and 28 days have been presented in the Fig. 11. It can be seen from Fig. 11 that inclusion of bacteria in concrete has a positive influence in terms of compressive strength increment in concrete. It can be clearly seen that with the increase in curing period, the compressive strength is also increasing for all types of mixes. The maximum compressive strength is found to be for the N-SP-3 mix as 34.2 MPa at 28 days of curing and higher compared to controlled concrete by about 30%.

3.4 Effect of bacteria on flexural strength of concrete

The effect of Bacteria on the flexural strength of various concrete mixes at 28 days have been presented in Fig. 12. It can be clearly observed that inclusion of bacteria increases the flexural strength of concrete. The maximum flexural strength found to be 4.61 MPa for N-SP-B1 mix which is 24% more compared to the controlled concrete.

4 Conclusions

The main objective of this research work was to check the viability of using two types of bacteria as auto-healing cracks in concrete and to experimentally investigate the effect of the bacteria on the fresh properties and mechanical properties of concrete. On the basis of the present experimental investigation, the following conclusions have been made:

-

Both types of bacteria i.e., B. subtilis and S. pasteurii are efficient in self-healing of the cracks formed in concrete.

-

Sporosarcina pasteurii bacteria has a better self-healing capability compared to B. subtilis.

-

The best nutrient media for growth of B. subtilis and S. pasteurii bacteria is found to be Broth.

-

The workability of concrete increases by the inclusion of bacteria in concrete.

-

Compressive strength of concrete is enhanced maximum upto 43% by the addition of bacteria in controlled concrete.

-

Flexural strength of concrete is enhanced maximum upto 24% by the addition of bacteria in controlled concrete.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Uomoto T, Mutsuyoshi H, Katsuki F, Misra S (2002) Use of fiber reinforced polymer composites as reinforcing material for concrete. J Mater Civ Eng 14:191–209

Nandakumar S (2020) Repair of cracks in concrete structures. J Prog Civ Eng 2:19–29

Talaiekhozani A, Abd Majid MZ (2014) A review of self-healing concrete research development. J Environ Treat Tech 2:1–11

Luo M, Qian CX (2016) Performance of two bacteria-based additives used for self-healing concrete. J Mater Civ Eng 28:04016151

Hager MD, Greil P, Leyens C, van der Zwaag S, Schubert US (2010) Self-healing materials. Adv Mater 22:5424–5430

Xu J, Yao W (2014) Multiscale mechanical quantification of self-healing concrete incorporating non-ureolytic bacteria-based healing agent. Cem Concr Res 64:1–10

Wang J, Soens H, Verstraete W, De Belie N (2014) Self-healing concrete by use of microencapsulated bacterial spores. Cem Concr Res 56:139–152

Vijay K, Murmu M, Deo SV (2017) Bacteria based self healing concrete—a review. Constr Build Mater 152:1008–1014

Wiktor V, Jonkers HM (2011) Quantification of crack-healing in novel bacteria-based self-healing concrete. Cement Concr Compos 33:763–770

Chidara R, Nagulagama R, Yadav S (2014) Achievement of early compressive strength in concrete using Sporosarcina pasteurii bacteria as an admixture. Adv Civ Eng 2014:1–7

Van Tittelboom K, Wang J, Araújo M, Snoeck D, Gruyaert E, Debbaut B, Derluyn H, Cnudde V, Tsangouri E, Van Hemelrijck D (2016) Comparison of different approaches for self-healing concrete in a large-scale lab test. Constr Build Mater 107:125–137

Xu J, Wang X (2018) Self-healing of concrete cracks by use of bacteria-containing low alkali cementitious material. Constr Build Mater 167:1–14

Seifan M, Samani AK, Berenjian A (2016) Bioconcrete: next generation of self-healing concrete. Appl Microbiol Biotechnol 100:2591–2602

Tziviloglou E, Wiktor V, Jonkers H, Schlangen E (2016) Bacteria-based self-healing concrete to increase liquid tightness of cracks. Constr Build Mater 122:118–125

De Belie N, Gruyaert E, Al-Tabbaa A, Antonaci P, Baera C, Bajare D, Darquennes A, Davies R, Ferrara L, Jefferson T (2018) A review of self-healing concrete for damage management of structures. Adv Mater Interfaces 5:1800074

Khaudiyal S, Rawat A, Das SK, Garg N (2021) Bacterial concrete: a review on self-healing properties in the light of sustainability. Mater Today Proc 6:23

Luhar S, Luhar I, Shaikh FUA (2022) A review on the performance evaluation of autonomous self-healing bacterial concrete: mechanisms, strength, durability, and microstructural properties. J Compos Sci 6:23

Nodehi M, Ozbakkaloglu T, Gholampour A (2022) A systematic review of bacteria-based self-healing concrete: biomineralization, mechanical, and durability properties. J Build Eng 49:104038

Jonkers HM (2021) Bacteria-based self-healing concrete. In-Genium

Mass GR (1982) Proportioning mass concrete a incorporating Pozzolans using ACI 211. 1. Concr Int 4:48–55

Acknowledgements

The authors sincerely thank Ethiopian Bio-diversity Institute, Ethiopian Roads Authority and Hawassa University for their technical and financial support for conducting this research.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Eshetu, E., Wondimu, T., Patnaik, B. et al. Healing concrete crack by using bacteria. J Build Rehabil 7, 90 (2022). https://doi.org/10.1007/s41024-022-00233-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41024-022-00233-7