Abstract

Conducting numerical and physical models to investigate the flow behavior through morning glory spillways (MGSs) are the only two methods usually used in the design phase of such spillways. The numerical models are the newest trend applied in the last two decades. In this regard, recently, significant efforts have been made to improve the flow behaviors of MGS by establishing numerical simulations and experimental works. Following the PRISMA checklist procedure, the current investigation employed a systematic review to carefully select and review the pertinent literature. Sixty-six articles from academic journals and conference proceedings were included, focusing specifically on the utilization of numerical and physical models for studying the flow characteristics of MGS. The current trend of the studies includes; modified inlet, vertical bend modifications, placing anti-vortex devices on the spillway crest, and readapting the boundaries of the spillway entrance. The performed techniques to examine various aspects of flow in MGS were reviewed, classified, analyzed, and discussed in detail. In addition, the modifications’ effects on improving the spillwayʼs hydraulic performances were demonstrated, and the operative ones were highlighted. Finally, after analyzing and comparing several empirical relations proposed in past studies to predict the discharge coefficient (Cd), an artificial neural network model was developed to estimate the Cd value. So far, few studies have focused on investigating the air entrainment process and slug flow regime in this type of spillway due to the lack of information and measurement difficulties; thus, further studies in this path will be considered valuable.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The spillway is a crucial component of a dam, playing a vital role in safely directing the overflow discharge from the upstream to the downstream side. Designing the spillway correctly is of utmost importance to ensure its effectiveness. During the design phase, thorough analysis and testing of the spillway are necessary to prevent any abnormal flow conditions. Furthermore, it is essential to reassess and verify the design and construction of various hydraulic structures that were built in the past, as they may have been based on limited hydrological data. This revision and examination are crucial to guarantee the safety and reliability of their operations (Nohani 2015c). The optimal design of spillways holds significant importance in dam construction due to their high cost, which constitutes a major portion of the overall construction expenses. The construction cost of spillways typically accounts for approximately 20 and 80% of the total dam construction cost for large and small dams, respectively (Haddad et al. 2010).

The morning glory spillway (MGS) is a unique hydraulic structure that operates independently from the main dam body. It is characterized by a funnel-shaped entrance, along with vertical and horizontal shafts. The MGS is specifically utilized in situations where alternative spillway options are impractical or infeasible. The performance and behavior of the MGS are influenced by several factors, including the topography of the surrounding boundaries, the size and shape of the inlet, and the dimensions of the outlet tunnel (Sabeti et al. 2019).

The flow characteristics across the spillway crest can be classified into three distinct types depending on the water level above the spillway: crest control, orifice control, and pipe control. MGSs are typically engineered to operate efficiently under crest control conditions. This is because their discharge efficiency is significantly reduced in both orifice and pipe control scenarios (Alkhamis 2021).

Various studies have been conducted to enhance the hydraulic performance of MGS. These investigations have involved the use of numerical and physical modeling to explore the effects of different techniques aimed at improving spillway efficiency. These techniques include modifying the geometries of the spillway crest and vertical bend, installing vortex breakers (VB) over the spillway crest, and making adjustments to the spillway boundaries.

One of the most common approaches to increasing spillway efficiency is examining the spillwayʼs discharge capacity for various inlet shapes (Aghamajidi 2013; Aghamajidi et al. 2013; Alkhamis 2021; Asadsangabi et al. 2014; Bagheri et al. 2010; Bagheri and Nohani 2014; Banejad et al. 2016; Bordbar et al. 2010; Brakeni and Guryev 2020; Cicero et al. 2011; Djillali et al. 2021; Gur’yev et al. 2021; Kabiri-Samani and Keihanpour 2021; Kamanbedast and Mousavi 2017; Kashkaki et al. 2019; Keihanpour and Kabiri-Samani 2021; Liu et al. 2018; Naderi et al. 2013; Nan et al. 2017; Nasiri et al. 2021, 2022; Rouzegar et al. 2019; Sabeti et al. 2019; Shemshi and Kabiri-Samani 2017; Aydin and Ulu 2023b; Talebi et al. 2022). The circular piano key (CPK) inlet is one of the newest reformed shapes of traditional MGS studied (Kashkaki et al. 2019; Nasiri et al. 2021; Shemshi and Kabiri-Samani 2017). Also, different entrance polygonal shapes were investigated (Brakeni and Guryev 2020; Djillali et al. 2021; Gur’yev et al. 2021; Nan et al. 2017) and examined stepped MGS (Aghamajidi 2013; Aghamajidi et al. 2013; Alkhamis 2021; Bordbar et al. 2010; Haghbin et al. 2022; Parsaie and Haghiabi 2019).

Vortex formation above the spillway crest is one of the problems that cause a decrease in the spillway capacity, so many researchers tested various anti-vortex devices to overcome it. During the vortex phenomenon, the tangential velocity increases due to changes in the flow path of the direct mode. Then, more flow energy will dissipate, reducing the spillway discharge capacity (Rahimi and Razavi 2018). One effective solution for mitigating the adverse effects of the vortex phenomenon is the implementation of inserted piers on the spillway crest (Christodoulou et al. 2010). Accordingly, various types and numbers of VB on the crest of MGS have been used to effectively reduce and eliminate this problem (Aghamajidi 2013, 2022; Aghamajidi et al. 2013; Akbari et al. 2015; Broucek et al. 2021; Christodoulou et al. 2010; Emami and Schleiss 2016; Fattor and Bacchiega 2009; Kamanbedast and Mousavi 2017; Mirabi et al. 2021; Musavi-jahromi et al. 2016; Nohani 2014, 2015a; Nohani and Emamgheis 2015; Noruzi and Ahadiyan 2017; Rahimi and Razavi 2018; Sayadzadeh et al. 2020; Radmanesh et al. 2022).

Pyramidal, triangular, rectangular, and baleen bodies are distinct shapes of VB that have been installed on spillway crests to assess their impact on spillway performance. These various VB shapes have undergone evaluation to determine their effectiveness in mitigating the negative effects of vortex formation and improving overall spillway operation (Nohani and Emamgheis 2015; Sayadzadeh et al. 2020). Anti-vortex pier with different thicknesses is another VB form used to control vortex problems (Akbari et al. 2015; Christodoulou et al. 2010; Kamanbedast and Mousavi 2017; Mirabi et al. 2021; Nohani 2014, 2015a; Noruzi and Ahadiyan 2017; Rahimi and Razavi 2018). In order to determine the most effective number of VB for reducing vorticity, a range of numbers (i.e., 2, 3, 4, 5, 6, 8, and 12) were investigated by several researchers (Aghamajidi 2013; Aghamajidi et al. 2013; Christodoulou et al. 2010; Emami and Schleiss 2016; Musavi-jahromi et al. 2016; Nohani 2014; Nohani and Emamgheis 2015; Noruzi and Ahadiyan 2017; Sayadzadeh et al. 2020). The findings from these studies consistently indicated that the optimal number of anti-vortex devices is 6, as it provides the most effective reduction in vorticity.

Furthermore, researchers have examined the impact of altering the vertical bend configuration between the vertical shaft and the horizontal outlet tunnel in order to mitigate the risk of cavitation and enhance the hydraulic performance of spillways (Ehsani et al. 2019; Fais et al. 2015; Savic et al. 2014). The locations of the elbowʼs start and end points are particularly susceptible to cavitation due to geometric variations that cause a shift in the flow direction (Ehsani et al. 2019).

When the reservoir boundaries are located near the MGS crest, the occurrence of vortex flow can have a significant adverse impact on spillway capacity (Christodoulou et al. 2010). To address this issue, modifications have been made to the spillwayʼs design in order to promote radial flow along the crest (Christodoulou et al. 2010; Emami and Schleiss 2016; Fattor and Bacchiega 2009). Fattor and Bacchiega (2009) enhanced the hydraulic characteristics of the spillway by lowering its location and excavating the area adjacent to the upstream face of the spillway. Also, Emami and Schleiss (2016) employed flow-directing piers on the spillway crest to eliminate flow disturbances caused by the proximity of reservoir abutments.

Cavitation is a potential issue that can occur in the MGS, particularly at the entrance of the spillway and during the transitions of the funnel inlet, shaft, and inside elbow, as highlighted by Ehsani et al. (2019). Some researchers studied the cavitation risk for various forms of MGS (Aghamajidi et al. 2013; Asadsangabi et al. 2014; Bordbar et al. 2010; Brakeni and Guryev 2020; Djillali et al. 2021; Ehsani et al. 2019; Aydin and Ulu 2023a; Salehi et al. 2023). To mitigate cavitation issues, modifications have been made to the traditional circular inlet of the spillway, transforming it into polygonal sections (Brakeni and Guryev 2020; Djillali et al. 2021). Different inlet profiles and elbow radii have been examined to control cavitation problems. It has been observed that, under free-flow conditions, increasing the elbow radius leads to a higher probability of cavitation occurrence, while under submerged flow conditions, enlarging the elbow radius reduces the likelihood of cavitation (Asadsangabi et al. 2014; Ehsani et al. 2019). Stepped MGS configurations have been tested and demonstrated to exhibit better resistance against cavitation hazards compared to classical smooth spillways (Aghamajidi et al. 2013; Bordbar et al. 2010).

In recent times, there has been a growing focus on employing a reliability-based design optimization approach for the safe and efficient design and operation of different types of spillways, including morning glory, labyrinth, stepped, and ogee structures (Ferdowsi et al. 2019; Mooselu et al. 2019; Haddad et al. 2010; Hosseini et al. 2016; Jafari et al. 2021a, 2021b; Jafari and Aghamajidi 2022; Kardan et al. 2017; Tabari and Hashempour 2019; Ohadi and Jafari 2021; Oukaili et al. 2021). The characteristics of the studies done in this field are listed in Table 1.

Moreover, several numerical models were developed to derive an equation to predict Cd (Aghamajidi 2013; Aghamajidi et al. 2013; Alfatlawi and Alshaikhli 2015; Camargo et al. 2006; Fais et al. 2015; Fais and Genovez 2009; Gouryev et al. 2020; Kamanbedast 2012; Kashkaki et al. 2018; Keihanpour and Kabiri-Samani 2021; Musavi-jahromi et al. 2016; Nohani 2015b; Sayadzadeh et al. 2020; Shemshi and Kabiri-Samani 2017). Some of them applied the ANN approach to estimate Cd (Alfatlawi and Alshaikhli 2015; Kamanbedast 2012; Kashkaki et al. 2018).

In the past two decades, extensive research has been conducted to enhance the hydraulic performance of the MGS using both numerical and physical models. Thus, the main aim of this review was to understand and identify the current trends that investigate the hydraulic properties of MGS, systematically review the most common and effective approaches, then find out the research gaps and provide recommendations for future trends. To the authorsʼ knowledge, no review paper has been written in this field. So, a full review article is required to provide more details on the studies done in this field and compare their results and findings.

This research is divided into six sections and follows a specific structure. Section 2 introduces the research methodology. Section 3 provides an explanation of numerical and physical modeling in MGS, explores current literature trends, and presents the proposed ANN modeling approach for Cd prediction. Sections 4 and 5 focus on the results and discussions, respectively. Finally, Sect. 6 concludes the research with the findings, recommendations, and conclusions.

2 Methodology

A systematic review is performed to identify how scholars conducted studies to investigate MGSʼs hydraulic properties through developed numerical and physical models. This systematic review was conducted by following the procedures that were reported in the checklist of the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) (Moher et al. 2009). For this purpose, an exhaustive literature search was undertaken to find the related studies published until the end of June 2023.

To systematically identify relevant literature for our survey, we employed Harzingʼs Publish or Perish (Version 8) software, which facilitated searches within the renowned academic databases of Google Scholar and Scopus. In certain cases, we extended our search efforts to include specific journalsʼ websites, enabling us to locate targeted publications. Our search strategy encompassed the utilization of diverse combinations of terms in titles or keywords, intentionally disregarding constraints related to publication date or language, to ensure comprehensive coverage of the literature pertinent to our study. The specific keyword combinations employed were as follows: “morning glory spillway” OR “shaft spillway” OR “bell mouth spillway,” “numerical model*” AND “morning glory spillway,” “numerical model*” AND “shaft spillway,” “numerical model*” AND “bell mouth spillway,” “morning glory spillway” AND “physical model*” OR “experimental model*,”“shaft spillway” AND “physical model*” OR “experimental model*,” and “bell mouth spillway” AND “physical model*” OR “experimental model*”.

Additionally, the title, abstract, authorsʼ names, journalsʼ names, publication year, and citations of the identified records were gathered into an MS Excel worksheet. The included articles were chosen based on this review paperʼs objectives to investigate the hydraulic properties of MGS using numerical and physical models. More specifically, unpublished papers, master and doctoral dissertations, editorial notes, textbooks, book chapters, and any articles that were not well organized or had vague ideas were excluded. Afterward, the reviewers performed an eligibility assessment by carefully screening the full texts of the remaining papers individually. At this time, disagreements between the reviewers were discussed and solved by consensus.

Searching for literature in the databases and search engines identified 338 records (Google Scholar (224), Scopus (106), and other sources (8)); 120 were removed due to duplicates, and 140 were eliminated in the initial screening of titles and abstracts, despite mentioning one or more of the selected keywords in their titles and/or keywords. Out of remained 78 papers, 70 full-text articles were carefully screened, while five articles were not accessible and three pieces were not found. At the end of the screened process, four full-text papers were excluded because they did not meet the eligibility criteria. Only Sixty-six full-text studies from 35 different Journals and 13 conference proceedings for systematic review were obtained. The adopted screening procedure is summarized and illustrated in Fig. 1.

Subsequently, the gathered information from the selected articles was meticulously summarized and reviewed to facilitate the conduction of this study. In addition, articles were reviewed and summarized according to various criteria such as journals or conferences names, the year of publication, the number of citations, the case studyʼs location, applied method, research objectives, results, and findings. All the literature included in this study was classified into two main categories: numerical and physical approaches. Furthermore, these categories were further divided into more specific subcategories, as illustrated in Table 3.

Moreover, detailed figures and graphs were redrawn and discussed in detail using the previous data. We also developed an ANN model to predict the Cd based on the extracted data and relations from the literature. Figure 2 demonstrates a flowchart diagram that followed in this study.

3 Numerical and Physical Modeling of Flow in Morning Glory Spillways

Numerical and physical models are essential techniques for assessing the hydraulic performance of flow through spillways. From the reviewed papers, one can notice that most of the literature in which numerical models were developed, physical models were constructed, or experimental data was used to verify and validate the numerical results.

In the past, the assessment of hydraulic systems predominantly relied on physical models. However, with advancements in numerical methods, there is now a broader range of cost-effective options available that significantly reduce computational time while still providing accurate results (Nohani 2015c). Calibration of the numerical model is a crucial initial step to minimize the influence of external factors and align model behavior with prototype conditions. Therefore, it is imperative to calibrate and simulate the numerical model using appropriate boundary conditions to ensure its accuracy and reliability (Razavi and Ahmadi 2017a).

The introduction of computational fluid dynamics (CFD) models in hydraulic engineering has fundamentally transformed the conventional notion that physical models are the sole means for evaluating flow dynamics. Over the last few decades mesh-based CFD codes have dominated advanced studies and proven their accuracy in supporting decision-making processes (Moreira 2021). However, the process of generating and refining meshes has been time-consuming and challenging. Moreover, mesh-based models face limitations when simulating specific problems like large free-surface deformations or complex geometries (Kevorkijan and Biluvs 2021). Handling free-surface computations in these models involves solving additional equations, often using the volume of fluid (VOF) method.

Furthermore, ensuring accurate specification of boundary conditions is essential for achieving realistic spillway modeling, must be accurately defined based on the design and operational conditions of the spillway. Also, calibration of numerical models using field or laboratory data is imperative to ensure precise predictions. Despite the significant achievements of traditional mesh-based numerical methods, these limitations hinder their computational efficiency and restrict their broader applications. Consequently, to mitigate these challenges researchers are continuously seeking improved numerical methods to overcome these challenges. In recent years, meshfree methods have emerged as a successful class of computational methods. These methods have made significant advancements in overcoming the initial limitations they faced during their early development (Moreira 2021). Meshfree methods are widely acknowledged for their advantages in simulating certain fluid problems. Most notably, they offer the freedom to simulate real-world scenarios with minimal to no simplifications, allowing for a more realistic representation of the system.

Physical models are constructed to properly simulate the prototype behavior and identify the most practical and reasonable solutions (Novak 1984). It should be built correctly to obtain reliable models (Yalin 1989). Some numerical ratios and scales should be considered. One of the most important things is the scale ratio between the physical model and the prototype. Decreasing the scale ratio will cause a scale effect because of changes in the coefficient related to the force ratio between the model and the prototype; thus, the amount of error will increase and causes more discrepancy between the model and the prototype results (Yildiz and Yarar 2018).

Spillway physical models are made according to Froude laws of similitude, and they are valid as the effect of surface tension and viscosity can be ignored (Fais and Genovez 2009). To control scale effects in physical models, the scientists recommend specific values of Reynold number (Re), Weber number (We), and minimum water depth over the spillway crest.

Usually, scale effects occur for low water depths above the spillway crest and small flow rates. Novák and Čabelka (1981) demonstrated that the minimum acceptable water depth is 30 mm, which means all measures above this value can be reliable. Also, Fais and Genovez (2009) reported that the water level above the spillway crest should be at least 12 mm. Fais et al. (2015) displayed that the lowest overflow depth is 40 mm to eliminate substantial scale effects.

The minimum values of Re and We to eliminate the effects of viscosity and surface tension according to different authors are demonstrated in Table 2.

Furthermore, Heller (2011) recommended that the scale of the spillwayʼs physical model should be in the range of 1:50–1:100 to minimize scale effects.

3.1 Current Trends to Improve the Hydraulic Performance of MGS

Many techniques have been applied to increase the efficiency of MGS performance, such as crest geometry modification and VB installation. Figure 3 shows the percentage of each technique used in the literature. Table 3 presents the methods used to investigate the hydraulic properties of MGS.

The main reason for modifying the crest geometry and placing anti-vortex devices is to control vortex formation above MGSʼs crest and increase the discharge capacity. Also, the most common commercial code applied to develop numerical modeling was the Flow-3D program.

Furthermore, a detailed comparative analysis of the features regarding input parameters, performance metrics, and applicability of the previously discussed developed trends across a wide range of scenarios is presented in Table 4. The purpose of this specific comparison is to offer a comprehensive understanding and evaluation of how these trends measure up in different situations.

3.1.1 Inlet Modification

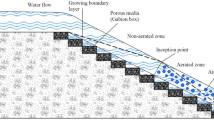

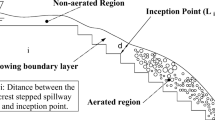

The modification of the traditional inlet shape of MGS is a commonly utilized approach in research studies, serving as a prominent method to enhance flow capacity and effectively tackle issues associated with vortex formation. Within the realm of crest modifications, various methods have been explored, such as incorporating steps or altering the shape to sectorial, polygonal, multifaceted, CPK inlet, and marguerite-shaped inlets. These techniques have been extensively discussed and examined in the relevant literature. Table 5 demonstrates the developed inlet shapes and their influences on improving spillway efficiency.

Based on Table 5, the CPK inlet, stepped MGS, and polygonal sections are the most popular types of crest modification. The hydraulic properties of the CPK inlet were investigated as a new entrance and compared with simple MGS (Kashkaki et al. 2019; Nasiri et al. 2021, 2022; Shemshi and Kabiri-Samani 2017). By investigating the hydraulic properties of the CPK inlet, engineers and researchers can assess the performance of this new entrance design in terms of flow rate, energy dissipation, and flow patterns. Understanding these hydraulic characteristics helps determine if the CPK inlet is capable of achieving the desired discharge capacity and hydraulic efficiency. Shemshi and Kabiri-Samani (2017) investigated swirling flow and spillway capacity at the CPK entry using an experimental model. The results showed that the whirling flow strength for flow through the CPK spillway is much less than for normal shaft spillways and improves release capacity by 6, 2, and 1.5 times larger than simple vertical shaft spillway, MGS, and PS, respectively.

Kashkaki et al. (2019) employed a physical model to study the CPK spillway and compared the hydraulic performance with the traditional shaft spillway without a reformed inlet. Experiments revealed that a CPK intake provided better hydraulic performance and improved the discharge capacity by 15.16%. Also, it can alleviate the cavitation risk at the vertical bend compared to the normal shaft spillway. Nasiri et al. (2021) tested the flow characteristics for various geometries of the CPK inlet spillways by applying numerical modeling. The outcomes showed that the CPK entrance substantially improves the discharge capacity by up to 40% compared to a standard vertical shaft and decreases the turbulent flow intensity.

The impacts of step configurations on the flow behavior and hydraulic parameters of a stepped MGS were examined via CFD simulation. Simulation consequences showed that the Cd rose, and the energy dissipation in the stepping MGS was significant for the measured discharge rates (Alkhamis 2021). Furthermore, the flow behavior of a smooth MGS was investigated and compared to a stepped spillway. The results indicated that a stepped spillway with six steps is the optimum number of steps in design and resistance to cavitation risk and concrete erosion (Aghamajidi et al. 2013). However, Bordbar et al. (2010) reported that eleven steps is the best number of steps to overcome cavitation risk. In addition, the performance of the spillway regarding energy dissipation was improved, when the step sizes increase for a specific value of chuteʼs slope (Parsaie and Haghiabi 2019).

Different polygonal inlet sections were used as an alternative to the circular sections (Brakeni and Guryev 2020; Djillali et al. 2021; Gur’yev et al. 2021; Nan et al. 2017). It has been reported that a polygonal cross section is simpler to construct and reduces construction and technical costs. Brakeni and Guryev (2020) showed that a 12-side polygonal configuration (see Fig. 4) allows the water jet to enter without separation in the elbows and maintain a direct connection to the wall. The maximum water level (MWL) was reduced by 0.68 m, and the Cd was improved up to 12%, allowing for greater dependability and reducing the risk of cavitation.

Plan of the shaft of the polygonal cross section (Brakeni and Guryev 2020)

Djillali et al. (2021) reported that a polygonal shape of 12 sides for a free entrance funnel could boost the Cd by 20% without increasing the water head over the spillway crest to risk cavitation. The polygonal funnel prevented the rotational flow, which aids in increasing the spillwayʼs discharge capacity and efficiency rate and decreases the erosion of the downstream river channel (Nan et al. 2017).

Another modern entrance shape called the marguerite-shaped inlet has been the subject of examination in recent studies (Kabiri-Samani and Keihanpour 2021; Keihanpour and Kabiri-Samani 2021). Samani and Keihanpour (2021) studied the vertical shaft spillways with a different number of lobed marguerite-shaped inlets experimentally, as shown in Fig. 5. The findings of the study revealed that the implementation of three-lobed inlets yielded the highest efficiency. These inlets demonstrated the capability to increase the discharge release up to four times more than a conventional MGS without submergence, while simultaneously reducing the likelihood of vortex formation and air entrainment.

(c–f) Images of two- to five-lobed marguerite-shaped inlet (Kabiri-Samani and Keihanpour 2021)

The hydraulic characteristics of flow at marguerite-shaped inlets with holes at the bottom of their lobes were also explored with minor variations (Keihanpour and Kabiri-Samani 2021). It raised the discharge capacity by approximately 6, 3, and 2 times compared to a simple shaft spillway, a CPK inlet, and a standard marguerite-shaped inlet, respectively. Additionally, this improvement resulted in reduced vortex flow intensity and enhanced hydraulic performance for simple shaft spillways.

Based on the combination of a regular MGS with a piano key weir, a new type known as PS was established (Banejad et al. 2016; Cicero et al. 2011). Three various angles of PSs (45, 60, and 90 degrees), as displayed in Fig. 6, were investigated (Banejad et al. 2016). The papaya model with a 90-degree angle had lower circulation effects than the other models. So, it can release more discharge through the shaft.

Physical models of PS with various angles (Banejad et al. 2016)

Cicero et al. (2011) emphasized the possibility of using PS and showed that this technique improves the crest length by 85% without varying the spillwayʼs standard sizes. Also, the discharge was 70% greater for the same water level than the traditional MGS.

The hydraulic characteristics of circular and square labyrinth inlets were examined, revealing that the square inlet outperforms the circular inlet in terms of circulation control and enhancing discharge release (Kamanbedast and Mousavi 2017; Rouzegar et al. 2019; Aydin and Ulu 2023b).

Some researchers conducted an empirical investigation to assess the suitability of polyhedral shapes, namely the trihedral, pentahedral, and heptahedral configurations, as alternatives for a spillway crest shape depicted in Fig. 7 (Bagheri et al. 2010; Bagheri and Nohani 2014). The results showed that the trihedral form is more efficient than other forms.

Trihedral, pentahedral, and heptahedral MGS with a crest diameter of 17 cm (Bagheri et al. 2010)

In addition, sectorial MGS, displayed in Fig. 8, was examined using different angles, demonstrating the influences of these changes on the flow characteristics for different water elevations in the reservoir (Sabeti et al. 2019).

Crest plan of MGS with different angles to create the crest sectors (Sabeti et al. 2019)

3.1.2 Installing Vortex Breaker (VB) over the Spillway Crest

Generally, MGS operates as a free mode with radial and axial velocity; therefore, the overflow discharge directly enters the spillway, while during the occurrence of the vortex phenomenon, the tangential velocity increases due to changes in the flow path of the direct mode, then the flow energy is dissipated, and it lowers the discharge capacity of the spillway (Rahimi and Razavi 2018). Therefore, this section is dedicated to investigating various methodologies aimed at mitigating this phenomenon. Among the proposed solutions, the installation of anti-vortex devices on the spillway crest emerges as an effective strategy to alleviate the occurrence of vortices. By preventing the formation of vortices, a more consistent and controlled flow pattern can be maintained. This, in turn, promotes stability, reduces flow disturbances, and ensures the reliable conveyance of water downstream, eliminating the potential for hydraulic instabilities. Table 6 demonstrates different types and numbers of VBs installed at spillwayʼs crests. Figures 9 and 10 show the frequency of the number and optimum number of VBs used in the literature.

From Fig. 9, the most common numbers of VBs installed in the past studies are 3, 4, and 6 VBs with different forms. Also, Fig. 10 demonstrates that the most efficient number of VB applications in the past is six VBs (Aghamajidi 2013; Aghamajidi et al. 2013; Christodoulou et al. 2010; Emami and Schleiss 2016; Musavi-jahromi et al. 2016; Nohani 2014, 2015a; Nohani and Emamgheis 2015; Noruzi and Ahadiyan 2017; Sayadzadeh et al. 2020; Aghamajidi 2022; Radmanesh et al. 2022). It is worth noting that installing more than six VBs blades on spillway crests does not appear to be beneficial (Musavi-jahromi et al. 2016). Also, increasing the thickness of VB blades causes a reduction in the spillway discharge capacity because it decreases the effective length of the shaft spillway, which decreases the outflow from the spillway (Nohani 2015a).

The effect of different VB (pyramidal, square, and triangular bases) was investigated through a physical model (Sayadzadeh et al. 2020). The findings demonstrated that when a group of six VBs was employed, it resulted in a significant increase in the Cd by up to 50.97% for crest control. Furthermore, in the case of orifice control, the utilization of six VBs led to an improvement of up to 16.13% in the coefficient of discharge.

The study conducted by Christodoulou et al. (2010) comprehensively investigated the effects of the number and configuration of anti-vortex piers. Notably, their findings revealed that the inclusion of 5–6 piers resulted in a substantial reduction of approximately 50% in the water level for discharges exceeding the design value. However, it is important to consider that the piers exhibited only a minor adverse effect for cases with small H values (H/R < 0.2). Also, it has been reported that increasing the spillway shaft height above the reservoir bed and placing piers on the spillway leads to a reduction in flow asymmetry.

The influence of different forms of anti-vortex blades, including rectangular, triangular, and baleen bodies (as shown in Fig. 11) on the Cd of the MGS was investigated (Nohani and Emamgheis 2015). The findings demonstrated that among the different blade forms investigated, the baleen types exhibited a more notable influence in enhancing the efficiency of the spillwayʼs Cd.

Different sizes of rectangular, triangular, and baleen body anti-vortex blades (Nohani and Emamgheis 2015)

Noruzi and Ahadiyan (2017) established a Flow-3D numerical model to assess the effects of putting different numbers of VB blades on the MGS crest. The outcomes were compared to experimental results, and the findings revealed that inserting blades raises the Cd by 42% and drops the reservoir water level by 25%.

Utilizing a blade-VB leads to improved Cd, which is greater in a sharp edge than a wide-edge. The blade VB shifts the flow lines into the shaft spillway from a spiral to a straight path due to the compressed flow lines; as a result, it offered a greater Cd (Nohani 2014).

In contrast to the aforementioned papers, four anti-vortex devices were identified as optimum numbers to improve hydraulic performance and eliminate vortex flow problems (Kamanbedast and Mousavi 2017; Mirabi et al. 2021; Rahimi and Razavi 2018). Anti-vortex piers increase the submergence threshold, cope circulation, and vortexes and then allow the spillway to release more discharge without being submerged.

Furthermore, various numbers of VBs (as displayed in Fig. 12) were tested to discover the optimal number for increasing the flow rate. The outcomes showed that using 12 VBs of dimensions of 5 × 8 × 10 cm significantly boosted the flow rate compared to the normal spillway without VB (Akbari et al. 2015).

A view of the shaft spillwayʼs physical model with different VB numbers in the laboratory (Akbari et al. 2015)

3.1.3 Cavitation Problem and Modifications in the Vertical Bend

Generally, cavitation is one of the problems facing designers due to the existence of high flow velocity in spillways. Usually, it occurs when the flow pressure falls below the fluid vapor pressure and should be avoided as much as possible (Aghamajidi et al. 2013). Cavitation can be estimated using the cavitation index according to the following equation (Asadsangabi et al. 2014):

where (P) is the absolute pressure, (\({P}_{\mathrm{v}})\) vapor pressure, (V) flow velocity, and \(\left(\rho \right)\) fluid density.

Cavitation occurrence is expected at the spillwayʼs entrance, the funnelʼs entrance junction, the vertical shaft, and within the elbow (Ehsani et al. 2019). Many research studies have been devoted to determining the most probable locations of this problem and providing possible solutions to control it (Aghamajidi et al. 2013; Asadsangabi et al. 2014; Bordbar et al. 2010; Brakeni and Guryev 2020; Djillali et al. 2021; Ehsani et al. 2019; Aydin and Ulu 2023a; Salehi et al. 2023).

Replacing the standard circular inlet of the spillway with a polygonal section allows the water jet to enter without separation in the connecting elbow and maintain a direct connection to the wall. It allows for more dependability and reduces cavitation risk (Brakeni and Guryev 2020; Djillali et al. 2021).

Ehsani et al. (2019) developed a numerical model utilizing the Flow-3D program to investigate flow velocity and pressure close to the elbow wall, and the findings were compared with experimental results. The results showed that the highest-pressure heads were found in the bottom of the elbow for different discharges and various elbow radii, which is demonstrated in Fig. 13. So, the start and end points of the elbow are the most likely places for cavitation due to geometric changes that cause variation in the flow course.

Left side: pressures for different points in the elbow for different cell sizes. Right side: location of the piezometers on the bottom and roof of the elbow (Ehsani et al. 2019)

Asadsangabi et al. (2014) investigated three different types of MGS inlet shapes (Wagner, Creager, and circular forms). The primary focus of their study was to assess the minimum probability of cavitation by evaluating the cavitation index. Cavitation indexes for various inlet configurations were calculated and compared with each other. The results showed that the Creager model performed better than the Wagner and the circular model, as shown in Fig. 14.

Cavitation index versus relative head for the three models (Asadsangabi et al. 2014)

Furthermore, it was observed that the stepped MGS design demonstrated enhanced efficiency in terms of design and resistance to the risks of cavitation and concrete erosion when compared to a smooth spillway (Aghamajidi et al. 2013; Bordbar et al. 2010).

Additionally, new geometry for the vertical bend between the shaft and the tunnel was examined (Fais et al. 2015; Salehi et al. 2023). Fais et al. (2015) compared the performance of a new parabolic shape with a 90o circular bend and a polycentric bend with a variable radius. The study was conducted in a spillway model of the Paraitinga hydropower plant in Brazil. Figure 15 presents a schematic representation of three bend configurations. The findings of the study revealed that the proposed novel bend exhibited an enhanced discharge rating curve compared to the existing configurations. These results underscore the importance of considering the new bend configuration when designing MGS.

Schematic of the three tested bends (Fais et al. 2015)

3.1.4 Modification in Physical Boundaries of MGS

Usually, this type of spillway is located close to hills or dam abutments; therefore, local boundary circumstances could significantly affect the flow behavior. To ensure radial flow and eliminate vortex flow over the crest, a MGS should be constructed as far away from reservoir rims as possible (Christodoulou et al. 2010).

Fattor and Bacchiega (2009) conducted an investigation focused on enhancing flow behaviors in spillway boundaries. They explored several modifications including lowering the spillway position, adjusting the physical boundaries to improve approximation, modifying the placement and number of anti-vortex piers, and excavating the ground to deeper levels near the upstream face of the spillway. These modifications resulted in increased discharge capacity, reduced circulation currents directly upstream of the inlet section, and enabled larger discharges without submergence or drowning.

Emami and Schleiss (2016) applied an experimental study to examine the impact of the proximity of the spillway to dam abutments. The researchers observed disruptions in the flow lines of the approaching flow near the abutments, which had a negative influence on the efficiency and performance of the spillway. It was determined that the placement of piers at specific locations along the crest of the spillway was the most effective solution for mitigating flow disturbances.

3.1.5 Proposed Empirical Equations to Calculate the Discharge Coefficient (Cd)

Musavi-jahromi et al. (2016) and Sayadzadeh et al. (2020) used the SPSS software to obtain numerical equations to calculate the Cd of MGS with different kinds of VB. The following two equations were derived for the crest and orifice control, respectively (Sayadzadeh et al. 2020):

Additionally, Musavi-jahromi et al. (2016) proposed Eq. (4) to estimate Cd:

where H is the water level above the spillway crest, D is the crest diameter, h, and b are the height and width of VB, n is the number of VB, \(\alpha\) is the inclination angle of pyramidal VB with vertical axis, and \(\theta\) is the angle of VB that makes with the horizontal in radian.

Haghbin et al. (2022) investigated the ability of some computational methods to estimate Cd, based on obtained results they reported that the Support Vector Regression-Invasive Weed Optimization (SVR-IWO) is more efficient than other models to evaluate the Cd value. Several authors have also used ANN as a powerful tool to investigate the Cd of MGS (Alfatlawi and Alshaikhli 2015; Camargo et al. 2006; Kamanbedast 2012; Kashkaki et al. 2018). Kamanbedast (2012) evaluated Cd values for different vortex numbers, with the results demonstrating that 55.93% of the estimated outputs closely matched the actual values, indicating the accuracy of the modelʼs evaluation. Also, Camargo et al. (2006) utilized ANN to interpolate and extrapolate nonlinear relation curves. The outcomes highlighted the importance of ANN as a valuable support tool in the design and analysis of MGS, particularly in predicting Cd and flow rating curves, as depicted in Fig. 16.

ANNʼs capabilities to interpolate and extrapolate Cd and predict discharge rating curve (Camargo et al. 2006)

Furthermore, for comparison purposes, ANN and multiple nonlinear regression (MNLR) methods were applied to predict the Cd of circular and quadrate-stepped MGS (Alfatlawi and Alshaikhli 2015). The outcomes indicated that the highest recorded RMSE for the ANN approach prediction is 1.4%, while the maximum RMSE for MNLR formulae is 1.74% for four-stepped circular MGS. Both the ANN and MNLR approaches accurately anticipate the coefficient of discharge of the analyzed spillway. Also, from the MNLR results, two equations were extracted to predict the Cd for circular and quadrate shapes as written in Eq. (5) (\({R}^{2}=0.955)\) and Eq. (6) \({(R}^{2}=0.952)\) , respectively:

where H is the head above the spillway crest, R is the MGS crest radius, N is the number of steps, and l is the length of the quadrate side.

Kashkaki et al. (2018) predicted the Cd of a CPK spillway using an ANN model. The ANN models were trained and tested using the results obtained from an experimental study. The coefficient of determination (R2), mean absolute error (MAE), root mean square error (RMSE), and mean absolute percentage error (MAPE) were used to assess the ANN performance. The authors reported that the ANN model estimated the values of the Cd of the CPK spillway with higher accuracy.

However, Fais and Genovez (2009) investigated the discharge flow rating curve in a vertical shaft with a morning glory entrance to eliminate scale effects for low water heads. For this purpose, they conducted an experimental study on the Paraitinga dam spillway model on a scale of 1:51.02. As a result, equations for correcting the Cd for low water heads were developed as follows:

where H is the water head above the spillway crest and R is the crest radius. The corrected discharge rating curves were compared with the ones obtained by Genovez (1997) for the same spillway in model scales of 1:63.17 and 1:83.29 as shown in Fig. 17.

a Model discharge rating curves in scales 1:51.02, 1:63.17, and 1:83.29; b, c, and d are corrected discharge rating curves based on model scales 1:51.02, 1:63.17 and 1:83.29, respectively (Fais and Genovez 2009)

The lack of agreement between the discharge rating curves of the models and prototype is evident for discharges smaller than 0.002 m3/s (at a scale of 1:83.29), 0.004 m3/s (at a scale of 1:63.17), and 0.007 m3/s (at a scale of 1:51.02), as shown in Fig. 17a. While, the proposed equations showed a good agreement between the model and the prototype results, with a maximum divergence of 2.5%. On the other hand, Gouryev et al. (2020) mentioned that the value of the Cd of a shaft spillway working under a tiny head varies from 0.270 to 0.272.

Nohani (2015b) derived a relation between H/D and Cd using regression analysis. The H/D at shaft spillways is conversely related to the Cd values of the spillway.

Aghamajidi et al. (2013) developed two empirical equations to calculate the Cd value for smooth and stepped MGS as follows:

For a smooth spillway:

For stepped spillway:

Additionally, Aydin and Ulu (2023b) derived a new formula through regression analysis to estimate the discharge coefficients of the labyrinth-shaft spillway specifically for H/P ratios greater than 0.2.

where L is the length of the labyrinth weir crest and LS is the crest length of the bell mouth shape.

Figure 18 provides a summary of various relationships found in the literature, which depict the discharge coefficient as a function of relative submergence (H/D) for MGS

Figure 18 indicates that the coefficient of discharge (Cd) values exhibit a proportional decrease as the H/D ratio increases for MGS. It is worth noting that most of the available equations for estimating Cd are predominantly applicable to lower values of H/D, specifically in the crest control condition. This preference is attributed to the high variability observed in Cd values under this flow condition.

3.1.6 Further Studies on Flow Properties in MGS

Some researchers studied further problems that may happen during the spillway operation and might cause efficiency reduction. Razavi and Ahmadi (2017a) through a numerical model investigated the effect of adding suspended load to flow on discharge rate. For different water levels over the spillway crest, suspended loads of 3000, 6000, 9000, and 12,000 ppm were added to the flowing water. The findings revealed that as the amount of suspended loads in the flowing water increased, there was a corresponding reduction in the discharge rate passing through the spillway, as shown in Fig. 19.

Rating curve for net flow and flow with a suspended load of 9000 ppm (Razavi and Ahmadi 2017a)

The hydraulic parameters such as pressure, velocity, flow depth over the crest, and discharge rate were studied through employed numerical models to investigate the hydraulic performance of the MGS (Enjilzadeh and Nohani 2016; Nohani 2015c; Razavi and Ahmadi 2017b). Jalil et al. (2020) studied the effect of air entrainment and free-flow condition on flow properties through standard pipe elbow as shaft spillway by establishing a CFD numerical model. The visual results show that the switching flow conditionʼs speed depends on the radius of air entrainment, and it is dropped by 2.1 times when the water depth at the crest increases 3.3 times and disappears when the ratio of water depth to the length of the shaft reaches 40%. The amount of air entrainment and vortex formation directly leads to changing flow phenomenon.

Furthermore, the instability of an embankment was investigated due to the insufficient operation of MGS (Braz 2000). After several inspections inside and outside of the spillway tunnel, it is observed that air explosions in the downstream end of the dissipation basin during flood season caused some problems inside the spillway, such as developing a piping process and separating joints of the spillway tunnel. Also, when the outlet tunnel is submerged, air enters and subsequent release by floodwaters generated vibrations in the concrete tunnel and adjacent embankment.

Aghebatie and Hosseini (2020) examined the occurrence of slug flow and implemented various techniques for decreasing its negative consequences, such as modifications in tunnel slope, diameter, and radius of curvature. The results showed that the values of D/H > 1 employed in the spillway are more operative for decreasing the creation of strong slugs, with the maximum pressure decreased by 25% and the minimum pressure raised by 33% compared to the same situation for D/H ≤ 1.

3.2 Proposed ANN Modeling to Predict Cd

This section focuses on the development of a data-driven model to calculate the Cd of MGS. The MATLAB software (version 9.8) was utilized, employing the Levenberg–Marquardt algorithm for training the ANN tool. This algorithm was chosen due to its superior speed compared to other back-propagation algorithms available (Kashkaki et al. 2018). The network consisted of one input layer and one output layer. The modelʼs input was H/D, and the output was Cd. Several experimental studies in the past confirmed that the most important dimensionless parameter to control Cd values of MGS is H/D ratio (Aghamajidi et al. 2013; Bagheri et al. 2010; Bagheri and Nohani 2014; Christodoulou et al. 2010; Kamanbedast and Mousavi 2017; Nohani 2014, 2015b; Nohani and Emamgheis 2015; Noruzi and Ahadiyan 2017; Rouzegar et al. 2019; Sayadzadeh et al. 2020).

A trial-and-error process was applied to choose the suitable number of hidden layers and their neurons. Fifty experimental datasets from the literature were acquired and divided into three groups at random: 70% for training and 15% for each of the modelʼs testing and validation. Assessment criteria for evaluating the performance of the model, including R2, RMSE, MAE, and MAPE, were utilized to analyze and evaluate the effectiveness of the proposed model, and they can be calculated using the following formulas:

where n, \({\text{Cd}}_{{\text{m}}}\), \({\text{Cd}}_{{\text{p}}}\), \(\overline{{{\text{Cd}}_{{\text{m}}} }}\), \(\overline{{{\text{Cd}}_{{\text{p}}} }}\) are the number of data, measured Cd, predicted Cd, the average value of measured Cd, and the average value of the predicted Cd, respectively.

The best value for all the assessment factors mentioned before is zero, except for R2 where the optimum value is one.

Figure 20 represents the relation between target (actual) and output (predicted) Cd for training, validation, testing, and all datasets. Figure 21 illustrates the actual and predicted Cd versus H/D (input) with residual error for all dataset groups. The modelʼs R2, RMSE, MAE, and MAPE are 0.87, 0.224, 0.166, and 0.245, respectively. According to this model, the Cd values decrease with increasing the H/D ratio.

4 Results

A comprehensive search across multiple databases and search engines resulted in the identification of 338 records. After a careful screening and evaluation process, 66 complete research studies were selected from a diverse range of 35 different Journals and 13 conference proceedings. These chosen studies have been utilized to conduct a systematic review. Most of the included articles (about 85%) appear to have been published in the last decade, between 2013 and 2023, with the highest numbers of published papers (7, 7, 8, and 7, respectively) in the years 2015, 2017, 2021, and 2022. However, only 15% of the papers were published between 2000 and 2012. Figure 22 displays the number of published papers each year.

The geographical distribution of the studies is depicted in Fig. 23. The majority of the studies (7) were conducted in Iran, followed by Brazil (3), Algeria (3), Argentina (2), and the USA (2).

Table 7 displays the names of the journals and conferences along with the corresponding number of included articles. The results indicated that 74% of the reviewed articles were published in journals, and 26% were published in conference proceedings. The top three journals based on the number of articles published are Flow Measurement and Instrumentation (four papers), Civil Engineering Journal (three papers), and World Applied Sciences Journal (three papers) as well as both the Advances in Water Resources and Hydraulic Engineering and the Institution of Civil Engineers-Water Management, stand out as prominent conference proceedings, each publishing of three research papers.

Table 8 lists the most cited papers with the author names, article titles, journal or conference names, and the number of citations. The article citations were determined using the Google Scholar web portal as the primary source.

5 Discussion

A comprehensive review, analysis, and evaluation of many research studies related to the MGS topic is provided. The following paragraph wraps up and summarizes some of the major points.

-

Research interests in flow characteristics through MGS increased substantially in the last decade (2013–2023), with almost 85% of studies surveyed published in this period. However, only 15% of the research studies were conducted between 2000 and 2012.

-

The diversity of the journals and conference proceedings that published the articles is also observed. Based on our survey statistics, the top three journals are Flow Measurement and Instrumentation, Civil Engineering Journal, and World Applied Sciences Journal. The most popular location for case study research is Iran, with seven studies, followed by Brazil and Algeria, with three articles for each.

-

Several researchers tried to improve the spillway hydraulic performance by applying different techniques to avoid abnormal flow conditions and increase the discharge capacity.

-

The MGS spillways have three flow conditions: crest control for low water heads over the crest, orifice control, and pipe control for high water levels. MGSs are typically designed to operate as crest control conditions due to reduced discharge efficiency in the orifice and pipe controls.

-

Investigation of the MGS spillways was focused on modifying the crest geometry, installing VB at the spillway crest, vertical bend modification, excavation of the physical boundaries of the spillway, dealing with the cavitation problem, and deriving equations to predict the Cd value.

-

The surveyed studies make it abundantly evident that numerical and physical models are required to assess the hydraulic performance of flow conditions through the spillways.

-

Typically, physical models of spillways were built using Froude laws of similitude and certain restrictions on the values of head over the crest, Re, and We are advised to reduce the scale effects.

-

Vortex formation above the spillway crest is the most frequent issue that is likely to happen with this type of spillway. It causes a reduction in the discharge capacity and has negative consequences on spillway operation.

-

Placing VB over the crest is an effective method to overcome flow vorticity and improve spillway capacity, especially for high water levels. The most practical and efficient number of VBs is 6.

-

New forms of spillway inlet (CPK inlet, Marguerite-shaped inlets, polygonal sections, etc.) were developed to promote the capacity and eliminate malfunction of the spillway.

-

The elbow section connecting the vertical shaft and horizontal tunnel of the spillway exhibits the highest susceptibility to cavitation. This vulnerability is primarily attributed to flow direction changes and the presence of high velocities within this region.

-

Slug flow is an additional flow regime that can arise in the outlet tunnel of MGS, characterized by the presence of air–water flow where large air bubbles form within the tunnel. This flow pattern disrupts the smooth flow and induces pressure fluctuations that adversely impact the structural integrity and performance of the spillway.

-

The Cd of MGS varies according to the spillwayʼs nearby topography, physical boundaries, and inlet shape. Therefore, many pieces of research were carried out to derive a suitable equation to calculate the Cd value.

-

This study used the ANN approach to establish a new model to estimate Cd based on the gathered dataset from the literature.

6 Conclusions and Recommendations

Following the PRISMA reporting guidelines, a systematic review of 66 peer-reviewed articles was conducted to investigate and enhance the flow behavior of MGS. Based on the findings, the following conclusions can be drawn:

-

1.

Currently, the most prevalent approach for studying the hydraulic properties of spillways is the development of numerical models using commercial software. This method is favored due to its cost-effectiveness and the relatively shorter computational time required to obtain results compared to physical modeling techniques.

-

2.

Based on the classification of the included studies, it was determined that the articles were published across 35 journals and 13 conference proceedings.

-

3.

Several mechanisms were practiced to promote the hydraulic performance and investigate flow properties, like reformed inlet and vertical bend, testing various numbers and shapes of VBs, modifying the spillway boundaries, dealing with cavitation problems, and providing equations to predict Cd. Almost 39.4%, 30.3%, and 28.8% of the studies tried to improve spillway capacity by modifying the entrance shapes, deriving equations to estimate Cd, and applying VB, respectively.

-

4.

Regarding crest control, the performance of the MGS spillway is commendable. However, as the H/D ratio increases and the flow condition transitions to pipe control, there is a significant decline in the Cd value, which exhibits a converse relationship with the (H/D) value.

-

5.

The use of VB on the spillway crest has shown effective results in reducing vortex flow. Out of the available choices, utilizing six VB devices has been identified as the optimal solution, delivering superior performance and functionality.

-

6.

The proximity of the spillway inlet to the reservoir boundaries is one of the reasons for producing asymmetric flow above the crest.

-

7.

Using the ANN approach, we created a new correlation between H/D and Cd, achieving assessment parameters of 0.87 for R2, 0.224 for RMSE, 0.166 for MAE, and 0.245 for MAPE.

-

8.

In recent times, there has been extensive consideration given to the utilization of reliability-based design optimization approaches for achieving both safe and optimal design and operation of spillways.

Herein lie several research areas that necessitate further exploration, accompanied by recommendations for potential future studies:

-

1.

Limited attention has been given in the existing literature to studying air entrainment in the MGS. Consequently, conducting additional research in this area would significantly contribute to our comprehension of the aeration mechanism involved in MGS structures.

-

2.

Slug flow is an unfavorable occurrence that can occur within spillways, particularly in pressurized spillway tunnels where the flow does not emerge continuously. Instead, it discharges intermittently in a pulsating manner, leading to structural vibrations and instability. Consequently, it is strongly advised to conduct comprehensive studies on the phenomenon of slug flow and develop effective strategies for mitigating its destructive effects.

-

3.

In recent literature, optimization approaches have been utilized to address the safe and optimal design and operation of various spillway types such as labyrinth, Ogee, and stepped spillways. However, there is a limited amount of research focusing on the application of optimization methods to MGS and other types of flow control structures.

-

4.

Investigate and develop advanced two-phase flow models to accurately capture the complex interactions between air and water in MGS. Consider the effects of aeration, air–water interface dynamics, and the impact of entrained air on flow characteristics.

References

Aghamajidi R (2013) Investigation emptying & discharge coefficient function of semi short through shaft spillway considering stepped barrel and vortex breaker. Int J Farm Allied Sci 2(16):524–532. https://doi.org/10.5829/idosi.wasj.2013.28.12.1089

Aghamajidi R (2022) Investigating the impact of the vortex breaker on the hydraulics of the flow (empirical hydraulic coefficient) passing over the morning glory spillway. Civ Proj J 4(9):53–72. https://doi.org/10.22034/CPJ.2023.391020.1186

Aghamajidi R, Jahromi HM, Seghi H, Kashkoi HA (2013) Study effect of guide pier and stepped chamber on flow regime of morning glory spillway. Int J Agric Crop Sci 6(9):493

Aghebatie B, Hosseini K (2020) Investigation on slug flow phenomenon in Alborz morning glory spillway and preventing its destructive effects. Int J Mod Phys C 31(6):2050084. https://doi.org/10.1142/S0129183120500849

Akbari A, Nohani E, Afrous A (2015) Numerical study of the effect of anti-vortex plates on the inflow pattern in shaft spillways. Indian J Fundam Appl Life Sci 5(2011):3819–3826

Alfatlawi TJ, Alshaikhli HI (2015) Prediction the coefficient of discharge for stepped morning glory spillway using ANN and MNLR approaches. Int J Civ Environ Eng 37(2):1701–8285

Alkhamis MT (2021) Numerical evaluation of discharge coefficient and energy dissipation of flow over a stepped bell moth spillway. J Eng Res. https://doi.org/10.36909/jer.v9i2.9395

Anwar HO, Weller JA, Amphlett MB (1978) Similarity of free-vortex at horizontal intake. J Hydraul Res 16(2):95–105. https://doi.org/10.1080/00221687809499623

Asadsangabi F, Talebbeydokhti N, Rahnavard M (2014) Two phase flow modeling in shaft-spillways using volume of fluid (VOF) method. Iran J Sci Technol Trans Civ Eng 38(C1):99

Aydin M, Ulu A (2023a) Developing and testing a novel pressure-controlled hydraulic profile for siphon-shaft spillways. Flow Meas Instrum 90:102332. https://doi.org/10.1016/j.flowmeasinst.2023.102332

Aydin M, Ulu A (2023b) Numerical investigation of labyrinth-shaft spillway. Appl Water Sci 13(4):89. https://doi.org/10.1007/s13201-023-01896-4

Bagheri A, Nohani E (2014) Impact of making the crest of weir multifaceted on discharge coefficient of morning glory spillway. Indian J Fundam Appl Life Sci 4:3633–3639

Bagheri A, Bajestan MS, Jahromi HM, Kashkooli H, Sedghee H (2010) Hydraulic evaluation of the flow over polyhedral morning glory spillways. World Appl Sci J 9(7):712–717

Banejad H, Kashkaki Z, and Heidari M (2016) Study of circulation number fluctuations in papaya spillway. In: 15th Iranian Hydraulic Conference

Bordbar A, Jahromi HM, Bajestan MS, Sedghi H (2010) Step effects investigation on the flow regime and cavitation in stepped morning glory spillways. World Appl Sci J 10(9):1024–1031

Brakeni A, Guryev AP (2020) An experimental study of shaft spillway with a polygonal section. UPB Sci Bullet Ser D Mech Eng 82(2):255–268

Broucek M, Satrapa L, Kralik M, Soucek J (2021) Numerical and physical modelling of the performance of the pro-vortex vanes in shaft spillways. IOP Conf Ser Mater Sci Eng 1203(3):032082. https://doi.org/10.1088/1757-899X/1203/3/032082

Camargo SA, Dölling OR, and Varas EA (2006) Mathematical model of morning glory spillways using artificial neural networks. In: International symposium on hydraulic structures-XXII Congreso Latinoamericano de Hidraulica, October

Chen H, Deng J, Hu J, Xie B, Liu B, Liu J (2009) Experimental study on inner velocity and energy dissipation of shaft spillway with whirling current. Advances in water resources and hydraulic engineering. Springer, Berlin, pp 2118–2122

Christodoulou G, Mavrommatis A, and Papathanassiadis T (2010) Experimental study on the effect of piers and boundary proximity on the discharge capacity of a morning glory spillway. In: 1st IAHR European Congress, Edinburgh, Scotland, 2(1):1–6

Cicero GM, Barcouda M, Luck M, and Vettori E (2011) Study of a piano key morning glory to increase the spillway capacity of the Bage dam. In: Proceedings of the International Conference on Labyrinth and Piano Key Weirs-PKW2011, 81–86

da Braz GM (2000) The operation of a morning-glory-type spillway, as related to the embankment stability of an earthfill dam-a case study. Building Partnerships, pp 1–8

Daggett LL, Keulegan GH (1974) Similitude in free-surface vortex formations. J Hydraul Division 100(11):1565–1581

Djillali K, Abderrezak B, Petrovic GA, Sourenevna BE (2021) Discharge capacity of shaft spillway with a polygonal section: a case study of Djedra dam (East Algeria). Water Sci Technol Water Supply 21(3):1202–1215. https://doi.org/10.2166/ws.2020.366

Ehsani M, Behnamtalab E et al (2019) Investigation of elbow radius effect on formation of cavitation in morning glory spillway. Mod Civ Eng J 19(1):1–13

Emami S, Schleiss AJ (2016) Hydraulic scaled model tests for the optimization of approach channel excavation and approach flow conditions of haraz morning glory spillway. In: Proc. of the Int. symposium on appropriate technology to ensure proper development, operation and maintenance of dams in developing countries, CONF, 2a–87

Enjilzadeh MR, Nohani E (2016) Numerical modeling of flow field in morning glory spillways and determining rating curve at different flow rates. Civ Eng J 2(9):448–457

Fais LM, Ferreira Canno, Genovez AIB (2009) Discharge rating curve and scale effects correction in morning glory spillways. Advances in water resources and hydraulic engineering. Springer, Berlin, pp 2041–2046

Fais LMCF, Dalfre Filho J, and Genovez AIB (2015) Geometry influence and discharge rating curve correction in morning glory spillways. In: E-Proceedings of the 36th IAHR world congress, 1987, 1–8

Fattor CA, Bacchiega JD (2009) Design conditions for morning-glory spillways: application to potrerillos dam spillway. Advances in water resources and hydraulic engineering. Springer, Berlin, pp 2123–2128

Ferdowsi A, Farzin S, Mousavi S-F, Karami H (2019) Hybrid bat \& particle swarm algorithm for optimization of labyrinth spillway based on half \& quarter round crest shapes. Flow Meas Instrum 66:209–217. https://doi.org/10.1016/j.flowmeasinst.2019.03.003

Genovez AIB (1997) Evaluation of limit lenght in the study of air entrainment in shaft with morning glory entrance. Associate Professor Tesis, UNICAMP. Campinas, SP (in Portuguese)

Ghorbani Mooselu M, Nikoo MR, Bakhtiari Rayani N, Izady A (2019) Fuzzy multi-objective simulation-optimization of stepped spillways considering flood uncertainty. Water Resour Manage 33:2261–2275. https://doi.org/10.1007/s11269-019-02263-2

Gomez DM, Gessler D, and Donaghy J (2017) Evaluating the spillway capacity of the morning glory spillway at harriman dam. In: 2017 ASDSO-Dam Safety, Conference proceedings, 360–375

Gouryev AP, Brakeni A, Beglarova EC (2020) Discharge coefficient of shaft spillway under small heads. LARHYSS J 42:23–39

Gur’yev A, Khanov N, Chumicheva M, Verkhoglyadova A, Hayek B, Brakeni A (2021) Improvement of the theory of shaft spillway calculations. Web Conf 264:3031. https://doi.org/10.1051/e3sconf/202126403031

Haddad OB, Mirmomeni M, Marino MA (2010) Optimal design of stepped spillways using the HBMO algorithm. Civ Eng Environ Syst 27(1):81–94. https://doi.org/10.1080/10286600802542465

Haghbin M, Sharafati A, Aghamajidi R, Asadollah SBHS, Noghani MHM, Jalón ML (2022) Determination of discharge coefficient of stepped morning glory spillway using a hybrid data-driven method. Flow Meas Instrum 85:102161. https://doi.org/10.1016/j.flowmeasinst.2022.102161

Heller V (2011) Scale effects in physical hydraulic engineering models. J Hydraul Res 49(3):293–306. https://doi.org/10.1080/00221686.2011.578914

Hosseini K, Nodoushan EJ, Barati R, Shahheydari H (2016) Optimal design of labyrinth spillways using meta-heuristic algorithms. KSCE J Civ Eng 20:468–477. https://doi.org/10.1007/s12205-015-0462-5

Jafari J, Aghamajidi R (2022) optimizing geometric dimensions and vortex breaker of morning glory spillway using genetic algorithm: case study of physical model of San Louis Forebay Dam in California, USA. Int J Health Sci III:3926–3942

Jafari-Asl J, Seghier MEAB, Ohadi S, Plevris V (2021) Soft computing framework for the uncertainty-based optimization of the length and height of ogee-crested spillway. Eccomas Proceedia EUROGEN. https://doi.org/10.7712/140121.7954.18433

Jafari-Asl J, Seghier MEAB, Ohadi S, van Gelder P (2021) Efficient method using Whale Optimization Algorithm for reliability-based design optimization of labyrinth spillway. Appl Soft Comput 101:107036. https://doi.org/10.1016/j.asoc.2020.107036

Jain AK, Ranga Raju KG, Garde RJ (1978) Vortex formation in vertical pipe intakes. J Hydraul Division 104(10):1429–1448. https://doi.org/10.1061/JYCEAJ.0005087

Jalil SA, Hussein BS, Sarhan SA (2020) Visualization of elbow flow performance as shaft spillway. Ain Shams Eng J 11(4):865–873. https://doi.org/10.1016/j.asej.2020.03.017

Kabiri-Samani A, Keihanpour M (2021) Hydraulic characteristics of swirling flow at shaft spillways with the marguerite-shaped inlets. J Hydraul Res 59(5):724–738. https://doi.org/10.1080/00221686.2020.1818313

Kamanbedast AA (2012) The investigation of discharge coefficient for the morning glory spillway using artificial neural network. World Appl Sci J 17:913–918

Kamanbedast AA, Mousavi SR (2017) Experimental investigation of the effect of number and angle of anti-vortex piers in morning glory spillway with square inlet. J Water Soil Sci 20(78):171–182. https://doi.org/10.18869/acadpub.jstnar.20.78.171

Kardan N, Hassanzadeh Y, Shakooei Bonab B (2017) Shape optimization of trapezoidal labyrinth weirs using genetic algorithm. Arab J Sci Eng 42:1219–1229. https://doi.org/10.1007/s13369-016-2355-4

Kashkaki Z, Banejad H, Heydari M (2018) Application of ANN in estimating discharge coefficient of circular piano key spillways. J Soft Comput Civ Eng 2(3):39–49. https://doi.org/10.22115/SCCE.2018.118311.1048

Kashkaki Z, Banejad H, Heydari M, Olyaie E (2019) Experimental study of hydraulic flow of circular piano-key inlet in shaft spillways. J Rehabilit Civ Eng 7(3):96–102. https://doi.org/10.22075/jrce.2018.13050.1237

Keihanpour M, Kabiri-Samani A (2021) Effects of modern marguerite-shaped inlets on hydraulic characteristics of swirling flow in shaft spillways. Water Sci Eng 14(3):246–256. https://doi.org/10.1016/j.wse.2021.08.005

Kevorkijan L, Biluvs I (2021) Challenges of numerical modelling and simulation of flow inside the hydraulic tank. In: International conference fluid power 2021, Maribor, Slovenia. https://doi.org/10.18690/978-961-286-513-9.12

Liu Z-P, Guo X-L, Xia Q-F, Fu H, Wang T, Dong X-L (2018) Experimental and numerical investigation of flow in a newly developed vortex drop shaft spillway. J Hydraul Eng 144(5):4018014. https://doi.org/10.1061/(ASCE)HY.1943-7900.0001444

Mirabi MH, Akbari H, Alembagheri M (2021) Detailed vibrational analysis of unbalanced morning glory spillways using coupled finite volume-finite element method. SN Appl Sci 3(1):1–16. https://doi.org/10.1007/s42452-020-04006-0

Moher D, Liberati A, Tetzlaff J, Altman DG (2009) Preferred reporting items for systematic reviews and meta-analyses: the PRISMA statement. PLoS Med 6(7):e1000097. https://doi.org/10.1371/%0Ajournal.pmed.1000097

Moreira AMB (2021) Numerical modelling of spillways and energy dissipators using the smoothed particle hydrodynamics method. Ph.D thesis, University of Porto, Portugal

Musavi-jahromi SH, Hajipour G, Eghdam M (2016) Discharge coefficient in the morning glory spillways due to longitudinal angles of vortex breakers. Bullet Environ Pharmacol Life Sci 5(April):34–41

Naderi V, Farsadizadeh D, Hosseinzadeh Dalir A, Arvanaghi H (2013) Experimental study of bell-mouth intakes on discharge coefficient. J Civ Eng Urban 3(6):368–371

Nan F, Zhu W, Zhang L, Song T, Alim G, Shikulskaya O, and Boronina L (2017) Analysis of the domestic and foreign research on the shaft spillway. In: 2017 international conference on energy, power and environmental engineering (ICEPEE 2017), 99–103

Nasiri S, Kabiri-Samani A, Asghari K, Bagheri S (2021) Numerical modelling of flow field at shaft spillways with circular piano-key inlets. Proc Inst Civ Eng Water Manag. https://doi.org/10.1680/jwama.19.00085

Nasiri S, Kabiri-Samani A, Asghari K, Bagheri S (2022) Numerical modelling of flow field at shaft spillways with circular piano-key inlets. Proc Inst Civ Eng Water Manag 175(3):111–122. https://doi.org/10.1680/jwama.19.00085

Nohani E (2014) An Experimental study on the effect of vortex breakers on discharge coefficient for the shaft spillways with sharp edge and wide edge. J Civ Eng Urban 4(5):546–549

Nohani E (2015a) An experimental study on the effect of vortex breakers thickness on discharge efficiency for the shaft spillways. Sci Int 27(3):546–549

Nohani E (2015) Laboratory investigation of downstream submergence of shaft spillway on discharge efficiency. Sci Int 27(3):2301

Nohani E (2015c) Retracted: numerical simulation of the flow pattern on morning glory spillways. Int J Life Sci 9(4):28–31. https://doi.org/10.3126/ijls.v9i4.12671

Nohani E, Emamgheis JR (2015) Experimental investigation the effect of vortex breakers shape on discharge efficiency for the morning glory spillways. Iran J Irrig Drain 9(5):741–749

Noruzi S, Ahadiyan J (2017) Effect of vortex breaker blades 45 degree on discharge coefficient of morning glory spillway using flow-3D. J Irrig Sci Eng (JISE) 40(1):192–200. https://doi.org/10.22055/jise.2017.12677

Novak P (1984) Scaling factors and scale effects in modelling hydraulic structures. In: Kobus H (ed) Symposium on scale effects in modelling hydraulic structures, International association for hydraulic reasearch (IAHR)

Novák P, Čabelka J (1981) Models in hydraulic engineering: physical principles and design applications. Monographs & surveys in water resources engineering. Pitman Publications, London, UK

Odgaard AJ (1986) Free-surface air core vortex. J Hydraul Eng 112(7):610–620. https://doi.org/10.1061/(ASCE)0733-9429(1986)112:7(610)

Ohadi S, Jafari-Asl J (2021) Multi-objective reliability-based optimization for design of trapezoidal labyrinth weirs. Flow Meas Instrum 77:101787. https://doi.org/10.1016/j.flowmeasinst.2020.101787

Oukaili F, Bercovitz Y, Goeury C, Zaoui F, Le Coupanec E, kadi Abderrezzak k (2021) Surrogate-based optimization for overflow spillway design. LHB 107(1):1–11. https://doi.org/10.1080/27678490.2021.1935003

Padmanabhan M, Hecker GE (1984) Scale effects in pump sump models. J Hydraul Eng 110(11):1540–1556. https://doi.org/10.1061/(ASCE)0733-9429(1984)110:11(1540)

Parsaie A, Haghiabi AH (2019) The hydraulic investigation of circular crested stepped spillway. Flow Meas Instrum 70:101624. https://doi.org/10.1016/j.flowmeasinst.2019.101624

Radmanesh S, Bazaee A, Aghamajidi R (2022) Calculating the overflow coefficient of stepped and non-stepped morning glory spillway and investigating its behavior using antivortex blades. Civ Proj 4(2):51–64. https://doi.org/10.22034/CPJ.2022.04.02.1139

Rahimi H, Razavi E (2018) Determination of critical depth to avoid free vortex at morning glory spillway by numerical modeling. Int J Hydraul Eng 7(2):15–21. https://doi.org/10.5923/j.ijhe.20180702.01

Razavi AR, Ahmadi H (2017) Numerical modelling of flow in morning glory spillways using flow-3D. Civ Eng J 3(10):956. https://doi.org/10.28991/cej-030928

Razavi AR, Ahmadi H (2017) Three-dimensional simulation of flow field in morning glory spillway to determine flow regimes (case study: Haraz Dam). Civ Eng J 3(11):1133–1145. https://doi.org/10.28991/cej-030943

Rouzegar J, Kamanbedast AA, Masjedi A, Heidarnejad M, Bordbar A (2019) The influence of inlet section geometry in labyrinth-morning glory spillways with and without vortex blade on discharge coefficient. J Water Soil Sci Sci Technol Agric Nat Resour 23(3):1–13

Sabeti P, Karami H, Sarkardeh H (2019) Analysis of the impact of effective length of morning glory spillway on its performance (numerical study). J Instrum Measure Metrol 18(2):211–221. https://doi.org/10.18280/i2m.180217

Salehi S, Moghadam AM, Soori S (2023) Effect of the pipe bend of the morning glory spillway on the cavitation number. Flow Meas Instrum 92:102375. https://doi.org/10.1016/j.flowmeasinst.2023.102375

Savic L, Kapor R, Kuzmanovic V, Milovanovic B (2014) Shaft spillway with deflector downstream of vertical bend. Proc Inst Civ Eng Water Manag 167(5):269–278. https://doi.org/10.1680/wama.12.00111

Sayadzadeh F, Musavi-Jahromi SH, Sedghi H, Khosrojerdi A (2020) Pyramidal vortex breakers influences on the flow discharge of morning glory spillway. Ain Shams Eng J 11(2):455–463. https://doi.org/10.1016/j.asej.2019.08.013

Shemshi R, Kabiri-Samani A (2017) Swirling flow at vertical shaft spillways with circular piano-key inlets. J Hydraul Res 55(2):248–258. https://doi.org/10.1080/00221686.2016.1238015

Sukerta IM, Chen T-C, Mardizal J, Salih SM, Zulkarnain I, Islam MZ, Majeed MS, Mahdi AB, Mutlak DA, Aravindhan S (2022) Comparison of lateral spillway and morning glory spillway performance in flood control. J Water Land Dev. https://doi.org/10.24425/jwld.2022.140796

Tabari MR, Hashempour M (2019) Development of GWO–DSO and PSO–DSO hybrid models to redesign the optimal dimensions of labyrinth spillway. Soft Comput 23:6391–6406. https://doi.org/10.1007/s00500-018-3292-9

Talebi S, Mahtabi G, Karbasi M, Akbari M (2022) Experimental study of hydraulic properties of flow over vertical shaft spillway with bow-tied shape inlet. Irrig Drain Struct Eng Res 22(85):41–58. https://doi.org/10.22092/idser.2022.357719.1501

Yalin MS (1989) Fundamentals of hydraulic physical modelling. Recent advances in hydraulic physical modelling. Springer, Berlin, pp 1–37

Yildiz A, Yarar A (2018) Physical modeling of flow over an ogee spillway and investigation of scale effects by using Froude similarity. Int Symp Environ Ind. https://doi.org/10.21698/simi.2018.fp13

Funding

No funding affiliations are involved in this study.

Author information

Authors and Affiliations

Contributions

LSO was involved in conceptualization, investigation, analysis, and writing—original draft. KZA was involved in supervision, writing—review and editing, and validation.

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions