Abstract

When steel braces are used to retrofit an existing reinforced concrete frame, the paths through which the seismic loads are transferred change, resulting in new demands on the frame members. The brace positioning or configuration has a considerable effect on the new load paths and demands on the frame elements, particularly columns. In the present study, three different X-bracing configurations, termed: centrally stacked (C), end-stacked (E) and diagonally distributed (D), are considered and their effects on the seismic performance of 2D, RC frames; 4, 8 and 12 storeys high and 3 and 6 bays wide are evaluated. To this end, a number of nonlinear pushover analyses are carried out on different retrofitted and non-retrofitted frames and the resulting capacity curves are utilized to determine and compare the frames global seismic performance parameters, including: lateral capacity, stiffness, overstrength, ductility, behaviour factor and toughness. The results of pushover analyses are also used to evaluate and compare new shear, compressive and tensile force demands on the columns, as the most important members of the frames. It is found that the diagonally distributed brace configuration (D) has the most favourable effects on the global seismic performance of the retrofitted RC frames and the least complications and side effects regarding the new demands on columns compared to the common stack-type configurations, C and E.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Lateral load resisting systems such as shear walls, bracing and flexural frames are incorporated into framed buildings and designed to withstand lateral seismic or wind forces and to limit drifts by increasing the lateral stiffness. Although steel bracing has traditionally been used in steel frames, in recent years it has gained popularity in retrofitting existing deficient RC frames; mainly due to the speed and ease of construction, reduced weight and its less intrusive nature compared to the shear walls.

Three different techniques have been used to attach steel bracing systems to an existing RC frame (Maheri, 2005). The older, externally connected (Badoux and Jirsa 1990; Bush et al. 1991; Nateghi-Alahi 1995) and indirect internally connected (Sugano and Fujimura 1980; Usami et al. 1988; Hjelmstad et al. 1988; Tagawa et al. 1992) bracing systems are reported to have a number of drawbacks and shortcomings including architectural restraints and difficulty in providing appropriate connections (Tagawa et al. 1992; Maheri and Sahebi 1995). The later proposed, directly connected internal bracing (Maheri and Sahebi 1995, 1997) is shown to be a more efficient and robust technique to attach steel bracings to RC frames (Maheri and Sahebi 1995; Maheri et al. 2003; Maheri and Akbari 2003). In this method, similar to bracing of steel frames, braces of different types (concentric or eccentric) are directly connected to the RC members inside the individual unit frames using gusset plates. Therefore, the bracing system is concentric to the RC frame in relation to their plane of action.

A large body of research has been dedicated in recent years to investigate the merits of, and design considerations for, directly connected internal steel bracing of RC frames. Experimental studies (Maheri and Sahebi 1995; Maheri et al. 2003; Ghaffarzadeh and Maheri 2006a, b) and numerical investigations (Pincheira and Jirsa 1995; Abou-Elfah and Ghobarah 2000; Ghobarah and Abou-Elfah 2001; Maheri and Akbari 2003, Maheri and Ghaffarzadeh 2008; Viswanath et al. 2010; Niroomandi et al. 2010) have shown the ability of steel bracing of different types to substantially increase shear capacity and reduce drift of RC frames. The effects of bracing on some other seismic performance parameters of RC frames including ductility, overstrength, behaviour factor and ability to absorb energy have also been studied (Maheri et al. 2003; Ghaffarzadeh and Maheri 2006a, b; Akbari and Maheri 2013; Kheyroddin et al. 2019, Hemmati et al. 2020; Ahmad and Masoudi 2020; Khan et al. 2021). It has been observed that bracing of RC frames may adversely reduce ductility of the brace-frame (Maheri et al. 2003; Ghaffarzadeh and Maheri 2006a, b). To increase ductility, a number of investigators have studied the possibility of using eccentric bracing (Huang et al. 2015; Di Sarno and Manfredi 2010; Ozel and Guneyisi 2011; Ramin and Maheri 2018; Hemmati et al. 2020) and other energy-absorbent systems such as compression release devices (Ghaffarzadeh and Maheri 2006a, b) or ductile ring (Kheyroddin et al. 2019) and torsional dampers (Arish and Maheri 2020). Others have concentrated on providing design guidelines for steel bracing of RC frames (Maheri and Ghaffarzadeh 2008). An important practical feature of steel bracing of existing RC frames is the ability of connections between the brace and RC members to efficiently transfer the loads between the two systems. Different connection techniques have been proposed (Tasnimi and Masoomi 1999; Maheri and Hadjipour 2003) and tested (Maheri and Hadjipour 2003), and design guidelines for different connections have also been proposed (Maheri and Hadjipour 2003; Maheri and Yazdani 2016a, b).

In majority of works reported by different investigators on the subject of internally braced RC frames, the emphasis has been on the merits and advantages of this type of retrofitting and little has been reported regarding possible side effects of such a retrofitting method. In a major study by Rahimi and Maheri (2018, 2020), the adverse effects of retrofitting RC frames with steel bracing on the global response of the frame including its performance level, global displacement and inter-storey drift, as well as the effects on the individual members of the RC frame, including beams, columns and joints have been examined. They reported that steel bracing may be beneficial to the seismic performance of low-rise RC frames in almost every aspect; however, for mid to high-rise frames, the adverse effects of retrofitting on beams and connections and, in particular, columns attached to the bracing system, are considerable and in some instances necessitates local strengthening of RC frame elements (Rahimi and Maheri 2020).

1.1 Methodology

The present work furthers the work carried out by Rahimi and Maheri (2018, 2020) by investigating the effects of X-brace configuration on the retrofitted RC frames regarding its global performance, as well as the possible adverse effects on the local performance of frame columns.

Three different bracing configurations (centrally stacked, side-stacked and diagonal) are considered and their effects on the global seismic performance of 2D, RC frames; four, eight and twelve storey high and three and six bays wide are evaluated by performing nonlinear static pushover analyses on the retrofitted frames. The seismic performance parameters considered for the basis of comparison of the three, brace configurations include, global lateral capacity, initial stiffness, overstrength factor, ductility ratio, ductility reduction factor, behaviour factor and toughness; all evaluated using the force–displacement capacity curves. The effects of different brace configurations on the axial and shear capacities of columns are also investigated.

2 Numerical Modelling of Brace-Frame Assemblage

The SeismoStruct software (Nassar and Krawinkler 1991) was used to conduct the numerical investigation. This software is one of the strongest and latest finite element tools for structural analysis. It is capable of predicting large displacement behaviour of space frames under static or dynamic loadings, taking into account both geometric nonlinearities and material inelasticity. The software allows simulation of buckling of steel braces and confinement of concrete. It is capable of performing eight different types of analysis, including the conventional and adaptive pushover analyses.

2.1 Numerical Modelling

In modelling the material behaviour, the Chang-Mender constitutive model for confined and unconfined concrete (SeismoStruct 2018) was used. The software has two different solver types: Skyline and Frontal. In this research, the Skyline solver has been used as it tends to be more numerically stable and is thus the default option. From the SeismoStruct library of elements, an inelastic displacement-based frame element (infrmDB) was selected to model RC beams and columns. This is the displacement-based 3D beam-column element type capable of modelling members of space frames with geometric and material nonlinearities. A nonlinear truss element was used to model the steel braces, and braces were connected to the reinforced concrete frame via link elements.

In the numerical models, both geometrical and material nonlinearities were considered. To discretize the cross sections of brace-frame members, the fibre cross section was utilized, numbering 240 for beams and columns and 120 for braces. The cross-sectional areas of RC beams and columns consist of a core and a cover, modelled, respectively, by confined and unconfined concrete. The numerical model of cross section of RC beams and columns, showing the fibres in concrete core and concrete cover, is presented in Fig. 1a, and the numerical model of the cross section of steel brace elements is shown in Fig. 1b. The brace-frame systems were subjected to a 50-step displacement-controlled incremental loading and an inverted triangular load distribution was considered along the height of the frames. The compressive strength of concrete was assumed to be 28 MPa. The Menegotto and Pinto (1973) constitutive model with a yield stress of 400 MPa was utilized to model the behaviour of reinforcing steel, and the behaviour of steel material used in the braces was simulated by the Ramberg–Osgood(SeismoStruct 2018) constitutive model with a yield stress of 240 MPa (see Fig. 1). Both steel models can simulate stiffness degradation and buckling.

To ensure the accuracy of the numerical models and the efficiency of the selected software in analysing the problem at hand, two sets of validation were carried out. In the first set, small-scale models of unbraced and braced RC frames, tested previously by Maheri et al. (2003), were analysed and the numerical pushover capacity curves are compared with the experimental results. In the second validation, a four-storey, three-bay full-scale steel-braced RC frame, analysed previously by Maheri and Akbari (2003) using the DRAIN-2DX software, was also analysed using the SeismoStruct software and the results are compared.

2.2 Validation of Numerical Models

The scaled models tested by Maheri et al. (2003) were 1:3 scaled models of a 3 m × 3 m central unit frame of a four-storey, three-bay ductile RC frame, designed according to provisions of ACI 318-89 (1992) and retrofitted by X bracing, designed to sustain 100% of the original base shear using the AISC-LRFD (1999) method. Details of the scaled RC frame and the bracing system are shown in Fig. 2.

Dimensions and details of the scaled unit RC frame and bracing system used for verification (Maheri et al. 2003)

The nonlinear pushover response curves obtained for the unbraced and braced unit frames using the above-mentioned numerical models are compared with the experimental results reported by Maheri et al. (2003) in Figs. 3 and 4, respectively. The close agreement of the numerical and experimental results in both cases indicates the accuracy of the adopted numerical model and analysis software.

For the second verification, the pushover nonlinear response curve of a full-scale four-storey, three-bay RC frame, retrofitted in the central bay with steel X braces (see Fig. 5) was evaluated using the SeismoStruct and is presented in Fig. 6. This frame has been previously designed and retrofitted by Maheri and Akbari (2003), based on the provisions of the ACI-318-95 (1995) and the AISC-LRFD (1999) codes assuming 100% of the base shear to be sustained by the bracing system and then analysed using the DRAIN-2DX software. The capacity curve of this frame evaluated by Maheri and Akbari (2003) using the DRAIN-2DX software is also shown in Fig. 6. It can be noted that the two pushover curves are comparable, with the SeismoStruct model appearing to predict the ultimate capacity more rationally.

3 Details of the Selected Brace-Frame Systems

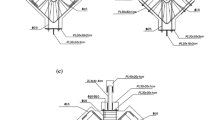

There are a number of topology configurations that can be used to brace a multi-storey frame (steel or RC), the most popular being the conventional stack configuration shown in Fig. 7a. The stack configuration is sometimes topped with a horizontal outrigger bracing system (Fig. 7b). The outrigger configuration is particularly popular in tall buildings. Another configuration is the diagonal form shown in Fig. 7c. Safari and Maheri (2006) showed that this type of bracing configuration is superior to the conventional stack configuration. They conducted a metaheuristic design optimization study and repeatedly found that the diagonal form of bracing is the optimal solution regarding both the shear capacity and the control of global drift (Safari and Maheri 2006).

Considering that the outrigger configuration is generally used in tower buildings, in the present study only the stack and diagonal configurations have been considered. However, it is reported that the location of the stack bracing also has an effect on the response of the frame (Rahimi and Maheri 2020); therefore, two different stack bracing systems, one located centrally (in a central bay of the 2D frame) and the other in the side bays of the 2D frame, were considered.

In order that the effects of bracing topology on the seismic response of retrofitted RC frames could be studied in detail, two other major affecting variables were also investigated, namely the height of the frame (number of storeys) and the length of the frame (number of bays). Frames having 4, 8 and 12 storeys, each with 3 and 6 bays, were selected. In all the frames, the length of each bay was considered to be 5 m and the height of each storey was taken as 3 m. Taking into consideration the above number of variables, in total, 24 non-retrofitted and retrofitted frames were analysed. The frame identities are abbreviated as shown in Fig. 8, in which N represents the original unbraced RC frame and C, E and D signify the frame retrofitted with, respectively, the centrally stacked, end-stacked and diagonally positioned configurations. The 18 retrofitted configurations are depicted in Figs. 9, 10 and 11 for the 4-storey, 8-storey and 12-strorey frames, respectively.

The original (non-retrofitted) and centrally stacked (C) retrofitted 4-, 8- and 12-storey RC frames, with three bays, have been previously designed by Rahimi and Maheri (2018) using the ACI-318-02 (2002) code to design the RC frame as an intermediate ductility moment frame and the LRFD-AISC-360 (2005) code to design the steel bracing. The seismic loading was evaluated using the Iranian Seismic Code (2014), with a design base acceleration, A = 0.3, the behaviour factor, R = 6 and considering the building to rest on soil type III (Iranian Seismic Code 2014). In the retrofitted frames, the centrally stacked steel bracing system was designed using the force-based approach to withstand 100% of the lateral load, based on recommendations by Maheri and Akbari (2003) and Niroomandi et al. (2010). In their design, the compressive and tensile strengths of concrete were considered as 28 MPa and 3.17 MPa, respectively, and the secant modulus of concrete and yield stress of steel reinforcement were taken as 27.6 GPa and 400 MPa, respectively (Rahimi and Maheri 2018). Details of the centrally stack retrofitted 3-bay, 4-stroey frame are shown in Fig. 12.

Details of the centrally stacked retrofitted 3-bay, 4-storey frame a RC frame b steel bracing (Rahimi and Maheri 2018)

In the present study, the same designs presented by Rahimi and Maheri (2018) are considered for the corresponding 6 frames. The same details of the beams and columns of the 3-bay frame are also considered for the 6-bay RC frames. Also, the same bracing details (box cross section shown in Fig. 12b) and number of braces are considered for the retrofitted frames, however, with different arrangements (configurations), such that in each floor of the 3-bay frames only one X brace and in every floor of the 6-bay frames, two X braces are placed. Therefore, all the corresponding retrofitted frames are exactly the same, except for the location of the brace (braces) in each storey. In this way, the only variable is the location, or topology configuration, of the braces.

4 The Effects of Brace Configuration on the Global Response

In the present study, the global response of retrofitted frames was evaluated using the nonlinear static pushover analysis. Typical load–displacement response curves obtained for the 4-, 8- and 12-storey frames are presented in Fig. 13a–c, respectively.

The resulting force–displacement capacity (or response) curves were then used to determine the seismic response parameters of each frame, including: the maximum lateral capacity (Vmax), initial stiffness (Ki), overstrength factor (Rs), ductility ratio (μ), ductility reduction factor (Rμ), behaviour factor (R) and toughness (T). FEMA-356 (2000) provisions were used to idealize each nonlinear capacity curve by a bilinear curve (see Fig. 13), so that the seismic performance parameters could be evaluated. With reference to Fig. 13 and based on FEMA-356, ductility ratio is evaluated as: μ = Δt/Δy, where Δt is the target displacement which, amongst others, depends on the fundamental period of vibration, T (SeismoStruct 2018), and Δy is the equivalent yield displacement, determined through bi-linearization of the capacity curve (Fig. 14). The overstrength factor is evaluated as: Rs = Vy/Vs in which, Vy is the equivalent yield force and Vs is the force corresponding to the formation of the first plastic hinge. The ductility reduction factor, Rμ, is the ratio of the elastic force Ve and the equivalent yield force Vy. The elastic force, Ve, cannot be explicitly obtained from the capacity curve, as it also depends on the fundamental period of vibration and ground seismicity. A number of other methods have been presented to evaluate Rμ (Maheri and Akbari 2003), the most widely used method being that proposed by Nassar and Krawinkler (1991) in the form of:

where

In Eq. (2), a and b are constants which depend on the post-equivalent yield angle, α (the angle of the second line in relation to the horizontal axis) (Nassar and Krawinkler 1991). In the present study, α was taken as zero, giving a = 1.0 and b = 0.42. Also, the behaviour factor R was evaluated as the product of the overstrength factor and ductility reduction factor (R = Rs × Rμ) and the toughness was evaluated as the area under the capacity curve (bilinear curve).

Bi-linearization of the pushover capacity curve (Niroomandi et al. 2010)

The seismic performance parameters discussed above were evaluated using the idealized bilinear capacity curves of the 24 non-retrofitted and retrofitted frames and are listed in Table 1.

4.1 Lateral Capacity (V max)

The maximum base shear (capacity) values evaluated for the 24 frames under consideration are also compared graphically in Fig. 15. The first point to note in Fig. 15 and Table 1 is that in frames of the same height, the frames with 6 bays expectedly exhibit capacities almost twice those with three bays. It is also noted that retrofitting the frames with steel bracing has increased the capacity of the 4-storey, 3-bay, centrally braced frame by 47% and the similar 8-storey and 12-storey frames by 70% and 60%. This indicates that as the height of the frame increases from 4 to 8 storeys, the bracing has a more advantageous effect; however, the effect of retrofitting on the global capacity reduces in taller frames. Similar results were reported by Rahimi and Maheri (2020). On the main question of the effects of brace configuration on the lateral capacity, Fig. 15 shows that there is indeed a sizable difference in capacities with different brace arrangements; with the highest increases in capacity occurring in frames braced with the diagonal configuration (D) and the lowest increases being related to frames with end-stacked configuration (E). With an increase in the number of storeys and bays, the effect of how the braces are arranged increases; as in the 4-storey frame with 3 bays there is 10% and in taller frames with 6 bays there is a 30% difference in the frame capacities when retrofitted by the two configurations (D and E).

4.2 Initial Stiffness (K i)

The initial stiffness is a suitable indicator regarding the effects of retrofitting on the overall stiffness of the frame-brace system. Initial stiffness (Ki), defined as the slope of the initial linear section of the capacity curve (joining point zero to the point at which the first plastic hinge in formed), was evaluated for the retrofitted and non-retrofitted frames as is listed in Table 1 and compared graphically in Fig. 16. The first point to note is that the bracing system has increased the initial stiffness of the RC frames by 35–50%; the more the number of bays, the higher the increase. Regarding the effects of brace configuration on the initial stiffness, it is noted that there is little difference in frames having three bays, the diagonal and centrally stacked arrangements (C) faring better than the end-stacked configuration (E). However, as the number of bays increases to six, the difference in the initial stiffness of the diagonal configuration D and configuration E becomes more profound, the former providing a stiffer system. The differences between the initial stiffness of frames braced by D configuration and E configuration (and even C configuration) are more evident as the height of the frame increases. For the 6-bay and 12-storey frame, this difference is around 15%.

4.3 Overstrength Factor (R S)

The overstrength factor Rs, as a parameter quantifying the ability of a structure to re-distribute the applied loads through its members (defined in Sect. 4), was calculated for each frame (see Table 1), and the results are also presented graphically in Fig. 17 for comparison. As is expected, the retrofitting of frames by steel bracing has substantially increased the overstrength factor by as much as 50%, the increases being almost the same in frames with different number of bays. This highlights the fact that the number of bays have little effect on the overstrength factor of the retrofitted frames. Regarding the effects of brace configuration on the overstrength factor, it is also noted that they are not substantial and are all less than 10%, with the D and C configurations again slightly outperforming the E configuration.

4.4 Ductility Ratio (μ) and Ductility Reduction Factor (R μ)

Ductility is an important parameter affecting the seismic response. With reference to Fig. 14 and discussion in Sect. 4, ductility ratio, μ, may be obtained using any of the three characteristic global displacements, including: the target displacement, Δt, which depends on, among other factors, the spectral acceleration and the effective fundamental period of vibration (FEMA-450 2013), the maximum displacement, Δmax, which is the maximum allowable roof displacement specified by the seismic codes to control global drift and is generally given as a percentage of the height of the building and the ultimate displacement, Δu, which is the actual ultimate displacement sustainable by the building before collapse. Using any of the above three characteristic displacements gives different values for the ductility ratio. In Fig. 18, the ductility ratios of the C-braced frames evaluated using the target displacement, Δt and the maximum displacement, Δmax (1.5% of the height of the frame as set out in FEMA-450 (2013) are compared. It can be noted that ductility ratios evaluated using the target displacements are generally less than those using the maximum displacement and the difference reduces as the number of storeys increases. In the present study, the ductility ratio is evaluated based on the target displacement, Δt.

Figure 19 compares graphically the ductility ratios evaluated for different retrofitted and non-retrofitted frames (see also Table 1). It is evident that as a result of retrofitting, ductility ratios reduce noticeably (by as much as 25%), except for the smallest frame (4-storey, 3-bay) which it has, in fact, increased by 10%. Considering the effects of brace configuration, it is noted that in low-rise frames (4-storey), the effects are negligible; however, as the height of frame increases, differences become more noticeable, with the end-stacked configuration, E, showing a more ductile behaviour. This is expected, as the Δt-based ductility ratio is directly proportional to the effective fundamental period of vibration, which in turn is inversely proportional to stiffness. The E-braced frames are less stiff, compared to the D and C-braced frames, and therefore more ductile. Similar trends can be seen in the ductility reduction factors (Rμ).

4.5 Behaviour Factor (R)

The behaviour factor (or force reduction factor), R, is an important seismic performance parameter, containing both the overstrength and ductility components of the response. The values of the behaviour factor evaluated for different braced and unbraced RC frames and listed in Table 1 are presented graphically in Fig. 20. The first point to note is that in the low-rise, 4-storey frames, the steel brace retrofitting has increased the behaviour factor by as much as 35%, irrespective of the number of bays. On the other hand, for the 8- and 12-storey frames, the effects of retrofitting on the behaviour factor is very small, except for the 8-storey, 3-bay frame in which the behaviour factor has in fact decreased due to retrofitting. The different performance of this frame is mainly due to the fact that retrofitting has not significantly increased the overstrength factor. Another observation is that the number of bays has almost no effects on the behaviour factor of the retrofitted frame. Regarding the effects of brace configuration on the behaviour factor, Fig. 20 shows that the effects are small, the C- and D-braced frames performing marginally better in the low-rise frames and the E-braced frames showing slightly higher R values in the high-rise (12-storey) frames.

4.6 Toughness (T)

Toughness is an all-inclusive seismic performance parameter, quantifying the total energy absorbed by the structure before failure. It is affected by and contains almost all the other seismic performance parameters, including the maximum capacity, stiffness, overstrength and ductility. In Fig. 21, toughness of different braced and unbraced frames is compared. With reference to this figure, it may be noted that the main parameters affecting the value of toughness relate to the geometrical dimensions of the frame, such that; it increases considerably as the number of storeys and the number of bays increase. On the other hand, the effects of brace configuration on toughness are less significant (less than 10%), particularly in the low-rise frames. In taller, 8 and 12-storey frames, it is noteworthy that the D- and C-braced frames exhibit higher toughness compared to the E-braced frames when there are more bays in the frame (6 bays), whereas in 3-bay frames the situation reverses and E-braced frames perform better. The reason behind this is that in the 6-bay frames, the effects of diagonal (D) and centrally stacked (C) bracing configurations on the capacity, stiffness and overstrength components of toughness are more profound than the end-stacked (E) frames, whereas in the 3-bay frames, the effects of E configuration on ductility component of toughness are more significant than the other two configurations.

5 The Effects of Brace Configuration on the Frame Columns

Retrofitting an existing RC frame with steel bracing should generally reduce the global demand on the RC frame and its elements, particularly when a very high share of the base shear is assigned to the bracing system. However, at is was stated earlier, adding steel bracing to the frame changes the load paths; more often in favour of the RC frame elements, but in some instances, it could have an adverse effect and increases the demand on the existing frame elements. This is particularly true for the columns as has been reported by Rahimi and Maheri (2018, 2020). In this section, the effects of different brace configurations on the capacity demands on columns are investigated. The RC columns of a frame are classified into two groups: (i) those connected to the bracing system, termed ‘connected’ columns and (ii) those not attached to the bracing system, termed ‘free’ columns.

The maximum shear, compressive and tensile forces of all columns were extracted from the nonlinear pushover analyses of the retrofitted frames (C, E and D) and were compared with the level of forces in the original non-retrofitted frames (N), so that the effects of retrofitting could be studied. For this purpose, in each storey of every frame, the highest demands on the critical columns before and after retrofitting are compared.

5.1 The Effects on Shear Force Demand in Columns

Shear failure is an undesirable brittle failure which should be avoided, particularly in RC columns. Therefore, it is necessary to investigate the level of shear forces in columns after retrofitting, and if it exceeds the shear capacity of a column, it is considered as a side effect of retrofitting and should be remedied by local strengthening of that column.

The critical shear forces in the connected and free columns of the 4-storey frames having three and six bays are shown in Fig. 22. It can be observed that for the low-rise frames the adverse changes in columns shear due to any form of retrofitting are less than 20%, but significant enough to be controlled. It appears that the increase in column shear demands due to retrofitting in the larger, 6-bay frame is less than the 3-bay frames. It is also noted that the increase in shear demand is more profound in the lower storeys. In the 3-bay frames, the performance of diagonally distributed brace configuration (D) appears to be better than the E and C configurations, all shear forces being reduced except in the first floor. However, as the frame becomes wider (6 bays), it appears that the type D retrofitting increases the columns shear demands for both the connected and free columns more than the E and C brace configurations.

The critical column demand shear forces for the mid-rise, 8-storey frames are compared in Fig. 23. The maximum increase in column shear demand amongst all cases is 15%. The E-type bracing appears to preform generally better than other configurations in reducing the shear demand in both the connected and free columns. The C brace configuration seems to fair better on reducing shear demands in free columns of the 3-bay frames, except in the first storey, and the D brace configuration appears to result in the least increased demand on the columns regarding shear compared to the C configuration. An important observation is that, in the 6-bay frame, a substantial increase in shear demand occurs in the free columns of the top storeys when E and C configurations are used (as much as 100% in the case of E configuration). This, however, does not occur in the diagonal configuration D.

With reference to Fig. 24, in the 12-storey, 3-bay frames, addition of the bracing system in most cases reduces the column shear demands, exceptions being at lower storeys in which the C configuration somewhat increases the shear demand. An interesting point to note is that the centrally stacked configuration (C), substantially decreases the shear demand in the connected columns of the first storey, at the expense of the free columns in that storey. Another noteworthy observation is that, similar to the 8-storey frame, in the wider 12-storey frames (6-bay frame), large increases in shear demand occurs in the free columns of the top storeys, irrespective of the type of brace configuration, with D configuration faring better (35% increase) and the E configuration performing the worst (100% increase). On the other hand, in the same frames, the E configuration has a more favourable effect on shear demands of both the free and connected columns at lower storeys.

5.2 The Effects on Compressive Force Demand in Columns

Columns sustain large levels of compressive forces in multi-storey buildings and are therefore designed to withstand these forces. Retrofitting an RC frame by steel X braces may increase the compressive force demands beyond the capacities of some existing columns.

The level of compressive forces in the critical columns in each storey (columns having the largest compressive demand in each storey) are plotted for the retrofitted and non-retrofitted low-rise (4-storey) frames in Fig. 25. This figure indicates that, in the 3-bay frames, adding the C and E brace configurations generally reduces the compressive force demand in the free columns and increases the demand in the connected columns (columns connected to the braces), with the C bracing system performing better for free columns and the E brace configuration faring better in the connected columns. In the wider, 6-bay frames, retrofitting appears to result in almost no change in the free columns compressive force demand, except that the D bracing system somewhat increases the demand in the first storey. However, in the connected columns, large increases in demand is observed, with the demand increasing as the height of storey reduces. This is particularly true when the C and E configurations are used, both increasing the compressive force demand by around 50% at the first storey. The D brace configuration appears to perform much better regarding the compressive force demand in the 4-storey frames.

Regarding the mid-rise frames (8 storeys), Fig. 26 shows that there is little change in the compressive force demand in the free columns, regardless of the type of brace configuration, except for the lower storey columns of the 3-bay frames when retrofitted with the D bracing configuration, in which demand increases by about 20%. Nevertheless, the increase in the compressive force demand on the connected columns is substantial in the lower storeys of the frames, particularly when the C and E configurations are used. The increase in demand at the first storey when the E configuration is used is over 100%. Such large increases in demand on columns and therefore on joints would require local retrofitting by using FRP, steel or RC jacketing (Zarandi and Maheri 2015; Torabi and Maheri 2017; Javanmardi and Maheri 2017), prior to application of the bracing system.

In the 12-storey frames, a similar trend to that observed in the 8-storey frames can be seen regarding the change in the compressive force demand in columns (see Fig. 27). Very little increase in demand is noted for the free columns of the tall frames, irrespective of the number of bays and the type of brace configuration, except for the D configuration, using which increases the demand at the lower storeys by as much as 25%. However, for the connected columns, the increase in compressive force demand is considerable, particularly in the case of the C and E configurations, the latter increasing the demand by as much as 90%. Again, the diagonally distributed configuration, D, performs much better, increasing the column compressive force demand by less than 30%.

5.3 The Effects on Tensile Force Demand in Columns

When a brace member, connected to a column undergoes tension, it transfers some of the tensile load to the column, reducing the compressive force in the column. It may even overpower the compressive force and cause the column to experience tension. The most critical tensile forces developed in the columns of each retrofitted and non-retrofitted frames were extracted and are plotted in Fig. 28 for comparison. In general, as the height of the frame increases, the critical tensile force demand increases, exceptions being the frames braced by the E configuration, in which the 8-storey frames experience larger tensile forces compared to the 12-storey frames. The D configuration appears to produce higher levels of tensile forces in columns of the 3-bay frames (over 7 times higher than the non-retrofitted frame in the 12-storey frame), and the E configuration produces higher tensile forces in the 6-bay frames (over 6 times higher than the non-retrofitted frame). The highest values of tensile forces expectedly occur in the lower storeys and decrease in the upper storeys as the overturning moment decreases.

Although these are high tensile forces, possibly in excess of the RC column capacities, Rahimi and Maheri (2018) through time history dynamic analysis showed that under seismic condition the time in which a column experiences high tension is very small and the tensile crack closes very fast as the column returns to compression. On the other hand, when the column undergoes tension, concrete cracks and the forces are transferred mainly by the longitudinal bars. During the earthquake return cycle, when the axial force of the column suddenly changes back to compression, since the tensile crack is still open, at the first instance of the return of the compressive force, this force will be carried out primarily by the longitudinal bars, increasing the risk of buckling in the longitudinal bars if the transverse ties are insufficient.

Not every column may experience tensile force and the high tensile forces developed may occur in one or a very limited number of columns. A better judgement as to the effect of brace configuration on the level of tensile forces in columns may be reached by considering the number of columns in each frame undergoing tension. For this purpose, another parameter, in the form of the ratio of the number of columns experiencing tension in each frame to the total number of columns in that frame, is defined. Variations in this ratio with changing brace configuration, number of bays and height of the frame were evaluated and are plotted in Fig. 29. It can be seen that the number of columns experiencing tension in the 4-storey frames is far less than that in the 8-storey and 12-storey frames, with the exception of the 6-bay frame retrofitted with E configuration and that the 8-storey frame has generally less columns experiencing tension compared to the taller, 12-storey frame. Also, the diagonally distributed bracing configuration, D, seems to generally result in lower number of columns undergoing tension.

6 Conclusions

In this study, the effects of steel X-brace configuration on the global seismic response of retrofitted 2D RC frames were investigated. The effects of steel brace retrofitting on the shear, compressive and tensile force demands in columns and the side effects arising from different brace configurations were also examined. Three different brace configurations, namely: diagonal (D), centrally stacked (C) and end-stacked (E) were considered to retrofit RC frames, 4, 8 and 12 storeys high and 3 and 6 bays wide. The results of the numerical investigations presented in this paper may be summarized as follows:

-

1.

Adding a steel X-bracing system to an RC frame considerably increases the lateral shear capacity of the frame. Of the three brace configurations studied, the diagonal (D) bracing configuration has the best performance in increasing the frame shear capacity, followed by the C configuration. As the number of storeys increases, the beneficial effects of diagonal D configuration become more profound, increasing the capacity by as much as 30% compared to the E configuration.

-

2.

The change in the initial stiffness of the RC frames when retrofitted with steel bracing, follows a similar trend as the lateral capacity. It may increase as much as 50%, with the diagonal brace configuration (D), causing the highest increase, closely followed by the C configuration. Regarding the effects of brace configuration on the overstrength factor, it is noted that they are not substantial (less than 10% in all cases), with the D and C brace configurations slightly outperforming the E configuration.

-

3.

As a result of retrofitting, ductility ratio (μ) reduces noticeably (by as much as 25%), except for the smallest frame (4-storey, 3-bay) which it has, in fact, increased by 10%. Considering the effects of brace configuration, it is noted that in low-rise frames (4-storey), the effects are negligible. However, as the height of frame increases, differences become more noticeable, with the end-stacked configuration, E, showing a more ductile behaviour.

-

4.

In the low-rise frames, steel brace retrofitting noticeably increases the behaviour factor, R. However, in taller frames (8- and 12-storey), the change in the value of R due to retrofitting is negligible. Also, the effects of different brace configurations on the behaviour factor are small; the C and D brace configurations performing marginally better in the low-rise frames and the E brace configuration resulting in slightly higher R values in the high-rise (12-storey) frames.

-

5.

Toughness is highly affected by the size of the frame and much less by the type of brace configuration (less than 10%), particularly in the low-rise frames. In taller, 8 and 12-storey frames having 6 bays, the D and C brace configurations exhibit higher toughness compared to the E-braced frames, whereas in the 3-bay frames the situation reverses and the E configuration performs better.

-

6.

An important observation is that in the taller frames (8-storey and 12-storey) steel bracing substantially increases the shear demand in columns not attached to the bracing system (free columns) in the upper storeys, regardless of the brace configuration. The increase in demand may be as much as 100% when the frame is braced by E configuration. Also, the diagonal brace configuration, D, performs better in limiting the increase in shear demand in both the free and connected columns of the upper storeys

-

7.

The diagonally distributed brace configuration, D, appears to perform much better regarding the column compressive force demand in the 4-storey frames. D bracing performs even better in the taller frames, increasing the column compressive force demand by at most 30% compared to the E and C configurations which may cause as much as 100% increase in demand.

-

8.

In general, as the height of the frame increases, the tensile force demand in columns increases. The diagonally distributed brace configuration, D, produces higher levels of tensile force demands in columns of the narrower, 3-bay frames, and the E brace configuration produces higher tensile forces in the wider, 6-bay frames. Also, the D brace configuration seems to generally result in lower number of columns undergoing tension.

Finally, it is concluded that the diagonally distributed brace configuration (D) in general has the most favourable effects on the global seismic performance of the retrofitted RC frames and the least complications and side effects regarding the change in the shear, compressive and tensile force demands in the columns compared to the common stack-type configurations, C and E.

References

Abou-Elfath H, Ghobarah A (2000) Behaviour of reinforced concrete frames rehabilitated with concentric steel bracing. Can J Civ Eng 27:433–444

ACI Committee 318 (1992) Building code requirements for reinforced concrete (ACI 318-89, Revision 1992). American Concrete Institute, Detroit, Michigan

ACI Committee 318 (1995). Building code requirements for reinforced concrete (ACI 318-95). American Concrete Institute, Detroit, Michigan

ACI Committee 318 (2002) Building code requirements for reinforced concrete (ACI 318-02) and commentary (ACI 318R-02). American Concrete Institute, Detroit, Michigan

Ahmad N, Masoudi M (2020) Eccentric steel brace retrofit for seismic upgrading of deficient reinforced concrete frames. Bull Earthq Eng 18(6):2807–2841

AISC-LRFD (1999) Specification for structural steel buildings. American Institute of Steel Construction (AISC)

AISC 360-05 (2005) Specification for structural steel buildings. American Institute of Steel Construction (AISC)

Akbari R, Maheri MR (2013) Analytical investigation of response modification (behaviour) factor, R, for reinforced concrete frames rehabilitated by steel chevron bracing. Struct Infrastruct Eng 9(6):507–515

Arish G, Maheri MR (2020) Retrofitting RC frames with eccentric steel bracing and OADAS torsional damper. Submitted for publication, 2020

Badoux M, Jirsa O (1990) Steel bracing of RC frames for seismic retrofitting. Struct Eng 116(1):55–74

Bush TD, Jones EA, Jirsa JO (1991) Behaviour of RC frame strengthened using structural steel bracing. Struct Eng 117(4):1115–1126

Di Sarno L, Manfredi G (2010) Seismic retrofitting of existing RC frames with buckling restrained braces. Improving the seismic performance of existing buildings and other structures. Soil Dyn Earthq Eng 30(11):1279–1297

FEMA-356 (2020) American Society of Civil Engineering (ASCE) prestandard and commentary for the seismic rehabilitation of buildings, Prepared for the Federal Emergency Management Agency, FEMA 356

FEMA-450 (2013) Recommenced provisions for seismic regulations for new buildings and other structures. Building Seismic Safety Council

Ghaffarzadeh H, Maheri MR (2006a) Cyclic tests on the internally braced RC frames. J Seismol Earthq Eng (JSEE) 8(2):177–186

Ghaffarzadeh H, Maheri MR (2006b) Mechanical compression release device in steel bracing system for retrofitting RC frames. Earthq Eng Eng Vib 5(1):151–158

Ghobarah A, Abou-Elfath H (2001) Rehabilitation of reinforced concrete frames using eccentric steel bracing. Eng Struct 23:745–755

Hemmati A, Kheyroddin A, Farzad M (2020) Experimental study of reinforced concrete frame rehabilitated by concentric and eccentric bracing. J Rehabil Civ Eng 8(1):97–108

Hjelmstad KD, Foutch DA, Del Valle E, Downs RE (1988) Forced vibration studies of an RC building retrofit with steel bracing. In: Proc 9th World Conf. Earthquake. Eng, Tokyo-Kyoto, vol 2m pp 469–474

Huang L, Tan H, Yan L (2015) Seismic behavior of chevron braced reinforced concrete spatial frame. Mater Struct 48(12):4005–4018

Iranian code of practice for seismic resistance design of buildings. Standard No. 2800. 4th. ed. (2014)

Javanmardi MR, Maheri MR (2017) Anisotropic damage plasticity model for concrete and its use in plastic hinge relocation in RC frames with FRP. Structures 12:212–226

Khan MS, Basit A, Khan U (2021) Seismic upgrade of deficient RC frames using different configurations of eccentric steel braces. Asian J Civ Eng 22(3):461–475

Kheyroddin A et al (2019) Experimental evaluation of RC frames retrofitted by steel jacket, X-brace and X-brace having ductile ring as a structural fuse. J Build Pathol Rehabil 4(1):1–13

Maheri MR, Sahebi A (1995) Experimental investigation on the use of steel bracing in reinforced concrete frames. In: Proc 2nd Int. Conf. Seism. Earthquake. Eng., Iran 1995, pp 775–784

Maheri MR, Sahebi A (1997) Use of steel bracing in reinforced concrete frames. Eng Struct 19(12):1018–1024

Maheri MR, Kousari R, Razazan M (2003) Pushover test on steel X-braced and knee-braced RC frames. Eng Struct 25:1697–1705

Maheri MR, Hadjipour A (2003) Experimental investigation and design of steel brace connection to RC frame. Eng Struct 25(13):1707–1714

Maheri MR, Akbari R (2003) Seismic behaviour factor, R, for steel X-braced and knee-braced RC buildings. Eng Struct 25:1505–1513

Maheri MR (2005) Recent advances in seismic retrofit of RC frames. Asian J Civil Eng (AJCE) 6(5):395–413

Maheri MR, Ghaffarzadeh H (2008) Connection overstrength in steel-braced RC frames. Eng Struct 30(7):1938–1948

Maheri MR, Yazdani S (2016a) Efficiency of the uniform force method in designing steel brace connection to RC frame. Construct Steel Res 116:131–140

Maheri MR, Yazdani S (2016b) Seismic performance of different types of connection between steel bracing and RC frames. Iranian J Sci Techol Trans Civ Eng (IJSTC) 40(4):287–296

Menegotto M, Pinto PE (1973) Method of analysis of cyclically loaded RC plane frames including changes in geometry and non-elastic behavior of elements under normal force and bending. Prelim Rep IABSE 13:15–22

Nassar A, Krawinkler H (1991) Report No. 95. Stanford, California: The John A. Blume Earthquake Engineering Center, Stanford University

Nateghi-Alahi F (1995) Seismic strengthening of eight story building using steel braces. Eng Struct 17(6):455–461

Niroomandi A, Maheri A, Maheri MR, Mahini SS (2010) Seismic performance of ordinary RC frames retrofitted at joints by FRP sheets. Eng Struct 32(8):2326–2336

Ozel AE, Guneyisi EM (2011) Effects of eccentric steel bracing systems on seismic fragility curves of mid-rise R/C buildings: a case study. Struct Safety 23(1):82–95

Pincheira JA, Jirsa JO (1995) Seismic response of RC frames retrofitted with steel braces or walls. J Struct Eng 121(8):1225–1235

Rahimi A, Maheri MR (2018) The effects of retrofitting RC frames by X-bracing on the seismic performance of columns. Eng Struct 173:813–830

Rahimi A, Maheri MR (2020) The effects of steel X-brace retrofitting of RC frames on the seismic performance of frames and their elements. Eng Struct 206:110–149

Ramin K, Maheri MR (2018) The seismic investigation of off-diagonal steel braced RC frames. Slovak J Civil Eng 26(3):49–64

Safari D, Maheri MR (2006) Genetic algorithm search for optimal brace positions in steel frames. Adv Steel Const 2(4):400–415

SeismoStruct 2018 (2018) A computer program for static and dynamic nonlinear analysis of framed structures. http://www.seismosoft.com.

Sugano S, Fujimura M (1980) Seismic strengthening of existing reinforced concrete buildings. In: Proc.7th World Conference. Earthquake. Eng, Istanbul, vol 5, pp 449–456

Tagawa Y, Aoki H, Huang T, Masuda H (1992) Experimental study of new seismic strengthening method for existing RC structures. In: Proc 10th World Conf. Earthq. Eng, Rotterdam, pp 5193–5198

Tasnimi A, Masoomi A (1999) Evaluation of response reinforced concrete frames strengthening with steel bracing. In: Proc. 3rd Int. Conf. on Seism. and Earthq. Engng. (in Persian)

Torabi A, Maheri MR (2017) Seismic repair and retrofit of RC beam-column joints using stiffened steel plates. Iranian J Sci Technol Trans Civ Eng 41:13–26

Usami H, Azuchi T, Kamiya Y, Ban H (1988) Seismic strengthening of existing reinforced concrete buildings in Shizuoka prefecture, Japan. In: Proc 9th World Conf. Earthquake. Eng, Tokyo-Kyoto, vol 2, pp 421–426

Viswanath KG, Prakash KB, Anant D (2010) Seismic analysis of steel braced reinforced concrete frames. Int J Civ Struct Eng 1(1):114–122

Zarandi S, Maheri MR (2015) Seismic performance of RC frames retrofitted by FRP at joints using a flange-bonded scheme. Iranian J Sci Technol Trans Civil Eng 39(C1):103–123

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maheri, M.R., Fathi, A. The Effects of X-Brace Configuration on the Seismic Performance of Retrofitted RC Frames. Iran J Sci Technol Trans Civ Eng 46, 3995–4018 (2022). https://doi.org/10.1007/s40996-022-00944-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40996-022-00944-4