Abstract

Multiple sub-projects in a construction program (CP) generally involve overlapping construction times and serious resource conflicts, and the decision-making environment is complex and changeable. Optimizing the schedule plan is an effective way to ensure that the mandatory CP duration is met. Based on multi-objective optimization theory, an optimization model for CP schedule plans is established to achieve CP duration optimization and resource leveling. An improved adaptive NSGA-II algorithm (IANSGA-II) is proposed to enhance the convergence, uniformity, and spread of the optimization results. An optimization process for CP schedule plans is presented based on the proposed model and algorithm. A case study of a geological disaster treatment program is conducted, and an optimized schedule plan set containing three schedule plans is obtained based on the proposed model and algorithm. The case study shows that the proposed optimization model and algorithm are reasonable and adaptive. Compared with the results of the standard NSGA-II and adaptive NSGA-II (ANSGA-II), the Pareto solutions obtained by the IANSGA-II dominate up to 75.6% of the solutions of the ANSGA-II and 91.8% of the solutions of the NSGA-II. This proves that the uniformity and spread of the Pareto solutions obtained by the IANSGA-II are better than those of the other two algorithms. In addition, a metric that can characterize convergence shows that the IANSGA-II has the best convergence. Two theoretical cases show that the proposed algorithm will also work in higher-dimensional search spaces. Optimizing the schedule plan of CPs based on the proposed process will provide decision-makers with more schedule plans to adapt to different decision-making environments.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

A CP is composed of multiple sub-projects with shared resources and overlapping construction times (Ferns 1991). There are a number of factors affecting the decision-making environment of a CP. The process and method of achieving the program schedule objectives are highly uncertain (Lima et al. 2019; Wang and Yuan 2017). However, progress indexes are generally mandatory, especially for programs that affect livelihood, such as programs that address geological disasters (Adam et al. 2017). The characteristics above make it difficult to select a feasible schedule plan. A feasible schedule plan should reasonably consider the duration and resource consumption level based on a fixed total investment. Therefore, the optimization of a CP schedule plan is a multi-objective optimization problem, which is NP-hard (Liu and Wang 2020). The contradiction and incommensurability between the duration optimization and resource leveling objectives cause the optimized schedule plan to vary. A diverse range of optimized schedule plans is beneficial in choosing a schedule plan under an uncertain environment.

Considerable research into duration optimization and resource leveling has already been reported. Duration optimization generally refers to optimizing the schedule plan to shorten the duration under resource constraints (Naik and Kumar 2015). The critical path method (CPM) is widely used (Moselhi 1993), but it insufficiently considers the complex time relations and logical relations of CPs. Therefore, duration optimization models based on mixed-integer programming were proposed by Floudas and Lin (2005) and Nolz (2021). However, CPs usually have a large number of variables and constraints, resulting in the low efficiency of such analytical methods. In recent years, various meta-heuristic algorithms have been applied to solve the duration optimization problem for CPs (El-Abbasy et al. 2017; Kaveh and Ilchi Ghazaan 2017; Qiao and Yang 2019; Zheng et al. 2004). For instance, when optimizing the duration of a large infrastructure maintenance program, Antoniol et al. (2005) compared the optimized results of the genetic algorithm with those of the simulated annealing algorithm. This proved that the genetic algorithm performed better.

Resource availability can significantly affect the construction process. Particularly for CPs such as pre-fabricated construction systems, improving resource allocation and scheduling in terms of project time, cost, and the life cycle assessment (LCA) can identify and eliminate process waste and improve resource efficiency (Heravi et al. 2021, 2020a). Resource leveling is generally measured by the maximum resource usage, resource consumption variance, and other indexes (Ponz-Tienda et al. 2013). For the resource leveling problem of simple engineering projects, the optimal solution is commonly obtained using analytical methods such as the branch-and-bound method (Ponz-Tienda et al. 2017). For the resource leveling problem of CPs, the optimal solution can also be obtained by using mate-heuristic algorithms due to the complexity of the problem (Li and Demeulemeester 2015; Piryonesi et al. 2019; Prayogo et al. 2018). For instance, Gaitanidis et al. (2016) applied the hybrid evolutionary algorithm to perform resource leveling for an actual large construction project, a 50,000 DWT ship.

When preparing schedule plans for CPs, it is necessary to consider both duration optimization and resource leveling. An indirect approach is to convert the multi-objective problem into a single-objective optimization problem and then solve it (Cococcioni et al. 2018). The principle of the indirect method is to linearly weigh multiple targets and solve them based on a single-objective optimization algorithm (Alrifai et al. 2010; Qi et al. 2010). Converting the multi-objective optimization problem into a single-objective optimization problem is conducive to simplifying and efficiently solving the problem. However, the method has the essential shortcoming that it cannot provide multiple optimized schedule plans to select from (Lin et al. 2015). Therefore, this method is not conducive to determining the schedule plans of CPs.

Generally, a shorter duration corresponds to a larger resource consumption variance. The optimization of the duration and resource leveling cannot be achieved simultaneously. Therefore, the solution to the multi-objective optimization problem is not unique. It is necessary to find the Pareto optimal solution set to adapt to different decision-making environments. Another approach to solving the problem directly is calculating and obtaining a set of schedule plans for a CP based on multi-objective optimization theory. Multi-objective evolutionary algorithms (MOEAs) are commonly adopted to obtain the Pareto optimal solutions of multi-objective optimization problems. Many methods have been proposed, such as the NSGA (Srinivas and Deb 1994) and NSGA-II (Deb et al. 2002). Based on the NSGA-II, Kar et al. (2021) developed an optimum material procurement schedule by integrating the construction program and budget using the NSGA-II, which aided in completing the project within the stipulated time and budgeted cost. In addition, Heravi et al. (2020b) adopted the NSGA-II to identify the cost-optimal options for designing a residential nearly zero-energy building in a city. These studies showed the usability of the NSGA-II. The NSGA-II is a fast nondominated sorting algorithm with an elite strategy, which is improved by the NSGA algorithm and performs better in solving multi-objective optimization problems. The algorithm has the following three main features: (1) the population is ranked by nondominated sorting to reduce the computational complexity; (2) the elite strategy is introduced to improve the accuracy of the optimization results; and (3) a crowdedness comparison is used to ensure the diversity of the population. The algorithm has been applied to the duration-cost optimization (Fallah-Mehdipour et al. 2012; Zahraie and Tavakolan 2009), the time-robustness optimization (Wang and Lian 2020), and the duration-resource leveling optimization of engineering projects (Heon Jun and El-Rayes 2011). However, the genetic operators of this algorithm are set to certain values by default, which results in the poor convergence, uniformity, and spread of the Pareto optimal solutions. Therefore, Gu and Chen (2015) improved the genetic operators by using the number of iterations to make appropriate adjustments to the crossover and mutation probabilities and created an ANSGA-II. However, the adaptive operators require too many subjectively determined coefficients (Li 2017; Yan et al. 2021). Reducing the number of subjectively determined coefficients in the adaptive operators simplifies the algorithm and improves its performance (Claesen and De Moor 2015; Fatyanosa and Aritsugi 2020). Therefore, it is necessary to design concise and dynamically adaptive genetic operators to improve the NSGA-II to solve schedule plan optimization problems for CPs.

This paper establishes a schedule plan optimization model for CPs to perform duration optimization and resource leveling based on the multi-objective optimization theory. For the schedule optimization process, an improved adaptive nondominated sorting genetic algorithm named the IANSGA-II is proposed. The optimal schedule plan set of CPs is then determined, and it meets the demands of different decision-making environments. The remainder of this paper is organized according to the general research framework shown in Fig. 1.

Section 2 constructs a schedule plan optimization model for CPs based on multi-objective optimization theory. Section 3 proposes the IANSGA-II to solve the model and systematically introduces the overall framework of the algorithm, its improvements, and its operation process. Section 4 illustrates the adaptability of the method with a case study of a geological disaster treatment program. Section 5 discusses the optimization results and proves that the convergence, uniformity, and spread of the Pareto optimal solutions obtained by the proposed method are better than those obtained by the other two existing algorithms. In addition, two theoretical cases are considered in Sect. 5 to illustrate the adaptability of the proposed algorithm to higher-dimensional search spaces. Finally, several conclusions and directions for future work are derived based on the optimization process.

2 Schedule Plan Optimization Model for CPs Based on Multi-objective Optimization Theory

2.1 Problem Description

A CP contains \(N\) sub-projects, the mandatory duration is \(T\), and \(M\) types of resources are consumed. A schematic diagram of the composition and resource consumption of a CP is shown in Fig. 2. To meet the mandatory duration and resource leveling requirements, the following assumptions are adopted when modeling the schedule optimization of CPs:

-

(1)

Resource \(k\) (\(k\in \left[1,M\right]\)]) is consumed \({r}_{i,j,k}\left(t\right)\) by work package \(i,j\) of sub-project \(i\) (\(i\in \left[1,N\right]\), \(j\in \left[1,{n}_{i}\right]\), where \({n}_{i}\) is the number of work packages in the \(i\) th sub-project). The resources considered have critical impacts on the schedule plan and are consumed throughout the duration of the CP.

-

(2)

The maximum total supply of resource \(k\) in the \(t\) th unit of work time is \({R}_{k}\left(t\right)\). There will be no design changes during project implementation. The types and quantities of resources consumed per unit time by the work packages of each sub-project are already determined.

-

(3)

The project schedule is not affected by other factors, except for the constraints of resources, mandatory duration, and logical relationships of the work package.

-

(4)

When establishing a schedule plan for the CP, the decision-maker assigns a priority to each sub-project according to the importance of the sub-project.

2.2 Schedule Plan Optimization Model

Based on multi-objective optimization theory, an objective function suitable for optimizing the schedule of CPs is formulated, and the corresponding schedule optimization model is proposed.

2.2.1 Objective Function

Duration optimization and resource leveling are closely related to the start time \({S}_{i,j}\) of the work package \(i,j\). Therefore, the start time \({S}_{i,j}\) of each work package in the CP is selected as an independent variable of the objective function. The mapping relationship between the objective and independent variables is expressed as \(F\left({f}_{1}\left({S}_{\mathrm{1,1}},{S}_{\mathrm{1,2}},\dots {S}_{i,j},{\dots ,S}_{N,{n}_{i}}\right),{f}_{2}\left({S}_{\mathrm{1,1}},{S}_{\mathrm{1,2}},\dots {S}_{i,j},{\dots ,S}_{N,{n}_{i}}\right)\right)\), and the objective functions are explained as follows:

-

(1)

Duration optimization objective function.

In a single-objective optimization problem with duration optimization as the objective, the duration calculation follows the CPM, which means that the path with the longest time is the critical path. Taking the time of the critical path as the duration, the optimization objective function of the duration is established as Eq. (1).

where \({\upomega }_{i}\) is the priority of a sub-project and \({D}_{i}\) is the duration of the \(i\) th sub-project; \({D}_{i}\) is the difference between the maximum end time of all work packages and the minimum start time of all work packages for the sub-project.

When conducting multi-objective optimization, directly setting the duration as an integer will cause the distribution of the final Pareto frontier to be too narrow. According to Assumption (4), minimizing the sum of the weighted duration of each sub-project is taken as the duration optimization objective to enhance the spread of the Pareto frontier distribution and reflect the importance of each sub-project. \({{\varvec{S}}}^{*}\) is defined as

By substituting \({{\varvec{S}}}^{*}\) into Eq. (3), the total duration of the CP is obtained.

where \({\varvec{d}}\) is a row vector composed of the duration of each work package and its size is \(1\times \sum_{i=1}^{N}{n}_{i}\). \(D\) is the total duration of a CP, taken as the difference between the maximum end time and the minimum start time of all work packages.

-

(2)

Resource leveling objective function.

Many indicators can represent resource leveling, including the resource consumption variance, the maximum resource usage, the sum of the absolute deviations in resource usage, etc. Damci and Polat (2014) compared nine different indicators for solving the resource leveling problem, and the sum of the squares of the deviations in resource usage for a determined time interval provided the best solution in their study. The resource consumption variance works in the same way as the sum of the squares of the deviations in resource usage for a determined time interval because they differ by only a constant coefficient. Therefore, resource leveling is measured by resource consumption variance in this paper. The degree of resource leveling has a negative correlation with the variance of resource consumption. For CPs, the resource leveling objective is to minimize the sum of the resource consumption variance of each kind of resource in the total duration. The resource leveling objective function is shown as Eq. (4).

where \(\sigma\) is the total variance of resource consumption under the schedule plan and \(\overline{{r}_{k}}\) is the average consumption of the \(k\) th resource in the total duration \(D\) of the CP.

2.2.2 Optimization Model

According to the description of the optimization problem and its four assumptions, the optimization model of a CP is as follows:

where the first function is the objective function. The constraints in Model (5) are explained as follows:

-

(1)

(1) \({r}_{k}\left(t\right)\le {R}_{k}\left(t\right)\) is a resource constraint, which means that the consumption of the \(k\) th resource in the \(t\) th unit time \({r}_{k}\left(t\right)\) shall not exceed the supply of the resource in the \(t\) th unit time \({R}_{k}\left(t\right)\). The calculation method of \({r}_{k}\left(t\right)\) is shown in Eq. (6); its value equals the sum of all work packages' consumptions of the \(k\) th resource in the \(t\) th unit time.

$$r_{k} \left( t \right) = \mathop \sum \limits_{i}^{N} \mathop \sum \limits_{j}^{{n_{i} }} r_{i,j,k} \left( t \right)$$(6)where

$$r_{i,j,k} \left( t \right) = \left\{ {\begin{array}{*{20}c} {r_{i,j,k} \left( t \right),\quad S_{i,j} \le t \le S_{i,j} + d_{i,j} } \\ {0,\quad t > S_{i,j} + d_{i,j} } \\ \end{array} } \right.\quad k \in \left[ {1,M} \right]$$(7) -

(2)

\(T{E}_{i,j}\le {S}_{i,j}\) indicates that the start time \({S}_{i,j}\) of work package \(i,j\) cannot be before the earliest start time \(T{E}_{i,j}\).

-

(3)

\({S}_{i,j}+{d}_{i,j}\le {S}_{i,j+1}\) represents the predecessor constraint. Work package \(i,j\) of sub-project \(i\) is the predecessor of its work package \(i,j+1\). Work package \(i,j+1\) must be started after work package \(i,j\) ends.

3 Schedule Plan Optimization for CPs Based on the IANSGA-II

The NSGA-II (Deb et al. 2002) can yield the Pareto optimal solution set for general multi-objective optimization problems. However, the crossover and mutation operators are set as fixed values during the iteration. In dealing with the schedule plan optimization problem for a CP, such a setting will make it difficult for the algorithm to converge. Most importantly, the number of optimized schedule plans obtained from the Pareto optimal solutions will be smaller, and they will be unable to fully meet different decision-making environment requirements. The existing adaptive method of the ANSGA-II (Gu and Chen 2015) attempts to adjust the crossover and mutation operators appropriately according to the number of iterations. However, the designed adaptive operators require excessive subjectively determined coefficients, causing inconvenience in solving the problem.

This paper designs adaptive operators with fewer subjectively determined coefficients and improves the convergence, uniformity, and spread of the distribution of the Pareto optimal solutions. The operators are inserted into the NSGA-II to form the IANSGA-II, which efficiently optimizes the schedule plan of a CP. The optimization process and related instructions are shown in Fig. 3.

First, we collect the data of the CP, determine the work breakdown structure, and develop an initial schedule plan set based on the logical relationships of the work packages. The initial schedule plan set is then optimized, including making adjustments, performing iterative optimization, and other steps. Finally, the optimized schedule plan set is obtained. The following is a detailed description of the optimization process of the CP schedule plan.

-

(1)

Collect the data of the CP and determine the work breakdown structure.

The data of the CP are collected to determine the work breakdown structure. After the work breakdown structure is determined, the number of sub-projects, the work packages in each sub-project, and the logical relationships of each work package are clarified. Finally, the resource constraints, the mandatory duration constraint, and the start time constraints of the model are obtained.

-

(2)

Develop an initial schedule plan set

Based on the logical relationships determined for each work package, an event diagram is drawn to determine the earliest possible start time and the latest end time of each work package. The start time of the work package can be adjusted within the total float. The initial schedule plan set is generated according to Eqs. (8)–(10).

$${\varvec{P}}^{0} = \left[ {{\varvec{P}}^{0}_{1} ,{\varvec{P}}^{0}_{2} , \ldots ,{\varvec{P}}^{0}_{{{pop}}} } \right]^{{\text{T}}} = \left[ {{\varvec{S}},{\varvec{\sigma}}} \right] = \left[ {\begin{array}{*{20}l} {{\varvec{S}}_{1} } & {\sigma_{1} } \\ {{\varvec{S}}_{2} } & {\sigma_{2} } \\ \vdots & \vdots \\ {{\varvec{S}}_{{{pop}}} } & {\sigma_{{{pop}}} } \\ \end{array} } \right]$$(8)where \({{\varvec{P}}}^{0}\) is the initial schedule plan set, \(pop\) is the total number of initial schedule plans, \({\varvec{S}}\) is the start time set of each work package corresponding to each schedule plan, and \({\varvec{\sigma}}\) is the total variance set for each resource consumption corresponding to each schedule plan. Additionally,

$${\varvec{S}} = \left[ {{\varvec{S}}_{1} ,{\varvec{S}}_{2} , \ldots ,{\varvec{S}}_{{{pop}}} } \right]^{{\text{T}}} = \left( {\begin{array}{*{20}l} {{\varvec{TE}} + \left( {{\varvec{TL}} - {\varvec{d}} - {\varvec{TE}}} \right).*{\varvec{rand}}_{1} \left( {1,\mathop \sum \limits_{i = 1}^{N} n_{i} } \right)} \\ {{\varvec{TE}} + \left( {{\varvec{TL}} - {\varvec{d}} - {\varvec{TE}}} \right).*{\varvec{rand}}_{2} \left( {1,\mathop \sum \limits_{i = 1}^{N} n_{i} } \right)} \\ \vdots \\ {{\varvec{TE}} + \left( {{\varvec{TL}} - {\varvec{d}} - {\varvec{TE}}} \right).*{\varvec{rand}}_{{{pop}}} \left( {1,\mathop \sum \limits_{i = 1}^{N} n_{i} } \right)} \\ \end{array} } \right)$$(9)$$\varvec{\sigma} = \left[ {\sigma_{1} ,\sigma_{2} , \ldots ,\sigma_{{{pop}}} } \right]^{{\text{T}}} = \left( {\begin{array}{*{20}l} {\frac{1}{{D_{{{\varvec{P}}^{0}_{1} }} }}\mathop \sum \limits_{k = 1}^{M} \left( {\mathop \sum \limits_{t = 1}^{{D_{{{\varvec{P}}^{0}_{1} }} }} \left( {\mathop \sum \limits_{i = 1}^{N} \mathop \sum \limits_{j = 1}^{{n_{i} }} r_{i,j,k} \left( t \right) - \overline{{r_{k} }} } \right)^{2} } \right)} \\ {\frac{1}{{D_{{{\varvec{P}}^{0}_{2} }} }}\mathop \sum \limits_{k = 1}^{M} \left( {\mathop \sum \limits_{t = 1}^{{D_{{{\varvec{P}}^{0}_{2} }} }} \left( {\mathop \sum \limits_{i = 1}^{N} \mathop \sum \limits_{j = 1}^{{n_{i} }} r_{i,j,k} \left( t \right) - \overline{{r_{k} }} } \right)^{2} } \right)} \\ \vdots \\ {\frac{1}{{D_{{{\varvec{P}}^{0}_{pop} }} }}\mathop \sum \limits_{k = 1}^{M} \left( {\mathop \sum \limits_{t = 1}^{{D_{{{\varvec{P}}^{0}_{pop} }} }} \left( {\mathop \sum \limits_{i = 1}^{N} \mathop \sum \limits_{j = 1}^{{n_{i} }} r_{i,j,k} \left( t \right) - \overline{{r_{k} }} } \right)^{2} } \right)} \\ \end{array} } \right)$$(10)where \({\varvec{T}}{\varvec{E}}\) is a row vector of size \(1\times \sum_{i=1}^{N}{n}_{i}\) composed of the earliest possible start times of the work packages; \({\varvec{T}}{\varvec{L}}\) is a row vector of size \(1\times \sum_{i=1}^{N}{n}_{i}\) composed of the latest end times of the work packages; and \({\varvec{r}}{\varvec{a}}{\varvec{n}}{\varvec{d}}\left(1,\sum_{i=1}^{N}{n}_{i}\right)\) is a random number vector of size \(1\times \sum_{i=1}^{N}{n}_{i}\), where the random number values range from 0 to 1. The symbol “\(.*\)” represents the multiplication of the elements at the corresponding positions in the two vectors.

-

(3)

Optimization of the schedule plans

The initial schedule plan set obeys only the logical relationships among the work packages and the mandatory duration requirement, which does not limit its resource consumption. Moreover, the duration and resource leveling performance of the schedule plans in the set may not be optimal, and they may need to be further optimized. The optimization process of the initial schedule plan set includes four steps: adjusting the initial schedule plan set, generating a new schedule plan set, iteratively adjusting the new schedule set based on the adjusted initial schedule plan set, and finally obtaining the optimized schedule plan set. The four steps are described in detail as follows:

-

(i)

Adjustment of the initial schedule plan set.

The objective function in Model (5) is taken as the fitness function. Each sub-project is given a specific priority according to its importance. The fitness value of each plan in the initial schedule plan set is calculated, and the nondominated ranking of each plan is carried out after error normalization. Then, the crowding distance comparison method of the NSGA-II is used to obtain and save the adjusted initial schedule plan set \({{\varvec{P}}}^{i}\left(i=0\right)\). Through this operation, the distribution of individuals in the same layer is made more uniform.

-

(ii)

Generation of a new schedule plan set.

The initial schedule plan set is selected, crossed, and mutated. In the process of crossover and mutation, adaptive operators are proposed to prevent the premature or slow convergence of the algorithm, as shown in Eq. (12). The new schedule plan set thus obtained is denoted as \({{\varvec{P}}}^{{i}^{^{\prime}}}\left(i=0\right)\). The adaptive operators are explained below.

The original NSGA-II sets the crossover and variation probabilities as constants, and this method is prone to having premature convergence (i.e. falling into locally optimal solutions) or difficulty in ultimately converging. To avoid this problem, the crossover and mutation operators should be larger in the early stage to prevent the algorithm from falling into locally optimal solutions and gradually decrease as the algorithm runs to promote the convergence of the algorithm. Based on this rule, we improve the form of the tan-sigmoid activation function, which is often used to organize neural networks, and propose new adaptive operators.

The tan-sigmoid function (Olgac and Karlik 2011) is expressed as follows:

$${\text{tansig}}\left( x \right) = \frac{2}{{1 + e^{ - 2x} }} - 1$$(11)By making appropriate transformations and introducing the three variables of crossover probability (\({P}_{c}\)), mutation probability (\({P}_{m}\)), and the number of generations (\(gencount\)) of the algorithm, Eq. (12) can be derived.

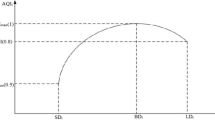

$$\left\{ {\begin{array}{*{20}l} {P_{c} = P_{{c{\text{max}}}} - \left( {P_{{c{\text{max}}}} - P_{{c{\text{min}}}} } \right) \cdot \left( {\frac{2}{{1 + e^{{ - n \cdot {gencount}}} }} - 1} \right)} \\ {P_{m} = P_{{m{\text{max}}}} - \left( {P_{{m{\text{max}}}} - P_{{m{\text{min}}}} } \right) \cdot \left( {\frac{2}{{1 + e^{{ - n \cdot {gencount}}} }} - 1} \right)} \\ \end{array} } \right.$$(12)where \(gencount\) is the number of generations, \({P}_{c{\text{max}}}\) is the maximum crossover probability, \({P}_{c{\text{min}}}\) is the minimum crossover probability, and \({P}_{c}\) is the \(\left(gencount+1\right)\) th-generation crossover probability.\({P}_{m}\) is the \(\left(gencount+1\right)\) th-generation mutation probability, \({P}_{m{\text{max}}}\) is the maximum mutation probability, and \({P}_{m{\text{min}}}\) is the minimum mutation probability. \(n\) is a constant that can be obtained by computer experiments.

Determine the adaptive operators requires determining the maximum and minimum crossover and mutation probabilities and an unknown coefficient, and the unknown coefficient can be obtained by simple computer experiments.

-

(iii)

Adjustment of the new schedule plan set.

We combine \({{\varvec{P}}}^{i}\left(i=0\right)\) and \({{\varvec{P}}}^{{i}^{^{\prime}}}\left(i=0\right)\), conduct nondominated sorting and obtain several layers of nondominated sets \({F}_{1},{F}_{2},\dots\). Then, the crowding distance is calculated and sorted, and optimal individuals are selected to form a new schedule plan set \({{\varvec{P}}}^{1}\left(i=1\right)\). The principle of optimal individual selection is as follows: first, sort by nondominated sets and select schedule plans from the nondominated set \({F}_{1}\). If the number of schedule plans in \({F}_{1}\) is not less than \(pop\), select only the first \(pop\) schedule plans from \({F}_{1}\); otherwise, select schedule plans from \({F}_{2}\), \({F}_{3}\dots\) in turn until the number of schedule plans in the new set equals that in the original set.

Set \(i=i+1\). Then, the schedule plan set that needs to be selected, crossed, mutated, and evaluated is replaced with a new schedule plan set \({{\varvec{P}}}^{1}\left(i=1\right)\).

-

(iv)

Determination of the optimized schedule plan set.

The operations in (ii) and (iii) are repeated until the maximum generation number is reached. Note that when repeating operation (ii), the schedule plan set used for the selection, crossover, and mutation operations is the updated schedule plan set. The final set that has completed nondominated sorting is denoted as \({{\varvec{P}}}^{gencount}\left(i=gencount\right)\). The schedule plan set in layer \({F}_{1}\) is selected as the Pareto optimal solution set, which is the optimized set for selecting schedule plans for the CP.

-

(i)

4 Case Study

4.1 Case Background

A case study is conducted on the schedule plan optimization of a geological disaster treatment program on the national highway G318 in China. This highway passes through mountainous areas in southwestern China, and geological disasters occur frequently. The total cost of the program reached 54.23 million. This program involves a total of 21 disaster sections with a total length of 106 km, including 14 rock collapse problems, mainly treated by frame anchors and ecological bags combined with anchors, and 7 landslide problems, mainly treated by rail anti-slip piles. The technological process and logical relationships are shown in Table 1. Only human resource leveling and the optimization of the project duration are considered.

According to different treatment methods, this CP is divided into three sub-projects numbered 1, 2, and 3. All the sub-projects jointly consume the amount of human resources \(K\). The maximum supply of \(K\) per unit work time is \({R}_{K}\left(t\right)=50\), and the mandatory duration of this CP is \(T=20\). The event diagram and the resource consumption of each sub-project are shown in Fig. 4 and Table 1, respectively.

4.2 Initial Schedule Plan Set

The initial schedule plan set is generated by Eq. (8), and we set \(pop=5000\). Due to the large number of plans in the set, only two of the initial schedule plans in it are listed here.

-

(1)

Initial schedule plan 1

Each work package starts at the earliest possible start time in this plan. The initial schedule plan and its resource consumption are shown in Fig. 5a (the work package number in Fig. 5a omits the sub-project number, as in the later figures).

As shown in Fig. 5a, the total duration of the CP is 18 units of work time. The consumption of \(K\) in the first 10 units of work time exceeds the limit of 50, and the variance of resource consumption is as high as 784.4183. Therefore, this initial schedule plan does not meet the resource constraints, and the plan needs to be further optimized.

-

(2)

Initial schedule plan 2.

The initial schedule plan and its resource consumption are shown in Fig. 5b Under this schedule plan, the total duration of the CP is 19 units of work time. The resource consumption of \(K\) is within the resource limit during the total duration, but the resource consumption variance is 69.5906. The initial schedule plan satisfies the resource constraints; it cannot be determined whether it is optimal, and further optimization is needed.

4.3 Schedule Plan Optimization Based on the IANSGA-II

The three sub-projects are assigned priority values according to their risk levels. Among the slopes to be treated, those that are treated by frame anchors (sub-project 1) have the highest risk level, followed by those treated by rail anti-slip piles (sub-project 3). The slopes to be treated by ecological bags combined with anchors (sub-project 2) have the lowest risk level. Therefore, the importance ranking of the sub-project priorities is 1 > 3 > 2, and the priority values are assigned as 0.5, 0.3, and 0.2, respectively. The proposed IANSGA-II is used to optimize the initial schedule plan set, and optional optimized schedule plans are provided.

According to the optimization process of CP, we calculate each plan's fitness value in the initial schedule plan set, adjust the initial plan set, and update the adjusted initial schedule plan set. The computer experiment to determine the coefficient \(n\) in Eq. (12) is analyzed as below.

4.3.1 Determination of the Coefficient n in the Adaptive Operators

The coefficient \(n\) in Eq. (12) is a factor that determines the performance of the algorithm, and a reasonable value for it is obtained through a computer experiment. Considering the needs of the case study, combined with Gonçalves et al. (2008)'s recommended values for the crossover and mutation probabilities, we set \({P}_{c{\text{max}}}=0.9\), \({P}_{c{\text{min}}}=0.6\), \({P}_{m{\text{max}}}=0.0625\), and \({P}_{m{\text{min}}}=0.01\). When \(gencount\) is small, \(n\) should make \({P}_{c}\) and \({P}_{m}\) close to their maximum values and make them converge to the minimum values slowly as \(gencount\) grows. When the total number of generations is 100, we take \(n=0.01, 0.05, 0.1, 0.2, 0.3, 0.4, 0.5\) for the experiment according to the above rule. After comparing the variation trend of the crossover probability (\({P}_{c})\) and mutation probability (\({P}_{m}\)) with the generation (\(gencount\)) under different \(n\) values, the experimental results are shown in Fig. 6a and b.

It can be seen from Fig. 6a and b that when \(n\ge 0.1\), \({P}_{c}\) and \({P}_{m}\) decrease too quickly with the increase in \(gencount\). In the early stage of the algorithm, small \({P}_{c}\,\mathrm{ and }\,{P}_{m}\) values are not conducive to maintaining population diversity. When \(n=0.01\), \({P}_{c}\) and \({P}_{m}\) are still large when \(gencount=100\), which is not conducive to the convergence of the algorithm. When \(n=0.05\), \({P}_{c}\) and \({P}_{m}\) decrease slowly with the increase in \(gencount\) and converge to the values \({P}_{c{\text{min}}}\) and \({P}_{m{\text{min}}}\) at \(gencount=100\), so \(n=0.05\) is recommended as a suitable value.

4.3.2 Optimization Results

In the IANSGA-II, we take \(n=0.05\), \(pop=5000\), and \(gencount=100\). The algorithm is run 30 times, and the Pareto optimal solutions obtained in each run are further nondominated sorted. The solutions in the \({F}_{1}\) layer are taken as the final Pareto optimal solutions, which are shown in Fig. 7.

Figure 7 shows that the Pareto optimal solutions are more uniformly distributed. The fractional portion of the objective function \({f}_{1}\) is a result of prioritizing the sub-projects beforehand. Since the duration is generally an integer, it is processed according to Eq. (3) to obtain the total duration of the CP.

As shown in Fig. 8, the schedule plan with the smallest variance in resource consumption under the same duration is selected as the optimized schedule plan, as shown in Table 2. The optimized plans and their resource consumptions are shown in Fig. 9. The resource consumption per unit work time of each plan is relatively uniform, and the consumption does not exceed the limit.

5 Discussion

5.1 Comparisons Among the Optimized Schedule Plans

Three optimized schedule plans were obtained during the case study. Further discussion of these schedule plans is as follows:

-

(1)

It can be seen from Fig. 8 that when the duration is 18, the resource consumption variance corresponding to each schedule plan is generally large. When the duration is 19 or 20, the resource consumption variance corresponding to each schedule plan does not clearly differ.

-

(2)

It can be seen from Table 2 that the resource consumption variance of the optimized schedule plan decreases with increasing duration. The variance of the resource consumption of the optimized schedule plan with a duration of 19 decreased significantly compared with that of the optimized schedule plan with a duration of 18.

-

(3)

The second optimized schedule plan is the most suitable under the mandatory duration constraint. It not only limits the delay time but also dramatically reduces the variance of the resource consumption.

5.2 Extended Evaluations of IANSGA-II Performance

To verify the adaptability of the IANSGA-II for solving the optimization problem of the schedule plans of CPs, the Pareto optimal solutions obtained by the NSGA-II (Deb et al. 2002) and ANSGA-II (Gu and Chen 2015) are selected as references in comparing the convergence, uniformity, and spread of the solutions. In addition, based on the ZDT1 and ZDT3 problems (Zitzler et al. 2000), the effect of changing the dimensionality of the search space on the computational cost of the IANSGA-II is explored by changing the number of independent variables.

-

(1)

Evaluation of convergence.

The convergence of multi-objective optimization algorithms can be compared using the \(C\) metric (Zitzler et al. 2000), which is calculated as

where \(A\) and \(B\) are the two sets of Pareto optimal solutions obtained by the two algorithms and \(a\) and \(b\) are the elements in \(A\) and \(B\), respectively. The value \(C\left(A,B\right)=1\) indicates that all solutions in \(B\) are dominated by or equal to solutions in \(A\). The value \(C\left(A,B\right)=0\) means that no solution in \(A\) dominates solutions in \(B\).

The parameters of each algorithm are taken to be the same as those in the case study and are run 30 times separately to obtain the respective Pareto optimal solutions. Since \(C\left(A,B\right)\) is not necessarily equal to \(1-C\left(B,A\right)\), six sets of \(C\) metrics are calculated to compare the convergence of the three algorithms, which are shown in Fig. 10. The statistics of \(C\) are shown in Table 3.

Figure 10 shows that the Pareto solutions obtained by the IANSGA-II cover a large proportion of those obtained by the ANSGA-II and NSGA-II. Table 3 shows that the IANSGA-II converges better than the other two methods, and the ANSGA-II converges slightly better than the NSGA-II in terms of the maximum, minimum, median, and mean values of the \(C\) metric. The Pareto solutions obtained by the IANSGA-II dominate up to 75.6% of the solutions of the ANSGA-II and 91.8% of the solutions of the NSGA-II. The ANSGA-II and NSGA-II dominate only 70.7 and 59.2% of the solutions of the IANSGA-II, respectively. Therefore, the IANSGA-II has better convergence in solving the optimization problem of CP schedule plans.

-

(2)

Evaluation of the uniformity and spread of the Pareto optimal solutions.

The uniformity and spread of the Pareto optimal solutions also affect the adaptability of the multi-objective optimization algorithm for solving optimization problems of CP schedule plans. Based on the Euclidean distance (Deb et al. 2002), Eq. (14) is used to comprehensively evaluate the uniformity and spread of the Pareto optimal solutions.

where \({N}_{P}\) is the number of Pareto optimal solutions, \({d}_{f}\) and \({d}_{l}\) are the Euclidean distances between the extreme solutions and the boundary solution of the obtained Pareto optimal solutions, and \({d}_{i}\) and \(\overline{d }\) are the Euclidean distance between a pair of solutions and the average value of these distances, respectively. Equation (14) shows that when the uniformity and spread of the obtained Pareto optimal solutions are better, \(\varDelta\) is closer to 0.

The parameters of each algorithm are taken to be the same as those in the case study and are run 30 times separately to obtain the respective Pareto optimal solutions. The \(\varDelta\) values of all algorithms are shown in Table 4.

Table 4 shows that the mean, maximum, and minimum values of \(\varDelta {}_{\mathrm{IANSGA}-\mathrm{II}}\) are all smaller than \(\varDelta {}_{\mathrm{ANSGA}-\mathrm{II}}\) and \(\varDelta {}_{\mathrm{NSGA}-\mathrm{II}}\). The Kolmogorov–Smirnov test is used to verify the normality of the distributions of the \(\varDelta\) values obtained by the three algorithms, and all of them conform to the normal distribution. Furthermore, the Tukey method is used for post hoc analysis. The results show that the comparisons of the \(\varDelta\) values of the IANSGA-II with those of the ANSGA-II and NSGA-II are significantly different. The results prove that the distribution of the obtained Pareto optimal solutions is wider and more uniform when the proposed IANSGA-II algorithm is applied.

-

(3)

Effect of the dimensionality of the search space on the time cost of the IANSGA-II

Two theoretical problems, ZDT1 and ZDT3 (Zitzler et al. 2000), are chosen to further explore the influence of the dimensionality of the search space on the time cost of the algorithm. The two problems are shown in Eqs. (15) and (16), respectively. ZDT1 and ZDT3 have a convex Pareto front and a discontinuous Pareto front, respectively. ZDT3 can reflect the discrete property of the optimization results of the schedule plans of CPs well.

where \({x}_{i}\in \left[\mathrm{0,1}\right]\) , and \(m\) represents the number of independent variables. The effect of the dimensionality of the search space on the time cost of the IANSGA-II can be explored by changing the value of \(m\).

Critical works affect the scheduling result, and the number of critical works in CPs can be controlled within a limited range, so \(m\) is set to vary from 10 to 100. For each value of \(m\), the IANSGA-II is run 30 times. The relationships between the time cost and \(m\) are shown in Fig. 11. Figure 11 shows that the time cost of each algorithm grows with the increase in the dimensionality of the search space. However, the time cost grows approximately linearly, and the growth is small. The time cost at \(m=100\) is only twice that at m = 10 in both problems, which shows that the IANSGA-II is not sensitive to the problem, and the IANSGA-II is also applicable in solving multi-objective optimization problems with higher-dimensional search spaces.

6 Conclusions and Future Work

Under a fixed investment, optimizing the schedule plan is a key way to guarantee that CPs will achieve the program objectives within the mandatory construction duration. In the management of CPs, objectives such as duration optimization and resource leveling are incommensurable, and a number of uncertain factors affect the success of the program. Enhancing the diversity of the optimization schedule plan set is conducive to adapting to different decision-making environments. Based on multi-objective optimization theory, we studied the schedule plan optimization problem for CPs, and the conclusions are as follows:

-

(1)

(1) Based on multi-objective optimization theory, a schedule plan optimization model for CPs with the objective of duration optimization and resource leveling was established. Under the mandatory duration and resource constraints, minimizing the weighted sum of the difference between the maximum end time and the minimum start time of all work packages was taken as the objective function of duration optimization. Minimizing the sum of resource consumption variance was taken as the resource leveling objective function.

-

(2)

The NSGA-II was improved, and an optimization process for a CP schedule plan was proposed. Adaptive operators were proposed based on the tan-sigmoid function. The new operators were inserted into the NSGA-II. Thus, a self-adaptive multi-objective evolutionary optimization algorithm, IANSGA-II, was proposed. This algorithm can be used to optimize the schedule plan set of a CP.

-

(3)

Three optimized schedule plans were selected from among the Pareto optimal solutions in the case study, indicating that the proposed model and algorithm are reasonable and adaptive. The proposed model and algorithm provided more references for selecting a CP schedule plan in different decision-making environments.

-

(4)

Comparisons with the NSGA-II and ANSGA-II showed that the Pareto solutions obtained by the IANSGA-II dominate up to 75.6% of the solutions of the ANSGA-II and 91.8% of the solutions of the NSGA-II. The \(\varDelta\) metric of the IANSGA-II was the smallest. Therefore, the convergence, uniformity, and spread of the Pareto solutions of the proposed IANSGA-II were improved. The good adaptability of the IANSGA-II for solving the optimization problem of CP schedule plans was proven.

The duration optimization and resource leveling methods are only applicable to the optimization management of CPs under a fixed investment. However, this study ignored the construction quality and cost, which are also important parts of the management of CPs. It is necessary to further consider the goal of "duration-resources-cost-quality" optimization to complement the multi-objective optimization theory of CPs.

Abbreviations

- \(T\) :

-

Mandatory duration

- \(N\) :

-

Number of sub-projects

- \(M\) :

-

Number of resource types

- \(i,j\) :

-

The \(j\) th work package in the \(i\) th sub-project

- \({n}_{i}\) :

-

Number of work packages in the \(i\) th sub-project

- \(k\) :

-

The \(k\) th type of resource

- \(t\) :

-

The \(t\) th unit of work time

- \({R}_{k}\left(t\right)\) :

-

Maximum total supply of resource \(k\) in the \(t\) th unit of work time

- \({r}_{i,j,k}\left(t\right)\) :

-

Total amount of resource \(k\) consumed by work package \(i,j\)

- \({S}_{i,j}\) :

-

Start time of work package \(i,j\)

- \({f}_{1}\) :

-

Duration optimization objective function

- \({f}_{2}\) :

-

Resource leveling objective function

- \({\upomega }_{i}\) :

-

Priority of each sub-project

- \({D}_{i}\) :

-

Duration of the \(i\) th sub-project

- \({\varvec{d}}\) :

-

A row vector composed of the duration of each work package

- \(D\) :

-

Total duration of a schedule plan

- \(\sigma\) :

-

Total variance of the resource consumption of a schedule plan

- \(\overline{{r}_{k}}\) :

-

Average consumption of resource \(k\)

- \({{\varvec{P}}}^{0}\) :

-

Initial schedule plan set

- \({{\varvec{P}}}^{i}\) :

-

Schedule plan set \(i\)

- \(pop\) :

-

Total number of initial schedule plans

- \({\varvec{S}}\) :

-

Start time set of each work package corresponding to each schedule plan

- \({\varvec{\sigma}}\) :

-

Total variance set of each resource consumption corresponding to each schedule plan

- \({\varvec{T}}{\varvec{E}}\) :

-

A row vector composed of the earliest possible start time of each work package

- \({\varvec{T}}{\varvec{L}}\) :

-

A row vector composed of the latest end time of each work package

- \({\varvec{r}}{\varvec{a}}{\varvec{n}}{\varvec{d}}\) :

-

A random number vector

- \({P}_{c}\) :

-

Crossover probability

- \({P}_{c{\text{max}}}\), \({P}_{c{\text{min}}}\) :

-

Maximum/minimum crossover probability

- \({P}_{m}\) :

-

Mutation probability

- \({P}_{m{\text{max}}}\), \({P}_{m{\text{min}}}\) :

-

Maximum/minimum mutation probability

- \(n\) :

-

A constant obtained by a computer experiment

- \(gencount\) :

-

Number of generations

- \({F}_{i}\) :

-

The \(i\) th layer of nondominated sets

- \(C\left(A,B\right)\) :

-

\(C\) Metric, where \(A\) and \(B\) are the two sets of Pareto optimal solutions obtained by the two algorithms

- \(a, b\) :

-

Elements corresponding to A and B

- \(\varDelta\) :

-

\(\varDelta\) Metric

- \({N}_{P}\) :

-

Number of Pareto optimal solutions

- \({d}_{f}\), \({d}_{l}\) :

-

Euclidean distances between the extreme solutions and the boundary solution

- \({d}_{i}\), \(\overline{d }\) :

-

The Euclidean distance between a pair of solutions and the average value of these distances

- \({x}_{i}\) :

-

Independent variable in ZDT1 and ZDT3

- \(m\) :

-

Number of independent variables

References

Adam A, Josephson P-EB, Lindahl G (2017) Aggregation of factors causing cost overruns and time delays in large public construction projects. Eng Constr Archit Manag 24:393–406. https://doi.org/10.1108/ecam-09-2015-0135

Alrifai M, Skoutas D, Risse T (2010) Selecting skyline services for QoS-based web service composition. Paper presented at the Proceedings of the 19th international conference on World wide web, Raleigh, North Carolina, USA. https://doi.org/10.1145/1772690.1772693

Antoniol G, Di Penta M, Harman M (2005) Search-based techniques applied to optimization of project planning for a massive maintenance project. In: IEEE International Conference on Software Maintenance, pp 240–249. https://doi.org/10.1109/ICSM.2005.79

Claesen M, De Moor B (2015) Hyperparameter search in machine learning. arXiv e-prints:arXiv:1502.02127

Cococcioni M, Pappalardo M, Sergeyev YD (2018) Lexicographic multi-objective linear programming using grossone methodology: theory and algorithm. Appl Math Comput 318:298–311. https://doi.org/10.1016/j.amc.2017.05.058

Damci A, Polat G (2014) Impacts of different objective functions on resource leveling in construction projects: a case study. J Civ Eng Manag 20:537–547. https://doi.org/10.3846/13923730.2013.801909

Deb K, Pratap A, Agarwal S, Meyarivan T (2002) A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans Evol Comput 6:182–197. https://doi.org/10.1109/4235.996017

El-Abbasy MS, Elazouni A, Zayed T (2017) Generic scheduling optimization model for multiple construction projects. J Comput Civ Eng 31:04017003. https://doi.org/10.1061/(ASCE)CP.1943-5487.0000659

Fallah-Mehdipour E, Haddad OB, Tabari MMR, Mariño MA (2012) Extraction of decision alternatives in construction management projects: application and adaptation of NSGA-II and MOPSO. Expert Syst Appl 39:2794–2803. https://doi.org/10.1016/j.eswa.2011.08.139

Fatyanosa TN, Aritsugi M (2020) Effects of the Number of Hyperparameters on the Performance of GA-CNN. In: 2020 IEEE/ACM International Conference on Big Data Computing, Applications and Technologies (BDCAT), 7–10 Dec. 2020, pp 144–153. https://doi.org/10.1109/BDCAT50828.2020.00016

Ferns DC (1991) Developments in programme management. Int J Project Manage 9:148–156. https://doi.org/10.1016/0263-7863(91)90039-X

Floudas CA, Lin X (2005) Mixed integer linear programming in process scheduling: modeling, algorithms, and applications. Ann Oper Res 139:131–162. https://doi.org/10.1007/s10479-005-3446-x

Gaitanidis A, Vassiliadis V, Kyriklidis C, Dounias G (2016) Hybrid Evolutionary Algorithms in Resource Leveling Optimization: Application in a Large Real Construction Project of a 50000 DWT Ship. Association for Computing Machinery. https://doi.org/10.5281/zenodo.3607880

Gonçalves JF, Mendes JJM, Resende MGC (2008) A genetic algorithm for the resource constrained multi-project scheduling problem. Eur J Oper Res 189:1171–1190. https://doi.org/10.1016/j.ejor.2006.06.074

Gu P-c, Chen H-q (2015) Improved adaptive NSGA-2 Algorithm Based on “Bilateral Range Difference.” International Academic Conference for Graduates, NUAA 1:93–97

Heon Jun D, El-Rayes K (2011) Multiobjective optimization of resource leveling and allocation during construction scheduling. J Constr Eng Manag 137:1080–1088. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000368

Heravi G, Rostami M, Kebria MF (2020a) Energy consumption and carbon emissions assessment of integrated production and erection of buildings’ pre-fabricated steel frames using lean techniques. J Clean Prod 253:120045. https://doi.org/10.1016/j.jclepro.2020.120045

Heravi G, Salehi MM, Rostami M (2020b) Identifying cost-optimal options for a typical residential nearly zero energy building’s design in developing countries. Clean Technol Environ Policy 22:2107–2128. https://doi.org/10.1007/s10098-020-01962-4

Heravi G, Kebria MF, Rostami M (2021) Integrating the production and the erection processes of pre-fabricated steel frames in building projects using phased lean management. Eng Constr Archit Manag 28:174–195. https://doi.org/10.1108/ECAM-03-2019-0133

Kar S, Kothari C, Jha KN (2021) Developing an optimum material procurement schedule by integrating construction program and budget using NSGA-II. J Constr Eng Manag 147:04021017. https://doi.org/10.1061/(ASCE)CO.1943-7862.0002028

Kaveh A, Ilchi Ghazaan M (2017) A new meta-heuristic algorithm: vibrating particles system. Scientia Iranica 24:551–566. https://doi.org/10.24200/sci.2017.2417

Li H, Demeulemeester E (2015) A genetic algorithm for the robust resource leveling problem. J Sched 19:43–60. https://doi.org/10.1007/s10951-015-0457-6

Li N (2017) Research on optimization method of torsion beam structure based on Kriging approximation model. Dissertation, Hunan University

Lima R, Tereso A, Faria J (2019) Project management under uncertainty: resource flexibility visualization in the schedule. Procedia Computer Science 164:381–388. https://doi.org/10.1016/j.procs.2019.12.197

Lin C, Chen Y, Huang J-W, Xiang X-D (2015) A survey on models and solutions of multi-objective optimization for QoS in services computing. Jisuanji Xuebao/Chin J Comp 38:1907–1923. https://doi.org/10.11897/SP.J.1016.2015.01907

Liu J, Wang X (2020) The development of optimization and decision theory in systems engineering. Xitong Gongcheng Lilun yu Shijian/System Eng Theory Pract 40:1945–1960. https://doi.org/10.12011/1000-6788-2020-0106-16

Moselhi O (1993) Schedule compression using the direct stiffness method. Can J Civ Eng 20:65–72. https://doi.org/10.1139/l93-007

Naik MG, Kumar DR (2015) Construction project cost and duration optimization using artificial neural network. AEI 2015:433–444. https://doi.org/10.1061/9780784479070.038

Nolz PC (2021) Optimizing construction schedules and material deliveries in city logistics: a case study from the building industry. Flex Serv Manuf J 33:846–878. https://doi.org/10.1007/s10696-020-09391-7

Olgac AV, Karlik B (2011) Performance analysis of various activation functions in generalized MLP architectures of neural networks. Int J Artif Intell Expert Syst 1:111–122

Piryonesi SM, Nasseri M, Ramezani A (2019) Resource leveling in construction projects with activity splitting and resource constraints: a simulated annealing optimization. Can J Civ Eng 46:81–86. https://doi.org/10.1139/cjce-2017-0670

Ponz-Tienda JL, Yepes V, Pellicer E, Moreno-Flores J (2013) The resource leveling problem with multiple resources using an adaptive genetic algorithm. Autom Constr 29:161–172. https://doi.org/10.1016/j.autcon.2012.10.003

Ponz-Tienda JL, Salcedo-Bernal A, Pellicer E (2017) A parallel branch and bound algorithm for the resource leveling problem with minimal lags. Comp-Aided Civil Infrastructure Eng 32:474–498. https://doi.org/10.1111/mice.12233

Prayogo D, Cheng M-Y, Wong FT, Tjandra D, Tran D-H (2018) Optimization model for construction project resource leveling using a novel modified symbiotic organisms search. Asian J Civil Eng 19:625–638. https://doi.org/10.1007/s42107-018-0048-x

Qi L, Tang Y, Dou W, Chen J Combining local optimization and enumeration for QoS-aware Web service composition. In: 2010 IEEE International Conference on Web Services, 5–10 July 2010. pp 34–41. https://doi.org/10.1109/ICWS.2010.62

Qiao W, Yang Z (2019) Solving large-scale function optimization problem by using a new metaheuristic algorithm based on quantum dolphin swarm algorithm. IEEE Access 7:138972–138989. https://doi.org/10.1109/access.2019.2942169

Srinivas N, Deb K (1994) Muiltiobjective optimization using nondominated sorting in genetic algorithms. Evol Comput 2:221–248. https://doi.org/10.1162/evco.1994.2.3.221

Wang R, Lian J (2020) Research on construction schedule optimization of assembly building based on NSGA-II. In: 2nd International Conference on Civil Architecture and Energy Science (CAES 2020), 06055. https://doi.org/10.1051/e3sconf/202016506055

Wang J, Yuan H (2017) System dynamics approach for investigating the risk effects on schedule delay in infrastructure projects. J Manag Eng 33:04016029. https://doi.org/10.1061/(asce)me.1943-5479.0000472

Yan J, Shen Y, Liu S, Wei J, Gao C (2021) Multi-objective optimization of SWISS rectifier. J Harbin Univ Sci Technol 26:86–92. https://doi.org/10.15938/j.jhust.2021.01.012

Zahraie B, Tavakolan M (2009) Stochastic time-cost-resource utilization optimization using nondominated sorting genetic algorithm and discrete fuzzy sets. J Constr Eng Manag 135:1162–1171. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000092

Zheng DXM, Ng ST, Kumaraswamy MM (2004) Applying a genetic algorithm-based multiobjective approach for time-cost optimization. J Constr Eng Manag 130:168–176. https://doi.org/10.1061/(ASCE)0733-9364(2004)130:2(168)

Zitzler E, Deb K, Thiele L (2000) Comparison of multiobjective evolutionary algorithms: empirical results. Evol Comput 8:173–195. https://doi.org/10.1162/106365600568202

Acknowledgements

The authors would like to acknowledge the financial support from the National Natural Science Foundation of China (No. 71801175).

Funding

This work was supported by the National Natural Science Foundation of China under Grant [number 71801175].

Author information

Authors and Affiliations

Contributions

Yibiao Liu contributed to the conception of the study and prepared the manuscript. Hongqun Cheng reviewed and edited the manuscript. Chenchen Liu prepared and debugged the code.

Corresponding author

Ethics declarations

Conflicts of interest/Competing interests

The authors have no relevant financial or nonfinancial interests to disclose.

Availability of data and material

All data analyzed during this study are included in this article.

Code availability

The custom code used during the current study is available from the corresponding author.

Rights and permissions

About this article

Cite this article

Liu, Y., Cheng, H. & Liu, C. Optimization of Construction Program Schedule Plans Based on Multi-Objective Optimization Theory. Iran J Sci Technol Trans Civ Eng 46, 4763–4782 (2022). https://doi.org/10.1007/s40996-022-00865-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40996-022-00865-2