Abstract

In this study, a damage identification method based on observing the changes in frequency response functions (FRFs) of a structure, due to damage, with taking advantage of differential evolution algorithm (DEA) as an optimization solver is presented. Firstly, by using the FRFs of a healthy structure, damaged structure and analytical model of the structure, an efficient objective function is defined for the optimization. Then, the DEA is employed to solve the optimization-based damage detection problem for finding the location and severity of the damage. The performance of the proposed method is evaluated for a beam and two planar frames by making a parametric study. The numerical results indicate that the method can provide a reliable tool to accurately identify the structural damage.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

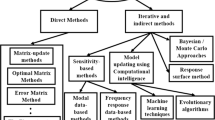

The early detection of structural damage is one of the major challenges in aerospace, civil and mechanical engineering. Many structures are subjected to loading forces bigger than their design capacity or have been utilized in a different manner compared to their standard expectation. Therefore, most of the structural systems may experience some local damages during their lifetime which‚ by neglecting them‚ may lead to decreasing in the functional age or even an overall failure of structures. The structural damage is assigned to any susceptible factor in elements of a structure which would have adverse effects on the condition of the structure. Structural damage may be caused by the irreversible changes in structural materials, the change of physical properties or structural integrity. In addition, the damage would alter the static and dynamic responses of the structure in different ways. These changes can be considered as a damage identification indicator. In the past two decades, to avoid the unexpected huge costs and increase in the lifetime of the structure, the issues related to damage detection have been paid considerable attention to by the research community. The classic methods were capable of identifying the surface damage, therefore, the needs to more accurate methods for damage identification were led to developing the methods which operate using the changes in the vibrating characteristics of a structure. Within the presented methods, the dynamic damage detection methods based on changes in frequency response functions (FRFs) have attracted more attention.

During the last few years, the application of damage detection techniques using FRFs has been examined in many researches. Mannan and Richardson (1990) utilized the FRFs measurement and their changes for not only detecting and locating cracks but also introducing a method for determining the mass, stiffness and damping properties of structures. Sampaio et al. (1999) theoretically described the damage detection based on FRF and compared it with two most referenced methods in the literature. They used a lumped-mass system as a numerical model and information related to a real bridge as an experimental model. They showed that the FRF curvature method performed well in detecting, locating and quantifying the damage. A frequency-domain method for damage identification was introduced by Lee and Shin (2002). They tested the method through some numerically simulated damage identification analyses and then an experimental verification was conducted for a cantilevered beam with damage caused by introducing three slots. The results showed that the presented method can locate and quantify multiple local damages at the same time. A damage detection methodology based on local modal stiffness was proposed by Perra et al. (2008). The stiffness matrix could be determined from the FRFs and, unlike the usual detection methods, it was dependent on both frequencies and mode shapes. Liu et al. (2009) showed that some modifications like using the imaginary parts of FRF shapes and normalizing FRF shapes have positive effects on accurate damage localization. A technique of damage detection based on the measurement of real and imaginary parts of FRFs was presented by Salehi et al. (2010). The experimental results demonstrated that the real part of FRFs is more useful than the imaginary part for damage detection. Samali et al. (2012) proposed a damage identification method that utilizes damage fingerprints embedded in FRFs to identify the location and severity of notch-type damage in a two-story framed structure. They used residual FRFs, which are differences in frequency response function (FRF) data between the undamaged and the damaged structures, as input data to artificial neural networks for structural damage detection. Mohan et al. (2013) used the FRFs with particle swarm optimization (PSO) and genetic algorithm (GA) for structural damage detection and quantification. The performance of the method has been assessed for beam and planar frame structures with various damage scenarios. It was observed that the use of FRFs as a response to the damaged structure and its combination with PSO can lead to a better accuracy compared with its combination with GA. Valdéz-González et al. (2015) conducted an experimental study on a two-story RC frame that was progressively damaged until it reached significant structural damage. They demonstrated that it is possible to characterize the damage state of the RC frame in terms of the simple statistical correlation between a pair of FRFs obtained for the initial damage condition and the subsequent stages.

In this study, the changes in FRF values of structures due to damage are considered as an efficient indicator for damage identification. The problem of structural damage detection is firstly transformed into the standard form of an optimization problem dealing with real damage variables. Differential evolution as an optimization algorithm is used to minimize an objective function based on the FRFs to identify the location and severity of structural damages. The efficiency of the proposed method is assessed by numerical examples simulated by finite element modeling.

2 Application of FRFs for Damage Detection

The frequency response function (FRF) expresses the structural response to an applied force as a function of frequency. Based on the fundamentals of dynamic of structures, the differential equation of motion for the multi-degree of freedom systems is a second-order equation and can be defined as follows (Paz and Leigh 2004):

where M, C and K represent the structural mass, damping and stiffness matrix, respectively; \(\ddot{X}\left( t \right)\), \(\dot{X}\left( t \right)\) and \(X\left( t \right)\) are the nodal acceleration, velocity and displacement vectors of the structure in time t, respectively, and F(t) is an externally time-dependent load applied at the nodal degrees of freedom of the structure.

Considering harmonic forces applied to the structure, the structural forces and displacements can be represented as follows (He and Fu 2001):

where \({{\Omega }}\) is the frequency of excitation force and \(X\left( {{\Omega }} \right)\) and \(F\left( {{\Omega }} \right)\) are the amplitude of displacement and applied force to the structure in the frequency domain, respectively.

By substituting Eqs. (2) and (3) into Eq. (1) and after some simplification, it results

The matrix \(\left[ {K - i{{\Omega }}C - {{\Omega }}^{2} M} \right]\) is known as the dynamic stiffness matrix and it is a function of the frequency of excitation force \({{\Omega }}\). Accordingly, Eq. (4) can be represented as:

where \(H\left( {{\Omega }} \right)\) is the frequency response function (FRF), which represents the displacement over force and can be considered as the response of the structure in the frequency domain (He and Fu 2001). The computational cost involved in obtaining the matrix of FRFs using Eq. (6) is too expensive. Using the technique of modal decomposition and assuming Rayleigh damping for the system, the FRFs matrix of a multi-degree of freedom structure can also be stated with respect to modal parameters as (Begambre and Laier 2009):

where \(\left[ \phi \right]\) is the matrix of mode shapes, \(\omega_{j}\) is the jth circular frequency of the structure, and the sign diag stands here for representing a diagonal matrix.

The FRFs of a structure represented by Eq. (7) contain useful information related to the structure which can be applied to the structural damage detection as more effective data than other dynamic characteristics (Liu et al. 2009; Salehi et al. 2010; Samali et al. 2012). They can also be extracted from acceleration responses that can be directly measured by accelerometer sensors, in practice.

3 Damage Detection Method Based on Optimization

The aim of this research is to identify local damage in structures based on the application of optimization methods (Gholizadeh and Fattahi 2014; Gholizadeh 2015; Gholizadeh et al. 2016). Indeed, the problem of damage detection can be transformed into a standard optimization problem as (Seyedpoor 2011; Nobahari and Seyespoor 2011; Seyedpoor 2012):

where X is a damage variable vector containing the location and severity of n unknown damages; Xl and Xu are the lower and upper bounds of the damage vector, and w is an objective function that should be minimized.

3.1 Objective Function

The objective function is one of the most important parts of an optimization problem. It is considered as a criterion by which the convergence of an algorithm will be controlled. In this study, based on the correlation index proposed by Nobahari and Seyedpoor (2011), an objective function that uses the FRFs is defined as

The vectors D and S(X) are represented by the following equation:

where FRFh is the FRF of the healthy structure, FRFd is the FRF of the damaged structure, and FRF(X) is signified for damage variable dependent FRF obtained by an analytical model of the structure; frfdi and frfi(X) represent the ith component of FRFd and FRF(X), respectively. Also, nf is the size of the FRF vector.

The objective function w varies from a minimum value − 1 to a maximum value 0. It will be minimal when the vector of analytical FRF becomes identical to the FRF vector of the damaged structure, that is, FRF(X) = FRFd. For m number of measuring points, the FRF vector is composed of m FRF vectors corresponding to m measuring points where Eq. (11) illustrates this condition.

where FRF denotes the response vector used in the objective function; FRF1, FRF2 and FRFm denote the vector of FRF corresponding to measuring points 1, 2 and m, respectively; and m denotes the number of measuring points.

3.2 Differential Evolution Algorithm

Differential evolution algorithm is an intelligent and population-based optimization algorithm which was introduced by Storn and Price (1997). The first version of the algorithm applied just for continuous optimization problems but in later versions, and it is capable of solving discontinuous problems. The most significant distinction of the algorithm compared to the others is its unique capability in new solution production. The general procedure in the algorithm for producing the new solution includes four main operators: Crossover operator, Mutation operator, Recombination operator and Selection operator. The main steps of the algorithm can be summarized as (Storn and Price 1997; Seyedpoor et al. 2015; Seyedpoor and Montazer 2016):

Step 1

Initial population

At the first step, the initial population is randomly selected. The initial population is considered as the first generation of search space in DEA, and they would be replaced with more improved generations in the next steps. The initial population in the algorithm is defined with a matrix in which the number of columns and rows represents the population size (np) and the number of design variables (n), respectively. To generate the initial population, the lower bound \(x_{i}^{l}\) and upper bound \(x_{i}^{u}\) for each variable are defined and then the initial generation randomly is produced in the bound \(\left[ {x_{i}^{l} ,x_{i}^{u} } \right]\).

Step 2

Mutation

In biology context, the mutation is defined as the change in a gene that leads to change mutant phenotype. This function is simulated in DEA with some changes and recombination of variable vectors. Firstly, in Gth generation for each defined vector \(X_{j,G}\), three members of population \(X_{r1,G}\),\(X_{r2,G}\) and \(X_{r3,G}\) are randomly selected from search space. It is important to be mentioned that r1, r2 and r3 must be distinct. Therefore, for each particle an initial mutant vector Vj,G+1 is created as

where mf is a mutation factor and varies in the range of [0, 2].

Step 3

Crossover

In this step, a new combination of phenotypes is produced. The new generation vectors are resulted in combining vectors \(V_{j,G + 1}\) and \(X_{j,G}\). In fact, the trial vector \(U_{j,G + 1}\) is extracted from the elements of target vector \(X_{j,G}\) and mutant vector \(V_{j,G + 1}\). The crossover ratio cr controls the fraction of the parameter values that are copied from the mutant vector.

where \({\text{rand}}_{i,j} \in \left[ {0,1} \right]\) and \(I_{rand}\) is a random integer number among numbers \(\left[ {1,2, \ldots ,n} \right]\).

Step 4

Selection

The next step in DEA is the selection of the better individual for the minimization of the objective function. This process can be defined as follows:

The selection process involves a simple replacement of the original individual with the obtained new individual if it has better fitness.

Step 5

Convergence

In this step, the optimization process will be stopped if the convergence appears. Otherwise, the process would repeat from the mutation step.

4 Damage Detection Steps Based on Proposed Method

The main steps of identifying damage in structures through the combination of FRFs and DEA can be stated as

-

Step 1 Perform a modal analysis based on the fundamentals of the dynamic of structures in order to extract natural frequencies and mode shapes of the healthy and damaged structure.

-

Step 2 Construct the FRF matrix by Eq. (7) using data of the first step and extract some FRF vectors related to some degrees of freedom of the structure.

-

Step 3 Form the objective function for the optimization based on FRFs of the healthy, damaged and analytical models of the structure using Eqs. (9) to (11).

-

Step 4 Minimize the objective function defined in the previous step using DEA for finding X containing the location and severity of structural damage.

5 Test Examples and Parametric Study

In order to demonstrate the efficiency of the proposed method for damage identification, three numerical examples are considered. A 10-element beam and a 15-element planar frame described below are chosen to make some parametric studies, and a 45-element planar frame as a larger structure is also considered to assess the performance of the method. The damage is simulated by decreasing the elasticity modulus of elements. The proper parameters for DEA are obtained by a trial and error method. The DEA parameters are set to np = 20, mf = 0.6 and cr = 0.3 for the first two examples and for the last example np = 50, mf = 0.7 and cr = 0.5 are considered. The optimization algorithm will be terminated when the maximum number of iterations reaches 1000 or the objective function does not change after 500 successive iterations or it attains − 0.999.

Example 1

Ten-element cantilever beam

The cantilever beam shown in Fig. 1 which has 30 active degrees of freedom is considered to assess the efficiency of the proposed method for damage detection. The length (L) of the beam, the height (h) and width (w) of the rectangular section are 1, 0.2 and 0.2 m, respectively. The modulus of elasticity and material density of the structure are \(200\, {\text{GPa}}\) and \(7850\,{\text{kg/m}}^{3}\), respectively. The locations of excitation and FRF evaluations are shown in Fig. 1.

Example 2

Fifteen-element planar frame

The 15-element planar frame considered for the assessment of the damage detection method is shown in Fig. 2. The modulus of elasticity and material density of the structure are \(25\, {\text{GPa}}\) and \(2500\,{\text{kg/m}}^{3}\), respectively. The length of each element, the area section and inertia moment of the section are 0.2 m, 0.0336 m2, and 0.000161 m4, respectively. The locations of excitation and FRF evaluations are shown in Fig. 1.

5.1 Sensitivity to the Number of Mode Shapes

Since the FRFs are extracted from a limited number of mode shapes, the selection of a proper number of modal vectors is important. In order to investigate the effects of the number of mode shapes on the accuracy of damage detection results, different numbers of mode shapes are considered and a sensitivity study is conducted. For this purpose, for each structure, the damage scenario defined in Table 1 with two damaged elements is considered. The damage ratio is the ratio of decreased modulus of elasticity to the intact modulus of elasticity for the damaged element. In these examples, for estimating the FRFs, the excitation frequency Ω needed for Eq. (7), is changed by the step of 20 rad/s and the response data are contaminated with 3% noise and then, using these FRFs, the objective function is formulated. The damage detection results are shown in Figs. 3 and 4 for the beam and frame, respectively. As shown in the figures, in the frame example, by considering smaller than 6 modes, damaged elements and their damage extents cannot be predicted correctly. This situation is observed in the beam example for the minimum number of 5 mode shapes. Therefore, by considering 5 and 6 modal vectors of the beam and frame, respectively, the proposed method can predict the damage extent and location with high accuracy.

5.2 Sensitivity to the Number of Damaged Elements

In order to investigate the capability of the proposed method to detect the damage of various elements, a sensitivity study is conducted. For this purpose, four damage scenarios are defined as listed in Table 2 with a different number of damaged elements. Then, 6 mode shapes are extracted from each structure and contaminated with 1% noise. Considering the excitation frequency step of 20 rad/s in Eq. (7), the data are used for constructing the objective function. The predictions of the various damage scenarios using the proposed method are shown in Figs. 5 and 6 for the beam and frame, respectively. It can be seen that for all damage scenarios, the method can predict the damaged elements with high accuracy. For additional numbers of the damaged elements, the method should be examined.

5.3 Sensitivity to Noise

In order to investigate the noise effects on the performance of the proposed method, a sensitivity study with respect to measurement noise is considered. For each example, as listed in Table 1, a damage scenario with two damaged elements is considered. For both examples, FRFs are extracted from 6 mode shapes and then contaminated with random noise at levels of 0, 1%, 3% and 5%. The damage detection results of noise free data along with noise contaminated data are shown in Figs. 7 and 8 for the beam and frame, respectively. The results shown in the figures reveal that the proposed method is capable of identifying the damage location and severity for various levels of noise. It can be observed that adding noise up to 5% has no considerable effects on the accuracy of results. Although for the noise level of 5% some false predictions has occurred, the percentages of them are less than 1%. It is concluded that the optimization process can obtain the actual site and extent of two damaged elements of the structures even in high levels of noise.

5.4 Sensitivity to Excitation Frequency Steps

The effect of changes in excitation frequency increment on the performance of the proposed method for damage cases of Table 1 are shown in Figs. 9 and 10. Frequency increment ΔΩ ranges from 10 to 40 rad/s by the step of 10. During this analysis, 6 modes contaminated with 1% noise are considered. It should be mentioned that by considering the increment less than 10 rad/s, for some cases, the results will be slightly accurate, however, it increases the computational efforts significantly. The results show that the accuracy of the method is independent of the selected excitation frequency steps. By increasing the step, the speed of the damage detection process is significantly increased.

5.5 Assessing the Method for a Larger Structure

The 45-element planar frame with 45 damage variables shown in Fig. 11 is considered for assessing the proposed method (Seyedpoor et al. 2018). The Young’s modulus and material density of the structure are 210 GPa and 7780 kg/m3, respectively. The sections (W12 × 87) and (W14 × 145) are used for the beam and the column, respectively. A horizontal excitation is applied to node 6 and four sensor locations for measuring horizontal FRF are shown in Fig. 11.

Four damage scenarios provided in Table 3 are considered to illustrate the performance of the method. Based on the try and error method, the best number of the mode shapes considered is 10 modes and the frequency step is 30 rad/s as well. The damage identification results of the method without considering noise are shown in Fig. 12. The outcomes confirm that the proposed method is able to identify the location and severity of damage properly, particularly when there are multiple damage cases in the frame.

The damage identification outcomes of noise contaminated data (5% noise) are illustrated in Fig. 13. The results shown in the figure reveal that the damaged elements can be accurately detected by the proposed method and the outcome considering 5% noise poses adequate precision. Although by considering noise, there are some disorders in the severity of damage, however, the damage location is identified correctly.

6 Conclusions

An efficient method to locate and quantify damage in the structures using the changes of frequency response functions (FRFs) as a valuable dynamic characteristic has been introduced. An objective function based on the FRFs of a healthy structure, damaged structure, an analytical model has been developed and then it has been minimized by taking advantage of DEA as an optimization solver. The performance of the proposed method is evaluated by a cantilever beam as well as planar frame structures with considering different parameters. By investigating the numerical results, it has been observed that the number of used modes can be considered as an influential factor in the accuracy of the proposed method. In fact, considering less than a specific number of modes leads to incorrect results in damage detection. The specific number of modes is different from one example to another and needs to be identified by a sensitivity analysis. The proposed method can accurately identify damaged elements up to 4 elements. For higher numbers of damaged elements, the method should be examined. In addition, the selection of exciting frequency increment as an effective parameter in FRF does not affect the performance of the method significantly. Moreover, the efficiency of the method is investigated in noisy environments via considering 1%, 3% and 5% standard error. Adding noise up to 5% has no considerable effects on the accuracy of the damage detection procedure. For the noise levels of higher than 5%, the sensitivity analysis should be carried out. The results showed that the proposed method is strongly capable of finding the location and severity of structural damages even in the presence of noise. The results demonstrate the high efficiency of FRF based objective function in collaboration with DEA for determining the damage site and extent, while it needs FRFs in a few degrees of freedom of the structure.

References

Begambre O, Laier JE (2009) A hybrid Particle Swarm Optimization-Simplex algorithm (PSOS) for structural damage identification. Adv Eng Softw 40(9):883–891

Gholizadeh S (2015) Performance-based optimum seismic design of steel structures by a modified firefly algorithm and a new neural network. Adv Eng Softw 81:50–65

Gholizadeh S, Fattahi F (2014) Design optimization of tall steel buildings by a modified particle swarm algorithm. Struct Des Tall Spec Build 23(4):285–301

Gholizadeh S, Gheyratmand C, Davoudi H (2016) Optimum design of double layer barrel vaults considering nonlinear behavior. Struct Eng Mech 58(6):1109–1126

He J, Fu ZF (2001) Modal analysis. Butterworth-Heinemann, London

Lee U, Shin J (2002) A frequency-domain method of structural damage identification formulated from the dynamic stiffness equation of motion. J Sound Vib 257(3):615–634

Liu X, Lieven NAJ, Escamilla-Ambrosio PJ (2009) Frequency response function shape-based methods for structural damage localization. Mech Syst Signal Process 23(4):1243–1259

Mannan MA, Richardson MH (1990) Detection and location of structural cracks using FRF measurements. In: Proceedings of 8th International Modal Analysis Conference (IMAC VIII), Kissimmee, January, pp 652–657

Mohan SC, Maiti DK, Maity D (2013) Structural damage assessment using FRF employing particle swarm optimization. Appl Math Comput 219(20):10387–10400

Nobahari M, Seyespoor SM (2011) Structural damage detection using an efficient correlation-based index and a modified genetic algorithm. Math Comput Model 53(9–10):1798–1809

Paz M, Leigh W (2004) Structural dynamics: theory and computation, 5th edn. Springer, New York

Perra R, Huerta C, Orquin JM (2008) Identification of damage in RC beams using indexes based on local modal stiffness. Constr Build Mater 22(8):1656–1667

Salehi M, Ziaei-Rad S, Gayour M, Vaziri-Zanjani MA (2010) A structural damage detection technique based on measured frequency response functions. Contemp Eng Sci 3(5):215–226

Samali B, Dackermann U, Li J (2012) Location and severity identification of notch-type damage in a two-storey steel framed structure utilising frequency response functions and artificial neural network. Adv Struct Eng 15(5):743–757

Sampaio RPC, Maia NMM, Silva JMM (1999) Damage detection using the frequency response function curvature method. J Sound Vib 226(5):1029–1042

Seyedpoor SM (2011) Structural damage detection using a multi-stage particle swarm optimization. Adv Struct Eng 14(3):533–549

Seyedpoor SM (2012) A two stage method for structural damage detection using a modal strain energy based index and particle swarm optimization. Int J Nonlinear Mech 47(1):1–8

Seyedpoor SM, Montazer M (2016) A damage identification method for truss structures using a flexibility-based damage probability index and differential evolution algorithm. Inverse Probl Sci Eng 24(8):1303–1322

Seyedpoor SM, Shahbandeh S, Yazdanpanah O (2015) An efficient method for structural damage detection using a differential evolution algorithm based optimization approach. Civ Eng Environ Syst 32(3):230–250

Seyedpoor SM, Ahmadi A, Pahnabi N (2018) Structural damage detection using time domain responses and an optimization method. Inverse Probl Sci Eng 27(5):669–688

Storn R, Price K (1997) Differential evolution-a simple and efficient heuristic for global optimization over continuous spaces. J Glob Optim 11(4):341–359

Valdez-González J, De-la-Colina J, González-Pérez CA (2015) Experiments for seismic damage detection of a RC frame using ambient and forced vibration records. Struct Control Health Monit 22(2):330–346

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Seyedpoor, S.M., Pahnabi, N. Structural Damage Identification Using Frequency Domain Responses and a Differential Evolution Algorithm. Iran J Sci Technol Trans Civ Eng 45, 1253–1264 (2021). https://doi.org/10.1007/s40996-020-00528-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40996-020-00528-0