Abstract

Shear band formation, as an instability problem, is often analyzed as a bifurcation problem under plane strain loading condition where the effect of intermediate principal stress is ignored. However, the effect of intermediate principal stress has a great impact on the strain localization of sands and it has already been investigated experimentally. In this study, “Single Hardening” constitutive model is employed to capture the stress–strain relationships and to predict the onset of strain localization under the true triaxial condition. The failure in dense sands is found to be caused by shear band initiation near plane strain loading condition and not by the theoretical failure employed in the Single Hardening model.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Shear banding as a bifurcation problem refers to the change in the stress–strain response of materials due to instabilities during loading (Rudnicki and Rice 1975). Many experimental (Mooney et al. 1998; Wang and Lade 2001; Lade and Wang 2001; Desrues and Viggiani 2004), theoretical and numerical (Bardet 1991; Hashiguchi and Tsutsumi 2007; Sanborn and Prévost 2011; Badie 2014; Perić et al. 2015; Guo and Zhao 2016) works have been conducted to understand the inception of localized deformation in soils. Moreover, study of the effect of intermediate principal stress on the onset and growth of the shear band is very important when some practical problems in the field of soil mechanics are investigated, such as the bearing capacity of surface footings or retaining wall thrust in contact with sand, in particular, when a 2D model is employed to represent a 3D problem. To account for this important effect, experimental studies have been performed under true triaxial condition at fixed intermediate principal stress ratio, b (defined as (σ 2 − σ 3)/(σ 1 − σ 3), where, σ 1, σ 2 and σ 3 are defined as major, intermediate and minor principal stress, respectively), and show that the formation of the shear band appears to cause the failure of soil samples, except for axisymmetric compression condition (Wang and Lade 2001).

Here, the “Single Hardening” constitutive model is used to numerically capture the stress–strain relationships of the geomaterial under the true triaxial loading condition. Then, the bifurcation analysis is conducted along with the numerical simulations to analyze the onset of shear banding and to compare the predicted results with a series of experimental data.

2 Bifurcation Criterion

According to bifurcation theory, the condition for the onset of shear banding is defined as follows (Rudnicki and Rice 1975):

\(\varvec{n}\) and \({\mathbb{D}}^{\text{ep}}\) are the unit normal vector to the shear band and the fourth-order elasto-plastic constitutive tensor, respectively. The second-order tensor \(\varvec{A}^{\text{ep}}\) is called the elasto-plastic acoustic tensor. For a defined loading path, in order for bifurcation to occur, Eq. (1) allows one or several real solutions for \(\varvec{n}\).

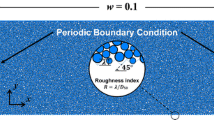

In Fig. 1 the geometric interpretation of n, under plane strain and true triaxial conditions, is illustrated. It is notable that Eq. (1) gives no information about the shear band inclination under true triaxial loading condition (Tamizdoust 2016).

3 Single Hardening Elasto-Plastic Constitutive Model

The prediction of the onset of shear banding is strongly dependent on the pre-localization constitutive relationship (Gutierrez 2011). In this work, the Single Hardening elasto-plastic constitutive model with a single yield surface is used which has been developed for the behavior of frictional materials such as sand, clay, concrete and rock (Lade and Kim 1988).

The elastic stress–strain behavior is assumed to be incrementally linear while a non-linear variation of Young’s modulus with stress state (i.e., the confining pressure) has been also involved (Lade and Kim 1995). The Young’s modulus, E, can be expressed as follows:

where P a is the atmospheric pressure, M is the modulus number, the exponent λ is a constant dimensionless number. I 1 and J 2 are the first invariant of stress tensor and the second invariant of deviatoric stress tensor, respectively. The failure criterion is expressed in terms of the first and the third stress invariants of the stress tensor as follows (Lade and Kim 1995):

The parameters η 1 and m are constant dimensionless numbers. Moreover, Eqs. (4) and (5) illustrate the yield function and plastic potential, respectively, which are written in terms of the three invariants of the stress tensor (Lade and Kim 1995):

The detailed interpretation of the material parameters, ψ 1, h, q, ρ, D, ψ 2 and \(\mu\) can be found in Lade and Kim (1995). W p is the plastic work which is a function of \(\varvec{\sigma}\). The Single Hardening constitutive model has 11 model parameters which are to be determined from triaxial and isotropic compression tests. These experimental data for dense Santa Monica Beach sand are available in the literature and used in this article after some slight modification.

4 Simulation of the True Triaxial Test

The Single Hardening constitutive model is employed to simulate the experimental results of the true triaxial tests on dense sands (Wang and Lade 2001) which are very versatile in comparison with other simple geomaterials models (e.g., that of Arabani and Veiskarami 2007). A computer code in MATLAB was developed for analyses. Specimens were dense Santa Monica Beach sand with the properties presented by Wang and Lade (2001). The tall rectangular prismatic specimens had a height-to-diameter ratio H/D = 2.47, and the confining pressure was 49 kPa.

The simulated true triaxial test results on dense sands at various b values comprising 0.0, 0.41, 0.60 and 1.0 are shown in Fig. 2. Comparison with experimental data shows that the model predicts the pre-bifurcation stress–strain relationships with a reasonable accuracy. For the true triaxial compression test, i.e., b = 0.0, no bifurcation point is numerically predicted. This is in agreement with the experimental results which also show no bifurcation. For the true triaxial extension test when b = 1.0, the point of bifurcation is less clear. Experimental results illustrate the bifurcation at ɛ 1 = 1% (peak point on experimental results trend); however, the bifurcation theory failed to predict the shear banding in hardening regime. In the mid-range of b values, i.e., b = 0.41 and b = 0.6, shear band occurs in hardening regime and the bifurcation point is predicted with good accuracy (the bifurcation point is in the vicinity of the peak of the experimental results). Figure 3 presents the bifurcated major principal strain ɛ b1 and bifurcated normalized major principal stress σ b1 at the onset of shear band predicted by Single Hardening constitutive model. ɛ b1 and σ b1 increase with increasing b values in hardening regime and slightly less than experimental results. For b > 0.60, the difference between the prediction and experiment results considerably increases. This may be due to the non-coaxiality between the principal stress and principal plastic strain rate directions which becomes more effective for higher b values. The investigation on the effect of non-coaxiality is beyond the scope of this paper. The bifurcation point coincides almost reasonably with the peak strength of the real stress–strain data, indicating that the softening regime could be due to the formation of narrow shear bands in the sample. This latter conclusion obviates any need for soil models with the ability to capture softening behavior which requires a negative plastic work hardening modulus and inconsistencies with elements of plasticity theory. In addition, the material strength at the onset of the shear banding is quite less than that of the theoretical failure. Having known this fact, many analyses in soil mechanics may require further and more subtle attention to properly include the material resistance when a limit load is required.

Principal major strain versus stress ratio, bifurcation point and principal major strain versus volumetric strain in true triaxial tests on prismatic specimens of dense Santa Monica Beach sand with confining stress of 49 kPa a b = 0 (axisymmetric compression), b b = 0.41 (plane strain), c b = 0.60, d b = 1.0 (axisymmetric extension) (experimental data after Wang and Lade 2001)

a Normalized major principal stress at the onset of shear band versus intermediate principal stress ratio b, b major principal strain at the onset of shear band versus the intermediate principal stress ratio b (experimental data after Wang and Lade 2001)

5 Conclusions

An advanced and realistic constitutive model is used to predict the behavior of sands under true triaxial test. The model and the corresponding bifurcation analysis are employed to simulate the true triaxial tests on dense sands. For dense sands, the model gives out good pre-bifurcation stress–strain relationship in all b values and the shear band is predicted to occur at a wide range of b values except for extreme values of b, i.e., near axisymmetric conditions where shear banding occurs in softening regime and smooth peak failure is obtained. But mid-range of the b value and in the proximity of the plane strain condition, the theoretical peak failure, serving as a target for the stress path is never reached due to the shear band formation. In contrast, a softening behavior is expected as a consequence of the localization of deformation into shear bands. The experiments are in agreement with this qualitative and quantitative interpretation of failure in sand under three-dimensional conditions. Therefore, the simple hardening soil model can be reasonably applied to capture the shear band formation and also to analyze the material strength at the onset of shear banding.

References

Arabani M, Veiskarami M (2007) A simple nonlinear-elastic model for prediction of lime stabilized sand behavior. Iran J Sci Technol 31(5):573–576

Badie A (2014) Shear band analysis in granular soils under 3-D condition. M.Sc. thesis, Shiraz University of Technology, Shiraz

Bardet JP (1991) Orientation of shear bands in frictional soils. J Eng Mech 117(7):1466–1484

Desrues J, Viggiani G (2004) Strain localization in sand: an overview of the experimental results obtained in Grenoble using stereo photogrammetry. Int J Numer Anal Methods Geomech 28(4):279–321

Guo N, Zhao J (2016) 3D multiscale modeling of strain localization in granular media. Comput Geotech 80:360–372

Gutierrez M (2011) Effects of constitutive parameters on strain localization in sands. Int J Numer Anal Methods Geomech 35(2):161–178

Hashiguchi K, Tsutsumi S (2007) Gradient plasticity with the tangential subloading surface model and the prediction of shear-band thickness of granular materials. Int J Plast 23(5):767–797

Lade PV, Kim MK (1988) Single Hardening constitutive model for frictional materials. II. Yield criterion and plastic work contours. Comput Geotech 6(1):13–29

Lade PV, Kim MK (1995) Single Hardening constitutive model for soil, rock and concrete. Int J Solids Struct 32(14):1963–1978

Lade PV, Wang Q (2001) Analysis of shear banding in true triaxial tests on sand. J Eng Mech 127(8):762–768

Mooney MA, Finno RJ, Viggiani MG (1998) A unique critical state for sand? J Geotech Geoenviron Eng 124(11):1100–1108

Perić D, Zhao G, Khalili N (2015) Onset of strain localization in unsaturated soils subjected to constant water content loading. In: Bifurcation and degradation of geomaterials in the New Millennium, pp 169–173

Rudnicki JW, Rice JR (1975) Conditions for the localization of the deformation in pressure sensitive dilatant materials. J Mech Phys Solids 23(6):371–394

Sanborn SE, Prévost JH (2011) Frictional slip plane growth by localization detection and the extended finite element method (XFEM). Int J Numer Anal Methods Geomech 35(11):1278–1298

Tamizdoust MM (2016) Shear band analysis as a bifurcation problem in Granular matters under plane strain condition. M.Sc. thesis, University of Guilan, Rasht

Wang Q, Lade PV (2001) Shear banding in true triaxial tests and its effect on failure in sand. J Eng Mech ASCE 127(8):754–761

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mir Tamizdoust, M., Veiskarami, M. & Mohammadi, H. A Note on the Effect of Intermediate Principal Stress on the Onset of Strain Localization in Granular Soils. Iran J Sci Technol Trans Civ Eng 41, 429–432 (2017). https://doi.org/10.1007/s40996-017-0078-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40996-017-0078-8