Abstract

The uniaxial compressive strength (UCS) and modulus of deformability (E s) of intact rocks are essential parameters in rock engineering and engineering geology projects. Because of the difficulty involved in measuring these parameters, indirect methods are often used to estimate these parameters. In this research, some predictive models using multiple regression analysis and Adaptive Neuro-Fuzzy Infrence System (ANFIS) were developed for predicting UCS and E s of the limestone outcropped of Asmari formation in Lordegan, Chaharmahal and Bakhtiari Province, Iran. For this purpose, a series of important and easy-to-obtain parameters, such as density, porosity, and indirect tensile strength (Brazilian test) were used as the model inputs. Because the measured values of UCS and E s of samples varied in a wide range, rock samples were classified as medium- to high- and very high-strength rocks according to the ISRM UCS classification (1978), and then, the ANFIS models were improved for these groups. The variation of coefficient of determination (R 2), Variance Accounted For (VAF), and Root Mean Square Error (RMSE) were calculated for the UCS and the modulus of deformability obtained from the multiple regression and the neuro-fuzzy models. The results revealed that the forecasting performance and accuracy of the neuro-fuzzy system are very higher than those of multiple regression models.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The rock engineering properties are among the important parameters in geological, mining, petroleum engineering, and geomechanical investigations. These properties are requisite for exploration, planning, and designing a given project and the optimal utilization of earth resources. Design and construction of structures are influenced by mechanical properties of rocks. An essential stage of the geotechnical investigation is to determine the strength and deformability of rocks. There are many methods for measuring uniaxial compressive strength (UCS) and elastic properties of rocks (Young’s modulus or E s) in the laboratory (McCann and Entwisle 1992).

It is complicated, time-consuming, and tedious to determine UCS and E s in both field and laboratory. The laboratory tests for UCS and E s are wearisome and costly which need good instrumentation (Eissa and Kazi 1988). A plenty of laboratory data of mechanical properties are required to provide valuable insight for geotechnical site characterization. To overcome this difficulty and to determine an index to indirectly estimate mechanical properties of rock samples, many experiments such as point load index, Schmidt hammer test, punch test, and P-wave velocity have been developed by many researchers (Fahy and Guccione 1979; Howarth and Rowlands 1986; Cargill and Shakoor 1990; Shakoor and Bonelli 1991; Edet 1992; Ulusay et al. 1994; Grima 2000; Gokceoglu 2002; Gokceoglu and Zorlu 2004; Sonmez et al. 2006; Zorlu et al. 2008; Gokceoglu et al. 2009; Gurocak et al. 2012; Kaya and Karaman 2016).

In addition, many researchers have proposed meaningful relationship using fuzzy to adaptive neuro-fuzzy inference system (ANFIS) to characterize the rock properties (Tahmasebi and Hezarkhani 2010; Aali et al. 2009). It was found that construction of a well-performing fuzzy system is not always as easy as it seems. In the fuzzy logic, membership function and rules are determined by the trial and error process. For complex systems, a significant matter of time is required to find out the correct membership function and rules to obtain a reliable solution. The generalization capability of the fuzzy logic is very poor as it uses the heuristic algorithms for defuzzification, rule evolution, and antecedent processing.

Although the artificial neural networks (ANNs) are among the most widely used intelligence techniques, they suffer some shortcomings. The main drawback of ANNs is to determine the proper size and optimal structure of the neural network. The relationships of weight variation with input–output behavior during the training and use of the trained system to generate correct output using the weights is a very complicated task to understand. Another difficult issue involved in ANNs is manipulating the learning parameters for learning and convergence.

Therefore, a combination of fuzzy system ANNs handles limitations of both methods, and offers an excellent data-mining opportunity to solve the critical and complex problems in geotechnics (Singh et al. 2005; Gokceoglu et al. 2004). In this connection, one of the most common techniques is ANFIS that combines both fuzzy system and ANN. Therefore, fuzzy rules based ANN approach is a good and flexible technique to define uncertainties in rock properties.

As it is difficult and expensive to determine all the geomechanical parameters of the rocks, in this study, an attempt was made to determine the UCS and E s from basic low-cost tests such as indirect tensile strength (TS), porosity (n), and density (ρ) of rock, using the statistical method and fuzzy system with membership functions based on ANFIS technique. To construct the models, mechanical properties of different samples of limestone were determined according to the proposed methods (ISRM 2007).

Statistical and fuzzy logic approach to data analysis is completed by DATAFIT 8 and MATLAB (matrix laboratory) software packages, respectively.

2 Geological Background of the Study Area

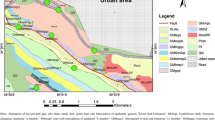

Study area (Khersan 1 and 2 dam sites) is located in Khersan River in the southwest of Lordegan, Chaharmahal and Bakhtiari Province, Iran.

According to geological zoning of Iran, this region belongs to Folded Zagros and Arabian Shield craton.

The Folded Zagros consists of resistant layers such as thick limestone, relatively less thin limestone, marl and shale mainly covered with gray and pink limestone (Aghanabati 2004). The formation in the abutments and bedrock of Khersan dams is composed of the upper Asmari limestone (Fig. 1).

Case study area in geographical and geological maps [reference of the geological map: geological map of the Borujen–Ramhormoz with the scale of 1/250,000, Geological Survey of Iran (Geological Survey of Iran 2001)]

Limestone studied in the dam sites is often dolomitized, with an increase of porosity, which consequently leads to decrease in rock strength. Besides, the micritic limestone rocks (fine crystals), which are more resistant compared to sparitic (coarse crystals) ones, are observed in the study area. These rocks may contain varying amounts of impurities such as oxide, iron hydroxide, organic matter, quartz, and clay minerals.

Because limestone has a more complex structure due to calcium carbonate dissolution (thus easier diagenesis), their mechanical behavior is often controlled by porosity, cleavage, crystal size, density, petrification, and small cracks.

Asmari formation is exposed extensively in the west and southwest of Iran. A large number of development projects such as dams, tunnels, and hydropower plants including Khersan 1, 2, and 3, Karun 4, and Seimareh are constructed in this formation.

3 Petrographic Aspects

Petrographic investigations of limestone cropped out from the Asmari formation consist of routine observations and measurements on thin sections using a polarized microscope. A set of 22 thin sections were prepared from drilled boreholes of the upper Asmari limestone (access tunnels of the Khersan 1 and 2 dams). The sections reveal that the rocks mainly consist of calcite, aragonite, and opaque minerals (iron oxides and hydroxides, organic matter) and a small trace of clay and quartz (Fig. 2).

The fine-grained calcite with a diameter varying from 1 to 4 μm makes 20–80% of these rocks and often contains significant amounts of fossils. Since over 50% of the constituents include carbonate (calcite type) minerals, these rocks are considered as carbonate. According to Dunham’s classification, they can be classified as “mudstone”, “wackestone”, “packstone”, and “grainstone”. Besides, using Folk classification, they are classified as “biomicrite” and “biosparite”. Skeletal grains in these rocks are bivalve, coral, bioclast, nummulites, etc., which are Oligocene–Miocene in age. In Fig. 2, microscopy images of two thin sections of the Asmari limestone are shown.

4 Physical and Mechanical Properties

According to ISRM suggested methods (ISRM 2007), physical and mechanical properties such as UCS, indirect tensile strength (TS), secant Young’s modulus (E s), porosity (n), and density (ρ), were measured for 87 limestone samples in geotechnical laboratory of Khersan dam sites, Iran.

The results obtained from the laboratory tests are presented in Table 1.

Because the measured values of UCS and E s of samples listed in Table 1 vary in a wide range, rock samples are classified as medium, high- and very high-strength rocks by ISRM UCS classification (1978).

According to Table 2 and Fig. 3, only five samples are in the range of medium strength, therefore, samples classified in two main groups (medium- to high-strength and very high-strength samples) and predictive models were developed for these two groups.

5 Statistical Analysis of Laboratory Results

The statistical approach is among the most common methods used in rock engineering and engineering geology to evaluate predictive models. It can often be used in two options of simple and multivariate regression. In this study during the simple regression analyses, linear (y = ax + b), power (y = ax b), exponential (y = ae bx) and logarithmic (y = alnx + b) functions were employed. Correlation matrix between physical and mechanical properties of Asmari limestone is shown in Fig. 4. In addition, the coefficient of determination for all functions used was derived and the best of which are shown in Table 3.

The results shown in Table 3 indicate that there is a weak correlation between UCS and E s versus TS, n, and ρ.

The best-fit trend lines for all samples, medium- to high-strength samples and very high-strength samples, are shown in Fig. 5. As shown in this figure, by reducing the number of data and dividing the samples in two groups of medium- to high- and very high-strength samples, the performance of regression models is reduced significantly; as a result, the regression analysis for all samples provides the best performance.

Also, multivariate regressions including three independent variants and one dependent variant were used in this study. The best-fit obtained multivariate equations to estimate UCS and E s are written as Eqs. 1 and 2, respectively.

Comparison between the measured and predicted UCS and E s upon the base of Eqs. 1 and 2 is shown in Fig. 6.

6 Data Analysis by ANFIS Technique

General principles of fuzzy logic are fundamentally set up by Lotfizadeh (1965) who applied logic operators to estimate precise values from fuzzy data. Fuzzy Inference Systems (FIS) are generally designed according to one of two methods proposed by Mamdani and Assilian (1975) and Sugeno (1985).

Over the past recent years, FIS have been successfully applied in the field of rock engineering and engineering geology. One of the reasons for using fuzzy logic in earth sciences and rock engineering is the high capability of this approach to solving multivariate and nonlinear problems rather than statistical approaches. In fact, the efficiency of FIS in estimating the mechanical properties of rocks is related to using non-precise and low-relative data to achieve high-relative and relatively precise models so that it has become an efficient and applicable method. The high efficiency of FIS has been proven by numerous studies completed on the base of some non-precise data as the input of FIS to reach the valuable and confident outputs (Gokceoglu et al. 2004).

In the present study, parameters including TS, n, and ρ are used as simple and rudimentary inputs to design predictive models to estimate UCS and E s of Asmari formation limestone. Although none of these three inputs shows a highly meaningful relation with UCS, using these inputs result in the more efficient predictive models of FIS in comparison to those designed by statistical approaches. The FIS presented in this study was designed according to one-order Sugeno method using ANFIS technique (Grima and Babuška 1999), which is a neuro-fuzzy approach completed by MATLAB software. In this work, four distinctive ANFIS models are presented for estimating UCS and E s for medium- to high-strength and very high-strength samples. The common inputs including TS, n, and ρ are used to predict output parameters including UCS and E s (Fig. 7).

The inputs of FIS are non-fuzzy sets that should be fuzzified sets in the first step. To convert non-fuzzy sets to fuzzy, specific functions known as Membership Functions are employed. In this study, membership functions were derived by ANFIS technique (Figs. 8, 9, 10, 11). In Sugeno method, output MF can either be constant values (zero-order functions) or one- or high-order functions. The MF of FIS designed here are one-order (linear) functions, which can be presented in the form of a m × n matrix; where m is the number of rows and n is the number of columns. Every row in this matrix indicates factors of a particular output MF. The number of rows (m) equals to the number of output MF. In every FIS, to create a logical relation among inputs and outputs, several conditional rules are required (Gustafson and Kessel 1978). In this case, nine rules were built for all FIS to estimate UCS and E s for medium- to high-strength and very high-strength samples (Figs. 8, 9, 10, 11).

The models were designed to estimate UCS for medium- to high-strength and very high-strength, after six and seven training steps (Fig. 12). Then, they were designed to estimate E s for medium- to high-strength and very high-strength samples after eight and five training steps, where the minimum error was reached, respectively (Fig. 13).

These models predict UCS and E s according to the following outlined steps:

-

1.

In the first stage, input data are converted to fuzzy sets using the membership functions presented in Figs. 8, 9, 10, 11.

-

2.

As shown in Figs. 8, 9, 10, 11 and according to the rules designed on the basis of the logic operator (prod function [25]), all three inputs are turned into Z i function and degree of infection (Wt i ) using Eqs. 3 and 4, respectively.

$$Z_{i} = a_{i} x_{i} + b_{i} y{}_{i} + c_{i} h_{i} + k_{i} ,$$(3)where a, b, c, and k are parameters presented as every row in matrixes of Figs. 8, 9, 10, 11. It means that x i is TS y i is n and h i is ρ for each sample.

-

3.

The function 4 is applied to make the output defuzzified and to gain value of Z, which is the answer of the model (Eq. 4).

$$Z = \sum\limits_{i = 1}^{n} {Z_{i} } \left( {\frac{{Wt_{i} }}{{\sum {Wt_{i} } }}} \right),$$(4)where n is the number of rules, Wt i is the degree of infection derived from the operation of the method (prod function) on the membership functions in each rule, and Z i is derived from Eq. 3.

Figures 14 and 15 show how these four ANFIS models work to estimate UCS and E s for limestone samples. As shown in Fig. 14 (models for medium- to high-strength samples), for a limestone with TS = 6.15 (MPa), n = 8.43 (%), and ρ = 2.56 (g/cm3) outputs are UCS = 87.8 (MPa) and E s = 24.7 (GPa). Also, in Fig. 15 (models for very high-strength samples), for a limestone with TS = 7.21 (MPa), n = 3.84 (%), and ρ = 2.62 (g/cm3), outputs are UCS = 150 (MPa) and E s = 51.7 (GPa).

Relations between UCS and E s resulted from ANFIS models and laboratory measuring are shown in Fig. 16. These relations provide the determination coefficients (R 2) of 0.95 and 0.96 for UCS of samples with medium to high and very high strength, respectively. Also, the R 2 values for E s of samples with medium to high and very high strength are 0.89 and 0.91, respectively. Obviously, the predictive capability of the models is significant.

Also, we tested the predictive neuro-fuzzy models using 63 samples of limestone (39 samples with medium to high strength, and 24 samples with very high strength), outcrops of Asmari formation in Khersan 3, and Behesht Abad dam site projects, in Chaharmahal and Bakhtiari Province, Iran. Results are shown in Fig. 17.

Figure 18 presents error values in predicting UCS and E s with methods of multivariate regression and neuro-fuzzy inference system models.

7 Performance Controls of the Presented Models

Relations between the predicted UCS and E s resulted from multiple statistical and ANFIS methods versus the measured values in the laboratory are displayed in Figs. 6 and 16. In fact, the coefficient of determination (R 2) between the measured and predicted values and error values for two approaches (ANFIS and multiple statistics) are good indicators of checking the prediction performance of the models.

In addition, Variance Accounted For, VAF, (Eq. 5) and Root Mean Square Error (RMSE), (Eq. 6) indices were also calculated to control the performance of predicting capacity of predictive models developed in the study, as they were employed by Grima and Babuška (1999), Finol et al. (2001), and Gokceoglu et al. (2004).

where y and y′ are data measured in the laboratory and predicted values by ANFIS technique, respectively. The calculated indices are given in Table 4. The model will be excellent, provided that the VAF is 100 and RMSE is 0. When making a comparison between ANFIS and multivariate statistical methods, the predicting performance of the ANFIS is very higher than that of the multivariate statistic models, taking into consideration the performance indices (see Table 4).

8 Conclusion

Although the determination of mechanical properties of intact rocks is necessary for most rock mechanics studies and civil engineering projects, it is difficult and expensive to obtain them all at once. Hence, we attempted to predict UCS and E s of Asmari limestone by other necessary and easier measurable parameters such as regression analyses and ANFIS technique.

Because the measured values of UCS and ES of samples varied in a wide range, in this research, rock samples were classified as medium- to high-strength and very high-strength rocks and predictive models developed for each class.

Using the results of simple regression analyses, it was found that the relations between UCS and E s versus TS, n, and ρ are not strong enough to be relied upon for prediction of UCS and E s. Moreover, by reducing the number of data and dividing samples in two groups of medium- to high- and very high-strength samples, the performance of regression models was reduced significantly and the regression analysis gave the best performance for all samples. Hence, two multiple regression equations for predicting UCS and E s were developed in the next step for all samples. According to their coefficients of determination (R 2), both equations have a better predicting performance and show more efficiency compared to simple regression method. However, the predicted values of UCS and E s from these equations are not very close to actual values measured in the laboratory.

In the next step, four ANFIS models with common inputs TS, n, and ρ and two outputs including UCS and E s were developed for medium- to high- and very high-strength rock samples. These models exhibit most reliable predictions when compared with simple and multiple regression models. Predicted values of UCS and E s from these FIS’s are very closer to actual values measured in a laboratory rather than values derived from statistical methods.

The higher accuracy and efficiency of ANFIS models can be easily verified by comparing the values of VAF and RMSE. Values of VAF and RMSE for UCS predicted through multiple regression are 30.583 and 37.856, respectively; whereas the values predicted through ANFIS are 94.886 and 8.943 for medium- to high-strength samples; and 95.661 and 7.933 for very high-strength samples, respectively. Likewise, values of VAF and RMSE for E s predicted through multivariate regression are 32.855 and 13.721, respectively; whereas the values predicted through ANFIS are 89.853 and 5.021 for medium- to high-strength samples; and 90.011 and 6.861 for very high-strength samples, respectively.

Results show that simple and multivariate regression analyses are not efficient for prediction of UCS and E s in Asmari limestone, but ANFIS technique was found very efficient for prediction of these difficult parameters, using simple easily measurable parameters.

References

Aali KA, Parsinejad M, Rahmani B (2009) Estimation of saturation percentage of soil using multiple regression, ANN, and ANFIS techniques. Comput Inf Sci 2(3):127–136

Aghanabati A (2004) Geology of Iran. Geological survey of Iran, Tehran, p 586

Cargill JS, Shakoor A (1990) Evaluation of empirical methods for measuring the uniaxial compressive strength of rock. Int J Rock Mech Min Sci Geomech Abstr 27(6):495–503

Edet A (1992) Physical properties and indirect estimation of microfractures using Nigerian carbonate rocks as examples. Eng Geol 33(1):71–80

Eissa EA, Kazi A (1988) Relation between static and dynamic Young’s moduli of rocks. Int J Rock Mech Min Sci Geomech Abstr 25(6):479–482

Fahy MP, Guccione MJ (1979) Estimating strength of sandstone using petrographic thin-section data. Bull Assoc Eng Geol 16(4):467–485

Finol J, Guo YK, Jing XD (2001) A rule based fuzzy model for the prediction of petrophysical rock parameters. J Petrol Sci Eng 29(2):97–113

Geological Survey of Iran (2001) Brujen-Ramhormoz sheet. In: Vahdati-Daneshmand F (ed) Geological Quadrangle Map of Iran, scale 1:100000, sheet 6262, Geological Survey of Iran, Tehran

Gokceoglu C (2002) A fuzzy triangular chart to predict the uniaxial compressive strength of the Ankara agglomerates from their petrographic composition. Eng Geol 66(1–2):39–51

Gokceoglu C, Zorlu K (2004) A fuzzy model to predict the uniaxial compressive strength and the modulus of elasticity of a problematic rock. Eng Appl Artif Intell 17(1):61–72

Gokceoglu C, Yesilnacar E, Sonmez H, Kayabasi A (2004) A neuro-fuzzy model for modulus of deformation of jointed rock masses. Comput Geotech 31(5):375–383

Gokceoglu C, Sönmez H, Zorlu K (2009) Estimating the uniaxial compressive strength of some clay bearing rocks selected from Turkey by nonlinear multivariable regression and rule-based fuzzy models. Expert Systems 26(2):176–190

Grima MA (2000) Neuro-fuzzy modeling in engineering geology. AA Balkema, Rotterdam, p 244

Grima MA, Babuška R (1999) Fuzzy model for the prediction of unconfined compressive strength of rock samples. Int J Rock Mech Min Sci 36(3):339–349

Gurocak Z, Solanki P, Alemdag S, Zaman M (2012) New considerations for empirical estimation of tensile strength of rocks. Eng Geol 145–146:1–8

Gustafson D, Kessel W (1978) Fuzzy clustering with a fuzzy covariance matrix. In: 1978 IEEE conference on decision and control including the 17th symposium on adaptive processes, vol 17, pp 761–766

Howarth DF, Rowlands JC (1986) Development of an index to quantify rock texture for qualitative assessment of intact rock properties.ASTM. Geotechn Test J 9(4):169–179

Isrm BE (1978) Committee on standardization of laboratory and field tests. Suggested methods for the quantitative description of discontinuities in rock masses. Intl J Rock Mech Min Sci Geomech Abstr 15:319–368

Isrm BE (2007) Suggested methods: rock characterization, testing and monitoring. ISRM Commission on Testing Methods, Pergamon, p 211

Kaya A, Karaman K (2016) Utilizing the strength conversion factor in the estimation of uniaxial compressive strength from the point load index. Bull Eng Geol Env 75(1):341–357

LotfiZadeh LA (1965) Fuzzy sets. Inf Control 8(3):338–353

Mamdani EH, Assilian S (1975) An experiment in linguistic synthesis with a fuzzy logic controller. Int J Man Mach Stud 7(1):1–13

McCann DM, Entwisle DC (1992) Determination of Young’s modulus of the rock mass from geophysical well logs. Geol Soc Lond Spec Publ 65(1):317–325

Shakoor A, Bonelli RE (1991) Relationship between petrographic characteristics, engineering index properties, and mechanical properties of selected sandstones. Bull Assoc Eng Geol 28(1):55–71

Singh TN, Kanchan R, Verma AK, Saigal K (2005) A comparative study of ANN and neuro-fuzzy for the prediction of dynamic constant of rockmass. J Earth Syst Sci 114(1):75–86

Sonmez H, Nefeslioglu C, Gokceoglu HA, Kayabasi A (2006) Estimation of rock modulus: for intact rocks with an artificial neural network and for rock masses with a new empirical equation. Int J Rock Mech Min Sci 43(2):224–235

Sugeno M (1985) Industrial applications of fuzzy control. Elsevier Science Pub. Co, New York, p 269

Tahmasebi P, Hezarkhani A (2010) Application of adaptive neuro-fuzzy inference system for grade estimation; case study, Sarcheshmeh porphyry copper deposit, Kerman, Iran. Austr J Basic Appl Sci 4(3):408–420

Ulusay R, Türeli K, Ider MH (1994) Prediction of engineering properties of a selected litharenite sandstone from its petrographic characteristics using correlation and multivariate statistical techniques. Eng Geol 38(1):135–157

Zorlu K, Gokceoglu C, Ocakoglu F, Nefeslioglu HA, Acikalin S (2008) Prediction of uniaxial compressive strength of sandstones using petrography-based models. Eng Geol 96(3):141–158

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aghda, S.M.F., Kianpour, M. & Mohammadi, M. Estimation of Uniaxial Compressive Strength and Modulus of Deformability of the Asmari Limestone, Using Neuro-Fuzzy System. Iran J Sci Technol Trans Sci 42, 2005–2020 (2018). https://doi.org/10.1007/s40995-017-0351-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40995-017-0351-5