Abstract

In this paper, design and fabrication of a diode pumped Nd:YAG laser using a new design of laser head and high beam quality factor is reported. Appropriate diode lasers are prepared. Driver circuit, which works at quasi continuous wave (QCW) mode is fabricated. This circuit has a tunable pulse repetition rate and input current. Heat distribution in the active material and output beam profile is simulated by LASCAD software. Output pulses with 14 mJ energy, 200 μs time duration, and 1 Hz pulse repetition rate are achieved. High beam quality factor with M 2 ≤ 1.08 is obtained.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Optical pumped solid-state lasers are a grate class of under progress lasers that are applicable in different types (Wang and Groves 1992; Boulon 2012; Davarcioglu 2010; Kunda et al. 2001). Selection of a suitable pump source in laser designing is important and affects the total optical efficiency and beam quality (Byer 1988). The need for laser systems with a high power and high efficiency has led to the development of solid-state lasers pumped by laser-diodes. High efficiency and small size of the system compared to solid-state laser pumped by flash lamp make it applicable in different areas (Koechner 1999). Solid-state lasers, which are side-pumped by laser-diodes, possess higher power and efficiency, improved beam quality, and longer functionality compared to those pumped by flash lamp (Garrec et al. 1996; Konno and Yasui 1998; Leger and Goltsos 1992). Laser-diodes consist of linearly juxtaposed tiny emitters, which may emit at various wavelengths. Laser-diode 808 nm wavelength lies at the absorption peaks of Nd atoms and is a suitable source for pumping the Nd:YAG. More spectral coincidence in diode pumped lasers is compared to flash lamp pumped ones reduces unuseful wavelengths absorbed in the gain medium. This causes the reduction of the thermal effects (Panahy et al. 2008).

Laser diode beam represents a high divergence and low coherence, which reduces the feasibility of their concentration into an active medium. Moreover, provision of optical components is costly for this purpose. In the near-coupling method, laser-diode is positioned as close to the active medium as possible. However, due to the existence of cooling system surrounding the active medium, in high power system designs, laser-diodes could not be placed too close to the active medium. Thus, appropriate interference optics is utilized in such cases (Eryilmaz 2004; Sipes 1985). In this paper, a simple and low-cost design method is proposed for this aim. The design and simulation of the system are discussed in Sect. 2 of the present paper. The experimental results are given in Sect. 3 and finally a brief conclusion is reported in Sect. 4.

2 Design and Simulation

The following equation is used for a new and different laser head design,

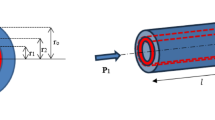

where “p” and “q” are the distances of laser-diode and active medium from the reflector, respectively. “f” is the focal length of the reflector. The reflector was gold-plated, which had a good reflection (98 %) at 808 nm wavelength. Cross-section of the designed air-cooled laser head is shown in Fig. 1.

For an optimal design and accomplishment of research objectives (achieving maximum efficiency), laser system was simulated using LASCAD software. In this simulation, thermal analysis of the active medium was done by studying the volume under pumping. To acheive a high beam quality, we attempted to reduce cavity mode volume. Figure 2 shows thermal stresses of laser rod. In this figure, maximum heat rate is clearly observable at the input of laser-diode beam. To decrease this thermal stress a cooling fan is used above the laser head.

Figure 3 shows the output beam profile of the laser, which indicates a high quality beam. In Fig. 4, diagram of the laser quality factor is presented. A laser beam with the beam quality factor of M 2 ≤ 1.08 can be observed in this figure.

3 Experimental Results

The solid-state gain medium was 0.8 % Nd:YAG cylindrical crystal rod, which was 4 mm in diameter and 50 mm long. To employ a suitable laser-diode for pumping, the absorption spectra were obtained using UV–VIS deviceFootnote 1 as shown in Fig. 5. As it can be observed in the absorption spectrum of Nd:YAG crystal, the most intensive absorption peak lies on 808 nm wavelength.

The selected pumping source was GaA1As laser-diode with an emitting wavelength of 808 nm. The emitted spectrum was recorded by Spectral Star S100 spectrometer (a CCD array detector with a grating as diffraction element). The results are shown in Fig. 6.

Laser-diode consists of a radiative line with the width of 960 µm (12 rods of 80 µm) and length of 13.1 mm. Its vertical divergence is 45° and horizontal divergence is 12°. Output power of the laser is 1200 W at pulse duration of 230 µs.

Figure 7 illustrates laser-diode output energy versus input current. As the figure shows, there is a linear relation between the input current and output energy from laser-diode. To prevent the variation of laser-diode wavelength caused by temperature rise, laser-diode is cooled by a heat sink.

The laser resonator was 100 mm in physical length, with two flat mirrors, a high reflector with the reflecting coefficient of 100 % as back mirror and the other one with the reflecting coefficient of 90 % as output coupler. The experimental setup is shown in Fig. 8.

The energy measurement results are shown in Fig. 9. Based on this figure the maximum output pulse energy is 14 mJ which corresponds to the optical efficiency of 6 %.

The temporal shape of the output pulses of laser, which is recorded by a Techtroniks oscilloscope, is shown in Fig. 10. Its width is about 200 µs at half maximum. Utilizing a Z-scan setup with a (Gentech) beam profiler, the beam waist and divergence of laser output were measured. Then M 2 factor was calculated using Eq. 2. The experimental value of beam quality factor was M 2 = 1.1. Simulation by LASCAD software confirmed this value for M 2 which was about 1.08.

4 Conclusion

A new, simple laser head was designed, simulated, and fabricated for a diode side-pumped Nd:YAG laser. By the proposed system, the inadvisable effects caused by flash lamp were eliminated due to good consistency between the output of the laser-diode and absorption spectrum of the active medium. Considering the simulation and experimental results, it was shown that using uniform diode pump of laser active medium can prevent thermal stresses. These stresses reduce the beam quality factor (M 2) in laser oscillators. Furthermore, reduction of mode volume and efficient mirror surfaces accompanied by uniform pump of laser active medium using laser-diodes can serve as a suitable method to obtain high beam quality factor.

Notes

Ultra-violet spectrometry with Cary 100 bio assisting photoluminescence device manufactured by Varian Company, Australia.

References

Boulon G (2012) Fifty years of advance in solid-state laser materials. Opt Mater 34:499–512

Byer RL (1988) Diode laser-pumped solid-state lasers. Sci New Ser 239(4841):742–747

Davarcioglu B (2010) An overview of diode pumped solid state (DPSS) lasers. Int Arch Appl Sci Tech 1:1–12

Eryilmaz E (2004) Design and construction of CW mode Nd:YAG laser prototype. Middle East Technical University Library. E-Thesis Archive

Garrec BJ, Raze GJ, Thro PY, Gilbert M (1996) High average-power diode-pumped frequency-doubled YAG laser. J Laser Electro Opt Soc Annu Meet 96(2):222–223

Koechner W (1999) Solid-state laser engineering. Springer Series in Optical Science, Washington

Konno S, Yasui K (1998) Efficient high-power green beam generation by use of an intra-cavity frequency-doubled laser-diode-pumped Q-switched Nd:YAG laser. J Opt Soc Am 37(3):551–554

Kunda et al (2001) High efficiency diode laser side- pumped Nd:YAG rod laser. Opt Laser Eng 36:65–73

Leger JR, Goltsos WC (1992) Geometrical transformation of linear diode laser arrays for longitudinal pumping of solid-state lasers. IEEE J Quantum Electron 28:1088–1100

Panahy H, Ebadeian H, Saghafefar H, Maleky A (2008) Design and construction of diode pump Nd:YAG Laser. In: Iranian Conference on Photonics Engineering, Malek-Ashtar University

Sipes DL (1985) Highly efficient neodymium:ytterbium aluminium garnet laser end pumped by a semiconductor laser array. Appl Phys Lett 47:74–77

Wang CA, Groves SH (1992) New materials for diode laser pumping of solid-state laser. IEEE J Quantum Electron 28:942–951

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pourhashemi, S., Khalilzade, J., Rahimi, M. et al. Simulation, Design and Fabrication of transverse diode-pumped Nd:YAG Solid-State Laser with 1.08 Beam Quality Factor. Iran J Sci Technol Trans Sci 40, 233–236 (2016). https://doi.org/10.1007/s40995-016-0092-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40995-016-0092-x