Abstract

The efficacy of ionic liquid (IL)-based pretreatment of lignocellulosic biomass (LB) can be enhanced by simultaneous application of surfactants/salts/deep eutectic solvent (DES) systems which may realize more effectual biorefining of LB to biofuels or other commodities. However, due to inhibitory nature of IL, IL-stable saccharification enzymes (cellulase/xylanase) are desired for enzymatic hydrolysis of IL-pretreated biomass. Bacillus spp. are considered as the super microbial factories for production of commercially important robust enzymes. The current study presents the enhanced production (1.438-fold) of an IL-stable cellulase from a newly isolated IL-tolerant Bacillus amyloliquefaciens SV29 by statistical optimization using agroindustrial residues as carbon (groundnut shell) and nitrogen source (mustard cake). The process variables such as groundnut shell and mustard cake, incubation time, and inoculum size were optimized. The enzyme preparation (cellulase/xylanase) was evaluated for its saccharification potential of Prosopis sp. (twigs/pods) biomass that was pretreated either with IL (1-ethyl-3-methylimidazolium methanesulfonate, EMIMS) standalone or IL along with surfactants/salts/DES systems in a consolidated bioprocess (CBP), i.e., one pot consolidated bioprocess, due to several technoeconomic advantages of the latter. No reported studies are available on bioconversion of Prosopis sp. biomass using IL or CBP. Sugar yield was enhanced when IL was used along with either DES choline chloride glycerol (54.4%) or with FeSO4 (51%). Thus, the pretreatment efficacy of EMIMS is substantially enhanced when used in combination with choline chloride glycerol or FeSO4 for getting increased sugar yield upon enzymatic hydrolysis of Prosopis sp. biomass with IL-stable enzymes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Lignocellulosic biomass (LB) represented by agricultural and forestry residues (wheat straw, sugarcane bagasse, corn stover), dedicated crops (switchgrass, salix), and weeds (wild sugarcane, mesquite) constitutes the most abundantly available renewable feedstock for biorefineries (Kumar et al. 2016; Vaid et al. 2018). LB has the potential to meet the ever-growing energy demand and to mitigate environmental issues such as green house gas emissions and climate change (Chen et al. 2017). LB bioethanol technology has recently gained immense research impetus, especially in view of rapidly depleting fossil fuel reserves and environmental problems. Cellulose and hemicellulose, the major polysaccharides of LB, may be enzymatically saccharified, and resultant sugars be fermented to bioethanol fuel which might be used especially for fueling the transportation sector.

However, LB bioethanol technology faces several limitations such as highly recalcitrant nature of LB, lack of process-apt enzymes, and ethanol-fermenting microorganisms (Gupta and Verma 2015; Chen and Fu 2016; Kumar et al. 2016; Zabed et al. 2016). The LB requires ample pretreatment to overcome its recalcitrance and to mobilize its polysaccharides for enzymatic saccharification. Most of the available pretreatment regimes including physical (pyrolysis, high temperature, high pressure, etc.), chemical (acid or alkali), and/or physicochemical pretreatments are not only cost and energy intensive but are environmentally hazardous (Chang et al. 2017; Liu et al. 2018). Furthermore, harsh pretreatments cause loss of sugars and production of inhibitors (furfurals) which may potentially inhibit the saccharifying enzymes and/or fermentation microorganisms (Vaid and Bajaj 2017). Thus, a suitable pretreatment technology needs to be devised which works under ambient process conditions, involves less energy, and produces low or minimal inhibitors (Pérez-Pimienta et al. 2017).

Ionic liquids (ILs), the green organic solvents with unique physical and chemical properties, have recently gained attention as the potential pretreatment agents for LB feedstocks (Chang et al. 2017). ILs can decrystallize cellulose, with partial removal of hemicellulose and lignin but without generating any inhibitory products (Yuan et al. 2017). However, the residual lignin in the IL-pretreated LB may precipitate back on the surface of biomass by forming hydrophobic compounds, thus hindering the effective enzymatic hydrolysis (Pandey and Negi 2015; Chang et al. 2017). Surfactants due to their hydrophilic and hydrophobic properties help in decreasing the surface tension between the two liquid phases during pretreatment (Chang et al. 2016). Surfactants may form emulsion with lignin-based hydrophobic compounds and prevent their redeposition on pretreated biomass, and this results in higher yield of fermentable sugars upon enzymatic saccharification (Pandey and Negi 2015). Application of surfactants with different ILs for LB pretreatment has been reported to have an additive effect (Nasirpour et al. 2014).

Deep eutectic solvents (DESs) are being explored as potential LB pretreatment agents as their physicochemical properties resemble those of ILs (Procentese et al. 2015; Zhang et al. 2016; Hou et al. 2017). The components of DESs, i.e, hydrogen bond donors and acceptors, individually do not have the ability to pretreat the biomass, but when combined together in a homogeneous mixture, their individual properties get transformed, and the mixture makes an effective LB pretreatment agent (Zhang et al. 2016; Fang et al. 2017). DESs offer additional advantages over conventional ILs such as their easy preparation, biodegradability, and biocompatibility. However, application of DESs for LB pretreatment is still in its infancy and it requires intensive research for elucidating their detailed mechanism of action (Fang et al. 2017).

ILs are inhibitory for saccharifying cellulase/xylanase enzymes; therefore, IL-pretreated LB requires extensive washing to remove the traces of residual IL. But this step generally causes sugar loss and generates huge amount of waste water. Therefore, there is a critical need for IL-stable saccharification enzymes to obviate the washing step (Nargotra et al. 2016; Xu et al. 2016). Furthermore, availability of IL-stable enzymes may help developing the consolidated bioprocess wherein IL pretreatment and enzymatic saccharification may be executed in a single reaction vessel (bioreactor). Consolidated bioprocessing refers to the execution of pretreatment of biomass, its saccharification, and fermentation in a single vessel, i.e., one pot consolidated bioprocess, OPCB (Favaro et al. 2015; den Haan et al. 2015; Lynd et al. 2016). OPCB offers several technoeconomic advantages over conventional multi-vessel operational strategies: It reduces processing cost and time, simplifies process scheme, and requires single operational unit (Brethauer and Studer 2014). High cost of the saccharifying enzymes is another issue that hinders the LB bioethanol technology. Low-cost agroindustrial residues may be exploited as substrates for cost-effective and economic production of enzymes (Vaid and Bajaj 2017).

Exploration of novel LB feedstocks for biorefining is an ongoing process. Prosopis sp., a perennial deciduous thorny shrub, is an invasive weed which damages the environment and is indigestible to livestock. However, due to high holocellulose content (60–65%) Prosopis sp. biomass may have application potential as prospective feedstock for bioethanol fuel production (Gupta et al. 2009; Amdebrhan et al. 2016). Though Prosopis sp. biomass has been used for bioethanol production (Gupta et al. 2009; Naseeruddin et al. 2017), no reported studies are available on its consolidated bioprocessing involving IL-based pretreatment and enzymatic saccharification.

Bacillus amyloliquefaciens SV29, a bacterial isolate in our laboratory, produced IL-stable cellulase/xylanase enzymes; the current study presents the application of design of experiments-based optimization for enhanced enzyme production using agroindustrial residues as substrates. The IL-stable cellulase/xylanase enzyme blend was examined for its saccharification potential for surfactants/DESs-assisted IL-pretreated Prosopis sp. biomass under consolidated bioprocess.

2 Materials and methods

2.1 Chemicals, materials, and process organism

Ionic liquid, 1-ethyl-3-methylimidazolium methanesulfonate (EMIMS), was purchased from Sigma-Aldrich (St. Louis, MO, USA) (95% purity). Carboxymethylcellulose sodium (CMC-Na), filter paper, 3,5-dinitrosalic acid (DNS), media, and various other reagents and chemicals were purchased from suppliers like HiMedia Laboratories, Merck and Co, Ranbaxy Fine Chemicals, and Sigma-Aldrich. All chemicals were of high purity and analytical reagent grade. The Prosopis sp. biomass (twigs and pods) collected from New Campus of University of Jammu, Jammu, were washed well with tap water and dried at 70 °C for 24 h. The dried biomass (twigs and pods) was minced, ground in a laboratory blender, and sieved to attain a particle size of < 4 mm. The ground biomass was stored in an air-tight container at room temperature. The cellulolytic bacteria used in this study were obtained from culture collection of Fermentation Biotechnology Laboratory, School of Biotechnology, University of Jammu, Jammu, India.

2.2 Qualitative and quantitative screening of cellulolytic bacteria

Cellulolytic potential of bacterial cultures was examined qualitatively by plate assay using Congo red staining (Nargotra et al. 2016). Briefly, bacterial isolates were spotted on carboxymethylcellulose (CMC) agar plates and allowed to grow for 24 h at 37 °C, and then plates were flooded with Congo red (1% w/v in distilled water), and after 15 min plates were washed with NaCl (1 M). A zone of clearance around the bacterial growth is suggestive of cellulolytic activity (Sharma and Bajaj 2014). The ability of the cellulolytic bacterial cultures (J2, L10, and SV29) to grow in CMC–peptone–yeast extract broth (CPYE, % w/v, CMC 1.0, peptone 0.4, yeast extract 0.4) in the presence of EMIMS (1% w/v) was examined spectrophotometrically (A600).

The cellulolytic bacteria (J2, L10, and SV29) were subjected to submerged fermentation (SmF) for quantitative analysis of their cellulase-producing ability. The fresh CPYE production medium was inoculated (2% v/v) with 18-h-grown bacterial culture (A600 0.9–1.0). Fermentation was allowed to proceed at 37 °C under shaking (180 rpm) for 24–72 h. Samples withdrawn at different time intervals were centrifuged (10,000×g, 4 °C, 10 min), and supernatant (crude enzyme) was assayed for cellulase activity (Sharma and Bajaj 2014). Carboxymethyl cellulase (CMCase, cellulase) and filter paperase (FPase) activities were assayed by quantifying the amount of reducing sugar released from CMC-Na and Whatman No. 1 filter paper as substrates, respectively (Vaid and Bajaj 2017). The amount of reducing sugar released was measured spectrophotometrically at 575 nm (UV-1800, Shimadzu, Japan) using 3,5-dinitrosalicylic acid (DNSA) method (Miller 1959). One unit (IU) of CMCase and FPase was defined as the amount of enzyme required to release one µmole of glucose equivalent per mL per min under standard assay conditions. Xylanase activity was determined in crude enzyme preparation by quantifying the release of reducing from xylan substrate. One unit of xylanase was defined as the amount of enzyme required to release one µmole of xylose equivalent per mL per min under assay conditions (Vaid et al. 2017).

2.3 Selection of ionic-liquid-stable cellulase-producing bacterium

For ionic liquid stability analysis, cellulase from the three bacterial cultures, viz. J2, L10, and SV29, was examined for activity in the presence of IL. Each of the cellulase (crude enzyme) was pre-incubated with EMIMS (10% v/v) at room temperature in 1:1 ratio. Residual cellulase activity was examined at various time intervals (6, 24, 48, and 72 h). Enzyme activity in the beginning was considered as control (Vaid and Bajaj 2017). The bacterial isolate which produced the maximum IL-tolerant cellulase was earmarked and studied for culture morphology, microscopic characteristics, and 16S rDNA sequence analysis. Colony morphology of the selected bacterial strain was examined on CMC agar.

Protelolytic activity of bacterial isolate SV29 was ascertained by cultivating it in skimmed milk broth for 24 h at 37 °C. The cultural supernatant obtained after centrifugation (10,000×g, 4 °C, 10 min) was poured into the wells (6 mm diameter) on the skimmed milk agar plates and incubated for 24 h at 37 °C. Formation of clear zones around the wells was indicative of the proteolytic activity (Singh and Bajaj 2017). Gelatinase activity of the bacterium SV29 was examined by stabbing the culture on gelatin slants and incubating at 37 °C for 24 h. Appearance of liquefaction in the gelatin slants was suggestive of the gelatinolytic activity of the bacterium (Singh and Bajaj 2017; Vaid and Bajaj 2017). For amylase-producing ability, bacterial isolate SV29 was grown in starch broth for 24 h (Singh and Bajaj 2017). The culture was centrifuged and the supernatant was poured in the wells cut on the starch agar plates. Plates were incubated for 24 h at 37 °C. Plates were then flooded with iodine solution; appearance of clear zones around the wells in otherwise blue-colored starch agar plates indicated amylolytic activity of the bacterium.

For lipolytic activity, bacterial isolate SV29 was cultivated for 24 h at 37 °C in tributyrin broth; supernatant was centrifuged, poured into the wells cut on the tributyrin agar plates, and incubated for 24 h at 37 °C. Formation of clear zones around the wells against opaque tributyrin agar plates was suggestive of its lipolytic activity (Nargotra et al. 2016; Singh and Bajaj 2017). The bacterium SV29 was spotted on xylan agar plates for examining its xylanase-producing ability. The plates were incubated for 24 h at 37 °C and subjected to Congo red staining. Clear halos around the bacterial growth were indicative of the xylanolyitc activity (Vaid and Bajaj 2017).

For 16S rDNA sequence analysis, DNA was isolated (Wizard Genomic DNA Preparation Kit, Promega Co, Madison, WI, USA) and subjected to PCR amplification based on universal 16S rDNA primers (forward primer 5′-GTGTTTGATCCTGGCTCAG-3′, reverse primer 5′-CGGCTACCTTGTTACGACTTT-3′) (Sharma and Bajaj 2014). Elution of the PCR-amplified product was executed using Axygen DNA gel extraction kit (Axygen Union City, CA, USA). The PCR product was sequenced (SciGenom Labs Pvt. Ltd, Chennai, India), and the sequence was subjected to BLAST for revealing its closest homology with the other related sequences available in the GenBank database (NCBI). The neighbor-joining phylogenetic analysis and construction of phylogenetic tree were carried out using MEGA 6 software (http://www.megasoftware.net).

2.4 Optimization of bioprocess variables for cellulase production

Central composite design (CCD) tool of response surface methodology (RSM) (Design-Expert 7, Stat-Ease, Inc, Minneapolis, USA) was used to generate a total of 30 experimental runs for model development and for determination of the optimum level of the various process variables for cellulase production. The input variables consisted of crude carbon (groundnut shell A), nitrogen source (mustard cake B), inoculum size (C), and incubation time (D). The maximum and minimum range of these independent variables was selected based on the already reported studies (Table 1). The five coded levels (− α, − 1, 0, + 1, + α) at maximum and minimum values are presented in Table 2, and the developed model is shown in Table 3. Analysis of variance (ANOVA) was conducted for the observed experimental cellulase yield “Y” (IU/mL) and was used for ascertaining the significance of fit of the second-order polynomial equation which relates the variables to the cellulase yield (response). The validation of the model was done by executing an experiment based on optimal level of the each variable calculated by point prediction tool of the model. The response values (Y) were measured as the average of triplicate experiments.

2.5 Acetone precipitation of cellulase/xylanase preparation

Cellulase produced under optimized process conditions was concentrated by acetone precipitation. The cellulase was mixed with precooled acetone in the ratio of 1:4, vortexed well, and incubated for 60–90 min at − 20 °C. The mixture was centrifuged for 10 min at 10,000×g. Supernatant was discarded carefully so as not to extricate the protein pellet. The pellet was allowed to dry at room temperature for 30 min in order to evaporate acetone and then suspended in phosphate buffer (50 mM, pH 7.0). The enzyme preparation was examined for CMCase, FPAse, xylanase activity, and protein content before and after the acetone precipitation.

2.6 Pretreatment and enzymatic saccharification of Prosopis sp. biomass under OPCB

Prosopis sp. twigs and pods were pretreated with EMIMS separately. The pretreatment was performed with EMIMS alone and with EMIMS in combination with different surfactants/salts/deep eutectic solvent, viz. Tween 80, Tween 20, ferrous sulfate (FeSO4), and choline chloride glycerol (CCG). For determination of the most suitable pretreatment regime, several combinations were examined, viz. (a) EMIMS + tween 80, (b) EMIMS + tween 20, (c) EMIMS + FeSO4, and (d) EMIMS + choline chloride glycerol (CCG) (Nasirpour et al. 2014; Pandey and Negi 2015; Zhang et al. 2016). The appropriate control experiments were set up simultaneously. A 100 mg of each of the biomass (twig and pod biomass) was suspended in 2 mL of EMIMS (10% v/v, in phosphate buffer) containing 1% (w/v) of either of the surfactant, salt, or CCG. The reaction contents were incubated at 70 °C for 24 h with occasional stirring. After 24 h, a 2.0 mL (3.6950 IU/mL) of acetone concentrated cellulase/xylanase enzyme preparation was added to each of the pretreated biomass in situ, i.e, under one pot consolidated bioprocess (OPCB) conditions (Vaid and Bajaj 2017). The contents were incubated for 24 h at 37 °C under shaking (180 rpm). Reducing sugar released was analyzed for each sample using DNSA assay. The saccharification efficacy was examined by quantifying the reducing sugars produced from biomass as represented in equation I (Vogel et al. 2011). All analytical experiments were conducted in triplicates, and data present the mean values

where 1.1 is the conversion factor of holocellulose to glucose equivalent.

3 Results and discussion

3.1 Ionic-liquid-stable cellulolytic bacteria

The cellulolytic activity of bacterial isolates (J2, L10 and SV29) was examined by Congo red staining. The ability of cellulolytic bacterial isolates to grow in the presence of EMIMS was examined. The cellulolytic bacterial isolates, i.e, J2, L10 and SV29, showed tolerance toward IL and grew well in the presence of EMIMS, and growth was comparable with that in control, i.e., without IL. The growth was measured spectrophotometrically (A600). The CPYE broth was inoculated with log phase grown cells at 1% v/v (A600 0.9–1.0). The absorbance was measured periodically against uninoculated broth as control. The absorbance (A600) of different bacterial cultures, i.e., SV29, J2, and L10, was 0.045, 0.039, and 0.030, respectively, at 0 h. The growth of isolate L10 declined after 24 h while the isolates J2 and SV29 showed consistent growth up to 48–72 h (Fig. 1a). Several complex factors are responsible for IL resistance of bacteria. Various biochemical and physiological functions, and genes associated with stress response, membrane transport, detoxification, osmotic stress, ABC, and energy coupling factor (ECF) transport are involved in imparting resistance to bacteria against the toxic effects of IL (Khudyakov et al. 2012; Kurata et al. 2014). The decrease in growth during prolonged incubation may be due to cell lysis or cell rupture (Nizamudeen and Bajaj 2009; Sharma and Bajaj 2014).

Quantitative analysis of cellulolytic activity of bacterial isolates showed that the isolate SV29 exhibited higher activity (1.7411 IU/mL) after 24 h as compared to other isolates, i.e, J2 (0.8971 IU/mL) and L10 (0.8794 IU/mL). The cellulase activity of the isolate SV29 increased further, up to 48 h, but that of isolates J2 and L10 declined (Fig. 1b). Time profile analysis for FPase production showed that maximum FPase production occurred after 48 h of fermentation. The isolate L10 showed maximum FPase activity (Fig. 1c). The growth and cellulase production may have differential relationships, i.e, a direct relation where growth and cellulase production go side by side, or a partial relation where growth and cellulase production are partly associated (Sharma and Bajaj 2014; Vaid and Bajaj 2017).

The three IL-tolerant bacterial isolates were hypothesized to be producers of IL-stable cellulase. The organisms which are capable of thriving in the presence of IL must have its metabolic machinery well adapted to resist the IL, and correspondingly its enzyme complement must have adequate IL stability (Yu et al. 2016). All the three bacterial isolates (J2, L10, and SV29) which exhibited considerable CMCase and FPase activities and growth in the presence of IL were made to produce cellulase under submerged fermentation and the enzyme was examined for EMIMS stability. The cellulase from isolate SV29 was observed to have the maximum IL stability (117.8%) for prolonged time period of 72 h, followed by cellulase from isolate J2 (92%) (Fig. 1d). Considering the adequate IL stability of cellulase from bacterial isolate SV29, the bacterium was selected for further investigation.

Cellulases from several microbial sources have been studied for their IL stability (Trivedi et al. 2013; Singh et al. 2015). The cellulolytic fungus Penicillium oxalicum GS exhibited IL tolerance when investigated for growth in IL, dimethylimidazolium methylphosphonate–Luria–Bertani (LB) medium. Also the cellulase produced by P. oxalicum GS showed excellent stability in the presence of IL (Xu et al. 2016). Similarly, cellulase from IL-stable fungus Aspergillus fumigatus HY isolated from chemically polluted microhabitats showed substantial stability in the presence of 1-ethyl-3-methyl-imidazolium dimethylphosphate, 1-allyl-3-methylimidazolium chloride, and 1-ethyl-3-methylimidazolium methylammonium-methylsulfate (Xu et al. 2014) while cellulase from Pseudoalteromonas sp. showed more than 90% of tolerance in the presence of five different ILs (Trivedi et al. 2013). More than 95% IL stability was reported for cellulase from B. subtilis G2 (Vaid and Bajaj 2017). A compatible microbe/cellulase IL system allows IL pretreatment and subsequent enzymatic saccharification of LB in a single reactor (consolidated bioprocessing) which could be of great technoeconomic importance. However, rare reports are available on the application of IL-stable cellulases in consolidated bioprocessing (Vaid and Bajaj 2017).

3.2 Identification of bacterial isolate SV29

The cellulolytic bacterial isolate SV29 which has the potential to produce IL-stable cellulase was identified based on morphological, microscopic, and 16S rDNA sequence analysis. The bacterial isolate SV29 showed good growth on nutrient agar as well as on CMC agar plates, and formed discreet, off-white colonies with irregular margins. The bacterial isolate SV29 is gram-positive, rod shaped (bacillus) with spore forming ability. The 16S rDNA sequence (about 1500 bp, Fig. 2a) analysis of bacterial isolate SV29 depicted its close homology with those of several Bacillus amyloliquefaciens strains available in GenBank database (NCBI) (Fig. 2b). Based on the results, the isolate SV29 was identified as one of the strains of Bacillus amyloliquefaciens and designated as B. amyloliquefaciens SV29. The sequence has been submitted to NCBI GenBank database under accession number MF116305. The bacterial isolate SV29 also successfully hydrolyzed the xylan, starch, proteins (gelatin, casein), and triglycerides, thus exhibiting xylanolytic, amylolytic, proteolytic, and lipolytic activities, respectively (Fig. 3a–e).

3.3 Design of experiments for cellulase production B. amyloliquefaciens SV29

Central composite design of RSM is applied for the optimization of process variables and to study the interactions between them. Four process variables were selected, i.e, groundnut shell (A), mustard cake (B), inoculum size (C), and incubation time (D). A total of 30 experiments were executed as per the design. The response (cellulase production, IU/mL) obtained was fed into the response column in the design matrix (Table 4). Close resemblance between the actual responses (obtained after experimentation) and predicted responses demonstrated the accuracy of the model. The fitness of the model was assessed by analysis of variance (ANOVA) and results were examined (Table 5).

The model F-value of 18.61 and p value of < 0.0001 suggest the significance of the model. In addition, the F-value of 3.88 and p value > 0.0738 of lack of fit imply its insignificance and suggest the goodness of the fit of model. The value of coefficient of determination R2 (0.9456) indicates that 94.56% of the variation was accounted by the developed model in the observed data. Low standard deviation of 0.19 was the strong indicator of the robustness of the model with high degree of predictability. An adequate precision of 17.873 was obtained which points toward an adequate signal. All the statistical parameters showed that the generated model was effective in explaining the effect of variables on the response obtained. The results obtained clearly imply that quadratic model could be used to navigate the design space. The polynomial Eq. 2 obtained after multiple regression analysis for CMCase production is as follows:

Y indicates the response, i.e, cellulase yield as a function of different independent variables, i.e, A—groundnut shell, B—mustard cake, C—inoculum size, and D—incubation time.

ANOVA results show that A, B, D, A2, B2, D2, and BC are significant model terms. It was determined that incubation time (D) was the most significant parameter (p value < 0.0001) of all the variables and has the most positive influence on cellulase production followed by groundnut shell A (p value = 0.0006) and mustard cake B (p value = 0.0493). All the statistically significant variables in squared terms A2, B2, D2 had negative influence on cellulase production. The interaction between variable B (mustard cake) and C (inoculum size) had statistically positive significance on cellulase yield.

The three-dimensional response surface plots were generated to investigate the interactions between various variables, viz. groundnut shell, mustard cake, inoculum size, and incubation time, and to visualize their combined effects on cellulase production (Fig. 4). The effect of interaction between mustard cake and inoculum size (BC) on cellulase production is shown in Fig. 4a. An increase in cellulase production was observed from 2.09 to 2.48 IU/mL with the increase in concentration of mustard cake (2–4% w/v) and inoculum size (2–5% v/v) as observed in Fig. 4a. The combined effect of mustard cake and inoculum size was shown to have a significant positive effect on cellulase production. The interactive effect of groundnut shell concentration (3–5% w/v) and incubation time (24–60 h) led to enhanced cellulase production from 1.26 to 2.52 IU/mL (Fig. 4b). However, this interaction was statistically nonsignificant.

The combined effect of mustard cake (2–4% w/v) and incubation time (24–60 h) had a positive effect on cellulase production and increased the cellulase yield from 1.48 to 2.52 IU/mL, but the interaction was nonsignificant (Fig. 4c). Figure 4d shows the perturbation plot which explains the change in the response with respect to the chosen reference point when altering the value of each variable and keeping the value of other variables constant. The variable D (inoculum size) deviated maximally with respect to the reference point while variable C (incubation time) showed minimal deviation (Fig. 4d).

The validation of designed statistical model was done by using point prediction tool of RSM. The value of variables predicted by the point prediction tool, i.e, groundnut shell (4.73% w/v), mustard cake (3.62% w/v), incubation time (59.68 h), and inoculum size (5% v/v), was used, and experiments were conducted. The close proximity of experimental (2.505 IU/mL) and predicted value (2.812 IU/mL) of cellulase titer indicated the validity of the model. A 1.438-fold enhanced cellulase yield was obtained upon optimization (2.505 IU/mL) of medium components and environmental variables as compared to that under unoptimized conditions (1.741 IU/mL).

Although response surface methodology-based optimization of cellulase production has been reported from various Bacillus spp. (Sharma and Bajaj 2014; Irfan et al. 2017), but relatively fewer reports are available on IL-stable cellulase production, especially using crude substrates as carbon and nitrogen sources (Singh et al. 2015; Nargotra et al. 2016). Wheat bran and spirulina powder were used as crude carbon and nitrogen sources for achieving 1.41-fold enhanced production of IL-tolerant cellulase from B. subtilis SV1 (Nargotra et al. 2016). Sequential optimization of medium components and environmental variables enhanced IL-stable cellulase yield to 4.1-fold from B. subtilis I-2 (Singh et al. 2015) and 2.66-fold from B. subtilis G2 (Vaid and Bajaj 2017). Optimization of medium components and environmental variables using RSM increased the cellulase production from Enhydrobacter sp. ACCA2 by 2.39-fold as compared to that in nonstatistical method (1.07-fold) (Premalatha et al. 2015). RSM-employed optimization of process parameters led to enhanced cellulase production (3.50 ± 0.11 IU/mL) from Bacillus subtilis K-18 (Irfan et al. 2017).

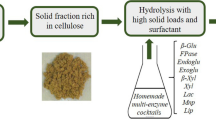

3.4 Saccharification potential of cellulase/xylanase from B. amyloliquefaciens SV29

The B. amyloliquefaciens SV29 was subjected to submerged fermentation under optimized conditions, and crude enzyme preparation of extracellular cellulase/xylanase was concentrated using acetone precipitation. The concentrated enzyme preparation exhibited high cellulase (36.950 IU/mL) and xylanase (7.31 IU/mL) activities. This enzyme preparation was used for the saccharification of Prosopis sp. twigs and pods biomass that was pretreated variously with ionic liquid alone or in combination with surfactants/salts/deep eutectic solvent system.

The pretreated biomass was subjected to enzymatic saccharification using in-house developed cellulase/xylanase enzyme preparation from B. amyloliquefaciens SV29 under one pot consolidated bioprocess (OPCB), and sugar release was analyzed (Fig. 5). It was observed that the sugar release was enhanced upon IL pretreatment of Prosopis twigs (35.95 mg/g) and pods (49.78 mg/g) as compared to the control I and control II. The control I represented no IL pretreatment (biomass + buffer) and no enzymatic saccharification of Prosopis sp. twigs and pods biomass. The control II represented no IL pretreatment but direct enzymatic saccharification of biomass. Control I showed sugar content of 9.00 mg/g from twigs and 8.99 mg/g from pods, while control II showed sugar content of 10.88 mg/g (from twigs) and 15.61 mg/g (from pods).

Reducing sugar yield obtained after various IL based pretreatments, and enzymatic saccharification of Prosopis sp. twigs and pods biomass. Controls (C) and tests (T), C1: biomass + buffer; C2: biomass + enzyme; T1: biomass + IL + enzyme; T2: biomass + IL + Tween 80 + enzyme; T3: biomass + IL + Tween 20 + enzyme; T4: biomass + IL + FeSO4 + enzyme; T5: biomass + IL + CCG + enzyme

Several combinatorial pretreatment approaches involving IL along with surfactants/salts and deep eutectic solvents were attempted for pretreatment of twigs and pods of Prosopis sp. followed by enzymatic saccharification using consolidated bioprocessing (OPCB). The IL pretreatment along with Tween 20 or Tween 80 resulted in enhanced sugar yield upon enzymatic saccharification, from Prosopis sp. twig but not from pods biomass. Furthermore, IL pretreatment coupled with FeSO4 was found to be a highly efficient pretreatment approach for Prosopis sp. biomass. It (IL + FeSO4 pretreatment) resulted in massive increase in sugar release from Prosopis sp. twig and pod biomass after enzymatic saccharification. Furthermore, IL + FeSO4 pretreatment was observed to be more efficacious for pods as compared to twigs (Fig. 5). This pretreatment regime (IL + FeSO4) led to 51% enhanced sugar release from pods as compared to only IL pretreatment followed by enzymatic saccharification.

Similarly, the pretreatment regime involving IL in combination with eutectic solvent choline chloride glycerol, CCG (IL + CCG) was found to be highly effective for Prosopis biomass (twigs and pods). Furthermore, this pretreatment was more effective for pods as compared to twigs (Fig. 5). Sugar release from Prosopis sp. pod biomass by application of IL + CCG pretreatment was increased by 54.4% as compared to that in pretreatment regime involving only IL pretreatment and enzymatic saccharification. The saccharification efficiency of 10.7% was obtained in case of both Prosopis pod and twig biomass.

IL decrystallizes cellulose with partial removal of hemicelluloses and lignin. The presence of lignin in the solution after pretreatment may precipitate back on the surface of biomass and may hinder the subsequent saccharification under consolidated bioprocess. Surfactants such as Tween 80 and Tween 20 prevents the lignin redeposition on pretreated biomass and helps in enhancing reducing sugar yield (Chang et al. 2016). Various inorganic salts such as FeSO4 act as catalysts during pretreatment and accelerate the degradation of hemicelluloses, thus increasing the accessibility of cellulase to cellulosic biomass. Also Fe2+ ions might promote cellulase activity, thus enhancing the subsequent saccharification in one pot consolidated process (Zhao et al. 2011; Mussatto 2016). Similarly, deep eutectic solvents such as CCG help in enhancement of glucan digestibility to glucose (Fang et al. 2017).

Pretreatment of different LB using IL in combination with surfactants/salts followed by separate enzymatic saccharification has been reported by several researchers. However, rare reports are available on IL pretreatment of biomass and enzymatic saccharification using OPCB, and no such reports are available on Prosopis sp. Nasirpour et al. (2014) observed a significant enhancement in enzymatic digestibility by using surfactant assisted (Tween 80 and polyethylene glycol) ionic liquid (1-butyl-3-methylimidazolium chloride, [BMIM]Cl) pretreatment of sugarcane bagasse under separate pretreatment and saccharification process.

Increased lignin removal during pretreatment enhances the efficacy of enzymatic saccharification. Application of sodium dodecylsulfate and cetrimonium bromide (surfactants) along with IL 1-butyl-3-methylimidazolium chloride for pretreatment of rice straw resulted in increased removal of lignin by 49.48 and 34.76%, respectively, as compared to that with IL only (Chang et al. 2016). In another study, the impact of various surfactants was studied on IL (1-allyl-3-methylimidazolium chloride) pretreatment of rice straw. The cellulose conversion using biosurfactant, i.e., rhamnolipid and IL-pretreated rice straw was higher (36.21%) as compared to only IL pretreatment (28.25%) (Chang et al. 2017). IL pretreatment and enzymatic saccharification of pine needle biomass were executed under OPCB, and a saccharification efficiency of 65.9% was obtained (Nargotra et al. 2016).

4 Conclusion

It may be concluded form the current study that B. amyloliquefaciens SV29 has got potential of secreting IL-stable enzymes by utilizing low-cost agrowastes as carbon and nitrogen sources. IL-stable cellulase production has been optimized to get enhanced yield, however, more process variables may be included in the optimization regime to increase the yield even further. The efficacy of ionic liquid 1-ethyl-3-methylimidazolium methanesulfonate for the pretreatment of Prosopis sp. biomass is enhanced when used in combination with deep eutectic solvent system choline chloride glycerol as well as with FeSO4. However, the IL-based pretreatment in combination with surfactants/salts and deep eutectic solvents needs optimization of various process variables for further enhancing sugar yield. One pot consolidated bioprocess has successfully been used in the current study, but it needs comprehensive and in-depth investigation for interactive influence of various components on the final outcome of sugar yield.

References

Amdebrhan BT, Asfaw S, Assefa G (2016) Acid hydrolysis optimization of Prosopis Juliflora stem for bioethanol production. Science 4:1–11

Brethauer S, Studer MH (2014) Consolidated bioprocessing of lignocellulose by a microbial consortium. Energy Environ Sci 7:1446–1453

Chang KL, Chen XM, Han YJ, Wang XQ, Potprommanee L, Ning XA, Liu JY, Sun J, Peng YP, Sun SY, Lin YC (2016) Synergistic effects of surfactant-assisted ionic liquid pretreatment rice straw. Bioresour Technol 214:371–375

Chang KL, Chen XM, Wang XQ, Han YJ, Potprommanee L, Liu JY, Liao YL, Ning XA, Sun SY, Huang Q (2017) Impact of surfactant type for ionic liquid pretreatment on enhancing delignification of rice straw. Bioresour Technol 227:388–392

Chen H, Fu X (2016) Industrial technologies for bioethanol production from lignocellulosic biomass. Renew Sust Energ Rev 57:468–478

Chen S, Zhang X, Ling Z, Xu F (2017) Characterization of the Micromorphology and topochemistry of poplar wood during mild ionic liquid pretreatment for improving enzymatic saccharification. Molecules 22:115

den Haan R, van Rensburg E, Rose SH, Görgens JF, van Zyl WH (2015) Progress and challenges in the engineering of non-cellulolytic microorganisms for consolidated bioprocessing. Curr Opin Biotechnol 33:32–38

Fang C, Thomsen MH, Frankær CG, Brudecki GP, Schmidt JE, AlNashef IM (2017) Reviving pretreatment effectiveness of deep eutectic solvents on lignocellulosic date palm residues by prior recalcitrance reduction. Ind Eng Chem Res 56:3167–3174

Favaro L, Viktor MJ, Rose SH, Viljoen-Bloom M, van Zyl WH, Basaglia M, Cagnin L, Casella S (2015) Consolidated bioprocessing of starchy substrates into ethanol by industrial Saccharomyces cerevisiae strains secreting fungal amylases. Biotechnol Bioeng 112:1751–1760

Gupta A, Verma JP (2015) Sustainable bio-ethanol production from agro-residues: a review. Renew Sust Energ Rev 41:550–567

Gupta R, Sharma KK, Kuhad RC (2009) Separate hydrolysis and fermentation (SHF) of Prosopis juliflora, a woody substrate, for the production of cellulosic ethanol by Saccharomyces cerevisiae and Pichia stipitis-NCIM 3498. Bioresour Technol 100:1214–1220

Hou XD, Feng GJ, Ye M, Huang CM, Zhang Y (2017) Significantly enhanced enzymatic hydrolysis of rice straw via a high-performance two-stage deep eutectic solvents synergistic pretreatment. Bioresour Technol 238:139–146

Irfan M, Mushtaq Q, Tabssum F, Shakir HA, Qazi JI (2017) Carboxymethyl cellulase production optimization from newly isolated thermophilic Bacillus subtilis K-18 for saccharification using response surface methodology. AMB Express 7:29

Khudyakov JI, D’haeseleer P, Borglin SE, DeAngelis KM, Woo H, Lindquist EA, Hazen TC, Simmons BA, Thelen MP (2012) Global transcriptome response to ionic liquid by a tropical rain forest soil bacterium, Enterobacter lignolyticus. Proc Natl Acad Sci 109:E2173–E2182

Kumar R, Tabatabaei M, Karimi K, Sárvári Horváth I (2016) Recent updates on lignocellulosic biomass derived ethanol—a review. Biofuel Res J 9:347–356

Kurata A, Hirose Y, Misawa N, Hurunaka K, Kishimoto N (2014) Draft genome sequence of the ionic liquid-tolerant bacterium Bacillus amyloliquefaciens CMW1. Genome Announc 2:e01051-14

Liu Z, Li L, Liu C, Xu A (2018) Pretreatment of corn straw using the alkaline solution of ionic liquids. Bioresour Technol 260:417–420

Lynd LR, Guss AM, Himmel ME, Beri D, Herring C, Holwerda EK, Murphy SJ, Olson DG, Paye J, Rydzak T, Shao X (2016) Advances in consolidated bioprocessing using Clostridium thermocellum and Thermoanaerobacter saccharolyticum. In: Wittmann C, Liao JC (eds) Industrial biotechnology: microorganisms. Wiley, Weinheim, pp 365–394

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Mussatto SI (2016) Biomass fractionation technologies for a lignocellulosic feedstock based biorefinery. Elsevier, Amsterdam. https://doi.org/10.1016/b978-0-12-802323-5.01001-x

Nargotra P, Vaid S, Bajaj BK (2016) Cellulase production from Bacillus subtilis SV1 and its application potential for saccharification of ionic liquid pretreated pine needle biomass under one pot consolidated bioprocess. Fermentation 2:19

Naseeruddin S, Desai S, Rao LV (2017) Ethanol production from lignocellulosic substrate Prosopis juliflora. Renew Energy 103:701–707

Nasirpour N, Mousavi SM, Shojaosadati SA (2014) A novel surfactant-assisted ionic liquid pretreatment of sugarcane bagasse for enhanced enzymatic hydrolysis. Bioresour Technol 169:33–37

Nizamudeen S, Bajaj BK (2009) A novel thermo-alkalitolerant endoglucanase production using cost-effective agricultural residues as substrates by a newly isolated Bacillus sp. NZ. Food Technol Biotechnol 47:435–440

Pandey AK, Negi S (2015) Impact of surfactant assisted acid and alkali pretreatment on lignocellulosic structure of pine foliage and optimization of its saccharification parameters using response surface methodology. Bioresour Technol 192:115–125

Pérez-Pimienta JA, Vargas-Tah A, López-Ortega KM, Medina-López YN, Mendoza-Pérez JA, Avila S, Singh S, Simmons BA, Loaces I, Martinez A (2017) Sequential enzymatic saccharification and fermentation of ionic liquid and organosolv pretreated agave bagasse for ethanol production. Bioresour Technol 225:191–198

Premalatha N, Gopal NO, Jose PA, Anandham R, Kwon SW (2015) Optimization of cellulase production by Enhydrobacter sp. ACCA2 and its application in biomass saccharification. Front Microbiol 6:1046

Procentese A, Johnson E, Orr V, Campanile AG, Wood JA, Marzocchella A, Rehmann L (2015) Deep eutectic solvent pretreatment and subsequent saccharification of corncob. Bioresour Technol 192:31–36

Sharma M, Bajaj BK (2014) Cellulase production from Bacillus subtilis MS 54 and its potential for saccharification of biphasic-acid-pretreated rice straw. J Biobased Mater Bioenergy 8:449–456

Singh S, Bajaj BK (2017) Agroindustrial/forestry residues as substrates for production of thermoactive alkaline protease from Bacillus licheniformis K-3 having multifaceted hydrolytic potential. Waste Biomass Valor 8:453–462

Singh S, Sambhyal M, Vaid S, Singh P, Bajaj BK (2015) Two-step sequential optimization for production of ionic liquid stable cellulase from Bacillus subtilis I-2. Biocatal Biotransfor 33:224–233

Trivedi N, Gupta V, Reddy CRK, Jha B (2013) Detection of ionic liquid stable cellulase produced by the marine bacterium Pseudoalteromonas sp. isolated from brown alga Sargassum polycystum C. Agardh. Bioresour Technol 132:313–319

Vaid S, Bajaj BK (2017) Production of ionic liquid tolerant cellulase from Bacillus subtilis G2 using agroindustrial residues with application potential for saccharification of biomass under one pot consolidated bioprocess. Waste Biomass Valor 8:949–964

Vaid S, Nargotra P, Bajaj BK (2017) Consolidated bioprocessing for biofuel-ethanol production from pine needle biomass. Environ Prog Sustain Energy 37:546–552

Vaid S, Bhat N, Nargotra P, Bajaj BK (2018) Combinatorial application of ammonium carbonate and sulphuric acid pretreatment to achieve enhanced sugar yield from pine needle biomass for potential biofuel–ethanol production. Energ Ecol Environ 3:126–135

Vogel KP, Dien BS, Jung HG, Casler MD, Masterson SD, Mitchell RB (2011) Quantifying actual and theoretical ethanol yields for switchgrass strains using NIRS analyses. Bioenergy Res 4:96–110

Xu J, He B, Wu B, Wang B, Wang C, Hu L (2014) An ionic liquid tolerant cellulase derived from chemically polluted microhabitats and its application in in situ saccharification of rice straw. Bioresour Technol 157:166–173

Xu J, Wang X, Liu X, Xia J, Zhang T, Xiong P (2016) Enzymatic in situ saccharification of lignocellulosic biomass in ionic liquids using an ionic liquid-tolerant cellulases. Biomass Bioenergy 93:180–186

Yu C, Simmons BA, Singer SW, Thelen MP, VanderGheynst JS (2016) Ionic liquid-tolerant microorganisms and microbial communities for lignocellulose conversion to bioproducts. Appl Microbial Biotechnol 100:10237–10249

Yuan X, Duan Y, He L, Singh S, Simmons B, Cheng G (2017) Characterization of white poplar and eucalyptus after ionic liquid pretreatment as a function of biomass loading using X-ray diffraction and small angle neutron scattering. Bioresour Technol 232:113–118

Zabed H, Sahu JN, Boyce AN, Faruq G (2016) Fuel ethanol production from lignocellulosic biomass: an overview on feedstocks and technological approaches. Renew Sust Energ Rev 66:751–774

Zhang CW, Xia SQ, Ma PS (2016) Facile pretreatment of lignocellulosic biomass using deep eutectic solvents. Bioresour Technol 219:1–5

Zhao J, Zhang H, Zheng R, Lin Z, Huang H (2011) The enhancement of pretreatment and enzymatic hydrolysis of corn stover by FeSO4 pretreatment. Biochem Eng J 56:158–164

Acknowledgements

Dr. Bijender Kumar (Bajaj) gratefully acknowledges the Institute of Advanced Study, Durham University, UK, for providing COFUND International Senior Research Fellowship for “Research Stay” at Department of Biosciences, Durham University, Durham, UK; Department of Science and Technology (Govt. of India) is acknowledged for financial support (Research Project Ref. SR/SO/BB-66/2007), and Commonwealth Scholarship Commission, UK, for providing Commonwealth Fellowship (INCF-2013-45) for “Research Stay” at Institute of Biological, Environmental and Rural Sciences (IBERS), Aberystwyth University, Aberystwyth, UK. Authors thank the Director, School of Biotechnology, University of Jammu, Jammu, for necessary laboratory facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Vaid, S., Mishra, T. & Bajaj, B.K. Ionic-liquid-mediated pretreatment and enzymatic saccharification of Prosopis sp. biomass in a consolidated bioprocess for potential bioethanol fuel production. Energ. Ecol. Environ. 3, 216–228 (2018). https://doi.org/10.1007/s40974-018-0095-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40974-018-0095-x