Abstract

Considerable number of Indian and international studies has focused on the environmental implications of sewage treatment plants. However, not many studies have taken up a comprehensive assessment of the collection phase of the Indian sewage systems. The aim of the present study is to carry out an integrated life-cycle assessment for the collection phase of an Indian wastewater treatment system. The paper develops in the form of a case study for Begusarai sewerage project and attempts to estimate life-cycle air pollution, greenhouse gas emissions and energy consumption for the collection phase of the project. The work consists of developing a life-cycle inventory for pipelines, manholes, pumps and transportation facilities in a typical collection phase, by making use of existing activity data and emission factors from secondary literature (see graphical abstract). Further, the normalized factors for different environmental damage categories are incorporated within the developed inventory to estimate overall life-cycle damage. Initially, the major components for each damage category are identified. For instance, side walls of manholes are major contributors towards PM2.5 emissions while pumping stations are major energy consumers and CO2 emitters. High resource consumption is identified as the major damage category, compared to atmospheric emissions. As larger quantities of water need to be treated owing to increasing water use in the country, a discussion on water–energy nexus is required to estimate the implications of sewage systems.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

1.1 Context

India is the second most populous country in the world with an estimated population of 1.32 billion. Various models project the population rise to 1.5–2.5 billion by 2050 (Sathaye and Shukla 2013). Recent population dynamics have seen a strong urbanization trend, with urban population registering a growth of 32.2% during the past decade (CPCB 2013). The all-India water requirement for the year 2010 was 813 BCM of which ~85% is used for irrigation purposes. However, due to urban expansion and development of the economy, higher amounts of water are anticipated to be consumed by the industry (increment of five times during 2010–2050) and energy sector (increment of 26 times during the said period; CPCB 2009). Also, the domestic demand is expected to increase by 40%, i.e. from 41 to 55 BCM (KPMG 2010). Domestic wastewater from urban areas is also likely to increase to the tune of 132,253 MLD by 2051, resulting in high sewage generation (Kapshe et al. 2013).

Table 1 lists the wastewater generation projections from 2009 to 2051 by various sources. The increasing magnitude of sewage generation poses problems in its disposal and treatment. Due to the environmental concerns (air, land and water pollution), the sewage generated is subjected to various treatment facilities via sewage treatment plants (STPs). The entire chain of sewage treatment involves substantial energy usage and atmospheric emissions. The collection of wastewater, for instance, requires fuel oil for excavation for manholes, operation of pumps and use of maintenance trucks.

Treatment also involves energy usage for operation of multiple units of treatment plants, emissions from organic degradation and sludge treatment. Sewage disposal is the fifth-largest source of GHG emissions in India (Garg et al. 2006). Globally, they are the seventh-largest contributors to methane (CH4) and nitrous oxide (N2O) emissions (Dong 2012). The wastewater system contributes to direct and indirect energy consumption, which has been a source of important research in the recent years. Several Excel-based models such as Water–Energy Simulator (WESim),Footnote 1 Water–Energy Sustainability Tool (WEST)Footnote 2 and Wastewater–Energy Sustainability Tool (WWEST)2 have surfaced to understand the water–energy dynamics of such systems. Multiple techniques have also been proposed to reuse and recycle the treated wastewater to reduce the environmental, energy and cost implications of such systems. Thus, a quantitative analysis of the energy requirements of processes involved and the subsequent emissions obtained from various facilities is imperative to understand the environmental impacts of wastewater infrastructure and operation.

1.2 Objectives and scopes

This paper aims at carrying out an integrated life-cycle assessment (LCA) for the collection phase of an Indian wastewater system. The paper develops in the form of a case study for Begusarai sewerage project and attempts to estimate life-cycle air pollution, greenhouse gas emissions and energy consumption for the collection phase of the project. The work consists of developing a life-cycle inventory for pipelines, manholes, pumps and transportation facilities in a typical collection phase, by making use of existing activity data and emission factors from secondary literature. This has been followed by carrying out sensitivity analysis for various parameters based on efficiency of pumping stations and variation of materials for manhole constructions and determining the effect of such variations on different social perspectives. Further, the paper discusses the implications of the present work on improving the design of wastewater collection systems.

Collection systems are an integral part of the overall wastewater cycle. However, treatment and disposal phases also contribute significantly to the total energy usage and atmospheric emissions of the wastewater treatment life-cycle. This analysis lies beyond the scope of this paper and can be addressed subsequently. Also, the system boundaries of the collection phases have been restricted to include components that contribute considerably to the resource consumption and environmental footprints. The manufacturing of raw materials and equipment, maintenance and reuse and recycle of waste have not been taken into account in the study definition area. It is hoped that the results obtained in this study can be incorporated into a more extensive study on the entirety of wastewater system including the preceding and consequent activities.

1.3 Organization of the paper

This paper applies LCA to determine the environmental impacts in the wastewater collection phase in Indian sewerage system and discusses its implications. Section 2 provides an overview of India’s water and wastewater scenario. It presents an extensive literature survey of national and international studies on LCA for wastewater systems along with the current situation of the Indian sewerage system. Section 3 delineates the methodology used for carrying out the current study. It describes the system boundaries and the preparation of inventory using secondary literature for various components of the wastewater cycle. In addition, it also discusses the importance of various perspectives and the normalization, weighting and damage calculations used for the LCA technique. The net life-cycle outputs and sensitivity analysis have been detailed in Sect. 4. In this section, the contribution of each component in the system towards net life-cycle outputs in terms of energy consumption (Sect. 4.2), air pollution (Sect. 4.3) and climate change (Sect. 4.4) and finally normalized results (Sect. 4.5) have been discussed. In Sect. 4.6, we also discuss the effect of enhanced efficiency of pumping stations and change of materials in manhole construction to the net life-cycle outputs. Finally, Sect. 4.7 discusses the importance of the present study and the implications of the work towards improvement of wastewater system design and a culmination to water–energy nexus.

2 Brief literature review

2.1 Water and wastewater in India: present and future

India has the largest water footprint in the world, contributing to 13% of the world water usage. However, on a per capita basis, India has a lower footprint than most of the developed and developing countries, with a per capita usage less than 21% of the global average (Hoekstra and Chapagain 2007). The gross per capita availability is projected to decline by ~38% by 2050, as compared to 2001 levels due to rising population, shrinking groundwater resources and increased water contamination (Gupta and Deshpande 2004). Haddeland et al. (2014) have also indicated human impacts on the hydrological cycle which have complex interrelations with the climatic change processes. It is estimated that groundwater depletion due to climate change will be most pronounced in countries such as India and China (Taylor et al. 2013). In view of the above, the Government of India initiated National Water Mission in 2011, with the following goals:

-

Formulating a comprehensive water database in public domain and assessment of the impact of climate change on water resource.

-

Promotion of citizen and state actions for water conservation, augmentation and preservation.

-

Focused attention on vulnerable areas including over-exploited areas.

-

Increasing water use efficiency by 20%, and

-

Promotion of basin-level integrated water resources management.

The utilizable water resources in the country are 1086 BCM, of which around 64% are surface water and the rest are ground water resources (Verma and Phansalkar 2007). Future predictions suggest that India will become water-stressedFootnote 3 by 2020 (FICCI 2011). It has also been projected that the water demand will rise by 22 and 32% by 2025 and 2050, respectively (Amarasinghe et al. 2007). Currently, more than 80% of the water resources are utilized by the agricultural sector, whereas that used by the industries is less than 10%. The latter is bound to increase, since the developed economies have an average industrial water consumption of more than 50%. Ranade and Bhandari (2014a) predict the growth in industrial water demand to about 18% by 2050. As large amount of water will be used by industries and urban settlements, the wastewater generation is also projected to rise. The urban population constitutes nearly 32% of the total population of the country, generating municipal wastewater of about 38,000 MLD. The sewerage network is utilized by 10% of the population in rural areas and by 67% in urban settlements (IPCC 2007). The maximum concentration of municipal sewage generation is found in the states of Maharashtra (~27%), followed by Uttar Pradesh (~11%) and Delhi (~10%) (CPCB 2013). Despite construction of large number of WWTPs in the country, about 74% of the domestic wastewater and 41% of the industrial wastewater remain untreated (Ranade and Bhandari 2014b).

2.2 Review of major international and Indian studies on the collection phase

LCA has evolved as a standard methodology to analyse the environmental burdens associated with any product, processes and/or services. The technique successfully quantifies the impacts of all stages of product, service and processes by adopting a cradle-to-grave approach. LCA-based studies on wastewater treatment can be cited dated back to 1990s. These have evaluated environmental and societal impacts of wastewater treatment (WWT) but only taking treatment and disposal phases into consideration (Emmerson et al. 1995; Roeleveld et al. 1997). Wastewater treatment plants (WWTPs), an end-of-pipe technology, remain a common (sometimes the sole) element of the system definition that is evaluated for their sustainability and performance (Yoshida et al. 2014; Meneses et al. 2015; Rodriguez-Garcia et al. 2014). The end-of-life stages such as dismantling of the infrastructure and recycling are usually not included in the system boundary in most of the studies (Risch et al. 2015). In a review carried out by Corominas et al. (2013), only 18 studies out of 45 reviewed took the collection phase as a part of the system boundary, while carrying out LCA for the entire wastewater system. Risch et al. (2015) confirm that sewer system (collection phase) contributes significantly (~64%) to the overall impacts of urban wastewater systems. The work reviews nearly twenty studies that have included sewer systems in the system boundaries for conducting LCA on wastewater systems. Table 2 complements the review by Risch et al. (2015) by listing the variable approaches and inventory taken up for analysing sewer systems. Most of the literature for Indian context has focused mainly on the treatment phase, and little or no mention of the collection phase has been made. Nevertheless, this phase also contributes to a significant amount of energy usage and emission sources as stated in earlier references. Therefore, a life-cycle analysis of collection phase of typical Indian sewerage system is necessary to get a complete view of the environmental impacts of the wastewater cycle.

2.3 Indian sewerage system: the current scenario

Sewerage and water sanitation systems have gradually developed in India. Inadequate sanitation and sewage facilities in India were reported to cause economic losses of the order of US$ 53.8 billion for the year 2006 (WSP-SA 2010). The current fleet of India STPs is composed of 816 units with a total treatment capacity of approximately 23,300 MLD (CPCB 2015). Of the total installed capacity, about 64% of the units are operational and the rest are either in dormant condition or are under construction. This has built up a capacity gap of ~27,000 MLD between the generated and treated sewage. Therefore, emphasis is being put on setting up new STPs and planning of sewerage networks, under the 11th 5-year plan initiated by the Government of India. This targeted at 100% coverage of urban sewerage system and rural sanitation by 2012.

Under the National Urban Sanitation Policy scheme (NUSP 2008), decentralized wastewater management system (DWMS) with new pipe materials for sewer construction, treatment and non-conventional sewers has been proposed. The wastewater generated is generally assumed to be 80% of the total water supplied to a particular area (MoEFCC 2007). For the newly commissioned plants, a design period of thirty years is adopted for sewer system and all its components and 15 years for the pumping machinery and STPs (MoUD 2015). The construction material used for all the units is preferably reinforced concrete following the standards IS: 456 and IS: 12330. Table 3 lists the norms prescribed by Central Public Health and Environmental Engineering Organization (CPHEEO 2015) to be followed while designing a typical sewer network in India.

Based on these standards, several sewerage projects have been proposed and are under construction across the country. Table 4 summarizes few such projects with their specifications.

It can be noted that the sewage generated per kilometre of the sewerage network for Mumbai is nearly four times as compared to Delhi and Bangalore which have similar magnitudes of sewage generation. This can be attributed to the high population density of 19,652/km2 for Mumbai as opposed to 11,320 and 4381/km2 in case of Delhi and Bangalore, respectively (Census 2011). The layout for sewerage network also depends on the availability of the land and the topography of the region. This is evident from the fact that there is an intensive sewerage network without the presence of any pumping stations in Bangalore as compared to Mumbai, where the sewage is transported by an intensive network of pumping stations. The land requirements for various treatment technologies vary from 0.002 to 0.01 km2/MLD. For the optimization of land area, the multi-tier STPs with common walls for sewage holding structures have been proposed by the Ministry of Urban Development (MoUD 2015). With the problem of increasing water scarcity and unavailability of adequate supply of water for irrigation purposes, the ministry has advised the reused of treated sewage for farm forestry, horticulture and in industries (non-human contact cooling towers).

3 Methodology

3.1 System definition

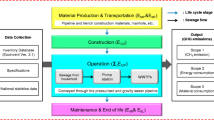

The wastewater life-cycle constitutes of three distinct phases, i.e. collection phase, treatment phase and disposal phase (Fig. 1). The collection phase includes the unit processes involved for collecting the wastewater from different point sources and transporting it to the treatment plants, and forms the area of interest for this study.

The collection phase comprises of three basic components viz. the sewer network (consisting of pipeline and manholes), pumping stations and transportation facilities. The sewer network comprises of a network of pipelines with manholes (inspection chambers) at regular intervals. Pumping stations or lift stations are located at intermediate locations to deliver the sewage to higher elevations for further transport by pipelines via gravity flow. Transportation [using Heavy Earth Moving and Mining (HEMM), trucks and cars] occurs along all the processes of the collection phase. It is used for transporting sewage as well as for commuting purposes by the officials for operation and maintenance of different units. The system life-cycle is depicted in Fig. 2.

3.2 Inventory preparation

For the present study, we select a typical Indian sewerage project, viz. Begusarai sewerage project under the National Ganga River Basin Authority of India (NGRBA) in Bihar. The project was proposed by the Bihar Urban Development Agency under the Urban Development and Housing Department, Government of Bihar, in the year 2010. The sewerage project aims at serving a population of 117,516 and is spread over an area of 7.51 km2. The inventory for each component is discussed in details in the following subsections.

3.2.1 Pipeline

The pipelines used in the sewer network are of diameter 150–1100 mm with the lengths depicted in Fig. 3. This profile helps us to calculate the amount of material used.

The proposed project uses concrete pipes due to their durability, low corrosion rate and widespread availability at cheaper costs. According to this, thickness for various diameters is assumed as shown in Table 5 (IS: 458). The parameters for pipeline construction are shown in Table 6.

The average density for light graded concrete ranges from 1800 to 2200 kg/m3 and that for heavy graded concrete is 2200–2500 kg/m3 (Panasyuk et al. 2014). By inspection of several sewerage projects around the country, we assume heavy graded concrete. Ma et al. (2016) have carried out an inventory analysis to evaluate the GHG emissions from concrete pavement construction using similar concrete characteristics. Accordingly, we assume the energy required for 1 m3 of concrete produced to be 2 kWh.

3.2.2 Manholes

The construction of a manhole involves three basic steps, i.e. excavation of soil, construction of beds and side walls and construction of cover. Manholes should be constructed at every change in alignment, gradient or diameter, at the head of all sewers and branches and at every junction of two or more sewers with a maximum distance of 30 m between consecutive manholes (IS: 4111). Lewinski (2015) have indicated that circular manholes are preferable with regard to stress. The depth of the manhole is chosen as 4.5 m. As per the manhole depth, the prescribed nominal diameter of the manholes is 1.5 m (CPHEEO 2015). Corresponding to the manhole depth, the thickness of the side walls for circular manhole is two brick lengths. The length of brick is 190 mm as per IS: 1077 standards along with 10 mm of mortar. The standard also specifies the bed thickness to be 300 mm for manhole depths >2.30 m. As regards to the manhole covers, concrete structures are heavy, and hence, cast iron has been assumed as the material for construction of covers. Based on strength considerations, we assume medium-duty MD-10 grey cast iron (FG 150) (IS: 1726). The opening of the cover is taken to be 500 mm, which is the maximum for circular manholes of the grade.

The specific energy for concrete production is taken from Table 5. The specific power consumption for cast-iron foundries in India was found to be 620 kWh/t (Arasu and Rogers 2009). For excavation purpose, we assume medium-sized excavators having fuel consumption of 0.1941 l/m3 (Trani et al. 2016). The parameters for construction of manholes used for the above project are listed in Table 7.

3.2.3 Transportation

For transportation purposes, two types of vehicles are proposed: Heavy-duty truck (HDT) and light-duty vehicle (LDV). Stokes and Horvath (2010) have assumed truck usage of 10 km/year and LDV usage of 1.5 km/year for each metre of pipeline. The fuel characteristics are assumed from Sadavarte and Venkataraman (2014). The details for transportation are shown in Table 8.

3.2.4 Pumping station

The sewerage project uses two pumping stations using diesel pumps. The fuel characteristics are same as those assumed in Table 9. Considering pumping station I, we find that Kirloskar SVI NW4+ is a suitable pump for the desired needs. This pump has a specific fuel consumption of 185 g/hp-h. For the second station, Kirloskar KS8B 3503 pump is selected with the specific fuel consumption assumed to be proportional to the capacity of the pump.

Table 10 lists the emission characteristics of each material/component used in the study. For excavator, the emission characteristic is assumed to be similar to that of the truck and for pumps it is assumed to be that of the diesel generators. In India, about 50% of cement production is done using dry kiln technology (Taylor et al. 2006). Therefore, we have also assumed emission characteristics of dry kiln type technology.

3.3 Normalization and weighting based on cultural theory

The perception of environmental impacts varies from individual to individual. The Ecoindicator model (EI99) categorizes individuals into three archetypes of perspectives, i.e. Egalitarian, Hierarchist and Individualist, based on fundamental differences in attitude towards resources and environmental impacts (Thompson et al. 1990; Hofstetter 1998). The category chosen determines the normalization results and the weightage of different damage categories to the LCA. Table 11 includes some of the main differences between the three categories. The impact of cultural theory on the LCA of the collection phase has been discussed in detail in Sects. 4.5 and 4.6.1.

The normalization and weighting factors, for the three perspectives, i.e. Egalitarian, Hierarchist and Individualist, for Indian scenario were obtained from Singh et al. (2016b) and EI99 methodology (Table 12).

The final damage factors are used to compute the EIC. These are listed in Table 13.

3.4 Calculation of damage

Final environmental impact of collection (EIC) is obtained using the following equation (Singh et al. 2016b),

where b f represents the normalized factor for energy usage, b e stands for the normalized factor for each pollutant (both from Table 13) while m f denotes the energy consumption (in kgoe) of the plant and m e stands for emission of a particular pollutant in the plant inventory (from Table 12).

4 Results and discussion

4.1 Net life-cycle outputs

Table 14 shows the material requirements for the collection phase of plant studied.

The fuel consumption for HDTs is approximately 17 times than LDV in transportation phase. This is due to the higher mileage and lower vehicle usage for LDVs. For pumping stations, the fuel consumption for PS II is 20 times greater than PS I, because of higher flow rate and power capacity for pumps in PS II. The total fuel consumed annually for operation of pumping stations is three times higher than the transportation unit. The concrete required for manhole construction is 13 times greater than that required for construction of pipelines. This is so as to maintain the integrity of structures for manholes, to protect contamination of groundwater and to prevent entry of external materials into the sewage system.

The results of Table 14 coupled with the emission factors and specific energy requirements lead to total life-cycle outputs for the entire design period (30 years) of the sewerage project (see Fig. 4; Table 15).

4.2 Energy consumption

Pumping stations and transportation units collectively contribute to more than 99% of the total energy consumption for the entire sewerage project. This is attributed to the constant requirement of diesel combustion by these units. This is in line with the finding of (Risch et al. 2015; Barjoveanu et al. 2014) who have indicated a dominance of the operation stage of the collection system to energy consumption. Diesel pumps used in pumping stations result in approximately 76% of the total life-cycle energy usage. The brake specific fuel consumption for 6 hp pump is around 185 g/hp-h. A reduction in this requirement will be helpful since India possesses low petroleum reserves. Electric pumps (having power capacity of ~3 hp) can be used in pumping stations as a replacement to diesel pumps for sewerage systems where the net wastewater generation is low. Renewable sources of energy such as renewable electricity can also be explored for reducing the dependence on carbon-based fuels (Pensini et al. 2014). Hybrid energy systems (HSPs) have become more prevalent to facilitate the efficient utilization of renewable resources (Qi et al. 2014). The transportation units consume a total of 222 kl of diesel per year resulting in about 23% of energy consumption.

4.3 Air pollution

The contribution to particulate matter pollution is dominated by the manhole unit (~73%). The construction of side walls leads to 81% of these emissions within the manhole. This is due to the larger concrete requirement of walls, which are required for their integrity. Although transportation and pumping stations are the most energy-intensive units, their relative contribution to particulate matter emissions is considerably lower. This can be attributed to the use of petroleum-based fuels (diesel) for operation of these units, which have a lower PM2.5 emission factor than coal-based industries.

Due to higher rate of fuel combustion, pumping stations produce maximum amount of SO2 (~76.5%) and NO x (83.1%) for the entire life cycle. These gases are hazardous for human health. India is the second-highest emitter of SO2 after China (Lu et al. 2013), and numerous initiatives have focused towards lower SO2 emissions. Therefore, low NO x and SO2 solutions such as use of selective catalytic reduction and low-sulphur content fuels can significantly help in reducing these emissions. The sewer network (construction phase) has impacts only on particulate matter and N2O emissions. Transportation units contribute to over 80% of NMVOC emissions. This may be due to poor efficiency of heavy-duty vehicles. Similar trends are exhibited by these units for CO emissions, due to incomplete fuel combustion.

4.4 Climate change

The cumulative GHG emissions are calculated to be 78,166 t-CO2 eq/year. The operational sewage treatment capacity for India is approximately 22,700 MLD (CPCB 2015). This results in annual production of about 71 Tg-CO2 eq/year of GHG emissions from collection phase of sewerage systems. There may be considerable uncertainty in this amount, but the associated avenues are well known. A better understanding of the usage of maintenance trucks in this phase can lead to substantial uncertainty reduction. General understanding on our part indicates that the actual value would be lower than the aforementioned one. Further, these emissions are already a part of India’s national GHG inventory from the fuel combustion sector (Sharma et al. 2011).

The global warming potential GWP of CH4 has increased from 25 to 28 (IPCC 2007). This is bound to increase if the methane removal from atmosphere decreases. This also serves as a precursor for increasing environmental impact of ozone depletion category. Although GWP of N2O has decreased significantly from 298 to 265, the effect is less pronounced due to lower amount of N2O emissions from the collection phase units. Operation phase contributes to over 80% of the CH4 emissions and 97% of CO2 emissions. This is mainly due to flaring and venting during petroleum extraction.

4.5 Normalized results

The environmental impacts due to energy use and atmospheric emissions are made comparable by the method of normalization and weighting. The effect of these damage categories is studied for various perspectives that represent the various types of people in a society. The categorywise contribution to various damage categories for various perspectives is shown in Fig. 5.

Of the three perspectives, Individualists do not consider resource depletion as a problem due to long-term perspective, and therefore, the contribution of resource category (Re) is zero and respiratory inorganic (RI) category has the maximum impact, contributing nearly 80% to the EIC. , while for the remaining two perspectives, resource category has maximum impact on EIC. The resource category contributes to over 50 and 62% in Egalitarian and Hierarchist perspective, respectively. The Egalitarian perspective pushes for alternative energy sources, whereas Hierarchists do not prefer substitution of resources. Water and wastewater systems are energy-intensive but emit relatively lower amount of atmospheric emissions. The higher need felt by these perspectives for resources category has put emphasis on developing variety of water–energy models such as WESim and WWEST models. An important debate surrounding this area is that of the water–energy nexus, i.e. an increase in the amount of water treatment requirements will lead to less water scarcity but higher energy scarcity, and vice versa. Therefore, improvement in technologies should focus at reduction in energy requirement of water collection per unit amount of water treated.

The Re category is followed by RI category with 43.7 and 33.65% of the overall impact in Egalitarian and Hierarchist perspectives, respectively. The impact of respiratory organic (RO) category is almost negligible (<1%) in all the three perspectives. Acidification and eutrophication (AE) category does not significantly affect the EIC, with <3% impact for all the perspectives. Damage by climate change (CC) category can be noticeably seen in Individualist perspective (~17%) but not for Egalitarians (3.35%) and Hierarchists (2.6%).

4.6 Sensitivity analysis

4.6.1 Sensitivity analysis for impact categories

Figures 6, 7 and 8 show the percentage deviation in EIC due to 10% increment and decrement in particular component (b) for various perspectives. This is obtained by varying a particular component and keeping all other parameters constant and then determining the change in EIC.

where EICnew denotes the total EIC obtained after 10% change in a particular damage category and EICbase denotes the total EIC without any changes.

For Egalitarians and Hierarchists, the variation of EIC with change in damage categories is almost similar. The maximum impact is due to energy (resources category ~5 and 6%, respectively) and minimum is due to CO2 (climate change category <0.001% for both). But for Individualists, maximum variation is due to PM2.5 (respiratory inorganic ~6%) and least is due to energy (resource category 0%) and CO2 (climate change category <0.01%). For Individualists, energy and associated resource depletion is not a major concern, because of their short-time perspective. Therefore, the impact of resource category is taken to be zero, and a business-as-usual attitude is advocated by them. Similar is the case for climate change category, which has long-term consequences, and in case of Individualists, these parameters do not contribute much to the variation of EIC. This is not the case for the other two perspectives, where long-term effects are more focused on. Therefore, energy and climate change affecting parameters have greater impact on EIC for Egalitarians and Hierarchists. Effect of CH4 is more prominent in Egalitarian (2.6%) and Hierarchist (1.9%) perspectives, whereas it contributes to merely 0.5% for Individualist perspective. The respiratory organic category does not contribute significantly to EIC. The variation in EIC due to acidification and eutrophication category varies nearly 0.6% for Egalitarians and Hierarchists and about 2% for Individualists for 10% change in SO2 and NO x . Apart from studying the effect of various damage categories to EIC for various perspectives, it is prudent to analyse the impact of various components of collection phase studied on the total EIC (Table 16).

The contribution to EIC is maximum by pumping stations in all the three perspectives, contributing to 68.5% for Egalitarians, ~70% for Hierarchists and 40.3% for Individualists. This is followed by usage of HDTs in Egalitarian (17%) and Hierarchist (18.3%) perspective, whereas construction of side walls (37.5%) for Individualist perspective. The excavator contributes the least to EIC in all the three perspectives (<0.5%). The EIC is dominated by operation and maintenance phases for Egalitarians and Hierarchists, whereas both construction and operation phases contribute evenly to EIC in Individualist perspective. Manhole unit represents nearly 46% of the total EIC in case of Individualists, whereas about 10% of EIC for the other two perspectives. The sensitivity analysis of individual units is discussed in the subsequent sections.

4.6.2 Improved efficiency of pumping stations

Pumping stations are the most energy-intensive unit and contribute significantly to atmospheric emissions. For the pumps taken into consideration, the most important parameter affecting the fuel usage is the brake specific fuel consumption (BSFC). Assuming a reduction of 10% in BSFC of the pumps used, we analyse the variation of EIC. With the decrease in BSFC, diesel consumed per MLD of sewage pumped reduces, and thus, the energy requirements for operation of pumps will decrease (Fig. 9). The EIC reduces to approximately 93% for Egalitarian and Hierarchist perspective, and up to 96% for Individualists.

4.6.3 Variation of manhole materials

Clay bricks are one of the common materials used for infrastructure construction in India (Kumbhar et al. 2014). For the current study, nearly 272.5 million bricks are required for construction of side walls and bed. Table 17 lists the life-cycle emissions due to use of clay bricks for manhole construction. Also a comparison has been presented with concrete as the construction material, which is used in the current study.

The fuel used for brick production is essentially coal (nearly 20 tonnes/million bricks). With a calorific value of 0.022 GJ/kg (Guttikunda et al. 2013), total energy consumption amounts to 11,926.4 GJ. This is nearly 400 times the energy consumed when the material used in concrete.

4.7 Implications for sustainable design and water–energy nexus

The net life-cycle outputs indicate that manhole unit is the major contributor towards atmospheric emissions. This is mainly from the concrete used in construction of side walls. Use of concrete as raw material for manholes is environmentally friendlier than the commonly used clay bricks (Sect. 4.6.3). However, for further reduction in emissions, low-carbon concrete can be preferred for manhole construction. This can be achieved by using different cement mix for concrete manufacturing which can result in about 4.6–24% reduction in CO2 emissions (Kim et al. 2013; Limbachiya et al. 2014). Concrete production also involves non-value adding activities which contribute to an increase in the carbon emissions. Wu et al. (2013) list out these activities and suggest the use of green building material and adoption of better guidance practices to achieve low-carbon installations in concrete manufacturing units. For more radical reductions in CO2 emissions from concrete production, CO2 capture processes may also be thought of in the cement sector (Li et al. 2013).

Pumping stations and transportation unit have the largest share in the total energy consumption and GHG emissions. We have assumed the use of diesel as the primary fuel for operation of HDT and LDV and also excavators. Under low-carbon scenario with 2° policy, electric vehicles will play an important role in the Indian transport sector and will contribute appreciably to mitigation of emissions (Shukla et al. 2014). Increasing the fuel efficiency and fuel quality standards in these units will also add to reduction in energy usage and emissions. Use of renewable energy for power production is an effective way of decreasing the environmental impacts from pumping stations. Pumping stations running on photo-voltaic (PV) motor pumps have been incorporated in various irrigation and water supply facilities. The normalized cost of energy and life-cycle costs for PV pumping stations is 61 and 30% lesser than diesel pumping stations (Chandel et al. 2015; Gherbi et al. 2017). These can be thus be used in wastewater systems for sustainable design of collection phase units.

Increasing population, stricter water quality norms and rising energy prices and concerns regarding climate change pose risks of increased energy usage and costs for wastewater systems. Energy consumed at various stages of the collection phase of sewerage system is closely associated with water resources. A considerable amount of water is used in concrete production, operation of pumping stations and extraction of fuels for transportation segment. In the face of growing need for wastewater treatment for cleaner water resources, utilization of water resources at various stages of wastewater cycle must be carefully planned to avoid potential water crisis. Furthermore, the stringent water quality norms for disposal of wastewater to water bodies have led to adopting water-intensive treatment techniques. This necessitates the evaluation of water–energy nexus in wastewater system. The reuse phase such as production of energy from secondary/tertiary treatment by-products such as sludge and methane must be given emphasis so as to recover a part of the expended energy. This can help to reduce the net energy requirements, thereby reducing the water requirement.

5 Conclusion

This paper presents a case study of a typical Indian sewerage network to carry out life-cycle assessment of wastewater supply systems. The total energy requirements and atmospheric emissions from the major units of collection phase have been calculated based on real-time data, and its effect on different societal perspectives has been studied. This is the first Indian study to carry out a detailed analysis of the collection phase of wastewater life cycle and quantify the environmental impact of various damage categories using EIC, to the best of our knowledge.

The net life-cycle outputs are dominated by the operation and maintenance units of the collection phases. In all the three perspectives, energy consumption has maximum impact on the overall EIC, and major source of impact is the intermediate pumping of wastewater. Sensitivity analysis carried on in pumping station units shows that increasing the efficiency of pumps will curb their environmental impacts considerably. Also, local topography and proper networking of pipelines are important criteria to be taken into account for designing the overall sewerage system.

In order to estimate the overall environmental effects of the sewerage system, treatment and disposal phases should also be taken into account. Various studies have indicated that the treatment units contribute significantly to the energy usage as well as methane emissions. Apart from the construction of various units, renovation and modernization at regular intervals also considerably affect the environmental assessment of the sewerage system (Morera et al. 2016). Therefore, these factors can be coupled together to provide a more improved evaluation of the environmental impacts of Indian sewerage system.

Notes

Developed by the Pacific Institute and Dr. Bob Wilkinson, with support from the WateReuse Research Foundation, the California Energy Commission and the Canadian Mortgage and Housing Corporation.

Developed by Dr. Jennifer Stokes and Prof. Arpad Horvath, University of California at Berkeley Department of Civil and Environmental Engineering, with funding from the California Energy Commission Public-Interest Energy Research (PIER) programme.

Water availability of <1700 m3/person/year is considered as a ‘water-stressed’ country and that of <1000 m3/person/year is considered as a ‘water-scarce’ country (Gupta and Deshpande 2004).

References

Amarasinghe U, Shah T, Turral H, Anand BK (2007) India’s water future to 2025–2050: business-as-usual scenario and deviations. IWMI, Battaramulla

Amores MJ, Meneses M, Pasqualino J, Antón A, Castells F (2013) Environmental assessment of urban water cycle on Mediterranean conditions by LCA approach. J Clean Prod 43:84–92

Arasu M, Rogers JL (2009) Energy consumption studies in cast iron foundries. In: Transactions of 57th Indian Foundry Congress, pp 331–336

Barjoveanu G, Comandaru IM, Rodriguez-Garcia G, Hospido A, Teodosiu C (2014) Evaluation of water services system through LCA. A case study for Iasi City, Romania. Int J Life Cycle Assess 19:449–462

BWSSB (2016) Bangalore Water Supply and Sewerage Board. https://bwssb.gov.in/content/about-bwssb-2. Accessed on 26 Dec 2016

CDPC (2004) City development plan Chandigarh, Ministry of Urban Development

Census (2011). http://censusindia.gov.in/. Accessed on 26 Dec 2016

Chandel SS, Naik MN, Chandel R (2015) Review of solar photovoltaic water pumping system technology for irrigation and community drinking water supplies. Renew Sust Energy Rev 49:1084–1099

Corominas L, Foley J, Guest JS, Hospido A, Larsen HF, Morera S, Shaw A (2013) Life cycle assessment applied to wastewater treatment: state of the art. Water Res 47:5480–5492

CPCB (2009) Status of water supply, wastewater generation and treatment in class-I cities and class-II towns of India. Central Pollution Control Board, New Delhi

CPCB (2013) Performance evaluation of sewage treatment plants under NRCD. Central Pollution Control Board, New Delhi

CPCB (2015) Inventorization of sewage treatment plants. Central Pollution Control Board, New Delhi

CPHEEO (2015) Manual on sewerage and sewage treatment systems part a engineering. Ministry of Urban Development, New Delhi

De Sousa MR, Montalto FA, Spatari S (2012) Using life cycle assessment to evaluate green and grey combined sewer overflow control strategies. J Ind Ecol 16:901–913

Dong B (2012) Life-cycle assessment of wastewater treatment plants. Dissertation, Massachusetts Institute of Technology

DJB (2016) Delhi Jal Board. http://www.delhi.gov.in/wps/wcm/connect/DOIT_DJB/djb/home. Accessed on 26 Dec 2016

Emmerson RHC, Morse GK, Lester JN, Edge DR (1995) The life-cycle analysis of small-scale sewage-treatment processes. Water Environ J 9:317–325

FICCI (2011) Water use in Indian industry survey. Federation of Indian Chambers of Commerce and Industry, New Delhi

Flores Rosell L (2015) Life cycle assessment of a constructed wetland system for wastewater treatment and reuse in Nagpur, India. BS thesis, Universitat Politècnica de Catalunya

Garg A, Shukla PA, Kapshe M (2006) The sectoral trends of multigas emissions inventory of India. Atmos Environ 40:4608–4620

Gherbi AD, Arab AH, Salhi H (2017) Improvement and validation of PV motor-pump model for PV pumping system performance analysis. Sol Energy 144:310–320

Goel R, Guttikunda SK (2015) Evolution of on-road vehicle exhaust emissions in Delhi. Atmos Environ 105:78–90

Gupta SK, Deshpande RD (2004) Water for India in 2050: first-order assessment of available options. Curr Sci 86:1216–1224

Guttikunda SK, Begum BA, Wadud Z (2013) Particulate pollution from brick kiln clusters in the Greater Dhaka region, Bangladesh. Air Qual Atmos Health 6:357–365

Haddeland I, Heinke J et al (2014) Global water resources affected by human interventions and climate change. Proc Natl Acad Sci 111:3251–3256

Hoekstra AY, Chapagain AK (2007) Water footprints of nations: water use by people as a function of their consumption pattern. Water Res Manag 21:35–48

Hofstetter P (1998) Perspectives in life cycle impact assessment: a structured approach to combine models of the technosphere, ecosphere and valuesphere. Kluwer Academic Publishers, Norwell

IPCC (2007) Climate change 2007: mitigation. Contribution of working group III to the fourth assessment report of the intergovernmental panel on climate change. Cambridge University Press, Cambridge

Kalbar PP, Karmakar S, Asolekar SR (2012) Selection of an appropriate wastewater treatment technology: a scenario-based multiple-attribute decision-making approach. J Environ Manag 113:158–169

Kalbar PP, Karmakar S, Asolekar SR (2016) Life cycle-based decision support tool for selection of wastewater treatment alternatives. J Clean Prod 117:64–72

Kamyotra JS, Bhardwaj RM (2011) Municipal wastewater management in India. India Infrastructure Report. IDFC and Oxford University Press, pp 299–311

Kapshe M, Kuriakose PN, Srivastava G, Surjan A (2013) Analysing the co-benefits: case of municipal sewage management at Surat, India. J Clean Prod 58:51–60

Kim D, Yi S, Lee W (2012) Life cycle assessment of sewer system: comparison of pipe materials. In: Advances in civil, environmental, and materials research, pp 2963–2965

Kim T, Tae S, Roh S (2013) Assessment of the CO2 emission and cost reduction performance of a low-carbon-emission concrete mix design using an optimal mix design system. Renew Sust Energy Rev 25:729–741

KMC (2016) Kolkata Municipal Corporation. http://www.ndwml.com/. Accessed 26 Dec 2016

KPMG (2010) Water sector in India: overview and focus areas for the future, PanIIT Conclave 2010

Kumbhar S, Kulkarni N, Rao AB, Rao B (2014) Environmental life cycle assessment of traditional bricks in western Maharashtra, India. Energy Proc 54:260–269

Lewiński J (2015) The effect of manhole shape and wall thickness on stress state in a cylindrical pressure vessel. J Theor Appl Mech 53:59–68

Li J, Tharakan P, Macdonald D, Liang X (2013) Technological, economic and financial prospects of carbon dioxide capture in the cement industry. Energy Policy 61:1377–1387

Limbachiya M, Bostanci SC, Kew H (2014) Suitability of BS EN 197-1 CEM II and CEM V cement for production of low carbon concrete. Constr Build Mater 71:397–405

LMC (2015) Revised city development plan of Lucknow City-executive summary. Lucknow Municipal Corporation

Lu Z, Streets DG, de Foy B, Krotkov NA (2013) Ozone Monitoring Instrument observations of interannual increases in SO2 emissions from Indian coal-fired power plants during 2005–2012. Environ Sci Technol 47:13993–14000

Ma F, Sha A, Yang P, Huang Y (2016) The greenhouse gas emission from portland cement concrete pavement construction in China. Int J Environ Res Public Health 13:632. doi:10.3390/ijerph13070632

MCDP (2004) Mumbai City Development Plan 2005–2025

Meneses M, Concepción H, Vrecko D, Vilanova R (2015) Life cycle assessment as an environmental evaluation tool for control strategies in wastewater treatment plants. J Clean Prod 107:653–661

Miller L (2011) Sustainability assessment of wastewater treatment plants with water reuse for urban agriculture: a case study in Hyderabad, India. Dissertation, University of Colorado at Denver

MoEFCC (2007) Manual on norms and standards for environment clearance of large construction projects. Ministry of Environment, Forest and Climate Change, New Delhi

Morera S, Remy C, Comas J, Corominas L (2016) Life cycle assessment of construction and renovation of sewer systems using a detailed inventory tool. Int J Life Cycle Assess 121:1121–1133

MoUD (2015) Handbook of service level benchmarking. Ministry of Urban Development, New Delhi

NGRBA (2010a) Sewerage Project, Begusarai, Detailed project report. Bihar Urban Development Agency, Government of Bihar

NGRBA (2010b) Sewerage Project, Begusarai: Detailed project report. National Ganga River Basin Authority, Bihar Urban Development Agency

NMC (2011) Annual preliminary report. Nashik Municipal Corporation

NUSP (2008) Septage management in urban India. National Urban Sanitation Policy, New Delhi

Panasyuk VV, Marukha VI, Sylovanyuk VP (2014) Injection technologies for the repair of damaged concrete structures. Springer, Dordrecht

Pensini A, Rasmussen CN, Kempton W (2014) Economic analysis of using excess renewable electricity to displace heating fuels. Appl Energy 131:530–543

Petit-Boix A, Sanjuan-Delmás D et al (2014) Environmental assessment of sewer construction in small to medium sized cities using life cycle assessment. Water Res Manag 28:979–997

Qi Z, Gao Q, Liu Y, Yan YY, Spitler JD (2014) Status and development of hybrid energy systems from hybrid ground source heat pump in China and other countries. Renew Sustain Energy Rev 29:37–51

Ramachandra TV (2009) Emissions from India’s transport sector: statewise synthesis. Atmos Environ 43:5510–5517

Ranade VV, Bhandari VM (2014a) Industrial wastewater treatment, recycling and reuse: an overview. Industrial Wastewater Treatment, Recycling and Reuse. Butterworth-Heinemann, pp 1–80

Ranade VV, Bhandari VM (2014b) Industrial wastewater treatment, recycling and reuse-Present, Past and Future. Industrial Wastewater Treatment, Recycling and Reuse. Butterworth-Heinemann, pp 521–535

Risch E, Gutierrez O, Roux P, Boutin C, Corominas L (2015) Life cycle assessment of urban wastewater systems: quantifying the relative contribution of sewer systems. Water Res 77:35–48

Rodriguez-Garcia G, Frison N et al (2014) Life cycle assessment of nutrient removal technologies for the treatment of anaerobic digestion supernatant and its integration in a wastewater treatment plant. Sci Total Environ 490:871–879

Roeleveld PJ, Klapwijk A, Eggels PG, Rulkens WH, Van Starkenburg W (1997) Sustainability of municipal wastewater treatment. Water Sci Technol 35:221–228

Roux P, Boutin C, Risch E, Heduit A (2010) Life cycle environmental assessment (LCA) of sanitation systems including sewerage: case of vertical flow constructed wetlands versus activated sludge. In: 12th IWA international conference on wetland systems for water pollution control, vol 2, pp 879–889

Sadavarte P, Venkataraman C (2014) Trends in multi-pollutant emissions from a technology-linked inventory for India: I. Industry and transport sectors. Atmos Environ 99:353–364

Sathaye J, Shukla PR (2013) Methods and models for costing carbon mitigation. Annu Rev Environ Res 38:137–168

Sharma SK, Choudhury A, Sarkar P, Biswas S, Singh A, Dadhich PK, Singh AK, Majumdar S, Bhatia A, Mohini M, Kumar R (2011) Greenhouse gas inventory estimates for India. Curr Sci 101:405–415

Shi J, Li Z, Cao Z, Wang H, Lu Y, Wang Y (2015) Environmental impacts research for scroll compressor based on life cycle assessment. In: International conference on materials, pp 9–12

Shukla PR, Dhar S, Bhaskar K (2014) Electric vehicle scenarios for India. Development and Mitigation Forum, Cape Town

Singh P, Kansal A, Carliell-Marquet C (2016a) Energy and carbon footprints of sewage treatment methods. J Environ Manag 165:22–30

Singh U, Sharma N, Mahapatra SS (2016b) Environmental life cycle assessment of Indian coal-fired power plants. Int J Coal Sci Technol 2:212–225. doi:10.1007/s40789-016-0136-z

Slagstad H, Brattebø H (2014) Life cycle assessment of the water and wastewater system in Trondheim, Norway—a case study: case study. Urban Water J 11:323–334

Stokes JR, Horvath A (2010) Supply-chain environmental effects of wastewater utilities. Environ Res Lett 5:23–37

Taylor M, Tam C, Gielen D (2006) Energy efficiency and CO2 emissions from the global cement industry. In: IEA-WBSCD workshop, Paris, vol 50, pp 61–67

Taylor RG, Scanlon B et al (2013) Ground water and climate change. Nat Clim Chang 3:322–329

Thompson M, Ellis R, Wildavsky A (1990) Cultural theory. Westview Print, Boulder, USA

Trani ML, Bossi B, Gangolells M, Casals M (2016) Predicting fuel energy consumption during earthworks. J Clean Prod 112:3798–3809

UDD (2010) Environmental and social assessment with management plan-Sahibganj. Urban Development Department Jharkhand

Vahidi E, Jin E, Das M, Singh M, Zhao F (2015) Comparative life cycle analysis of materials in wastewater piping systems. Proc Eng 118:1177–1188

Venkatesh G, Brattebø H (2011) Energy consumption, costs and environmental impacts for urban water cycle services: case study of Oslo (Norway). Energy 36:792–800

Venkatesh G, Hammervold J, Brattebø H (2009) Combined MFA-LCA for analysis of wastewater pipeline networks. J Ind Ecol 13:532–550

Verma S, Phansalkar SJ (2007) India’s water future 2050 potential deviations from ‘business-as-usual’. Int J Rural Manag 3:149–179

WSP (2010) The economic impacts of inadequate sanitation in India. Water and Sanitation Programme, New Delhi

Wu P, Low SP, Jin X (2013) Identification of non-value adding (NVA) activities in precast concrete installation sites to achieve low-carbon installation. Resour Conserv Recycl 81:60–70

Yoshida H, Clavreul J, Scheutz C, Christensen TH (2014) Influence of data collection schemes on the life cycle assessment of a municipal wastewater treatment plant. Water Res 56:292–303

Acknowledgements

The first author would like Prof. S.S. Mahapatra and Udayan Singh, NIT Rourkela, for their continuous support and guidance throughout the work. We also thank the three anonymous reviewers for their valuable suggestions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Sharma, N., Rao, B. Life-cycle atmospheric emissions and energy use of the collection phase of a typical Indian sewerage system. Energ. Ecol. Environ. 3, 48–68 (2018). https://doi.org/10.1007/s40974-017-0066-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40974-017-0066-7