Abstract

Brick manufacturing is the fastest-growing industrial sector in Bangladesh and among the top three sectors, along with vehicle exhaust and resuspended road dust, contributing to the air pollution and health problems in Dhaka. The brick manufacturing in the Greater Dhaka region, from ~1,000 brick kilns spread across six districts, is confined to the winter season (October to March) as current technologies do not allow production during the monsoon. The total emissions are estimated at 23,300 t of PM2.5, 15,500 t of sulfur dioxide (SO2), 302,000 t of carbon monoxide (CO), 6,000 t of black carbon, and 1.8 million tons of CO2 emissions from these clusters, to produce 3.5 billion bricks per year, using energy-inefficient fixed chimney bull trench kiln technology and predominantly using coal and agricultural waste as fuel. The associated health impacts largely fall on the densely populated districts of Dhaka Metropolitan Area (DMA), Gazipur, and Narayanganj. Using the Atmospheric Transport Modeling System dispersion model, the impact of brick kiln emissions was estimated over DMA—ranging from 7 to 99 μg/m3 (5th and 95th percentile concentration per model grid) at an average of 38 μg/m3; and spatial contributions from the surrounding clusters—with 27 % originating from Narayanganj (to the south with the highest kiln density), 30 % from Gazipur (to the north with equally large cluster spread along the river and canals), and 23 % from Savar. The modeling results are validated using evidence from receptor modeling studies conducted in DMA. An introduction of emerging vertical shaft combustion technology can provide faster benefits for public health in DMA and reduce climate precursor emissions by selecting the most influential clusters discussed in this paper.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Dhaka, with more than 15 million inhabitants, is one of the 20 megacities in the world (UN HABITAT 2008) and facing severe urban air pollution problems. WHO (2011) studied publicly available air quality data from 1,100 cities, including cities with populations of more than 100,000 people. Based on World Health Organizations assessment, Dhaka is among the top 20 cities with the worst air pollution.

The Greater Dhaka region, spread over an area of 1,500 km2, includes the districts of Dhaka, Gazipur, Savar, Dhamrai, Rupganj, Manikganj, Kaliganj, and Narayanganj. The air quality in the Dhaka city has deteriorated over the last decade due to a rapid change in the vehicular fleet, increased congestion, and a large increase in the industrial activity, resulting in mortality and morbidity impacts (World Bank 2006, 2007; WHO 2011). The economic costs associated with mortality and morbidity due to poor air quality is estimated at US$500 million per year (World Bank 2006). An overview of the measured monthly average PM2.5 concentrations at a monitoring station near the Sangsad Bhaban (Parliament House; SB, urban site) and another station located at the Atomic Energy Center (Dhaka; AECD, campus site) are presented in Fig. 1 (PM2.5 refers to the particulate matter (PM) with aerodynamic diameter less than 2.5 μm). The average concentration of PM2.5 due to all sources is 100 μg/m3at SB and 30 μg/m3at AECD; much above the health guidelines of 10 μg/m3 prescribed by the World Health Organization and Bangladesh national ambient air quality standard of 15 μg/m3.

In the Dhaka city, emissions from vehicle exhaust (motorcycles, aged busses, three-wheeler passenger vehicles, passenger cars, commercial vans, and freight trucks), resuspended road dust (due to the vehicular movement), and industries are dominant (Hasan and Mulamoottil 1994; Azad and Kitada 1998; Begum et al. 2006, 2008, 2011). Among the industries, brick kiln emissions form a major source of pollution measured over the Dhaka Metropolitan Area (DMA). The contribution of brick kiln emissions to the ambient air quality is estimated from the source apportionment studies conducted in 2001–2002, 2005–2006, and 2007–2009 (Begum et al. 2006, 2008, 2011). In these studies, the filter samples were analyzed for chemical markers, relevant for various sectors like motor vehicle exhaust, coal and biomass burning in the brick kilns, resuspended road dust, domestic fuel burning, and industries. These receptor modeling studies estimated an average contribution of 30–40 % originating from brick kilns to total ambient PM2.5 pollution. Simulations using CMAQ chemical transport dispersion modeling system over Dhaka and Bangladesh, estimated at least 35 % of ambient PM10 and at least 15 % of the ambient PM2.5 in DMA is associated with brick kiln emissions (Billah Ibn Azkar et al. 2012).

In Bangladesh, the brick kiln industry is one of the fastest-growing sectors, supporting the booming infrastructure and construction industry, with current manufacturing capacity of 12 billion bricks a year from 4,500 brick kilns surrounding all major cities of Dhaka, Khulna, Rajshahi, and Chittagong, and expected to grow 50 % by 2020 (World Bank 2007; UNDP 2011). To support an effective urban air quality management in Dhaka and in other cities in Bangladesh, there is limited understanding of the movement of the kiln emissions and contributions attributable to various brick kilns clusters. Given the uncertainties and deficiencies in the source apportionment studies (Johnson et al. 2011), which assess contributions to a certain location, qualitatively and quantitatively, results from emissions and dispersion modeling can further support and compliment the need for an integrated urban air quality management (Hidy and Pennell 2010). Dispersion of the pollutants is especially important for policy makers, since any air quality management policy generally targets the emissions and the policy induced changes in the spatial and temporal distribution of the emissions can have a large impact on the ambient concentrations and interlinked health impacts.

A very few studies have addressed the dispersion of air pollutants in Dhaka and fewer for the brick kiln emissions from the clusters in the Greater Dhaka region. With this background, in this paper, we studied the impact of emissions from brick kiln surrounding DMA via dispersion modeling of particulate pollution, with supporting information from ongoing source apportionment studies, and discuss possible interventions to benefit Dhaka’s air quality.

Inputs and methods

Brick kiln clusters

In the Greater Dhaka region presented in Fig. 2, ~1,000 brick kilns were mapped in the vicinity of DMA. The location of the brick kilns, in the six districts surrounding DMA were digitized using the visual images from Google Earth and physically verifying the location of some clusters. Most of these kilns are located along the intracity canals linking the rivers, which also serve as the arteries for transporting raw material to the kilns and delivery of the finished product to the distribution and construction sites. A composite of the Google Earth image of a kiln cluster in Narayangunj is also presented in Fig. 2. The particulate pollution modeling domain extends from 89.7 to 90.8 °E in longitude and 23.3 to 24.4 °N in latitude at a grid resolution of 0.02°, subdivided into 55 × 55 grids in longitude and latitude.

The largest clusters are located in Gazipur (~320) and Narayanganj (~270), followed by Savar, Dhamrai, and Kaliganj, each with over 100 kilns, and Rupganj with less than 100 kilns. The brick manufacturing in Bangladesh is dominated by small individual operators, each consisting of 200–300 daily wage workers per kiln, employed on a seasonal basis. Most of these are conventional fixed chimney bull trench kilns (FCBTK), which are relatively more polluting and energy-inefficient when compared to the newer, cleaner technologies, e.g., Hoffmann kilns, high draft kilns, or vertical shaft brick kilns (CAI-Asia 2008; World Bank 2010). A summary of various kiln technologies and comparison to in-use FCBTK is presented in Table 1. Of the technologies listed in Table 1, FCBTK is the most common technology and only the vertical shaft technology is under pilot stage (World Bank 2010). Due to the lack of information on the brick manufacturing rates by individual kiln, an average production rate of 20,000 bricks per day is assumed per kiln (World Bank 2007). Since all the kilns are following same design framework for heating and stacks, the assumption of an average production rate per stack was a reasonable for estimating the final emissions.

Combustion emissions

Brick kilns are primarily associated with PM, CO, SO2, volatile organic compounds, nitrogen oxides (NOx), and heavy metals depending on the type of fuel burnt. In this study, a combination of local surveys (World Bank 2007) and recent measurement campaigns (Maithel et al. 2012) are utilized to estimate activity based combustion emissions. Maithel et al. (2012) is the first set of measurements in South Asia to quantify the emission factors for brick kilns in the Indo-Gangetic plains. While these factors cannot be translated and used directly for the brick kilns in Dhaka, due to variations in the fuel mix between India and Bangladesh, they do provide a baseline for comparison given the technologies in use are similar between the regions.

At the brick kilns in the Greater Dhaka region, the energy required for baking 100,000 bricks is estimated at 20 t of coal with a calorific value of 22 MJ/kg and the majority of the energy needs is supplemented by coal (~80 %) and occasional use of biomass (~10 %) and heavy fuel oil (~10 %; World Bank 2007). For comparative purposes, in India, most of the kiln clusters are located closer to the agricultural areas, which results in a higher portion of field residue available for combustion at the kilns. A majority of the coal used at the kilns in Dhaka is imported from India’s northeastern states, with an ash content of 20–25 % and sulfur content of 1.0 % by weight. The use of biomass is limited to the harvest season when the agricultural residue from the neighboring lands is acquired at a price lower than that of coal. However, this is not a sustainable option for the entire season. The heavy fuel oil is used as a replacement fuel during the occasional rainy days to avoid using wet coal. No specific pollution control measures are implemented at the kilns, either to control SO2 emissions or to settle the total suspended particulates. The kiln’s chimney extending up to 50 m is designed to settle most of the heavier particles and release most of the PM10 and PM2.5 into the flue gas.

World Bank (2007) presents an emissions inventory for the kilns located north of Dhaka, in the Gazipur district, including a measured emissions factor of 44.0 g/s for total suspended particulates, which for an average production rate of 20,000 bricks per day translates to 190 g per brick. GAINS (2010) presents an average PM10 emissions factor for brick kilns in Asia as 1,750 t per million tons of bricks, which for an average weight of 3 kg per brick translates to 5.85 g per brick. Le and Oanh (2010) measured PM2.5 emissions of 0.64–1.4 g per brick produced in kilns smaller in design and production capacities than those available in Dhaka. For the base year 2010, based on fuel consumption and fuel characteristics data, we estimated the emission factors in this study, in grams per brick produced as 6.8 for PM2.5, 9.7 for PM10, 4.6 for SO2, 4.7 for NOx, 90.0 for CO, 520 for CO2, and 2.8 for black carbon (BC).

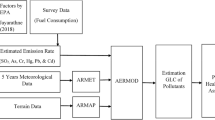

Modeling pollutant concentrations

Previously, dispersion models were utilized under varying conditions to evaluate air pollution at regional and urban scale. To characterize the movement of brick kiln emissions, the Atmospheric Transport Modeling System (ATMoS) dispersion model—a forward trajectory Lagrangian Puff-transport model (Calori and Carmichael 1999) was utilized. The model was previously utilized to study regional and urban scale pollution management in Asia for sulfur, nitrogen, and PM pollutants (Guttikunda et al. 2001, 2003; Holloway et al. 2002; Li et al. 2004; Guttikunda and Gurjar 2012). ATMoS is a modified version of the USA National Oceanic Atmospheric Administration, Branch Atmospheric Trajectory model (Heffter 1983). The layers include a surface layer, boundary layer (designated as the mixing layer height), and a top layer. The multiple layers allow the model to differentiate the contributions of diffused area sources like transport and domestic combustion emissions and points like brick kilns and power plant emissions. The model has flexible temporal and spatial resolution and can be run for periods ranging from 1 month to a year and from regional to urban scales and including chemical mechanism to convert SO2 to sulfates and NOx emissions to nitrate concentrations, which are added to the PM2.5 totals as part of the secondary contributions (Guttikunda et al. 2003).

For the domain presented in Fig. 2, the dispersion modeling was conducted for a period of 6 months, corresponding to the brick manufacturing season—for the months of October to March. The manufacturing season corresponds to the nonmonsoonal season with less precipitation. A typical precipitation pattern, along with wind speed, wind direction, and mixing heights, from the years 2004, 2006, and 2008 is presented in Fig. 3. This meteorological data utilized for ATMoS model simulations is obtained from National Centers for Environmental Prediction reanalysis (NCEP 2012). The ATMoS model produces monthly average concentrations as output and then converted to seasonal averages for further analysis. The dispersion modeling was conducted for PM2.5 fractions only, given the propensity of this fraction to penetrate further into the human lungs and result in exacerbated respiratory and cardiovascular diseases and, in some cases, leading to premature mortality (HEI 2004, 2010).

Results and discussion

Pollutant emissions

The total emissions from the brick kilns located in the six districts are estimated at 33,100 t of PM10, 23,300 t of PM2.5, 15,500 t of SO2, 16,100 t of NOx, 302,000 t of CO, and 6,000 t of BC per year. The total emissions by district clusters are presented in Table 2. For convenience, only the PM2.5 shares are presented in the table and the shares are the same for other pollutants. The brick production rates varied from 10,000 to 45,000 per day per kiln depending on their manufacturing capacity and availability of raw material and labor. For the clusters around DMA, during the operational season, the manufacturing averages to 3.5 billion bricks per year consuming 1.0 million tons of coal and producing 1.8 million tons of CO2. The spatial spread of the emissions follow the density map presented in Fig. 2 with highest densities observed over Gazipur and Narayanganj. We acknowledge the spatial uncertainty associated with the production rates and related emissions by region and by kiln. However, since all the kilns in the region are designed in similar fashion, this allows for averaging the energy consumed per brick produced and thus the emissions by grid.

Modeled particulate pollution due to brick kiln emissions

The modeled brick manufacturing seasonal average PM2.5 concentrations are presented in Fig. 4a. The averaging season corresponds to the brick manufacturing months from October to March. It is important to note that modeled concentrations are due to brick kiln emissions only and does not include emissions like those from vehicle exhaust, road dust, industries, or domestic fuel combustion. For analytical purposes, each of the six districts surrounding DMA is boxed to the area covering the location of the kilns in that province. A summary of the modeled concentrations due to these emissions is presented in Table 3. The modeled concentrations of PM2.5 over DMA ranged from 7 to 99 μg/m3 over the 6-month period (the range indicates the 5th and 95th percentile concentration per model grid) at an average of 38 μg/m3.

Also presented in Table 3 are the concentration ranges modeled for each of the boxed regions. The variation in the concentrations is primarily due to the selection of a large area around each district cluster. For the boxed regions in Fig. 4, the modeled data is extracted by grid (~2 × 2 km2) to estimate the range of modeled concentrations. The contribution of the brick kilns in the respective regions is proportional to the number of the kilns located in the vicinity, except for DMA, which is surrounded by regions with kilns and experiences dispersed pollution. The Narayanganj (N) area with the highest density of kilns and closet to DMA experiences averages as high as 120 μg/m3 (and 180 μg/m3 in December and January) of PM2.5 from brick kilns emissions alone, which is already above the WHO guidelines for exposure risks.

Bi-monthly average PM2.5 concentrations clubbed as October–November, December–January, and February–March were analyzed for seasonal patterns (Fig. 4). The average concentrations modeled for the months of December and January, presented in Table 3, is at least two times higher than the seasonal averages. The monthly averages of PM2.5 measured (due to all sources) at the two monitoring stations (Fig. 1) also observed peaks in December or January. At the Sandsad Bhaban, PM2.5 concentrations averaged 168 ± 35 μg/m3 between 2002 and 2008 and peaking at 230 μg/m3 in January, 2008. The peak concentrations also increased from 130 μg/m3 in 2004 to 230 μg/m3 in 2008; an indication of the growing demand for the fired bricks, increase in the operational kilns, and booming demand in the construction industry. The peaks in concentrations are also partly due to slow moving winds in December and January, which are known to enhance unfavorable dispersion characteristics and exacerbate the ground-level concentrations (Guttikunda and Gurjar 2012).

The source apportionment studies estimated an average contribution of 30–40 % originating from the brick kilns (Begum et al. 2006, 2008, 2011). This was used as proxy to compare the modeled concentrations in Fig. 4 to the measured PM2.5 concentrations in Fig. 1. The PM2.5 monitoring data is also split between the brick manufacturing season and the remaining months, which present a distinct change in the pollution trends, coinciding with the brick manufacturing cycles. On the basis of the source apportionment results, the seasonal average measured PM2.5 concentration of 140 μg/m3 at the Sangsad Bhaban translates to 42–56 μg/m3. The site at the Atomic Energy Center in Dhaka located on campus is deemed a background site for monitoring activities, experienced a seasonal average PM2.5 concentration of 50 μg/m3, with limited exposure to vehicle exhausts. For the boxed region covering DMA, we modeled an average concentration of 38 μg/m3 due to the emissions from brick kiln clusters (Table 2). We did not make point to point comparison between measured and modeled concentrations, due to limited monitoring activities carried out in DMA. In Fig. 1, though we split the averages to brick manufacturing and nonmanufacturing months, this is in no way concluding that emissions from other sources are contributing any less to the growing PM pollution in the city.

Provincial apportionment of particulate pollution to DMA

The emissions from the low-lying sources like vehicle exhaust and the domestic fuel use are fairly constant over all months of a year and confined to the city limits, and thus contribute more to the locally attributable pollution levels. However, the brick kilns, spread across the Greater Dhaka region are operated with a stack height of 50 m each and capable of transporting the emissions to larger distances as it is evident in the monitoring data presented in Fig. 1 and the modeled concentrations presented in Fig. 4. While the source apportionment is a resource to estimate the contribution of brick kilns to a particular location (where the monitoring is conducted), they fail to assess the spatial origin of the pollution. This is especially difficult when all the kilns (irrespective of their location) are operating with similar fuel characteristics and the receptor modeling depends on the fuel characteristics to apportion pollution loads. An added advantage of dispersion modeling is the spatial allocation of the emissions and tagging the sources to estimate contributions to a select location. In this study, the emissions from kilns are tagged by source (for the boxes presented in Fig. 4) and aggregated to estimate the percentage contributions to DMA and to the monitoring stations, presented in Fig. 5. The highest contributions to DMA originate from the kilns in Narayanganj (N) and Gazipur (G), 27 and 30 %, respectively. Though the density of kilns in Savar (S) is not a large as those in Narayanganj and Gazipur (11 % of the total emissions compared to 25 and 30 %, respectively), due to the proximity of kilns in Savar and favorable winds (Fig. 3), contribution of these kilns is also substantial at ~23 %.

In the districts, the contribution of in situ kilns is the highest, as expected, followed by those originating from the neighboring provinces. Gazipur was identified as one of the troubled hotspots which contributed the most to Dhaka’s poor air quality. Similar to DMA, Gazipur is also densely populated and experiences the highest pollution exposure problems (World Bank 2007).

Similar to the boxes drawn over the districts to calculate respective contributions, we extracted concentrations over 3 × 3 grid cells surrounding the monitoring station, with the central grid corresponding to the location of the station. The percentage contributions to PM2.5 pollution estimated at these locations is presented in Fig. 5. The AECD (campus site) is more centrally located in DMA (Fig. 2) and thus experiences pollution from all the neighboring districts. These concentrations averaged 37 μg/m3 over the brick manufacturing months with most originating from Savar (32 %), Gazipur (21 %), and Narayanganj (26 %). The Sangsad Bhaban is located to west of DMA, averaged 32 μg/m3, and being closer to Savar district boundary, experienced the most pollution (61 %) from here.

Summary and implications

Brick kilns are thought to be a major source of rural and urban air pollution throughout South Asia. Few studies have rigorously analyzed this issue and fewer have measured the emissions factors and/or modeled their contribution to the ambient particulate pollution levels in and around the cities in South Asia. This study marks one of the first to do so—in both mapping the kiln clusters and modeling the particulate pollution for the Greater Dhaka region. Given the nature of an unorganized form of this sector, we believe that the uncertainties in estimating the fuel consumption patterns, production cycles, and emission rates is unavoidable; yet it is important to raise the necessary scientific awareness on a growing sector and highlight their contributions to air quality and climate precursors.

The energy and environmental consequences are already evident in the daily monitoring data in DMA. In this paper, we modeled emissions and dispersion of pollution from these kiln clusters and estimated the percentage contributions of various clusters to DMA. The main conclusion of this study is the spatial apportionment of brick kiln pollution in DMA, with majority originating from three clusters—Narayanganj (to the south with the highest kiln density), Gazipur (to the north with equally large cluster spread along the river and canals), and Savar (to the west with winds favoring the movement of pollution towards the city). An introduction of the emerging technologies can provide faster benefits to air quality and public health by selecting the most influential clusters in the region.

Given the severity of the pollution observed during the 6-month period of October to March, especially during the months of December and January, when the brick manufacturing is at its peak, there is an acute need to leap frog from the outdated and inefficient FCBTK technology and introduce newer and cleaner technologies like zigzag (high and natural) draft kilns, hoffmann kilns, tunnel kilns, and vertical shaft brick kilns (Zhihong 1997; World Bank 2010). From Table 1, at least 40 % reduction in the PM emission rates is possible by shifting away from the currently in use FCBTK technology; which based on the average concentrations in Fig. 4, translates to a reduction of 20 μg/m3 of ambient PM2.5. World Bank (2010) and UNDP (2011) are working with the regional bodies and kiln owners in Bangladesh to pilot and promote one of the emerging technologies (vertical shaft brick kilns) in Dhaka. The combination of energy savings and reduction in pollution is a win–win situation, in which industry benefits because of savings in energy costs and the city benefits because of reduction in health impacts.

Addendum

The potential for combined benefits for health and climate, by controlling the climate precursors like CO2 and BC is an emerging science. Since anthropogenic climate change is largely driven by fossil fuel combustion (IPCC 2007), analysis of emissions also provides insight into climate forcing and associated mitigation strategies. In 2010, the kiln clusters surrounding DMA manufactured 3.5 billion bricks, consuming 1.0 million tons of coal, and producing an estimated 1.8 million tons of CO2 and 6,000 t of BC emissions. BC, a subfraction of particulate matter, also plays a role in altering climate forcing (Ramanathan and Carmichael 2008), and efforts to limit BC emissions from the brick kilns have a dual benefit in reducing health costs associated with exposure to this pollutant and limiting climate forcing impacts (Shindell et al. 2012).

From a broader perspective, use of monitoring and modeling approaches to build an effective source-based air quality management plans is vital for clean air and better health. The capacity to conduct top-down receptor modeling to identify the percent contributions of emissions in the cities and bottom-up inventory and dispersion modeling studies to identify the pollution origins, is an acute need for most of the cities in Asia. With proper training and capacity building (technical and financial) to conduct such studies, in-country implementation of these methodologies can make a valuable contribution to urban air quality management and to the climate policy community, given the potential for controlling the short-lived climate forcers from sources like the brick kilns.

References

Azad AK, Kitada T (1998) Characteristics of the air pollution in the city of Dhaka, Bangladesh in winter. Atmos Environ 32:1991–2005

Begum BA, Biswas SK, Hopke PK (2006) Temporal variations and spatial distribution of ambient PM2.2 and PM10 concentrations in Dhaka, Bangladesh. Sci Total Environ 358:36–45

Begum B, Biswas S, Hopke P (2008) Assessment of trends and present ambient concentrations of PM2.2 and PM10 in Dhaka, Bangladesh. Air quality. Atmos Health 1:125–133

Begum BA, Biswas SK, Hopke PK (2011) Key issues in controlling air pollutants in Dhaka, Bangladesh. Atmos Environ 45:7705–7713

Billah Ibn Azkar MAM, Chatani S, Sudo K (2012) Simulation of urban and regional air pollution in Bangladesh. J Geophys Res 117:D07303

CAI-Asia (2008) Clean brick making technology—success of VSBK in Kathmandu. Clean Air Initiative for Asia Cities, Manila

Calori G, Carmichael GR (1999) An urban trajectory model for sulfur in Asian megacities: model concepts and preliminary application. Atmos Environ 33:3109–3117

GAINS (2010) Greenhouse gas and air pollution interactions and synergies—South Asia program. International Institute of Applied Systems Analysis, Laxenburg

Guttikunda S, Gurjar B (2012) Role of meteorology in seasonality of air pollution in megacity Delhi, India. Environ Monit Assess 184:3199–3211

Guttikunda SK, Thongboonchoo N, Arndt RL, Calori G, Carmichael GR, Streets DG (2001) Sulfur deposition in Asia: seasonal behavior and contributions from various energy sectors. Water Air Soil Pollut 131:383–406

Guttikunda SK, Carmichael GR, Calori G, Eck C, Woo J-H (2003) The contribution of megacities to regional sulfur pollution in Asia. Atmos Environ 37:11–22

Hasan S, Mulamoottil G (1994) Environmental problems of Dhaka city: a study of mismanagement. Cities 11:195–200

Heffter JL (1983) Branching atmospheric trajectory (BAT) model, NOAA Tech. Memo. ERL ARL-121, Air Resources Laboratory, Rockville

HEI (2004) Health effects of outdoor air pollution in developing countries of Asia: a literature review, special report 15. Health Effects Institute, Boston

HEI (2010) Outdoor air pollution and health in the developing countries of Asia: a comprehensive review, special report 18. Health Effects Institute, Boston

Hidy GM, Pennell WT (2010) Multipollutant air quality management. J Air and Waste Manag Assoc 60:645–674

Holloway T, Levy Ii H, Carmichael G (2002) Transfer of reactive nitrogen in Asia: development and evaluation of a source-receptor model. Atmos Environ 36:4251–4264

IPCC (2007) Climate change 2007: impacts, adaptation & vulnerability (fourth asseessment report). Cambridge University Press, Cambridge

Johnson TM, Guttikunda SK, Wells G, Bond T, Russell A, West J, Watson J (2011) Tools for improving air quality management. A review of top-down source apportiontment techniques and their application in developing countries. ESMAP Publication Series, The World Bank, Washington DC

Le H, Oanh N (2010) Integrated assessment of brick kiln emission impacts on air quality. Environ Monit Assess 171:381–394

Li J, Guttikunda SK, Carmichael GR, Streets DG, Chang Y-S, Fung V (2004) Quantifying the human health benefits of curbing air pollution in Shanghai. J Environ Manag 70:49–62

Maithel S, Uma R, Bond T, Baum E, Thao VTK (2012) Brick kilns performance assessment, emissions measurements, & a roadmap for cleaner brick production in India. Study report prepared by Green Knowledge Solutions, New Delhi

NCEP (2012) National Centers for Environmental Prediction. National Oceanic and Atmospheric Administration, Maryland, USA

Ramanathan V, Carmichael G (2008) Global and regional climate changes due to black carbon. Nat Geosci 1:221–227

Shindell D, Kuylenstierna JCI, Vignati E, van Dingenen R, Amann M, Klimont Z, Anenberg SC, Muller N, Janssens-Maenhout G, Raes F, Schwartz J, Faluvegi G, Pozzoli L, Kupiainen K, Höglund-Isaksson L, Emberson L, Streets D, Ramanathan V, Hicks K, Oanh NTK, Milly G, Williams M, Demkine V, Fowler D (2012) Simultaneously mitigating near-term climate change and improving human health and food security. Science 335:183–189

UN HABITAT (2008) State of the world’s cities 2008/2009—harmonious cities. UN HABITAT, Nairobi

UNDP (2011) Improving kiln efficiency in the brick making industry. GEF-United National Development Program, UNDP, Dhaka

WHO (2011) Outdoor air pollution in the world cities. World Health Organization, Geneva

World Bank (2006) Country environmental assessment, Bangladesh. The World Bank, Washington DC

World Bank (2007) Small study on air quality of impacts of the North Dhaka brickfield cluster by modeling of emissions and suggestions for mitigation measures including financing models. Consultant report prepared by Bangladesh University of Engineering and Technology for the World Bank, Washington DC

World Bank (2010) Vertical shaft brick kiln—design manual. ESMAP Publication Series, The World Bank, Washington DC

Zhihong Z (1997) Energy efficiency and environmental pollution of brickmaking in China. Energy 22:33–42

Author information

Authors and Affiliations

Corresponding author

Additional information

Highlights

• An updated map of brick kiln clusters surrounding the Dhaka Metropolitan area • An inventory of brick kiln emissions by district in the Greater Dhaka region • A spatial apportionment of particulate pollution from the kilns by district • An assessment of implications of upgrading the combustion technologies by cluster

Rights and permissions

About this article

Cite this article

Guttikunda, S.K., Begum, B.A. & Wadud, Z. Particulate pollution from brick kiln clusters in the Greater Dhaka region, Bangladesh. Air Qual Atmos Health 6, 357–365 (2013). https://doi.org/10.1007/s11869-012-0187-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11869-012-0187-2