Abstract

The trend of growth and aging of population worldwide will pose new challenges in health care, which will require faster solutions addressed to specific pacient needs. In this regard, additive manufacturing (AM) is a group of promising technologies capable of delivering custom biomedical parts of high complexity in reduced lead time. Although it has emerged commercially in the 1980s as a rapid prototyping and modeling technique, it is now applied to production of a wide range of shapes with various possible materials. In this work, the technological aspects of each type of AM process were reviewed according to their advantages, limitations and potential or current applications for the production of medical devices. Direct comparisons of resolution, price and printing speed made possible to identify the most important niche for each AM process in health care sciences. In one hand, the many variables involved make these processes difficult to model and control, but in the other hand, they allow fine tuning of the microstructure to produce purposeful anisotropy, porosity and varying chemical composition, which may be desired in many medical devices. In addition, since the AM technologies have different working principles and feedstock requirements, the historic concept and classification of biomaterials were also assessed in view of their application for tissue engineering, implantable devices and surgery equipment among other uses. The discussion of materials and manufacturing methods was based on several research works and commercial products, which show a extremely fast developing field with a broad range of current and future possibilities in terms of biomedical applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Facing the speed with which the world’s population ages is a major challenge for many countries. Besides an increase in the world’s population of almost 8 billion today to over 10 billion expected by 2050, life expectancy has been consistently increasing, from 65 years in 1990 to 73 years in 2019 and possibly 77 years in 2050, as shown in Fig. 1. The elderly population (above 64 years old) is about 700 million at present, however, it could increase to more than 2 billion before the end of this century according to UN estimations [1].

Average life expectancy at birth by of world population since 1950 [1]

Such an evolution is being noticed as a result of recent advances in medicine. There is a growing concern about the diet and comfort produced by the typical “modern life”. Consequently, there is an increase in the older population, leading to the onset of diseases related to old age, obesity, and lack of physical activity [2]. With this average increase in population age, some factors are gaining importance in the human lifestyle, namely the musculoskeletal condition and osteoporosis, causing devastating effects. This further gives rise to the need of extensive research in this area to improve the quality of human life [3]. Table 1 shows the distribution of musculoskeletal problems as a function of age.

The latest projections revealed that one of the main factors causing problems in the musculoskeletal system was obesity. In 2005, 400 million obese inhabitants were considered globally, out of which 20 million were children under 5 years [4]. By 2018, one in eight adults in the world were found to be obese. Treatments for musculoskeletal system problems are extremely costly, representing an average 3% of gross domestic product (GDP) in more developed countries [1].

Another condition that is closely related to the modern lifestyle, aging, and numerous systemic complications is the diagnosed diseases, such as diabetes. About 415 million people were estimated to have this disease in 2017 with a projection of it reaching 642 million people by 2040. In addition, this infirmity represents the leading cause of hospitalization and increases the risk of amputation in diabetic patients by more than tenfold [5]. Fractures and diseases related to the musculoskeletal system are the main causes of death in the first 38 years of life. Further, they become responsible for a greater reduction in the productive years when compared to heart disease and cancer, altogether.

The most important factor that distinguishes a biomaterial from any other material is its ability to be in contact with human body tissues without causing any harm to the body. Most of the “materials for use in health” are classified as biomaterials and used for the manufacturing of: prostheses, lenses, grafts, stents, catheters, extracorporeal circulation tubes, tissue engineering frameworks, dental implants, orthopedic screws etc. In recent years, biomaterials have found their immense applications in the fields of joint and limb replacement, eye implants, artificial arteries, and skin surgery as well [6]. Therefore, the durability and comfort of human life can be considerably enhanced with the application of biomaterials.

Numerous challenges can be faced when performing the implantation of intracorporeal prosthesis. Some of the major issues inherent to implant placement are the difficulties in positioning and aligning the prosthesis and also the selection of model according to patient body and structure, as stated by Ranawat [7]. Moreover, improper implant design can lead to implant deterioration followed by its failure. This may further require a secondary surgery, as in the case of premature wear or stress induced bone remodeling, two of the most common failure causes of total arthroplasties [8]. Thus, there is a growing interest in developing personalized implants which can promise a comfortable life to the patient.

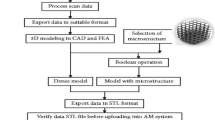

The need of fabrication of 3D anatomical models rises from the possibility of visualizing an anatomical replica of the patient, which further allows the evaluation and simulation of surgical techniques. Figure 2 presents a methodology for manufacturing prostheses in patients with some type of disease. This structure consists of: (1) acquiring two-dimensional medical images by CT (Computed Axial Tomography) or NMR (Nuclear Magnetic Resonance), (2) transforming medical images into three-dimensional virtual models; (3) modeling the virtual prosthesis and 3D CAD fixation systems, (4) fabricating the model (prosthesis and fixation systems) by AM technologies, and (5) fabricating the prostheses with biocompatible materials.

Adapted from Devgan and Sidhu [6]

Methodology for manufacturing anatomical models.

In certain cases, it may become essential for the medical team to plan the surgery with the use of a biomodel, since this allows the palpable verification of the area which has to be operated and replaced by the implant. The medical practitioners involved can also manipulate the physical object and perform surgery simulations, handling all surgical instruments and the implant itself. They can also make prosthesis connections with the region of interest to be replaced in the human anatomy (biomodel) [9]. Therefore, the development of highly biocompatible materials is appearing to be a greater need of the hour so as to improve reliability and reduce the risk of rejection by the human body.

Advanced manufacturing technologies are constantly being explored for the processing of biomaterials, mostly to reduce costs and facilitate customization as reviewed by Culmone et al. [10], and also to minimize inventory and maximize performance. These technologies are capable of producing single-component design and even structures with increasingly complex geometries [11]. Moreover, anatomical models such as the liver (as shown in Fig. 3), can be directly produced with the aid of various examination of the patient. By creating textures ranging from hard bones to soft tissues, healthcare professionals can plan, practice, and determine therapeutic approaches or surgical techniques, which are already in use for planning complex heart surgeries [12, 13].

Liver produced by additive manufacturing [17]

2 Additive manufacturing: evolution and concept

In the late 80s, some manufacturing technologies initially used for prototype manufacturing, were known as Rapid Prototyping (RP) [14]. Prototypes that took days, weeks or even months to develop, due to the high number of steps or phases, were performed within a few hours by RP. However, in the last 2 decades, advances in manufacturing have presented another possibility, known as three-dimensional printing or additive manufacturing (AM). It is noteworthy that despite being a technology on the rise in conjunction with Industry 4.0, additive manufacturing is not a new conecept. According to Zhou et al. [15], AM technologies have actually migrated from the Rapid Prototyping (RP) process to a direct digital manufacturing solution, applied to the production of final goods and not just prototypes. According to Miller [16], the industry began to use RP in prototype development, but the cost of equipment and materials as well as limited applications prevented the access for several companies in the 1980s. In the 1990s, the Wake Forest Institute for Regenerative Medicine in the United States used additive manufacturing to print structures in three dimensions for reproducing the human organs. In the 2000s, AM brought a revolution in the area of development of prostheses for human body. This technique allowed manufacturing industries to develop complex shapes and structures more efficiently that are often difficult to be developed with traditional injection molding or machining methods, as in the parts showed in Fig. 4. There is also less waste, resulting in shorter setup times and lower material costs [17]. These advantages could be so accentuated that even in traditional segments such as construction, there have been many researches exploring AM capabilities and possible applications, as reviewed by Paolini et al. [18].

In general, additive manufacturing technologies have as their basic operating principle of generation of three-dimensional (3D) objects through the process of adding material in a layer-by-layer fashion [19]. In the early stages of product development the mechanical characteristics, in many cases, may resemble with those of traditional processes. On the other hand, in some cases, AM technologies allow the construction of much freer forms than traditional processes with mechanical strength close to conventional ones.

According to Jamróz et al. [20], during this same period, studies focused on the identification of new materials including polymers, that could be used in additive manufacturing. According to Karunakaran et al. [21], one of the major concerns that emerged between the 1980s and 2000s, was the inflexibility of equipment and materials for AM. This concern led to the emergence of studies that provide hybrid technologies for materials. The major studies between the late 1980s and the 2010s dealt with the aspects of materials and machines of AM. However, no studies related to the production systems of AM were observed. After 2010, studies began to be conducted on the advantages of applying additive manufacturing over traditional manufacturing processes. An example of these studies is the work presented by Ford [22] that sought to expose how AM would impact the US companies.

Therefore, in short, the history of additive manufacturing can be divided into four phases. The first phase which is prototyping, has a limited use mainly by academic institutes for prototyping, but with high costs for both equipment and materials. The second phase deals with the applications of additive manufacturing. The research sought to show all the possible areas where AM could be employed. In verifying that the applications were pertinent, the third phase of research turned to materials and equipment. The demand for equipment expansion in AM always faces a challenge due to the high cost and variety of materials to be used. The most recent phase of the studies is concerned with the possible replacement of so-called “traditional” manufacturing processes by additive manufacturing.

Over the years, many authors [23,24,25,26] basically used the American Society for Testing and Materials (ASTM) concept of Additive Manufacturing [19] in the literatures. However, Ford [22] proposed a concept that complements ASTM, which actually did not present additive manufacturing as a manufacturing process contrary to traditional manufacturing. According to Ford [22], additive manufacturing is a set of emerging technologies that manufacture three-dimensional objects directly from digital models through a material addition process. Frazier [27] defined additive manufacturing as: “process of joining materials to make objects from information in the three-dimensional model, usually layer after layer, as opposed to subtractive manufacturing methodologies”. This definition is applicable to all classes of materials, including metals, ceramics, polymers, composites, and biological systems. Huang et al. [28] defined AM as a material adhesion process for making objects from 3D model data, usually layer by layer. It is also known as rapid manufacturing and unlike subtractive manufacturing processes (material removal), AM achieves the final shape by adding materials.

Thus, the rising demand for AM processes in health areas is increasingly imminent [29]. This technology is progressively gaining visibility not only in various manufacturing industries, but also in all the areas of market, society, and health. In biomedical applications, AM includes engineers to assist the medical and health professionals for treating the patients with damaged tissues or fractured bones, mostly in the cases of patient-specific implants. That is the case of printed organs such as liver, skull, urether, and ribs, among others, some of which have already been successfully implanted [30]. An example of this can be seen in medical applications, usually focused on implants and prosthetics. In dentistry, the advent of digital radiography has enabled orofacial scanning of fractured patients in three dimensions. AM has been proven to be efficient enough of producing implants and prostheses which are precisely adapted to patients. In addition to providing faster availability of prostheses and implants, AM enables dental surgeons to execute precise and safe surgeries with the aid of precisely customized parts [31]. However, this application is giving a way to a new branch in health sector by organ transplantation. At the Wake Forest Institute for Regenerative Medicine Institute, additive manufacturing equipment are being developed to replicate and generate human tissues and organs to be transplanted into patients (Fig. 4b) [32].

In this paper, the authors attempted to analyze the application of AM in the world, the desired variations as required by the manufacturing industries, and the effect of the same on the competitiveness among world’s manufacturing industries.

3 Technological aspects of AM

According to Huang et al. [28], additive manufacturing technology consists of three basic steps:

-

1.

A solid computerized 3D model developed and converted into a standard file with the traditional format and standard language (Fig. 5a).

-

2.

Exportation of this file to an AM equipment for its further manufacturing (Fig. 5b).

-

3.

Layer-to-layer construction in additive manufacturing equipment (Fig. 5c).

a Scan of the 3d model; b exploration of the file sent to equipment; c part manufactured by additive manufacturing [35]

According to Oliveira et al. [34], the classification of AM technologies is totally linked to three-dimensional printing equipment. Figure 6 presents the classification of AM technologies based on the state of the material to be used. Figure 7 shows schematic representations of the same processes, which are further discussed and compared.

Additive manufacturing technologies [34]

3.1 Material extrusion

The Fused Deposition Modeling (FDM) patent was granted on June 9, 1992, but the technique was previously described by Huang et al. [28]. This process is also called fused filament fabrication (FFF) and uses a thermoplastic and a heating chamber to liquify the polymer. Material deposition occurs through an extruder head that moves along the x and y axes by adding material filaments. After finishing a layer, the deposition platform moves down in z direction to build the next layer, and so on until the part is finished, as represented in Fig. 7a. The main variables are the temperature of the head and of the table, the scanning speed and path, and the wire speed.

Over the past few years, significant progress has been made in the finally produced parts. For example, nowadays many parts manufactured by FDM exhibit higher strength than the parts manufactured by classical processes of same material. This can be easily identified by comparing the yield stress values of Stratasys FDM thermoplastics material with those of molded materials. While the material values for FDM remain between 22 and 71 MPa, the equivalents for injection molds are between 20 and 60 MPa [42].

One of the main limitations is the resolution which depends on wire thickness, currently at the minimum of 0.127 mm [28]. In addition, the other limitation is the deposition rate which is very low compared to other AM technologies due to inertia of the printing table. Moreover, the process is limited to polymers, with thermoplastics among the most common.

Material extrusion is one of the oldest AM processes and its use for biomedical parts has been substantially researched. Its main application is the production of scaffolds with bioinert-resistant polymers such as PEEK [43], which can be combined with HA to induce cell attachment in bone repair. There are already several commercial applications of this technology for facial reconstruction [44] and joint pads in total arthroplasty, but full PEEK implants for more loaded joints such as knee and hip are not yet ready for commercial applications [45], although there have been many studies in this regard [46,47,48].

Biodegradble and porous scaffolds can also be extruded by employing PLA and PCL. Although their mechanical properties are usually lower, adjusting process parameters can help to minimize this drawback. de Ciurana et al. [49] showed that different FDM deposition paths can be chosen to tailor porosity and achieve a good combination between strenght and cell growth in the interconected pores [50]. This balance can be further improved using especial geometries [51] and topological optimization [52]. Waris et al. [41] produced porous biodegradable scaffolds to promote fibrous tissue growth in minipigs which could be useful for small human joints, such as thos in the fingers. Duan et al. [53] further filled the pores with stem cells and obtained faster osteochondral repair in rabbits. The convenient lower melting temperatures of the PCL wire also allow printing living cells with FDM technology as shown by Zheng et al. [54], who printed a goat meniscus within a hydrogel matrix rich in stem cells and connective tissue growth factors.

The major challenge in this regard is that there are still no degradable materials with the same resistance of high-performance polymers such as PEEK, however, composites containing ceramic nanoparticles and nanofibers could help to further improve resistance of resorbable polymers [55]. Moreover, the added material helps in the adhesion and proliferation of cells along the scaffolds, as in the case of bone cell growth induced by nanoHA crystals in PCL feedstock wire [56].

Other possible application is the construction of structure for in vitro studies of growth tissue. Rabionet et al. [57] studied the selection of printing parameters for FDM scaffolds used in cancer cell cultures. It was shown that three-dimensional culture supports are more appropriate to mimic physiological behavior [58]. The use of material extrusion was also investigated towards the manufacturing of biodegradable stents. Guerra et al. [59] combined FFF with a cylindrical spinning base to produce PCL stents and found that nozzle temperature, printing speed, and path were the most important factors for dimensional accuracy [60]. Moreover, it was discovered that an increase in these parameters could accelerate the degradation rate of the polymer in the body [61]. Furthermore, the drug release capability has stimulated commercialization of bioresorbable stents produced by FDM and other traditional technologies, such as laser cutting in human surgeries. However, while there is an advantage of these materials in avoiding in-stent restenosis compared to conventional nitinol stents [62], their development has been hampered by the lack of randomized clinical data guaranteeing its efficacy. The reason is that the parts could degrade within as little as 2 weeks. Currently, there is no unanimity among the medical professionals regarding the superiority of these biomaterials. However, their use is expected to increase once their mechanical and chemical properties are improved.

3.2 Stereolithography (SLA)

Stereolithography (SLA) is one of the most widespread additive manufacturing technologies, initially marketed by 3D Systems. Although the validation of its functional principle has been published by Kodama [63], SLA technology was initially pioneered by the founder of 3D Systems only in 1984 [64]. In addition, it is most widely used in relation to other additive manufacturing techniques. It is also known as photo-polymerization of liquid resin, which gets solidified as a result of electromagnetic irradiation.

The functional principle of this process is the localized curing of photosensitive resin by UV laser beam moving along the X and Y axes. It is possible to use other sources that promote polymerization, such as electron beam (EB), radiation, high-energy particle beam, X-ray, UV light beam, and conventional UV light [65]. The beam focuses on a resin-immersed container to construct the silhouette of the previous computationally calculated layer. Upon completion of each layer, a material support platform moves down along the Z axis to begin construction of the new layer, as represented in Fig. 7b. This process is repeated until the part is finished. Afterwards the platform is raised allowing the unpolymerized resin to drain [37]. The polymerization of the manufactured part is between 80 and 90% [65]. This further implies the completion of post-processing to finish the polymerization and increase mechanical strength. In this stage, the finished part is kept in an oven with a maintained UV light emission. Moreover, the removal of support material is also part of post-processing [66].

The materials typically used by this process are based on acrylates and epoxies, which provide suitable mechanical strength for manufacturing functional parts. Moreover, mechanical strength can be quantified and expressed as yield stress ranging from from 28 to 78 MPa [67]. With regard to the accuracy of this technology, layer resolution of up to 50 μm are currently found, while values about 25 μm are usual for sweeping accuracy. In this case, the construction speed of objects can reach up to 35 m/s. However, there are specific cases, such as microsterolithography, whose values of layer resolution (z) and scan accuracy (x–y) can reach upto 0.1 and 0.25 μm, respectively [68], although the printing speed becomes severely smaller.

The main advantage of the stereolithography process is the production time, which is shorter than FDM due to higher speed of laser scanning. Disadvantages include the size of the product which is limited to small dimensions (approximately the size of a 2-foot cube). Another disadvantage is the cost, as the photopolymer costs between $300 and $500, in addition to the value of the equipment itself. The materials used in SLA are even more limited compared to FDM, because not all thermoplastics can be easily processed from photocuring resin [28].

SLA is used in biomedical applications for production of scaffolds, with many works combining calcium phosphates dispersed in the resin to create porous ceramics for bone repair [69]. Zhou et al. [70] produced spine-shaped bodies from a mix of powdered β-TCP, resin, and dispersant. About 14% porosity and average grain size of 0.7 μm were obtained after sintering, reaching an adequate structure as bone scaffolds. Having allied to the better resolution of SLA, these characteristics are superior than other AM processes used for the same applications, such as SLM. However, the later may reach the same structure faster and without sintering, meaning a less expensive product. Pure polymeric scaffolds and models for surgery planning and didactic purposes are also a possible use of this technique, but FDM would be more advantageous due to versatility and price.

The most interesting feature of SLA is in the biofabrication of scaffolds containing living tissue and growth factors or drug delivery systems. Pereira et al. [71] explained how cells, proteins, and pharmaceutical components can be dispersed in hydrogels, which are crosslinked hydrophilic solid polymers that present physiochemical characteristics similar to soft tissues. Chartrain et al. [72] showed that microfeatures ranging from 5 to 250 µm can be produced by µSL, which would be ideal to produce vascular networks for tissue engineering. However, the current fast curing resins necessary to attain good resolutions do not exhibit good cell biocompatibility. Actually, most common feedstock material that possesses adequate mechanical resistance is not biocompatible according to Szymczyk-Ziółkowska et al. [73], and this limits the application to hard tissue. But the development of new resins and incorporation of microfibers might overcome this challenge. For instance, Kim et al. [74] designed a photocurable bioink mixed with silk fibers that have similar properties to cartilage and could be used to build complex organ structures, such as heart and vessels.

3.3 Powder bed fusion

This technology consists of the construction of 3D objects by melting or sintering material powder. The construction of the layers occurs by fusion of the metallic, ceramic or polymeric particulate through a high power energy source that scans the powder bed along the x–y axes. After completion of each layer, the construction platform moves along the z-axis and material is spread into the bed to form a new layer [39], as shown in Fig. 7d.

The two types of power sources are laser and electron beam, which have different process requirements and yield different part charactheristics for similar parameters. The first yields the commercial names Direct Metal Laser Melting (DMLM), Selective Laser Melting (SLM), and Selective Laser Sintering (SLS), whereas the second is known as Electron Beam Melting (EBM). In both cases, the powder bed may be pre-heated by scanning it between layers to minimize thermal distortion and facilitate fusion with the previous layer [28].

Laser-based equipment can achieve better resolution since the spot can be focused to a smaller diameter. This allows the production of very thin walls with tight dimensional tolerances. EBM on the other hand depends on electrons accelerated by voltage ranging from 30 to 60 kV [75]. It usually presents higher power output and power conversion efficiency compared to laser, producing a larger melt pool that allows it to produce high volume parts faster than the former process [76]. This process demands an expensive high vaccumm chamber to avoid dispersion of the electrons [39], however, it allows processing of highly reactive materials as in the case of pre-alloyed powder metals [77]. The scanning speed of about 1000 m/s achieved by electronically controlled solenoids is much larger than the 10 m/s of laser, which is mechanically controlled by moving mirrors. The later occurs under inert gas atmosphere to avoid oxidation of the melt pool and powder, which also helps to cool down the chamber and part [29]. This represents a better control of the melt pool for laser which helps to reduce surface roughness [78].

Both processes depend on many variables such as powder bed compactation, power and size of the beam [79], scanning path and speed [80], powder size distribution and chemical composition, and cooling rate of the melting pool. Due to the large number of parameters, there is still a lot of variation in the final characteristics of the parts. Achievable surface finish is not as good as stereolithography technology [64] and porosity level (according to process parameters and particulate material properties) can vary between 50 and 90% of the volume of the final object, with better results for EBM. On this account, the mechanical properties are noticeably varied, with yield stress ranging between 5.5 and 90 MPa [81]. This can be corrected by the use of hot isostatic pressing (HIP), but this process is also very expensive.

The advantages of these processes are: best resolution and tolerances for metal products among the AM processes; wide range of materials that can be processed, which include mainly metals and ceramics, enabling even the mixing of different powders. Nevertheless, the use of EBM requires power bed conductivity [82], of course. It is important to highlight that the most equipment manufacturers today also supply the recommended feedstock, and the lack of an established market hinders the autonomy of the buyer.

Some of the major drawbacks of EBM are the price of equipment and low productivity [83]. In addition, an important drawback of powder-based techonologies are the environmental and health risks [84]. The high surface to volume ratio makes it extremely flammable, requiring especial procedures for storing and transporting the material [85]. Besides, the fine metal particles are prone to get airborne and exposed operators could develop inflammations in the respiratory tract [86]. The high cost of the powders is also another concern because they are manufactured by energy intensive methods, such as gas or plasma atomization [87].

SLM and EBM have been widely employed to manufacture metal and metal-ceramic implants for hard tissue replacement, for which Dallago et al. [88] showed that adjusting process parameters to control dimensional errors is one of the main goals in this process. Many commercial implants are already manufactured by SLM, SLS, and EBM, such as acetabular components for hip arthroplasty [89], dental abutments [90], and knee implants [91], in which porosity proved to be beneficial for osseointegration. Furthermore, Zheng et al. [54] studied the influence of final porosity in the tendon growth along Ti–6Al–4V scaffolds during in vivo tests in rabbits and found that there is an ideal pore size which can be obtained according to laser scan speeds and powder size. These particularities show that there is still a need to improve process predictability to guarantee quality in customized products, because each one might require different printing parameters. It is expected that the improvement in FEM simulations might overcome this difficulty in the forthcoming years [92].

Another area of interest is the production of orthesis in patients with neurological diseases that affect muscle contraction of hand or fingers [93], in which the printed device acts as an exoskeletal apparatus. PBF processes have an advantage at producing metal parts tailored to patient morphology in this case, but cheaper conventional processes still have the advantage for the less complex components. SLM of engineering and biodegradable polymers has also been extensively studied, especially for bone-implant applications, whereas it is possible to combine HA powder to produce composite implants more favorable to osseointegration [94]. However, the lower mechanical properties of polymers compared to trustworthy alloys such as Ti–6Al–4V hinders their application in PBF techniques, especially when there are less expensive AM processes to work with polymers.

3.4 Directed energy deposition (DED)

DED processes work by directly depositing material in the form of powder or wire heated up to the melting temperature. The heat sources include laser and plasma arc in the same way used during welding operations. However, even the thinner wire feedstocks produce much larger melt pools than in the case of EBM and SLM.

The variation with better resolution and speed is Laser Engineered Net Shaping (LENS) with powder [28], in which the substrate is moved under the laser beam depositing a thin cross-section of material to create the desired geometry. Consecutive layers are deposited sequentially to build a 3D part, as shown in Fig. 7e. As an advantage, it can be used to repair old parts besides new ones, and good mechanical properties are easily achievable [28]. However, LENS technology requires some post-finishing processes to ensure better quality such as milling, turning, and polishing, for example. In addition, its geometric limitation is noteworthy for complex surfaces.

The main applications of this AM process in medical field is to produce titanium implants for orthopedic surgeries, being an alternative to PBF processes. Attar et al. [95] compared the mechanical properties of parts produced by LENS and SLM, and found the later yields better tensile resistance. This is due to the finer microstructure of titanium as result of the faster cooling rates in SLM, which was also better for corrosion and wear resistance. Nevertheless, these characteristics have still been found superior in comparison to titanium products manufactured by conventional methods such as casting or hot pressing [96]. A major concern is the fatigue strength as pointed by Harun et al. [97], due to the formation of microcracks between pores. DED processes are behind PBF for manufacturing biocomponents due to versatility and better tolerances and roughness achieved by SLM or EBM for instance. Therefore, the only advantage of LENS would be its easier ability to change between powder feedstock to produce composites with bioceramics. This has been done by Bandyopadhyay [98], and although the authors were more interested in the formation of a low friction tribofilm, this could prove most useful for incorporating HA progressively in the surface of the titanium implant within a single process, dispensing the traditional post-processing by plasma jetting.

3.5 3D binder jet printing (3DP)

The binder jet 3D printing technology is licensed by the Massachusetts Institute of Technology under the commercial name Prometal, and is based on the deposition of a binder onto a powder layer, generating a cluster. In this process, as shown in Fig. 7f, a dust-containing reservoir lifts a platform while a roller distributes over the workpiece construction platform. For layer generation, an inkjet head moves along x–y for printing the sticky material onto the dust layer. This process is called 3DP because of its similarity to the inkjet printing process that is used for two-dimensional paper printing. According to Huang et al. [28], the material is first stabilized by spraying with water droplets to avoid excessive disturbance when struck by the binder. In addition, an infiltration process may be performed during deposition, since the binder might not be enough to guarantee enough green resistance for handling. After the sequential application of layers, unbound dust is removed and the so-called ‘green’ part is subjected to debinding and sintering. At first, the temperature is kept at lower values, enough only to vaporize the binder, whereas later, a high temperature is used to promote diffusion and further strengthen the bonding of the material. In some cases, hot isostatic pressing is performed at post-processing to reduce porosity, which may further lead to yield stresses higher than 400 MPa.

This process can be applied to the production of metal, ceramics, and ceramic composites. As an advantage, it enables fast and low-cost material manufacturing. Regarding the deposition thickness, this technology provides layer thickness between 0.089 and 0.2 mm, while the resolution is between 600 × 540 DPI. In addition, it can be said that this overall accuracy is approximately 0.125 mm [28]. Just like in EBM and SLM, this process can be used with different powders within the same part to produce complex alloys, composites, and varying properties throughout the volume [64].

This AM technology is one of the fastest technologies in terms of printing time. However, there are some limitations, such as high porosity after sinterization, size limitation and too many post-processing stages. Although the consolidated inkjet technology lowers the cost of the printer, most sintering ovens and HIP equipment are quite expensive [28]. Just like in SLS and EBM, the powders require careful handling, and the many variables related to the binder and sintering further increase the complexity when adjusting material and process parameters [40].

The application of 3DP by binder jetting has been mostly applied to the production of metal and ceramic parts or scaffolds for bone and joint surgeries [99]. Most common materials for these purposes are Ti–6Al–4V alloy and calcium phosphates, but there has also been research with biodegradable iron alloys too [100]. Seidenstuecker et al. [101] produced composite scaffolds from bioglass and tricalcium phosphate which favored cell growth, but with poor mechanical resistance. Sun et al. [102] observed that the use of fine powders provide better resistance after sintering, but create more difficulty during printing because of low flowability in the powder bed. Very low resistance was obtained by de Melo et al. [103] in the production of TCP and silica scaffolds, but their results are still close to the lower strength of spongeous bone and the high porosity of 70% could be of benefit for replacing this tissue. On the other hand, Shao et al. [104] employed wollastonite containing magnesium and obtained flexural strength of 31 MPa, which is fairly close to that of human cortical bone, but at the cost of lower porosity. There is great variation in final mechanical properties since even the type of binder may interfere [105, 106].

Drug delivery systems are another major field for application of 3DP. Wu et al. incorporated antibiotics in polymeric bioresorbable bone implants and treated infected rabbits with success [107], but it is unlikely similar implants for larger animals would present adequate resistance. The drug release principle can be applied for subcutaneous implants and resorbable sutures aswell [108], which could increase in the next years to attend patient-specific needs. Pills and tablets can also be tailored to combine several pharmaceutical ingredients that are released in the body at different rates or in different organs of the digestive system [109], but most techniques are not yet fit for mass production at reasonable price.

The last application is the construction of 3D models for surgery planning and medical teaching purposes [110]. Kondo et al. [111] used this AM technology to produce transparent brain models showing colorful regions simulating tumors, taking advantage of the diverse color printing capability. Tai et al. also produced bone models with different volume composition to simulate resistance to drilling during surgery [112]. Although the production of composite models supersedes the other AM processes, the main goal for 3DP currently is to incorporate growth factors, stem cells or drug release capabilities within mechanical resistant parts [73], which has not been achieved yet [113].

3.6 Inkjet printing (IJP)

This technology consists of the use of inkjet printing to deposit thin layers of photopolymer (up to 16 microns) that are cured by heat or ultraviolet rays after each layer has finished printing [28]. The inkjet head moves on the “x” and “y” and after completion of each layer, the construction platform moves in z direction [114]. The inkjet technology was extensively developed for conventional 2D printing in paper using piezoelectric valves to deposit droplets of liquid material, and this same principle is employed in this AM technique, as displayed in Fig. 7c [38].

Materials typically used are based on acrylates, epoxes, thermoplastics and wax, which differ from each other in terms of the solidification process of these materials. This allows these technologies to be divided into two groups: photopolymerizable IJP and thermopolymerizable IJP. For example, the EDEN equipment, developed by Objet, is an IJP type of light-curing material and its inkjet head deposits material through 1536 individual nozzles arranged in line simultaneously in 15 μm layers. In this process the degree of polymerization of the final part is usually higher than SLA, and so the need for post-processing is not identified [115].

The main advantages of this process is its ability of producing parts with high degree of precision and surface finish at high resolution. The technology is well consolidated which lowers the price of equipment and feedstock. In addition, one great capability is to vary the ink source within the layers to produce colored parts, polymer composites, and seed living cells in polymeric scaffolds [116]. The disadvantages are the poor strength, durability of materials, and mechanical properties, besides the same limitations of SLA in terms of photocurable polymers. Products built on this technology are considered more fragile when compared to stereolithography and FDM.

The biomedical applications of IJP are very similar to some of binder jetting. The production of models for didactic purposes and surgery planning is a common trend [117], and there are studies for commercial application in fast production of dental trays [118] due to better geometric tolerances than SLA. There is usually a misconcept regarding IJP as an AM process for production of enhanced pharmaceutical pills and trablets [73]. The lack of UV light and photocurable resins in most reported cases [119] characterize the process as the binder jetting technique instead. Actually, the use of UV light can degrade the active principles in the pills or in other possible applications like bioprinting, and therefore, this process is fairly limited in medical field. However, it may prove more relevant in biosciences in the future for building lattice structures with low form errors [120] that could serve as ultra light structure for tissue engineering. As an example, Egan et al. [121] produced polymer beam-based lattices for bone fusion with spinal cage, presenting up to 213 MPa of elasticity modulus and 50% porosity.

3.7 Laminated object manufacturing (LOM)

This technology combines additive and subtractive techniques for building the layers made by adhesive laminate materials cut by laser [28], as displayed in Fig. 7g. Laser beam velocity and focus are adjusted so that the depth of cut corresponds exactly to the thickness of the layer, thus, avoiding damage to the underlying material.

A variety of materials may be used, including paper, metals, plastics, fabrics, synthetic materials and composites. LOM technology is cheap and can be automated to require little attention from an operator, making it easy to produce large parts. However, it does have some accuracy issues resulting in dimensional stability problems. It may generate some internal cavities that affect product quality. Besides that, postproduction time is required to eliminate waste and, in some cases, secondary processes are required to generate parts more accurately [122]. Disadvantages are related to material waste (resulting from the combination of additive and subtractive techniques), and the difficulty of producing complex internal cavities [28]. In addition, in the case of metals, the bonding has much lower resistance than the alloys itself, making it less attractive in comparions to the other AM processes.

Regarding biomedical applications, LOM is mostly restricted to manufacturing models for teaching and surgery planning [156], but mostly other methods are more suitable. One possible application that could develop in the future is the manufacturing of microporous scaffolds from ceramic materials. Zhang et al. [123] were able to produce alumina scaffolds with regular pores of 80 μm and 50% overall porosity. Although these could be useful as membranes, their stacking in LOM would have the same resistance issues typical from this AM process.

3.8 Summary and comparison of AM processes

Each additive manufacturing process provides unique and interesting features. Thus, through the comparative analysis among these technologies, it can become possible to identify the prime advantages and disadvantages of each of these processes. Table 2 summarizes the advantages and disadvantages of AM techniques presented in this text, and Table 3 presents a survey of the leading technologies marketed in Europe, showing cost and resolution ranges.

In addition, it can be observed that despite the high resolution, these technologies are subjected to process variations, resulting in dimensional distortions in the final product. This analysis can be clearly seen in Fig. 8, where the warping of a part manufactured by FDM at the end of the manufacturing process is presented [127]. In the study performed by Domingos et al. [56], it was possible to identify dimensional differences provided by the 4 most widespread AM processes today. The summary of the main results found was statistically discussed. In Table 4, this analysis is presented, where stereolithography is indicated as the most accurate process among the studied.

Bending of part manufactured by FDM process [127]

4 Biomaterials: evolution and application in manufacturing of biomedical devices

Biomaterials comprise a representative fraction of the products used in healthcare. Biomedical devices (such as biosensors, blood circulation tubes, hemodialysis systems etc.), implantable materials (such as sutures, plaques, bone substitutes, screens or meshes, heart valves, lenses, and teeth), drug delivery devices (in the form of films, subdermal implants, and particles), and artificial organs (such as heart, kidney, liver, pancreas, lungs, and skin) are some of the examples of healthcare products made up of various biomaterials. According to Paital and Dahotre [128], biomaterials are metallic, ceramic, polymeric or composite materials designed to function adequately in a bioenvironment. They are also used to replace or repair damaged structures, diseased or damaged tissues, and “diseased” organs.

The field of biomaterials gained due recognition after the first meeting on this subject at Clemson University, South Carolina in 1969 [128]. In 1974, at the request of the World Health Organization (WHO), the term “biomaterial” was defined as “a systemically and pharmacologically inert substance designed for implantation or incorporation into living tissue”, while it was later defined as “a nonviable material used in a medical device intended to interact with biological systems” in the 1986 Conference of the European Society for Biomaterials, held in England. Due to the wide range of products that emerged or are under research, the definition had to evolve. According to Bose et al. [11], “biomaterial” can be used to design the functional restoration of different tissues to improve human health and quality of life, whether natural or synthetic.

The use of these materials is not recent, and their application in correcting the most diverse types of problems related to human health goes back to antiquity [129]. For example, there are records of the use of flax and gold sutures in ancient Egypt (2000 BC), cat intestines in Europe during the middle ages, artificial teeth made by Mayan shells (600 BC), iron by the French (200 BC), gold and wood by the Romans, Chinese, and Aztecs. Bone substitutes made of wood were also found in ancient Egypt and Europe in the middle ages, and efficient osseointegration was observed. There are also records of biomaterials in the early twentieth century as an application of wound healing.

The characterization of a biomaterial does not enable its use as a biocomponent, but can and should be used as a pre-selection of conditions to be tested in the following steps. Materials “approved” at this stage will have to undergo laboratory tests in cell culture (in vitro tests) and then in vivo (animal) tests, and finally clinical tests. However, in this sequence, the tests become increasingly expensive and complex. Therefore, the same should be restricted to the fewest possible conditions. Zhou et al. [15] defined some criteria that a material must meet to be identified as a biomaterial:

-

The material must be biocompatible, i.e., its presence should not cause short or long-term damage to the implant site or the immune system.

-

Tissues should not cause degradation of implanted material, such as corrosion to metals unless tolerable.

-

Material must be biofunctional, i.e., it must have the proper characteristics to fulfill the desired function (static or dynamic) for the desired period of time.

-

The material must be sterilizable.

Usages and sale of biocomponents in each country is supervised by the pertinent regulatory agency(s). In the United States, the product must be approved by FDA before market introduction, who has already discussed and published that AM products must undertake the same regulatory pathways of the ones produced by other methods. As discussed by Di Prima et al. [130], the FDA certification is granted to products with specified intended uses, manufactured by determined methods and equipment, and not a material or technology with unspecified application. Nevertheless, the certification process can be simplified if it is proved the AM product is capable of fulfilling the functions of an already marketed similar item, which means a new model or adaptation of AM biocomponents might be more easily approved if the same material and technology have already been approved for a similar item.

According to Paital and Dahotre [128], surgical procedures with the application of biomaterials were not very successful, since they caused infections after surgery. The discovery of an aseptic surgical technique, developed by Joseph Lister in the 1960s, caused the turning point in the application of biomaterials. The first successful cases of orthopedic implant surgical applications were related to skeletal system corrections. They consisted of the application of bone fracture fixation plates, but at the given mechanical design deficiencies, these plates broke very easily due to their very thin thickness and flat geometry (they had straight corners, which are susceptible to stress concentration). Similarly, the use of materials such as vanadium steel (selected because of improved mechanical properties) had opposite consequences to the desired results. It got quickly eroded, subsequently, causing adverse effects on rehabilitation processes [131].

However, in the 1930s, with the introduction of stainless steels and cobalt–chromium (CoCr) alloys, there was an increase in successful cases of fracture fixation, which led to the first interventions to replace joints. Table 5 describes some of the most important developments at implant level chronologically.

In the beginning, bioinert materials (focus on the material itself) were sought. Over the time, the goal became the bioactivity of biomaterials. Recently, the goal has become the regeneration of a functional tissue indeed, with the focus on the biological aspect [129]. In other words, initially, the objective was to obtain biocompatible materials that could replace a damaged tissue and provide mechanical support, with minimal biological response of the patient. Over the years, attempts were made to increase the life of the implants by their interaction with the host tissue interface. Later, the focus became the development of biodegradable materials capable of being incorporated or absorbed (after dissolution). In recent years, biomimetic concept came into notice, looking for actively participating materials in the recovery process. It acts on the tissue specifically with stimulation at the cellular level.

Figure 9 shows the evolution in the development and use of biomaterials. It is possible to observe that the materials used for clinical purposes are mostly from biocompatible, bioactive, and biodegradable categories. However, the most researched are those which fall in the category of bioactive, biodegradable, and biomimetic materials.

Evolution of functionality and regenerative capacity of biomaterials throughout its development [111]

Biomaterials are used in the manufacturing of medical devices and can directly interact with the biological systems [131]. Table 6 presents the main application areas of biomaterials. The performance of biomaterials in relation to the human body can be classified depending on their perspective. In other words, it can be considered from the point of view of a particular area where there is a problem that needs to be solved. There can be several steps involved from identifying the need of a biomaterial to the use and final analysis of the product (Fig. 10). In general, the need may be the treatment of a disease, the replacement of an organ or the purely cosmetic use, etc.

Following is the design and synthesis of the materials for various tests (composition, structure, mechanical properties, toxicology, bioreaction of the material, and biostability). Based on the choice of the most appropriate ones, manufacturing followed by sterilization and packaging of the biomaterial (which is then directed to more detailed toxicology, in vitro and in vivo biointeraction testing) will be performed. Next focus is on the regulatory aspects related to pre-market approval, initial clinical studies, clinical screening and long-term follow-up. Development continues even after approval and clinical use of the biomaterial, with the analysis and registration of explants extracted from patients to understand possible failures for their correction.

The inclusion of biomaterials has a major impact on human life. These materials, for example, can be used as an excellent way to restore defects using facial prostheses when reconstruction by surgery is not optimal. Figures 11 and 12 present applications of biomaterials (produced by additive manufacturing) in various parts of the human body.

Dental device manufactured by additive manufacturing [17]

Titanium custom prosthesis design [132]

Figure 13 shows the application of a titanium alloy prosthesis to the maxillofacial reconstruction tailored to the patient. This jaw implant was developed to accommodate a bone graft inside, creating anchors on the surface, in which the graft evolves and expands into the existing healthy bone.

a Filling the interior of the titanium alloy implant with bone graft; b coverage with cortical bone; c implant placement [133]

Figure 14 shows the application of a metal prosthesis applied to the healthy part of the femoral. It fits into the acetabular pelvic cavity and is coated with ultra-high-molecular weight polyethylene (UHMWPE) to resist friction wear [134]. This type of prosthesis has a normal average life cycle of 10–15 years. Some more typical applications using the same materials described in the previous examples are the knee, elbow, ankle, and wrist prosthesis, as shown in Fig. 15.

Components in different models of hip joint implant [135]

Implant examples for total arthroplasty of knee, elbow, ankle, shoulder, and hip [136]

Other applications of biocompatible alloys are the immobilization of bone fractures through plates. They are usually marketed in standard models. The metal plates, screws, and threads are used during the healing process to join and consolidate the fractured bone segments (Fig. 16). Depending on the extent of the injury, these devices may or may not be removed after the bone has fully recovered, so there may be some interaction between the soft tissue and the screws, which is not harmful.

a Metal plates, threading, and screws used for bone fixation; b radiograph and outcome of tibial implantation of a fully recovered patient [137]

Still other implants serve to connect the spinal segments when the vertebral bones fracture due to osteoporosis or back injury. This procedure involves the implementation of a metal cage, which will accommodate the particles of the patient's own bone to allow the formation of new bone that will adjust with the adjacent vertebrae in future (Fig. 17).

Metal implants of metallic segments of the spine [134]

Orthodontics is another large area of large biomaterials acting as an alternative to traditional dentures. Dental implants are implanted directly into the bone and can replace each missing tooth. The implant is subsequently covered at the top by a ceramic crown (Fig. 18). The great advantage of these implants over dentures is that they transmit stress to the jaw, stimulate it, and thus, result into bone resorption and growth over time.

Dental implants [134]

Another application of biomaterials is their use as bone plates and meshes for cranial reconstruction (Fig. 19), both made to order (cranioplasty, maxillofacial, etc.). They are fixed to the skull with the help of titanium screws. Bone plates are ductile, come in a variety of shapes, and have sizes designed for the particular attachments.

a Titanium meshes for cranial reconstruction; b mesh implant and titanium mini-plate for craniofacial reconstruction [132]

Different biodegradable materials have been used lately for the manufacturing of these screws to eliminate a series of complications associated with the use of some metallic screws, such as the need to remove it after it is done with its purpose. This removal requires a second surgical intervention. The cost of removal procedures for such metal devices is enormous compared to treatment using biodegradable materials. On the other hand, the psychological advantages for the patient, in being able to treat his fracture with a single surgical intervention, are profoundly striking.

Biodegradability is also useful for stent making. These devices are used to treat cardiac patients with narrowing of the heart arteries. They are placed in arteries of the heart or in peripheral vessels in other parts of the body, which are partially obstructed by plaques of fat or calcium (Fig. 20). Over the time, this stent is absorbed by the cells to become part of the artery—an essential process for its success as removal would cause further damage to the artery. They can be made of metal alloys or polymers, depending on the characteristics required by each type of surgery and specifications from medical doctors [138]. Some require more flexibility to ease implantation, while others need more chemical stability, which is why the development of new and custom products depends on the joint work between physicians and engineers.

Heart stenting to improve blood flow around organs [139]

Laser cutting is a consolidated technique for stent manufacturing [140], but AM through selective laser melting (SLM) technique is a promising operation [141]. On the other hand, researchers at the Eindhoven University of Technology in the Netherlands published a proof of concept article on biodegradable, 3D printed, and self-expanding stents. Stents are designed to be minimally invasive, supporting narrow or weak heart arteries, especially in cases involving children. Eindhoven stents are made up of an absorbable polymer rather than a metal alloy (CoCr, NiTi, among others) to promote body comfort and acceptance. Using the design parameters of a typical nitinol stent, the researchers created a computerized design of a plastic polymer stent. Through simulated crush tests, the design of the Thermoplastic Co-Polyester (TPC) FDM printed stent is modified in degrees until it meets or exceeds the required response obtained on nitinol.

5 The trade-in biomaterials

Trade-related to the area of biomaterials is significant from the point of view of the number of units sold annually and the observed financial movement. This can be conveniently segmented based on two different criteria [142]:

-

1.

Types of compounds from which biomaterials are constituted, such as metals, ceramics, polymers, and materials of natural origin.

-

2.

Form of application of biomaterial, such as orthopedic, cardiovascular, dental, ophthalmic, plastic surgery, engineering, tissue, injury treatment, neurological, and central nervous system disorders. It also includes devices with other applications such as gastrointestinal and urinary, or as drug delivery systems, and for bariatric surgery.

According to Tofail et al. [142], trade-in orthopedic implants reached $ 57.9 billion in 2018. Although there is a conflicting record of prediction regarding this segment, orthopedic biomaterials are undoubtedly highly economic. Another noteworthy branch is biomaterials for cardiovascular applications, with an estimated market share of 34.5%. Although metallic biomaterials currently dominate the world market by about 50%. The sharp growth of the polymeric biomaterials market is expected in the near future due to more appropriate characteristics such as flexibility, elasticity, biological inertia, longevity, and biocompatibility. According to Ghasemi-Mobarakeh et al. [143], the term biocompatibility is defined as: “The ability of a material to perform its desired functions in relation to an organism to interact with living systems without having any risk of injury, toxicity or rejection by the immune system.” This means that the implant should not release substances in the body that could cause systemic damage to the patient.

In 2000, the world market for biomaterials was estimated at 16.9 billion euros, with a growth rate of 12% per year, which means that it exceeded 110 billion reais in 2010. In this sense, a considerable progress is expected in the field of biomedical engineering. This basically aims at applications in the field of regenerative medicine, which will certainly require significant improvements in the design and execution of the supports used for the growth of cells of normal tissues or even cells. Scaffolds for instance have functions that go far beyond providing a biocompatible matrix with porosity, roughness, three-dimensional structure, degradability, mechanical and mass-transport properties, including potential growth stimulation, cell migration, interaction, and differentiation. It may further dispense growth factors and other appropriate biochemical signals to cells, which can be incorporated into or adsorbed on them, to provide a microenvironment that refers to the extracellular matrix. Only in the stem cell-based therapies segment it is estimated that the global market will reach US $ 330 million by 2020 Xie et al. [132].

6 Classification of biomaterials

It is not possible to generalize what the required characteristics of biomaterials should be, as they depend fundamentally on their applications. Some properties are often evaluated so that the device design can be carried out effectively and economically. In this sense, biological properties are highlighted, such as biocompatibility, often associated with hemocompatibility, cytotoxicity, allergenicity, adhesion stimulation, and cell proliferation. According to Devgan and Sidhu [6], such properties have a vital requirement associated with the ability to attach tissues within the human body without causing unwanted discomfort. The posterior osseointegration process supports the regeneration of new bone by encapsulating new tissues that spread around the reconstructed bone and the implant surface.

Physical properties (such as surface morphology, surface energy, anatomical fit, roughness, porosity, color, transparency, and permeability), mechanical properties (such as tensile strength, elongation, and flexibility), and chemical properties (such as density, stability, sterilization resistance, and shape) also play their considerable role. This comprehensive set of parameters in represented in Fig. 21.

Demonstration of other factors that are considered for biomaterial selection [6].

In general, biomaterials encompass a broad class of natural or synthetic substances with mechanical, physical, and chemical properties suitable for the recovery of original functions of tissues, organs or systems. Synthetic materials are divided into metals and their alloys, polymers, composites, and ceramic materials. Tables 7 and 8 show, respectively, the types of materials, their classification, main applications, advantages and disadvantages of artificial and natural biomaterials.

6.1 Metallic biomaterials

Metallic biomaterials, compared to other ceramic and polymeric biomaterials, have the ability to withstand higher stresses, even of a dynamic nature. This is why various alloys are used as structural materials for skeletal reconstructions subjected to high load application. Major applications of metal biomaterials include fracture fixation wires, screws and plates, dental implants and joint replacement prostheses [144]. Moreover, metals can be used in the manufacturing of artificial heart valves and expandable stents, which require, in addition appropriate mechanical strength, durability, and visualization on X-ray images [145]. Good electrical conductivity, another common attribute of these materials, has facilitated neuromuscular stimulation devices, such as cardiac pacemakers [146].

The great versatility of metals for biomedical use is also due to the possibility of their surface polishing and abrasion. Sterilization is responsible for the extensive application of metals in surgical instrumentation, such as scissors, needles, forceps, and retractors. In addition, the following properties are highly desired in metallic biomedical devices:

(a) Corrosion resistance

Corrosion occurs when chemicals contained in human body fluids react with the metal implant, forming oxides or other compounds (resulting from a chemical reaction). This may weaken the implant and the particles produced may lodge in the tissues around the metallic implant, and in some cases may increase the concentration of metals in the blood [6]. Thus, selecting a material that has high corrosion resistance is crucial for the success of the implanted component.

(b) Biocompatibility

Biocompatibility is the surface exhibiting the formation of oxide films. The oxides also act as a passivation layer to protect the surface against corrosion. The examples are chromium oxide in stainless steels and CoCr (cobalt–chromium) alloys, or titanium dioxide in titanium alloys. The alumina-identical oxide films exhibit inert behavior in relation to the prosthesis processing environment up to its packaging or even during the surgical intervention [147].

(c) Biofunctionality

Biofunctionality is the relationship between the mechanical and physical properties of the material compatible with its specific function in the human body. Some mechanical properties such as modulus of elasticity, fatigue strength, fracture strength, tensile strength, and elongation, should be considered for the selection of biocompatible alloys.

To be safely applied to the human body, metals or alloys must meet other requirements: not producing inflammatory, toxic or allergic reactions, being chemically stable and preventing degradation in the biological environment. Table 9 presents some possible causes of degenerative and inflammatory problems due to the high rate of implant degradation.

In the case of bone implants, in addition to modulus of elasticity similar to that of human bone and fatigue strength, high adhesion strength between the osteoblasts and the implant should also be required. In general, the modulus of elasticity of bone is much smaller compared to metallic materials commonly used as biomaterials. Devgan and Sidhu [6] stated that depending on the type of human bone or joints, bone modulus values range from 4 to 30 GPa, which is considerably lower than the implanted material modulus (Table 10).

Research indicates that insufficient load transfer from the implant to adjacent areas may result in bone resorption and eventual implant loosening. Due to this fact, there is great interest in the production of biomaterials with low modulus of elasticity (closer to that of bone), which can stimulate a better stress distribution. This can be done by altering geometric and manufacturing parameters of sponge or lattice cell structures until the proper mechanical response is obtained.

In a recent work, Li et al. [149] studied that how varying geometry of cell units and their interconnection would change stiffness, energy absorption, maximum compressive strength, and modulus strength of cellular panels produced by SLM. Using AlSi10Mg alloy, the later property ranged from 99 to 305 MPa. Besides varying geometry of cells between different parts, Plocher and Panesar [150] also evaluated how lattices produced by FDM using carbon fiber-reinforced Nylon would behave with graded density within a single part. Apart from the effect of fine-tuning of implant mechanical properties, the porosity could enable cell growth intertwined in these structures. Moreover, active chemical compounds to further induce cell attachment and replication could be incorporated in such parts, either after additive manufacturing or mixed in the powder and wire stock used in SLM and FDM processes, respectively.

Once implanted, biomaterials remain in contact with body fluid, which consists of an aqueous solution containing dissolved oxygen, proteins, and various ions such as chloride and hydroxides [151]. In the case of dental implants or orthodontic materials, metal alloys are also susceptible to temperature and pH variations, presence of microbial biofilm, and the physical and chemical properties of ingested foods. These media can be aggressive to metals, causing their corrosion. In addition to these factors, most implants work under the action of mechanical loads that generate friction, slip and, consequently, the possible release of metallic particles [152].

Noble metals, such as gold and silver, are not susceptible to corrosive processes. However, other attributes such as high density, insufficient strength, and high cost make their orthopedic applications unfeasible [131].

In general, the resistance to this process comes from a thin oxide film formed spontaneously by exposure of the metal surface to air. This film, in the form of a passivation layer, prevents ion exchange, and thus, protects the surface. Some factors, however, may compromise the corrosion resistance, such as lack of homogeneity in the microstructure related to variation in composition, surface deformation, presence of impurities, precipitation, segregation, and inclusions. Thus, during the manufacturing process, to improve corrosion resistance by strengthening the protective film, implants may undergo further treatment and deposition of oxides on their surfaces.

According to Brockett et al. [153], a disadvantage of metals relates to the possible noise resulting from friction in implants composed of two metals in contact. The incidence of this problem in patients with hip implants, for example, can be as high as 10% and usually begins within 6 months–2 years after surgery. In addition, the high metal density may lead to high mass implants which are uncomfortable for the patient. Specific characteristics of some categories of metals most often used as biomaterials components are displayed in Table 11.

-

(i)

Co–Cr alloys

In the 1930s, Co–Cr–Mo (Vitallium) alloys first began to be used as casting alloys for dental applications. Later, in the 1940s, they were adapted for orthopedic applications. Nowadays, these materials have been mainly used in the manufacture of knee, shoulder, and hip orthopedic prostheses, as well as fracture fixation devices, maxillofacial, and dental implants [128]. These alloys are non-magnetic and highly resistant to wear, heat and corrosion. The wear resistance of Co–Cr alloys exceeds that of stainless steels and titanium alloys. The disadvantages of these alloys are related to their low plasticity and machinability [145].

According to ASTM, Co–Cr alloys used for implants can be divided into two distinct groups as shown in Table 11: cast and worked. Out of these alloys, Co28Cr6Mo and Co35Ni20Cr10Mo are the most used for the manufacturing of joint implants.

The ASTM F75 alloy is one of the most commonly used in implant casting. Its main feature is the high resistance to corrosion in harsh environments, particularly in contact with the fluids in the human body. The ASTM F75 alloy used in implant manufacturing requires a precision casting process. Unlike the melting temperature of Co–Cr binary alloys (with melting temperature ranges from 1450 ℃ at 1500 ℃), the carbon content (0.5%) of ASTM F75 alloy allows its melting temperature to be lowered to 1350 ºC, facilitating the melting and casting process. Higher quality castings can be obtained through the process of melting and vacuum casting to prevent oxidation [154]. Table 12 shows the chemical composition of the alloys mentioned in Table 11.

(ii) Stainless steels

Stainless steels are iron-based alloys, which contain carbon ranging from 0.03 to 1%, and at least 10.5% chromium. The most commonly used stainless steel in implants is rated 316L, which belongs to the group of austenitic stainless steels. The presence of chromium is important because it causes a corrosion resistant oxide layer [147]. The presence of molybdenum improves corrosion resistance at grain boundaries [155]. Nickel is the main element that stabilizes the austenitic form of iron and improves corrosion resistance. However, the presence of nickel alloys in implant manufacturing has been challenged due to the possible nickel toxicity with the human body [156] causing problems (in some situations) such as allergies, cancer, and genotoxic or mutagens [157]. Still, nickel and its alloys may be used in additive manufacturing of surgical equipment such as the instruments displayed in Fig. 22, which are used to manipulate knee ligaments during anterior cruciate ligament (ACL) repair surgery. In this case, the contact with the tissue is made only during surgery so there is no chance of it being released in the body.

Hence, investigations were performed to eliminate the use of nickel in the chemical composition of stainless steel alloys, such as the case of Carpenter Technology Corporation’s BioDur 108 alloy. This alloy does not contain nickel in its composition, but in comparison to alloy 316L, it has a high level of nitrogen to maintain the austenitic structure, which allows an improvement in its mechanical properties, namely the tensile strength, fatigue strength, and corrosion resistance [155].

These surgery guides for ACL repair were printed with Inconel 718 by DMLM [17]

(iii) Titanium and its alloys

Titanium is a low-density element (4.5 g/cm3), with approximately 60% of iron density. With the addition of alloying elements, its properties can be further improved. The increasing use of this material is mainly due to its low modulus of elasticity among metals (100 GPa), and superior biocompatibility and corrosion resistance compared to stainless steel and Co–Cr alloys. It was these attractive features that began their introduction, initially of pure titanium, later the α + β alloys (Ti–Al6–V4) and, recently, the β alloys.

Another additional advantage of this material is the greater tendency of osseointegration, an important feature for long-lasting implants. The reduced or nonexistent reaction of titanium with the tissues surrounding the implant is due to the passivation on the metal surface formed by titanium dioxide (TiO2) film, usually of nanometer thickness [145].

In recent years, a great effort has been made to formulate new titanium β alloys with biocompatible alloying elements such as niobium, tantalum, zirconium, and molybdenum for implant applications. The competitive advantage of β alloys over α + β alloys lies in their high strength and low modulus of elasticity. Another advantage in terms of precision casting of β alloys is that it is possible to obtain mechanical characteristics identical to the forged β alloys [158]. Other new β alloy implants include Ti15Mo5Zr3Al, Ti29Nb13Ta46Zr, and Ti29Nb13Ta4Mo. Their properties as well as microstructure are similar to those previously described [158].

Among the different alloys involving titanium, the Ni–Ti equiatomic alloy, known as Nitinol, has high prominence due to its remarkable shape memory properties, superelasticity, and fatigue and torsion resistance. Shape memory property refers to the ability of the material to return to its original shape after deformation by increasing temperature. Nitinol’s elastic behavior allows it to be deformed up to 20 times by re-engaging the original dimensions after stress release, which is ideal for stent implantation.

6.2 Ceramic biomaterials

Man discovered ceramics thousands of years ago when he found that the clay placed in fire turns into a rigid and hard mass. Ceramics can be defined as composed of metallic and non-metallic elements, for example Al2O3, MgO, and TiO2, which are ordinary ceramic materials.

Bioceramics have been used since 1969 to solve dental defects and orthopedics. These materials exhibit excellent properties such as oxidation and corrosion resistance, high elastic modulus, and excellent biological compatibility [132]. Applications cover the most diverse areas, such as diagnostic instruments (thermometers, endoscopy fibers), orthopedic prostheses, devices for dental and maxillofacial reconstruction, heart valves, artificial tracheas, and bone fillers. The wide field of application is largely due to the crystallographic properties and superior chemical compatibility of ceramics with the physiological environment and rigid tissues, such as bones and teeth [159].