Abstract

Metal casting foundries all across USA are increasingly adopting the recent development in additive manufacturing including 3D sand printing (3DSP) due to its unique ability to fabricate molds and cores without any tooling requirement such as patterns, cores, core boxes, flasks among others. This new method of rapid mold fabrication can accelerate process cycle times, reduce shrinkage defects, offer part consolidation, functional integration and customization that could facilitate the growth of foundry industries. This study demonstrates how the adoption of 3DSP technology has contributed to a conventional ferrous metal casting foundry that specializes in manufacturing impellers, turbine housings and other mining equipment. Four industrial case studies are presented to illustrate novel opportunities via 3DSP. These case studies validate that 3DSP has the ability to (1) reduce shrinkage by allowing casting in optimal orientation without hard-tooling requirements, (2) reduce lead time through rapid mold fabrication by easier facilitation of nesting multiple parts into a single mold, (3) allow hybrid molding by integrating 3DSP with conventional mold making and (4) fabricate tooling-less complex castings, respectively. Findings from this study would help foundries rethink their design process from traditional pattern-drawing to a new and radical freeform-based design process via 3DSP.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction and Background

Based on production capacity, sand casting foundries can be broadly divided into two categories: large production run and medium-to-small production run industries. In the latter case, foundries could take as long as 3–8 weeks to produce castings for each design. The patterns and core boxes in the latter case might never be used again or would be used only a few times till gradual degradation over the years causes the pattern to lose its dimensional conformability. Foundries that make complex castings in smaller batches face several problems as listed below1:

Patterns and core boxes

Patterns are conventionally manufactured by joining wooden sheets and machining. This operation requires highly skilled labor and is the most expensive processing step with significantly high lead time.2 Therefore, design iterations are very expensive and laborious to perform.

After initial casting runs, patterns are usually stored in a warehouse until subsequent production runs. The pattern storage requires significant amount of space, expensive to operate and do not directly generate any revenue.

Patterns are usually made of wood which is very sensitive to environmental conditions. A prolonged storage of patterns and core boxes results in a loss of dimensional conformability.3 Preservation of wood over a long period of time also demands explicit environmental specifications for storage space that could often be expensive.

Mold making

The requirement to draw the pattern out of the mold limits the feasibilities of geometries that could be cast.

Because of the necessity to draw the pattern out, drafts must be applied to all faces that are outward pointing perpendicular to the draw direction.4

Undercuts hinder the withdrawal of the pattern from the mold and which otherwise would require additional cores.4

Functional Performance

Often sub-optimal geometries are employed in castings, gating and feeding systems because of the geometrical limitations of traditional mold-making process.5

These inherent challenges in traditional sand casting have been detrimental to the metal casting industries. Compounded by higher labor costs in the USA, industries are forced to outsource manufacturing to countries with cheaper labor markets.6 In order to enhance the sustainability of the foundry sector in the USA, several foundries recently adopted the 3D sand printing (3DSP) additive manufacturing (AM) process because of the process’s versatility in making castings of higher geometrical complexity and flexible sizes without any tooling requirement.7,8 3DSP has ushered in a new age of sophisticated, rapid and reliable form of mold fabrication technology for metal castings. It was found that the average production batch of about half of surveyed foundries in the USA are less than 100 units with a significant number of foundries having a production batch of 5 or less.9 Core consolidation via 3DSP is often used in conjunction with traditional mold making.10 In summary, the most dominant cost driver to integrate 3DSP technology in foundries is the reduced labor cost. The most significant benefit is the reduced lead time and less tooling fabrication time, while the most prohibiting factor for 3DSP integration is the high initial capital cost of acquiring 3D sand printers.9 According to a recent survey, the capital cost accounts for 60% of challenges in acquiring 3DSP capabilities9 and it was shown that foundries are interested in investing in 3DSP if capital acquisition cost was less than $100,000. Production cost of 3DSP parts is relatively inexpensive (< $0.20 per in3,10–$0.13/in3.11). Although the authors are not aware of publicly available surveys that demonstrate the growth of 3DSP AM, the increase in number of machines/machine suppliers (ExOne™, VoxelJet™, EnvisionTEC™), service bureaus (Humtown™, Hoosier Pattern™11) and 3DSP-supplies,12 they hypothesize that it indirectly reflects the potential in 3DSP growth.

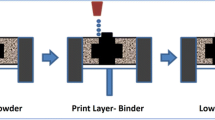

3DSP process falls under binder jetting category with higher production speed among the seven categories in AM processes.13 It uses silica sand as feedstock and selectively deposits binder (e.g., Furan) in a layer-by-layer approach to create complex molds.13 The loose sand is removed to create mold cavities and as there is no explicit requirement of patterns or core boxes, there is no need for drafts to vertical faces and cores for undercuts. The molds are expendable, and therefore, storage space and pattern wear are not applicable. However, 3DSP is a relatively newer technology and there is a knowledge gap that hinders its broader adoption.14 Hence, it is important to rethink traditional design and process-planning approach to fully exploit opportunities presented by 3DSP.

The aim of this research is to evaluate and demonstrate design opportunities to solve some of the foundational problems associated with traditional sand casting process. This is illustrated through examples of practical industrial applications to bridge the knowledge gap between conventional casting foundries and 3DSP process. Further, casting performance of conventional designs is compared against 3DSP’s reengineered designs which can produce freeform geometries without any tooling restrictions. Four case studies are presented to evaluate if design freedom in 3DSP can: (1) reduce shrinkage through allowing optimal casting orientation, (2) reduce lead time by allowing rapid mold fabrication by nesting multiple parts into a single mold, (3) seamlessly integrate with conventional mold making through hybrid molding and (4) fabricate tooling-less complex castings.

The objectives of these four case studies are not mutually exclusive to illustrate the benefits of both individual and integrated design features via 3DSP. Even though part functionality is a distinguishing opportunity for 3DSP as demonstrated in numerous studies,8,10 the research focus of this article is on cast part geometries that cannot be altered. Functional performance and economics are critically evaluated during the redesign of molds via 3DSP. “Literature Review” section presents a brief overview of reported studies on rigging design in traditional sand casting along with the 3DSP process, and its current applications in the metal casting industry. “3DSP for Optimal Casting Orientation” section through “3DSP to Fabricate Complex Castings” section details the four case studies and presents critical discussions pertinent to the respective case studies. Conclusions and future directions are outlined in final section.

Literature Review

3DSP is a binder-jetting-based technology which is part of additive manufacturing (AM, often referred as 3D printing) and is proven to be effective especially in low-volume production runs when compared to traditional molding since long setup time and significant labor expenses are involved in the latter process.15 The mechanical performance and hardness of aluminum castings were found to be identical between 3DSP molds and conventional molds.16 Castings with novel sprue designs that can harness 3DSP’s design freedom are found to have better mechanical performance and reduced porosity and inclusions.17 In another study, 3DSP molds were observed to have significantly higher mechanical performance and lower binder content for gas generation due to the controlled sand and binder distributions.18 Also, the furan binder that is typically used in 3D printed molds was observed to have a better cooling capacity due to the higher amount of heat required for decomposition of the mixture.19 Material properties and dimensional accuracy of the tensile test dumb bells, cylinders and geometric features were investigated for 3D sand-printed samples20 and ceramic binder-jet AM samples.21 However, the existing engineering knowledge does not include casting design rules specifically for 3DSP, thereby limiting its adoption in foundries. It is critical for foundries to produce (1) defect-free castings at (2) minimal cost in low-volume production runs.22 Casting defects can be classified into four categories: (1) filling-related defect, (2) shape related defect, (3) thermal defect and (4) defect by appearance.23 It was found that 90% of the defects in castings are caused by improper design of gating and feeding system.24 These defects are usually resolved using solidification and fluid flow simulations which have become routine and valuable tools in foundries to predict process characteristics such as metal filling pressure, velocity, solidification, hot spot location, stress distribution and porosity.25 Other studies have employed statistical tools, finite element tools, advanced optimization tools, topology optimization algorithms to reduce casting defects.26,27,28,29,30,–31 In the case of casting impellers, computational simulation of different gating designs was conducted to eliminate most casting defects.22 Rejection of castings due to rigging related defects has been reduced by 30% using casting simulation techniques.27 Defect-free casting with no internal porosity has been made possible by optimizing the riser location based on casting simulation studies.30 In summary, redesign of rigging system in functional castings using modeling and simulations has been shown to be successful in minimizing casting defects by several experimental studies.25,31,32,–33 However, no reported studies have experimentally evaluated the design freedom of gating via 3DSP to reduce casting defects (as opposed to redesign the casting).

3DSP for Optimal Casting Orientation

Enhancing directional solidification by strategically employing risers (also known as feeders) to shift shrinkage from the cast part into the riser is an established concept in feeding mechanism.1 Pressure, pressure gradient, thermal gradient, premature solidification and material-dependent solidification rate are major factors in design of feeder systems.1 While having an undersized riser volume is obviously undesired, it is also important to avoid an oversized riser due to higher accumulation of thermal energy. Such concentrated local thermal energy results in reduced cooling rate, undesired coarser microstructures and low yield.34 Therefore, optimal riser geometry and location are required to improve casting performance by reducing feeder-related defects. Unfortunately, the geometry of the cast part limits the riser placement at sub-optimal locations in the mold due to constraints in conventional tooling. Example of one such industrial component is discussed in this section, and the methodology to eliminate shrinkage by redesigning for 3DSP is presented.

Case Study I: Closed Vane Impeller

Conventional Tooling

Impellers are representative of difficult-to-machine castings comprising of highly complex geometries and thin sections. They are the foundational components of turbomachinery in mining, petrochemical and aerospace industries. Closed vane impeller castings enclose the vanes between two shrouds that are separated and parallel to each other. The geometry of the impeller shown in Figure 1 requires parting line that must be parallel to both shrouds due to limitations in conventional mold making. The pattern should be removed, and core needs to be inserted only when the shrouds are parallel to the parting line. The requirement to draw out the tooling to create cavity dictates the orientation of the impeller (i.e., cast part) in the mold. However, it can be observed that the bottom shroud ring is disconnected from any practical feed paths from risers in such orientations.

In the case of conventional tooling, Figure 2a shows the rigged model of the closed vane impeller casting simulated for cast iron. This design uses risers, chromite sand (as mild chills), riser sleeves and bottom gating system with two in-gates. Figure 2b shows the material density function (MDF) of the rigged model35 of conventional tooling featured casting after performing solidification simulations in SOLIDCast 8. MDF is used to visualize the flow of the liquid feed metal and contraction of the casting during and after solidification. An MDF value of 0.995 is the acceptable threshold for porosity in the casting in this study.32 As shown in Figure 2b, the bottom shroud ring has significant porosity despite the provision of large risers and chromite sand chills. This undesired porosity at the shroud ring is prevalent in castings of closed vane impellers via conventional tooling36 and often leads to rejection of the cast part. Therefore, complex, low-volume production runs and expensive castings such as a closed vane impeller provide an opportunity to explore non-traditional rigging design via 3DSP to produce defect-free castings to meet engineering specifications.

(a) Conventional rigged model of closed vane impeller casting along with various elements of rigging system. (b) Iso-surface showing material density function (MDF) [35] based on solidification simulations for conventional rigged model of closed vane impeller casting. Shrinkage porosity is observed in shroud ring.

Methodology for Eliminating Shrinkage Using 3DSP

The rationale for the redesign process lies in the principle that the high volume of metal in the shroud ring requires additional riser with a practical and connected feed path. However, it is difficult to hold a feasible feed path in the horizontal casting orientation in conventional mold-making process. Therefore, an alternative approach is proposed to orient the cast part vertically with its shrouds perpendicular to the direction of gravity as shown in Figure 3a to connect risers to the shroud ring. The presence of intensive and complex undercuts shown in Figures 1 and 3a makes it impossible to produce the mold using conventional tooling techniques.

(a) Vertical casting orientation facilitating access to feed metal to shroud ring. (b) Iso-surface showing material density function (MDF) based on solidification simulations for redesigned rigged model of vertical oriented closed vane impeller casting. No shrinkage porosity is observed in shroud ring.

3D sand printing has the ability to offer unparalleled design freedom and is ideal for such applications. The feasibility via 3DSP to connect risers to shroud rings in vertical orientation enables multiple rigging system possibilities. The redesigned rigging system is developed after numerous iterative casting simulations. This design employed only three risers and a single in-gate as opposed to four risers and two in-gates in conventional mold design. Figure 3b shows MDF of the redesigned rigged closed vane impeller is at 0.995. It can be observed that the cast part has drastically reduced shrinkage porosity when compared to casting from conventional mold making. With advanced chilling provisions such as addition of chromite cores and sleeves, the cast part could be produced without any porosity. Figure 4 provides such example where a parting line that is perpendicular to the plane of shroud has been made possible using 3D sand printing.

Discussion

Often in conventional mold making, the geometry of cast part dictates the orientation of the casting in the mold. However, orientations via traditional mold making cannot always accommodate risers of optimal size and/or position resulting in incomplete feed path. Often, designers in foundries are anticipating the occurrences of shrinkage but are restricted to employing sub-optimal orientations because of limitations in conventional tooling. With introduction of 3DSP technology in a foundry, optimal orientations can be cast without concerns of hard-tooling. This case study establishes the evidence that 3DSP has the ability to incorporate optimal casting orientation when conventional tooling is either impossible or extremely expensive. In addition to reducing casting defects, metallic yield can also be improved by employing freeform risers of optimal geometry at ideal locations.

3DSP for Lead Time Reduction

Introduction

As observed in reported studies,8,9,–10 lead time to fabricate molds and cores can be drastically reduced in foundry operations by 3DSP. Since the build volume ranges in currently available 3DSP systems are in the order of 6′-8′, it can further accelerate the cycle time by consolidating molds and cores required for multiple unique cast parts into a single build, thereby reducing unit AM printing time and potentially, the pouring time (if alloy is the same across different castings). This benefit is illustrated and validated experimentally through an industrial application in this section.

Case Study II: Complex Bracket

Problem Statement

The complex bracket geometry shown in Figure 5a has multiple undercuts and thin features which are extremely difficult to fabricate via conventional tooling. In this instance, eight units of this cast iron bracket was required and 3DSP of individual molds would take several days of print time. This is a common challenge in employing AM technology due to the economic uncertainties in printing a large batch production. However, the large build volume of 3DSP process enabled the authors to conceive a design where all eight cast parts can be incorporated into a single mold. The challenges involved in consolidating multiple complex parts into a single mold will be discussed in the rest of this section.

Nesting of Complex Brackets: Conventional Knowledge Base (Simulation Study)

If all the eight complex brackets were to be assembled into a single mold based on knowledge from conventional tooling, a single sprue would be connected to multiple runners to respective in-gates. After multiple design iterations, a rigging model based on conventional knowledge was developed and shown in Figure 5b. However, this configuration has a higher risk of misrun defects due to solidification of liquid metal prior to filling thinner sections of the cast part. Also, higher thermal energy loss has the potential to freeze feed paths from risers leading to shrinkage-related defects. In addition, misrun defects would be intensified due to lower superheat in alloys with lower freezing range or lower fluidity. Advanced filling systems via 3DSP could enable successful casting of multiple parts within a single mold.

Nesting of Complex Brackets: 3DSP Featured Freeform-Based Rigging: Iteration 1

In this subsection, rigging model featuring 3DSP freeform pouring basin, runner and sprue configurations will be presented. A pouring basin with undercuts and lateral and multiple sprue exits with sprue covers was proposed as a solution for the misrun defect problem in thin-walled castings.5 The objective of redesigning the gating and feeding system is to: (1) reduce 3DSP time by increasing packing factor in the mold and (2) eliminate misrun defect problem along with other casting defects. After several design iterations, reorienting the part by 60° was found optimal to increase metallic yield. The procedure for design iterations and optimization is not included in this report and can be found in literature.25,30,32,33,35 Novel sprue designs were found in literature to increase the strength and reliability of castings.17

Figure 6a shows the redesigned rigging for the consolidated eight cast part system. It can be observed that four non-vertical sprues laterally protrude from pouring basin and each sprue delivers metal to two cast parts through two in-gates. This 3DSP-centric design enables the sprues to function as conventional runners thereby decreasing thermal energy loss. Runner extensions are provided at the end of each sprue to mitigate turbulence in gating system based on a prior study.5 Runner extensions also act as vent holes as they are open to atmosphere. Based on solidification simulations, one full riser and two shared risers per cast part are provided as shown in Figure 6a. Vent holes are also provided at the top of each riser to provide an escape path for gases generated during the liquid metal filling process.

The molds are fabricated using Viridis3D RAM 3D sand printer with 0.4 mm layer thickness, and the loose sand in the cavities is removed prior to pouring. The molds are poured in cast iron, and Figure 6b shows the bottom of as-cast parts after the molds are shaken out. Figure 6c shows one of the eight cast parts after the risers and in-gates are removed from the parent casting. It can be observed that the casting is not completely filled and a misrun defect is observed in one of the brackets. Since this occurred in one of the eight castings, the authors believe that the misrun defect could be due to incomplete removal of the loose sand from the mold pieces rather than from loss of thermal energy. The reorientation of casting by 60° made the arms of the bracket span across several mold pieces leading to trapping of loose sand at difficult to remove locations. In addition, the position of risers made it difficult to access the casting for grinding and cleaning. Cast iron is not easily irreparable and since the arm is a critical structural part of the casting, this casting run was scrapped. Another iteration is required to produce a successful casting and will accommodate all the aforementioned observations to produce a defect-free casting.

Nesting of Complex Brackets: 3DSP Featured Freeform-Based Rigging: Iteration 2

The casting orientation is modified to position the bracket arms parallel to the parting line in order to easily remove loose sand after 3DSP. Based on simulation, each cast part required three independent risers along with a shared side riser for shrinkage free casting as shown in Figure 7a. Another major revision is the provision of four additional sprues to deliver metal at the location of misrun in the previous iteration in order to eliminate the likelihood of misruns due to incomplete filling.

After defining the parting lines, the molds are fabricated and all the mold pieces are completely drained out of loose sand. After pouring, the mold is shaken out, the resulted parent casting is shown in Figure 7b, and the final cast product after cleaning is shown in Figure 7c. It can be observed that the casting is free of misrun defects and shrinkage porosity defects. Location of the risers has been optimized compared to the first iteration to increase its ease of removal.

Fluid flow simulations with 10 s filling duration are performed in FLOWCast module in SOLIDCast 8 version. Figure 8 compares the filling velocity profile of the conventional and 3DSP featured gating system in the second iteration. It can be observed that the conventional-knowledge-based gating system generates very high turbulence with velocities reaching as high as 1.81 m/s in the cast part. On the other hand, 3DSP featured gating system in the second iteration facilitates uniform mold filling with velocities adhering to critical velocity condition of 0.5 m/s.1 It was also observed from thermal history that the conventional-knowledge-based cast part experienced higher temperature drop during filling to form misrun defect. On the other hand, the 3DSP featured casting demonstrated relatively isothermal filling in the casting with significantly lower thermal loss.

Another major takeaway from this case study is the ability to provide drain paths for removal of loose sand in complex molds. Even though 3DSP can make molds of any complexity, the cavities cannot be entirely enclosed within the mold, and therefore, a drain-path must be provided. Though it is typical to provide parting lines at such surfaces, it increases the chance of mold-shift, core-shift and cleaning labor time. The optimal casting orientation is not only affected by the access to risers as shown in case study 1 but also minimizes parting lines as shown in this case study.

This case study demonstrates that design freedom via 3DSP should be carefully coupled with the fundamentals of casting hydrodynamics and thermal management to produce defect-free castings. Draining access to remove the loose sand will be increasingly critical with increase in complexity of the cavity. Parting lines, casting orientation and complexity of the cavity are critical to define the draining paths. The individual mold halves must be perfectly aligned and could be implemented using alignment pins or assembly features. Any misalignment between mold halves would result in mismatch defect in the casting.20

Hybrid Molding

Background and Requirements

Center bearing housing (CBH) made of CD4MCu duplex stainless steel is a large industrial casting typically used in mining industry and often suffers from several subsurface defects that were found in the center bore as shown in Figure 9. Even though stainless steel is easily weldable, the intensity and multitude of subsurface defects made the casting irreparable and resulted in scrapping of the casting. In this industrial application, it was critical to achieve engineering specification and also produce a physical pattern for future conformity.

Case Study III: Center Bearing Housing (Experimental Study)

The porosity found in Figure 9 could be due to lack of either proper feeding system and/or proper gating system. A riser fed the center hub through the circular section at the top of the center hub which is a relatively narrow feed path to feed a high-aspect-ratio hollow cylinder. Upon observations, the authors hypothesize that top feeding mechanism will fail to eliminate shrinkage porosity from long hollow cylinders, and therefore, risers are needed inside the casting to render defect-free casting. According to the final engineering specifications, the inner surface of the hub needs to be machined. Since machining process (i.e., center-boring) is inevitable, risers could be placed inside the casting. This is accomplished by casting the center hub as a solid cylinder as opposed to a hollow cylinder. This configuration drives the shrinkage porosity to occur near the center of the solid cylinder as opposed to the surface. Since center-boring operation will always be required, the shrinkage porosity near the center will always be removed during machining. This method is highly suitable only for ductile alloys due to favorable machinability such as stainless steel in this application. To promote directional solidification, a cone-shaped cavity is provided at the bottom of the solid cylinder as shown in Figure 10. It should be noted that in the conventional mold design, a top riser and three additional side risers at the intersection of ribs and center hub are employed to feed the ribs. However, in the redesigned 3DSP mold design, the solid cylinder acts as the riser and feeding system for the entire casting.

In the previous design of gating system, a non-tapered straight sprue was used. Though a multi-gate runner system was employed, the cross section of the runner after each in-gate was not reduced which resulted in non-uniform pressure conditions across the in-gates. Therefore, all of the elements in the gating system must be redesigned. The authors believe that the most defective element in the previous gating system is the employment of non-tapered straight sprue. Conventionally, a non-tapered steel rod was assembled in the pattern and sand was packed around to create sprue geometry. However, this configuration is widely known to result in cavitation issues due to higher turbulence in the filling process.37 Therefore, a tapered sprue is recommended for this casting. The sprue and pouring basin elements are fabricated using 3DSP and later assembled on the physical pattern which was produced using traditional approach.

The sprue was connected to two symmetrical runners with gradually reduced cross sections after each in-gate to equalize the pressure at the in-gates. The detailed drawing of redesigned rigging system along with an example of assembly feature for hybrid molding is presented in “Appendix.” After assembling the sprue on the pattern, foundry sand is packed. The two mold halves are assembled, and the pouring operation with stainless steel alloy lasted for approximately 34 s. The slag and dross were found to intensely accumulate at the sprue well without entering subsequent gating system in 3DSP sprue design. Upon cleaning, grinding, machining and other post-processing operations, the casting was found to be successful and free of all casting defects. Center hub was free of all shrinkage defects, and additional repairing operations were not required.

Discussion

This case study proves that 3DSP offers freedom to fabricate the mold elements that are only necessary for the cast part and can be integrated with conventional mold making. Therefore, foundries can utilize 3DSP technology to fabricate difficult-to-fabricate mold pieces to reduce both AM printing time and lead time. The concept of hybrid molding, i.e., utilization of 3D printed mold and core pieces on conventional molds, has always been attractive to foundries. Complex cores are 3D printed instead of using core boxes to reduce lead time and tooling costs. 3DSP is established as a cost-effective production method for multiple piece cores over the traditional methods.38 Seventy-nine percent of the surveyed foundries produce cores in-house along with sand molds. If the volume of cores is small, they can be nested very closely in a build box to be packed all over the build volume to produce a large quantity of cores in a single build. Authors believe that the opportunity of 3DSP pf cores for integration into conventional sand molds is a promising feature of 3DSP technology. These concepts fall under hybrid molding, and the casting industry is adopting the effective strategy to balance the components of mold that are to be 3D printed vs conventionally manufactured to produce high throughput and high-quality castings. This case study is one such example that demonstrates that in addition to reducing lead time and tooling costs, hybrid molding enables improved casting performance.

3DSP to Fabricate Complex Castings

Structural designs in industries are rapidly transforming from feature-based to freeform-based geometries.39 Patterns of such complex freeform structures are expensive and not easy to construct,40 and sand casting is losing its market share to other high fidelity, more expensive casting processes such as investment casting and die casting. The dimensional conformability of the conventional pattern is also uncertain for complex features.40 3DSP can be used to produce highly complex molds relatively inexpensively when compared to other high fidelity casting processes. In this section, this ability of 3DSP is demonstrated via casting a highly complex freeform structure.

Case Study V: Nittany Lion

The geometry of Nittany Lion used in this case study is shown in Figure 11a. It can be seen that the part features, undercuts and change in cross section of this part make it extremely challenging to achieve such feature conformity using conventional patternmaking process. In addition to challenges in fabricating pattern and cores for this complex design, the costs of conventional process are not favorable to produce mold for this part. On the other hand, 3DSP is more suitable to produce molds for such complex castings as shown in Figure 11b. A 0.4 mm layer thickness in Viridis3D RAM 3D sand printer is used, and the resulting mold is shown in Figure 11c.

The molds are cast in aluminum 319 alloy, and the resultant casting after cleaning is shown in Figure 11d. It can be observed in Figure 11d that the layers inherent to AM printing are clearly reflected onto the sand casting. Typically, mold wash is applied to all internal surfaces of mold to enable smooth cast surfaces. However, mold wash was not applied for the printed mold under consideration because of its complex internal features that could be prone to non-uniform coating thickness (if mold wash is applied). Non-uniform coating thickness results in dimensional non-conformability and is undesired. This case study shows that even though 3DSP can produce complex and freeform castings with superior feature conformance, as-cast surface features will be coarse and “as-cast”, i.e., similar to traditional sand casting. Post-processing operations to improve surface finish are usually necessary which would result in additional cost and time added to the production cycle. Another study in the literature confirmed that the 3DSP process is limited by the achievable surface finish.41 The mean surface roughness of aluminum casting produced from 3DSP molds was found out to be about 10 μm.16 It was also observed that the surface roughness of aluminum castings produced using 3DSP molds is higher than traditional no-bake molds.16 These issues can be resolved by improving the resolution of 3DSP and/or by designing mold to enable uniform coating thickness. Three replicates of this mold are fabricated using 3DSP in 2 days which validates the critical processing capability of 3DSP to reduce lead time.

In summary, while this study presents novel design-mold fabrication-casting capabilities offered by 3DSP; there are further advancements desired in current state of 3DSP: higher production rate, lower capital and consumable costs, standardized procedures for core removal/design procedures, handling strength of 3DSP cores, etc.

Conclusions

3D sand-printing technology (3DSP) is offering a new age of sophisticated, rapid and reliable form of mold fabrication technique for metal castings. This technology could advance the modern foundry supply chains through capital investment, lead time, tooling expenses, quality management and among others. Four case studies are presented in which 3DSP is demonstrated to provide novel manufacturing solutions when conventional mold making is limited by its inherent manufacturing constraints. The summary of the four industrial case studies are:

- 1.

3DSP is demonstrated to resolve shrinkage-related porosity by offering freedom to optimally orient the cast part in the mold without the need for drafts, undercuts, etc.

- 2.

3DSP is shown to reduce lead time by nesting multiple cast parts within a single mold. Practical solutions to resolve misrun and shrinkage-related issues are also presented.

- 3.

3DSP is shown to integrate seamlessly with conventional casting system and help in its growth by offering unique advantages through enabling rapid fabrication of difficult-to-mold elements and among others.

- 4.

Complex castings with freeform-based geometries are shown to be successfully made through molds made via 3DSP. Higher surface roughness is observed as a current limitation of this process.

The concept of hybrid molding is very attractive for medium-to-small production run foundries due to the scalability of this approach. Any element of the conventional mold that affects the casting performance can be replaced with 3DSP mold parts. Through hybrid molding, only necessary parts such as complex cores can be 3D printed and their implementation can be adopted based on supply chain needs. Future effort would include cost and lead time comparative studies between 3DSP and conventional mold making for medium run production volume as a function of complexity of the cast part.

References

J. Campbell, Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design (Butterworth-Heinemann, Oxford, 2015)

C. Mendonsa, V.D. Shenoy, Additive manufacturing technique in pattern making for metal casting using fused filament fabrication printer. J. Basic Appl. Eng. Res. 1(1), 10–13 (2014)

Patternmaker’s Manual, 1st edn (American Foundry Society, Chicago, IL, 1953)

B. Ravi, M.N. Srinivasan, Features-based castability evaluation. Int. J. Prod. Res. 33(12), 3367–3380 (1995)

S.R. Sama, J. Wang, G. Manogharan, Non-conventional mold design for metal casting using 3D sand-printing. J. Manuf. Process. 34, 765–775 (2018)

H. Büchner, Global Economy and the Situation of the Foundry Industry. Dresden, September 23. IKB Deutsche Industriebank. Global Casting Magazine (2016). https://www.globalcastingmagazine.com/wp-content/uploads/2016/10/2_Buechner_IKB_77673.pdf

W. Van Wijck, D. Dimitrov, N. De Beer, An introduction to rapid casting: development and investigation of process chains for sand casting of functional prototypes. S. Afr. J. Ind. Eng. 18(1), 157–173 (2007)

J. Wang, S.R. Sama, G. Manogharan, Re-thinking design methodology for castings: 3D sand-printing and topology optimization. Int. J. Metalcast. 13, 2–17 (2018)

P.C. Lynch, C. Beniwal, J.H. Wilck IV, Integration of binder jet additive manufacturing technology into the metal casting industry, in IIE Annual Conference. Proceedings (Institute of Industrial and Systems Engineers (IISE), 2017), pp. 1721–1726

E.S. Almaghariz, B.P. Conner, L. Lenner, R. Gullapalli, G.P. Manogharan, B. Lamoncha, M. Fang, Quantifying the role of part design complexity in using 3D sand printing for molds and cores. Int. J. Metalcast. 10(3), 240–252 (2016)

https://hoosierpattern.com/additive-manufacturing/3d-sand-printing

A. Lowder, Voxeljet and TEI sign contract for supply of 500,000 liters of 3D printed sand. 3D Printing Media Network (2018). https://www.3dprintingmedia.network/voxeljet-tei-sign-3-year-3d-sand-contract/

M. Upadhyay, T. Sivarupan, M. El Mansori, 3D printing for rapid sand casting—a review. J. Manuf. Process. 29, 211–220 (2017)

Modern Casting Staff Report, 15 takeaways on additive manufacturing. Mod. Cast. 108(11), 32–37 (2018)

C. Achillas, D. Aidonis, E. Iakovou, M. Thymianidis, D. Tzetzis, A methodological framework for the inclusion of modern additive manufacturing into the production portfolio of a focused factory. J. Manuf. Syst. 37, 328–339 (2015)

D. Snelling, H. Blount, C. Forman, K. Ramsburg, A. Wentzel, C. Williams, A. Druschitz, The effects of 3D printed molds on metal castings, in Proceedings of the Solid Freeform Fabrication Symposium (2013), pp. 827–845

S.R. Sama, T. Badamo, P. Lynch, G. Manogharan, Novel sprue designs in metal casting via 3D sand-printing. Addit. Manuf. 25, 563–578 (2019)

D. Snelling, C. Williams, A. Druschitz, A comparison of binder burnout and mechanical characteristics of printed and chemically bonded sand molds, in SFF Symposium, Austin, TX (2014)

J. Tóth, J.T. Svidró, A. Diószegi, D. Stevenson, Heat absorption capacity and binder degradation characteristics of 3D printed cores investigated by inverse Fourier thermal analysis. Int. J. Metalcast. 10(3), 306–314 (2016)

P.M. Hackney, R. Wooldridge, Characterisation of direct 3D sand printing process for the production of sand cast mould tools. Rapid Prototyp. J. 23(1), 7–15 (2017)

M. Vaezi, C.K. Chua, Effects of layer thickness and binder saturation level parameters on 3D printing process. Int. J. Adv. Manuf. Technol. 53(1–4), 275–284 (2011)

S. Chaudhari, H. Thakkar, Review on analysis of foundry defects for quality improvement of sand casting. Int. J. Eng. Res. Appl. 4(3), 615–618 (2014)

R. Rajkolhe, J.G. Khan, Defects, causes and their remedies in casting process: a review. Int. J. Res. Advent Technol. 2(3), 375–383 (2014)

S.L. Nimbulkar, R.S. Dalu, Design optimization of gating and feeding system through simulation technique for sand casting of wear plate. Perspect. Sci. 8, 39–42 (2016)

H. Iqbal, A.K. Sheikh, A. Al-Yousef, M. Younas, Mold design optimization for sand casting of complex geometries using advance simulation tools. Mater. Manuf. Process. 27(7), 775–785 (2012)

J. Kor, X. Chen, H. Hu, Multi-objective optimal gating and riser design for metal-casting, in Control Applications (CCA) & Intelligent Control (ISIC), 2009 IEEE (2009, July), pp. 428–433

Z. Sun, H. Hu, X. Chen, Numerical optimization of gating system parameters for a magnesium alloy casting with multiple performance characteristics. J. Mater. Process. Technol. 199(1–3), 256–264 (2008)

C.E. Esparza, M.P. Guerrero-Mata, R.Z. Ríos-Mercado, Optimal design of gating systems by gradient search methods. Comput. Mater. Sci. 36(4), 457–467 (2006)

R. Tavakoli, P. Davami, Optimal riser design in sand casting process with evolutionary topology optimization. Struct. Multidiscip. Optim. 38(2), 205–214 (2009)

S. Kumar, P.S. Satsangi, D.R. Prajapati, Optimization of green sand casting process parameters of a foundry by using Taguchi’s method. Int. J. Adv. Manuf. Technol. 55(1–4), 23–34 (2011)

R.W. Lewis, K. Ravindran, Finite element simulation of metal casting. Int. J. Numer. Meth. Eng. 47(1–3), 29–59 (2000)

J. Jezierski, R. Dojka, K. Janerka, Optimizing the gating system for steel castings. Metals 8(4), 266 (2018)

C.M. Choudhari, B.E. Narkhede, S.K. Mahajan, Modeling and simulation with experimental validation of temperature distribution during solidification process in Sand casting. Int. J. Comput. Appl. 78(16), 23–29 (2013)

S. Lampman, Casting Design and Performance, 1st edn. (ASM International, Materials Park, 2009)

P. Muenprasertdee, Solidification modeling of iron castings using SOLIDCast. Master’s Thesis. West Virginia University (2007)

J.K. Kuo, P.H. Huang, H.Y. Lai, J.R. Chen, Optimal gating system design for investment casting of 17-4PH stainless steel enclosed impeller by numerical simulation and experimental verification. Int. J. Adv. Manuf. Technol. 92(1–4), 1093–1103 (2017)

R.W. Ruddle, The Running and Gating of Sand Casting. Inst. Met. Monogr. Rep. Ser. 19 (1956)

J. Thiel, Additive manufacturing for metal castings. Foundry Educational Foundation Keynote Presentation (2014)

B. Lu, D. Li, X. Tian, Development trends in additive manufacturing and 3D printing. Engineering 1(1), 85–89 (2015)

R. Patil, Development of complex patterns: scope and benefits of rapid prototyping in foundries. Int. J. Eng. Innov. Technol. 1(4), 68–72 (2012)

E. Bassoli, A. Gatto, L. Iuliano, M. Grazia Violante, 3D printing technique applied to rapid casting. Rapid Prototyp. J. 13(3), 148–155 (2007)

Acknowledgements

The authors would like to thank Hazleton Casting Company for providing opportunity to conduct experiments at their center for additive manufacturing facility. Authors would like to thank Steve Anderson, Tim Visgaitis, John Frutchey and Frank Lee at HCC for providing support with experiments. Authors would like to thank Dr. Robert Voigt, Chris Anderson and Travis Richner—FAME Lab for providing foundry resources to conduct aluminum casting experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Disclaimer Trademarks, Product and Company names used in this paper are for reference purposes only and do not imply that listing any of these commercial names is meant as an endorsement, recommendation or suggestion for purchase or licensing of them by the authors or their affiliations.

Appendix

Appendix

See Figure 12.

Rights and permissions

About this article

Cite this article

Sama, S.R., Badamo, T. & Manogharan, G. Case Studies on Integrating 3D Sand-Printing Technology into the Production Portfolio of a Sand-Casting Foundry. Inter Metalcast 14, 12–24 (2020). https://doi.org/10.1007/s40962-019-00340-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-019-00340-1