Abstract

The aim of the present work is the evaluation of effect of methanolic extract obtained from Daphne gnidium against biocorrosion caused by sulphate-reducing bacteria (SRB). Herein, the study of the influence of SRB consortium has been realized on the biological and electrochemical properties of the carbon steel API5LX60 immersed in water sample obtained from an Algerian oil field separator. The monitoring of the treatment effects on the SRB performance using kits test and weight loss methods showed a positive effect of the methanolic extract of D. gnidium as a corrosion inhibitor at a concentration of 0.8 g/L. In the other hand, the weight loss test has generated an efficiency rate of 95.99% at a concentration of 1.6 g/L. A linear polarization resistance approved these results, and they have given a yield of 91.14% with a polarization resistance value of 28.9 kΩ cm2 at a concentration of 0.25 g/L.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Corrosion problems caused by the presence of microorganisms affect a wide range of industries. This biocorrosion process, called microbiologically influenced corrosion (MIC) has received increasing attention by engineers and scientists from different fields. It refers to the possibility that microorganisms are involved in the deterioration of metallic and nonmetallic materials. MIC is a serious problem affecting the oil and gas and other industries. It degrades the integrity, safety, and reliability of pipeline operations and other systems [1].

The presence of certain bacteria species within a biofilm over steel can accelerate an already established corrosion process and promote the conditions to its development [2, 3]. This phenomenon occurred by the metabolic substances produced by bacteria that can corrode all the metallic surfaces of the industrial oilfield such as installations, production and water injection circuits in the industrial oil fields [4]. The sulfate-reducing bacteria are a group of microorganisms responsible of the anaerobic corrosion. These species are capable to produce hydrogen sulfide (H2S) by biochemical reactions, which can directly lead to electrochemical and anaerobic corrosions [5]. Thus, they are considered as one of the main challenges in the petroleum industry [6].

Corrosion can be highly insidious to economy. Therefore, corrosion takes place everywhere and may result in dangerous failures. However, an estimated 25–30% of the annual cost of corrosion can be avoided if optimum corrosion management practices are employed [7]. To prevent SRB growth, the Algerian oil industry spends up to US $30 million annually on chemical products such as biocides. The oil fields worldwide maintain their pressure by the water injection. These injection waters were treated with THPS biocide from startup in 1999. The pipeline system of water injection consists partly of carbon steel, and the amount of water injected varies between 13,000 and 15,000 m3/day [8]. Nowadays, different strategies are used by the petroleum industry to resolve corrosion problems. However, the use of inhibitors is one of the best techniques assuring the protection of metallic surfaces [9, 10]. Most of these synthetic compounds can exhibit a good anticorrosive action, but they can also have adverse effects on environment. Moreover, these inhibitors can cause damages to the enzymatic system of the human body [11].

The choice of the inhibitors is based on their toxicity. Therefore, the substances applied in the industries as corrosion inhibitors must be non-toxic or of low toxicity for the environment. Recently, eco-friendly corrosion inhibitors are mainly employed, owing to their low costs and biodegradability. Among these green inhibitors substances, the plant extracts are considered as efficient and nontoxic compounds. According to Emran et al. [12], plants are a rich source of bioactive molecules that could be used as natural inhibitors. There is an intensive effort underway to develop new plant origin corrosion inhibitors for metal subjected to various environmental conditions. Indeed, based on the literature, the corrosion inhibition of mild steel was performed by several plant extracts in acidic solutions [13]. Therefore, the crude methanolic extract from Artemisia pallens (Asteraceae) is used also as effective corrosion inhibitors in the same operational conditions [14]. So, a country like Algeria has a huge biodiversity of plant species and many of these plants are used in folk medicine. Because of the availability and chemical diversity of bioactive principles of the plant kingdom, plant extracts could provide unlimited sources of natural and safe inhibitors.

Daphne gnidium L. is a common species of the Thymelaeaceae family, which grows in the Mediterranean area. It is an evergreen shrub that grows to a height of 2 m and commonly known in the cancer related ethnobotanical use [15, 16]. This plant has been traditionally used worldwide despite its slight toxicity for its antioxidant, antimicrobial and antigenotoxic proprieties. These activities could be attributed to some compounds presented in the plant such as polyphenols and flavonoid [17]. In folk medicine, the leaves are used as hypoglycemic [18, 19] and to treat skin diseases [20]. The roots of these species are used in the traditional medicine as an abortifacient. The barks instead are used to treat hepatitis [21] toothache and as a diuretic agent [22]. Recently, it has been demonstrated that different organic matter extracted from this plant had an antiproliferative effect. According to Chaouki et al. [16], D. gnidium roots have an inhibitory potential on cell proliferation and induced apoptosis in the MCF 7 human breast cancer cell line.

On the other hand, D. gnidium is considered as a dangerous species because of its high toxicity [22, 23] attributed especially to the seeds and the barks, which contain toxic diterpenes. The major toxic substances present in this plant are daphnetoxin (bark) and mezereine (seeds) [24].

In the present study, the methanolic extract of D. gnidium was employed as a green biocide. The tests were based on the observation of the consequences contact of SRB consortium with a metallic surface in the presence of the methanolic extract of D. gnidium L. Biocorrosion inhibition was monitored by biological assays wherein we controlled the biofilm formation and the weight loss experiment. In the second step, we realized the different electrochemical measurements to control the corrosion in presence of our studied inhibitor.

2 Materials and Methods

2.1 Extraction of Plant Material

The aerial parts of D. gnidium L. commonly called Lazaz were collected from the region of Draa-El Mizane in Tizi-Ouzou province that is located in the north east of Algeria at an altitude of 363 m; it is characterized by a Mediterranean climate with hot summer. The sample was transported to the laboratory for processing; it was washed with clean water and dried at room temperature under shade. After drying, the plant was crushed, sieved several times and ground to obtain a fine powder. The resulting material was used for the preparation of the extract using methanol as an extraction solvent, which was mainly used for the phenolic compounds extraction from plants [25]. The extraction procedure was performed in a Soxhlet extractor [26, 27]. The methanol was then evaporated during 2 h at 70 °C in an oven. Finally, the extract was air dried at room temperature until total evaporation of methanol traces. The dry extract obtained was stored at 4 °C.

2.2 Isolation and Culturing of the Microbial Consortium

For this purpose, we used an SRB consortium, isolated from sample of water–oil separator obtained from the oil field situated in Hassi Messaoud in the Algerian south-eastern region. This latter was chosen because its oil field was more affected by a microbiological charge induced by the SRB corrosive bacteria. The isolation was performed on a specific medium, coded by the symbol APIRP 38 (American Petroleum Institute Recommended Practice 38). The composition of this medium is: C3H5NaO3 4 mL/L, yeast extract 0.1 g/L, C6H8O6 0.1 g/L, MgSO4⋅7H2O 0.2 g/L, K2HPO4 0.01 g/L, Fe(SO4)2(NH4)⋅6H2O 0.2 g/L and NaCl 10 g/L [28]. This medium stimulates the bacterial growth by providing sources of carbon (lactate and ascorbic acid), nitrogen (yeast extract), mineral salts, oxygen chelator and other growth factors. Therefore, 90 mL of separator water and 10 mL of the API RP 38 medium were placed in 250-mL Erlenmeyer flasks and then incubated at 37 °C for 28 days. This technique allowed isolation of the most dominant SRB species (able to grow in the medium) in the original sample.

2.3 Preparation of Mild Steel Coupons

The steel used in this study was a material commonly used for the design of the transporting hydrocarbons pipelines and the surface oil installations in Algeria; coded by API 5L X60 grade (ϼ = 7.8 g/cm3) with the following composition (%): 0.22 C, 0.23 Si, 1.31 Mn, 0.044 Ni, 0.05 Cr, 0.013 P, 0.01 S, 0.016 Mo, 0.06 Cu, 98.04 Fe. Carbon steel coupons were then polished by abrasive papers with increasing granulation of 80, 120, 600, 800 and 1200 using a polishing machine, and rinsed with acetone. All coupons have approximately the same weight and the same surface area. Finally, the coupons were packed with a filter paper, and stored in desiccators to avoid any oxidation reactions.

2.4 Study of the Inhibitory Effect of the D. gnidium Extracts

The prepared coupons were immersed in Erlenmeyer flasks which are closed away the oxygen and dabbled with nitrogen gas. An amount of 5 g of methanolic dried extract of D. gnidium was dissolved in 10 mL of ethanol and divided in different volumes, then placed in five sterile penicillin flasks and dabbled with nitrogen. These samples were inoculated with SRB. In each test, the optical density of the SRB consortium inoculate was 0.055 at 600 nm (initial load ~ 106 cells/mL). In addition, two control flasks were prepared; the first one contains 10 mL of SRB consortium with ethanol and without the extract and the second one contains a biocide with 10 mL of the SRB consortium. So, in the present study, commercially available biocide THPS, generally used to protect petroleum facilities, was evaluated to determine the nature of inhibition. Tetrakis hydroxymethyl phosphonium sulfate (THPS) is a quaternary phosphonium; it disrupts cell membrane with a rapid uptake mechanism through cell wall and inhibits lactate dehydrogenate activity [8]. The biocide was obtained from Sigma (St. Louis, MO). From pure THPS solution, a stock solution of 100 ppm was prepared.

After a contact time of 4 h at 37 °C, the contents of each flask were added into the conic flask previously prepared. The concentrations of the methanolic D. gnidium extract in the final volume of each flask were, respectively (g/L), 1.6, 0.8, 0.4, 0.2 and 0.1. All the samples were then incubated at 37 °C for 45 days. After incubation, samples were subjected to two tests, growth inhibition and weight loss.

2.4.1 Growth Inhibition Test

The growth inhibition test was controlled using the kits tests (norm Nace TM 0194, 1994). These kits were made to count the SRB of each sample every incubation day. The experiment was stopped when the SRB consortium number became constant. For this test, 42 Penicillin-type flasks containing 9 mL of the API RP 38 liquid medium were used. These flasks are divided into seven series, each one contains six flasks labeled and assembled. From each sample 1 mL of the mixture was sampled by a syringe and introduced into the first flask. After shaking and using the same syringe, 1 mL of the first flask was injected into the second flask of the same series and doing so until the sixth flask. These last flasks were incubated at 37 °C for 28 days and the sampling for the kits test was carried out every day. Thus, the darkness in flaks was considered as positive. In addition, the ability of SRB consortium to utilize sulfate in the medium was tested during growth in the penicillin-type flasks. The sulfate concentration was determined by mixing 50 µL of sample with 950 µL of conditioning agent (a 19-fold dilution in H2O 50 mL glycerol, 30 mL concentrated HCl, 75 g NaCl, 100 ml 95% ethanol, and deionized water). An excess of BaCl2 was added, and the sample was vortexed until the BaCl2 was completely dissolved. After 30 min, the OD480 was measured [29].

2.4.2 Weight Loss Method

All the weighing of the mild steels specimens was made using a normalized weight loss method coded by RP 0775-99-corrosion coupons installation and handling. This method consists in calculation of the corrosion rate by the measurement of the weight difference of the material before and after their exposure to a corrosive medium during 45 days. The corrosion rate was calculated by the following equation (Eq. 1):

where Vcorr is the corrosion rate (mm/year), t is the exposure time of the coupon (day), ρ is the carbon density (g/cm3), S is the surface area of the corrosion coupon (cm2) and the weight loss (g) is expressed by the equation ΔP = Pf − Pi. The steel coupons’ surfaces were examined by scanning electron and metallurgical microscope.

2.4.3 Electrochemical Tests

For the electrochemical test, a three-neck flask made by Pyrex glass was used as electrochemical cell. On the other hand, the graphite was used as counter-electrode and the carbon steel API5LX60 was used as working electrode. All the potential values were given relative to the saturated calomel electrode SCE as reference electrode. A volume of 700 mL of the separator water enriched with 10% of the API RP38 medium was placed on a three-neck flask. The graphite electrode was placed in the cell and the other orifices were sealed. After that, the cell was dabbled with nitrogen gas for 30 min, to exclude all the air and create the anaerobic environment. The test solution was autoclaved at 120 °C for 20 min at an over-pressure of 1 bar. In front of a Bunsen spout, contamination of the electrolytic medium in the cell was carried out by 5% of the SRB consortium solution at 106 germs/mL (optical density of the SRB consortium inoculate was 0.055 at 600 nm). Thus, the reference electrode was introduced in the electrochemical cell and finally the API5LX60 carbon steel was immersed in the medium after being polished and rinsed with acetone. The solution was then treated with the ethanolic extract of D. gnidium at increasing concentrations (0.1, 0.15, 0.2 and 0.25 g/L).

The considered electrochemical techniques for this study were; the open-circuit potential OCP, linear polarization strength measurement LRP, electrochemical impedance spectroscopy (EIS) and the dynamic-potential technique.

3 Results and Discussion

3.1 SRB Consortium Kinetic Growth

The kinetic growth of SRB consortium with and without D. gnidium methanolic extract obtained with the kits tests are shown in Fig. 1. The pattern of the negative control curve (without plant extract) showed a standard bacterial growth curve with a latency phase corresponding to the necessary time for the enzymes synthesis by the SRB that is able to adapt to the substrates of the medium. This phase lasted 4 days. Moreover, the SRB consortium is able to synthesize one or more metabolic products, so the bacteria transform the sulfate to sulfide ions; this biochemical reaction is catalyzed by adenosine phosphosulfate reductase [30]. According to Postgate [29], these SRB could produce sulfides ions by the energy released from internal cellular and carbohydrate substrate.

After that, an exponential phase appeared to represent the rigorous proportionality between the number of cells and their growth rate. Therefore, the consortium reached a concentration of 108 germs/mL since the 5th day as a maximum value. However, during the optimal growth period, an impoverishment of the culture medium from nutriment occurred, which consequently resulted in their enrichment by undesirable metabolism by-products. At this stage, the stationary phase was reached from the 6th day. Furthermore, the decline phase did not appear successively after the stationary phase, this could be explained by a strong activity of the consortium of SRB. Therefore, this result suggests that the used waters samples were very corrosives, it contained an excess of sulfate ions used as an energy source for the SRB [31]. According to Fig. 2, the concentration of the sulfate ions of our culture decreased from 3500 to 900 mg/L in the presence of the SRB consortium from the 6th day. This decrease was explained by an intense metabolic activity of our culture during the exponential growth phase, while the sulfate played the role of the final electrons acceptor [31].

According to Miranda et al. [9], Desulfovibrio capillatus, a species of SRB, is able to form a biofilm on the work electrode during the first 48 h of incubation. This incubation time is the same comparing with the theoretical incubation time for the exponential growth phase of this SRB consortium media, containing lactate as electron donor and thiosulfate as electron acceptor without iron ions [9]. At this stage and on, the main dominant reaction was the thiosulfate reduction to sulfide, suggesting that corrosive activity could proceed after significant sulfide production by this bacterium [9].

So, the major cause responsible for the biocorrosion is attributed to SRB consortium ability to perform dissimilatory reduction of sulfur compounds, such as sulfate, sulfite, and thiosulfate into sulfides [32].

Concerning the effect of the metabolic extract of D. gnidium on the growth of SRB, Fig. 1 shows that, the bacterial germs decreased with increasing plant extract concentration; whereas, at 0.1 g/L of the extract concentration, the contamination was zero during the first 6 days of incubation and it reached 102 germs/mL from the 7th day. At a concentration of 0.2 g/L, the bacterial growth did not occur until the 8th day of incubation, reaching a SRB consortium concentration of 102 germs/mL. Whilst, with a concentration of 0.4 g/L a bacterial growth has been observed since the 9th day reaching the same growth rate. These positive cultures showed a stable contamination rate of 108 germs/mL from the 11th day. Moreover, at the concentrations of 0.8 g/L and 1.6 g/L no contamination has been noticed throughout all the incubation period. Same results were obtained with the use of 100 ppm of a commercial biocide, which suggests that our extract has a biocide activity on SRB.

3.2 Weight Loss Experiment

The results obtained after 45 days of the contact between the steel and the enriched separator water and treated by different plant extracts concentrations and by the biocide are summarized in Table 1.

The loss of weight per unit area for each culture in presence of different concentrations of the plant extract showed an efficiency percentage of 95.99% for a plant extract concentration of 1.6 g/L. So, corrosion inhibition activity by our plant extract was effectively proved. In addition, this percentage was higher compared with the one obtained by a commercial biocide at a concentration of 0.1 g/L.

The corrosion inhibition of aluminum and mild steel metal by polyphenolics extracted from the flowers of Cassia auriculata in 2 M HCl by weight loss, polarization study and impedance methods were previously investigated by Rajendran et al. [33], it was ascertained that the percentage of inhibition increases with the increase in concentration of the extracts. This effect could be attributed to the functional groups present in the active components of the plant that formed a protective film on the metal surface by coordinating with the metal ion [34]. While, Sumita et al. [34], studied the corrosion inhibition of mild steel in 2 M sulphuric acid media by using ethanolic extract of Mimosa pudica (with a concentration of inhibitors in the range of 1–4 g/L) by weight loss method. Results revealed that inhibition efficiencies (IE%) increases with increasing inhibitor concentration [34].

3.3 Surface Analysis

A consortium was developed from a biofilm and the corrosion inhibition at different extract concentrations was proved by observation of various steel coupons surfaces, using a scanning electron microscopy and a metallographic microscope.

According to our results, SRB biofilm is formed in the control coupons and covers the steel surface after 45 days of immersion (Fig. 3). Hydrogen sulfide producing bacteria were present in the control consortium as evidenced by the formation of a black ferrous sulfide precipitate in the culture medium and the characteristic hydrogen sulfide odor. Figure 3b is a micrograph of the bacteria attached to the metallic surface. Several morphological types were observed, mainly short rods and some large curved rods (large vibrios). These SRB consortium decreased with the increase of the plant extract concentration until their total disappearance at a concentration of 1.6 g/L. This could be the result of toxic metabolites generated by the formed biofilm during the 45 days of incubation that caused the surface pitting. The treatment with the plant extract showed an effective result at a concentration of 1.6 g/L with the observation of a clear and completely clean steel surface like that obtained with commercial biocide.

3.4 Examination by Metallographic Microscope

After abrasion of the formed biofilm on the steel coupons surfaces, the observation with the metallographic microscope showed a significant difference between the coupons exposed to different concentrations of D. gnidium methanolic extract. The micrograph shows the severe localized corrosion in the presence of the consortium.

According to Fig. 4, biocorrosion was more significant in the coupons treated with low extract concentrations. The results revealed a localized corrosion by pitting with a black color due to the deposit formed by iron sulfide (FeS) (micrographs B, C, D, and E). Whereas, corrosion induced by SRB consortium was often characterized by formation of open stitches and filled with black products rich in iron sulfide. The number of stitches decreased when increasing the extract concentrations and it was less important than the number of stitches in the control steel coupon containing ethanol without extract (micrograph B). Therefore, the higher concentration of D. gnidium methanolic extract was more effective with the corrosive inhibition by SRB. The polished steel coupon treated with the commercial biocide (micrograph A) showed a smooth surface like for the coupons treated with extract concentrations greater than or equal to 0.8 g/L (micrographs F and G).

According to the literature, the ability of bacteria to form biofilms, produce exopolysaccharides, adsorb metallic ions, produce H2S, consume or produce H2, and use metallic ions for respiration are all properties that can affect the chemistry on the surface of metals and hence play a role in corrosion processes. The SRB consortium influence on the corrosion of steels can be elucidated mainly by two mechanisms: chemical MIC (CMIC) and electrical MIC (EMIC). CMIC of iron by hydrogen sulfide from microbial sulfate reduction occurs with organic substrates; SRB consortium corrode iron by direct utilization of the metal itself. This always occurs via direct electron uptake and in only a limited number of recently discovered SRB consortium [35, 36]. It should be noted that iron sulfide are good electrical conductors and that they can decrease the electrode surge by playing the role of cathode. Their electrode potential and imperfections in their structures give ferric sulfide cathode properties in galvanic corrosion cells with iron. It is understood under these conditions, that the rupture of the sulfide film and the direct contact of the medium with the bare metal may cause localized corrosion by H2S. The compact accumulation of sulfide particles on the surface of the metal does not prevent the transport of ferrous ions.

According to Leclerc et al. [37], bacteria tend to focus on metal surfaces, associating in communities to form biofilms. Thus, Queiroz et al. [38] have shown that metal supports are susceptible to microbial colonization, and consequently, the formed biofilm can effectively cause a localized corrosion. Some SRB are able to oxidize metallic iron using sulfate as electron acceptor [37]. The H2S product could cause corrosion plugging by FeS and reservoir souring, which impair the oil production efficiency [38, 39]. In addition, H2S causes several problems due to its reactivity and toxicity, especially to the Oilfield employees [40].

3.5 Electrochemical Study

3.5.1 Evaluation of Open-Circuit Corrosion Potential (OCP)

According to the obtained potential values of the treated and untreated samples shown in Table 2, the results suggested that these values varied with the injected plant extract concentrations. Thus, the potential tends towards electropositive values in the presence of 0.2 g/L of the plant extract. However, untreated samples tend towards electronegative or anodic values presenting a corrosion field according to the diagram of pourbaix (iron, pH, SRB) [41].

SRB biofilm was an electroactive specie that could play a key role in the improvement of the corrosion potential (Ecorr) and in the acceleration of the corrosion rate. So, the SRB mainly affected the cathodic reaction of carbon steel corrosion, they can capture electrons from carbon steel electrode which was polarized at − 740 mV by a direct electron transfer [42]. The main mechanism of the anaerobic biocorrosion induced by the SRB including a cathodic reaction and direct electron transfer can be described as follows (Eqs. 2, 3) [43].

Therefore, hydrogen was liberated by hydrogenase enzyme and consumed by SRB that reduce sulfate to sulfide. On the other hand, at acidic pH, the produced sulfide tends to be transformed to hydrogen sulfide according to Eq. (4) [37]:

The hydrogen sulfide formed by Eq. (4) with the oxidized iron conduct to produce iron sulfide by the following reactions (Eqs. 5–7) [37].

According to the literature, the SRB could improve the biocorrosion of several types of metals, such as stainless steel, carbon steel and iron. In the study of Aguirre et al. [45], the OCP measured for the stainless steel in the natural seawater were stabilized after 35 days of exposure at anodic values of − 150 mV. So, the coating of certain metals by a protective film could inhibit this corrosion and shift the OCP towards anodic values like observed for the stainless steel coated by poly(3,4-ethylendioxythiphene) [44]. Moreover, the galvanized tubes coating with zinc and zinc alloy of water distribution system suffered from corrosion and biocorrosion, the OCP moved to the positive values to the passive layer formed on the surface and consequently the system became nobler. However, in the presence of chloride and sulfide ions, the zinc coating was degraded by chemical and biological corrosion and the OCP moved towards to less noble values due to enrichment of the anodic dissolution of the coating [45].

Therefore, adding from our extract to the medium has firstly improved the corrosion potential towards the electronegative values from − 777 to − 788 V/ECS for the inhibitor concentrations varying from 0 to 0.15 g/L. Up to this concentration, the Ecorr values were increased to the electropositive values indicating that the specie at these concentrations were more effective and could inhibited the corrosion induced by the SRB.

3.5.2 Linear Polarization Resistance Technique (LRP)

Linear polarization resistance allowed measuring the corrosion rate from the polarization resistance, the potential and corrosion currents. The values of the polarization resistances obtained from the current intensities exploitation [E = f(I)] of a system (solution + vegetable extract at different concentrations + API5L grade carbon steel X60) are reported in Table 3.

According to these results, the Rp value noticed for the steel immersed in water contaminated by the SRB consortium was low and indicated a value of 2.480 kΩ cm2 that correspond to a Vcorr of 1.026 mm/year. After injection of D. gnidium methanol extract at different concentrations, the Rp increases as the current intensities decrease. Furthermore, at an extract concentration of 0.25 g/L, the recorded Vcorr are about 0.088 mm/year, which gives an important protective power of 91.14%.

According to Nwanonenyi et al. [46], polarization curves revealed that carboxymethyl cellulose (CMC) adsorption affected both anodic and cathodic partial reactions and acted as a mixed-type inhibitor [46].

3.5.3 Electrochemical Impedance Spectroscopy (EIS)

To confirm our results, the electrochemical impedance spectroscopy technique was used. This technique has the advantage of disturbing as little as possible the metal-solution interface.

According to the results given in Table 4, represented also by the Nyquist and Bode diagrams in Fig. 5, the half circles increased as the concentration of the plant extract increased in the medium. The Bode curves of the ethanol showed a corrosive characteristic that was observed by the lower frequencies, revealing an important dissolution of the steel by the bacterial activity [43].

On the other hand, the presence of the plant extract at different concentrations improved the impedance value of ethanol alone. Furthermore, the incubation time of the coupon with the extract plant in the separator water could enhance the electrochemical impedance value according to the formation of a passive layer on the coating surfaces [47].

The charge transfer resistance was 16.259 kΩ cm2 at an extract concentration of 0.25 g/L with a double layer capacity of the order of 0.0017 F/cm2 giving an efficiency of 74.45%. This value is higher than that obtained by Parthipan et al. [48], it was 21.3 ± 1 Ω cm2 as a higher value recorded in the abiotic system. The author studied the biocorrosion of a carbon steel API 5LX by a mixed consortia of bacteria biofilm, so the decrease of impedance value was observed in the presence of mixed consortia that was according to the deterioration of the protective effects so the diffusion phenomenon was more evident. Adding the extract to the solution as a corrosion inhibitor leads to an increase in the size of the semicircle in the impedance spectrum (a single capacitive loop). It characterizes a double layer formation of CDC capacity that was decreased with an increasing of the concentrations. This double layer form was a protective film [49]. Indeed, if the formed film was more absorbed on the surface of the steel, the thickness of the protective film and the double layer capacity were greater, according to the Helmholtz model (Eq. 8) [50].

where ε and ε0 are the medium permittivity and the vacuum, respectively, S is the active area of the sample and e is the thickness of the formed film.

The increase in the polarization resistance characterizing the good resistance to corrosion of the extract is already confirmed by the decrease in the corrosion current density that are inversely proportional according to the following Stern–Geary equation (Eq. 9):

where \({\beta _{\text{a}}}\;{\text{and}}\;{\beta _{\text{c}}}~\) are the anodic and the cathodic Tafel constants, respectively, Icorr is the corrosion current and Rp is the polarization resistance.

The double layer capacity decreases in the same way as the corrosion current density by adding our extract to the solution. These observations are a certificate of the formation of a protective film on the surface of the steel [51]. So several materials and methods were used as biocorrosion inhibitor like the aluminum and the nanoAl2O3 composite coatings. In this latest study, the impedance results were demonstrated that the composite gave a better corrosion resistance than the pure Al coating [52].

3.5.4 Potentiodynamic Technique (Tafel)

Based on the results obtained by the three electrochemical techniques, a comparison between the effect of our natural products with that of the commercially biocide was performed through the by potentiodynamic technique under the same operating conditions. API5LX60 carbon steel was immersed in APRP38-enriched separator water and contaminated with 5% of SRB consortium in the presence of 0.25 g/L of each product that was the optimal concentration.

The results summarized in Table 5 and illustrated in Fig. 6 showed that the natural product of D. gnidium has a greater anticorrosive effect than that performed by the commercial biocide with corrosion rates of 0.022 mm/year and 0.031 mm/year, respectively.

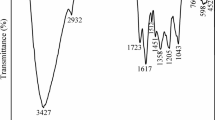

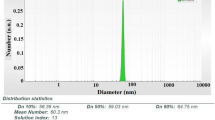

According to Aribo et al. [53], Tafel extrapolation method has been employed to determine the green inhibitors corrosion (Tridax procumbens and Chromolaena odorata extracts). The results showed that both inhibitors are effective at 100 ppm (90% inhibition efficiency) for protecting the alloy in the acidizing environment [53]. While, the biocide had an anticorrosive effect in the results of biological tests more important than our extract plant. In fact, the methanolic extract of the D. gnidium plant plays two roles; an antimicrobial effect against SRB and a protective film of the metal surface against corrosion. This extract would probably contain phenolic compounds because according to Falleh et al. [25], methanol is frequently the solvent used for the extraction of phenolic compounds. Indeed, Deiana et al. [54] isolated nine flavonoids from the methanol extracts of leaves and stems of D. gnidium L. (apigenin, luteolin, quercetin, orientin, isoorientin, luteolin 7-O-glucoside, apigenin 7-O-glucoside, genkwanin, and 5-O-β-d-primeverosyl genkwanine).

Our results are in agreement with the previous work, demonstrated by Emran et al. [12] who say that due to the adsorption of inhibitor molecules on the metal surface, a protective film is formed which isolates the metal from the aggressive environment. Thus, corrosion is controlled [12]. tannins which are a large polyphenolic naturally occurring product can participate in the corrosion inhibition, based on the experimental results, Agi et al. [55], concluded that Rhizophora mucronata tannin (RMT) is suitable as a corrosion inhibiting agent for both carbon steel and copper.

So, Xhanari et al. [56], say that plant material extracts contain many active principles. They contain polar or hetero atoms such as S, N, O, P and aromatic rings, favoring the adsorption by donor–acceptor interaction between π electrons of donor atoms S, N, O, P and aromatic rings of inhibitors, and the vacant d-orbitals of metal surface atoms [56]. On the other side, the works of Bammou et al. [57], worn on the tinplate corrosion study in hydrochloric medium using the plot of dynamic-potential polarization curves, electrochemical impedance measurements and scanning electron microscopy (SEM) showing that the oil extracted from the plant of Thymus satureioides exhibited an inhibitory efficiency exceeding 70% using a concentration of 4 g/L.

Furthermore, the influence of the natural extract of Chenopodium ambrosioides on the corrosion inhibition of carbon steel in sulfuric acid solution was studied by the weight loss method, potentiodynamic polarization and impedance spectroscopy measurements. The experimental results revealed a good inhibiting effect of the extract on the tested metal with 0.5 M of H2SO4 solution. The protection efficiency increased with a rise of inhibitor concentrations, which could reach a percentage of 94% at 4 g/L [58]. Hussin and Kassim [59] studied the corrosion inhibition activity of the ethyl acetate extract of Uncaria gambir using weight loss, potentiodynamic polarization measurements, electrochemical impedance spectroscopy (EIS) and scanning electron microscope technology with energy dispersive X-ray spectroscopy (SEM–EDX). Inhibition was found to be highest at a concentration of 150 ppm in solutions with a pH of 5. While Nasibi et al. [60] used the energy dispersion spectrometry analysis and other electrochemical experiments for soft steel samples in the presence of the natural extract inhibitor that confirmed the formation of a protective layer on the surface of the metal. The inhibition efficiency was 92.24% and achieved in the 1 M acidic solution containing 0.3 g/L of the natural inhibitor. According to Ogwo et al. [61], inhibitory effects of Ficus sycomorus leaves extracts on the corrosion of mild steel et aluminum in 1 M hydrochloric acid (HCl) solution was studied at temperature of 30 °C using gravimetric technique. Corrosion rates of mild steel and aluminum in the aggressive medium were found to increase as temperature increased, but decreased upon the addition of leaves extract of Ficus sycomorus compared to the blank.

Thereby, addition of substances that exert synergistic influence has been employed [62]. The inhibition efficiency (IE) of caffeine, in controlling corrosion of carbon steel immersed in neutral aqueous solution has been evaluated by the weight loss method, in the absence and presence of Zn2+. In the presence of Zn2+, caffeine has an excellent inhibition efficiency [63]. The mixture potential of carboxymethyl cellulose (CMC) and additives (PVP, PAA and PVAc) as an eco-friendly corrosion inhibitor for carbon steel in the acid et alkaline solutions, was shown using gravimetric and potentiodynamic polarization measurements and quantum chemical calculations [46].

4 Conclusion

In the case of the petroleum industry, microorganisms must be investigated to better identify and use the appropriate means of control. Indeed, our work focused on the study of microbial SRB consortium influence on the electrochemical properties of the carbon steel API5LX60 emerged in the separator oil field water. We noticed that this water is rich in sulfate that is a necessary element for the SRB growth. The treatment of this water by the methanolic extract of D. gnidium to inhibit the activity of SRB revealed very interesting and promising results. Indeed, the weight loss gave an efficiency of 95.99% with the used plant extract concentration of 1.6 g/L. Regarding the electrochemical results, we noticed that the resistance of polarization (Rp) increased while injecting the various concentrations of the extract plant methanolic extract, the current intensities decreased and the corrosion rate decreased also (0.088 mm/year in 0.250 g/L) which provided a protective power of 91.14%. By comparing our results with the previous works, we have deduced that D. gnidium has a good anticorrosive effect against SRB biocorrosion used in the petroleum industry.

References

Telegdi J, Shaban A, Trif L (2017) Microbiologically influenced corrosion (MIC). In: Trends in oil and gas corrosion research and technologies, pp 191–214. https://doi.org/10.1016/b978-0-08-101105-8.00008-5

Rubio C, Ameil C, Poisson A, Duont I, Mariey L (2004) Characterization of reductive sulfato/thiosulfato flora by Fourier transform infrared spectroscopy (FTIR). Mater Technol 92(7–9):71–75. https://doi.org/10.1051/mattech:2004040

Lin J, Ballim R (2012) Biocorrosion control: current strategies and promising alternatives. Afr J Biotechnol Acad J 91:15736–15747. https://doi.org/10.5897/ajb12.2479

Gana ML, Kebbouche Gana S (2015) Role of the injection water microorganisms on corrosion of fiberglass in TFT Algerian oil fields. In: Third international conference on advances in bio-informatics, bio-technology and environmental engineering—ABBE. Institute of Research Engineers and Doctors. https://doi.org/10.15224/978-1-63248-060-6-01

Kim BH, Lim SS, Daud WRW, Gadd GM, Chang IS (2015) The biocathode of microbial electrochemical systems and microbially-influenced corrosion. Bioresour Technol 190:395–401

Guan J, Xia LP, Wang LY, Liu JF, Gu JD, Mu BZ (2013) Diversity and distribution of sulfate-reducing bacteria in four petroleum reservoirs detected by using 16S rRNA and dsrAB genes. Int Biodeterior Biodegrad 76:58–66

Jai Dudeja P (2018) Efficient enhancement of corrosion resistance in steel by fiber lasers. Res Rev 03(3). https://doi.org/10.13140/RG.2.2.18976.02562. http://www.rrjournals.com

Gana ML, Kebbouche-Gana S, Touzi A, Zorgani ML, Pauss A (2011) Antagonistic activity of Bacillus sp. obtained from an Algerian oilfield and chemical biocide THPS against sulfate-reducing bacteria consortium inducing corrosion in the oil industry. J Ind Microbiol Biotechnol 38:391–404

Miranda E, Bethencourt M, Botana FJ, Cano MI, Sanchez-Amaya JM, Corzo A, Garcı´ de Lomas J, Fardeau ML, Ollivier B (2006) Biocorrosion of carbon steel alloys by an hydrogenotrophic sulfate-reducing bacterium Desulfovibrio capillatus isolated from a Mexican oil field separator. Corros Sci 48:2417–2431

Eddy NO (2010) Adsorption and inhibitive properties of ethanol extract of Garcinia kola and Cola nitida for the corrosion of mild steel in H2SO4. Pigment Resin Technol 39(6):348–354. https://doi.org/10.1108/03699421011085849

Ostovari A, Hoseinich SM, Shadizadeh SR, Hashemi SJ (2009) Corrosion inhibition of mild steel in 1 M HCl solution by henna extract: a comparative study of the inhibition by henna and its constituents (lawsone, gallic acid, α-d-glucose and tannic acid). Corros Sci 51:1935–1949

Emran KM, Ali SM, Lehaibi HAA(2018) Green methods for corrosion control. In: Corrosion inhibitors, principles and recent applications. In Tech, London, pp 61–77. https://doi.org/10.5772/intechopen.72762

Satapathy K, Gunasekaran G, Sahoo SC, Amit K, Rodrigues PV (2009) Corrosion inhibition by Justicia gendarussa plant extract in hydrochloric acid solution. Corros Sci 51:2848–2856

Kalaiselvi P, Chellammal S, Palanichamy S, Subramanian G (2010) Artemisia pallens as corrosion inhibitor for mild steel in HCl medium. Mater Chem Phys 120(2–3):643–648. https://doi.org/10.1016/j.matchemphys.2009.12.015

Ladhari A, Omezzine F, Rinez A, Haouala R (2011) Phytotoxicity of Daphne gnidium L. occurring in Tunisia. Int J Agric Biosyst Eng 5(11):697–700. https://doi.org/10.5281/zenodo.1071524

Chaouki W, Leger DY, Liagre B, Cherrah Y, Beneytout JL, Hmamouchi M (2009) Roots of Daphne gnidium L. inhibit cell proliferation and induce apoptosis in the human breast cancer cell line MCF-7. Pharmazie 64(8):542

Chaabane F, Boubaker J, Loussaif A, Neffati A, Kilani-Jaziri S, Ghedira K, Chekir-Ghedira L (2012) Antioxidant, genotoxic and antigenotoxic activities of Daphne gnidium leaf extracts. Complement Altern Med 12:153

Ziyyat A, Legssyer A, Mekhfi H, Dassouli A, Serhrouchni M, Benjelloun W (1997) Phytotherapy of hypertension and diabetes in oriental Morocco. J Ethnopharmacol 58(1):45–54. https://doi.org/10.1016/s0378-8741(97)00077-9

Bruneton J (1987) Elements of phytochemistry and pharmacognosy. Techniques and documentation. Lavoisier, Paris. https://books.google.dz/books?id=Jks-AAAACAAJ&dq=El%C3%A9ments+de+phytochimie+et+de+pharmacognosie&hl=fr&sa=X&ved=0ahUKEwjQ5ZWq3d3eAhWTVsAKHSN3APQQ6AEIJzAA

Borris RP, Blasko PG, Cordell GA (1998) Ethnopharmacologic and phytochemical studies of the Thymelaeaceae. Ethnopharmacol J 24:41–49

Bellakhdar J, Claisse R, Fleurentin J, Younos C (1991) Repertory of standard herbal drugs in the Moroccan pharmacopoeia. Ethnopharmacol J 35:123–143. https://doi.org/10.1016/0378-8741(91)90064

Bruneton J (1999) Pharmacognosy, phytochemistry, medicinal plants. Lavoisier Technique & Documentation, Paris (in French)

Mourya P, Banerjee S, Singh MM (2014) Corrosion inhibition of mild steel in acidic solution by Tagetes erecta (Marigold flower) extract as a green inhibitor. Corros Sci 85:352–363

Garai S, Garai S, Jaisankar P, Singh JK, Elango A (2012) A comprehensive study on crude methanolic extract of Artemisia pallens (Asteraceae) and its active component as effective corrosion inhibitors of mild steel in acid solution. Corros Sci 60:193–204

Falleh H, Ksouri R, Chaieb K, Karray-Bouraoui N, Trabelsi N, Boulaaba M, Abdelly C (2008) Phenolic composition of Cynara cardunculus L. organs, and their biological activities. C R Biologies 331:372–379

Grigonis D, Venskutonis PR, Sivik B, Sandahl M, Eskilsson CS (2005) Comparison of different extraction techniques for isolation of antioxidants from sweet grass (Hierochloë odorata). J Supercrit Fluids 33(3):223–233. https://doi.org/10.1016/j.supflu.2004.08.006

Suman T, Prabhu PS, Om Prakash C, Bhuvnesh K (2015) Antioxidant potential of selected medicinal plants of trans-Himalayan region. Int J Sci Res (IJSR) 5(5):1123–1128. https://doi.org/10.21275/v5i5.nov163576

Apha, American Public Health Association (APHA) (1975) Identification of iron and sulfur bacteria” Standard methods for the examination of water and waste water, 14th ed., New York

Postgate JR (1984) The sulfate-reducing bacteria. Cambridge University Press, Cambridge. https://doi.org/10.1002/jobm.3620250205

Kushkevych I (2016) Dissimilatory sulfate reduction in the intestinal sulfate-reducing bacteria. Stud Biol 10:197–228. https://doi.org/10.30970/sbi.1001.560

Haras D (2005) Biofilm and alteration of materials: from analysis of the phenomenon to prevention strategies. Mater Technol 93:27–41. https://doi.org/10.1051/mattech:2006003

Hubert C, Nemati M, Jenneman G, Voordouw G (2005) Corrosion risk associated with microbial souring control using nitrate or nitrite. Appl Microbiol Biotechnol 68(2):272–282

Rajendran A, Karthikeyan C (2012) The inhibitive effect of extract of flowers of Cassia auriculata in 2 M HCl on the corrosion of aluminium and mild steel. Int J Plant Res 2(1):9–14. https://doi.org/10.5923/j.plant.20120201.02

Sumita A, Nikhila G (2018) Adsorption and thermodynamic study of corrosion inhibition properties of Mimosa pudica on mild steel in 2 M H2SO4 international. J ChemTech Res 11(3):129–139. https://doi.org/10.20902/ijctr.2018.110341

Enning D, Garrelfs J (2014) Corrosion of iron by sulfate-reducing bacteria: new views of an old problem. Appl Environ Microbiol 80(4):1226–1236

Kebbouche-Gana S, Gana ML (2012) Biocorrosion of carbon steel by a nitrate-utilizing consortium of sulfate-reducing bacteria obtained from an Algerian oil field. Ann Microbiol 62(1):203–210

Leclerc H, Gaillard J-L, Simonet M (1995) Microbiologie générale: La bactérie et le monde bactérieu. Doin editeurs, Paris

Queiroz GA, Andrade JS, Malta TBS, Vinhas G, Lima MAGDA (2018) Biofilm formation and corrosion on carbon steel API 5LX60 in clayey soil. Mater Res 21(3):1–7. https://doi.org/10.1590/1980-5373-mr-2017-0338

Dihn HT, Kuever J, Mubmann M, Hassel AW, Stratmann M, Widdel F (2004) Iron corrosion by novel anaerobic microorganisms. Nature 427:829–832

Javaherdashti R (2011) Impact of sulphate-reducing bacteria on the performance of engineering materials. Appl Microbiol Biotechnol 91:1507–1517

Girault HH (2007) Analytical and physical electrochemistry. EPFL-Press, Lausanne

Lin Y, Jizhou D, Xiangqian D, Yanliang H, Baorong H (2013) Accelerated anaerobic corrosion of electroactive sulfate-reducing bacteria by electrochemical impedance spectroscopy and chronoamperometry. Electrochem Commun 26:101–104

Bhola SM, Alabbas FM, Bhola R, Spear JR, Mishra B, Olson DL, Kakpovbia AE (2014) Neem extract as an inhibitor for biocorrosion influenced by sulfate reducing bacteria: a preliminary investigation. Eng Fail Anal 36:92–103

Aguirre J, Daillec L, Fischera DA, Galarcea C, Pizarro G, Vargas I, Walczak M, de la Iglesia R, Armijo F (2017) Study of poly(3,4-ethylendioxythiphene) as a coating for mitigation of biocorrosion of AISI 304 stainless steel in natural seawater. Prog Org Coat 113:175–184

Delaunois F, Tosar F, Vitry V (2014) Corrosion behaviour and biocorrosion of galvanized steel water distribution systems. Bioelectrochemistry 97:110–119

Nwanonenyi SC, Obasi HC, Chidiebere AM (2018) Inhibitive performance of carboxymethyl cellulose and additives on corrosion of carbon steel in acidic et alkaline environments. J Bio Tribo Corros 4:34. https://doi.org/10.1007/s40735-018-0148-x

Abdoli L, Huang J, Li H (2016) Electrochemical corrosion behaviors of aluminum-based marine coatings in the presence of Escherichia coli bacterial biofilm. Mater Chem Phys 173:62–69

Parthipan P, Elumalai P, Ting PY, Rahman PKSM, Rajasekar A (2018) Characterization of hydrocarbon degrading bacteria isolated from Indian crude oil reservoir and their influence on biocorrosion of carbon steel API 5LX. Int Biodeterior Biodegrad 129:67–80

Dean JA (1973) Lange’s handbook of chemistry. McGraw-Hill, New York. http://depa.fquim.unam.mx/amyd/archivero/ManualdeLange_9164.pdf

El Bribri A, Tabyaoui M, Tabyaoui B, ElAttari H, Bentiss F (2013) The use of Euphorbia falcate as eco-friendly corrosion inhibitor of carbon steel in hydrochloric acid solution. Mater Chem Phys 141:240

Zarrok H, Zarrouk A, Salghi R, Oudda H, Hammouti B, Ebn Touhami M et al (2012) A combined experimental and theoretical study on the corrosion inhibition and adsorption behaviour of quinoxaline derivative during carbon steel corrosion in hydrochloric acid. Port Electrochim Acta 30(6):405–417. https://doi.org/10.4152/pea.201206405

Chandrashekar A, Ajaykumar BS, Reddappa HN (2018) Mechanical, structural and corrosion behavior of AlMg4.5/nanoAl2O3 metal matrix composites. Mater Today Proc 5(1):2811–2817. https://doi.org/10.1016/j.matpr.2018.01.069

Aribo S, Olusegun SJ, Ibhadiyi LJ, Oyetunji A, Folorunso DO (2016) Green inhibitors for corrosion protection in acidizing oilfield environment. J Assoc Arab Univ Basic Appl Sci 24(1):34–38. https://doi.org/10.1016/j.jaubas.2016.08.001

Deiana M, Rosa A, Casu V, Cottiglia F, Bonsignore L, Dessì MA (2003) Chemical composition and antioxidant activity of extracts from Daphne gnidium L. J Am Oil Chem Soc 80(1):65–70. https://doi.org/10.1007/s11746-003-0652-x

Agi A, Junin R, Rasol M, Gbadamosi A, Gunaji R (2018) Treated Rhizophora mucronata tannin as a corrosion inhibitor in chloride solution. PLoS One. 13(8):e0200595. https://doi.org/10.1371/journal.pone.0200595 (Kumar V (ed), Public Library of Science (PLoS))

Xhanari K, Finšgarv M, Hrnčič MK, Maver U, Knez Ž, Seiti B (2017) Green corrosion inhibitors for aluminum and its alloys: a review. RSC Adv 7(44):27299–27330

Bammou L, Chebli B, Salghi R, Bazzi L, Hammouti B, Mihit M, El Idrissi H (2010) Thermodynamic properties of Thymus satureioides essential oils as corrosion inhibitor of tinplate in 0.5 M HCl: chemical characterization and electrochemical study. Green Chem Lett Rev 3:173–178

Bammou L, Belkhaouda M, Salghi R, Benali O, Zarrouk A, Zarrok H, Hammouti B (2014) Corrosion inhibition of steel in sulfuric acidic solution by the Chenopodium ambrosioides extracts. J Assoc Arab Univ Basic Appl Sci 16:83–90

Hussin MH, Kassim MJ (2011) The corrosion inhibition and adsorption behavior of Uncaria gambir extract on mild steel in 1 M HCl. Mater Chem Phys 125(3):461–468. https://doi.org/10.1016/j.matchemphys.2010.10.032

Nasibi M, Mohammady M, Ghasemi E, Ashrafi A, Zaarei D (2013) Corrosion inhibition of mild steel by nettle (Urtica dioica L.) extract: polarization, EIS, AFM, SEM and EDS studies. J Adhes Sci Technol 27(17):873–1885

Ogwo K, Osuwa J, Udoinyang I, Nnanna L (2017) Corrosion inhibition of mild steel et aluminium in 1 M hydrochloric acid by leaves extracts of Ficus sycomorus. Phys Sci Int J 14(3):1–10. https://doi.org/10.9734/psij/2017/32708

Saviour A, Umoren Moses M, Solomon (2016) Synergistic corrosion inhibition effect of metal cations and mixtures of organic compounds: a review. J Environ Chem Eng 5:246–273. https://doi.org/10.1016/j.jece.2016.12.001

Rajendran S, John Amalraj A, Jasmine Joice M, Anthony N, Trivedi DC, Sundaravadivelu M (2004) Corrosion inhibition by the caffeine–Zn2+ system. Corros Rev 22(3):233–248

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Djouahra-Fahem, D., Angar, Y., Gana, L.M. et al. A Comprehensive Study on Crude Methanolic Extract of Daphne gnidium L. as Effective Corrosion Inhibitors of Mild Steel Induced by SRB Consortium. J Bio Tribo Corros 5, 18 (2019). https://doi.org/10.1007/s40735-018-0210-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-018-0210-8