Abstract

Food industries are facing growing pressure nowadays to confirm that their activities are environmentally sensitive, but there is also increased internal pressure to maintain or increase productivity as well as profitability due to market requirements. The main environmental issues for the food industries are water, energy and natural resources consumptions, solid and liquid waste management, chemicals, land use and air pollution. Therefore, it is necessary for each food industry to establish and implement an integrated management system to identify, manage and control those issues. EMS (Environmental Management System) is considered to be a tool in order to provide guidance and practical solutions to any kind of organizations to improve their performance on environmental aspects. The purpose of this paper is to analyse the barriers that arise during the implementation of an EMS in Cyprus food industry (acting in bakery and confectionary products) in the framework of the international standard of ISO 14001. The major problem arising from the implementation of the ISO 14001: 2004 was related with the requirements of the paragraph 4.5.3 which focuses on non-conformities, corrective actions and preventing actions, as well as on the requirements of the paragraph 4.4.6 which focuses on the operational control.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

According to Testa et al. (2014), an Environmental Management System (EMS) can be applied in any enterprise and organization aiming to improve their environmental aspects while at the same time set targets to improve their environmental performance. The most well-known EMSs are EMAS (Eco Management and Audit Scheme) regulated by the European Regulation EC 1221/2009 and ISO 14001 (which is an international standard) organized and proposed by a private body called International Organization for Standardization (ISO). Daddi et al. (2015) declared that enterprises and organizations mostly react on a voluntary basis to improve their environmental performance and with the implementation of an EMS they receive an authorization (equal to certification) to do so. Furthermore, the perceptions for environmental protection (from top managers) are considered to be part of the commercial world, through the idea and concept of the adoption of EMS. Environmental management looks to insert the concept of sustainable development in the food processing industry as well as on services. Any EMS helps organizations to control permanently the effects of the productive processes on the environment (da Silva and de Medeiros 2004). All EMSs stress the necessity for continual improvement in order to provide protection to the environment mainly for future generations to come (Chavan 2005; Daddi et al. 2016) besides their selves. The ISO 14001 standard can be applied from any kind of enterprises (Rezaee and Elam 2000; Poksinska et al. 2003; Zorpas 2010; Psomas et al. 2011) as it is sufficiently flexible to be implemented to the size of any kind of organization (even in very small or medium enterprises -SMEs- with less than 5 employees), regardless of the type of activities, and geographical, social and cultural circumstances of the organization (Proto and Supino 2000; Fortunski 2008).

The food industry (Djekic et al. 2014) focuses on the safe distribution of high quality of fresh or processed food. Nevertheless, each stage in the food chain, i.e., food manufacturing, handling, distribution, storage, transportation, and sales, has an environmental impact. In the European Union, food industries have had to control regulations relating to different environmental issues for many years (Foster 2010). The food industry is facing growing pressure to guarantee that their actions do not affect the environment as are considered sensitive, but there is also increased internal pressure to maintain or increase effectiveness and profitability. Environmental impacts arise from emissions into the environment as well as from the consumption of resources associated with the production of goods. Water, energy and natural resources consumption, as well as liquid and solid waste production, air pollution and even more the use of chemicals and land use are considered to be the main environmental issues arising from food business sector (Liberty and Echiegu 2015). It is therefore necessary, each food industry to propose, design, establish and implement an EMS to identify their environmental issues and aspects, in order to take several corrective measures to reduce their environmental impacts, as well as to ensure that its performance meets legal requirements. The EMS has several objectives, including: (i) encouraging SMEs to develop an EMS in their manufacture processes: (ii) supporting SMEs to apply concepts of EMS in real time of operation, in order to decrease pollution and comply with regulations, and at the same time, reduce their production cost and increase the efficiency; (iii) evolving environmental awareness among SME entrepreneurs; (iv) laying a solid foundation upon which SMEs could base a further step towards international standards such as EMAS or ISO 14001 (Zorpas 2010). An EMS supports an organization to address its regulatory demands and non-regulated issues, such as energy management and protection, and can endorse stronger and effective operational control and employee stewardship (Yin and Schmeidle 2009). According to Djekic et al. (2014) and Daddi et al. (2016), to develop an EMS, each organization has to evaluate, control and monitor its environmental impacts, set targets to reduce these impacts, and establish a strategy on how to achieve those targets. Additionally, according to the same researchers, the main reasons for applying an EMS are improved regulatory compliance, increased market share and profitability, as well as entering into new green markets.

1.1 EMS Historical Approach

The UK Parliament during 1300 approved laws to monitor the smell arising from Thames River, spoiling their own air. However, the environmental worries were increased due to the Industrial Revolution of the 18th and 19th centuries. In the 1970s, several external factors, like the increased regulatory pressure for environmental protection, the negative publicity on industries, and the concerns from the citizens over the environmental impacts from the industrial processes, forced a number of industries to adopt on a voluntary basis environmental auditing programs which was the beginning of EMSs (Ellis 2014). UNCED (United Nations World Commission on Environment and Development) during 1987 announced a report called “Our Common Future”, which first used the term “sustainable development” and focused on industry to design and establish effective EMSs. As mentioned by Voukkali and Loizia (2015), the recognised “Earth Summit” focus on the improvement of environmental performance was proposed by 50 leaders in Rio de Janeiro in 1992. In 1993, the European Commission announced a regulation (1836/93/EC) focussing on the environmental management and auditing, which is known as EMAS (EMAS 2011). At the same time, the ISO formed a new technical committee branded as TC 207 to propose an international EMS standard as well as several auditing methods, procedures and techniques. Within 1996, ISO 14001 EMS specification was announced and published (Marimon et al. 2011). Through the years, beside of the above standards, a number of associated EMSs were also proposed and established around the world (Table 1).

1.2 Environmental Management System ISO 14000

ISO 14000 (ISO 2015) was developed to help organizations prevent, minimize and reduce their negative effect on the environment from their activities as well as to comply with the existing applicable and related laws and regulations, and to design and establish a strategy for continual enhancement and improvement (ISO 2015). ISO 14001 general philosophy and requirements are very similar to those of ISO 9001 (quality management system), and as Marimon et al. (2009) mentioned, ISO 14001 certifications are strongly related to the certifications of ISO 9001. The ISO 14001 standard defines the organizational procedures and processes in detail, specific activities and employee’s responsibilities, as well as good manufacturing practises (in the concept of preventing, reducing and controlling environmental impacts), internal auditing, general reviewing and maintenance, and finally establishing the company’s environmental policy (Marimon et al. 2009). Moreover, to establish detailed objectives and targets to minimize its environmental impacts, as well as implement environmental programs to reach these objectives (Mezinska and Strode 2015). According to Daddi et al. (2015), the ISO 14001 was introduced in 167 countries until the end of 2012. Among these, the top three countries in terms of the total number of certificates issued were China, Japan and Italy, while the top three regarding the growing number of certificates in 2012 were China followed by Spain and Italy. According to the annual survey organized by ISO in December 2014, 324,148 facilities worldwide had received ISO 14001 certification (ISO 2015; Arimura et al. 2016).

ISO 14001 is a worldwide tool potentially applicable in all the organizations (governmental and non-governmental), aiming to provide actions and progress on their environmental impacts in order to have continual improvement regarding their environmental performance (Testa et al. 2014). The implementation of this type of standards is on a voluntary basis, although in some economy sectors (like in the hospitality industry, tour operators push hotel owners to adopt an EMS) there were pressures from clients (Bernardo et al. 2015). The main benefits from the implementation of an EMS according to Daddi et al. (2015) are associated to the development of preventive environmental actions, and the reduction in the consumption of energy, water, gas and fuel, and raw materials (Daddi et al. 2015). ISO 14001 follows Deming’s well known Quality Management method of “Plan, Do, Check and Act”, which is a four-step management method applied in businesses in order to control their processes and improve their products continually (Fig. 1).

The aim of this paper is to analyse the barriers and difficulties that arise after 8 years of implementation of an EMS in a bakery-confectionary industry in Cyprus, in the framework of ISO 14001.

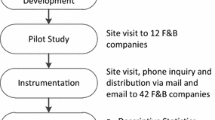

2 Materials and Methods

The industry under study is considered to be a SME (with less than 250 employees). The actual human resources are estimated to be up to 70 employees every year of operation and it was founded in 2005. The industry aims to produce bakery and confectionery products. The factory covers approximately 3400 m2, is located in the industrial area of Frenaros (Easter Region of Cyprus) and currently has 3 outlets located in the nearby Municipalities of Paralimni, Sotira and Agia Napa. The permanent population (in 2011) of the region according to the last inventory report is up to 40,000 citizens. The turnover of the industry is more or less 4–5 million €/y. Since 2006, the industry adopted the implementation of ISO 9001 (Quality Management System) and ISO 22000 (Food Safety Management System), while in 2008 they decided to implement ISO 14001 after receiving pressure from their clients (mostly from the hospitality industry).

The EMS of the industry covers all the stages of the production (including the receiving of raw materials, storage, packaging, distribution and sales). Within the EMS, the industry has recognized its environmental issues. To identify its environmental issues (Table 2), an initial environmental impact assessment was carried based on the guidances by the Department of Environment in Cyprus and presented by the National Law N 102(I)/2005 (National Law 2005).

For the evaluation of the implementation of the requirements of the ISO 14001 standard, outcomes that independent certification bodies provide were taken into consideration (Table 3) for a period of 8 years (2008–2015).

The certification of the EMS is the recognition that the implemented EMS meets the requirements of the ISO 14001. The external audit takes place from an independent certification body based on the requirements of the ISO 19011 which has set the guidelines for auditing (Jose de Oliveira 2013). Each certification is valid for a three-year period and the external audit takes place at least once a year in order to find out if a continual improvement exist and if the requirements of the ISO 14001 are still in place. The audit method allows continual improvement in an EMS because it recognises non-conformities, highlights occasions for improvement, and records how the EMS encourages optimistic practices (Searcy et al. 2012). Non-conformities (non-fulfilment of a requirement) are divided into three categories (this is not a rule of the standard but is an approach widely used from certification bodies): (i) observations, which are suggestions for improvement given by the Auditor; (ii) minor non-conformity, on which the organization needs to take corrective actions until the next evaluation (within 12 months); and (iii) major non-conformity, on which the organization has to take actions in a period of no more than 3 months, otherwise, if conformity cannot be ensured then no certification is given to the organization. According to ISO 14001, ‘Major Non-Conformance is based on objective evidence which shows the absence of, or a significant failure to implement and/or maintain conformance to the requirements of the applicable standard. (i.e. the absence of or failure to implement a complete Management System clause of the standard); or a situation which would on the basis of available objective evidence, raise significant doubt as to the capability of the Management System to achieve the stated policy and objectives of the customer’, and ‘Minor Non-Conformance represents either a management system weakness or minor issue that could lead to a major Non-Conformance if not addressed. Each minor Non-Conformity should be considered for potential improvement and to further investigate any system weaknesses for possible inclusion in the corrective action program’.

3 Results and Discussion

The data were evaluated from the reports that were given to the industry on a yearly basis from the independent certification body. Each report every year presents in details the progress of the organization compared to the implementation of ISO 14001 requirements. The Auditor(s) assesses the requirements of ISO 14001 (Table 3) and records any (if there are) non-conformities (minor or major).

Figure 2 indicates the observations in relation to the requirements of ISO 14001:2004 for the period of 8 years. Most of the audits indicated that the observations were related to the requirements in paragraphs 4.4.2 which focuses on the competence, training and awareness (for years 2009, 2013, 2014), 4.4.6 which focuses on the operational control (for years 2008, 2009, 2012, 2015), 4.5.3 which focuses on non-conformity, corrective action and preventing action (for years 2010, 2011, 2014) and 4.5.4 which focuses on control of records (for years 2009, 2013, 2014). As 2009 was the first year of the implementation, it was expected and it was logical to receive more observations (7). After 3 years of implementation (2011) those were reduced to 4.

Although minor non-conformities (Fig. 3) were observed during the yearly audit (in 2008, 7 minor non-conformities were identified) those were less than the observations. These minor non-conformities needed further attention in order to avoid any inconsistencies from ISO 14001 requirements. In case when no further attention is given to these inconsistencies, they will turn into major non-conformities. Figure 3 indicates that the requirements of paragraph 4.5.3 were the most relevant and frequent issue. The specific paragraph 4.5.3 requires that the organization shall establish, implement and maintain a procedure(s) to deal with real and potential non-confromity(ies) and to take corrective and preventing action(s). Mainly the problem was focused on the way that the representative (Environmental Management) from industry records the results of the corrective and preventing action(s) taken, as well as on the effectiveness of these action(s) as a specific written procedure exists.

As indicated in Fig. 4, no differences were observed on the total numbers of observations and non-conformities (minor and major) comparative to the years 2008, 2009, 2011, 2014. In total, and for the 8 years in reverse series (Fig. 5), the requirements of paragraph 4.5.3 received 12 numbers of observations, minor and major non-conformities, followed by paragraph 4.4.6 with 6, while the other paragraphs presented with 2–4 numbers of observations, minor and major non-conformities.

Table 4 presents the corrective actions taken from the top management regarding non-conformities. Regarding the requirements of paragraph 4.3.2, the non-conformities usually deal with missing legislations from the database. Also, regarding paragraph 4.3.3 of the ISO 14001, the organization shall establish, implement and maintain documented environmental objectives and targets at relevant levels within the organization. In addition, a specific programme(s) should be in place to achieve those objectives and targets. However, during the audit, the auditor(s) found that although those programmes were in place (covering solid and liquid waste management, water resources, energy consumption, noise control, air emissions, chemicals etc.) they were not updated. Usually SMEs give little attention regarding the training programmes that have to be organized for their employees believing that it is “a waste of time”. During the audit, the auditor(s) indicated that those programmes were insufficient (requirement of paragraph 4.4.1), and as a corrective action from the General Manager, specific training sessions had to be established on a yearly basis covering all the requirements of EMS as well as quality and safety. As a result of this action, the productivity of their employees was increased. Audits are a dynamic module of any EMS. The audit process allows continuous improvement in an EMS because it identifies non-conformities, highlights opportunities for improvement, and records how the EMS promotes positive practices.

The evaluation indicated that the implementation of the requirements of the ISO 14001 presents several difficulties. It is obvious that the main problems concern: (a) paragraph 4.5.3 non-conformity, corrective and preventing action (i.e., no corrective actions about the previous inspection observation/non-conformities); (b) paragraph 4.4.6 operational control (e.g., growing plants next to the oil and gas storage area, oil containers were found out of the planned disposal); (c) paragraph 4.5.1 monitoring measurement (i.e., non-compliance with certain legislations); (d) paragraph 4.4.1 resources, roles, responsibility and authority (i.e., roles and responsibilities were not defined); and (e) paragraph 4.4.2 competence, training and awareness (i.e., there is not any available documentation about training).

The main issue for the implementation of the requirements of ISO 14001 is considered to be paragraph 4.5.3, according to Searcy et al. (2012), which indicates that the most common weaknesses have to do with the top manager’s vision which does not demonstrate how important it is. Additionally, according to the same researcher, the problems are solved without any in depth investigation, once the problems first appeared. Probably an explanation for these issues is the fact that the standard does not provide an even more prescriptive clear distinction between a major and minor non-conformity, so it remains to the auditor(s) to justify if it is considered minor on major non-conformity; and this indicates how subjective the opinion of the auditor(s) is. The total cost, according to Massoud et al. (2010), is considered to be one of the main issues that the management team takes into consideration when a decision must be taken to apply or not the standard, and furthermore, if the system is applied, the same issues are presented when minor or major non-conformities are identified during the audit process and corrective actions must be taken.

Furthermore, ISO 14001 focuses on the environmental performance beyond environmental regulations (Rowland-Jones et al. 2005; Yin and Ma 2009). Hence, it does not lead to strict provisions regarding the environmental effect of a business’ activities (Fortunski 2008) which normally means that, it does not stipulate an environmental performance standard, nor environmental performance goals (Liyin et al. 2006). Regarding this, ISO 14001 certification does not assure or guarantee any performance, and assume improvement beyond meeting regulations (Yin and Ma 2009). An interesting internal parameter which affects the implementation of the EMS, as mentioned by To and Tang (2014), is the participation of employees. Employees are either unwilling to get involved in the application of ISO 14001 or it is tough to improve employees’ environmental awareness due to the fact that they are not educated or trained, or even more, they do not really care. One very interesting issue should be the decision from the top manager to turn into EMAS, as employees play a significant role for the successful implementation of EMAS. According to Daddi et al. (2016), the influence of an EMS, and especially EMAS, depends on the need to involve employees in the development and application of management practices reserving to them an active role in the development and application of the management system. Delmas and Pekovic (2012) mentioned that companies adopting an EMS, such as ISO14001, have employees who are 16% more productive than those that do not. Testa et al. (2014) mentioned that the decision to implement ISO 14001 is mainly encouraged by external stakeholders (like tour operators regarding hospitality industry or from supermarkets or from Malls), while the implementation of EMAS is mostly influenced by internal drivers. Internal drivers are, for example, the need to improve management in three areas: environmental compliance, environmental performance and resource efficiency, and organizational and managerial capabilities and awareness (Heras-Saizarbitoria et al. 2011; Daddi et al. 2016). On the other hand, according to Daddi et al. (2011, 2016) and Tourais and Videira (2016), external motivations include the need to obtain a third-party certification in order to boost the reputation in the eye of external stakeholders such as public institutions, clients, trade associations, local communities, and NGOs.

Therefore, lack of vision and specific goals (qualitative and quantitative) of the leadership and/or the management team of the organization, results to improper and ineffective implementation of the system (Zorpas 2010). Government support (i.e., special tax exemption for ISO 14001 certification, fees from external consultant, calibration, emissions measurements etc.) and stakeholder demand, as well as the fact that ISO 14001 is not a legal obligation, constitute the most relevant aspects hindering the implementation of the standard from several economical activities (Massoud et al. 2010).

In order to control and monitor non-conformities, each organization, and more specifically the top manager or the management team, should change their attitude and the way of handling the whole system. Specifically, the leadership must develop a long-term strategic planning, in which, each organization will seek to define roles and responsibilities to each of their employee(s) regarding their responsibilities in implementing the system, as well as to establish continual education program in the framework of lifelong learning (with emphasis, but not limited, on environmental science, development of environmental programs, environmental risk, environmental management systems etc.), and even-more to select suppliers who will satisfy specific environmental requirements (such as the adoption of an EMS in order to minimize their environmental impact by taking actions such as waste prevention, recycling etc).

Zorpas (2010) and Psomas et al. (2011) mentioned that motivations are needed in any organization to implement EMSs as well as to identify their environmental responsibilities. These motivations have to do with the reduction of taxes (the most catchable one), as well as with personal (but not ethical) views and believes. Also, “greening of manufacturing process” and “expected improvement in market performances” and “ecological concerns” seems to be among the most important motivations (Zorpas 2010).

Poksinska et al. (2003) mention that regardless of the increasing interest in voluntary EMSs for industry, limited empirical information exists on systematic experiences of the application processes, and only a few survey studies have been conducted on certified companies with ISO 14001. Additionally, there is a great need for research to indicate evidence on the benefits and dis-benefits of EMSs. The results from this study reveal that the advantages resulting from the adoption of the ISO 14001 are not tremendously high but they can be characterised as very important. Even though the company has been implementing an EMS (ISO 14001) for more than 8 years, it seems that the advantages entirely result after a long period of implementation. The benefits of the implementation start from the internal environment and are transferred in the external environment of the company as general improvement of the processing of the waste management (liquid and solid), monitoring and control of energy and water consumptions, reduction in chemical use, etc. within the framework of better environmental concern and performance. This helps the industry to improve the relationship with the society, and finally, its position in the market, although the internal advantages are most significant than the external ones.

4 Conclusions

Any EMS needs specific requirements which an organization has to implement to reduce its environmental impact. An EMS can be used as a tool for any organization to identify, prevent, improve, control and monitor its environmental performance and grow its business competence. The implementation of an EMS is not simple and easy because personal effort is required. Economic reasons and the typical structure of the organizations are the most important incentives to stimulate the employees and the management team to adopt EMSs. Additionally, the fact that the implementation of a standard is not a legal requirement and there is not any requirement or demand from customers or stakeholders constitutes a negative effect on applying the standard. It is, therefore, crucial to recognise effective and realistic incentives as mentioned above, to inspire SMEs to implement EMSs. SMEs seem to need support and guidance, in particular for the environmental review, environmental aspects and significance assessment. Moreover, the collaboration between the leadership and employees is crucial. Both of them must have a common purpose and goal to identify targets and objectives to minimize their environmental impact and operate their procedures in a sustainable way. By the end of 2018, the industry should adapt its EMS according to the new version of ISO 14001:2015, and must include leadership, risk analysis, context analysis etc. It could be very interesting in the near future to evaluate the implantation of the old ISO 14001 with the new version. Also, a very interesting issue could be the passage to EMAS rather than ISO 14001.

References

Arimura T, Darnall N, Ganguli R, Katayama H (2016) The effect of ISO 14001 on environmental performance: resolving equivocal findings. J Environ Manag 166:556–566

Bernardo M, Simon A, Jose Tarí J, Molina-Azorín FJ (2015) Benefits of management systems integration: a literature review. J Clean Prod 94:260–267

Chavan M (2005) An appraisal of environment management systems: a competitive advantage for small businesses. Management of Environmental Quality: An International Journal 16(5):444–463

da Silva GCS, de Medeiros DD (2004) Environmental management in Brazilian companies. Manage Environ Qual Int J 15(4):380–388

Daddi T, Frey M, Iraldo F, Nabil B (2011) The implementation of an environmental management system in a north-African local public administration: the case of the city council of Marrakech (Morocco). J Environ Plan Manage 54:813–832

Daddi T, Frey M, De Giacomo MR, Iraldo F, Testa F (2015) Macro-economic and development indexes and ISO14001 certificates: a cross national analysis. J Clean Prod 108:1239–1248

Daddi T, Testa F, Frey M, Iraldo F (2016) Exploring the link between institutional pressures and environmental management systems effectiveness: an empirical study. J Environ Manag 183(3):647–656

Delmas M, Pekovic S (2012) Environmental standards and labour productivity: understanding the mechanisms that sustain sustainability. J Organ Behav 34:230–252

Djekic I, Rajkovic A, Tomic N, Smigic N, Radovanovic R (2014) Environmental management effects in certified Serbian food companies. J Clean Prod 76:196–199

Ellis J (2014) A History of ISO 14001:2014 http://www.greenelement.co.uk/. Accessed 16 March 2016

EMAS (2011) European Commission. Brussels, Belgium http://ec.europa.eu/environment/emas/index_en.htm

Fortunski B (2008) Does the environmental management standard ISO 14001 stimulate sustainable development? An example from the energy sector in Poland. Manage Environ Qual Int J 19(2):204–212

Foster C (2010) Establishing an environmental management system in food industry. Environmental Assessment and Management in the Food Industry:333–355

Heras-Saizarbitoria I, Landin GA, Molina-Azorin JF (2011) Do drivers matter for the benefits of ISO 14001? Int J Op Prod Manag 31:192–216

International Organisation for Standardisation (2004) Environmental management systems – Requirements with guidance for use (ISO 14001)

International Organisation for Standardisation (2015) The ISO survey of management system standard certifications 2014. ISO, Geneva, Switzerland International Standard organizations http://www.iso.org/iso/home.html. Accessed 17 March 2016

Jose de Oliveira O (2013) Guidelines for the integration of certifiable management systems in industrial companies. J Clean Prod 57:124–133

Liberty J, Echiegu E (2015) An appraisal of the environmental impacts of food processing industrial waste in Nigeria. Journal of Natural Sciences Research http://www.iiste.org ISSN 2224-3186 (Paper) ISSN 2225-0921 (Online) 5

Liyin S, Hong Y, Griffith A (2006) Improving environmental performance by means of empowerment of contractors. Manage Environ Qual Int J 17(3):242–257

Marimon F, Heras I, Casadesus M (2009) ISO 9000 and ISO 14000 standards: a projection model for the decline phase. Total Qual Manage Bus Excellence 20(1):1–21

Marimon F, Llach J, Bernardo M (2011) Comparative analysis of diffusion of the ISO 14001 standard by sector of activity. J Clean Prod 19:1734–1744

Massoud AM, Fayad R, El-Fadel M, Kamleh R (2010) Drivers, barriers and incentives to implementing environmental management systems in the food industry: a case of Lebanon. J Clean Prod 18:200–209

Mezinska I, Strode S (2015) Emerging horizons of environmental management in food sector companies. Procedia - Social Behav Sci 213:527–532

National Law (2005). N. 102(I)/2005 regarding the Environmental Impact Assessment from industrial activities

Poksinska B, Dahlgaard JJ, Eklund JAE (2003) Implementing ISO 14000 in Sweden: motives, benefits and comparisons with ISO 9000. Int J Qual Reliab Manage 20(5):585–606

Proto M, Supino S (2000) Ecomanagement quality system: ISO 14000. The state-of-the-art in Italy. Total Qual Manage Bus Excellence 11(4):767–772

Psomas LE, Fotopoulos V, Kafetzopoulos PD (2011) Motives, difficulties and benefits in implementing the ISO 14001 environmental management system. Manage Environ Qual Int J 22(4):502–521

Rezaee Z, Elam R (2000) Emerging ISO 14000 environmental standards: a step-by-step implementation guide. Manag Audit J 15(1/2):60–67

Rowland-Jones R, Pryde M, Cresser M (2005) An evaluation of current environmental management systems as indicators of environmental performance. Manage Environ Qual Int J 16(3):211–219

Searcy C, Morali O, Karapetrovic S, Wichuk K, McCartney D, McLeod S (2012) Challenges in implementing a functional ISO 14001 environmental management system. International Journal of Quality & Reliability Management 29(7):779–796

Testa F, Rizzi F, Daddi T, Gusmerotti MN, Frey M, Iraldo F (2014) EMAS and ISO 14001: the differences in effectively improving environmental performance. J Clean Prod 68:165–173

To WM, Tang M (2014) The adoption of ISO 14001 environmental management systems in Macao SAR, China. Manage Environ Qual Int J 25:244–256

Tourais P, Videira N (2016) Why, how and what do organizations achieve with the implementation of environmental management systems? Lessons from a comprehensive review on the eco-management and audit scheme. Sustainability 8:283. doi:10.3390/su8030283

Voukkali I, Loizia P (2015) Policies and legislation. Sustainability Behind Sustainability, Eds A.A.Zorpas. Nova Science Publishers Inc, In, pp 7–16

Yin H, Ma C (2009) International integration: a hope for a greener China? Int Market Rev 26(3):348–367

Yin H, Schmeidle P (2009) Why do standardized ISO 14001 environmental management systems lead to heterogeneous environmental outcomes. Bus Strateg Environ 18:469–486

Zorpas AA (2010) Environmental management systems as sustainable tools in the way of life for the SMEs and VSMEs. Bioresour Technol 101(6):1544–1557

Acknowledgements

An initial version of the paper has been presented in the “13th International Conference on Protection and Restoration of the Environment”, 3rd to 8th July, 2016, Mykonos island, Greece.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Voukkali, I., Loizia, P., Pociovalisteanu, D.M. et al. Barriers and Difficulties Concerning the Implementation of an Environmental Management System in a Bakery-Confectionary Industry in Cyprus for 8 Years. Environ. Process. 4 (Suppl 1), 263–275 (2017). https://doi.org/10.1007/s40710-017-0242-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40710-017-0242-y