Abstract

Purpose of review

Heating, ventilation, and air-conditioning (HVAC) system control and building demand management play important roles in building energy efficiency and sustainability, and thus motivate numerous studies in recent decades. In this article, we provide a review of the developments in both HVAC control and demand management in recent 5 years, helping readers to understand the new significant trends and achievements in these both areas.

Recent findings

We collected and analyzed a number of representative publications and found that the developments of HVAC system control have two significant trends: to improve the robustness of control and to improve the efficiency of system level real-time optimization; while demand management emphasizes the coordinated control in building-group-level other than single-building-level.

Summary

The improvement of the robustness of the HVAC systems control can guarantee the control performance under uncertainties; the improvement of the efficiency of the system level real-time optimization can significantly enhance the building energy efficiency, while the coordinated demand management can optimize the aggregated load profile for better serving the actual needs of a grid. Because buildings are integrating more and more advanced systems with complex dynamics, continuous efforts are needed to deal with the challenges in both HVAC system control and demand management.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Buildings consume over 40% of end-use energy worldwide [1]. How to improve the building energy efficiency has gained much attention as the reduction of building energy use can effectively contribute to the environment sustainability. There are many ways to improve building energy efficiency, such as to improve the building design and to select more energy-efficient devices at the design stage. For existing systems, numerous studies have shown that building energy efficiency can be improved through enhancing the performance of HVAC system control [2] and demand management [3].

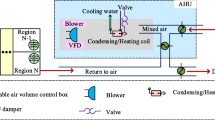

HVAC system is the most complex system in a building, representing the largest energy user among the building systems in many countries. The control of HVAC systems is implemented to maintain the environmental variables inside buildings, such as temperature, humidity, air movement, and fresh air percentage at the desirable level [1, 4]. HVAC system control has been developed for many years whether in the process control level or in the system optimization level [5, 6]. In the recent 5 years (2011–2016), HVAC system control still experienced fast development. One significant trend, as we observed, is how to improve the control robustness in both the process control level and the system optimization level. This gains wide attention because the uncertainties in the operation of HVAC systems are widely existent and have been found to affect the performance of HVAC system control substantially [7]. Another significant trend is the system level real-time optimization. This optimization presents a large-scale mathematic programming challenge because multiple decision variables for many control loops must be considered and a large number of nonlinear models, such as those for cooling towers, chillers, pumps, and fans, must be used to describe complex interactions between the controls of different components and subsystems, and predict overall energy use. In the review of HVAC system control, we will focus on these two trends. Several representative papers in each category will be introduced in order to illustrate the basic principles in these developments.

Demand management refers to the changes in electric usage by buildings from their normal use patterns in response to the changes in the price of electricity over time, or to incentive payments or when system reliability is jeopardized [8]. It becomes important because the power supply and the demand in a grid should be balanced. Real-time imbalance can cause grid instability or even total grid failure. To maintain the grid power balance, great efforts need to be made from the supply side. Nowadays, the supply side management becomes increasingly costly and technically more difficult as more and more renewable energy systems are integrated. Hence, the demand management, i.e., efforts from the demand side, is widely accepted as a better alternative. Among different users at the demand side, building plays a significant role in maintaining grid power balance since it represents a large energy user [9••]. Most of the demand management in residential buildings can be formatted as an optimal scheduling problem [10, 11]. In contrast, the demand management in commercial buildings involves more complex strategies and draws more attentions. The recent developments in the commercial building demand management can be grouped into two categories. First, the demand management is performed on individual-building-level which merely considers economic benefit of single building. Such demand management is denoted as “single building demand management” in this study. Second, the demand management is performed in a coordinated way which optimizes the aggregated load profile of building group for better serving actual needs of grid. Such demand management is denoted as “building group demand management” in this study. Once again, several representative papers in each category will be introduced in order to illustrate the basic principles in these developments.

In the rest of the paper, we will briefly introduce the building services systems firstly and then the developments in both HVAC systems control and demand management in recent five systems will be illustrated. Our personal views on the future development will also be given. The final part is the concluding remarks.

Brief Introduction of Building Services Systems

Buildings are equipped with many services systems in order to provide the functions of comfort, health, and safety for occupants. The major services systems in commercial buildings are shown in Fig. 1, including basic services systems, such as lighting/transportation system, fire protection system, security system and HVAC system, and advanced systems, such as power management system, renewable energy system, thermal storage system, and load management system. Building automation system (BAS) provides a platform to integrate all these systems and realize the functions of monitoring, control, optimization, and management [12]. Among these services systems, HVAC systems are used to guarantee occupants a thermal comfortable and healthy indoor environment. Since HVAC systems consume generally the major percentage of energy in a building, it needs to collaborate with other services systems, such as demand management system, renewable energy system, and thermal storage system, to enhance building energy efficiency and sustainability [1].

Recent Developments in HVAC System Control

Robustness-Enhanced Control

Robustness-enhanced control has been developed to improve the performance of HVAC control under uncertainty. Uncertainty arises from incomplete information about the state of the system, making it impossible to exactly describe or predict the state [13]. In the current HVAC literature, uncertainties are classified into three categories [7]: model-inherent uncertainty caused by inaccurate or incomplete data in the analytic model and/or lack of a reasonable regression (such as model topology, model resolution, and realism), process-inherent uncertainty caused by randomness and bias during control process (such as sensor bias and unknown characteristics of controllers), and scenario-forecast uncertainty due to unpredictable discrepancy in forecasting the driving forces located outside the system (such as weather forecast and building operation forecast). Robustness-enhanced control has been developed to deal with these uncertainties in both the process control level and the system optimization level.

In the process control, uncertainties affect the control performance by deteriorating the control stability, enlarging tracking errors and prolonging transient response [14]. In the process control design, uncertainties are always described using a uncertainty set, i.e., variables or parameters that are associated with uncertainty are limited into a range specified by known lower and upper bound, as shown in Eq. (1) [15]:

If possible, a simple figure how some of uncertainties are included in control and how it helps to improve the control should be given if possible.

where θ is a concerned uncertain variable, \( \underline{\theta} \) and \( \overset{-}{\theta } \) are its possible minimum and maximum value. The control design takes the associated uncertainty directly or indirectly but with the same objective to guarantee the predefined control objectives to be fulfilled when the concerned variables vary inside its uncertainty set. For example, Huang et al. [16•] studied the robust control of air-handling units that can be described by a first order plus time delay (FOPTD) model, where the process gain, time constant, and time delay were specified using uncertainty sets as shown in Eq. (1) and then the generalized eigenvalue minimization was adopted to calculate a feedback control law. Huang and Jordan [17] developed a model-based robust control for VAV terminal units to control the zone temperature. The zone temperature process was described by a bilinear model, where the cooling load of the zone is assumed to be inside an uncertainty set as shown in Eq. (a) as well, and a bilinear feedback controller was designed to deal with the input-output bi-linearity. Moradi et al. [18] proposed a PID-Fuzzy control of air-handling units in the presence of uncertainty, where all the AHU thermo-fluid parameters were assumed to be uncertain and the uncertainties were specified using uncertainty sets in the form of Eq. (1).

Robustness-enhanced control has been applied to the system optimization level as well, which aims to find the optimal decision variables for HVAC systems under uncertainty. Similar to the robust process control, the uncertainties in the system optimization level can be described using uncertainty sets, but other forms of stochastic distribution were also adopted. In the work of Liao et al. [19, 20], the uncertainties in chiller optimal sequencing control were studied, including operational uncertainty, control uncertainty, measurement uncertainty, and the uncertainties in setting thresholds. These uncertainties were described using whether normal distributions or uncertainty sets. Uncertainty analysis was carried out to understand how those uncertainties affect the sequencing operation regarding to energy use and unmet hours of the cooling supply [19]. Robust analysis was performed to investigate the sensitivity of chiller sequencing control to those uncertainties [20]. In the work of Oldewurtel et al. [21], the uncertainties in the weather and internal gains prediction were considered in their model-based predictive control (MPC) scheme, and those prediction uncertainties were modeled using a normal distribution. Stochastic MPC was developed to deal with the indoor environment control problem and their studies showed that the stochastic MPC was able to directly account for the uncertainty of the weather forecast in its control decisions and resulted in much smaller diurnal temperature variations compared with the traditional MPC. Zhang et al. [22] studied a similar problem using a similar description for the uncertainty in the weather forecast but additively considered the errors made when linearizing the nonlinear system dynamics and bounded them using an uncertainty set in the form of Eq. (1). Schirrer et al. [23] proposed a nonlinear modular MPC for the HVAC system of a low-energy office building, which took account of both model and prediction uncertainties.

System Level Real-Time Optimization

HVAC system is a large-scale system and it contains many local control loops. The set-points or control settings (such as on/off schedule) of many control loops have a significant influence on the energy performance [1]. Optimal control is therefore utilized to seek energy-efficient control settings or set-points (titled as decision variables thereafter) for local control loops without sacrificing indoor thermal comfort [24]. It is always carried out by taking account of interactions between HVAC components and the thermal characteristics of buildings according to the present or predicted load condition [1]. In current literature, real-time optimization can be grouped into prediction-based optimal control (normally referred as model predictive control) and non-prediction-based optimal control.

The prediction-based optimal control (or MPC) has gained popularity for HVAC system control [25, 26], and its effectiveness has been demonstrated through both numerical simulation and experiments in a number of recent papers [27•, 28, 29]. The prediction-based optimal control optimizes the decision variables using the system dynamic models (such as auto-regressive moving-average model [27•], resistance-capacitance (RC) model [21], or neural network model [28]) according to weather and internal gain predictions. In Bengea et al. [27•], the prediction-based optimal control was applied to a variable air volume (VAV) HVAC system in a building in the Midwestern US to control to generate optimal set-points for the building HVAC subsystems in real time by searching for the most energy-efficient control input sequences subject to system constraints (thermal comfort, component performance) and disturbances (weather, internal loads). Through simulation studies, they showed that the prediction-based optimal control was able to reduce energy usage while maintaining constraints on space temperatures. In Ferreira et al. 2012 [28], the prediction-based optimal control was applied to a building to reduce the energy use, where a neural network was used to describe the system dynamics. The work of Oldewurtel et al. [21], Zhang et al. [22], and Schirrer et al. [23] also belongs to this category, but all of them used an RC model to describe the system dynamics.

The non-prediction-based optimization, different from the prediction-based optimization, is to find the optimal decision variables only according to current operational conditions. In this category, system models are also needed to describe the system dynamics and the relationship between the decision variables and the concerned criteria, based on which the optimal decision variables are searched. Adopting a gray-box power model of HVAC systems, Sun et al. [30] developed a multiplexed real-time optimization scheme for complexed HVAC system, where the decision variables were optimized sequentially with one variable at one time but with a faster optimization frequency. Using a similar gray-box power model of HVAC systems, Wang et al. compared the advantages and disadvantages of event-based model-based optimization and time-driven model-based optimization in their work [31], and developed an event-based optimization strategy for chiller plants [32•].

Recent Developments in Demand Management

Single Building Demand Management

Load shedding and load shifting are two main means used for single building demand management. The load shedding control reduces the peak electric load in a building via turning off non-essential electrical load [33••]. Different approaches including priority-based load shedding [34] and statistics-based load shedding [35] have been developed and adopted in practice. Compared with the load shedding control, the load shifting is more commonly used for peak demand management. The load shifting aims at taking advantages of electricity rate difference via shifting on-peak load to off-peak hour. Since HVAC systems in commercial buildings consume the major percentage of energy, many studies focus on the load shifting control of HVAC systems [36, 37•]. The development of a load shifting control strategy consists of three essential parts including load prediction, cooling charging, and discharging controls [37•]. Since a certain amount of cooling loss is inevitable in both charging and discharging processes, peak demand reduction through load shifting control is mostly realized at the cost of energy increase.

Different charging and discharging controls have been developed as different thermal energy storage facilities are used. Four facilities have been widely used and they are building thermal mass-BTM [38,39,40,41], thermal energy storage system-TES [42••, 43,44,45], combined use of BTM and TES [46, 47], and phase change material (PCM) [48, 49, 50••, 51, 52]. No matter whatever facilities used, the trade-off between peak demand reduction and the associated energy increase need to be well considered. Otherwise, the economic benefits from building demand management can be partially or completely compromised by the energy cost increase [36].

One major limitation of the above single building demand management is that they merely focus on economic benefits of individual buildings and they are conducted in an uncoordinated way. With such uncoordinated control, the resulting aggregated load profile cannot be optimized for the actual needs of grid. Being aware of such limitation, both the grid and building researchers have raised an important question on how to coordinate the demand management of a group of end-users to better serve the actual needs of a grid in terms of power balance [9••, 42••, 53].

Building Group Demand Management

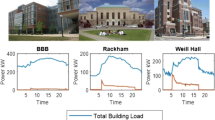

Conventional demand management is performed in an uncoordinated way which merely focuses on single-building-level economic benefits. To this end, its building-group-level performance, which is the real concern to grid, may not be optimized. In order to evaluate performance of conventional demand management at building-group-level, Shen et al. used operation data of real buildings to perform the simulation study under common electricity pricings [54]. The evaluation results disclosed several limitations of conventional demand management due to lack of coordination. Under time of use pricing, conventional demand management was found unable to effectively and efficiently reduce peak demand at building-group-level. Under dynamic pricing, conventional demand management can cause a new undesirable peak demand at building-group-level which could be much larger than the original one and imposed heavier stress on grid.

In order to overcome these limitations, a few studies have been carried out on coordinated demand management in a group of commercial buildings. A study was conducted to develop a coordinated demand management method based on Genetic Algorithm [55•]. Under the time of use pricing, the proposed control aimed to minimize the overall peak demand of a group of buildings by coordinating storage system charging and discharging control of individual buildings via GA. The case study results demonstrated the improved performance of the proposed coordinated demand management in terms of building group level peak demand limiting and the associated extra energy consumption. Similarly, using particle swarm optimization, a coordinated operation framework was proposed to determine the optimal operation strategies of a building cluster [56]. The operation framework utilized multi-objective optimizations to determine the operation strategies: building temperature set-points, energy storage charging, and discharging schedules, etc. The case study results showed that the developed building cluster collaborative operation framework was able to reduce the energy cost by 12.1–58.3% under different electricity pricing plans and thermal comfort requirements.

Meanwhile, considering the joint operation of multiple smart buildings could be more advantageous than the independent operation of each individual one, a multi-party energy management model for a building cluster based on game theory was proposed [57]. In the study, all participating smart buildings were viewed as players in the game and the energy management framework for achieving optimal operations of smart building cluster was introduced. The study proved the existence of Nash equilibrium in the game model and the process for solving the Nash equilibrium strategy was modeled as a multi-objective optimization problem. Via a practical example, the effectiveness of the model is verified. In addition, with the development and extensive use of building automation systems, information and communication technologies and grid energy management system, a bidirectional communication between buildings and a grid can be established and used for interacting and optimizing the power supply and the demand. Considering the potential bidirectional communication between buildings and grid, Xue et al. presented an interactive building power demand management strategy for the interaction of commercial buildings with a smart grid and facilitating the grid optimization [58]. The case study results showed that the power imbalance could be significantly reduced when the effective interaction between the power supply and the demand was established.

Discussions and Conclusions

This study provides a review of the recent developments in HVAC system control and demand management. In the recent 5 years, many studies on HVAC system control were found to emphasize the control reliability and robustness because the importance of uncertainty, such as in the weather prediction or the internal gain prediction, has been recognized. The robustness and reliability of the HVAC systems control, whether in the process control loop or the system real-time optimization level, remain a challenge because uncertainties are widely existent in building operation and they are difficult to be quantified due to the lack of data and the variations of building design, which needs more efforts in the future. On the system level, real-time optimization, except for uncertainty that needs further studies, continuous efforts are necessary for improving the computational efficiency. This is because more and more advanced systems (such as renewable energy system and thermal storage system) are integrated into buildings and their dynamic behaviors are complex. The system level real-time optimization will be a super complex programming problem with a large number of decision variables. This might seriously limit its application in practice if the computational efficiency cannot be solved.

Conventional demand management takes a single building/system as study object and they merely focus on maximizing their own economic benefits through load profile alterations. The load profiles of individual buildings are altered in an uncoordinated way and the resulting aggregated load profile (i.e., the sum of individual load profiles), which is the actual concern of a grid, is overlooked and cannot be optimized. In contrast, through coordinated control, the overall peak demand of the aggregated load profile can be more effectively and efficiently reduced in a desired way of a grid. Grid and building researchers started to realize the limitations of the conventional demand management, and studies have been carried out to develop coordinated demand management for a group of buildings. The study results have shown that the coordinated demand management is able to optimize the aggregated load profile for better serving the actual needs of a grid. In future studies, more efforts need to be made on how properly coordinating a number of buildings since the complexity of coordinated control may increase exponentially with the building number.

References

Papers of particular interest, published recently, have been highlighted as: • Of importance •• Of major importance

ASHRAE. ASHRAE handbook-HVAC applications (SI). Atlanta: ASHRAE Inc.; 2011.

Dounis AI, Caraiscos C. Advanced control systems engineering for energy and comfort management in a building environment—a review. Renew Sust Energ Rev. 2009;13:1246–61.

Strbac G. Demand side management: benefits and challenges. Energy Policy. 2008;36:4419–26.

Salsbury T. A survey of control technologies in the building automation industry. In: Proc. of the 16th IFACWorld Congress. Prague, Czech Republic; 2005. p. 331–341.

Underwood CP. HVAC control systems: modeling, analysis and design. E & FN Spon: London & New York; 1999.

Wang SW, Ma ZJ. Supervisory and optimal control of building HVAC systems: a review. HVAC&R Research. 2008;14:3–32.

Kim SH, Augenbroe G. Uncertainty in developing supervisory demand-side controls in buildings: a framework and guidance. Autom Constr. 2013;35:28–43.

IEA Statistics: World energy statistics and balances, international energy agency (IEA), 2014.

•• Larsen GKH, Foreest NDV, Scherpen JMA. Power supply–demand balance in a smart grid: an information sharing model for a market mechanism. Appl Math Model. 2014;38(13):3350–60. Different from existing network models with hierarchical structures, a novel network model was developed to describe how the information of power imbalance of individual agents can be more effectively exchanged.

Yoon JH, Bladick R, Novoselac A. Demand response for residential buildings based on dynamic price of electricity. Energy and Buildings. 2014;80:531–41.

Bartusch C, Alvehag K. Further exploring the potential of residential demand response programs in electricity distribution. Appl Energy. 2014;125(15):39–59.

Wang SW. Intelligent buildings and building automation. Abingdon, Oxon: Spon Press; 2009.

Kochenderfer MJ. Decision making under uncertainty—theory and application. Cambridge: The MIT Press; 2015.

Zhou K, Doyle CJ. Essentials of robust control. USA: Prentice Hall; 1999.

Underwood CP. Robust control of HVAC plant I: modeling; II: controller design. Building Serv Eng Res Technol. 2000;21(1):53–71.

• Huang GS, Ling KV, Xu XL, Liao YD. Generalized eigenvalue minimization for uncertain first order plus time delay processes. ISA Trans. 2014;53:141–9. The study proposed a complete design of a robust controller when the process suffers from the uncertainties associated with the process gain, time constant and time delay. The proposed design can be applied to many HVAC process for robustness enhancement.

Huang GS, Jordán F. Model-based robust temperature control for VAV air-conditioning system. HVAC&R Research. 2012;18(3):432–45.

Moradi H, Setayesh H, Alasty A. PID-fuzzy control of air handling units in the presence of uncertainty. Int J Therm Sci. 2016;109:123–35.

Liao YD, Huang GS, Sun YJ, Zhang LF. Uncertainty analysis for chiller sequencing control. Energy and Buildings. 2014;85:187–98.

Liao YD, Sun YJ, Huang GS. Robustness analysis of chiller sequencing control. Energy Convers Manag. 2015;103:180–90.

Oldewurtel F, Parisio A, Jones CN, Gyalistras D, Gwerder M, Stauch V, Lehmann B, Morari M. Use of model predictive control and weather forecasts for energy efficient building climate control. Energ Buildings. 2012;45:15–27.

Zhang X, Schildbach G, Sturzenegger D, Morari M. Scenario-based MPC for energy-efficient building climate control under weather and occupancy uncertainty. European Control Conference (ECC), July 17–19, Zürich, Switzerland; 2013

Schirrer A, Brandstetter M, Leobner I, Hauer S, Kozek M. Nonlinear model predictive control for a heating and cooling systemof a low-energy office building. Energy and Buildings. 2016;125:86–98.

Kao JY. Control strategies and building energy consumption. ASHRAE Trans. 1985;91(2B):510–817.

Afram A, Janabi-Sharifi F. Theory and applications of HVAC control systems—a review of model predictive control (MPC). Build Environ. 2014;72:343–55.

Killian M, Kozek M. Ten questions concerning model predictive control for energy efficient buildings. Build Environ. 2016;105:403–12.

• Bengea SC, Li P, Sarkar S, Vichik S, Adetola V, Kang K, Lovett T, Leonardi F, Kelman AD. Fault-tolerant optimal control of a building HVAC system. Science and Technology for the Built Environment. 2015;21:734–51. Good study to provide a comprehensive and systematic analysis on the application of model predictive control on HVAC systems.

Ferreira PM, Silva S, Ruano AE. Model based predictive control of HVAC systems for human thermal comfort and energy consumption minimization. IFAC Proceedings Volumes (IFAC-PapersOnline); 2012. p. 236–241.

Goyal S, Barooah P, Middelkoop T. Experimental study of occupancy-based control of HVAC zones. Appl Energy. 2015;140:75–84.

Sun YJ, Huang GS, Li ZW, Wang SW. Multiplexed optimization of complex AC systems. Build Environ. 2013;65:99–108.

Wang JQ, Huang GS, Sun YJ. Optimal control of complex HVAC systems: event-driven or time-driven optimization? CLIMA, may 22–25. Denmark: Aalborg; 2016.

• Wang JQ, Huang GS, Sun YJ, Liu XP. Event-driven optimization of complex HVAC systems. Energy and Buildings. 2016;133:79–87. A good study which firstly proposed a new optimization mechanism (event-driven optimization other than conventional time-driven optimization) that can deal with the stochastic behaviours in the operation of complex HVAC systems.

•• Rotger-Griful S, Jacobsen RH, Nguyen D, Sørensen G. Demand response potential of ventilation systems in residential buildings. Energy and Buildings. 2016;121(1):1–10. The study performed reliable experimental and simulation tests to demonstrate the significant demand response potential of fan control aggregation.

Kato T, Takahashi H, Sasai K, Kitagata G, Kim H, Kinoshita T. Priority-based hierarchical operational management for multiagent-based microgrids. Energies. 2014;7:2051–78.

Seem JE. Adaptive demand limiting control using load shedding. HVAC&R Research. 1995;1(1):21–34.

Patteeuw D, Henze GP, Helsen L. Comparison of load shifting incentives for low-energy buildings with heat pumps to attain grid flexibility benefits. Appl Energy. 2016;167(1):80–92.

• Sun YJ, Wang SW, Xiao F, Gao DC. Peak load shifting control using different cold thermal energy storage facilities in commercial buildings: a review. Energy Convers Manag. 2013;71:101–14. The study conducted a comprehensive literature review on the peak load shifting controls using different types of thermal storage facilities.

Favre B, Peuportier B. Application of dynamic programming to study load shifting in buildings. Energy and Buildings. 2014;82:57–64.

Li XW, Malkawi A. Multi-objective optimization for thermal mass model predictive control in small and medium size commercial buildings under summer weather conditions. Energy. 2016;112(1):1194–206.

Kim SH. An evaluation of robust controls for passive building thermal mass and mechanical thermal energy storage under uncertainty. Appl Energy. 2013;111:602–23.

Yin RX, Karaa EC, Li YP, DeForest N, Wang K, Yong TY, Stadler M. Quantifying flexibility of commercial and residential loads for demand response using setpoint changes. Appl Energy. 2016;177:149–64.

•• Yalcintas M, Hagen WT, Kaya A. An analysis of load reduction and load shifting techniques in commercial and industrial buildings under dynamic electricity pricing schedules. Energy and Buildings. 2015;88(1):15–24. Excellent study, by investigating potential cost conservation measures that focus on reducing energy at times of higher energy costs, the study demonstrated that even simple shifting work schedules in office buildings can reduce significant monthly electricity bill.

Molavi H, Ardehali MM. Utility demand response operation considering day-of-use tariff and optimal operation of thermal energy storage system for an industrial building based on particle swarm optimization algorithm. Energy and Buildings. 2016;127(1):920–9.

Patteeuw D, Bruninx K, Arteconi A, Delarue E, D’haeseleer W, Helsen L. Integrated modeling of active demand response with electric heating systems coupled to thermal energy storage systems. Appl Energy. 2015;151(1):306–19.

Arteconi A, Xu J, Ciarrocchi E, Paciello L, Comodi G, Polonara F, Wang RZ. Demand side management of a building summer cooling load by means of a thermal energy storage. Energy Procedia. 2015;75:3277–83.

Henzea GP, Felsmannb C, Knabeb G. Evaluation of optimal control for active and passive building thermal storage. Int J Therm Sci. 2004;43(2):173–83.

Hajiah A, Krarti M. Optimal control of building storage systems using both ice storage and thermal mass—part I: simulation environment. Energy Convers Manag. 2012;64:499–508.

Chernousov AA, Chan BYB. Numerical simulation of thermal mass enhanced envelopes for office buildings in subtropical climate zones. Energy and Buildings. 2016;118(15):214–25.

Barzin R, Chen JJJ, Young BR, Farid MM. Peak load shifting with energy storage and price-based control system. Energy. 2015;92:505–14.

•• Stathopoulos N, MEL M, Issoglio R, Michel P, Haghighat F. Air–PCM heat exchanger for peak load management: experimental and simulation. Sol Energy. 2016;132:453–66. Excellent study: the study presented a simple and reliable air-PCM heat exchanger model which can be used as a tool for the development of advanced control strategies taking into account various factors.

Rathod MK, Banerjee J. Thermal stability of phase change materials used in latent heat energy storage systems: a review. Renew Sust Energ Rev. 2013;18:246–58.

Porteiro J, Míguez JL, Crespo B, González LML, Lara JD. Experimental investigation of the thermal response of a thermal storage tank partially filled with different PCMs (phase change materials) to a steep demand. Energy. 2015;91:202–14.

Muratori M, Schuelke-Leech B-A, Rizzoni G. Role of residential demand response in modern electricity markets. Renew Sust Energ Rev. 2014;33:546–53.

Shen LM, Li ZW, Sun YJ. Performance evaluation of conventional demand response at building-group-level under different electricity pricings. Energy and Buildings. 2016;128:143–54.

• Gao DC, Sun YJ. A GA-based coordinated demand response control for building group level peak demand limiting with benefits to grid power balance. Energy and Buildings. 2016;110(1):31–40. Unlike conventional demand response controls focusing on individual-building-level, a novel coordinated demand response control with benefits to grid power balance was proposed to more effectively and efficiently limiting the overall peak demand of building groups.

Li XW, Wen J, Malkawi A. An operation optimization and decision framework for a building cluster with distributed energy systems. Appl Energy. 2016;178(15):98–109.

Ma L, Liu N, Wang LF, Zhang JH, Lei JY, Zeng Z, Wang C, Cheng MY. Multi-party energy management for smart building cluster with PV systems using automatic demand response. Energy and Buildings. 2016;121(1):11–21.

Xue X, Wang SW, Sun YJ, Xiao F. An interactive building power demand management strategy for facilitating smart grid optimization. Appl Energy. 2014;116(1):297–310.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflicts of interest.

Human and Animal Rights and Informed Consent

This article does not contain any studies with human or animal subjects performed by any of the authors.

Additional information

This article is part of the Topical Collection on Building Sustainability

Rights and permissions

About this article

Cite this article

Sun, Y., Huang, G. Recent Developments in HVAC System Control and Building Demand Management. Curr Sustainable Renewable Energy Rep 4, 15–21 (2017). https://doi.org/10.1007/s40518-017-0064-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40518-017-0064-6