Abstract

Accurate energy consumption modeling is an essential prerequisite for sustainable manufacturing. Recently, cutting-power-based models have garnered significant attention, as they can provide more comprehensive information regarding the machining energy consumption pattern. However, their implementation is challenging because new cutting force coefficients are typically required to address new workpiece materials. Traditionally, cutting force coefficients are calculated at a high operation cost as a dynamometer must be used. Hence, a novel indirect approach for estimating the cutting force coefficients of a new tool-workpiece pair is proposed herein. The key idea is to convert the cutting force coefficient calculation problem into an optimization problem, whose solution can be effectively obtained using the proposed simulated annealing algorithm. Subsequently, the cutting force coefficients for a new tool-workpiece pair can be estimated from a pre-calibrated energy consumption model. Machining experiments performed using different machine tools clearly demonstrate the effectiveness of the developed approach. Comparative studies with measured cutting force coefficients reveal the decent accuracy of the approach in terms of both energy consumption prediction and instantaneous cutting force prediction. The proposed approach can provide an accurate and reliable estimation of cutting force coefficients for new workpiece materials while avoiding operational or economic problems encountered in traditional force monitoring methods involving dynamometers. Therefore, this study may significantly advance the development of sustainable manufacturing.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction and literature review

The manufacturing sector constitutes a considerable portion of the total energy consumed worldwide [1, 2] but with remarkably poor efficiency [3], thereby suggesting substantial energy-saving potential. Therefore, both academia and industry are focusing more on improving energy efficiency in manufacturing. To achieve such an improvement, a reliable estimation of the manufacturing energy consumption is an essential prerequisite. Over the past decades, various models have been developed to estimate the energy consumed in various manufacturing processes. Distinguished by their approaches, these models can be categorized into two major groups.

In the first group, the total energy consumption is estimated by considering the energy required by different machine states. Several major models of this group are presented in Table 1 [4,5,6,7,8,9]. These models have been experimentally validated in terms of energy consumption estimation. However, owing to the difficulty in identifying and modeling many machine states, their implementation is typically tedious and challenging. In addition, some of the process parameters are not explicitly involved in these models, thereby limiting their application during process parameter optimization to achieve higher energy efficiency.

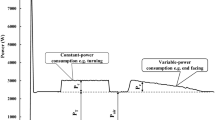

Unlike the first group, models in the second group aim to estimate energy consumption based on the process parameters of the manufacturing processes. Table 2 lists the major reported models. A pioneering work was demonstrated by Gutowski et al. [10] via a manufacturing analysis cast in an exergy framework. In that study, the energy consumed in the manufacturing process comprised two parts. The first part was a constant energy consumption of idle/auxiliary components, whereas the other part corresponded to variable energy consumption incurred by material removal. However, despite the strong theoretical background, the experimental validation was beyond the scope of this study. Using an empirical approach, Li and Kara [11] investigated the energy consumption of a turning process. Following a similar approach, Li et al. [12] modeled energy consumption empirically by additionally considering the spindle speed. Subsequently, Liu et al. [13] further revealed the effects of process parameters on milling energy consumption from the viewpoint of cutting power. In that study, most of the parameters used were for the cutting power analysis, such as the tool-workpiece properties and various cutting parameters. The proposed model was subsequently extended to the milling process with tool wear propagation [14], general end-milling processes [15], and drilling processes [16]. Compared with other energy consumption models, these cutting-power-based models have demonstrated remarkable advantages. For example, Liu et al. [13] successfully provided accurate power prediction, even for the same material removal rate (MRR) and rotation speed. In addition, the extended model reported by Shi et al. [14] could yield reasonable estimations for the milling process involving a worn tool. To further investigate effects of tool wear, Zhang et al. [17] established a mechanistic model for estimating energy consumption that emphasized the effect of stochastic tool wear combined with tool run-out in the micromilling process. In addition, the improved model by Shi et al. [15] proved its generality and reliability for different workpiece materials. However, for these cutting-power-based energy consumption models to function as intended, coefficients for the cutting force calculation must first be determined. As indicated by Shi et al. [15], such coefficients may change depending on the tool-workpiece pair. Therefore, implementing these models may be challenging.

Generally, the calculation of the cutting force coefficients requires a measured cutting force profile [18]. Based on literature review, direct measurement is the most extensively applied approach, in which the cutting force is estimated from the machining process directly using advanced dynamometers, e.g., a plate dynamometer on a workbench [19] and a rotatory dynamometer on a tool holder [20]. Using such devices, the cutting force can be measured accurately. However, for such devices to function as intended, strict requirements are imposed on their operating conditions and workpiece dimensions. For example, it is typically challenging to monitor the machining process of blades owing to the fixture incompatibility between the workpiece and dynamometer. In addition, the non-negligible weight of such devices may affect the dynamic characteristics of the machine tool or workpiece, resulting in instability in the machining process. Finally, such devices are generally expensive, which may further restrict their application in the industry. To solve the abovementioned problems using direct measurement, many indirect methods for cutting force estimation have been proposed from an electric perspective, such as current and power. For example, Jeong and Cho [21] revealed a relationship between the cutting force and current signals from the rotating and stationary feed drive motors of a milling machine [21]. Similarly, Li [22] proposed a model to evaluate the cutting forces from current data in the turning process; the model exhibited better performance than other approaches in terms of multi-direction cutting force monitoring. Furthermore, Kim and Jeon [23] analyzed the alternating current induction motor of feed and spindle systems and developed a current-based approach to estimate the milling force. The results suggested that the spindle motor current with a higher quasi-static sensitivity was more applicable for predicting the cutting force. To determine the tangential cutting coefficients, Aggarwal et al. [24] estimated the cutting torque via spindle motor current measurements in the milling process. Subsequently, Aslan and Altintas [25] presented a novel approach to estimate cutting forces in a five-axis milling process from the current of a CNC feed drive system. This approach is appropriate for the sensorless monitoring of the cutting force during the machining of complex components. Recently, power-based methods for cutting force monitoring have garnered attention. Using power signals in the turning process, Qiu [26] presented an approach for calculating turning force coefficients. The abovementioned indirect cutting force evaluation methods provided promising substitutes for direct cutting force measurement, and experimental results demonstrated their decent accuracy. However, to apply the abovementioned approaches, most of the sensors must be installed in the internal circuit of the machine tool. As such, the implementation of such approaches remains challenging owing to the highly dynamic operating environment of the sensors. Furthermore, the installation of such sensors may jeopardize the dynamic stability of the machining process. Therefore, a cutting force evaluation approach that is independent of the internal circuit/component of the machine tool is necessitated. In this regard, another power-based method was proposed by Lu et al. [27] to evaluate the cutting force in a micromilling process from real-time power reading. However, only the average cutting forces were obtained, i.e., the calculation of the cutting force coefficients and the prediction of the instantaneous cutting force were excluded. In addition, owing to the limitations of the micromilling force, their approach is not applicable to traditional milling processes.

In this study, recent developments in energy consumption modeling are utilized; subsequently, a novel approach is proposed to estimate milling force coefficients. The proposed approach can facilitate the implementation of cutting-power-based energy consumption models, thereby advancing the development of energy consumption modeling. In the proposed approach, sensors are installed at the mains of the machine circuit, independent of its internal circuit/component. Hence, the installation of the sensors is easy and straightforward, and the internal circuit of the machine tool is not exposed. More importantly, the sensors function in a stable environment impose negligible effects on the machining process.

The remainder of this paper is organized as follows. Firstly, in Sect. 2, the energy consumption model used in the proposed approach is briefly introduced, following which a simulated annealing (SA) algorithm for the estimation of milling force coefficients is described. Section 3 describes the experimental details, such as the installation of a power meter and dynamometer. In Sect.4, the application of the developed SA algorithm for solving the cutting force coefficients is discussed; subsequently, a comparative study with the measured cutting force profile is presented and discussed. Finally, Sect. 5 presents the conclusions and future studies.

2 Cutting force coefficients prediction in end-milling process

In this section, the relationship between cutting force and total power is established; subsequently, an SA developed for estimating the cutting force coefficient from the input power data is described.

2.1 Mapping from cutting force to total power consumption

Generally, the total power \(P_{{\text{total}}}\) of a milling machine tool includes the idle power required by the auxiliary component and the additional power due to the cutting material [14, 15]. The relationship can be expressed as

where \(P_{{\text{total}}}\) (W) and \(P_{{\text{idle}}}\) (W) are the total power and idle power, respectively; \(\overline{P}_{{\text{cutting}}}\)(W) is the power consumed at the tool tip owing to material removal; η denotes the energy efficiency for converting additional power into cutting power.

In Ref. [12], \(P_{{\text{idle}}}\) is described as the power consumed by the auxiliary components to obtain the machine tool for machining. When the machine tool is idle, the spindle rotates at a certain rotation speed, but the cutter is not engaged in cutting. Owing to the significant inertia of the spindle, \(P_{{\text{idle}}}\) is generally expressed as a function of the rotation speed, shown as

Depending on the specific energy consumption, the function f may be linear [28], quadratic [29], or piecewise [30].

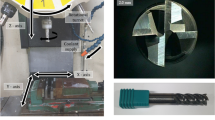

When the cutter is engaged in cutting, additional energy is consumed for material removal. To calculate the power consumed due to material removal at the tool tip, the cutting force model was introduced. For a general milling process involving a flat-end mill, as shown in Fig. 1, the cutting forces (N) are expressed as [31, 32]

where \(K_{{\text{c},{ - }}}\) (N/mm2) and \(K_{{\text{e},{ - }}}\) (N/mm) are the cutting and edge milling force coefficients, respectively; subscripts t, r, and a denote three orthogonal cutting directions, i.e., tangential, radial, and axial, respectively; st (mm/r), dS (mm), θ (rad), z (mm), and dz (mm), ψ (rad) denote the feed per tooth, edge length, cutter rotation angle, edge height, differential edge height, and edge rotation angle, respectively.

According to a previous study [15], the total instantaneous cutting power can be obtained as

where \({\text{d}}P_{{\text{cutting}}}\), \({\text{d}}P_{n}\), \({\text{d}}P_{f}\) (W), n (\({{\text{r}} \mathord{\left/ {\vphantom {{\text{r}} {\min }}} \right. \kern-\nulldelimiterspace} {\min }}\)) and f (\({{{\text{mm}}} \mathord{\left/ {\vphantom {{{\text{mm}}} {\min }}} \right. \kern-\nulldelimiterspace} {\min }}\)) are the total cutting power, rotating component of cutting power, feeding component of cutting power, spindle speed, and feed speed, respectively. In a practical milling process, \({f \mathord{\left/ {\vphantom {f {60\,000}}} \right. \kern-\nulldelimiterspace} {60\,000}}\) (\({{\text{m}} \mathord{\left/ {\vphantom {{\text{m}} \text{s}}} \right. \kern-\nulldelimiterspace} \text{s}}\)), the spindle moving speed, is typically sufficiently small; hence, the instantaneous power can be approximated as

The average power at the tool tip \(\overline{P}_{{\text{cutting}}}\) can be estimated over one cutter rotation as

where \(\theta_{1}\), \(\theta_{2}\)(rad), and z1, z2 (mm) denote the angular and axial ranges of the engaged cutting edges, respectively. \(\varGamma \left( \psi \right)\) is a binary function that determines the cutting edge status, with “true” representing cutting engagement.

Based on the abovementioned equations, the mapping from the cutting force to the energy consumption can be established using the tangential milling force coefficients as

2.2 Estimation of cutting force coefficients from power data

Theoretically, after performing mapping from the cutting force to the power, the cutting force coefficients can be solved inversely using the power data. However, owing to the complexity introduced by oblique cutting (e.g., cutter engagement issue), a direct inverse solution is not practical. An exhaustive search (EX) appears to be a feasible solution, but the time required is unreasonable owing to the high resolution of the solution space. In this study, the problem is converted to an optimization problem whose objective is to obtain a pair of cutting force coefficients \(\left( {K_{{\text{e}},t} ,K_{{\text{c}},t} } \right)\) that minimizes the following error function

where E represents the estimation error, and \(P_{\text{m}}\) (W) is the measured total power consumption.

To solve this optimization problem, an SA algorithm modified from Ref. [33] is proposed to obtain a solution for the cutting force coefficient from power data. The SA algorithm is a metaheuristic-based algorithm that probabilistically approximates the global optimal solution in a vast solution space. Similar to annealing in metallurgy, starting from a sufficiently high initial temperature (\(T_{{\text{initial}}}\)), which indicates high thermodynamic free energy, the SA process accepts a changing solution even if its quality is deteriorated, thereby encouraging exploitation to avoid local minima. As the temperature is reduced based on a specified annealing schedule, the exploitation probability (\(\exp \left( {{{\left( {E_{{\text{current}}} - E_{{\text{temp}}} } \right)} \mathord{\left/ {\vphantom {{\left( {E_{{\text{current}}} - E_{{\text{temp}}} } \right)} T}} \right. \kern-\nulldelimiterspace} T}} \right)\)) becomes increasingly lower, resulting in an increasing rejection chance for the solution without quality improvement. Finally, the process terminates at the final temperature (\(T_{{\text{final}}}\)) and the final solution is output. The details of the algorithm are shown in Fig. 2.

3 Experiment details

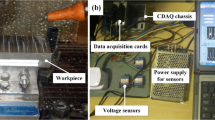

A set of experiments was designed and performed to evaluate the effectiveness of the proposed approach. A Panasonic Eco-Power Meter KW9M, which costs less than $300, was used for power data acquisition, the installation diagram of which is shown in Fig.3. At one side of the terminal block, three current transformers were used to proportionally convert the primary current to the secondary current; on the other side of the terminal block, three phases/four wires were directly connected. During the experiment, the power data were acquired at a sampling frequency of 10 Hz. To measure the average cutting power under a specific cutting condition, the power data acquired were averaged over 2 s during stable cutting.

To provide the ground truth of the cutting force, a Kistler 9255 B three-channel dynamometer was installed on the machining table to record the force profile at 20 kHz. The force registration and fixture details are shown in Fig.3. A charge amplifier (Kistler 5080) was used to amplify the cutting force signals obtained using Kistler 9255 B, and a digital collector (DEWE3010) was used to obtain the cutting force data.

Two three-axis vertical milling centers, LEADWELL MCV-1500i+ and VMC-850, were used to perform the cutting experiments. The experimental details are listed in Table 3. Firstly, two 165 mm × 60 mm × 42 mm aluminum alloy Al-7050-T7451 workpieces were used to calibrate the power model of the two machine tools. Subsequently, two titanium alloy Ti6Al4V workpieces with the same dimensions were used to test the proposed approach. In each experiment, a two-flute solid carbide flat-end mill (40° helix and 5 mm radius) was used for dry cutting. For each experiment, the cutting conditions were set based on the Taguchi L27 orthogonal array, with n and f varying in [1 000, 1 500, 2 000] and [100, 200, 300], respectively. When machining Al-7050-T7451 (i.e., Experiments I and II), ap (mm), the depth of cut, was varied in [1,2,, 2, 3]; when machining Ti6Al4V (i.e., Experiments III and IV), ap was varied in [0.3, 0.6, 0.9].

4 Results and discussions

4.1 Calibration of power models with Al-7050-T7451

Experiments I and II were performed to calibrate the power models of the machine tools according to the procedure specified in Ref. [15]. Firstly, the idle power model shown in Eq. (2) was calibrated using idle power data collected when the spindle was rotating at various speeds but not engaged in cutting. The calibrated results of the two machine tools are presented in Figs. 4(a) and 4(c), separately. Subsequently, 27 slot milling experiments were conducted to calibrate the relationship between the additional power (\(P_{{\text{addtional}}} = P_{{\text{total}}} - P_{{\text{idle}}}\)) and average cutting power, and the results are presented in Figs. 4 (b) and 4 (d). As shown, the coefficient of determination (R2) values were sufficiently close to 1, indicating the high accuracy of the calibrated power models. It is noteworthy that the model was calibrated using Al-7050-T7451, which serves as a reference to calculate the cutting force coefficients of the new Ti6Al4V workpiece subsequently.

4.2 Prediction of cutting force coefficients for new materials (Ti6A14V)

Upon the completion of model calibration, the objective function described in Eq. (8) can be obtained. \(K_{{\text{e}},t}\) and \(K_{{\text{c}},t}\) can be solved from the power data using the proposed approach. Subsequently, Experiments III and IV (see Table 3) were performed for further evaluation, in which titanium alloys were machined. The cutting parameters and measured power data of both machine tools are shown in Table 4, where PIII and PIV denote the measured power in Experiments III and IV, respectively.

To apply the developed SA algorithm, the solution space should first be specified. An appropriate size of the solution space will facilitate search efficiency and improve the solution quality. As \(K_{{\text{c}},t}\) is typically much larger than \(K_{{\text{e}},t}\), the solution spaces were defined as \(K_{{\text{c}},t}\) ∈ [0, 4 000] and \(K_{{\text{e},t}}\) ∈ [0,100]. Subsequently, the solution space was discretized at a resolution of 0.01. The initial and final temperatures were set as \(T_{{\text{initial}}} = 100\) °C and \(T_{{\text{final}}} = 0.2\) °C to ensure adequate annealing. The maximum reject count for a specified temperature was set as \(N_{{\text{max}}} = 5\) to allow sufficient exploitation. Subsequently, PIII and PIV in Table 4 were input to the SA algorithm for the solution search.

To evaluate the performance of the cutting force coefficient calculation, 20 numerical experiments were performed in Experiments III and IV. In each numerical experiment, 27 sets of power data points were randomly categorized into two subgroups: a training set comprising 14 data points and a validation set comprising 13 data points. The training data set was input to the SA algorithm to calculate the cutting force coefficients, following which the obtained cutting force coefficients were used to calculate the prediction error for the validation set.

4.3 Evalution of cutting force coeffients obtained

To further demonstrate the advantage of the SA algorithm, an EX was performed using the same training and validation datasets for comparison. The EX evaluates every solution within the discretized solution space and selects the solution with the best quality as the final solution. Instead of 0.01, the discretization resolution was set to 5 to limit the total search time to a reasonable value. The average search time required by the EX was 257.4 s, corresponding to 0.016 1 s per error calculation. Hence, the EX time with a resolution of 0.01, similar to that of the SA algorithm, will exceed 2 years, which is not a reasonable duration. By contrast, the SA algorithm requires less than 45 s, indicating a much higher searching efficiency.

A comparison of the solution quality is presented in Fig.5, in which the power prediction errors are visualized. As shown, the prediction errors changed based on the different training and validation sets. This is to be expected because different cutting conditions incur different cutting powers. For example, if n and \(a_{\text{p}}\) remain the same, a higher f will result in a larger \(s_{{t}}\), which will increase the cutting power, based on Eq.(5). Therefore, the portion of cutting power in the additional power will differ and may not be fully characterized by the established model shown in Figs. 3b, d. As such, the prediction error fluctuates owing to the different training and validation sets. Nonetheless, as shown, the proposed SA algorithm outperformed the EX in most cases. This may be because the EX can easily cause overfitting during the training with 14 data points, thereby resulting in a lower generality performance in the validation set. By contrast, by controlling the final temperature (stopping criterion), the SA algorithm can effectively avoid overfitting. As shown in Fig.5, the prediction errors of the SA algorithm were sufficiently small, with average errors of 2.3% and 3.2% for Experiments III and IV, respectively. It is noteworthy that no measured cutting force profile was used for the power prediction of the new workpiece material (Ti6Al4V), and that the prediction accuracy was comparable to the power prediction error (1.71%–2.81%) with the measured cutting force. This capability was achieved by calculating the cutting power, which considers the tool-workpiece property [15]. The results clearly show the reliable performance of the proposed approach in extending the application of cutting-power-based energy consumption models.

To gain a better insight into the SA performance, the search histories of a randomly selected training set for Experiments III and IV are presented in Fig.6. As shown, the search started from relatively large errors (12.37% and 8.15%) at T = 100 °C. By effectively traversing the solution space, the errors finally converged at much smaller errors (2.31% and 2.17%), thereby revealing effectiveness of the developed SA algorithm in solution searching.

Subsequently, the cutting force coefficients obtained from the same training set (shown in Fig.6) were compared with the coefficients measured using the standard linear least-squares method [34]. The results are listed in Table 5, where \(K_{{{\text{e}},t{ - }\text{m}}}\) and \(K_{{{\text{c}},t{ - }\,\text{m}}}\) represent the cutting force coefficients calculated from the measured cutting force, whereas \(K_{{{\text{e}},t{ - }\,\text{SA}}}\) and \(K_{{{\text{c}},t{ - }\,\text{SA}}}\) denote those obtained from the proposed SA algorithm. As the numerical value in Table 5 may not reflect the accuracy of the cutting force coefficients directly, a comparative study for the cutting force was performed. Specifically, the instantaneous cutting force (Fm, N) calculated using \(K_{{{\text{e}},t{ - }\text{m}}}\) and \(K_{{{\text{c}},t{ - }\text{m}}}\) was used as the ground truth. Subsequently, the cutting force calculated using \(K_{{{\text{e}},t{ - }\,\text{SA}}}\) and \(K_{{{\text{c}},t{ - }\,\text{SA}}}\), denoted as \(F_{{\text{SA}}}\), was compared with \(F_{\text{m}}\). Owing to the characteristics of the L27 orthogonal array, a comparison at a specified depth of cut is sufficient for force error evaluation. In this study, the greatest depth of cut (0.9 mm), corresponding to parameter settings 19–27 in Table 4, was selected for the comparative study. To provide a quantitative comparison, the average error (\(E_{{\text{avg}}}\)) is defined as

where N is the number of sampled data points in one cutter rotation; \(F_{{{\text{m}}{ - }i}}\) and \(F_{{{\text{SA}}{ - }i}}\) are the i-th sampled data points.

The results of \(F_{\text{m}}\) and \(F_{{\text{SA}}}\) are presented in Fig.7 in red and blue, respectively. As shown, the overall error remained low. The average errors of Experiments III and IV were 8.20% and 6.76%, respectively. Hence, it can be concluded that a good agreement between \(F_{{\text{SA}}}\) and \(F_{\text{m}}\) was achieved. Using only power data as input, the proposed method successfully provided an accurate cutting force evaluation when machining new workpiece materials. Hence, the effectiveness of the proposed approach was demonstrated.

5 Conclusions

Cutting power-based energy consumption models have garnered extensive attention. However, the required cutting force coefficients may severely restrict their applications. Hence, a novel approach for the indirect evaluation of cutting force coefficients was proposed herein. Using a pre-calibrated power model, the proposed approach can determine the cutting force coefficients of the new workpiece material based on measured power data. Specifically, the problem of calculating the cutting force coefficients was first converted into an optimization problem. Subsequently, an SA algorithm was developed to search for the cutting force coefficients. The experimental results demonstrated the decent performance of the method. The obtained cutting force coefficients achieved high accuracy in terms of power prediction and instantaneous cutting force evaluation.

Using a cost-effective power meter at the mains, the proposed approach can provide an accurate estimation of cutting force coefficients for new workpiece materials, thereby facilitating the implementation of cutting-power-based energy consumption models. Meanwhile, problems incurred by traditional force monitoring methods involving dynamometers, such as complicated implementation, expensive equipment, and dynamic effects on the machine tool, can be effectively avoided. As such, the proposed approach may serve as a promising platform for cleaner production and can be extended to applications for intelligent manufacturing.

In the next phase of the study, the existing approach will be extended to estimate more cutting force coefficients and address continuous cutting force estimation with tool wear propagation.

Abbreviations

- P :

-

Total power (W)

- \(P_{{\text{idle}}}\) :

-

Idle power (W)

- \(\overline{P}_{{\text{cutting}}}\) :

-

Average cutting power (W)

- \(f\left( {\overline{VB} } \right)\) :

-

Tool wear propagation pattern

- n :

-

Rotation speed (\({\text{r/min}}\))

- \(r_{{\text{MRR}}}\) :

-

Material removal rate (mm3/s)

- C 0, C 1, C 2, η :

-

Model coefficients

- \(P_{{\text{cutting}}}\) :

-

Instantaneous cutting power (W)

- \(\overline{P}_{{\text{cutting}}}^{0}\) :

-

Average cutting power without tool wear (W)

References

Dahmus JB, Gutowski TG (2004) An environmental analysis of machining. In: ASME 2004 international mechanical engineering congress and exposition, 13–19 November, Anaheim, California. https://doi.org/10.1115/IMECE2004-62600

Duflou JR, Sutherland JW, Dornfeld D et al (2012) Towards energy and resource efficient manufacturing: a processes and systems approach. CIRP Ann-Manuf Technol 61:587–609. https://doi.org/10.1016/j.cirp.2012.05.002

Liu N, Zhang YF, Lu WF (2019) Improving energy efficiency in discrete parts manufacturing system using an ultra-flexible job shop scheduling algorithm. Int J Precis Eng Manuf-Green Technol 6:349–365. https://doi.org/10.1007/s40684-019-00055-y

Avram OI, Xirouchakis P (2011) Evaluating the use phase energy requirements of a machine tool system. J Clean Prod 19:699–711. https://doi.org/10.1016/j.jclepro.2010.10.010

Mori M, Fujishima M, Inamasu Y et al (2011) A study on energy efficiency improvement for machine tools. CIRP Ann 60:145–148. https://doi.org/10.1016/j.cirp.2011.03.099

He Y, Liu F, Wu T et al (2012) Analysis and estimation of energy consumption for numerical control machining. Proc Inst Mech Eng Part B J Eng Manuf 226:255–266. https://doi.org/10.1177/0954405411417673

Balogun VA, Mativenga PT (2013) Modelling of direct energy requirements in mechanical machining processes. J Clean Prod 41:179–186. https://doi.org/10.1016/j.jclepro.2012.10.015

Sealy MP, Liu ZY, Zhang D et al (2016) Energy consumption and modeling in precision hard milling. J Clean Prod 135:1591–1601. https://doi.org/10.1016/j.jclepro.2015.10.094

Edem IF, Mativenga PT (2017) Modelling of energy demand from computer numerical control (CNC) toolpaths. J Clean Prod 157:310–321. https://doi.org/10.1016/j.jclepro.2017.04.096

Gutowski T, Dahmus J, Thiriez A et al (2007) A thermodynamic characterization of manufacturing processes. In: Proceedings of the 2007 IEEE international symposium on electronics and the environment, Orlando, FL, USA, 7–10 May 2007, pp 137–142

Li W, Kara S (2011) An empirical model for predicting energy consumption of manufacturing processes: a case of turning process. Proc Inst Mech Eng Part B J Eng Manuf 225:1636–1646. https://doi.org/10.1177/2041297511398541

Li L, Yan J, Xing Z (2013) Energy requirements evaluation of milling machines based on thermal equilibrium and empirical modelling. J Clean Prod 52:113–121. https://doi.org/10.1016/j.jclepro.2013.02.039

Liu N, Zhang YF, Lu WF (2015) A hybrid approach to energy consumption modelling based on cutting power: a milling case. J Clean Prod 104:264–272. https://doi.org/10.1016/j.jclepro.2015.05.049

Shi KN, Zhang DH, Liu N et al (2018) A novel energy consumption model for milling process considering tool wear progression. J Clean Prod 184:152–159. https://doi.org/10.1016/j.jclepro.2018.02.239

Shi KN, Ren JX, Wang SB et al (2019) An improved cutting power-based model for evaluating total energy consumption in general end milling process. J Clean Prod 231:1330–1341. https://doi.org/10.1016/J.JCLEPRO.2019.05.323

Wang Q, Zhang D, Tang K et al (2019) A mechanics based prediction model for tool wear and power consumption in drilling operations and its applications. J Clean Prod 234:171–184. https://doi.org/10.1016/j.jclepro.2019.06.148

Zhang X, Yu T, Dai Y et al (2020) Energy consumption considering tool wear and optimization of cutting parameters in micro milling process. Int J Mech Sci 178:105628. https://doi.org/10.1016/j.ijmecsci.2020.105628

Pang L, Hosseini A, Hussein HM et al (2015) Application of a new thick zone model to the cutting mechanics during end-milling. Int J Mech Sci 96/97:91–100. https://doi.org/10.1016/j.ijmecsci.2015.03.015

Sahoo P, Pratap T, Patra K (2019) A hybrid modelling approach towards prediction of cutting forces in micro end milling of Ti-6Al-4V titanium alloy. Int J Mech Sci 150:495–509. https://doi.org/10.1016/j.ijmecsci.2018.10.032

Totis G, Wirtz G, Sortino M et al (2010) Development of a dynamometer for measuring individual cutting edge forces in face milling. Mech Syst Signal Process 24:1844–1857. https://doi.org/10.1016/j.ymssp.2010.02.010

Jeong YH, Cho DW (2002) Estimating cutting force from rotating and stationary feed motor currents on a milling machine. Int J Mach Tools Manuf 42:1559–1566. https://doi.org/10.1016/S0890-6955(02)00082-2

Li X (2005) Development of current sensor for cutting force measurement in turning. IEEE Trans Instrum Meas 54:289–296. https://doi.org/10.1109/TIM.2004.840225

Kim D, Jeon D (2011) Fuzzy-logic control of cutting forces in CNC milling processes using motor currents as indirect force sensors. Precis Eng 35:143–152. https://doi.org/10.1016/j.precisioneng.2010.09.001

Aggarwal S, Nešić N, Xirouchakis P (2013) Cutting torque and tangential cutting force coefficient identification from spindle motor current. Int J Adv Manuf Technol 65:81–95. https://doi.org/10.1007/s00170-012-4152-x

Aslan D, Altintas Y (2018) Prediction of cutting forces in five-axis milling using feed drive current measurements. IEEE/ASME Trans Mechatronics 23:833–844. https://doi.org/10.1109/TMECH.2018.2804859

Qiu J (2018) Modeling of cutting force coefficients in cylindrical turning process based on power measurement. Int J Adv Manuf Technol 99:2283–2293. https://doi.org/10.1007/s00170-018-2610-9

Lu X, Wang F, Yang K et al (2019) An indirect method for the measurement of micro-milling forces. In: ASME 2019 14th international manufacturing science and engineering conference, West Lafayette, Indiana, USA, 4–7 October. https://doi.org/10.1115/MSEC2019-2769

Luo H, Du B, Huang GQ et al (2013) Hybrid flow shop scheduling considering machine electricity consumption cost. Int J Prod Econ 146:423–439. https://doi.org/10.1016/j.ijpe.2013.01.028

Ma F, Zhang H, Cao H et al (2017) An energy consumption optimization strategy for CNC milling. Int J Adv Manuf Technol 90:1715–1726. https://doi.org/10.1007/s00170-016-9497-0

Tian C, Zhou G, Zhang J et al (2019) Optimization of cutting parameters considering tool wear conditions in low-carbon manufacturing environment. J Clean Prod 226:706–719. https://doi.org/10.1016/j.jclepro.2019.04.113

Lee P, Altintas Y (1996) Prediction of ball-end milling forces from orthogonal cutting data. Int J Mach Tools Manuf 36:1059–1072. https://doi.org/10.1016/0890-6955(95)00081-X

Budak E, Altintaş Y, Armarego EJA (1996) Prediction of milling force coefficients from orthogonal cutting data. J Manuf Sci Eng 118:216–224. https://doi.org/10.1115/1.2831014

Ma GH, Zhang YF, Nee AYC (2000) A simulated annealing-based optimization algorithm for process planning. Int J Prod Res 38:2671–2687. https://doi.org/10.1080/002075400411420

Liu N, Wang SB, Zhang YF et al (2016) A novel approach to predicting surface roughness based on specific cutting energy consumption when slot milling Al-7075. Int J Mech Sci 118:13–20. https://doi.org/10.1016/j.ijmecsci.2016.09.002

Acknowledgements

The authors would like to acknowledge the financial support provided by the National Natural Science Foundation of China (Grant Nos. 51905442, 51775444), the Fundamental Research Funds for the Central Universities (Grant No. 31020190502006), and the National Science and Technology Major Project (Grant No. J2019-VII-0001-0141).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, KN., Liu, N., Liu, CL. et al. Indirect approach for predicting cutting force coefficients and power consumption in milling process. Adv. Manuf. 10, 101–113 (2022). https://doi.org/10.1007/s40436-021-00370-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-021-00370-1