Abstract

The incorporation of carbon nanotubes (CNTs) into cementitious matrices, and more specifically to concrete, has enhanced their strength and durability. With this perspective, this manuscript aims to review the main engineering properties of concrete with carbon nanotubes (CNT-concrete). To this end, ProKnow-C methodology was used to find the most relevant papers published in the last five years, and 19 articles were selected for a complete analysis. The data collected were the CNT type, content, and dispersion technique, as well as CNT-concrete type and properties, namely the compressive, tensile, and flexural strength, elastic modulus, water absorption, porosity and permeability, electrical conductivity and resistivity, carbonation and chloride penetration resistance, and fracture energy and toughness. This systematic review of the literature revealed that CNT addition generally enhances concrete strength, but its influence on other engineering properties, such as carbonation and chloride penetration resistance, creep and shrinkage, still requires further investigation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Concrete is the most consumed construction material in the world and also the most polluting, whose production is responsible for about 7% of global CO2 emissions [1]. Due to its several ways of use, millions of reinforced concrete (RC) structures face daily adverse weather conditions, pollution, and other chemical attacks that penetrate it and damage their reinforcement steel bars. Repairing these damages, however, may have high costs, as those presented by the American society of civil engineers (ASCE) yearbooks [2].

In this sense, several RC structures constantly present a series of durability problems associated mainly with corrosion, moisture, chloride ions’ attack, sulfates, and alkali-aggregate reaction, among others [3]. Besides, one of the characteristics of concrete is its brittle fracture and low tensile strength [4].

According to Khitab et al. [5], conventional concrete may no longer bear the different loads and service demands to which it is subjected. Khalid et al. [6] complement that concrete production with exceptional mechanical properties and with less cement is highly desired to achieve structures that are not only economical but also more environmentally appropriate, from the reduction of carbon dioxide (CO2) emissions in the atmosphere.

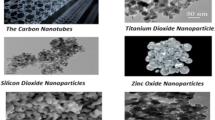

With this perspective, Khitab et al. [7] state that using nanotechnology to modify properties at the nanoscale is not new in construction materials. Several studies in the literature have proven that cementitious composites properties can be extensively modified by working not only the nano but also the micro-scale of these materials’ matrices [8,9,10].

In this context, a product that has attracted the scientific community is carbon nanotubes (CNTs). These allotropes of the chemical element carbon have been studied for multiple applications in various areas of knowledge and different materials. It also happens with the cement-based matrices and a composite that can benefit from this is concrete, becoming more resistant, less porous, and more durable [2]. According to Sanchez and Sobolev [11], advances in the characterization of the nanometric structure of cement-based materials and computing have provided scientists and engineers with new and promising tools to better understand the concrete structure and improve its mechanical performance and durability. This is evidenced by the increasing number of research related to concrete with carbon nanotube additions (CNT-concrete), as shown in Fig. 1.

However, there are many issues to be solved, such as the CNT dispersion in the cement matrix and its large-scale manufacture and distribution to the market. These are relevant aspects that should be considered when implementing CNTs at the industrial scale. Hence, this manuscript discusses the effects of adding carbon nanotubes to concrete, covering topics such as CNT types, dispersion techniques, and CNT content in the matrix. More specifically, this work presents a systemic analysis of the CNT-concrete’s engineering properties and answers the following questions: (1) What is the CNT-concrete type whose properties are most studied by the literature? (2) What type of CNT is most recommended for addition in cementitious matrices? (3) What is the most employed dispersion technique for CNTs in powder and aqueous suspension form? (4) What is the maximum CNT content to be used in concrete recommended for future research? (5) How does CNT incorporation influence the mechanical properties of concrete? (6) How does CNT addition influence the durability and mechanical properties of concrete? For this, it was performed a systematic review of the literature aimed to discuss future directions and consolidated findings concerning the CNT-concrete.

2 Materials and methods

A systematic review of the literature was performed using the bibliography selected through the ProKnow-C (Knowledge Development Process—Constructivist) methodology [12], whose main steps are described in Fig. 2.

Figure 2 shows that the keywords specified in the first step (“concrete” and “carbon nanotube”) were used in the search for recent papers, published in the last five years in four bases consolidated in the scientific community. It is noteworthy that this work focused only on CNT-concrete, not including, therefore, studies related to pastes and mortars. Considering the 728 articles initially selected, 19 were completely aligned with the topic of CNT-concrete’s engineering and durability properties in the last step.

Once the bibliography was selected, a bibliometric analysis was performed considering: (1) the journals’ relevance within the selected portfolio, i.e., how many articles were published in each one of them, and also their scientific relevance, through the Journal Citation Reports (JCR) impact factor, according to the Web of Science basis; (2) the papers’ scientific recognition, through the number of citations in Scholar Google [n.d.] on October 31, 2022; and (3) the most frequent keywords, through cluster analysis.

Finally, after the selected articles were fully read, a so-called “lensing” approach was used. In this work, the research lenses were the type of CNT-concrete, whether there was a modification in the concrete (other additions and/or substitutions), the CNT type, content, and dispersion technique used. The engineering properties studied were also noted for further discussion, and the main conclusions about them as well. In the selected portfolio the following properties were studied: compressive strength, elastic modulus, tensile strength, flexural strength, bond strength, fracture energy, fracture toughness, microstructure, pore distribution, water absorption, electrical resistivity and conductivity, and carbonation and chloride penetration resistance.

3 Results and discussion

3.1 Selected bibliography

Table 1 lists the articles that make up the bibliographic portfolio selected through the ProKnow-C methodology and their main information: authorship, title, journal, JCR impact factor, publication year, and the number of citations. References are listed in descending order of total citations.

3.1.1 Bibliometric analysis

The first analysis aimed to determine how many manuscripts of the selected bibliography were published by each journal. As reported in Table 1, the 19 articles were published in 14 different journals, among which the Construction and Building Materials journal stands out, with six papers. This same journal has the third-highest JCR impact factor in the portfolio (7.693). All other journals had one publication each, highlighting Cement and Concrete Research and Composites Part A: Applied Science and Manufacturing, which have the highest impact factors among the journals in the portfolio, 11.968 and 9.463, in that order. In general, a higher impact factor represents greater scientific relevance of the journal. It is noteworthy that many journals do not even have an impact factor indexed by the Web of Science, which happened with only one manuscript in the portfolio. Thus, it is understood that the filter applied in Step 5 of the ProKnow-C methodology was sufficient to select not only the most cited articles but relevant journals.

Next, the scientific recognition of all manuscripts was analyzed according to their citations from the publication date until October 31, 2022, according to Scholar Google [s.d.]. Table 1 shows that papers published longer ago tend to have more citations, which is expected, but such recognition is also influenced by the relevance of the journal. This is evidenced by verifying, for example, that the paper by Jung et al. [14] was not the oldest (published in 2020) and yet is the most cited (128 citations) or that the paper by Shao et al. [29] is one of the most recent (published in 2022) and has already been cited seven times.

Finally, it was checked the keywords with the highest frequency in the selected portfolio, because they are essential search parameters in scientific paper databases and systematic literature reviews. 93 different keywords were identified in the 19 manuscripts, among which it should be highlighted: carbon nanotube and carbon nanotubes, with 6 and 4 occurrences, respectively; compressive strength, with four; concrete and mechanical properties, with three each; and durability, with two. Figure 3 shows the cloud of the most relevant keywords in the portfolio, in which one can identify other terms commonly used in studies about the mechanical and durability properties of CNT-concrete.

3.2 Systematic analysis

Table 2 presents the CNT-concrete types of the selected bibliography, which differ by type of modification, which can occur by addition to the matrix, partial or total replacement of natural aggregates (NA), partial replacement of cement, or even addition and substitution at the same time. Table 3 lists the engineering properties—mechanical properties, durability and other mechanisms or factors—studied in the selected bibliography, indicating the main findings of each reference.

3.2.1 Concrete types and CNT aspects

In this portfolio, conventional concrete (CC) was employed in ten studies (52%), one of them modified by CNF addition, one by the BF addition and partial replacement of NA by WGP, and one by partial replacement of NA by RTR. The second most frequent was ultra-high-performance concrete (UHPC), used five times (26%), all of them modified by some addition (e.g., silica fume) to the cement matrix and one also incorporating SF. Studies with lightweight concrete (LWC) (10%), with NA replacement, geopolymer concrete (GC), with NC addition and partial cement replacement, reactive powder concrete (RPC), with partial cement substitution, and high-strength concrete (HSC), modified by CNF addition, were also less frequent. Considering the main cement-based materials, it is important to mention that the difficulty of dispersing CNTs in the matrix makes them mostly employed in pastes and mortars, because the presence of coarse aggregates in concrete occupies large space in the mixture and favors the agglomeration [20] and also because these nanomaterials are not yet produced on an industrial scale and therefore are expensive compared to other addition types [33]. However, as concrete is the most consumed material in the world after water [4] and whose production emits large amounts of CO2 into the atmosphere, studies on CNT-concrete must be carried out in further research, especially modifying it by replacing NA with recycled aggregates (RA), such as civil construction demolition waste (CDW) or even rubber waste. As reported by Reis et al. [34], the use of CDW in CNT-concrete contributes to the buildings’ sustainability, and CNTs addition, in this case, can contribute to the RC structure reaching the required mechanical strength.

Considering the two types of CNTs, single-walled (SWCNTs) and multi-walled (MWCNTs), in the selected bibliography the latter was employed in 16 references (84%), only one used SWCNTs (5%), and two manuscripts did not provide this information. According to Rashad [35], this predominance of MWCNTs occurs because they are easier to process through advanced chemical vapor deposition (CVD) methods, allowing them to be produced on a larger scale than SWCNTs and, consequently, have a lower price. Other authors add that MWCNTs’ use leads to a more homogeneous mixture because they have less tendency to agglomerate compared to SWCNTs [36]. Six references (32%) experimented with functionalized CNTs in dispersion, but the results were controversial.

Regarding the CNT form, powder or aqueous, they were used in powder form in nine studies (47%), in aqueous suspension in six (32%), and six did not explicit this information. The CNT form is relevant because it directly influences dispersion techniques. Theoretically, for aqueous suspensions, the process is simpler because the CNTs are already pre-dispersed. In the selected literature, considering the five studies that used this supply type, two (10%) only sonicated the CNTs, two (10%) did magnetic stirring with surfactant followed by sonication, and one (5%) did only dispersion in distilled water. Regarding the ten that used the powder form, one (5%) employed only sonication, while the others associated sonication with some other additive (surfactant or superplasticizer) or process (manual mixing, mechanical agitation, or magnetic stirring). It is noteworthy that some papers did not specify either the CNT form or the dispersion technique. In summary, 13 papers (68%) used superplasticizer to reduce the water/cement (w/c) ratio and increase the fluidity of the mixture, 17 employed at least sonication (19%) and 9 used surfactant as well (47%). Liew et al. [37] point out that using some dispersants during the sonication process helps in the dispersion effectiveness because they prevent agglomeration and ensure the stability of the mixture, while sonication promotes a temporary dispersion.

Finally, considering the tendency of CNTs to agglomerate due to Van der Waals forces, their adequate dispersion is also conditioned to their content in the mixture. In the selected articles, contents between 0.01 and 2.00% by weight of cement were employed, being the dosage of 0.10% used in 10 manuscripts (52%), while 0.05 and 0.50% were used in seven manuscripts each (37%). Also considering this bibliography, 16 papers (84%) investigated at least two different CNT contents, and generally, very high concentrations were more difficult to disperse and in some cases generated pores in the cement matrix, worsening the mechanical properties. This fact and also considering the still expensive price of CNTs suggests that further investigations concerning CNT-concrete focus on contents up to 0.10% by weight of cement, which is consistent with the literature [34].

3.2.2 Mechanical strength

Compressive strength was studied in 17 references (89%) of the total selected, the CNT-concrete property best known. Tensile strength was the next one, measured in nine (47%), followed by flexural strength and elastic modulus, investigated in eight each (42%). The adherence of steel bars in CNT-concrete, although not a mechanical property, is an essential mechanism for the performance of RC structures, and was studied in two papers in the portfolio (10%).

From Table 3, it is safe to conclude that, regardless of the concrete type, strength is generally enhanced with the CNT addition to the cement matrix. This enhancement may be related to pore-filling, bridging effect, and formation of a denser C–S–H structure with higher stiffness, as reported by Jung et al. [14], However, it will certainly depend on the CNT characteristics, such as type, treatment, aspect ratio (length/diameter), and especially the content and dispersion techniques, because such nanomaterials may agglomerate due to the presence of Van der Waals forces if they are poorly or insufficiently dispersed [38].

Regarding steel–concrete bonding, Hawreen and Bogas [25] indicated that for 12-mm steel bars, CNT addition to concrete in contents between 0.05 and 0.10% by weight of cement can increase bond strength by up to 14% compared to concrete without CNTs. Qasem [26], in turn, reported that the maximum bond strength between steel bars and UHPC was about 35 and 48% higher than between carbon fiber-reinforced polymer (CFRP) bars and UHPC, for 12 mm and 16 mm bars, respectively, and CNT contents between 0.01 and 0.10% by weight of cement. These references suggested the role of CNTs as crack propagation controllers, which contributed to the mechanical portion of the adhesion, but further research is necessary to better understand the influence of CNT addition in the bonding of reinforcement bars in concrete. This is because adherence depends on factors such as bar diameter, bar surface, and anchorage length, among others [34]. This topic can be considered for future studies.

3.2.3 Water absorption, porosity and permeability

Water absorption was studied in five manuscripts (26%), porosity in two (10%), and permeability in only one (5%). Carriço et al. [15] reported a reduction of water absorption by immersion in concretes with dispersed MWCNTs of up to 12%, considering contents of 0.05 and 0.10% by weight of cement. Adhikary et al. [22] indicated that all the LWC nanocomposite specimens decreased their water absorption rate by an increase in the CNT content, from 0.04 to 0.60% by weight of cement, while Mosallam et al. [30] indicated that CNT addition in content up 0.30% by weight of cement reduced the water absorption of LWC by 28.3%. Mohsen et al. [23], in turn, indicated that the addition of MWCNTs to the cementitious matrix of concrete resulted in a denser composite compared to concrete without the nanomaterials, reporting that the permeability coefficient was reduced by at least 45%. Considering the aforementioned references and the data in Table 3, it can be concluded that CNT incorporation into cement-based materials leads to a reduction of their water absorption, porosity, and permeability, which is a positive factor in terms of durability. Still, research on these properties needs to be developed, considering the increasingly frequent use of different types of concrete by the construction industry. This topic can be used for further research.

3.2.4 Electrical conductivity and resistivity

Only four articles (21%) studied the electrical properties of CNT-concrete. Jung et al. [14] reported an enhancement in the electrical conductivity of UHPC up to the percolation threshold due to CNT incorporation, which is consistent with the literature [39, 40]. Lim et al. [32] indicated that although the electrical conductivity of UHPC increased as the content of CNTs increased, its conductivity was not as high. Jung et al. [31], in turn, registered a consistent reduction in the electrical resistivity of UHPC at contents up to 0.8% by weight of cement, which they attributed to the stable dispersion of CNTs in aqueous suspension in the cement matrix. Parvaneh and Khiabani [24] pointed out that the electrical resistivity of CNT-concrete was also reduced, with the best results being achieved with a CNT content equal to 0.1% by weight of cement.

Considering the aforementioned references, it can be concluded that CNT addition to concrete leads to increased electrical conductivity and/or reduced electrical resistivity. It happens due to the low density and the high aspect ratio of CNTs, which favors the formation of conductive networks in the cement matrix [35].

3.2.5 Carbonation and chloride penetration resistance

Only two articles in the portfolio (10%) studied the carbonation and chloride penetration resistance of CNT-concrete. Carriço et al. [15] added three types of CNT (CNTPL, CNTCOOH, and CNTSS) to conventional concrete at contents of 0.05% or 0.10% by weight of cement. These authors reported that, due to an improved concrete microstructure, the carbonation resistance of CNT-concrete increased up to 16% compared to concrete without addition, and the chloride penetration resistance was little influenced by CNT incorporation. In both properties, the CNT type was found to have no influence. In the study developed by Kotop et al. [27], the influence of CNT and NC addition on GC was investigated. The results revealed that the hybrid use of CNT and NC improved by up to 29% the chloride penetration resistance of GC compared to the reference sample. These authors indicated that the GC became highly compacted and denser with the addition of the nanomaterials, which prevented crack formation and propagation and, as a consequence, increased the chloride penetration resistance.

Considering the low frequency of manuscripts on these properties in the selected bibliography and given their great importance in the durability of concrete against the diffusion of corrosive agents inside [41], experimental studies must be conducted with different types of CNT-concrete to investigate whether the addition of CNTs is beneficial to carbonation and chloride penetration resistance. This topic can be used for future research.

3.2.6 Fracture energy and toughness

Two references (10%) studied fracture energy and toughness of CNT-concrete. Ruan et al. [18] added four different types of MWCTN (see Table 2) to RPC in contents equal to 0.25 or 0.50% by weight of cement and investigated the fracture energy. These authors concluded that the fracture energy of RPC with water curing can be improved by approximately 42% using the optimum dosage of 0.25% by weight of cement of CNT functionalized with carboxyl groups. Hawreen et al. [20], on the other hand, tried five types of MWCNTs (see Table 2) in conventional concrete at contents equal to 0.05 or 0.10% by weight of cement and studied fracture toughness. They observed that in the concrete’s pre-peak behavior the CNTs were able to contain crack propagation and, as a consequence, reported gains of up to 42% in the fracture energy of the CNT-concrete.

It is understood that further studies are necessary to reach assertive conclusions regarding the fracture energy and toughness in CNT-concrete, especially in concretes modified by the replacement of NA by RA, which changes the aggregate phase of the mixture. This topic can be considered for further research.

4 Conclusions

A systematic review of the literature on the engineering properties of CNT-concrete was hereby developed. The following conclusions were reached:

-

1.

The bibliometric analysis confirmed that the articles selected through the ProKnow-C methodology are relevant, both for the quality of the journals in which they were published and for the number of citations obtained to date.

-

2.

The most frequent CNT-concretes in the selected literature were CC (52%) and UHPC (26%), to the detriment of LWC, GC, RPC, and HSC. Considering the high consumption of concrete in the world and its high rates of CO2 emission to the atmosphere, studies on CNT-concrete must be carried out in further research, for example modifying it by replacing NA with RA, a more sustainable trend in the construction industry.

-

3.

MWCNTs were used in 84% of the references. Compared to SWCNTs, they are easier to process through advanced CVD methods, so they are produced on a larger scale and therefore have a lower price. In addition, MWCNTs’ use leads to a more homogeneous mixture because they have less tendency to agglomerate compared to SWCNTs.

-

4.

CNTs in powder form were used in 47% of the selected literature. All of these papers associated sonication with some other additive (surfactant or superplasticizer) or process (manual mixing, mechanical agitation, or magnetic stirring) to disperse the nanomaterials, except one, which only sonicated them. CNTs in aqueous suspension, on the other hand, were employed in 32% of the manuscripts. In these cases, two only sonicated the CNTs, two did magnetic stirring with surfactant followed by sonication, and one did only dispersion in distilled water. From the works studied, it can be concluded that sonication is the best dispersion technique, and can be further improved when associated with the use of dispersants because they prevent agglomeration and ensure the stability of the mixture.

-

5.

CNT contents equal to 0.10 and 0.05% by weight of cement were applied in 52 and 37% of the portfolio, respectively, being the most frequent ones. Considering the difficulty to disperse CNTs, their tendency to agglomerate due to Van der Waals forces, their expensive price, and the results presented by the literature so far, future investigations on CNT-concrete should avoid contents higher than 0.10% by weight of cement.

-

6.

The mechanical strength of concrete is generally increased when CNTs are added to it, as they fill pores, act as a bridge for stress transfer, and form a denser C–S–H structure with higher stiffness in the cement matrix. These improvements, however, depend on CNT characteristics and mainly the content and dispersion techniques, because they may agglomerate due to the presence of Van der Waals forces if they are poorly or insufficiently dispersed.

-

7.

Only two papers in the portfolio (10%) studied the bonding of reinforcing bars in CNT-concrete. Although they presented promising results, evidencing the role of CNTs as crack propagation controllers, the adherence depends on several factors, such as bar diameter, bar surface, and anchorage length. Therefore, this topic needs to be further investigated in future research.

-

8.

Water absorption, porosity, and permeability were studied in 26, 10, and 5% of the selected literature, in that order. The incorporation of CNT in concrete reduced these properties, which is a positive factor in terms of durability. However, considering the increasingly frequent use of different concrete types by the construction industry, it is still necessary to develop research on these properties.

-

9.

The electrical properties of CNT-concrete were investigated in 21% of the selected bibliography. From these papers, it is concluded that the addition of CNT to concrete leads to increased electrical conductivity and/or reduced electrical resistivity, which occurs as a consequence of the low density and high aspect ratio of CNTs, which favors the formation of conductive networks in the cement matrix.

-

10.

Carbonation and chloride penetration resistance of CNT-concrete were studied in only 10% of the selected articles. The results indicated improvement of concrete microstructure when CNTs were incorporated into the matrix and, consequently, improvement of these properties. However, experimental studies on this topic should still be carried out considering different types of CNT-concrete.

-

11.

The fracture energy and toughness of CNT-concrete were studied in only two references (10%). Although gains of up to 42% were reported in these works, additional studies are needed to reach assertive conclusions regarding the fracture energy and toughness of CNT-concrete, especially in concretes modified by replacing NA by RA.

These findings reveal that a majority of the studies on CNT-concrete focused on their mechanical properties, while those on durability had less interest from researchers (Fig. 4). It is emphasized that these conclusions are limited to the study of the selected articles. In addition, other properties were not considered in the review, such as mass loss, ductility, ultrasonic pulse velocity, creep, and shrinkage, among others. These can be used as topics for further investigation.

References

IEA (2020) The challenge of reaching zero emissions in heavy industry. International Energy Agency. https://www.iea.org/articles/the-challenge-of-reaching-zero-emissions-in-heavy-industry (accessed October 18, 2022).

Borges LA (2019) Performance of concretes produced with carbon nanotubes synthesized directly on clinker. Master’s Thesis, Federal University of Minas Gerais, (in Portuguese)

Fávero RB (2016) Mechanical characterization of advanced cementitious composite material based on reactive powders. Master’s Thesis, Federal University of Rio Grande do Sul. (in Portuguese)

Tyson BM (2010) Carbon nanotube and nanofiber reinforcement for improving the flexural strength and fracture toughness of Portland cement paste. Master’s Thesis, Texas A&M University, 2010.

Khitab A, Ahmad S, Khushnood RA, Rizwan SA, Ferro GA, Restuccia L et al (2017) Fracture toughness and failure mechanism of high performance concrete incorporating carbon nanotubes. Frattura Ed Integrita Strutturale 11:238–248. https://doi.org/10.3221/IGF-ESIS.42.26

Khalid AR, Rizwan SA, Hanif U, Hameed MH (2016) Effect of mixing time on flowability and slump retention of self-compacting paste system incorporating various secondary raw materials. Arab J Sci Eng 41:1283–1290. https://doi.org/10.1007/s13369-015-1885-5

Khitab A, Anwar W, Mansouri I, Tariq MK, Mehmood I (2015) Future of civil engineering materials: a review from recent developments. Rev Adv Mater Sci 42:20–27

Raki L, Beaudoin J, Alizadeh R, Makar J, Sato T (2010) Cement and concrete nanoscience and nanotechnology. Materials 3:918–942. https://doi.org/10.3390/ma3020918

Lopez A, Ferro G, Jagadale P, Tulliani JM (2013) Influence of carbon nanotubes addition onto the mechanical properties of restoration mortars. Gruppo Italiano Frattura Convegno Nazionale IGF Acta Fracturae 22:278–286

Ferro G, Tulliani JM, Lopez A, Jagdale P (2015) New cementitious composite building material with enhanced toughness. Theoret Appl Fract Mech 76:67–74. https://doi.org/10.1016/j.tafmec.2015.01.005

Sanchez F, Sobolev K (2010) Nanotechnology in concrete: a review. Constr Build Mater 24:2060–2071. https://doi.org/10.1016/j.conbuildmat.2010.03.014

Ensslin L, Ensslin SR, Lacerda RT de O, Tasca JE (2010) ProKnow-C, knowledge development process-constructivist. Processo Técnico com Patente de Registro Pendente Junto ao INPI Brasil,10. (in Portuguese)

Google S. Scholar Google n.d. https://scholar.google.com.br/?hl=pt (accessed October 31, 2022).

Jung M, Lee Y-S, Hong S-G, Moon J (2020) Carbon nanotubes (CNTs) in ultra-high performance concrete (UHPC): Dispersion, mechanical properties, and electromagnetic interference (EMI) shielding effectiveness (SE). Cem Concr Res. https://doi.org/10.1016/j.cemconres.2020.106017

Carriço A, Bogas JAA, Hawreen A, Guedes M (2018) Durability of multi-walled carbon nanotube reinforced concrete. Constr Build Mater 164:121–133. https://doi.org/10.1016/j.conbuildmat.2017.12.221

Hawreen A, Bogas JA (2019) Creep, shrinkage and mechanical properties of concrete reinforced with different types of carbon nanotubes. Constr Build Mater 198:70–81. https://doi.org/10.1016/j.conbuildmat.2018.11.253

Lee SH, Kim S, Yoo D-Y (2018) Hybrid effects of steel fiber and carbon nanotube on self-sensing capability of ultra-high-performance concrete. Constr Build Mater 185:530–544. https://doi.org/10.1016/j.conbuildmat.2018.07.071

Ruan Y, Han B, Yu X, Zhang W, Wang D (2018) Carbon nanotubes reinforced reactive powder concrete. Compos Part A Appl Sci Manuf 112:371–382. https://doi.org/10.1016/j.compositesa.2018.06.025

Mohammadyan-Yasouj SESE, Ghaderi A (2020) Experimental investigation of waste glass powder, basalt fibre, and carbon nanotube on the mechanical properties of concrete. Constr Build Mater 252:119115. https://doi.org/10.1016/j.conbuildmat.2020.119115

Hawreen A, Bogas JA, Kurda R (2019) Mechanical characterization of concrete reinforced with different types of carbon nanotubes. Arab J Sci Eng 44:8361–8376. https://doi.org/10.1007/s13369-019-04096-y

Konsta-Gdoutos MSMS, Danoglidis PAPA, Shah SPSP (2019) High modulus concrete: effects of low carbon nanotube and nanofiber additions. Theor Appl Fract Mech 103:102295. https://doi.org/10.1016/j.tafmec.2019.102295

Adhikary SK, Rudžionis Ž, Tučkutė S, Ashish DK (2021) Effects of carbon nanotubes on expanded glass and silica aerogel based lightweight concrete. Sci Rep. https://doi.org/10.1038/s41598-021-81665-y

Mohsen MO, Al Ansari MS, Taha R, Al Nuaimi N, Taqa AA (2019) Carbon nanotube effect on the ductility, flexural strength, and permeability of concrete. J Nanomater. https://doi.org/10.1155/2019/6490984

Parvaneh V, Khiabani SH (2019) Mechanical and piezoresistive properties of self-sensing smart concretes reinforced by carbon nanotubes. Mech Adv Mater Struct 26:993–1000. https://doi.org/10.1080/15376494.2018.1432789

Hawreen A, Bogas JA (2018) Influence of carbon nanotubes on steel–concrete bond strength. Mater Struct Materiaux et Constr. https://doi.org/10.1617/s11527-018-1279-8

Qasem A, Sallam YS, Hossam Eldien H, Ahangarn BH, Eldien HH, Ahangarn BH (2020) Bond-slip behavior between ultra-high-performance concrete and carbon fiber reinforced polymer bars using a pull-out test and numerical modelling. ConstrBuild Mater. https://doi.org/10.1016/j.conbuildmat.2020.119857

Kotop MAMAMA, El-Feky MSS, Alharbi YRYR, Abadel AAA, Binyahya ASAS (2021) Engineering properties of geopolymer concrete incorporating hybrid nano-materials. Ain Shams Eng J 12:3641–7. https://doi.org/10.1016/j.asej.2021.04.022

Vesmawala GR, Vaghela AR, Yadav KD, Patil Y (2020) Effectiveness of polycarboxylate as a dispersant of carbon nanotubes in concrete. Mater Today Proc 28:1170–1174. https://doi.org/10.1016/j.matpr.2020.01.102

Shao J, Zhu H, Zhao B, Haruna SI, Xue G, Jiang W et al (2022) Combined effect of recycled tire rubber and carbon nanotubes on the mechanical properties and microstructure of concrete. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2022.126493

Jalali Mosallam S, Pesaran Behbahani H, Shahpari M, Abaeian R (2022) The effect of carbon nanotubes on mechanical properties of structural lightweight concrete using LECA aggregates. Structures 35:1204–1218. https://doi.org/10.1016/j.istruc.2021.09.003

Jung M, Park J, Hong S-G, Moon J (2022) The critical incorporation concentration (CIC) of dispersed carbon nanotubes for tailoring multifunctional properties of ultra-high performance concrete (UHPC). J Market Res 17:3361–3370. https://doi.org/10.1016/j.jmrt.2022.02.103

Lim K, Lee N, Ryu G, Koh K, Kim K (2022) Electrical Characteristics of ultra-high-performance concrete containing carbon-based materials. Appl Sci Switzerland. https://doi.org/10.3390/app12157858

Gillani SSUH, Khitab A, Ahmad S, Khushnood RA, Ferro GA, Saleem Kazmi SM et al (2017) Improving the mechanical performance of cement composites by carbon nanotubes addition. Procedia Struct Integ. https://doi.org/10.1016/j.prostr.2017.04.003

Reis ED, Resende HF, Ludvig P, de Azevedo RC, Spitale F, Poggiali J et al (2022) bonding of steel bars in concrete with the addition of carbon nanotubes : a systematic review of the literature. Buildings 12:1–15. https://doi.org/10.3390/buildings12101626

Rashad AM (2017) Effect of carbon nanotubes (CNTs) on the properties of traditional cementitious materials. Constr Build Mater 153:81–101. https://doi.org/10.1016/j.conbuildmat.2017.07.089

Parveen S, Rana S, Fangueiro R, Paiva MC (2015) Microstructure and mechanical properties of carbon nanotube reinforced cementitious composites developed using a novel dispersion technique. Cem Concr Res 73:215–227. https://doi.org/10.1016/j.cemconres.2015.03.006

Liew KM, Kai MF, Zhang LW (2016) Carbon nanotube reinforced cementitious composites: an overview. Compos Part A Appl Sci Manuf 91:301–323. https://doi.org/10.1016/j.compositesa.2016.10.020

Sáez De Ibarra Y, Gaitero JJ, Erkizia E, Campillo I (2006) Atomic force microscopy and nanoindentation of cement pastes with nanotube dispersions. Phys Status Solidi A Appl Mater Sci 203:1076–81. https://doi.org/10.1002/pssa.200566166

Camacho-Ballesta C, Zornoza E, Garcés P (2016) Performance of cement-based sensors with CNT for strain sensing. Adv Cem Res 28:274–284. https://doi.org/10.1680/adcr.14.00120

Bautista-Gutierrez KP, Herrera-May AL, Santamaría-López JM, Honorato-Moreno A, Zamora-Castro SA (2019) Recent progress in nanomaterials for modern concrete infrastructure: advantages and challenges. Materials. https://doi.org/10.3390/ma12213548

EL-sayed N, Kohail M, Khalaf MA (2021) The efficiency of chloride extraction using un-galvanized steel anode. Ain Shams Eng J 12:1353–60. https://doi.org/10.1016/j.asej.2020.11.001

Acknowledgements

The authors thank the Federal Center for Technological Education of Minas Gerais (CEFET-MG) for funding this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Tulio H. Panzera.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Reis, E.D., Borges, L.A., Camargos, J.S.F. et al. A systematic review on the engineering properties of concrete with carbon nanotubes. J Braz. Soc. Mech. Sci. Eng. 45, 205 (2023). https://doi.org/10.1007/s40430-023-04117-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04117-w