Abstract

Natural stones are exposed to sudden and slow-developing thermal cycles, affecting their physico-mechanical and surface properties. In this study, changes in the physico-mechanical properties of natural stones in response to sudden (thermal shock) and slow-developing (thermal aging) thermal cycles were investigated on natural stone samples with various compositions (magmatic, sedimentary, metamorphic). Both the thermal shock and thermal aging cycles were simulated by first heating the specimens to 105 °C for 18 h. In case of the thermal shock cycles, the heating phase was followed by placing the samples in purred water for 6 h. To simulate the thermal aging cycles, specimens were allowed to cool at room temperature (23 °C) for 6 h. At the end of the cycles, a selection of physico-mechanical properties was evaluated and compared with the initial values. Results indicate that thermal treatments have a significant negative effect on the strength of the natural stone samples. Regression models were developed to estimate uniaxial compressive strength, point load strength, Brazilian tensile strength from non-destructive test parameters (Schmidt hardness, P wave velocity, porosity) of natural and treated samples. Results show that there are strong correlations between mechanical properties and non-destructive test parameters (R2 > 0.96, MAPE values between 2 and 5%).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Natural stones are materials that are widely used in everyday life such as in the construction of buildings (cladding, flooring etc.) or to decorative purposes (relief, monuments). They are frequently used in historical buildings, columns, bearing walls, flooring and exterior surface coating materials. Several types of natural stones may experience significant damage, especially if they are used outdoors. Determining physico-mechanical, chemical, petrographic properties of natural stones are important to map potential utilization areas and to ensure stability. Building materials are subjected to some deterioration factors such as solar radiation, salt crystallization effect, temperature changes, acid rains etc. These factors can cause changes in the physical and mechanical properties of natural stones, deterioration of their texture and degradation of their surface properties such as color and gloss. Therefore, not only the engineering properties of natural stones but also their resistance to environmental influences should be investigated (Kılıç 2017; Murru et al. 2018).

Previous studies investigating the effects of environmental conditions on natural stones such as freeze–thaw (Sarici and Ozdemir 2018; Ma et al. 2018; Freire-Lista 2015; Fener and Ince 2015; Ozcelik et al. 2012; Tan et al. 2011), water content (Zhou et al. 2016; Ozcelik and Ozguven 2014; Karaca 2010; Çobanoğlu et al. 2009; Vásárhelyi and Ván 2006; Ozdemir and Sarici 2018), salt crystallization (Çelik and Aygün 2018; Sarıcı et al. 2018; Derluyn et al. 2014; Beck and Al-Mukhtar 2010; Angeli, et al. 2008) and acidic-basic environment (Vazquez et al. 2016; Ozdemir et al. 2022; Bonazza et al. 2009; Müller 2008; Sharma et al. 2007). Frequent thermal changes are considered as the main cause of deterioration of natural stones. Thermal expansion of stones and chemical reactions could result in the growth of previous micro cracks and the creation of new cracks, accompanied by apparent porosity increase. Therefore, temperature changes may alter the mechanical properties of natural stones, depending on the rock type and the duration and amplitude of temperature variations.

In the recent decades, the effect of thermal shock and thermal aging on the physical and mechanical properties of rock materials has been widely studied. For instance, Yavuz et al. (2006) carried out freeze–thaw and thermal shock tests consisting of 20 cycles on 12 different sedimentary rocks. They found that the index and mechanical properties of the rocks subjected to freeze–thaw and thermal shock decreased at varying levels according to their initial values. Yavuz (2011) subjected the andesite samples to freeze–thaw and thermal shock cycles and determined the alterations in the physico-mechanical properties of the samples. As a result of 50 cycles in total, uniaxial compressive strength, P-wave velocity and Schmidt hardness values of andesite decreased. Demirdag (2013) investigated the effects of freeze–thaw and thermal shock cycles on physical and mechanical characteristics of filled and unfilled travertines and found that the strength of the samples has considerably decreased by the end of the cycles. Ghobadi and Babazadeh (2015) conducted 20 freezing–thawing, salt crystallization and thermal shock cycles on sandstones samples and reported the reduction of uniaxial compressive strength and P-wave velocity. They suggested that the main reason for the decreasing of uniaxial compressive strength and P-wave velocity are related to the increasing of porosity values. Huhta et al. (2016) developed a new method to determine the strength losses of rocks exposed to thermal shock and determined the strength capacities of rocks depending on cycle number. Wang et al. (2016a) studied physical (micromorphology, density, porosity), static mechanical (P-wave velocity, uniaxial compressive strength) and dynamic mechanical (deformation modulus) changes by performing 10, 20, 30 and 40 artificial thermal shock cycles on red sandstone. Wang et al. (2016b) carried out an experimental study on a red sandstone sample using the accelerated test method to determine the effects of freeze–thaw (FT) and thermal shock (TS) on rock behavior. They found that F-T or TS caused significant deterioration in physical–mechanical properties of the red sandstone. Çelik and Sert (2020) performed accelerated aging tests to determine the effect of cyclic conditions such as salt crystallization, freeze–thaw and thermal shock on the durability of hydrophobic treated and untreated andesite. They reported that treated samples were less susceptible to the destructive effects of accelerated aging tests than untreated samples. Strength tests are relatively simple, but they are costly and time-consuming, and specimen arrangement is difficult. Therefore, prediction of strength parameters by non-destructive test methods is commonly applied.

Most of the studies on thermal shock (TS) and thermal aging (TA) have focused on the change of uniaxial compressive strength. Therefore, there are limited information about the changes in point load and Brazilian (indirect tensile) strengths of rocks. The aim of this study is to determine the effects of abrupt and slow thermal change cycles on strength parameters, and quantify these parameters by non-destructive methods. In this study, physico-mechanical properties of three types of rocks with different composition that underwent cyclic thermal treatments were investigated. Changes in mechanical strength values (uniaxial compressive strength, point load strength, Brazilian tensile strength) of rocks were determined. In addition, regression models were developed to predict these three mechanical strength properties from non-destructive testing (Schmidt hardness, P-wave velocity, and porosity).

2 Research significance

Environmental conditions such as TS-TA cycles result in changes of the physico-mechanical properties of the natural stones. As the number of cycles increases, damages and deteriorations may reach macro dimensions. Therefore, it is important to use natural stones that are able to preserve their physico-mechanical properties when exposed to environmental cycles such as TS-TA. Natural stones that are often used as coating materials in the construction industry produced in Turkey are used in the experimental studies. Samples were exposed to TS-TA cycles and the changes in their physico-mechanical properties were investigated. In addition, regression models were established to estimate the decline of the mechanical properties of the natural stones from non-destructive test parameters.

3 Material and method

3.1 Experimental setup

In this study, thermal ageing and thermal shock cycles were applied on three types of natural stones. The physico-mechanical properties of rock samples (uniaxial compressive strength, point load strength, Brazilian tensile strength, Schmidt hammer hardness and ultrasonic wave velocities) were determined before and after the cycles. In this study, Nuve KD 400 oven, UTEST UTR-0580-point load test machine, L-type Schmidt hammer, ELE 500 compressive press and PUNDIT 6 Model PC 1000 ultrasonic were used as testing equipments.

3.1.1 Materials

In this study, three types of rock samples with different origin (sedimentary, magmatic and metamorphic) were investigated. Samples were collected from Malatya and Afyon regions of Turkey (Fig. 1). In total, 15 blocks with dimensions of 20 × 20 × 20 cm were collected from the study areas. In this selection, we measured the durability of samples from each rock unit against thermal change for determination of physico-mechanical properties. Tests were carried out on fresh samples. Preparation and testing of samples were conducted by the suggested Turkish Standards Institute and International Society for Rock Mechanics procedures (ISRM 1978a, 1978b, 1981, 1985, ISRM 2007 and TS EN 1925). The physical properties of samples are reported in Table 1, together with stone origin and commercial names of the selected natural stones. For the determination of mineralogical and petrographical characteristics XRD, XRF and thin section analysis were carried out. XRD patterns are shown in Fig. 2, XRF analysis results are presented in Table 2 and thin section analysis are shown in Fig. 3.

The MB and AB samples mainly consist of calcite, YB samples are built up by plagioclase, olivine, biotite minerals (Figs. 2 and 3, Table 2). XRF analysis result showed that AB and MB samples contain mainly calcite minerals (56.88%, 54.74% respectively), YB samples mainly contain SiO2 (45.41%).

3.2 Thermal treatments

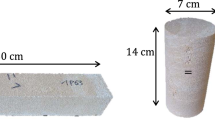

Prior to the thermal treatments, core samples with length/diameter (L/D) ratios of 2.5 were drilled from the blocks (Fig. 4) and prepared for testing. Two types of thermal treatments were applied on the samples. Thermal ageing was performed by slowly cooling the samples at room temperature after the heating phase, while thermal shock was simulated by the rapid cooling of the samples by placing them to water (Fig. 5). A total of 30 thermal aging and thermal shock cycles were performed on the rock samples. The changes in the physico-mechanical properties and decomposition rates of the rocks were deduced.

3.2.1 Thermal ageing treatments

Thermal ageing cycles were carried out by applying procedures described in Sarici (2016). The specimens were heated at 105 °C in an oven for 18 h and then they were placed to room temperature (23 °C) for cooling in air for another 6 h. This treatment corresponds to one cycle of thermal ageing. In total 225 specimens were subjected to thermal aging treatment through 30 cycles. After the 30 cycle treatment, mechanical tests (uniaxial compressive strength, point load strength, Brazilian thermal strength, Schmidt hardness, ultrasonic wave velocity) were performed on each sample.

3.2.2 Thermal shock treatments

Thermal shock treatments on 225 samples were performed according to the TS EN 14,066 guides. The samples were heated at 105 °C in an oven for 18 h. Subsequently, they were rapidly immersed in distilled water of 23 °C for 6 h. This treatment corresponds to one cycle of thermal shock. During the cooling phase, the temperature of water was ensured to remain constant (23 ± 1 °C). Similar to the thermal aging treatments, 30 thermal shock cycles were conducted in total, and mechanical tests were carried out on each sample after the treatments.

3.3 Mechanical tests

A series of mechanical tests (uniaxial compressive strength, point load strength, Brazilian tensile strength, Schmidt hammer hardness, ultrasonic wave velocity) were carried out in accordance with the ISRM standards (ISRM 1978a, 1978b, 1981, 1985, 2007) and TSE (TS EN 1925).

3.3.1 Uniaxial compressive strength (UCS) test

UCS tests were carried out following the ISRM (1978a) guides on core samples with a diameter of 54 mm and a L/D ratio of 2–2.5. Compressive tests were carried out under axial load with 0.5 MPa/s loading rate.

The compressive strength values of the test sample were calculated by Eq. 1:

where;\(f_{b}\) is the compressive strength of sample (MPa), Pk is the maximum breaking load (kN), and A represents the surface area of the applied load of the sample (cm2). The resulting UCS values are reported in Table 3.

3.3.2 Point load strength

The diameter point load strength tests were performed as suggested by the ISRM (1985). Test samples with L/D ratios > 1 were prepared and tests were carried out before and after the thermal cycles. The formulas for the calculations are given in Eqs. 2 and 3 and the resulting values are reported in Table 5.

where Is is the point load strength index (MPa), P is the maximum breaking load (kN), De represents the equivalent core diameter (mm). In Eq. 3, Is50 is the adjusted point load strength index (MPa) and F is the dimensionless size correction factor. The resulting point load strength values (Is(50)) are reported in Table 3.

3.3.3 Brazilian tensile strength

The Brazilian tensile strength tests were conducted based the ISRM (2007). 10 disc samples with a L/D ratio of 0.5 were prepared. Constant loading speeds were applied on the samples until their breakpoint and the maximum load was recorded for each sample.

The Brazilian tensile strength of the sample was calculated by Eq. 4:

where \(\sigma _{{\text{\c{c}}}}\) is the indirect tensile strength of the sample (MPa), Pk is the maximum fracture load (kN), D is the Diameter of sample (mm), and t is the thickness of sample (mm). The resulting strength values are reported in Table 3.

3.3.4 Ultrasonic wave velocity

Ultrasonic wave velocities of the rocks were determined according to the ISRM (1978b). The tests were performed on cylindrical core specimens with L/D ratios of 2–2.5, using the Pundit 6 ultrasonic wave generator. Ultrasonic pulse velocities were obtained by direct transmission. The transmit time was recorded for each sample as the mean of 10 separate readings. The average values of the ultrasonic pulse velocities were procured by dividing the path length by the mean transfer time of the 10 readings. The ultrasonic wave velocities Vp and Vs were calculated by the following formulas:

where L is the length of cylindrical test specimen (path length of the signal, mm), Vp is the P wave velocity (m/s), Vs is the S wave velocity (m/s), tp is the measured propagation time of P wave (μs), ts is the measured propagation time of S wave (μs), and to is the starting time (μs). Tp and Ts represents the effective feed rates of P and S waves (μs), respectively.

3.3.5 Elastic and dynamic modulus of samples

The elastic and dynamic Young modulus values were calculated from ultrasonic wave velocities (Vp and Vs) which were recorded at the beginning and end of the thermal cycles. The Young modulus (Eu) and poisson ratio (Vdyn) were calculated from Eqs. 9–10.

where Vp and Vs are the velocities of P and S waves (m/s) and ρ is the unit weight (kg/m3).

3.3.6 Schmidt hammer hardness

Schmidt hammer hardness test was carried out as suggested by the ISRM (1981) at the beginning and end of the thermal cycles. An L-type Schmidt hammer was used and 20 reading were recorded on each sample, targeting different points of the specimens. The average hardness values were calculated that are reported in Table 3.

3.3.7 Capillary water absorption test

Capillary water absorption capacity has a significant effect on the degradation of natural stones under poor environmental conditions. The liquid that seeps into the capillary cavities directly affects the resistance of natural stones. Capillary water absorption tests were carried out according to TS EN (1925). Five cylindrical specimens were cut from the blocks and surface areas that became in contact with water were measured by a caliper. Samples that were included in the capillary water absorption tests were properly placed on a grid (Fig. 6). Sample weights (Mi) were determined at 1, 3, 5, 10, 15, 30, 60, 480, 1440, 2880 and 4320 min. The capillary water absorption of the samples was calculated by Eqs. 11 and 12.

where Cy is capillary water absorption values at certain times (%), A is the area of the surface where the sample that is in contact with water (m2), Mi is the weight of the sample at specific testing times (g), Md is the weight of sample at the end of the experiment (g), and ti is the time (sec).

3.4 Alteration velocity

Natural building stones are exposed to various physical and chemical interactions, depending on the type of utilization in the building sector. During these interactions, deformation in the internal structure of the materials occur. Physical disintegration caused by minor chemical changes can also be called as physical degradation. In this study, physical–mechanical degradation was investigated. The changes in the alteration velocity in the physical–mechanical strength of natural stones were carried out using techniques proposed by Angeli et al. (2007). The alteration velocities of samples were calculated by Eq. 13.

where; Mk is the Last strength of rock (g), Mf is the First strength of rock (g), and D represents the number of days. The resulting alteration velocities values are given in Table 4.

4 Result and discussion

4.1 Results of mechanical tests

At the beginning and end of the 30 thermal shock and thermal ageing cycles, uniaxial compressive strength (UCS), point load strength (PL), Brazilian tensile strength (BT), Schmidt Hardness (Hr), ultrasonic wave velocities (Vp and Vs) and weights were recorded. The elastic and dynamic modulus values were calculated from the ultrasonic wave velocities. The resulting values are reported in Table 3. Point load and Brazilian tensile strength test samples before and after thermal treatments are shown in Figs. 7 and 8, respectively.

4.2 Results of the capillary absorption tests

The evolution of capillary water absorption values over time is presented in Fig. 9. When YB samples have high capillary water absorption values and also high water absorption values (Fig. 9). Capillary water absorption values of MB and AB samples are lower and show a similar trend.

4.2.1 Changes in physico-mechanical properties after thermal treatment

In dry conditions, physico-mechanical properties of rocks were considered to be 100%. The changes in the physico-mechanical properties of natural stones after thermal treatments are presented in terms of percentages (Fig. 10).

Physico-mechanical values of all rock samples were reduced after the thermal treatments (Fig. 10). The most significant decrease in UCS, PL and BT were observed in case of the MB samples (Fig. 10a, b and c). The most pronounced changes in P and S wave velocities and Hr values were measured on the recrystallized limestone samples (AB, Fig. 10d, e and f). The YB samples having magmatic origin showed the lowest overall percentage change. The uniaxial compressive strength values of YB, MB, AB samples decreased by 8.64%, 28.91% and 20.30% after thermal shock, and by 3.99%, 16.25% and 11.61% after thermal ageing, respectively (Fig. 10a). It is important to note that the change in the uniaxial compressive strength of the MB sample is 28.91%. The point load strength of YB, MB, AB samples decreased by 6.59%, 29.91% and 15.92% after thermal shock, 2.79%, 16.52% and 7.82% after thermal aging, respectively (Fig. 10b). The change in the point load strength after thermal shock application of MB sample was the most significant, almost reaching 30%.

Brazilian tensile strength of YB, MB, AB samples decreased by 10.22%, 28.11% and 17.94% after thermal shock, 3.73%, 14.30% and 7.05% after thermal aging, respectively (Fig. 10c). Similar to the previous two mechanical tests (UCS and PL), the change in Brazilian tensile strength of the YB sample is lower than in case of the other two natural stones. This could be caused by the anisotropic thermal expansion of calcite minerals which is the main component of the YB samples. Due to different amount of thermal expansion and crystal phase transition of minerals, a local thermal stress concentration will develop between minerals, generating potential micro cracks. Micro cracks and holes inside the samples caused a reduction in intergranular adhesion resulting in the decrement of bearing capacity. This process leads to the weakening rock strength (Feng et al. 2022; Su et al. 2017).

P-wave velocity of YB, MB, AB samples decreased by 1.62%, 7.46% and 11.32% after thermal shock, 0.95%, 2.50% and 1.77% after thermal aging, respectively (Fig. 10d). S wave velocity of YB, MB, AB samples decreased by 3.15%, 5.17% and 8.33% after thermal shock, 3.35%, 3.90% and 2.32% after thermal aging, respectively (Fig. 10e). The main reason for the decreasing velocities is considered to be the increasing porosity of the samples as a result of thermal treatment. As the micro and macro porosity of the rock samples increase, the seismic waves dissipate in space. This increase indicated that when temperature changed rapidly, new micro cracks were formed and propagation of pre-existing micro crack occurred. Previous studies also found that cyclic thermal shock treatments decrease the intergranular adhesion, leading to the formation of micro cracks and holes which delay the propagation time of waves, resulting in decreased P wave velocity (Liu et al. 2015; Zhang et al. 2016).

Schmidt hardness of YB, MB, AB samples decreased by 7.78%, 13.54% and 16.33% after thermal shock, 4.0%, 6.54% and 9.80% after thermal aging, respectively (Fig. 10f). The percentage reduction in the Schmidt hardness value of the AB sample is higher than in case of the other two natural stones. The petrographic analysis (Fig. 3) indicated that MB sample had smaller grain size than AB and YB samples. The grain boundaries of the YB samples are sharp and irregular (Fig. 3). In general, the test results suggest that the marbles with small and irregular grains are more resistant against the ageing test whereas the ones with large and straight (smooth) grains are non-resistant, in agreement with Yavuz and Topal (2007).

4.2.2 Alteration velocity values

Alteration velocities reported in Table 4 suggest that thermal shock cycles result in a higher degree of deterioration (associated with larger alteration values) of the samples. Thermal shock and thermal ageing cycles have a more significant wearing effect on the mechanical strength of MB and AB samples containing calcite mineral than YB sample containing silicate minerals.

4.3 Statistical analysis

Regression analysis is a widely used method in mechanical strength estimations by creating models based on various rock parameters. In this study, multiple regression analyses were performed to investigate the relationship between strength parameters (uniaxial compressive strength, point load strength and Brazilian tensile strength) and other non-destructive rock parameters (Schmidt hardness values (Hr), P wave velocity (Vp), porosity (N)) for dry conditions and after thermal aging and thermal shock cycles. For this purpose, the SPSS 20 package was used. Statistically significant correlations were identified between the mechanical and non-destructive test results. Multiple regression models for the prediction of UCS, PL and BT values of dry and thermally treated samples based on Schmidt hardness, P wave velocity and porosity are given in Table 5, 6 and 7. The performance results of the values obtained from the multiple regression models are given in Table 8.

In order to assess the performance of the multiple regression models, mean absolute percentage error (MAPE) and coefficient of determination (R2) were calculated. The performance results of the values obtained from the multiple regression models are reported in Table 8. Results show that multiple regression models are quite successful in predicting the mechanical properties of the rocks. A MAPE value less than 10% indicate a “very good model”, MAPE between 10 and 20% indicate “good models”, MAPE between 20 and 50% indicate “acceptable model” and MAPE values > 50% indicate “false and incorrect models”. The MAPE values of the models are between 2 and 5% (Table 8) suggest that the models can very well predict strength parameters. Furthermore, the proximity of R2 to 1 indicates that the model is adequate, and values close to 0 indicate that the model is wrong or a correlation does not exist. R2 values reported in Table 8 are close to 1, suggesting that the models are valid and highly meaningful.

5 Conclusion

In this study, the effects of thermal shock and thermal aging treatments on the physico-mechanical properties of the natural stones were investigated. The main conclusions obtained from the experimental and statistical studies are as follows;

-

1

The porosity of samples increased with the number of cycles. However, a more significant increase of porosity was observed in case of the water cooling process corresponding to the thermal shock (TS) treatment. It can be explained by the enlargement of the pores of the existing micro cracks due to abrupt cooling. Due to the increased porosity, P-wave velocities of the natural stones decreased. This variation appears to be more pronounced in samples exposed to TS cycles.

-

2

The natural stones lose their initial strength properties over time. The magnitude of changes depends on both the structural properties of the stone and the atmospheric conditions (simulated by the thermal cycles) they are exposed to. Thermal effects such as TS and TA cause expansion and contraction in rock grains. During the thermal treatment, first micro cracks are formed. These micro cracks may transform into macro structured cracks depending on the type of exposure and the number of cycles (repeated events), resulting in porosity increase and decreased rock strength. Subsequently, major strength loss such as disintegration, splitting and finally fragmentation may occur. In this study, the mechanical strength of natural stones with various origins (magmatic, sedimentary, metamorphic) exposed to TS-TA conditions decreased. The YB sample having magmatic origin appeared to be more resistant than the other two natural stones samples. In addition, the change in uniaxial compressive and point load strengths after the thermal shock treatment of MB sample reached almost 30%.

-

3

Models that predict mechanical parameters (uniaxial compressive strength, point load strength, Brazilian tensile strength) based on using non-destructive tests were developed. These models are based on the multiple regression analysis of more than one independent test (wave velocity, Schmidt hardness and porosity), and the coefficients of the models were determined for dry, thermal shock and thermal aging conditions. Strong correlations between the mechanical properties and non-destructive stress results were identified, with MAPE values between 2 and 5%.

-

4

Models that predict mechanical parameters (uniaxial compressive strength, point load strength, Brazilian tensile strength) using non-destructive tests were developed. These models are based on the multiple regression analysis of more than one independent test (wave velocity, Schmidt hardness and porosity), and the coefficients of the models were established for dry, thermal shock and thermal aging conditions. Strong correlations between the mechanical properties and non-destructive stress results were identified, with MAPE values between 2 and 5%.

Results indicate that thermal treatments have significant negative effect on the strength of the natural stones. Quantifying changes of resistance values of the natural stones under thermal shock and thermal aging conditions in therefore very important in areas where the ambient temperature changes rapidly.

References

Angeli M, Bigas JP, Benavente D, Menendez B, Hebert R, David C (2007) Salt crystallization in pores: quantification and estimation of damage. Eng Geol 52:187–195

Angeli M, Benavente D, Bigas JP, Menendez B, Hebert R, David C (2008) Modification of the porous network by salt crystallization in experimentally weathered sedimentary stones. Mater Struct 41:1091–1108

Beck K, Al-Mukhtar M (2010) Evaluation of the compatibility of building limestones from salt crystallization experiments. Geol Soc Lond Spec Publ 333:111–118

Bonazza A, Messina P, Sabbioni C, Carlota MG, Brimblecombe P (2009) Mapping the impact of climate change on surface recession of carbonate buildings in Europe. Sci Total Environ 407(6):2039–2050

Çelik MY, Aygün A (2018) The effect of salt crystallization on degradation of volcanic building stones by sodium sulfates and sodium chlorides. Bull Eng Geol Environ 78(5):3509–3529

Çelik MY, Sert M (2020) Accelerated aging laboratory tests for the evaluation of the durability of hydrophobic treated and untreated andesite with respect to salt crystallization, freezing–thawing, and thermal shock. Bull Eng Geol Environ 79:3751–3770

Çobanoğlu I, Çelik SB, Dinçer I, Alkaya D (2009) Core size and time effects on water absorption values of rock and cement mortar samples. Bull Eng Geol Environ 68:483–489

Demirdag S (2013) Effects of freezing–thawing and thermal shock cycles on physical and mechanical properties of filled and unfilled travertines. Constr Build Mater 47:1395–1401

Derluyn H, Moonen P, Carmeliet J, Carmeliet J (2014) Deformation and damage due to drying-induced salt crystallization in porous limestone. J Mech Phys Solids 63(1):242–255

Fener M, Ince I (2015) Effects of the freeze–thaw (F–T) cycle on the andesitic rocks (Sille-Konya/Turkey) used in construction building. J African Earth Sci 109:96–106

Feng Y, Su H, Nie Y, Zhao H (2022) Role of cyclic thermal shocks on the physical and mechanical responses of white marble. Machines 20:58. https://doi.org/10.3390/machines10010058

Freire-Lista DM, Fort R, Varas-Muriel MJ (2015) Freeze-thaw fracturing in building granites. Cold Reg Sci Technol 113:40–51

Ghobadi MH, Babazadeh R (2015) Experimental studies on the effects of cyclic freezing-thawing, salt crystallization, and thermal shock on the physical and mechanical characteristics of selected sandstones. Rock Mech Rock Eng 48:1001–1016

Huhta A, Kärki A, Hanski E (2016) A new method for testing thermal shock resistance properties of soapstone – effects of microstructures and mineralogical variables. Bull Geol Soc Finl 88(1):21–46

ISRM (1978a) Suggested method for determining he uniaxial compressive strength and deformability of rock materials. Int J Rock Mech Min Sci Geomech Abstr. https://doi.org/10.1016/0148-9062

ISRM (1978b) Suggested methods for determining sound velocity. Int J Rock Mech Min Sci Geomech Abstr 15:53–58

ISRM (1981) Suggested methods for determining hardness and abrasiveness of rocks. Part 3. commission on standardization of laboratory and field tests. Int J Rock Mech Min Sci Geomech Abstr 15(3):89–97

ISRM (1985) Suggested method for determining point load strength. Int J Rock Mech Min Sci Geomech Abstr 22(2):51–60

ISRM (2007) Suggested methods for determining tensile strength of rock materials. Int J Rock Mech Min Sci 15:99–103

Karaca Z (2010) Water absorption and dehydration of natural stones versus time. Constr Build Mater 24:786–790

Kılıç İ (2017) Physical and mechanical properties of yenimuhacir sandstone as construction material. Gaziosmanpasa J Sci Res 6(3):01–11

Lam dos Santos JP, Rosa LG, Amaral PM (2011) Temperature effects on mechanical behavior of engineered Stones. Constr Build Mater 25:171–174

Liu S, Xu J (2015) An experimental study on the physico-mechanical properties of two post-high-temperature rocks. Eng Geol 185:63–70

Ma Q, Ma D, Yao Z (2018) Influence of freeze-thaw cycles on dynamic compressive strength and energy distribution of soft rock specimen. Cold Reg Sci Technol 153:10–17

Müller U (2008) The mineralogical composition of sandstone and its effect on sulphur dioxide deposition. Mater Constr 58:81–95

Murru A, Freire-Lista DM, Fort R, Varas-Muriel MJ, Meloni P (2018) Evaluation of post-thermal shock effects in Carrara marble and Santa Caterina di Pittinuri limestone. Constr Build Mater 186:1200–1211

Ozcelik Y, Ozguven A (2014) Water absorption and drying features of different natural building stones. Constr Build Mater 63:257–270

Ozcelik Y, Careddu N, Yilmazkaya E (2012) The effects of freeze-thaw cycles on the gloss values of polished stone surfaces. Cold Reg Sci Technol 82:49–55

Ozdemir E, Sarici DE (2018) Combined effect of loading rate and water content on mechanical behavior of natural stones. J Min Sci 54(6):931–937

Ozdemir E, Kantarcı F, Sarıcı DE (2022) Effects of acid–base solutions on some Turkish natural building stones: physico-mechanical and color changes. Innov Infrastruct Solut 7:103

Ozgüven A, Özcelik Y (2014) Effects of high temperature on physico-mechanical properties of Turkish natural building stones. Eng Geol 183:127–136

Sarici DE (2016) Thermal deterioration of marbles: gloss, color changes. Constr Build Mater 102:416–421

Sarici DE, Ozdemir E (2018) Determining point load strength loss from porosity, Schmidt hardness, and weight of some sedimentary rocks under freeze–thaw conditions. Environ Earth Sci 77:62

Sarıcı DE, Kızılkaya N, Özdemir E, Polat F (2018) Evalution of salt crystallisation effects on artificial marble. J Phys Chem Funct Mater 1(2):20–24

Sharma PK, Khandelwal M, Singh TN (2007) Variation on physico-mechanical properties of Kota stone under different watery environments. Build Environ 42:4117–4123

Su H, Jing H, Yin Q, Yu L, Wang Y, Wu X (2017) Strength and deformation behaviors of veined marble specimens after vacuum heat treatment under conventional triaxial compression. Acta Mech Sin 33:886–898

Tan X, Chen W, Yang J, Cao J (2011) Laboratory investigations on the mechanical properties degradation of granite under freeze-thaw cycles. Cold Reg Sci Technol 68:130–138

TS EN 14066 (2004) Doğal Taşlar-Deney Metodları-Termal Şok Etkisiyle Yıpranmaya Direncin Tayini, TSE, Ankara (in Turkish)

TS EN 1925 (2000) Natural stone test methods: determination of water absorption coefficient by capillarity, TSE, Ankara (in Turkish)

Vásárhelyi B, Ván P (2006) Influence of water content on the strength of rock. Eng Geol 84:70–74

Vazquez P, Carrizo L, Thomachot-Schneider C, Gibeaux S, Alonso FJ (2016) Influence of surface finish and composition on the deterioration of building stones exposed to acid atmospheres. Constr Build Mater 106:392–403

Wang P, Xu J, Liu S, Wang H (2016a) Dynamic mechanical properties and deterioration of red-sandstone subjected to repeated thermal shocks. Eng Geol 212:44–52

Wang P, Xu J, Liu S, Wang H, Liu S (2016b) Static and dynamic mechanical properties of sedimentary rock after freeze-thaw or thermal shock weathering. Eng Geol 210:148–157

Yavuz H (2011) Effect of freeze–thaw and thermal shock weathering on the physical and mechanical properties of an andesite stone. Bull Eng Geol Environ 70:187–192

Yavuz AB, Topal T (2007) Thermal and salt crystallization effects on marble deterioration: examples from Western Anatolia, Turkey. Eng Geol 90:30–40

Yavuz H, Altindag R, Sarac S, Ugur I, Sengun N (2006) Estimating the index properties of deteriorated carbonate rocks due to freeze–thaw and thermal shock weathering. Int J Rock Mech Min Sci 43(5):767–775

Zhang W, Sun Q, Hao S, Geng J, Lv C (2016) Experimental study on the variation of physical and mechanical properties of rock after high temperature treatment. Appl Therm Eng 8:1297–1304

Zhou Z, Cai X, Cao W, Li X, Xiong C (2016) Influence of water content on mechanical properties of rock in both saturation and drying processes. Rock Mech Rock Eng 49:3009–3025

Acknowledgements

Authors are grateful for financial support from Inonu University Research Funding. (Inonu University, Project No: FDK-2017-879).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Özdemir, E., Eren Sarıcı, D. Effects of thermal shock and aging on natural stones: an experimental and statistical study. Acta Geod Geophys 58, 285–304 (2023). https://doi.org/10.1007/s40328-023-00410-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40328-023-00410-1