Abstract

Arsenic is a global environmental contaminant that imposes a big health threat which requires an immediate attention to clean-up the contaminated areas. This study examined the biosorption ability of a novel Bacillus strain for the removal of arsenate (pentavalent arsenic) from aqueous solution. The optimum biosorption condition was studied as a function of biomass dosage, contact time and pH. Dubinin-Radushkevich (D-R), Freundlich, and Langmuir models were applied in describing the biosorption isotherm. The maximal biosorption capacity (92%) was obtained at 25 °C, biomass concentration 2000 mg/L at pH value of 4 and contact period of 50 min. Strain 139SI act as an admirable host to the arsenate. Thermodynamic assessment (ΔG0, ΔH0, and ΔS0) also suggested the chemisorption and feasible process of As(V) biosorption. The reuse study illustrated the highest recovery of 93% using 1 M HCl, and a decrease of 25% in recovery of As(V) ions after 10 times desorption process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Large volume of metal-burdened wastewater is generated as a result of human activities as well as fast industrialization [1]. The metal (loid)s polluted water constitute a great environmental and health threat. Due to their possible toxic and cancer-causing effects, strict restrictions have been implemented for discharge of several metal ions in wastewaters so as to avoid environmental contamination. Based on the United State Environmental Protection Agency (EPA) priority pollutants list, arsenic (As) being a naturally occurring metalloid is considered highly toxic. Terribly, it has been reported that more than 250 million people worldwide, particularly from developing nations, are facing As toxicity, which causes neurological harm and even death [2, 3]. In developing countries as India, Pakistan, Bangladesh, Iran and Mexico, the impact of As toxicity is particularly alarming. For example, despite visible health effects related to As toxicity in Malaysia based on the soil, water and plant analysis in Malaysia [4, 5] potential of bioaugmentation for treatment of As-contaminated water has been marginally explored which makes it a very attractive research subject to explore. Recently, In Malaysia expert on environmental health announced that public consumption of seafood harvested from the area with high concentration of As should be avoided [6]. This is due to disposal of untreated industrial wastewaters into rivers and consequently accumulation of As in fish body. The authority concern must move in hurriedly to lessen the risks associated to public. Moreover, a study conducted by Kato et al., [7] indicated the concentration levels of As reached up to 19% of well water samples in Sabah, Malaysia in 2010. Since this As level is exceeded the permissible level as far WHO health-based guidelines permission level, it can be concluded that the level of As in Malaysia has had increased due to anthropogenic activities. Hence, an urgent need to establish cost-efficient treatment technology proficient of separating arsenic from both industrial effluents and drinking water is of paramount importance. An ideal treatment strategy is to concentrate on accumulating and recovering metals during the treatment process rather than treatment and disposal. Therefore, this research focuses on the establishment of technological answers, that are economically achievable and environmentally friendly which are able to reduce the costs and take full advantage of the treatment efficiency. Arsenic is present both in +5 and + 3 oxidation forms in aqueous solution depending on the prevalent redox conditions [8]. In majority of water system, arsenate (As(V)) in inorganic forms, prevails over arsenite [9]. While considering remediation studies, speciation of As is an important factor and it is importantly species dependent. In addition pH and redox potential are the two utmost vital parameters which controls As speciation [10]. In oxidizing states, As(V) exist as HAsO42− and H2AsO4− at high pH (7–11) and at low pH (2–6.9), respectively. Generally, in extremely acidic and alkaline conditions, As(V) are present as H3AsO4, and AsO43− respectively. Several studied have illustrated that As can be removed by various techniques namely, iron-oxide coated sand, oxidation/precipitation, metal oxide adsorption, polymer ligand exchange, electrocoagulation, ion exchange resin, followed by nanofiltration, reverse osmosis, etc. [11,12,13]. Indeed, these techniques suffer some certain drawback such as high maintenance cost as well as require expensive mineral adsorbents. Among the biological techniques, bioaugmentation, involving microbial biomass is regarded as a potential technology involved in As removal. The main advantageous of microbial method is the present of functional groups on cell wall structure that serves as a site for metal binding as well as reducing operation cost and time, and regeneration of biomass for reuse. Many researches have been cited the biosorption ability of bacterium on removing metal ions from aqueous solution such as Bacillus cereus [14], Pseudomonas resinovorand [9], and Desulfitobacterium hafniense [15]. However, the biosorption process depends on the microbe’s ability to immobilize and reduce the metal ions via sorption and redox reactions. Bacillus salmalaya strain 139SI as a native strain isolated (in Selangor, Malaysia) from an agricultural soil [16] has been found to be potentially suitable in remediation of petroleum compounds from contaminated environments as well as high capacity in sorption of Cr(VI) from aqueous Solution [17].

This study is aimed at examining the possible biosorption capacity of this novel strain, for doing away with As(V) ions from the watery (aqueous) solution under the controlled laboratory condition. Optimum biosorption conditions were determinate at different biomass dosage, pH, temperature, and contact time. The mechanism of the As(V) biosorption was investigated in terms of kinetics and thermodynamics. Models including; Dubinin-Radushkevich, Freundlich, and Langmuir isotherm were used for the evaluation of the equilibrium data.

Materials and methods

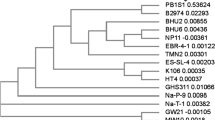

Bacillus salmalaya strain 139SI

B. salmalaya strain 139SI, was previously isolated from an agricultural soil sample in a private farm located in Selangor, Malaysia (2.99917˝N 101.70778˝E), the appropriate permissions from the responsible authorities for obtaining soil sample from ‘private farm’ was provided. This strain is a gram-positive and rod-shaped bacterium that exhibited strong haemolytic activity [18], and is routinely cultured on the Brain–Heart Infusion (BHI) blood sheep agar and sustained in a glycerol stock suspension. The 139SI strain inoculated from the plates onto the BHI agar and kept at 4 °C until needed for further experimentations.

Determination of minimum inhibitory concentrations (MICs)

MIC is considered the lowest concentration which hindered the growth of bacteria; in this work it was assessed as previously described. The stock solution of sodium arsenate (Na2HAsO4 · 7H2O) was prepared (0, 350, 700, 1400, 2800, 5600 ppm). Each of the tubes was then inoculated using approximately 1.5 X 106 CFU. The absorbance (optical density) was measured at 600 nm after one day incubation [19].

Arsenate biosorption assay

Before the beginning of sorption experiment strain was enriched by transferring one loop of cells from the agar slants to previously sterilized liquid BHI broth in a shake flask cultured (37 °C and 150 rpm) for two days (OD600 = 1). Viable cells were collected by centrifugation/spinning for 20 min at 8000 rpm. The pelleted cells obtained were washed using deionized water, followed by several times wash with suspended phosphate buffer before prepared as biosorbents for biosorption process. Arsenate stock standard solution (1000 ppm) was prepared from KH2AsO4 and the sorption experiment was performed by adding cell pellet to a sequences of 100 mL conical flask containing 50 mL of test solution (contains mineral salt medium and arsenate solution according to the required concentration) at 130 rpm. Optimization of experiments were carried out at the chosen pH value (3 to 9), contact period/time (0 to 80 min), biomass dosage (0.5 to 7 g/L), and temperature (20 to 60 °C). The biosorption assays was performed until the equilibrium condition was reached. Residual metal ion concentration of the Samples were analysed using inductively coupled plasma atomic emission spectroscopy (ICP-OES). The biosorption experimentations were conducted in triplicate and the values of ion sorbate (S) and biosorption capacity (Qe) were calculated according to the following equations:

Where S is a sorption; Qe represent the metal uptake (mg/g); Ca stands for the initial metallic concentration (mg/L); Cb is a final metal concentrations (mg/L); V stands for the volume of the solution (L); W stands for the amount of adsorption (g cell/ L).

Uptake kinetics and thermodynamics

A quantitative understanding of biosorption dynamics is possible through investigating the mechanism of the biosorption process. To evaluate the adsorption kinetic data, the pseudo-first-order and pseudo-second order (Eq. 4) models were introduced in this study [20, 21]. Moreover, the Kinetic study describes the essential qualities (characteristics) of the sorption process towards its positive utilization [17]. The first kinetic order was not included in this paper as the values of correlation coefficient (R2) were relatively low. The following formula has been used to calculate the pseudo second-order kinetic model:

Where K2 represents rate constants of the pseudo-second order (g/mg min), qt and qe are sorption capacities at time t and sorption capacities at equilibrium (mg/g), respectively.

Effects of different temperature (20 to 60 OC) in the biosorption process were calculated through thermodynamic parameters from the equations as follows:

Where ΔG0 is Gibbs free energy change, ΔH0and ΔS0 are the enthalpy change and entropy change, respectively. KD is distribution coefficient. R represent the universal gas constant value (8.314 X10−3 KJ/mol K) and T stands for absolute Kelvin temperature.

Biosorption equilibrium

The plots of the three sorption isotherm models that are Langmuir, Freundlich, and Dubinin-Radushkevich (D-R) were employed in order to study the mechanism of biosorption and surface properties of the biomass. These models used, described the nature of the adsorption potentiality of As(V) onto live biomasses of the novel B. salmalaya strain 139SI, which is expressed in terms of the amount of As(V) adsorbed for each unit of mass of adsorbent utilised (mg/g).

Langmuir sorption isotherm

One of the basic assumptions of the Langmuir model is that, it predicts adsorption of monolayer by means of a kinetic approach that is carried out as a single layer positioned onto surface cells and defined by the following equation:

Where qe and qm are amount of arsenate adsorbed per unit mass biomass at equilibrium state (mg/g) and maximal adsorption capacity (mg/g), respectively. β represents the equilibrium constant for adsorption (L/mg) related with the free energy biosorption and Ce indicates residual ion concentration in solution (mg/L).

Freundlich sorption isotherm

The Freundlich isotherm predicted a heterogeneous adsorption surface. This model can be explained by following formula:

Where Kf and n indicate constant relating the biosorption capacity and the intensity of the sorbent, respectively.

Dubinin-Radushkevich sorption isotherm

The equiblrium data were applied to evaluate the mechanism of biosorption process using D-R isotherm model. This model expects the dissimilarity of the surface energies and can be written as follow formulas:

Where α and qm are slope and intercept of the plot (ln qe against Ɛ2), respectively. E is defined as the mean sorption energy to transfer 1 mol of ions to the surface of the biomass from solution. To analyse the results statistically, a universal SPSS 19 linear model was utilised for the Analysis of variance (ANOVA) among the means of the treatments.

Evaluation of desorption efficiency (DE)

Desorption protocol was performed in order to study the capability of biosorbents of being used again (reusability). Biosorption-desorption experiment was carried out by using 25 ml volume of sample containing 10 ppm As(V) and 10 ml buffer solutions (0.1, 0.5, and 1 M of HNO3 and HCl). After fast shaking, 2 g/L of biomass was added and sample was shacked for a period of 1.5 h at 130 rpm, before determining the final arsenate concentration.

Where Mr and Ma denotes the amount of arsenate released into the supernatant and initial amount of adsorbed As(V) respectively.

Results

The tolerance of strain 139SI to various concentration of As(V) was achieved using MICs experiment. B. salmalaya strain 139SI represented high resistant to As- toxicity under aerobic condition. Bacterial growth was inhibited at 5600 ppm; consequently, this concentration was considered as the MIC. This concentration is considered considerably high [22].

The pH of the solution is one of the vital parameters which control the biosorption process. It is well known that it can heavily effect the competition of sorbets for the binding sites, activity of functional groups present on the biomass cells as well as sorption chemistry of the sorbets [20]. The effect of pH on sorption process of arsenate was monitored for a range of pH from 3 to 9 (Fig. 1). The highest amount of sorption was recorded in acidic condition at pH 3 to 6. The maximum value of arsenate biosorption was about 92.1% at pH 4; however, more than 70% of biosorption was observed in an alkaline condition i.e. at pH 8. It is evident from Fig. 1 that biosorption of As(V) decreases with a further increase in pH. Thus, all experiments were conducted at pH 4 for biosorption of As(V).

The influence of contact time with changed (at different) initial metal concentration on biosorption of As(V) was studied (Fig. 2). In order to examine the effect of time on biosorption of arsenate onto B. salmalaya biomass, 2.0 g/L of biosorbents was mixed with sorbate (500 and 1000 μg/L) in pH 4 and temperature 25 °C. maximum sorption of As(V) were recorded 86.9% and 54.6% after 50 min of mixing sorbent with 1000 and 500 μg/L of sorbate, respectively (Fig. 2). Results indicated that the number of ions adsorbed from solution with higher metal concentration (1000 μg/L) is more than from solution with less concentration of metal (500 μg/L). The biosorption efficiency in various biomass doses (0.5 to 7 g/L) was investigated at pH 4, temperature 25 °C, and metal concentration 10 ppm. The biosorption rate sharply increased with increasing the biomass doses beyond 2 g/L. It was observed that the sorption efficiency for biomass doses of 2 and 7 g/L were 83% and 85%, respectively.

The effect of temperature on equilibrium biosorption of arsenate was studied at pH 4, contact time 100 min, sorbent dose 2.0 g/L and As(V) concentration of 500 μg/L. Results shows a rapid adsorption in all temperatures for the first 50 min followed by a slow rate of adsorption in the later stage. The highest and lowest biosorption capacity was recorded about 305.89 μg and 196.2 μg at 25 °C and 60 °C, respectively. It is illustrating that temperature might be an important factor for metal sorption by microbial cells. Thermodynamics parameters are shows according to the Fig. 3 (the lnKD vs. 1/T plot). The enthalpy (ΔH0) was determined from the slope of the plot while entropy (ΔS0) was determined from the intercept of the plot. Gibbs free energy (ΔG0) was computed as −2.21, −1.87, +0.093, +1.81, and + 3.01 for the As(V) biosorption at following temperature values; 20, 30, 40, 50, and 60 °C, respectively. The free energy values with negative signs implied that biosorption of As(V) onto B. salmalaya strain 139SI is spontaneous in nature and thermodynamically feasible. The ΔH0 and ΔS0 parameters were found to be 0.276 (KJ/mol K) and − 41.3 (KJ/mol), respectively.

The prediction of adsorption rate through the kinetics of pollutant uptake provide an imperative information for selecting batch adsorption schemes under optimum operating conditions. To clarify the sorption kinetics of arsenate ions onto living cells of B. salmalaya strain 139SI biomass, the pseudo-first-order and pseudo-second order models were employed. The values of K1 and Qe of the first model were obtained from intercept and slope of the plot [(ln qe-qt) against time]; while the value for the second model were computed from the intercept and slope of the plot [t/qt against time]. The lowest coefficients of determination (R2 = 0.66) was recorded in the pseudo-first-order, while pseudo-second order showed 0.96 correlation. The pseudo-second-order model for the sorption of arsenate ions onto B. salmalaya at 10–50 °C is shown in Fig. 4.

Equilibrium biosorption isotherm describes the capacity of living biomass, which is defined by certain constants whose values are expressing affinity of biomass and the surface properties [23]. Therefore, the analysis of isotherm data is vital in order to develop an equation which could be used for design purpose. The result of Freundlich isotherm was investigated by plotting qe versus Ce values, which showed a non-linear association linking the concentration of As(V) ions sorbed for every unit biomass against the arsenate ions concentration of remaining in solution (mg/L). Based on the statistical analysis the correlation coefficients for the Langmuir isotherm presents a higher value (R2 = 0.94), which demonstrated more suitable model in comparison to for both dead and Freundlich isotherm (R2 = 0.87). Values of qm, 1/n, and Kf found to be 76.5 (mg/g), 0.52 and 3.1, respectively.

Desorption study was performed using HNO3 and HCL at different concentration, so as to assess the capability of biomass for repeated biosorption process. The number of ions were adsorbed from B. salmalaya with each eluent (10 mL) was studied. Results shows the highest recovery about 93% and 85%, at 1 mol L−1 HCl and HNO3, respectively. Moreover, it was found the stability of biomass after repeated 10 times desorption process with a decline in about 25% As(V) ions recovery. Therefore, biomass has shown a good potential for its possible re-use in industrial process.

Discussion

Many factors would have affect As bioavailability and tolerance of bacterium which consequently cause variation in MIC values. However, strain 139SI with high stability to arsenic toxicity allows it to use in bioremediation process as it can survive in high As-contaminated sites. This high resistant to As is critical because an effective bioremediation technology significantly correlated with the activity of native bacteria at contaminated sites.

Many researchers reported a similar trend on the effect of pH on arsenic biosorption process using diverse forms of biosorbents [24, 25]. It is indicated that at low pH the surface of bacteria cell is highly protonated thus, there would be a strong attraction between surface of the biosorbent and oxyanion. Consequently the uptake rate increased due to an increase in H2AsO4− ions along with the pH [26]. It is also expected that as the pH rose the bacteria cell would positively charge and became increasingly negative. The sorption at pH 3 is slightly decreased in compare to pH 4, as shown in Fig. 1. This might be correlated to the interaction involving hydroxyl (-OH) groups on the biomass surface and the negatively charged arsenate ions [25] . The gradual decrease in metal uptake from pH 4 to 9 maybe explained as a repulsive force between anions and the negatively charged surface.

It is further noted that sorption capacity increased as the reaction time increased until the state of equilibrium was reached due to saturation of vacant biomass surface. Thus, the curve suggested that for an equilibrium to be attained, a contact time of 50 min is required and indicate the probability of monolayer coverage of the As(V) on the surface of biomass. Similar sorption pattern was observed for the removal of arsenic and arsenate by [27]. They reported 85.67% removal rate of As(V) after 30 min mixing of Arthrobacter sp. as biosorbents and 100 ppm sorbent. The difference in the duration time might be due to using different type of bacterium and arsenic concentration.

Probably the increase in sorption rate along with increase in biomass concentration is due to availability of more biomass surface and consequently interaction between binding sites. However, there was no significant change in biosorption rate after dosage of 2 g/L (Fig. 5).

The endothermic nature of the adsorption in the exothermic nature of the biosorption processes is revealed by the negative and positive values of ΔH0. In this study, the negative value of ΔH0 shows the nature of biosorption process (20 to 60 °C) which is either physical or chemical. It has been acknowledged that, when the ΔH0 values ranges between 2.1 to 20.9 (KJ/mol), it implies a physical sorption whereas the values found in the range from 20.9 to 418.4 (KJ/mol) illustrated the chemisorption process of As(V). Hence, our results on thermodynamic assessment suggested that the mechanism involved in As(V) sorption is chemisorption. The same trend was observed in study previously carried out on chromium ions biosorption onto B. salmalaya strain 139SI [17].

The result of sorption capacity is in line with finding of Biswas et al. [26], in which the pseudo-second-order kinetic model presented a appropriate correlation for the biosorption of arsenic onto I. hispidus in contrast to the pseudo-first-order model. Prasad et al. [27] also reported higher correlation coefficient values (0.99) of the pseudo second- order model for biosorption of As+5 from aqueous solution by Arthrobacter sp. Biomass. This indicates that pseudo-second order is more likely to predict kinetic behaviour of arsenate biosorption. Therefore, As(V) biosorption onto bacterial cell was through chemisorption process and the rate determining stage is possibly surface biosorption, which gives explanation that the process happens via valence forces like exchange or sharing of electrons between adsorbent and As(V) metallic ions.

Since the two Biosorption isotherms constants do not provide information on the mechanism of biosorption process as chemical or physical, the Dubinin-Radushkevich isotherm plot was calculated. Figure 6, shows the linear plots of ln qe vs Ɛ2, with high correlation coefficient of 0.98. In this study, the estimated value of E was found to be 11.2 KJ/mol. This value provides useful information regarding the type of biosorption. It is known that if E is between values 8 and 16 KJ/mol, the process of sorption is taking place chemically [28]. Thus, results suggested that metal ions onto B. salmalaya strain 139SI could be through chemical ion exchange mechanism.

Consequently, the obtained results suggested that it was insufficient enough for the Freundlich to illustrate the association between the equilibrium concentration and the amounts of metal biosorption in the solution. Since the Langmuir and D-R isotherm models demonstrated higher correlation coefficient values than the Freundlich model, so that it represents better fitted into equilibrium. However, a comparison of biosorption capacity between B. salmalaya biomass for arsenate ions with various types of biomass reported in the literature reviews indicated the high capacity of B. salmalaya strain 139SI in biosorption of As(V) than that of majority of biomasses. So, it is remarkable to mention that B. salmalaya biomass has great potentiality in As(V) ions removal from the aqueous solution.

Numerous organisms have been reported for As removal from contaminated environments, for instance bacteria [14], algae [29]. Although, in the majority of cases the organisms were isolated from As-contaminated areas [30, 31]. To our knowledge there is no application of indigenous bacteria in Malaysia for bioremediation of As polluted areas. Therefore, providing an alternative effective way through using a novel native bacterium would be a great option for bioremediation studies as strain 139SI exhibited effective sorption for As(V) ions from polluted aqueous solutions. The current research is focused on the As(V) treatment development from wastewater and in the next study the application of live biomass cells will be considered for arsenite (As(III)) remediation from aqueous solution along with evaluation of various environmental parameters on sorption process. The results obtained will be compared with the current achievements and the potential competition for As sorption in the present of other ions such as Zn2+and CO2+ [32] also will be examined.

Conclusions

This work focused on As(V) biosorption on a novel Bacillus strain biomass from aqueous solution. B. salmalaya has been found to be a prospective biosorbent for As(V) removal when compared to other biosorbent. The process of biosorption onto sorbent was highly depend on the pH, temperature, biomass concentration as well as contact time. The maximum percentage of biosorption found was 92% at pH 4, biomass concentration 2 g/L, temperature 25 °C, and contact time of 50 min. The pseudo-second-order kinetic model presented a reliable relationship of the As(V) the biosorption on biomass. The D-R isotherm models demonstrated higher correlation coefficient value, and the mean free energy values was found to be between 8 and 16 KJ/mol which suggested the chemisorption mechanism of sorption process. Thermodynamic evaluation also suggested that the chemisorption and feasible process of As(V) biosorption. The reuse study illustrated the highest recovery of 93% using 1 M HCl, and a decrease of 25% As(V) ions recovery following 10 times desorption process. Therefore, B. salmalaya strain 139SI biomass exhibited a considerable high potential of sorption capacity and can serve as an efficient biosorbent alternative to treatment of As(V) ions-containing aqueous solution.

References

Ayangbenro AS, Babalola OO. A new strategy for heavy metal polluted environments: a review of microbial biosorbents. Int J Env Res Public Health. 2017;14(1):94. https://doi.org/10.3390/ijerph14010094.

Jaishankar M, Tseten T, Anbalagan N, Mathew BB, Beeregowda KN. Toxicity, mechanism and health effects of some heavy metals. Inter Toxico. 2014;7(2):60–72. https://doi.org/10.2478/intox-2014-0009.

Tchounwou PB, Yedjou CG, Patlolla AK, Sutton DJ. Heavy metal toxicity and the environment. Experientia supplementum Exp Suppl. 2012;101:133–64. https://doi.org/10.1007/978-3-7643-8340-4_6.

Azlan A, Khoo HE, Idris MA, Ismail A, Razman MR. Evaluation of minerals content of drinking water in Malaysia. The Sci World J. 2012;2012:10–0. https://doi.org/10.1100/2012/403574.

Ong GH, Yap CK, Maziah M, Suhaimi H, Tan SG. An investigation of arsenic contamination in peninsular Malaysia based on Centella asiatica and soil samples. Environ Monit Assess. 2013;185(4):3243–54. https://doi.org/10.1007/s10661-012-2787-6.

Shah A. Water, fish contain high level of arsenic. New Straits Times, Pahang. 2015. Accessed 22nd April 2017.

Kato M, Onuma S, Kato Y, Thang ND, Yajima I, Hoque MZ, et al. Toxic elements in well water from Malaysia. Toxic Environ Chem. 2010;92(9):1609–12. https://doi.org/10.1080/02772241003707454.

Panagiotaras D, Nikolopoulos D. Arsenic occurrence and fate in the environment; a geochemical perspective. J Earth Sci Clim Chan. 2015;6(4):269. https://doi.org/10.4172/2157-7617.1000269.

Banerjee A, Sarkar P, Banerjee S. Application of statistical design of experiments for optimization of as(V) biosorption by immobilized bacterial biomass. Eco Eng. 2016;86:13–23.

Nicomel NR, Leus K, Folens K, Van Der Voort P, Du Laing G. Technologies for Arsenic Removal from water: current status and future perspectives. Int J Environ Res Public Health. 2016;13(1):62. https://doi.org/10.3390/ijerph13010062.

Balasubramanian N, Kojima T, Basha CA, Srinivasakannan C. Removal of arsenic from aqueous solution using electrocoagulation. J Hazar Mat. 2009;167(1–3):966–9.

Yao S, Liu Z, Shi Z. Arsenic removal from aqueous solutions by adsorption onto iron oxide/activated carbon magnetic composite. J Environ Health Sci Eng. 2014;12(1):58. https://doi.org/10.1186/2052-336x-12-58.

An B, Steinwinder TR, Zhao D. Selective removal of arsenate from drinking water using a polymeric ligand exchanger. Water Res. 2005;39(20):4993–5004. https://doi.org/10.1016/j.watres.2005.10.014.

Giri AK, Patel RK, Mahapatra SS, Mishra PC. Biosorption of arsenic (III) from aqueous solution by living cells of Bacillus cereus. Environ Sci Poll Res. 2013;20(3):1281–91. https://doi.org/10.1007/s11356-012-1249-6.

Niggemyer A, Spring S, Stackebrandt E, Rosenzweig RF. Isolation and characterization of a novel as(V)-reducing bacterium: implications for arsenic mobilization and the genus Desulfitobacterium. Appl Environ Micro. 2001;67(12):5568–80. https://doi.org/10.1128/aem.67.12.5568-5580.2001.

Ismail S, Dadrasnia A. Biotechnological potential of Bacillus salmalaya 139SI: a novel strain for remediating water polluted with crude oil waste. PLoS One. 2015;10(4):e0120931. https://doi.org/10.1371/journal.pone.0120931.

Dadrasnia A, Chuan Wei K, Shahsavari N, Azirun M, Ismail S. Biosorption potential of Bacillus salmalaya strain 139SI for removal of Cr(VI) from aqueous solution. Int J Environ Res Public Health. 2015;12(12):14985.

Dadrasnia A, Usman MM, Wei KSC, Velappan RD, Jamali H, Mohebali N, et al. Native soil bacterial isolate in Malaysia exhibit promising supplements on degrading organic pollutants. Proc Saf Environ Prot. 2016;100:264–71. https://doi.org/10.1016/j.psep.2016.02.001.

Kaushik P, Rawat N, Mathur M, Raghuvanshi P, Bhatnagar P, Swarnkar H, et al. Arsenic hyper-tolerance in four microbacterium species isolated from soil contaminated with textile effluent. Toxico Int. 2012;19(2):188–94. https://doi.org/10.4103/0971-6580.97221.

Yan L, Yin H, Zhang S, Leng F, Nan W, Li H. Biosorption of inorganic and organic arsenic from aqueous solution by Acidithiobacillus ferrooxidans BY-3. J Hazard Mat. 2010;178(1–3):209–17. https://doi.org/10.1016/j.jhazmat.2010.01.065.

Hansen HK, Ribeiro A, Mateus E. Biosorption of arsenic(V) with Lessonia nigrescens. Minerals Eng. 2006;19(5):486–90. https://doi.org/10.1016/j.mineng.2005.08.018.

Jackson CR, Harrison KG, Dugas SL. Enumeration and characterization of culturable arsenate resistant bacteria in a large estuary. System Appl Microb. 2005;28(8):727–34.

Melvin SS, AAM E, Ramalingam C. Isotherm modelling, kinetic study and optimization of batch parameters using response surface methodology for effective removal of Cr(VI) using fungal biomass. PLoS ONE. 2015;10(3):e0116884. https://doi.org/10.1371/journal.pone.0116884.

Rodriguez AI, Martinez-Ju. Biosorption of arsenic(III) from aqueous solutions by modified fungal biomass of paecilomyces sp. Bioin. Chem. Appl. 2013;2013:5. https://doi.org/10.1155/2013/376780.

Ranjan D, Talat M, Hasan SH. Biosorption of arsenic from aqueous solution using agricultural residue ‘rice polish’. J. Hazard. Materials. 2009;166(2–3):1050–9.

Biswas BK. Inoue J-i, Inoue K, Ghimire KN, Harada H, Ohto K et al. adsorptive removal of as(V) and as(III) from water by a Zr(IV)-loaded orange waste gel. J Hazard Materials. 2008;154(1–3):1066–74. https://doi.org/10.1016/j.jhazmat.2007.11.030.

Prasad KS, Ramanathan AL, Paul J, Subramanian V, Prasad R. Biosorption of arsenite (as+3) and arsenate (as+5) from aqueous solution by Arthrobacter sp. biomass. Environ. Tech. 2013;34(19):2701–8. https://doi.org/10.1080/09593330.2013.786137.

Massoudinejad M, Asadi A, Vosoughi M, Gholami M. Kakavandi B, Karami MA. A comprehensive study (kinetic, thermodynamic and equilibrium) of arsenic (V) adsorption using KMnO4 modified clinoptilolite. Korean J. Chem Engin. 2015;32(10):2078–86. https://doi.org/10.1007/s11814-015-0018-x.

Tuzen M, Sarı A, Mendil D, Uluozlu OD, Soylak M, Dogan M. Characterization of biosorption process of As(III) on green algae Ulothrix cylindricum. J. Hazard. Materials. 2009;165(1–3):566–72. https://doi.org/10.1016/j.jhazmat.2008.10.020.

Dey U, Chatterjee S, Mondal NK. Isolation and characterization of arsenic-resistant bacteria and possible application in bioremediation. Biotech Rep. 2016;10:1–7. https://doi.org/10.1016/j.btre.2016.02.002.

Liao VH-C, Chu Y-J, Su Y-C, Hsiao S-Y, Wei C-C, Liu C-W, et al. Arsenite-oxidizing and arsenate-reducing bacteria associated with arsenic-rich groundwater in Taiwan. J Contam Hydr. 2011;123(1–2):20–9. https://doi.org/10.1016/j.jconhyd.2010.12.003.

Prasad KS, Subramanian V, Paul J. Purification and characterization of arsenite oxidase from Arthrobacter sp. BioMetals. 2009;22(5):711. https://doi.org/10.1007/s10534-009-9215-6.

Acknowledgements

The authors are very grateful to the chief editor and the reviewers of this article for their valuable contribution. The authors would like to acknowledge the support of the Agro Premier Biotech Sdn Bhd and University of Malaya Research Program (UMRP) with grant number of RP023A-14AFR.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interests

The authors declare that they have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dadrasnia, A., Usman, M.M., Abutawila, Z. et al. Biotechnological remediation of arsenate from aqueous solution using a novel bacterial strain: Isotherm, kinetics and thermodynamic studies. J Environ Health Sci Engineer 17, 571–579 (2019). https://doi.org/10.1007/s40201-019-00371-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40201-019-00371-0