Abstract

Cementitious materials are commonly used to reinforce the bearing capacity of silty soils. However, there is very little data about how changes in arsenic (As) leaching from silty soils caused by the addition of cementitious materials. Therefore, batch leaching tests were conducted using As-bearing silty soil under different pH conditions. The pH was adjusted by changing the amount of slag cement added or the concentration of sodium hydroxide. This allows us to evaluate the effects of cement on As leaching. In addition, two different additives were applied to reduce As migration. The results show that high concentration of calcium ion (Ca2+) in leachates of soil-cement mixture has a significant effect in reducing the mobility of As even under hyperalkaline pH conditions. Arsenic immobilized by Ca2+ was observed in two patterns. The first mechanism was the help of Ca2+ to reduce the negative electrical potential on the surface of (hydr)oxide minerals under high pH conditions, thereby reducing the mobility of As by adsorption and coagulation of fresh precipitates of Fe and Al hydroxides. The second was the precipitation of calcium carbonate. This precipitate either directly adsorb/co-precipitate As or lower the concentration of strong competing ion, silica, both of which reduced the As mobility. When Ca- or Mg-based additive was added to the silty soil-cement mixture, As concentration in the leachate decreased. These findings are useful in developing sustainable soil-cement reinforcement techniques to avoid contamination.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Exposure to arsenic (As) causes many symptoms to various organs in the human body in which the toxicity is dependent on its chemical forms and intake dose (Glazener et al. 1968; Hong et al. 2014; Abdul et al. 2015). This metalloid is generally found in trace amount in soils and sediments (Smedley and Kinniburgh 2002). However, in certain conditions, it is easily leached at high concentrations. An example of this is when it is triggered by the change in pH (Vongphuthone et al. 2017). This can pose as environmental hazards and ecological risks to the surrounding area.

Arsenic could exist in solution as + 3 (arsenite) or + 5 (arsenate) oxidation state depending on the redox conditions (Brookins 1988). The former is more mobile than the latter because it could exist as an uncharged oxyanion under a wide pH range (Smedley and Kinniburgh 2002). However, under many typical natural aqueous environments (oxic and slightly-acidic to neutral conditions), arsenate is commonly found to be major species as negatively charged oxyanions (i.e., HAsO42−, H2AsO4−). These oxyanions are commonly found to be adsorbed onto surfaces of oxide minerals (Vink 1996; Smedley and Kinniburgh 2002; García-Sánchez et al. 2010; Giles et al. 2011; Kumpiene et al. 2012). The surfaces of these minerals have variable charges depending on pH (Bowell 1994). In general, the higher the pH, the more negative surface charge they become. As a result, increase in pH either causes As to be desorbed or prevents it from being adsorbed (Robertson 1989; Smedley et al. 2002). These are the most likely mechanisms contributing to As contamination with an increase in pH under aerobic condition.

Cementitious materials are commonly used to reinforce the bearing capacity of silty soils for many construction sites (Boschuk 1991; Bell and Maud 1994; Kolias et al. 2005; Cristelo et al. 2013; Sharifah et al. 2013; Dhiraj et al. 2015). These materials are produced from complex chemical reactions taking place when cement is mixed with water. They are inherently alkaline. Consequently, when the materials are added to reinforce the soils, they increase the soil pH (Douglas et al. 2003; Odler 2019). Therefore, this can be the main reason causing As to be released from reinforced soils into the surrounding environments. At the same time, cement solution also contains high calcium (Ca2+) concentration that has been reported to have the ability to immobilize As (Wilkie and Hering 1996). This may result in the lower leaching concentration of As. However, it is also possible that the amount of Ca2+ in cement solution may not be enough to compensate for the effect of pH. In other words, in-depth evidence of the effect of cement on As leaching from silty soils is still lacking. Therefore, As leaching from silty soils related to the addition of cement should be examined. We studied the leaching characteristics of As from a silty soil using batch leaching tests. Slag cement and sodium hydroxide (NaOH) were used to adjust the pH. This enabled us to evaluate the effect of cement on the mobility of As. In addition, the effectiveness of artificial materials to sequester As and reduce its leaching from the soil with added cement was also evaluated. The current study will allow a better understanding of As mobility from silty soil under hyperalkaline cement solution and will be useful in developing sustainable soil-cement reinforcement techniques to avoid As contamination.

2 Materials and Methods

2.1 Sample Collection and Preparation

A silty soil sample was collected from the town of Nanporo, Hokkaido, Japan. This town is located on the Ishikari plain where alluvial deposits are extensively distributed. Consequently, the ground is very weak (Matsushita 1971). The sample was taken from a boring core near the Ishikari River at 14.5 to 16 m deep from the ground surface (Fig. 1). Previous studies have reported that the flow of the Ishikari River near the sampling area can strongly affect the distribution of geogenic As. It tends to increase in content downstream of the Ishikari River and Ishikari plain. Therefore, soil samples collected in this area have shown leached As levels exceeding that of the Japanese environmental standard for drinking water (10 μg L−1) (Matsushita 1971; Tatsumi et al. 2006; Vongphuthone et al. 2017). Therefore, this soil is expected to release high concentration of As. In preparation, the sample was air dried, lightly crushed using a mortar and pestle, and sieved through a 2-mm aperture screen. It was then kept in air-tight containers prior to use.

Blast-furnace cement was taken from Taiheiyo Cement Corporation, Japan. It is a mixture of Portland cement and slag and can be classified by the mixing ratio into three types, type A (5–30% of slag), type B (30–60% of slag), and type C (60–70% of slag). Adding slag helps in reducing cement content as well as improving long-term strength and durability of concrete (Babu and Kumar 2000). The optimum range of the slag content for the maximum strength has been found to fall within that of type B (Oner and Akyuz 2007; Karri et al. 2015). Therefore, blast-furnace cement type B is commonly used as an additive to reinforce the soft ground in Japan (Umeki 2015) and was selected as an additive in this study.

Two As immobilizers, namely, Earth Tight ® (ET) (Nippon steel & Sumikin Cement, Japan) and Add Rock Magnum (AM) ® (Okamoto Kogyo, Japan), were used to immobilize As leached out by cement.

2.2 Characterization of Silty Soil

Fine particles, with a diameter less than 50 μm of the silty soil sample were prepared for chemical and mineralogical analyses. The analyses were conducted using an X-ray fluorescence spectrometer (XRF) (Spectro Xepos, Rigaku Corporation, Japan) and X-ray diffractometer (XRD) (MultiFlex, Rigaku Corporation, Japan). Total organic carbon (TOC) was measured using TOC-L (Shimadzu Corporation, Japan). The sequential extraction was conducted to identify solid phase As species using the procedure of Marumo et al. (2003). This method was modified from the techniques of Tessier et al. (1979) and Clevenger (1990). Table 1 shows a summary of the extraction procedure (Tabelin et al. 2012). After each extraction step, the suspension was centrifuged to separate the residue out of the leachate. Next, the residue was washed with 20 mL of deionized water. The washing solution and leachate were then mixed and diluted to 50 mL, before filtration using 0.45-μm Millex® filters for chemical analysis. This extraction procedure has been used in many of our previous studies (Tabelin et al. 2012; Tangviroon and Igarashi 2017; Vongphuthone et al. 2017; Huyen et al. 2019). It is also proven to be reproducible with an average precision of 7% (Vongphuthone et al. 2017; Huyen et al. 2019).

2.3 Batch Leaching Tests

Batch leaching experiments were conducted under ambient conditions by mixing 1:10 (15 g:150 mL) solid-to-liquid ratio of silty soil and deionized water while the ratio of cement to silty soil ranged from 1:1000 to 1:17. The pH, electrical conductivity (EC), oxidation-reduction potential (ORP), and temperature were measured immediately after mixing at 200 rpm for 6 h. Next, the centrifugation was performed at 5000 rpm for 40 to 70 min. The supernatants were then filtered through 0.45-μm Millex® filters. To evaluate the effects of cement on As leaching, batch experiments were conducted under the same conditions as that of the soil-cement case. However, instead of using cement, reagent-grade NaOH solution at concentration ranged from 1 to 80 mM was employed to adjust pH. In some selected batches, the filtrates were further filtered through ultrafilters with a cut-off molecular weight of 200 kDa (Advantec®, Japan) to evaluate the effects of colloidal particles on As leaching. After filtration, all leachates were kept in air-tight polypropylene bottles prior to chemical analysis.

2.4 Arsenic Sequestration Tests

Batch leaching tests to sequester As using ET and AM were conducted to evaluate the performance of the additives. Fifteen grams of silty soil and 150 mL of deionized water were mixed with 0.15 g of cement and 0.05 to 0.3 g of ET or AM. The leaching period was fixed at 6 h at the shaking speed of 200 rpm. After measurements of pH, EC, ORP, and temperature of the suspensions, the suspensions were centrifuged at 5000 rpm for 60 min and filtered through 0.45-μm Millex® filters. Then the filtrates were kept in air-tight polypropylene bottles prior to chemical analysis.

2.5 Chemical Analysis

Concentrations of metals, metalloids, and other coexisting ions were quantified by inductively coupled plasma atomic emission spectrometer (ICP-AES) (Shimadzu Corporation, Japan). In the case of solutions having As concentrations below the detection limit of the standard method (0.1 mg L−1), ICP-AES coupled with a hydride generator was used. For the hydride generation analysis, the leachates were pretreated with reagent-grade hydrochloric acid (HCl), potassium iodide (KI), and ascorbic acid (Tabelin et al. 2012). The standard ICP-AES method has a margin of error of approximately 2–3% while the more sensitive hydride generation process has uncertainties of about 5%.

2.6 Geochemical Simulation

A geochemical modeling software, PHREEQC (Parkhurst and Appelo 1999), was used to evaluate the precipitation of calcite (CaCO3) and calcium arsenates in the leachates. The input data were temperature, pH, ORP, and the concentrations of As and other coexisting constituents.

3 Results and Discussion

3.1 Mineralogical and Chemical Properties of Silty Soil and Immobilizers

The chemical and mineralogical compositions of silty soil and As immobilizers are given in Tables 2 and 3, respectively. The soil is mainly composed of silicate minerals, including quartz, albite, and gismondine without potential As-bearing minerals. The As content was in the lower region of the average baseline concentration for world soils, 5–10 mg kg−1 (Boyle and Jonasson 1973). However, the sequential extraction results show that more than 40% of the total content of As was in the exchangeable fraction (Table 4). Consequently, the significant quantity of As is expected to be leached from this soil under strong-alkaline pH conditions.

The most dominant chemical component found in ET was calcium oxide (CaO) whereas magnesium oxide (MgO) accounted for more than 80% in AM. Both immobilizers contained no As. Alite was identified in ET. When this mineral contacts with water, it gives Ca2+ (Kalinkin et al. 2005; Juilland et al. 2010). Consequently, by adding ET, it can increase the concentration of Ca2+ in solution, which has been reported in many studies to be the important factor in immobilizing As (Wilkie and Hering 1996; Meng et al. 2000; Tabelin et al. 2012). In the case of AM, magnesia was detected. The magnesia and its hydration product (magnesium hydroxide) are the potential substances having the ability to immobilize As under strong alkaline conditions (Yu et al. 2011; Jia et al. 2013; Li et al. 2016). As a result, these two additives are expected to have high sequestration potential to immobilize As.

3.2 Effects of Slag Cement and pH on the Leaching of Arsenic

Figure 2 shows the concentrations of As in the leachates as a function of pH in batch leaching tests. The leaching concentration of As from the soil with deionized water was lower than the Japanese environmental standard for drinking water (10 μg L−1). However, the As leaching concentrations over 10 μg L−1 were observed in the rest of the cases. When NaOH was used to adjust the pH, As concentration simply increased with pH. On the other hand, in the case of cement, the leaching concentration of As was directly proportional to pH only when pH was below 10.1. In hyperalkaline pH range (> pH 10.1), higher value of pH resulted in the decrease of As leaching concentration. Figure 3 illustrates the change of As contents of four important phases of the solid residuals from soil-cement and soil-NaOH mixtures at two representative pH values, lower and higher than 10.1. As the pH increased, the oxidizable fraction in both cases decreased (Fig. 3d). The same behavior was also observed in the other three fractions in the residuals of the NaOH case (Figs. 3a, b, and c). The reduction of As content indicates that the As has been leached into the solution. However, when the average precision of 7% is taken into consideration, the change of reducible As in the soil-NaOH residuals were considered to be unchanged. In the soil-cement residuals, the leaching concentrations of exchangeable, carbonate, and reducible fractions of As increased with pH. These results reveal that, in soil-cement mixtures under hyperalkaline conditions, the mobility of As from the soil does not depend only on pH, and for some reasons, the suspended As was immobilized and/or redeposited as these three solid phases.

The relationship between the leaching concentration of Ca2+ and pH is shown in Fig. 4. At lower pH, dissolved Ca2+ in both cases showed a slightly increasing trend starting from almost the same concentration as that in the case of pure soil. Then, in the case of cement, Ca2+ concentration exponentially increased with pH while Ca2+ concentration gradually increased in NaOH case. Figure 5 illustrates the relationship between Ca2+ and As in the leachate. It is recognized that the mobility of As started to reduce in the presence of Ca2+ concentration over 10 mg L−1. This clearly indicates that the rapid increase of Ca2+ as a result of cement addition caused As to be immobilized possibly due to the following mechanisms.

The first is the ability of Ca2+ to increase the positive charge on surfaces of (hydr)oxide minerals. Many studies have reported that the metal (hydr)oxides, in particular, those of Fe and Al, have high capacity in adsorbing As (Anderson et al. 1976; Pierce and Moore 1982; Tangviroon et al. 2017; Tangviroon and Igarashi 2017). However, their ability to bind As reduces as pH increases. Increasing pH makes the surfaces of these (hydr)oxides become more negatively charged due to an interaction between hydroxide ion (OH−) and oxides/hydroxides surface (Tombácz 2009). The high concentration of Ca2+ can reduce the negative electrical potential on the surface of these minerals under high pH conditions (Wilkie and Hering 1996; Meng et al. 2000; Tabelin et al. 2012), thereby increasing the adsorption of As oxyanions.

The alteration of the surface charge by Ca2+ can also immobilize As through the coagulation of fresh precipitates of Fe and Al hydroxides. In the batch tests using NaOH solution, the concentrations of Al and Fe linearly increased with pH, while those in cement solution decreased sigmoidally to almost zero at pH 11 (Figs. 6a and b). These two metals tend to hydrolyze and precipitate as hydroxide compounds under alkaline and oxic conditions (Gupta and Gupta 2005). Therefore, it is expected that a large portion of the detected amounts of Al and Fe in both systems was associated with solid-phase as colloidal particles since the fresh precipitates of these compounds were small enough to be easily passed through the pores of 0.45 μm membrane filter. This assumption was proven by the fact that the concentrations of Al and Fe after ultrafiltration became zero regardless of pH and system used. As mentioned in the previous paragraph, it can be implied that the fresh precipitates of Fe and Al hydroxides in the leachates of the soil-cement mixture can also adsorb As. Even though As can be bound to the surface of the fresh precipitates of Fe and Al hydroxides, it is considered to be a mobile phase if the particles of freshly precipitated Fe and Al hydroxides are small enough to be able to be suspended in the solution as colloidal particles. However, the negative correlation between the leaching concentrations of Ca2+ and those of Al or Fe in the leachates of the soil-cement mixture in Fig. 7 suggests that the presence of the high concentration of Ca2+ could enhance the coagulability of the colloidal Fe and Al hydroxides. In other words, it made the suspended particles of Fe and Al hydroxides to clamp so that they became bigger and could settle, or be filtrated by the 0.45 μm membrane filter, or both. In the actual situation, the coagulation of colloidal particles in soil pore water makes them harder to flow and finally stuck in the pore, thereby reducing the mobility of As. The occurrence of this mechanism can be confirmed by the higher exchangeable and reducible fractions of As with pH of soil-cement residual (Fig. 3a and c).

The second mechanism contributes to the precipitation of CaCO3. Figure 8 shows the simulated results of the situation index (SI) of CaCO3 in both NaOH and cement cases. The SI in both cases increased with pH and mostly stayed in the positive region. This means that most of the leachates were supersaturated with respect to CaCO3. However, the amount of newly precipitated CaCO3 seems to be more in the case of cement under higher pH conditions since higher value of SI was observed in soil-cement mixtures as compared with that in the NaOH case. In other words, using cement contributed to higher driving force of CaCO3 precipitation. This could lead to higher immobility of As in the case of cement since CaCO3 has been reported by many studies to have ability to adsorb and co-precipitate many heavy metals and metalloids, including As (Khalil et al. 2012; So et al. 2012; Renard et al. 2015; Tizo et al. 2018). In addition, the adsorption capacity can also be enhanced by the presence of higher concentration of Ca2+ in the leachates with cement (Huang et al. 1991; Moulin and Roques 2003; Eriksson et al. 2007). Besides the adsorption, CaCO3 can also function as a support to promote the nucleation and growth of calcium silicate hydrate (C-S-H) (Ouyang et al. 2017). The formation of C-S-H indirectly reduces the mobility of As, since the activity of silica (Si), one of the strongest competing ions, is reduced. This is supported by the lower concentration of Si in the leachates of soil-cement mixture compared with those in soil and soil-NaOH cases (Fig. 9). Consequently, the higher content of As in the exchangeable and carbonate fractions was observed at the hyper-alkaline region in the case of cement (Figs. 3a and b).

The last is the formation of hardly soluble calcium arsenates. These compounds have been reported by a number of studies to be formed and exhibit low solubility at high Ca2+ concentration and pH (Bothe and Brown 1999; Parks et al. 2003; Zhu et al. 2006). However, the results of PHREEQC showed that the precipitation of calcium arsenates was thermodynamically unfavorable regardless of changes of Ca2+ concentration (2.5–40 mg L−1) and pH (9–11.2) in this work. This agrees with the work of Parks et al. (2003). They have reported that calcium arsenates could not be formed at pH lowered than 11.5, even when the initial concentration of Ca2+ was as high as 825 mg L−1.

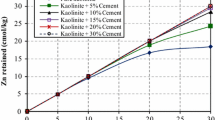

3.3 Arsenic Sequestration by Immobilizers

The performance of additives was evaluated on the batch with 0.15 g of cement since this batch released the highest concentration of As (Fig. 2). Therefore, it represents the worst-case scenario in terms of As leaching. Changes in pH of the leachate as a function of the amount of ET and AM are shown in Fig. 10. The pH increased with increasing addition of AM, while it was relatively stable at around 10.5 in the case of ET. This could be predominately attributed to the hydration of alite and magnesia in the case of AM and ET, respectively. The overall reaction representing the hydration of alite is given as (Juilland et al. 2010):

According to Eq. 1, calcium hydroxide (Ca (OH)2) is generated. This contributes to the production of more alkalinity in the case of AM (Kutus et al. 2016.). On the other hand, magnesia reacts with water and generates magnesium hydroxide (Mg (OH)2) (Xing et al. 2018) (Eq. 2).

Unlike calcium hydroxide, magnesium hydroxide has much lower solubility, resulting in a little shift of pH from 10.1 before stable at around 10.5 (Fu et al. 2018), regardless of the addition of ET.

Figure 11 shows the changes of As concentration as a function of the amount of the additives. The As leaching concentration decreases with the increasing addition of AM and ET. When 0.02 g of AM or ET was added, the leaching concentration of As decreased to below the level for the environmental standard of drinking water (10 μg L−1). This indicates that the addition of AM and ET effectively helped in sequestering As. In addition, using AM or ET contributed to almost the same immobilizing performance of As. This is supported by the same leaching concentration of As when the same amount of the additives was used (Fig. 11). However, different sequestration mechanisms are expected. In the case of AM, the majority of As was probably immobilized as a result of the dissolution of Ca (OH)2. Calcium hydroxide dissolution did not only contribute to the higher alkalinity but also to the higher Ca2+ concentration in the leachates. Due to these Ca2+ ions, the concentration of As was decreased possibly by the same mechanisms previously mentioned in section 3.2. On contrary, in the case of MT, adsorption is believed to be the main mechanism controlling the mobility of As due to the presence of magnesia and its hydration product (Mg (OH)2). The two compounds are known to have high affinity toward As even under high alkaline conditions since they have very high point of zero charge (Yu et al. 2011; Jia et al. 2013; Li et al. 2016).

4 Conclusions

Arsenic concentration leached from a silty soil increased with pH. When cement was used, the maximum leaching concentration of As was observed at pH 10.1. Above this pH, the mobility of As decreased due to the presence of high Ca2+ concentration. Arsenic immobilized by Ca2+ was interpreted by two different mechanisms. In the first mechanism, with the help of Ca2+ to increase the surface charge, the mobility of As was reduced by the adsorption onto the surfaces of (hydr)oxide minerals and the formation of the fresh precipitates of Fe and Al hydroxides flocs. The second immobilization mechanism was through the adsorption and co-precipitation with CaCO3 that freshly precipitated. This precipitate was also found to promote the formation of C-S-H, leading in the reduction of Si concentration (one of the strongest competing ion of As). As a result, the adsorption performance of As can be enhanced. In the sequestration tests, by adding adequate amounts of Ca- and Mg-containing additives, the leaching concentration of As deceased to below 10 μg L−1 even under high pH condition.

References

Abdul, K. S., Jayasinghe, S. S., Chandana, E. P., Jayasumana, C., & De Silva, P. M. (2015). Arsenic and human health effects: A review. Environmental Toxicology and Pharmacology, 40, 828–846.

Anderson, M. A., Ferguson, J. F., & Gavis, J. (1976). Arsenate adsorption on amorphous aluminum hydroxide. Journal of Colloid and Interface Science, 54, 391–399.

Babu, K. G., & Kumar, V. S. R. (2000). Efficiency of GGBS in concrete. Cement and Concrete Research, 30, 1031–1036.

Bell, F. G., & Maud, R. R. (1994). Dispersive soils and earth dams with some experiences form South Africa. Environmental and Engineering Geoscience, 31, 433–446.

Boschuk, J. (1991). Landfill covers – An engineer perspective. Geotechnical Fabrics Report., 9, 23–34.

Bothe, J. V., & Brown, P. W. (1999). Arsenic immobilization by calcium arsenate formation. Environmental Science & Technology, 3, 3806–3811.

Bowell, R. J. (1994). Sorption of arsenic by iron oxides and oxyhydroxides in soils. Applied Geochemistry, 9, 279–286.

Boyle, R. W., & Jonasson, I. R. (1973). The geochemistry of as and its use as an indicator element in geochemical prospecting. Journal of Geochemical Exploration, 2, 251–296.

Brookins, D. G. (1988). Eh-pH diagrams for geochemistry. Berlin: Springer.

Clevenger, T. E. (1990). Use of sequential extraction to evaluate the heavy metals in mining wastes. Water, Air, & Soil Pollution, 50, 241–253.

Cristelo, N., Glendinning, S., Fernandes, L., & Pinto, A. T. (2013). Effects of alkaline-activated fly ash and Portland cement on soft soil stabilization. Acta Geotechnica, 8, 395–405.

Dhiraj, K., Gourav, D., & Akash, P. (2015). Performance of different form of soil reinforcement. International Journal of Science Technology & Management, 4, 667–677.

Douglas, C., MacLaren, A. W., & Mary, A. W. (2003). Cement: Its chemistry and properties. Journal of Chemical Education, 80, 623–635.

Eriksson, R., Merta, J., & Rosenholm, J. B. (2007). The calcite/water interface: I. Surface charge in indifferent electrolyte media and the influence of low-molecular-weight polyelectrolyte. Journal of Colloid and Interface Science, 313, 184–193.

Fu, J., He, Q., Miedziak, P. J., Brett, G. L., Huang, X., Pattisson, S., Douthwaite, M., & Hutchings, G. J. (2018). The role of Mg (OH)2 in the so-called “base-free” oxidation of glycerol with AuPd catalysts. Chemistry, 24(10), 2396–2402.

García-Sánchez, A., Alonso-Rojo, P., & Santos-Francés, F. (2010). Distribution and mobility of arsenic in soils of a mining area (Western Spain). Science of the Total Environment, 408, 4194–4201.

Giles, D. E., Mohapatra, M., Issaa, T. B., Anand, S., & Singha, P. (2011). Iron and aluminium based adsorption strategies for removing arsenic from water. Journal of Environmental Management, 92, 3011–3022.

Glazener, F. S., Ellis, J. G., & Johnson, P. K. (1968). Electrocardiographic findings with arsenic poisoning. California Medicine, 109, 158–162.

Gupta, A. K., & Gupta, M. (2005). Synthesis and surface engineering of iron oxide nanoparticles for biomedical applications. Biomaterials, 26, 3995–4021.

Hong, Y. S., Song, K. H., & Chung, J. Y. (2014). Health effects of chronic arsenic exposure. Journal of Preventive Medicine and Public Health, 47, 245–252.

Huang, Y. C., Fowkes, F. M., Lloyd, T. B., & Sanders, N. D. (1991). Adsorption of calcium-ions from calcium-chloride solutions onto calcium-carbonate particles. Langmuir, 7, 1742–1748.

Huyen, D. T., Tabelin, C. B., Thuan, H. M., Dang, D. H., Truong, P. T., Vongphuthone, B., Kobayashi, M., & Igarashi, T. (2019). The solid-phase partitioning of arsenic in unconsolidated sediments of the Mekong Delta, Vietnam and its modes of release under various conditions. Chemosphere, 233, 512–523.

Jia, Y., Lou, T., Yu, X. Y., Sun, B., Liu, J. H., & Huang, X. J. (2013). A facile template free solution approach for the synthesis of dypingite nanowires and subsequent decomposition to nanoporous MgO nanowires with excellent arsenate adsorption properties. RSC Advances, 3, 5430–5437.

Juilland, P., Gallucci, E., Flatt, R., & Scrivener, K. (2010). Dissolution theory applied to the induction period in alite hydration. Cement and Concrete Research, 40, 831–844.

Kalinkin, A. M., Kalinkina, E. V., Zalkind, O. A., & Makarova, T. I. (2005). Chemical interaction of calcium oxide and calcium hydroxide with CO2 during mechanical activation. Inorganic Materials, 41, 1073–1079.

Karri, K. S., Rao, R. G. V., & Raju, P. M. (2015). Strength and durability studies on GGBS concrete. SSRG International Journal of Civil Engineering, 2, 34–41.

Khalil, A., Ijaz, A. B., Majid, M., Munawar, I., & Zafar, I. (2012). Removal of heavy metals (Zn, Cr, Pb, Cd, Cu and Fe) in aqueous media by calcium carbonate as an adsorbent. International Journal of Chemical and Biochemical Sciences, 2, 48–53.

Kolias, S., Rigopoulou, V. K., & Karaholias, A. (2005). Stabilisation of clayey soils with high calcium fly ash and cement. Cement and Concrete Composites, 27, 310–313.

Kumpiene, J., Fitts, J. P., & Mench, M. (2012). Arsenic fractionation in mine spoils 10 years after aided phytostabilization. Environmental Pollution, 166, 82–88.

Kutus, B., Gacsi, A., Pallagi, A., Palinko, I., Peintler, G., & Sipos, P. (2016). A comprehensive study on the dominant formation of the dissolved Ca (OH)2(aq) in strongly alkaline solutions saturated by Ca (II). RSC Advances, 51, 45231–45240.

Li, W., Chen, D., Xia, F., Tan, J. Z. Y., Huang, P. P., Song, W. G., Nursam, N. M., & Caruso, R. A. (2016). Extremely high arsenic removal capacity for mesoporous aluminium magnesium oxide composites. Environmental Science: Nano, 3, 94–106.

Marumo, K., Ebashi, T., & Ujiie, T. (2003). Heavy metal concentrations, leachabilities and lead isotope ratios of Japanese soils. Shigen-Chihsitsu, 53, 125–146 (in Japanese with English abstract).

Matsushita, K. (1971). Explanatory text of the geological map of Japan (Scale 1:50,000) EBETSU (Sapporo-22).

Meng, X., Bang, S., & Korfiatis, G. P. (2000). Effects of silicate, sulfate, and carbonate on arsenic removal by ferric chloride. Water Research, 34, 1255–1261.

Moulin, P., & Roques, H. (2003). Zeta potential measurement of calcium carbonate. Journal of Colloid and Interface Science, 261, 115–126.

Odler, I. (2019). Hydration, setting and hardening of Portland cement. In P. C. Hewlett & M. Liska (Eds.), Lea’s Chemistry of Cement and Concrete (5th ed., pp. 157–250). Oxford: Elsevier Science & Technology.

Oner, A., & Akyuz, S. (2007). An experimental study on optimum usage of GGBS for the compressive strength of concrete. Cement and Concrete Composites, 29, 505–514.

Ouyang, X., Koleva, D. A., Ye, G., & Breugel, K. V. (2017). Insight into the mechanisms of nucleation and growth of C-S-H on fillers. Materials and Structures, 50, 213–225.

Parkhurst, D. L., & Appelo, C. A. J. (1999). User's guide to PHREEQC (version 2): A computer program for speciation, batch-reaction, one-dimensional transport, and inverse geochemical calculations. U.S. Geological Survey: Earth Science Information Center.

Parks, J. L., Novak, J., Macphee, M., Itle, C., & Edwards, M. (2003). Effect of calcium on arsenic release from ferric and alum residuals. JWWA, 95, 108–118.

Pierce, M. L., & Moore, C. B. (1982). Adsorption of arsenite and arsenate on amorphous iron hydroxide. Water Research, 16, 1247–1253.

Renard, F., Putnis, C. V., Montes-Hernandez, G., Ruiz-Agudo, E., Hovelmann, J., & Sarret, G. (2015). Interactions of arsenic with calcite surfaces revealed by in situ nanoscale imaging. Geochimica et Cosmochimica Acta, 159, 61–79.

Robertson, F. N. (1989). Arsenic in groundwater under oxidizing conditions, south-West United States. Environmental Geochemistry and Health, 17, 117–185.

Sharifah, Z., Kamarudin, H., Mustafa, A. B., Binhussain, M., & Siti, S. (2013). Review on soil stabilization techniques. Australian Journal of Basic and Applied Sciences, 7, 258–265.

Smedley, P. L., & Kinniburgh, D. G. (2002). A review of the source, behavior and distribution of arsenic in natural waters. Applied Geochemistry, 17, 517–568.

Smedley, P. L., Nicolli, H. B., MacDonald, D. M. J., Barros, A. J., & Tullio, J. O. (2002). Hydrogeochemistry of arsenic and other inorganic constituents in groundwaters from La Pampa, Argentina. Applied Geochemistry, 17, 259–284.

So, H. U., Postma, D., Jakobsen, R., & Larsen, F. (2012). Competitive adsorption of arsenate and phosphate onto calcite: Experimental results and modeling with CCM and CD-MUSIC. Geochimica et Cosmochimica Acta, 93, 1–13.

Tabelin, C. B., Igarashi, T., & Takahashi, R. (2012). Mobilization and speciation of arsenic from hydrothermally altered rock in laboratory column experiments under ambient conditions. Applied Geochemistry, 27, 326–342.

Tangviroon, P., & Igarashi, T. (2017). Modeling and evaluating the performance of river sediment on immobilizing arsenic from hydrothermally altered rock in laboratory column experiments with Hydrus-1D. Water, Air, & Soil Pollution, 228, 465.

Tangviroon, P., Hayashi, R., & Igarashi, T. (2017). Effects of additional layer(s) on the mobility of arsenic from hydrothermally altered rock in laboratory column experiments. Water, Air, & Soil Pollution, 228, 191.

Tatsumi, K., Jin, K., & Tachibana, H. (2006). Dynamic state of arsenic and basin management in Toyohira River. Journal of Japan Society on Water Environment, 29, 671–677.

Tessier, A., Campbell, G. C., & Bisson, M. (1979). Sequential extraction procedure for the speciation of particulate trace metals. Analytical Chemistry, 51, 844–850.

Tizo, M. S., Blanco, L. A. V., Cagas, A. C. Q., Dela, B. R. B., Encoy, J. C., Gunting, J. V., Arazo, R. O., & Mabayo, V. I. F. (2018). Efficiency of calcium carbonate from eggshells as an adsorbent for cadmium removal in aqueous solution. Sustainable Environment Research, 28, 326–332.

Tombácz, E. (2009). pH-dependent surface charging of metal oxides. Periodica Polytechnica Chemical Engineering, 53, 77–86.

Umeki, Y. (2015). History and utilization of Portland blast furnace slag cement. Nippon Steel & Sumitomo Metal Technical Report, 109, 109–113.

Vink, B. W. (1996). Stability relations of antimony and arsenic compounds in the light of reversed and extended Eh-pH diagrams. Chemical Geology, 130, 21–30.

Vongphuthone, B., Kobayashi, M., & Igarashi, T. (2017). Factors affecting arsenic content of unconsolidated sediments and its mobilization in the Ishikari Plain, Hokkaido, Japan. Environmental Earth Sciences, 76, 645–659.

Wilkie, J. A., & Hering, J. G. (1996). Adsorption of arsenic onto hydrous ferric oxide: Effects of adsorbate/adsorbent ratios and co-occurring solutes. Colloids Surf. A: Physicochem. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 107, 97–110.

Xing, Z., Bai, L., Ma, Y., Wang, D., & Li, M. (2018). Mechanism of magnesium oxide hydration based on the multi-rate model. Materials (Basel), 11(10), 1835.

Yu, X. Y., Lou, T., Jia, Y., Zhang, X. Y., Liu, J. H., & Huang, X. J. (2011). Porous hierarchically micro/nanostructured MgO: Morphology control and their excellent performance in as (III) and as(V) removal. The Journal of Physical Chemistry C, 115, 22242–22250.

Zhu, Y. N., Zhang, X. H., Xie, Q. L., Wang, D. Q., & Cheng, G. W. (2006). Solubility and stability of calcium arsenates at 25∘C. Water, Air, & Soil Pollution, 169, 221–238.

Funding

The authors wish to thank the Japan Society for the Promotion of Science (JSPS) grant-in-aid for scientific research (Grant number: JP26289149) for the financial support and Hokkaido Development for supporting in collecting the core sample.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tangviroon, P., Endo, Y., Fujinaka, R. et al. Change in Arsenic Leaching from Silty Soil by Adding Slag Cement. Water Air Soil Pollut 231, 259 (2020). https://doi.org/10.1007/s11270-020-04630-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-020-04630-x

) Ishigari River and (

) Ishigari River and ( ) sampling point

) sampling point